Effect of yttrium doping on microstructure and mechanical properties of CoCrFeNi high entropy alloy prepared by molten salt electrolysis

-

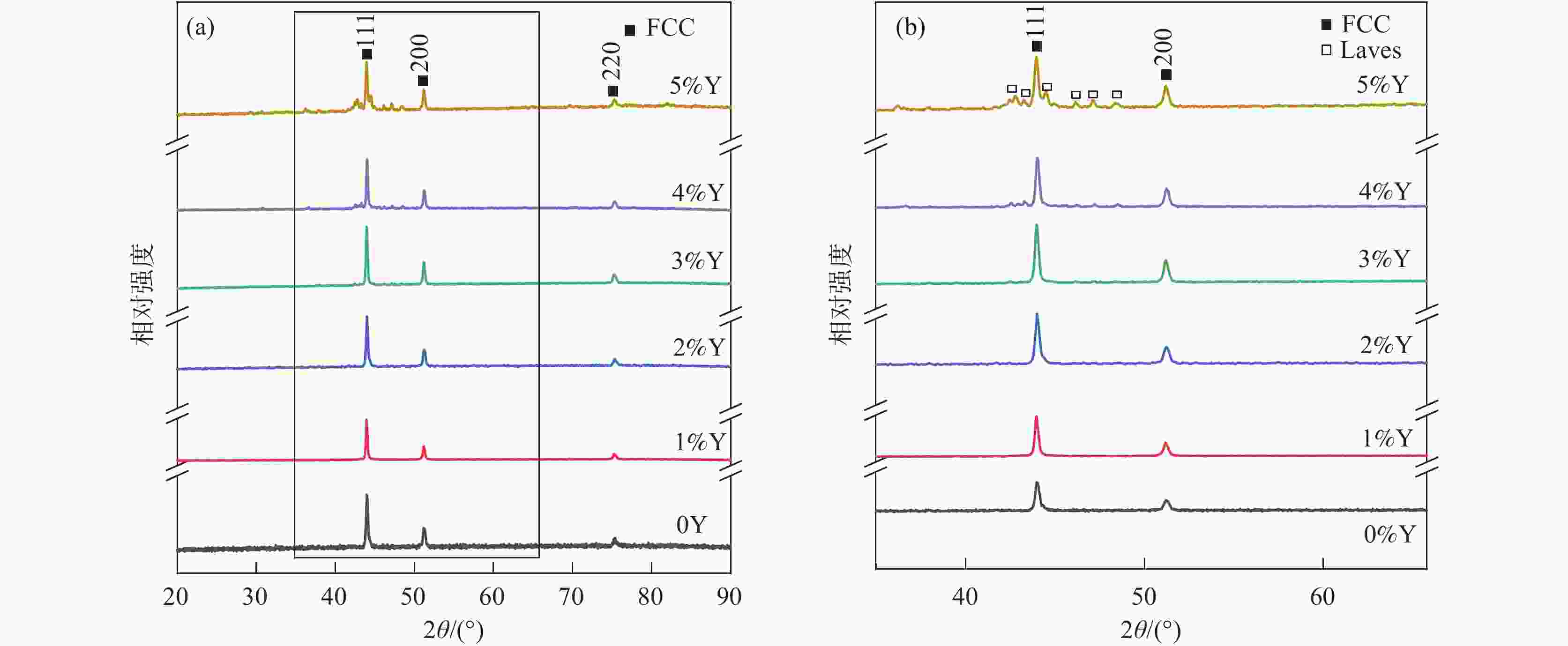

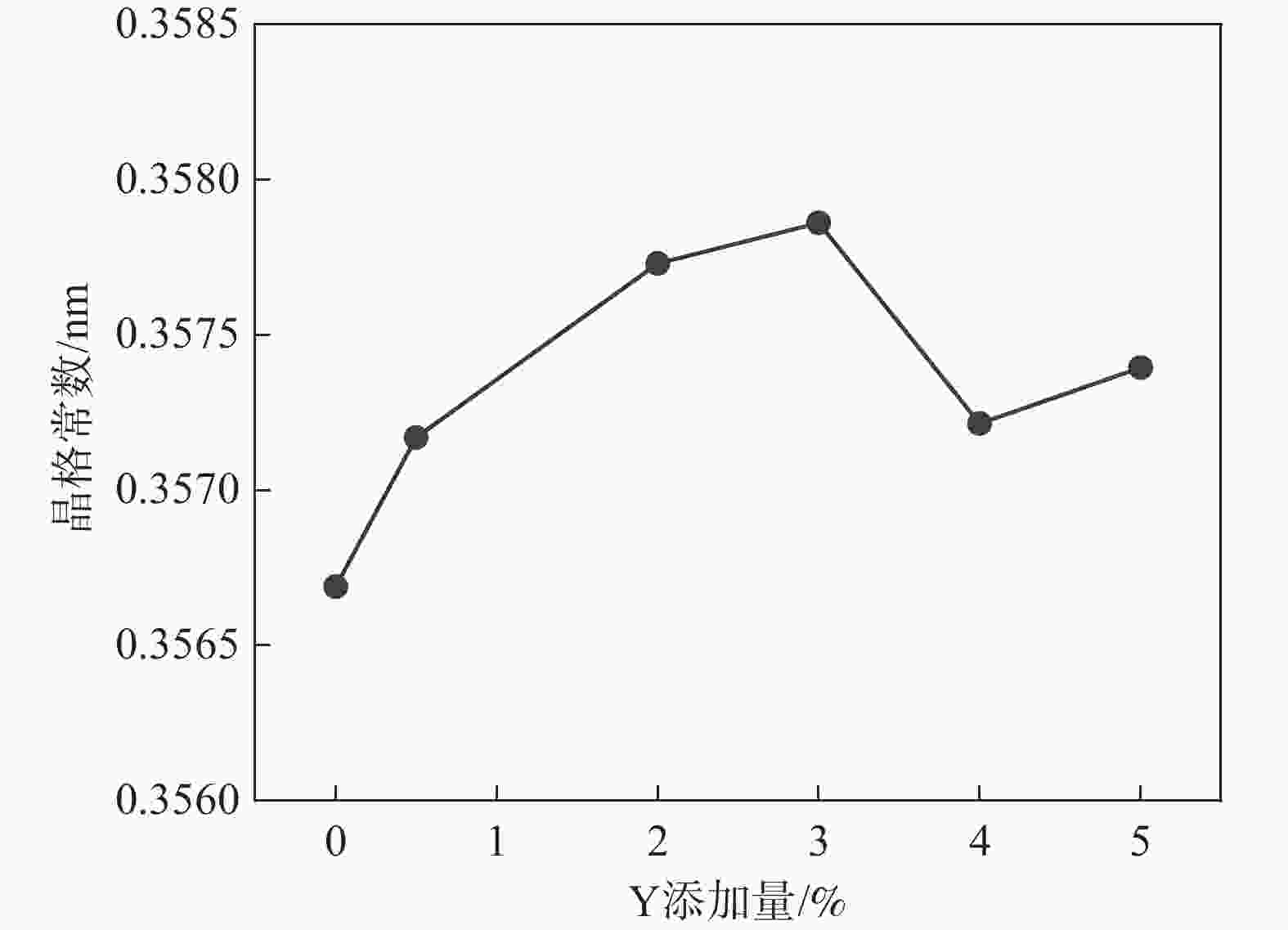

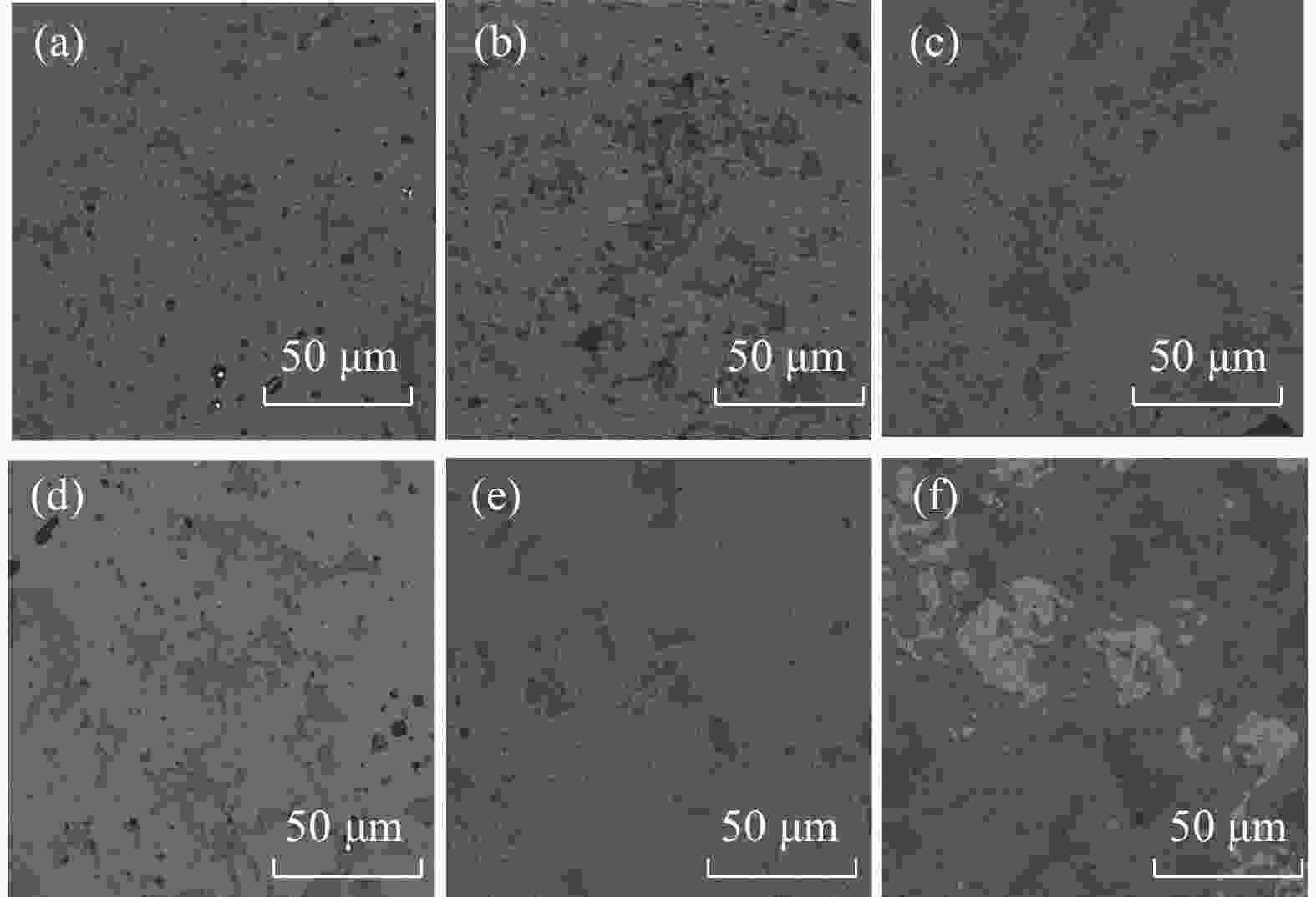

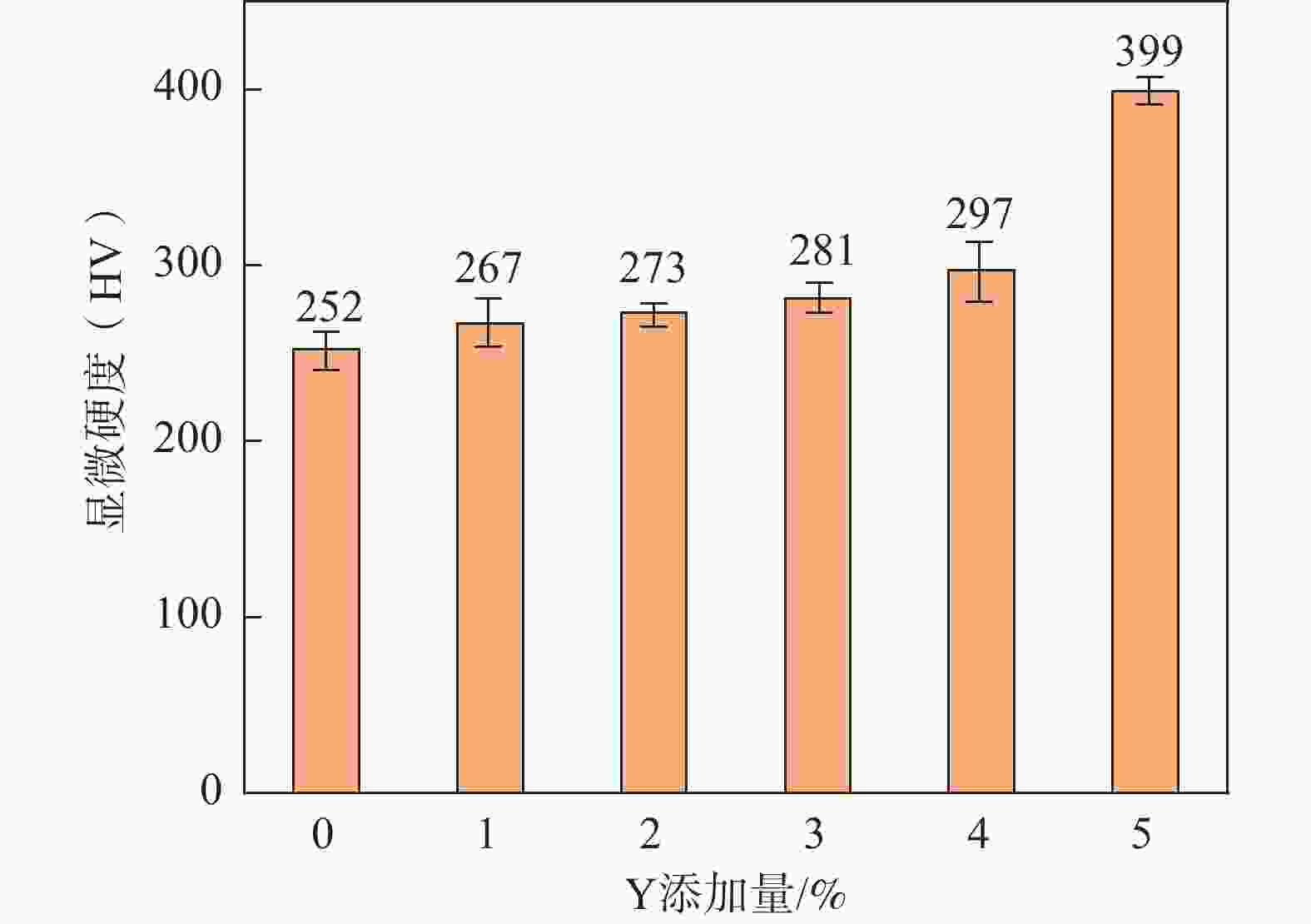

摘要: 采用熔盐电解混合氧化物直接固相脱氧制备CoCrFeNi高熵合金,并对稀土元素钇(Y)掺杂对CoCrFeNi高熵合金的物相、组织及力学性能的影响进行了系统研究。结果表明,可通过电解混合金属氧化物直接固相脱氧制备CoCrFeNi高熵合金,Y元素掺杂可直接以Y2O3的形态与主体氧化物混合后脱氧并实现元素掺杂,但该工艺制备过程会形成一定量Cr7C3相。适量Y掺杂可有效提升CoCrFeNi高熵合金的力学性能,当Y添加量达到5%后,高熵合金的显微硬度(HV)为399,比未添加Y的CoCrFeNi 高熵合金的硬度提升了58.3%。当Y添加量为1%时CoCrFeNi 高熵合金的抗拉强度提升10.7 %,断裂伸长率增加了5倍。Abstract: High-entropy alloys of CoCrFeNi had been prepared by electrolysis process using the mixed oxides as the raw materials, and the effects of rare earth element of Yttrium doping on the phase, microstructure and mechanical properties of CoCrFeNi high-entropy alloys were also studied. The results show that CoCrFeNi high-entropy alloy can be directly prepared by electrolysis from the mixed oxides of CoO, Cr2O3, NiO, Fe2O3, and Y doping can be directly mixed with the main oxide in the form of Y2O3 and deoxidized to achieve Y doping. The second phase of Cr7C3 appears in CoCrFeNi high-entropy alloy when using electrolysis process. The appropriate amount of Y can effectively improve the mechanical properties of CoCrFeNi high-entropy alloy. When the addition amount of Y reaches 5%, the hardness of the high-entropy alloy is 399 HV, which is 58.3% higher than that of the CoCrFeNi high-entropy alloy without Y addition. When the addition of Y is 1%, the tensile strength of CoCrFeNi high-entropy alloy increases by 10.7 % and the elongation increases by 5 times.

-

Key words:

- CoCrFeNi /

- high entropy alloys /

- Y /

- electrochemical process /

- hot press sintering

-

表 1 (CoCrFeNi)100-xYx高熵合金混合氧化物粉末的组成

Table 1. Compositions of mixed oxide powder (CoCrFeNi)100-xYx of high entropy alloy

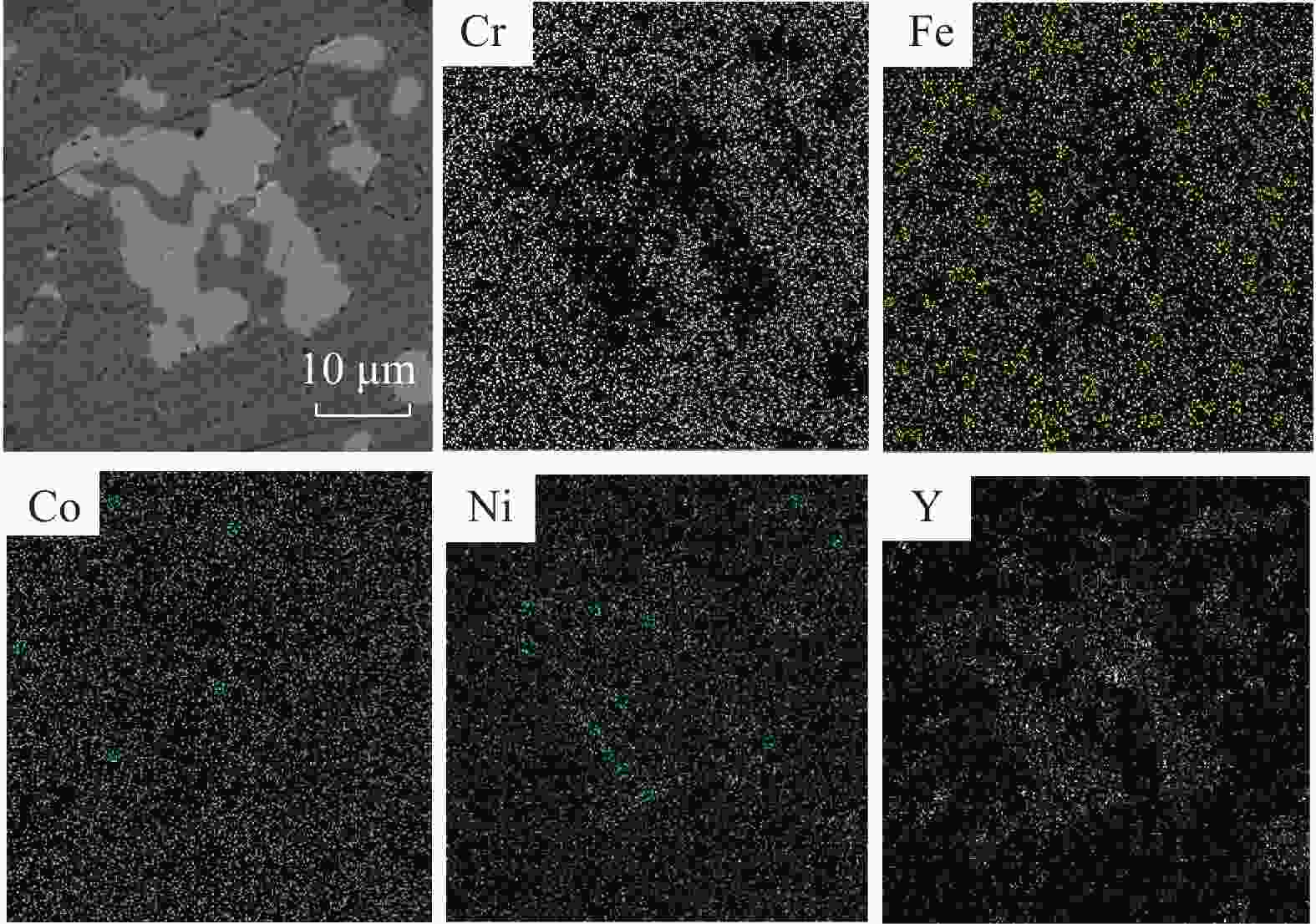

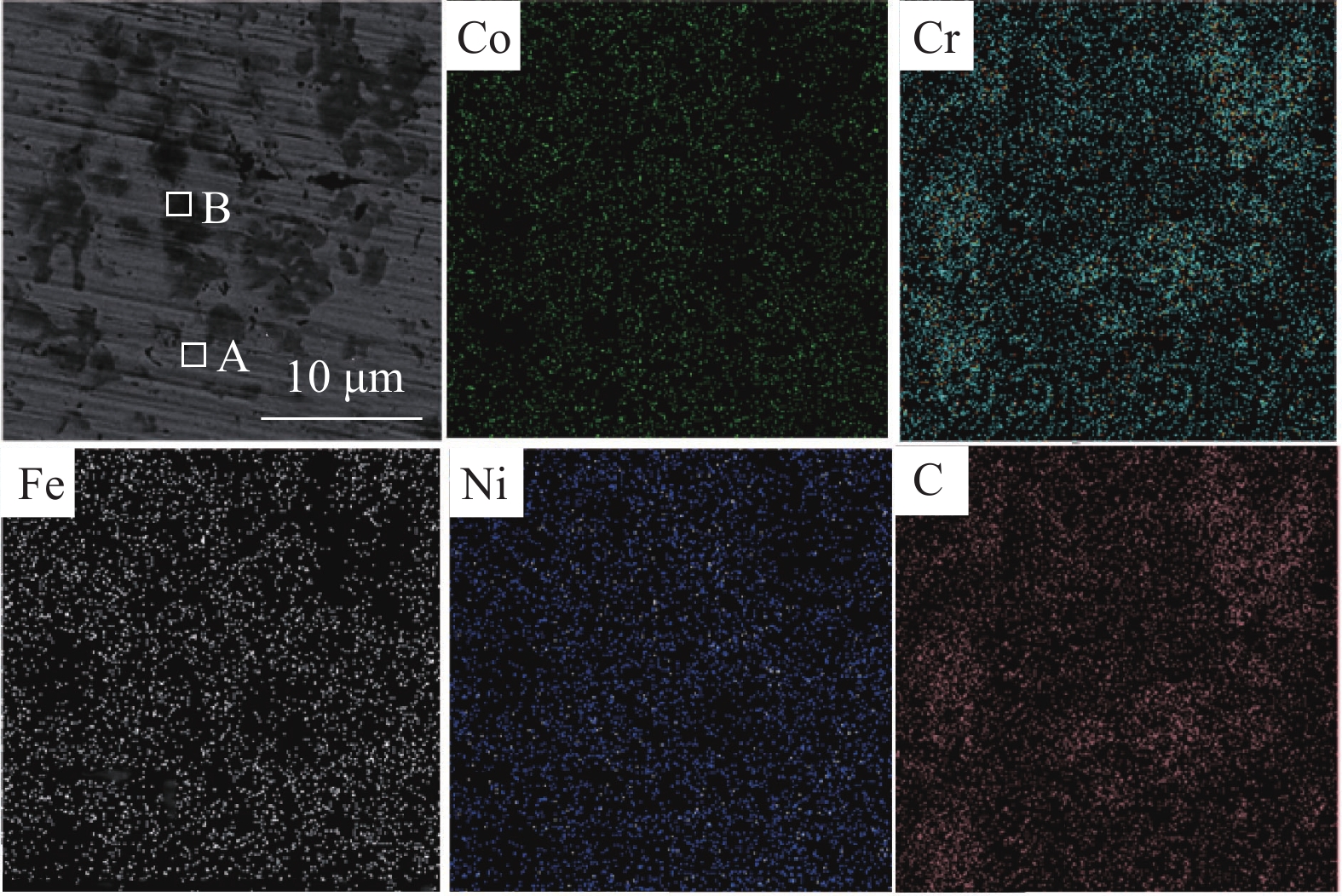

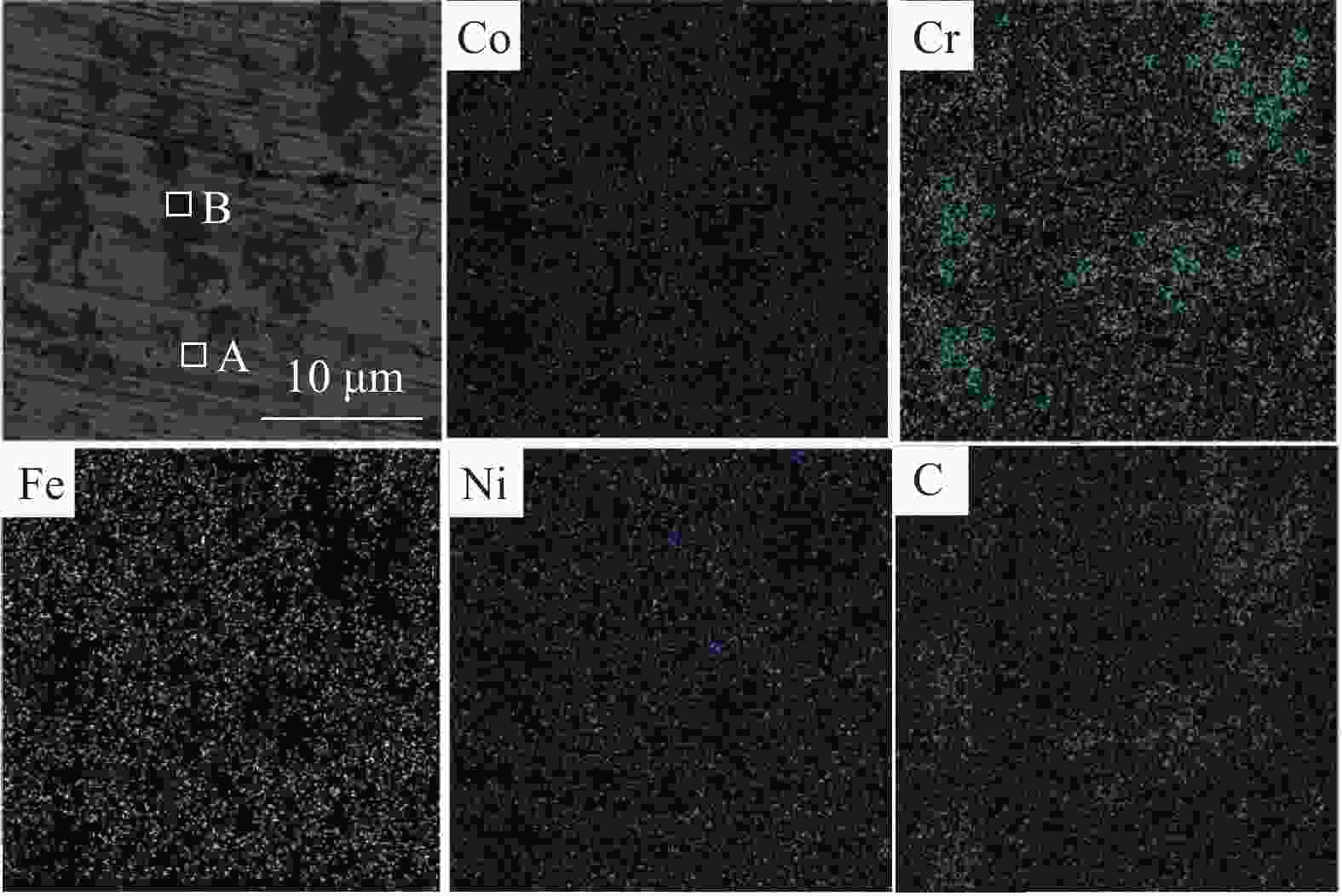

g x CoO Cr2O3 Fe2O3 NiO Y2O3 总质量 0 3.68 3.73 3.92 3.68 0 15 1 3.62 3.67 3.86 3.62 0.22 15 2 3.57 3.62 3.81 3.57 0.44 15 3 3.51 3.57 3.75 3.51 0.66 15 4 3.46 3.51 3.69 3.46 0.87 15 5 3.41 3.46 3.64 3.41 1.08 15 表 2 图1中样品A、B区域的元素组成及其体积含量

Table 2. Compositions and contents in region A and B of CoCrFeNi high entropy alloy

% Co Cr Fe Ni C A 26.84 22.27 26.81 25.19 0.03 B 2.47 21.49 2.47 2.00 71.07 表 3 (CoCrFeNi)100-xYx高熵合金中各元素的混合焓

Table 3. Enthalpy of mixing of elements in (CoCrFeNi)100-xYx high entropy alloy

kJ/mol 元素 Co Cr Fe Ni Y Co −4 −1 0 −22 Cr −1 −7 11 Fe −2 −1 Ni −31 Y -

[1] JAGADEESH S, MAHA V S, CARSTEN S. Direct electrochemical synthesis of high-entropy alloys from metal oxides[J]. Applied Materials Today, 2017, 9: 111-121. [2] WANG B, HUANG J, FAN J H, et al. Preparation of FeCoNiCrMn high entropy alloy by electrochemical reduction of solid oxides in molten salt and its corrosion behavior in aqueous solution[J]. Journal of The Electrochemical Society, 2017,164(14):E575-E579. doi: 10.1149/2.1521714jes [3] JIAO H D, WANG M Y, TU J G, et al. Production of AlCrNbTaTi high entropy alloy via electro-deoxidation of metal oxides[J]. Journal of the Electrochemical Society, 2018, 165(11): D574-D579. [4] WANG W R, WANG W L, WANG S C, et al. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys[J]. Intermetallics, 2012,26:15-22. [5] LIU L, ZHANG Y, ZHAO Z F, et al. Microstructure and mechanical properties of AlxCoCuFeNi high entropy alloys[J]. Special Casting & Nonferrous Alloys, 2016,36(6):570-574. (刘亮, 张越, 赵作福, 等. AlxCoCuFeNi 高熵合金的组织结构与力学性能[J]. 特种铸造及有色合金, 2016,36(6):570-574.LIU L, ZHANG Y, ZHAO Z F, et al. Microstructure and mechanical properties of AlxCoCuFeNi high entropy alloys[J]. Special Casting & Nonferrous Alloys, 2016, 36(6): 570-574. [6] XIE H B, LIU G Z, GUO J J, et al. Effects of Al addition on microstructure and wear properties of AlxFeCrCoCuV high-entropy alloys[J]. Journal of Materials Engineering, 2016,44:65-70. (谢红波, 刘贵仲, 郭景杰, 等. Al元素对AlxFeCrCoCuV高熵合金组织及摩擦性能的影响[J]. 材料工程, 2016,44:65-70. doi: 10.11868/j.issn.1001-4381.2016.05.011XIE H B, LIU G Z, GUO J J, et al. Effects of Al addition on microstructure and wear properties of AlxFeCrCoCuV high-entropy alloys[J]. Journal of Materials Engineering, 2016, 44: 65-70. doi: 10.11868/j.issn.1001-4381.2016.05.011 [7] LI A M, ZHANG X Y. Effect of Cr on microstructure and hardness of AlCrxCuFeNi high-entropy alloys system[J]. Nonferrous Metals, 2009,61(4):18-20. (李安敏, 张喜燕. Cr对AlCrxCuFeNi高熵合金组织与硬度的影响[J]. 有色金属, 2009,61(4):18-20.LI A M, ZHANG X Y. Effect of Cr on microstructure and hardness of AlCrxCuFeNi high-entropy alloys system[J]. Nonferrous Metals, 2009, 61(4): 18-20. [8] YE H M, YANG W C, PANG W C, et al. Effect of titanium content on wear resistance of CoCuFeNiVTix high-entropy alloys[J]. Journal of Guangxi University(Natural Science Edition), 2017,42(3):1187-1911. (叶海梅, 杨文超, 庞文超, 等. Ti元素对CoCuFeNiVTix高熵合金耐磨性能的影响[J]. 广西大学学报(自然科学版), 2017,42(3):1187-1911.YE H M, YANG W C, PANG W C, et al. Effect of titanium content on wear resistance of CoCuFeNiVTix high-entropy alloys[J]. Journal of Guangxi University(Natural Science Edition), 2017, 42(3): 1187-1911. [9] HSH C Y, SHEU T S, YEH J W, et al. Effect of iron content on wear behavior of AlCoCrFexMo0.5Ni high entropy alloys[J]. Wear, 2010, 268: 653-659. [10] LIU W H, HE J Y, HUANG H L, et al. Effects of Nb additions on the microstructure and mechanical property of CoCrFeNi high-entropy alloys[J]. Intermetallics, 2015,60:1-8. doi: 10.1016/j.intermet.2015.01.004 [11] LIN D Y, ZHANG N N, HE B, et al. Tribological properties of FeCoCrNiAlBx high-entropy alloys coating prepared by laser cladding[J]. Journal of Iron and Steel Research International, 2017,24(2):184-189. doi: 10.1016/S1006-706X(17)30026-2 [12] ZHUANG Y X, ZHANG X L, GU X Y. Effect of molybdenum on phases, microstructure and mechanical properties of Al0.5CoCrFeMoxNi high entropy alloys[J]. Journal of Alloys and Compounds, 2018,743:514-522. doi: 10.1016/j.jallcom.2018.02.003 [13] QIAN T B, CUI H B, GUO X F. Effects of Mo and V on microstructure of FeCoNiCrAl0.3 high entropy alloys[L]. Hot Working Technology, 2017, 46(8): 54-57. (钱天宝, 崔红保, 郭学锋. Mo和V对 FeCoNiCrAl0.3高熵合金组织的影响[J]. 热加工工艺, 2017, 46(8): 54-57.QIAN T B, CUI H B, GUO X F. Effects of Mo and V on microstructure of FeCoNiCrAl0.3 high entropy alloys[L]. Hot Working Technology, 2017, 46(8): 54-57. [14] ZHANG L J, ZHANG M D, ZHOU Z, et al. Effects of rare-earth element Y additions on the microstructure and mechanical properties of CoCrFeNi high entropy alloy[J]. Materials Science & Engineering A, 2018,725:437-446. [15] HAO C M, LIU G Z, XIE H B, et al. Effects of Cu addition on the microstructure and mechanical properties of AlFeCrCoTiCux high-entropy alloys[J]. Journal of Guangxi University(Natural Science Edition), 2016,41(3):876-882. (郝聪敏, 刘贵仲, 谢红波, 等. Cu对AlFeCrCoTiCux多组元高熵合金组织及其力学性能的影响[J]. 广西大学学报, 2016,41(3):876-882.HAO C M, LIU G Z, XIE H B, et al. Effects of Cu addition on the microstructure and mechanical properties of AlFeCrCoTiCux high-entropy alloys[J]. Journal of Guangxi University(Natural Science Edition), 2016, 41(3): 876-882. [16] XUE Y J, WEI W C, WANG M Q, et al. Effects of Si on microsture and mechanical properties of FeMoCrVTiSix high entropy alloy[J]. Special Casting & Nonferrous Alloys, 2020,40(1):112-116. (薛彦均, 尉文超, 王毛球, 等. Si对FeMoCrVTiSix高熵合金组织和力学性能的影响[J]. 特种铸造及有色合金, 2020,40(1):112-116.XUE Y J, WEI W C, WANG M Q, et al. Effects of Si on microsture and mechanical properties of FeMoCrVTiSix high entropy alloy[J]. Special Casting & Nonferrous Alloys, 2020, 40(1): 112-116. [17] NIKOLAI K, VOLKER V, NIKITA S, et al. Laser beam welding of a CoCrFeNiMn-type high entropy alloy produced by self-propagating high-temperature synthesis[J]. Intermetallics, 2018,96:63-71. doi: 10.1016/j.intermet.2018.02.014 [18] HU M J, JIANG X J, DONG M Y, et al. Preparation and effect of vanadium addition on the mechanical properties of CoCrFeNiVx high-entropy alloy. Journal of materials research and Technology, 2023, 27: 7705-7712. [19] YANG Y, LUO X Y, MA T X, et al. Effect of Al on characterization and properties of AlxCoCrFeNi high entropy alloy prepared via electro-deoxidization of the metal oxides and vacuum hot pressing sintering process[J]. Journal of Alloys and Compounds, 2021,864:158717. doi: 10.1016/j.jallcom.2021.158717 [20] WANG Z W, BAKER I, CAI Z H, et al. The effect of interstitial carbon on the mechanical properties and dislocation substructure evolution in Fe40.4Ni11.3Mn34.8Al7.5Cr6 high entropy alloys[J]. Acta Materialia, 2016,120:228-239. doi: 10.1016/j.actamat.2016.08.072 -

下载:

下载: