Competitive precipitation law of nitrides during continuous casting cooling process of boron-containing steel

-

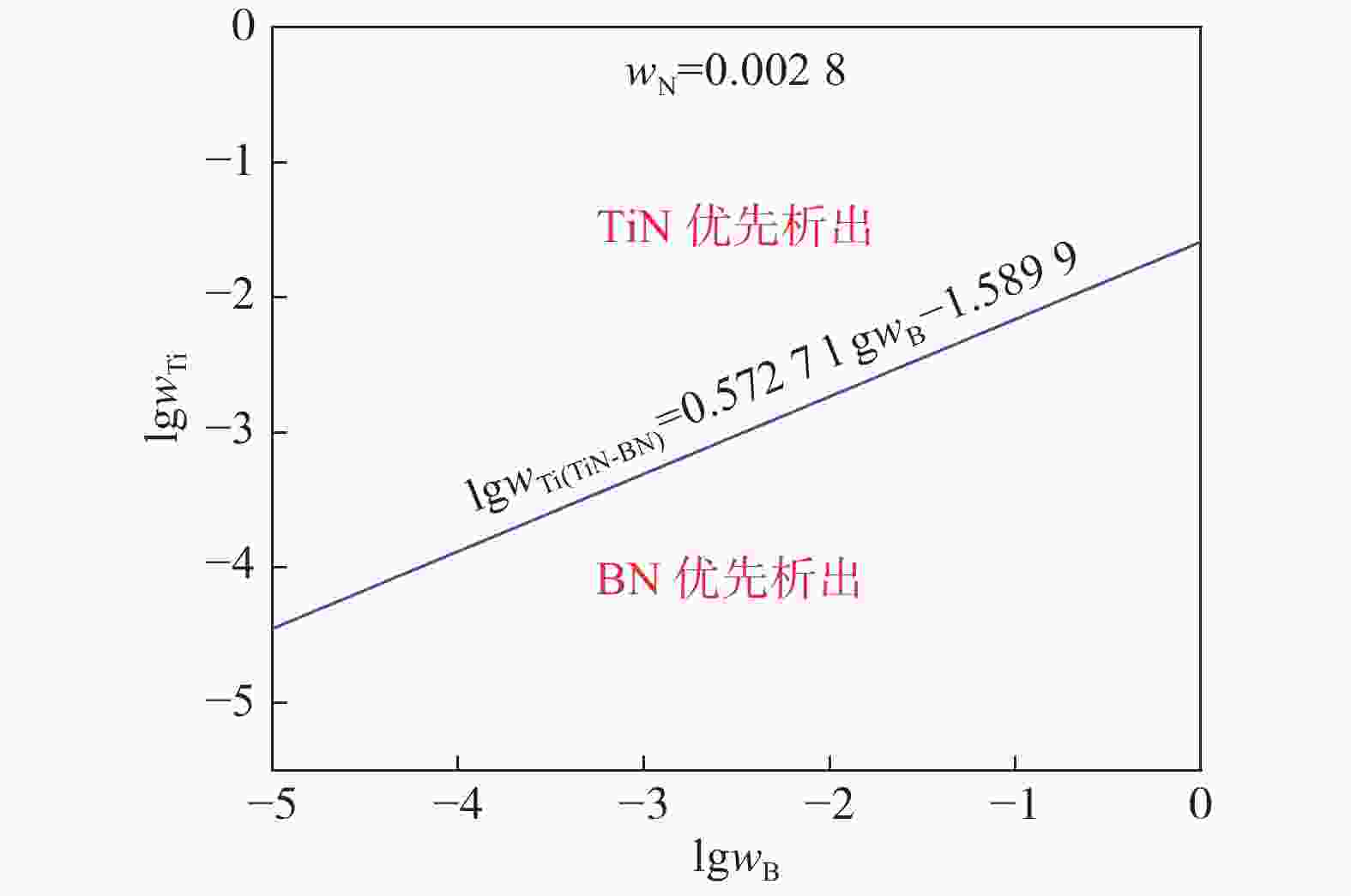

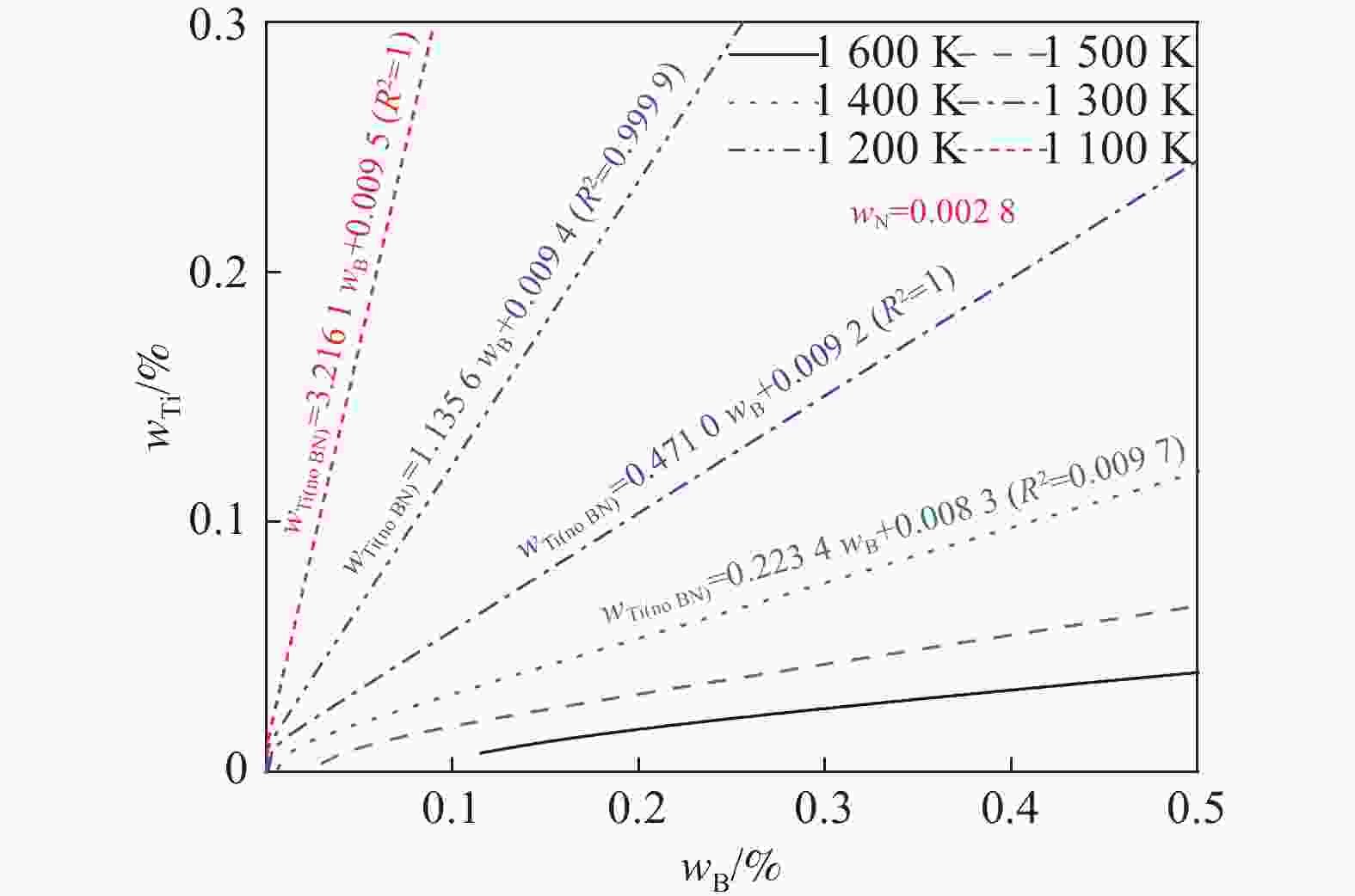

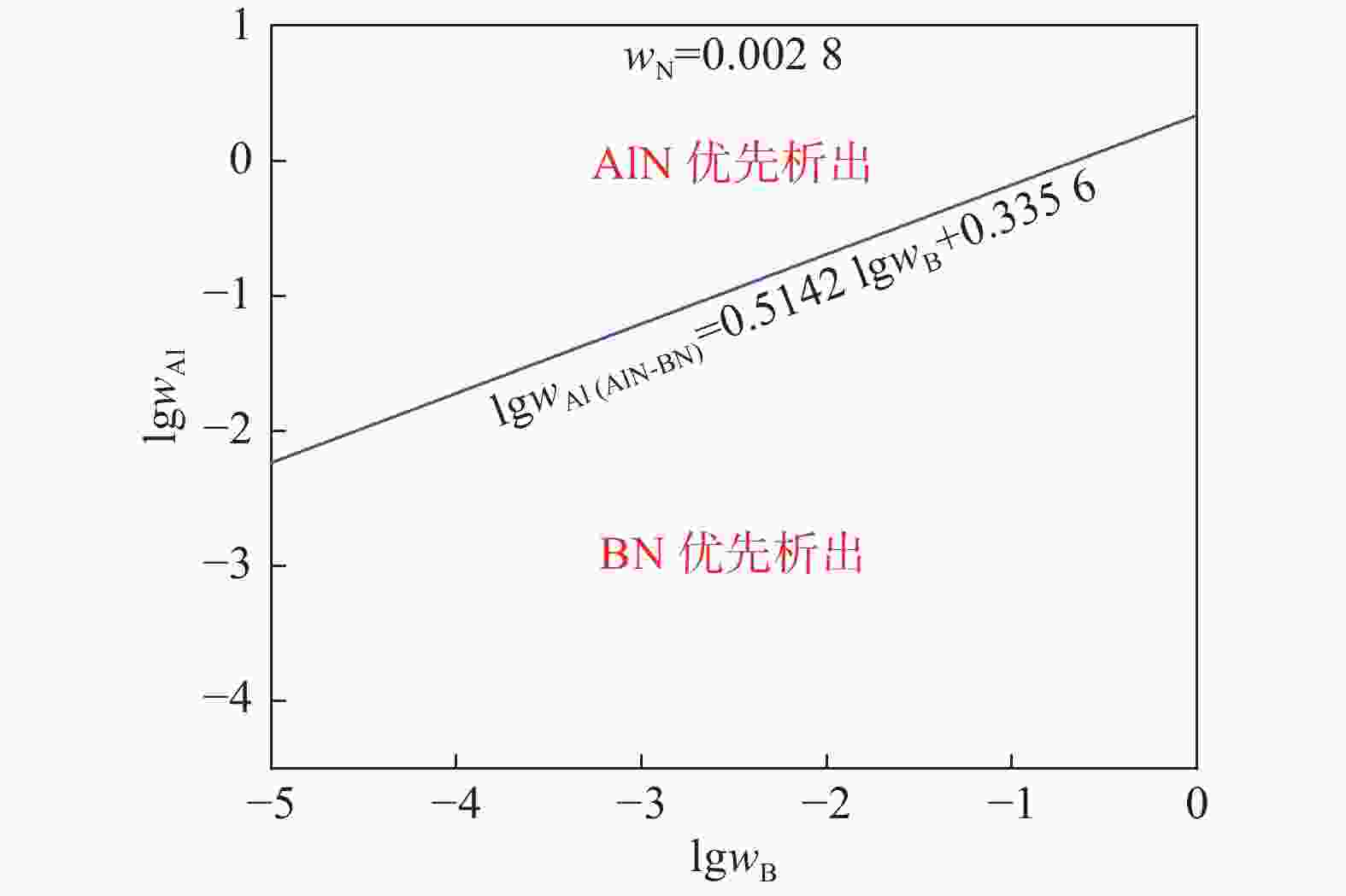

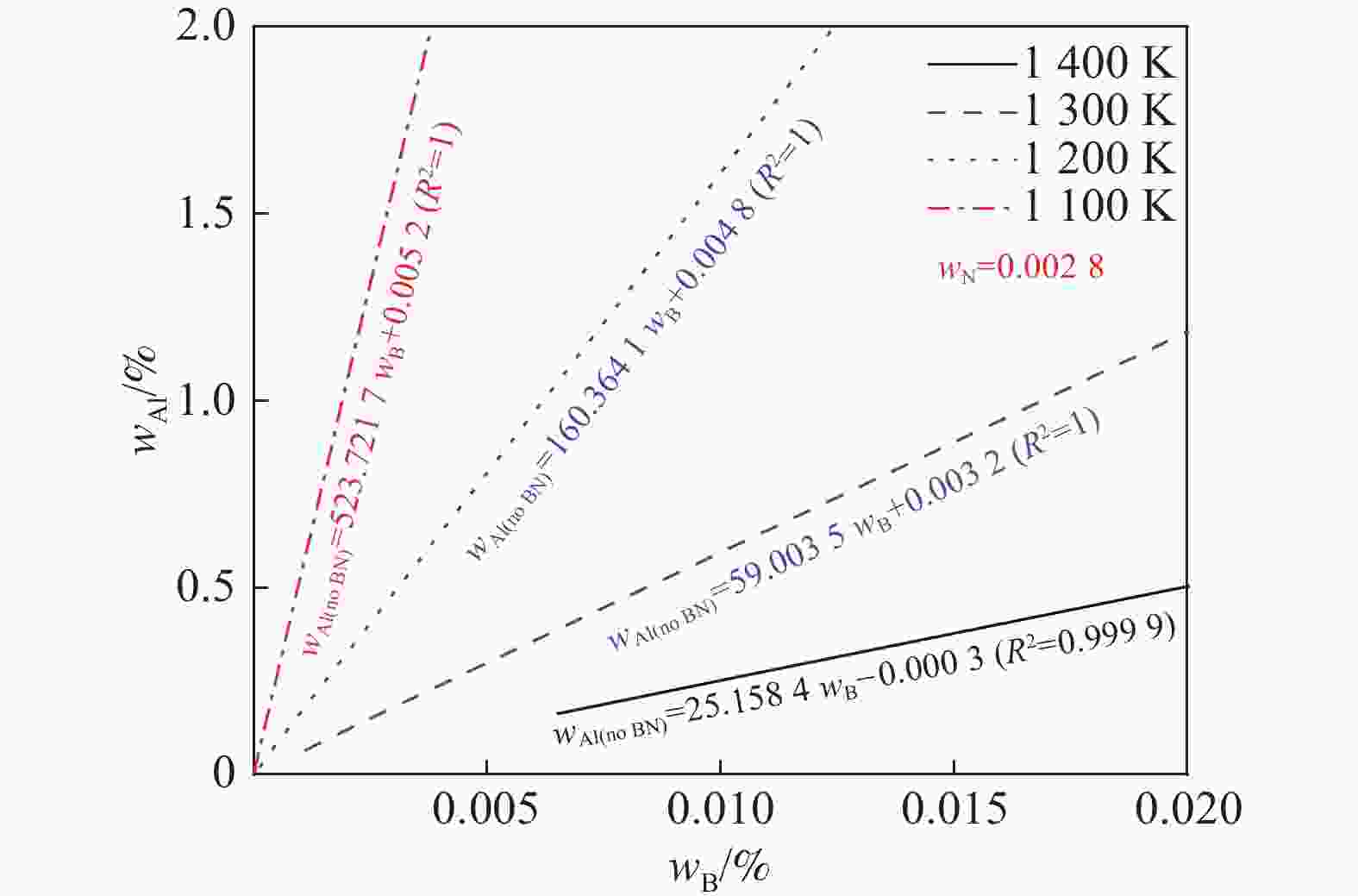

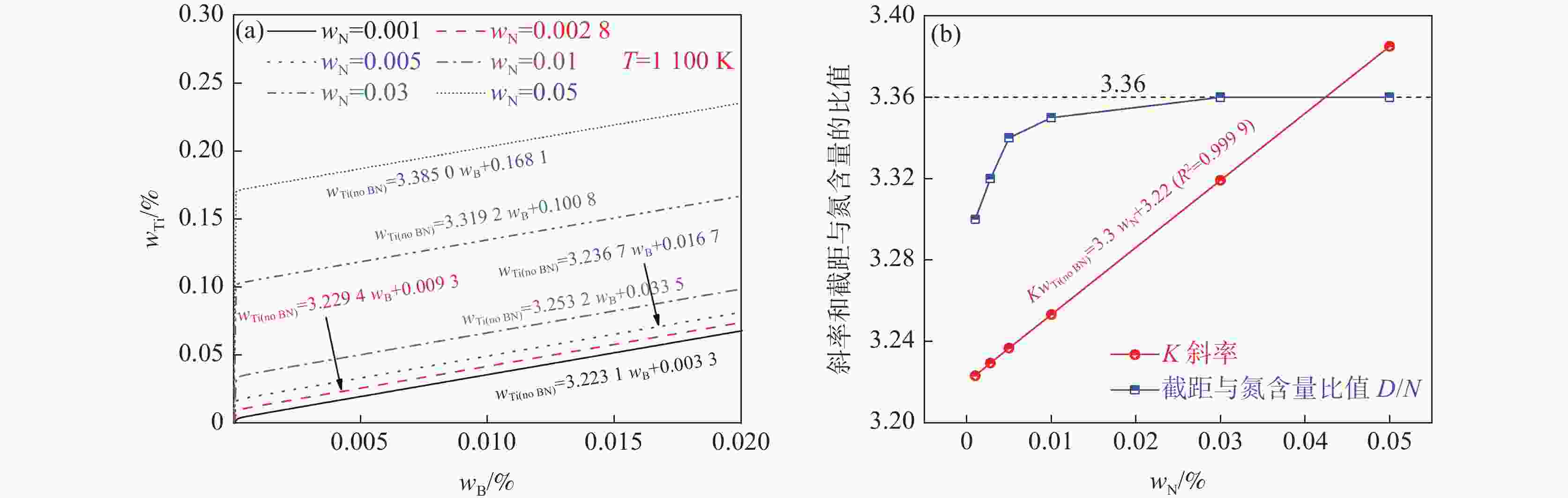

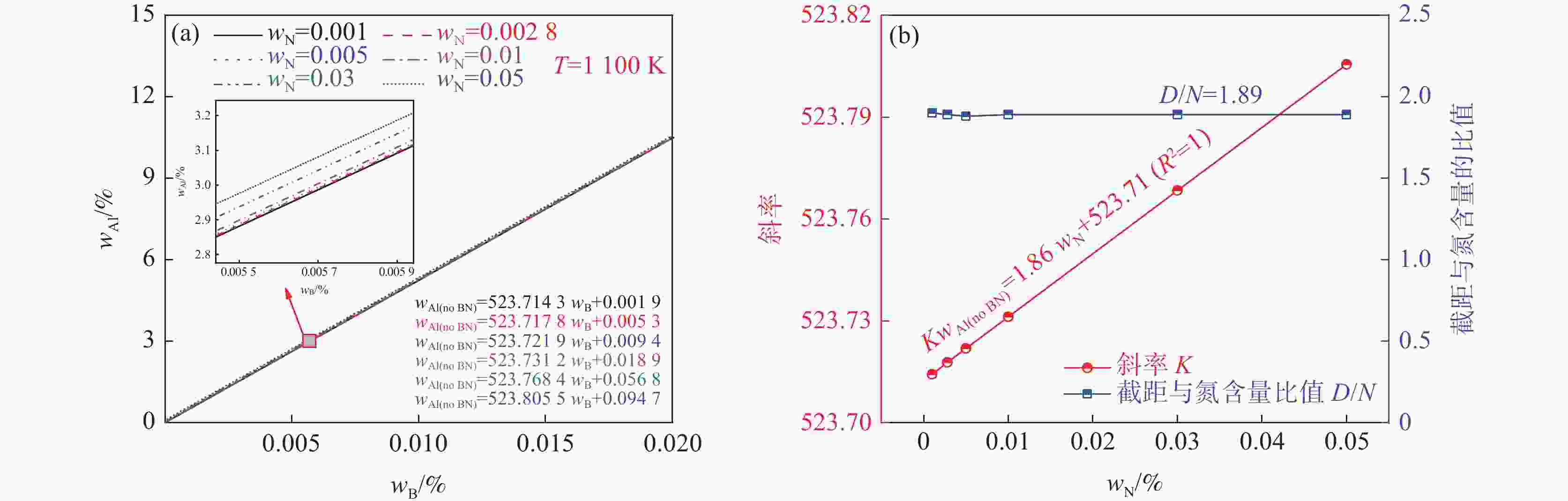

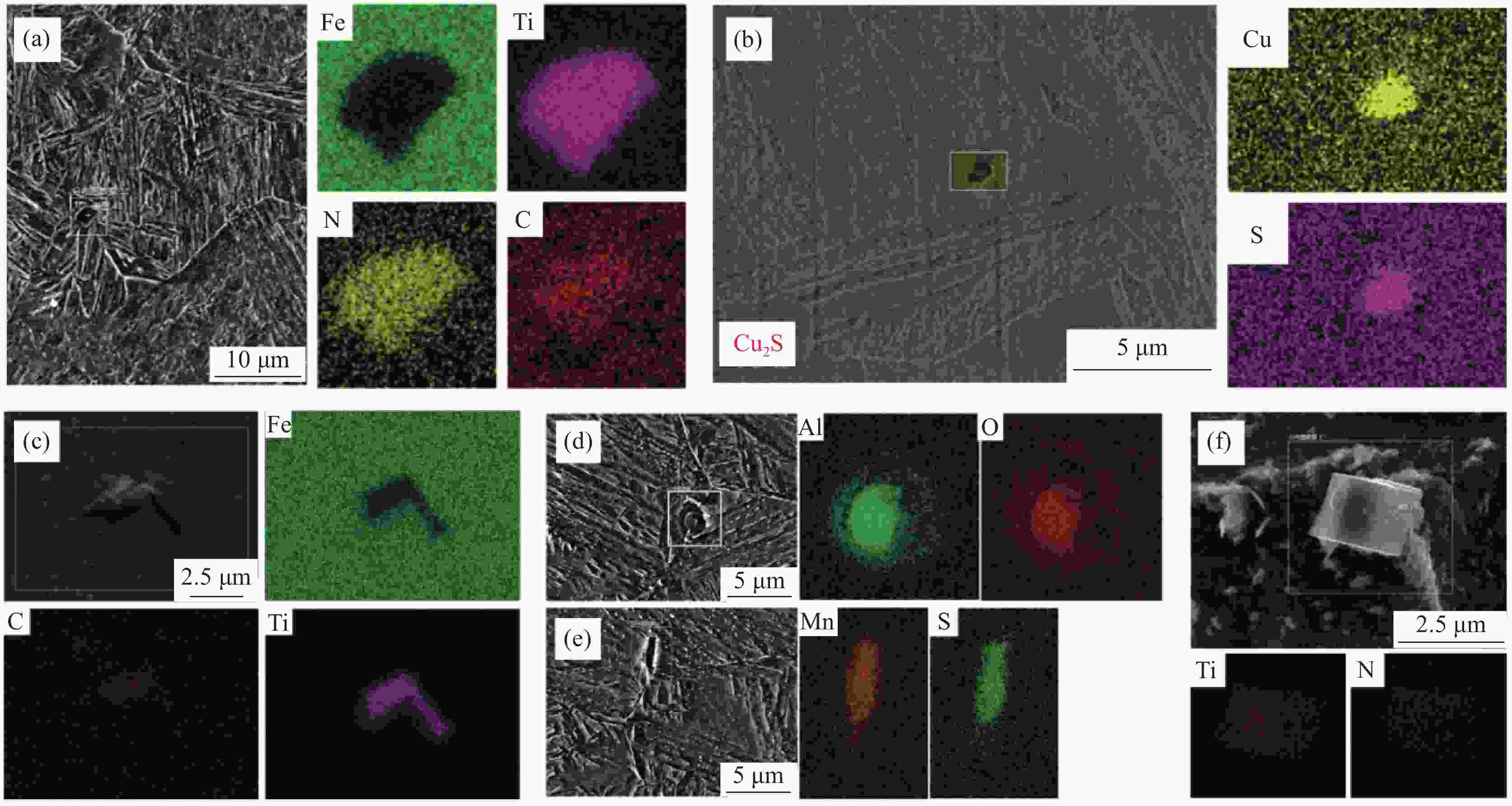

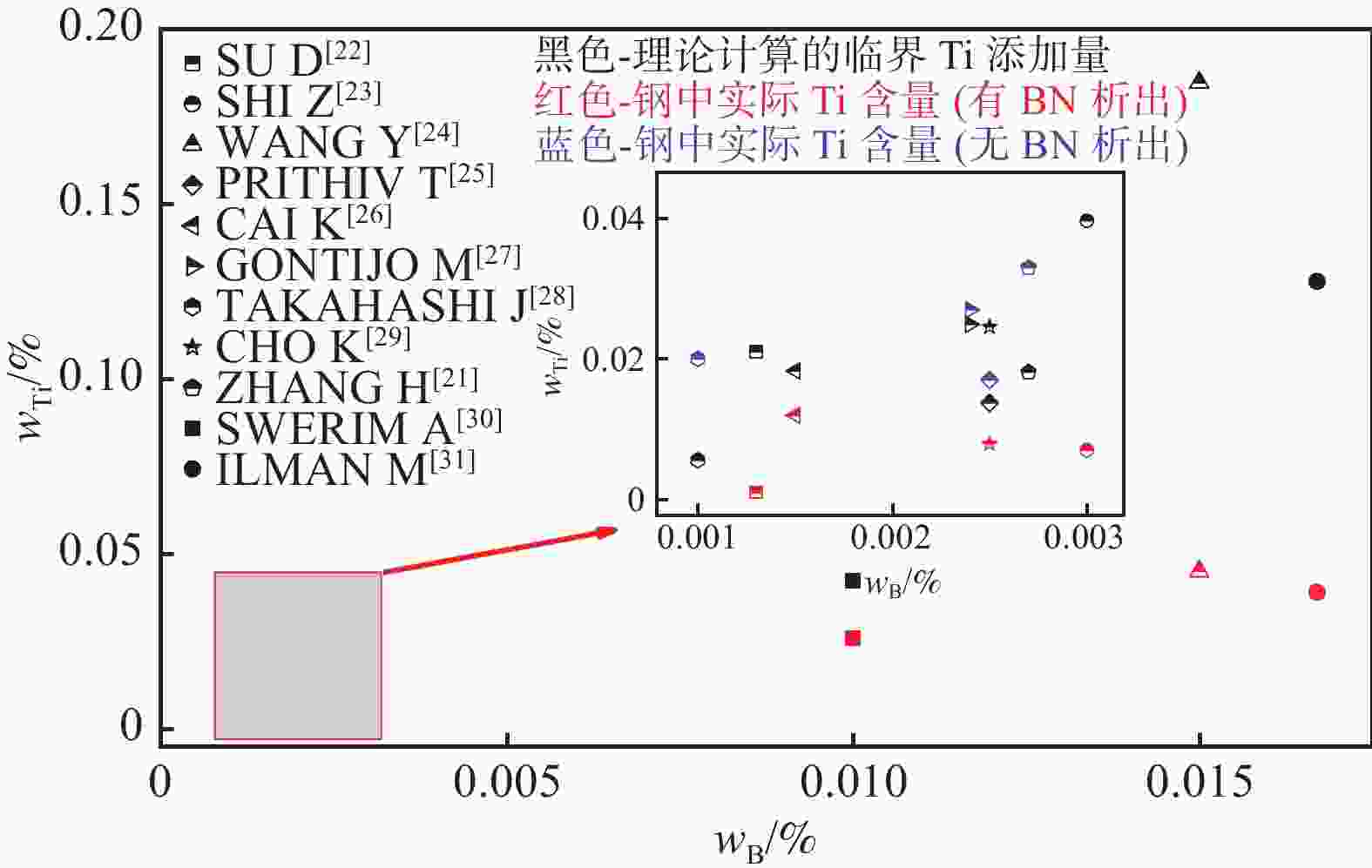

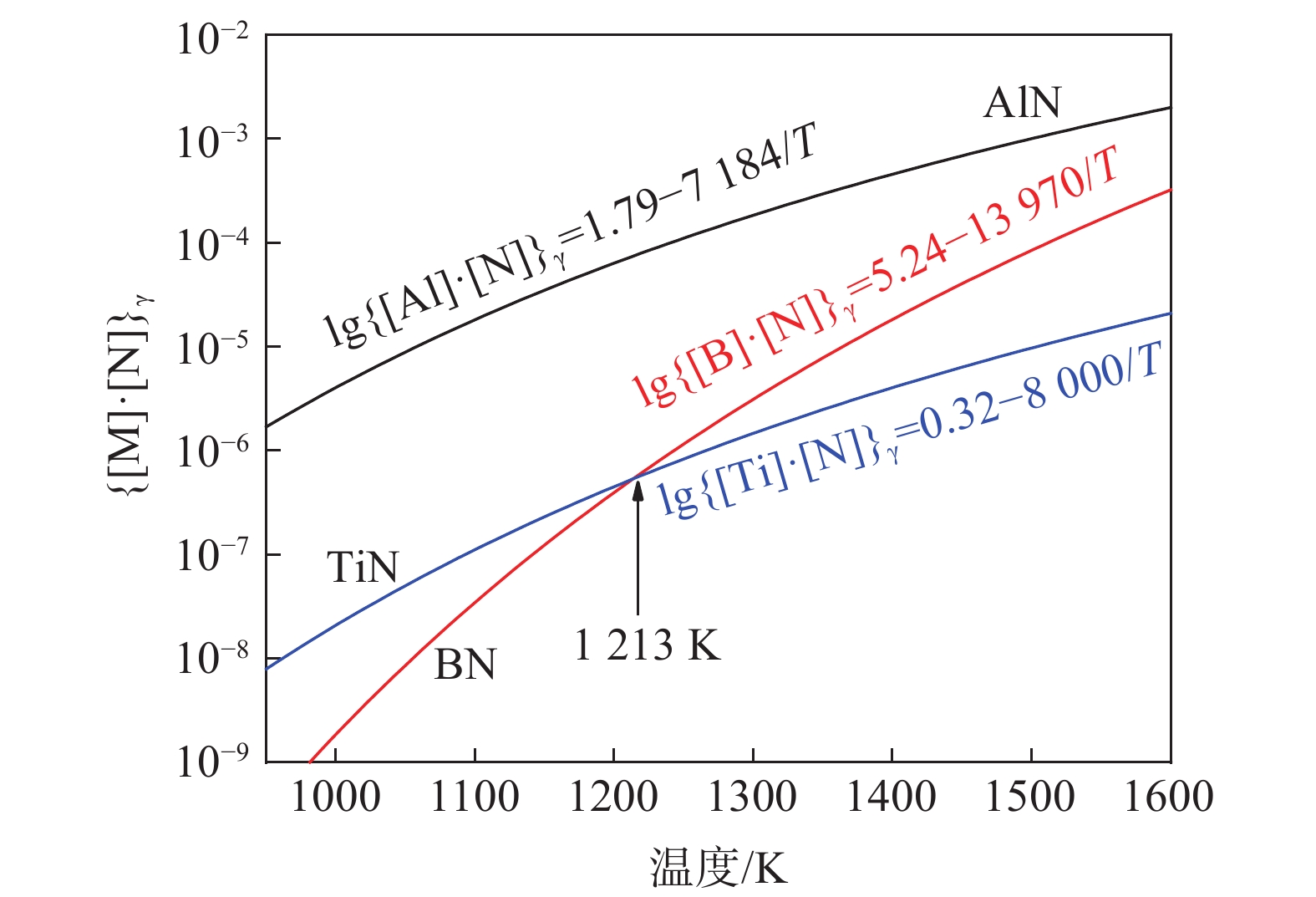

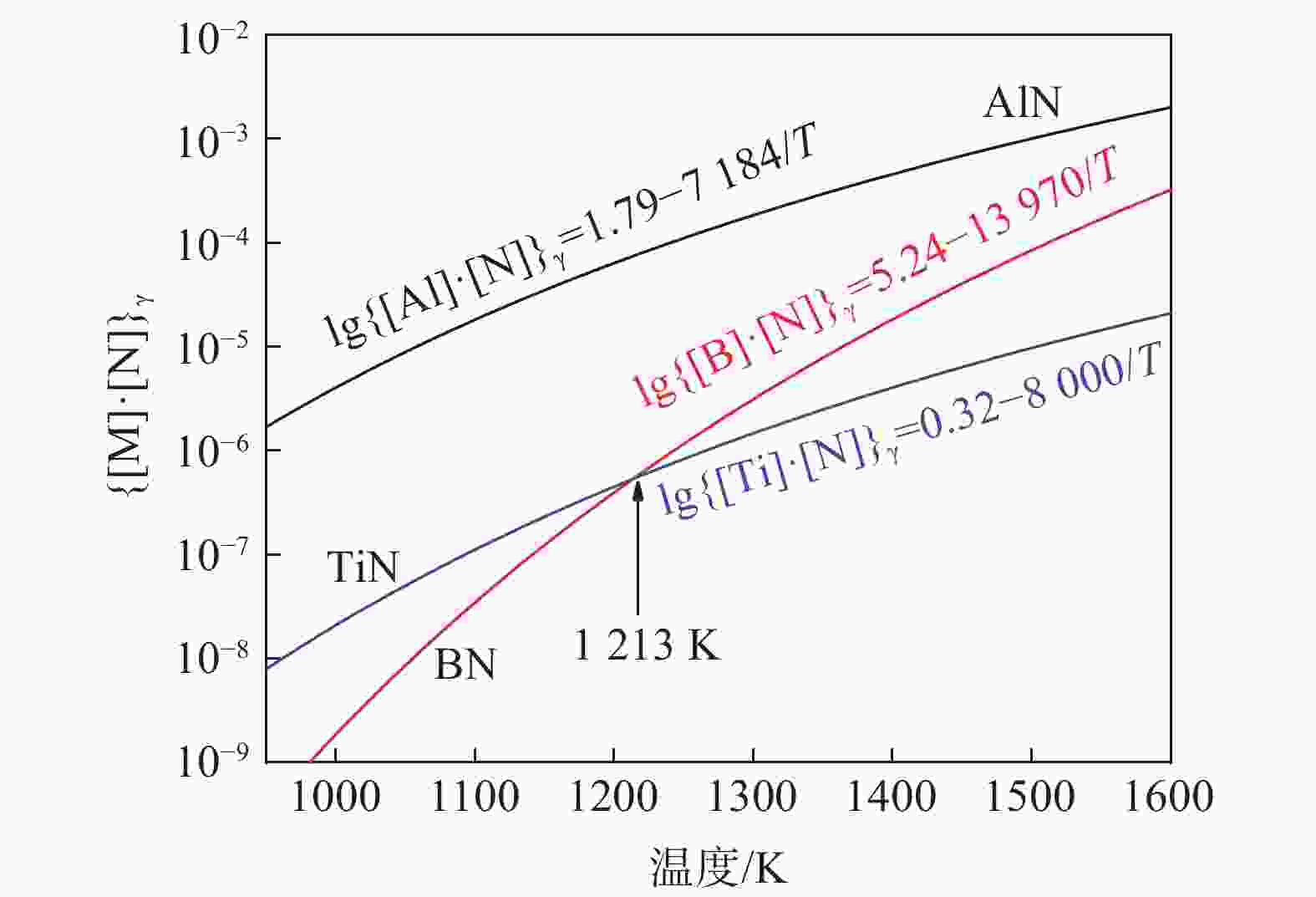

摘要: 含硼钢连铸冷却过程中BN析出不仅会减少钢中有效硼含量,削弱硼合金化的有益效果,而且还会导致铸坯裂纹敏感性增强。探明氮化物的竞争析出规律对含硼钢连铸冷却过程BN析出相的精准调控具有重要的意义。针对含硼钢连铸冷却过程,通过热力学计算研究了BN、TiN、AlN间的竞争析出行为,并探究了钢中Ti、Al、N含量对BN析出抑制效果的影响规律。结果表明,随着钢中Ti、Al含量增高,TiN、AlN析出时机提前,增大到一定程度时TiN、AlN会先于BN析出,从而抑制BN析出;进一步提高钢中Ti、Al含量,最终使得BN完全不析出;相较于Al元素,通过调节钢中Ti元素含量来调控BN析出行为更为经济可靠;抑制BN完全不析出的临界钛添加量与钢中硼、氮元素含量的关系式为:${w_{{\text{Ti(no BN)}}}} = \left( {3.3{w_{\text{N}}} + 3.22} \right){w_{\text{B}}} + 3.36{w_{\text{N}}}$,临界钛添加量$ {w_{{\text{Ti(no BN)}}}} $随钢中氮、硼元素含量的增大而增大。研究结果为含硼钢成分设计和连铸坯质量控制提供了重要的理论依据。Abstract: During continuous casting cooling process of boron-containing steel, the precipitation of BN not only reduces the effective boron content, weakening the beneficial effects of boron alloying, but also increases the crack sensitivity of the as-cast billet. Clarifying the competitive precipitation law of nitrides is crucial for precise control of BN precipitation during the continuous casting cooling process of boron containing steel. This study focuses on the continuous casting cooling process of boron containing steel, and investigates the competitive precipitation behavior among BN, TiN, and AlN through thermodynamic calculations. The influence of Ti, Al, and N content in steel on the suppression effect of BN precipitation is also explored. The results indicate that as the content of Ti and Al in steel increases, the timing of TiN and AlN precipitation advances. When the content reaches a certain level, TiN and AlN precipitate before BN, thereby inhibiting BN precipitation. Further increasing Ti and Al content in the steel ultimately prevents the precipitation of BN completely. Compared to Al element, regulating the precipitation behavior of BN by adjusting Ti content in steel is more economical and reliable. The critical Ti addition that completely suppress BN precipitation follows the relationship :${w_{{\text{Ti(no BN)}}}} = \left( {3.3{w_{\text{N}}} + 3.22} \right) $$ {w_{\text{B}}} + 3.36{w_{\text{N}}}$, where the critical Ti addition $ {w_{{\text{Ti(no BN)}}}} $increases with higher nitrogen and boron content in the steel. The results provide an important theoretical basis for the compositional design of boron-containing steel and quality control of continuous casting billets.

-

表 1 22MnB5钢的主要化学成分

Table 1. Main chemical compositions of 22MnB5 steel

% 试样 C Si Mn P S Cr Al Ti B N Ⅰ 0.21 0.27 1.18 0.008 0.001 0.23 0.0298 0.033 0.0027 0.0028 Ⅱ 0.23 0.034 1.47 0.010 0.003 0.18 0.0400 0.040 0.0020 0.0030 -

[1] LIU T, CHEN Y F, WANG D X, et al. Control of surface cracks in boron containing steel billet[J]. Continuous Casting, 2022(5):62-68, 75. (刘涛, 陈永峰, 王东兴, 等. 含硼钢铸坯表面裂纹缺陷控制[J]. 连铸, 2022(5):62-68, 75.LIU T, CHEN Y F, WANG D X, et al. Control of surface cracks in boron containing steel billet[J]. Continuous Casting, 2022(5): 62-68, 75. [2] ARDESHIR G, FANG L, HENRIK S, et al. Microstructure of a creep-resistant 10 pct chromium steel containing 250 ppm boron[J]. Metallurgical and Materials Transactions A, 2011,42:940-951. [3] WANG W, ZHOU L M, XIONG L, et al. High temperature mechanical property of SS400 B-bearing steel slab[J]. Iron & Steel, 2015,50(7):38-42. (王炜, 周律敏, 熊力, 等. SS400含硼钢连铸坯的高温力学性能[J]. 钢铁, 2015,50(7):38-42.WANG W, ZHOU L M, XIONG L, et al. High temperature mechanical property of SS400 B-bearing steel slab[J]. Iron & Steel, 2015, 50(7): 38-42. [4] WANG Z Y, JI C, GONG W X, et al. Formation mechanism and control of transverse corner cracking of containing boron steel slab[J]. Iron & Steel, 2012,47(5):35-38. (王朝阳, 祭程, 巩文旭, 等. 含硼钢板坯边角裂纹的成因与控制[J]. 钢铁, 2012,47(5):35-38.WANG Z Y, JI C, GONG W X, et al. Formation mechanism and control of transverse corner cracking of containing boron steel slab[J]. Iron & Steel, 2012, 47(5): 35-38. [5] XU H M, ZHANG Y, PAN X, et al. The influence of Ti and B on the continuous phase transformation behavior and strength of weathering welding wire steel[J]. Iron & Steel, 2013,48(10):50-56. (许红梅, 张宇, 潘鑫, 等. Ti和B对耐候焊丝钢连续相转变行为和强度的影响[J]. 钢铁, 2013,48(10):50-56.XU H M, ZHANG Y, PAN X, et al. The influence of Ti and B on the continuous phase transformation behavior and strength of weathering welding wire steel[J]. Iron & Steel, 2013, 48(10): 50-56. [6] WANG L J, LI F X, ZHANG J P, et al. Improving metallurgical quality measures of boron steel EAF process[J]. China Metallurgy, 2011,21(3):24-27. (王立君, 李法兴, 张君平, 等. 提高电炉流程生产含硼钢冶金质量的措施[J]. 中国冶金, 2011,21(3):24-27.WANG L J, LI F X, ZHANG J P, et al. Improving metallurgical quality measures of boron steel EAF process[J]. China Metallurgy, 2011, 21(3): 24-27. [7] HAN C, CAO R. Effects and characterization methods of boron in steel[J]. Materials Reports, 2022,36(S1):459-462. (韩成, 曹睿. 硼在钢中的作用及表征方式[J]. 材料导报, 2022,36(S1):459-462.HAN C, CAO R. Effects and characterization methods of boron in steel[J]. Materials Reports, 2022, 36(S1): 459-462. [8] MAM T H, JIANG C, LIU K, et al. Study on hardenability of large cross-sectional high strength medium-Mn forged steels[J]. Journal of Iron and Steel Research, 2022, 34(8): 834-839. (满廷慧, 江畅, 刘坤, 等. 大截面高强度中锰锻钢淬透性研究[J], 钢铁研究学报, 2022, 34(8): 834-839.MAM T H, JIANG C, LIU K, et al. Study on hardenability of large cross-sectional high strength medium-Mn forged steels[J]. Journal of Iron and Steel Research, 2022, 34(8): 834-839. [9] LIU G L, JI C X, NI Y J, et al. Formation and control of transverse corner cracks in boron steel slab[J]. Iron Steel Vanadium Titanium, 2013, 34(4): 94-98, 103. (刘国梁, 季晨曦, 倪有金, 等. 含硼钢板坯角横裂产生原因及控制研究[J]. 钢铁钒钛, 2013, 34(4): 94-8, 103.LIU G L, JI C X, NI Y J, et al. Formation and control of transverse corner cracks in boron steel slab[J]. Iron Steel Vanadium Titanium, 2013, 34(4): 94-98, 103. [10] YANG K M, LIU W F. Cause analysis and control of corner crack for boron-bearing steel billet[J]. Metal World, 2023(3):79-82. (杨阔鸣, 刘伟芳. 含硼钢铸坯角裂成因分析与控制[J]. 金属世界, 2023(3):79-82.YANG K M, LIU W F. Cause analysis and control of corner crack for boron-bearing steel billet[J]. Metal World, 2023(3): 79-82. [11] YANG J, TANG W, LUO D, et al. Thermodynamic analysis and control of BN precipitation in low carbon boron steel[J]. Metal Materials and Metallurgy Engineering, 2017,45(4):25-28, 35. (杨俊, 汤伟, 罗登, 等. 低碳含硼钢中BN析出的热力学分析与控制[J]. 金属材料与冶金工程, 2017,45(4):25-28, 35.YANG J, TANG W, LUO D, et al. Thermodynamic analysis and control of BN precipitation in low carbon boron steel[J]. Metal Materials and Metallurgy Engineering, 2017, 45(4): 25-28, 35. [12] JIANG Z K, XIA Z D, CAI Z Z. Cause of formation transverse corner crack and process in boron steel CC slab [C]//Proceedings of the 12th China Iron and Steel Annual Conference, The Chinese Society for Metals, 2019: 322-327. (江中块, 夏兆东, 蔡兆镇. 含硼钢板坯角横裂缺陷的成因与工艺控制[C]//中国金属学会. 第十二届中国钢铁年会论文集——2. 炼钢与连铸. 上海梅山钢铁股份有限公司;东北大学冶金学院, 2019: 322-327.JIANG Z K, XIA Z D, CAI Z Z. Cause of formation transverse corner crack and process in boron steel CC slab [C]//Proceedings of the 12th China Iron and Steel Annual Conference, The Chinese Society for Metals, 2019: 322-327. [13] GUI L T, LONG M J, ZHANG H H, et al. Study on the precipitation and coarsening of TiN inclusions in Ti-microalloyed steel by a modified coupling model[J]. Journal of Materials Research and Technology, 2020,9(3):5499-5514. [14] LIU T , CHEN D F, LONG M J, et al. Control of coarse precipitates of titanium nitride in high-strength low-alloy steel[J]. Metal Science and Heat Treatment, 2020, 61(9-10): 534-542. [15] CHEN J L, GUO M Y, LIU Z M, et al. Effect of nitrogen content on the hardenability of boron steel[J]. Steel Rolling, 2015,32(4):94-96. (陈继林, 郭明仪, 刘振民, 等. 氮含量对含硼钢淬透性的影响[J]. 轧钢, 2015,32(4):94-96.CHEN J L, GUO M Y, LIU Z M, et al. Effect of nitrogen content on the hardenability of boron steel[J]. Steel Rolling, 2015, 32(4): 94-96. [16] KIM K S, DU L X, GAO C R. Thermodynamic analysis of boron nitride formation in boron microalloyed steel[J]. Journal of Northeastern University(Natural Science), 2015,36(4):483-488. (金光秀, 杜林秀, 高彩茹. 含硼微合金钢中硼氮化物形成的热力学分析[J]. 东北大学学报(自然科学版), 2015,36(4):483-488.KIM K S, DU L X, GAO C R. Thermodynamic analysis of boron nitride formation in boron microalloyed steel[J]. Journal of Northeastern University(Natural Science), 2015, 36(4): 483-488. [17] LUO G H, ZHANG F, FAN Z J, et al. Thermodynamic analysis of BN inclusion precipitation in medium-carbon aluminum killed steel containing B and N[J]. Journal of Wuhan University of Science and Technology, 2014,37(6):406-410. (罗国华, 张帆, 范植金, 等. 含硼氮中碳铝镇定钢中BN夹杂析出热力学分析[J]. 武汉科技大学学报, 2014,37(6):406-410.LUO G H, ZHANG F, FAN Z J, et al. Thermodynamic analysis of BN inclusion precipitation in medium-carbon aluminum killed steel containing B and N[J]. Journal of Wuhan University of Science and Technology, 2014, 37(6): 406-410. [18] LI P S, XIAO L J, XIE Z. Thermodynamic analysis of AlN and BN competitive precipitation in low carbon steel[J]. Journal of Iron and Steel Research, 2009, 21(5): 16-18, 50. (李培松, 肖丽俊, 谢植. 低碳钢中AlN和BN竞相析出热力学分析[J]. 钢铁研究学报, 2009, 21(5): 16-8, 50.LI P S, XIAO L J, XIE Z. Thermodynamic analysis of AlN and BN competitive precipitation in low carbon steel[J]. Journal of Iron and Steel Research, 2009, 21(5): 16-18, 50. [19] YONG Q L, SUN X J, ZHENG L, et al. The role of the second phase in steel materials[J]. Science and Technology innovation Herald, 2009(8):2-3. (雍岐龙, 孙新军, 郑磊, 等. 钢铁材料中第二相的作用[J]. 科技创新导报, 2009(8):2-3. doi: 10.3969/j.issn.1674-098X.2009.08.002YONG Q L, SUN X J, ZHENG L, et al. The role of the second phase in steel materials[J]. Science and Technology innovation Herald, 2009(8): 2-3. doi: 10.3969/j.issn.1674-098X.2009.08.002 [20] WU D M, LI T, LIU Z H, et al. Study on process optimization for controlling corner cracks on boron-bearing steel by titanium micro-alloying[J]. Angang Technology, 2017(4):23-27. (吴东明, 李涛, 刘真海, 等. 钛微合金化抑制含硼钢角裂工艺优化研究[J]. 鞍钢技术, 2017(4):23-27.WU D M, LI T, LIU Z H, et al. Study on process optimization for controlling corner cracks on boron-bearing steel by titanium micro-alloying[J]. Angang Technology, 2017(4): 23-27. [21] ZHANG H H, WAN L H, LONG M J, et al. Quantitative investigation on the evolution of Ti(Cx, N1-x) in ultra-high strength steel slab during TSCR process: precipitation and redissolution[J]. Metallurgical and Materials Transactions B, 2023,54(5):2492-2502. doi: 10.1007/s11663-023-02850-0 [22] SU D X, ZHOU Q F, ZOU C D. Effect of precipitation characteristies of boron nitride on hot ductility of low carbon boron-bearing steel[J]. Journal of lron and Steel Research, 2018,30(6):476-481. (苏笃星, 周青峰, 邹长东. BN析出行为对低碳含硼钢高温塑性的影响[J]. 钢铁研究学报, 2018,30(6):476-481.SU D X, ZHOU Q F, ZOU C D. Effect of precipitation characteristies of boron nitride on hot ductility of low carbon boron-bearing steel[J]. Journal of lron and Steel Research, 2018, 30(6): 476-481. [23] SHI Z R, WANG J J, CHAI X Y, et al. Effect of boron on intragranular ferrite nucleation mechanism in coarse grain heat-affected zone of high-nitrogen steel[J]. Materials Letters, 2020,258:126819. doi: 10.1016/j.matlet.2019.126819 [24] WANG Y N, BAO Y P, WANG M, et al. Basic research on precipitation and control of BN inclusions in steel[J]. Metallurgical and Materials Transactions B, 2013,44:1144-1154. doi: 10.1007/s11663-013-9881-1 [25] PRITGIV T, GAULT B, LI Y, et al. Austenite grain boundary segregation and precipitation of boron in low-C steels and their role on the heterogeneous nucleation of ferrite[J]. Acta Materialia, 2023,252:118947. doi: 10.1016/j.actamat.2023.118947 [26] CAI K S, YAO Y K, LIU W J, et al. Study and control of boron existing forms in boron-bearing steel[J]. Steelmaking, 2015,31(3):45-49. (蔡可森, 姚永宽, 刘伟建, 等. 含硼钢中硼的存在形式及控制研究[J]. 炼钢, 2015,31(3):45-49.CAI K S, YAO Y K, LIU W J, et al. Study and control of boron existing forms in boron-bearing steel[J]. Steelmaking, 2015, 31(3): 45-49. [27] GONTIJO M, CHAKRABORTY A, WEBSTER R, et al. Thermomechanical and microstructural analysis of the influence of B-and Ti-content on the hot ductility behavior of microalloyed steels[J]. Metals, 2022,12(11):1808. doi: 10.3390/met12111808 [28] TAKAHASHI J, ISHIKAWA K, KAWAKAMI K, et al. Atomic-scale study on segregation behavior at austenite grain boundaries in boron-and molybdenum-added steels[J]. Acta Materialia, 2017,133:41-54. doi: 10.1016/j.actamat.2017.05.021 [29] KYUNG C, DONG J M, YANG M K, et al. Effect of niobium and titanium addition on the hot ductility of boron containing steel[J]. Materials Science and Engineering: A, 2011,528(10-11):3556-3561. doi: 10.1016/j.msea.2011.01.097 [30] ILMAN M, COCHRANE R, EVANS G. Effect of nitrogen and boron on the development of acicular ferrite in reheated C-Mn-Ti steel weld metals[J]. Welding in the World, 2012,56:41-50. [31] KOMENDA J, LUO C H, LÖNNQVIST J. Interaction of carbon, titanium and boron in micro-alloy steels and its effect on hot ductility[J]. Alloys, 2022,1(2):133-148. doi: 10.3390/alloys1020009 -

下载:

下载: