Efficient extraction metallurgy of vanadium slag: calcium-magnesium composite roasting vanadium extraction process

-

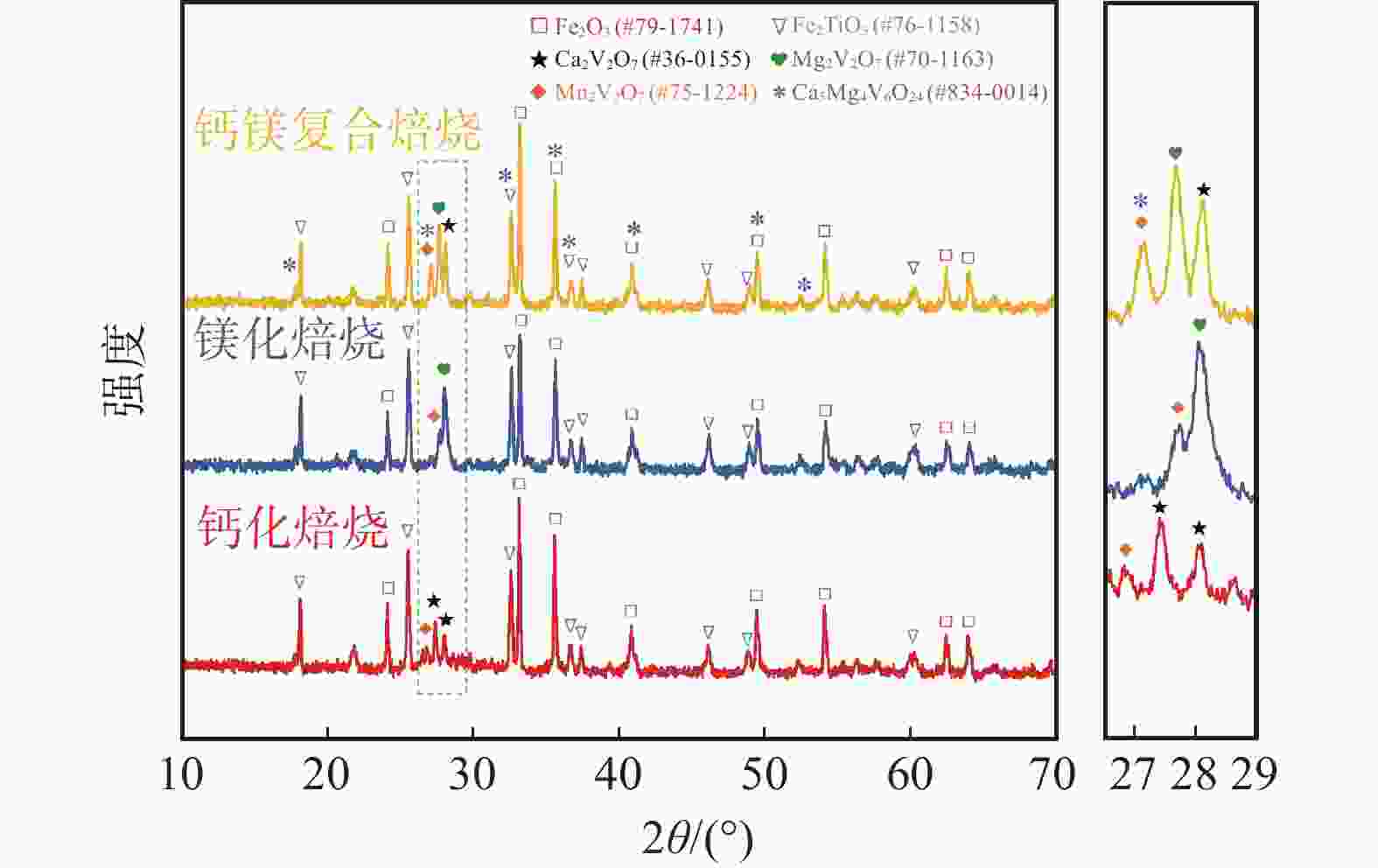

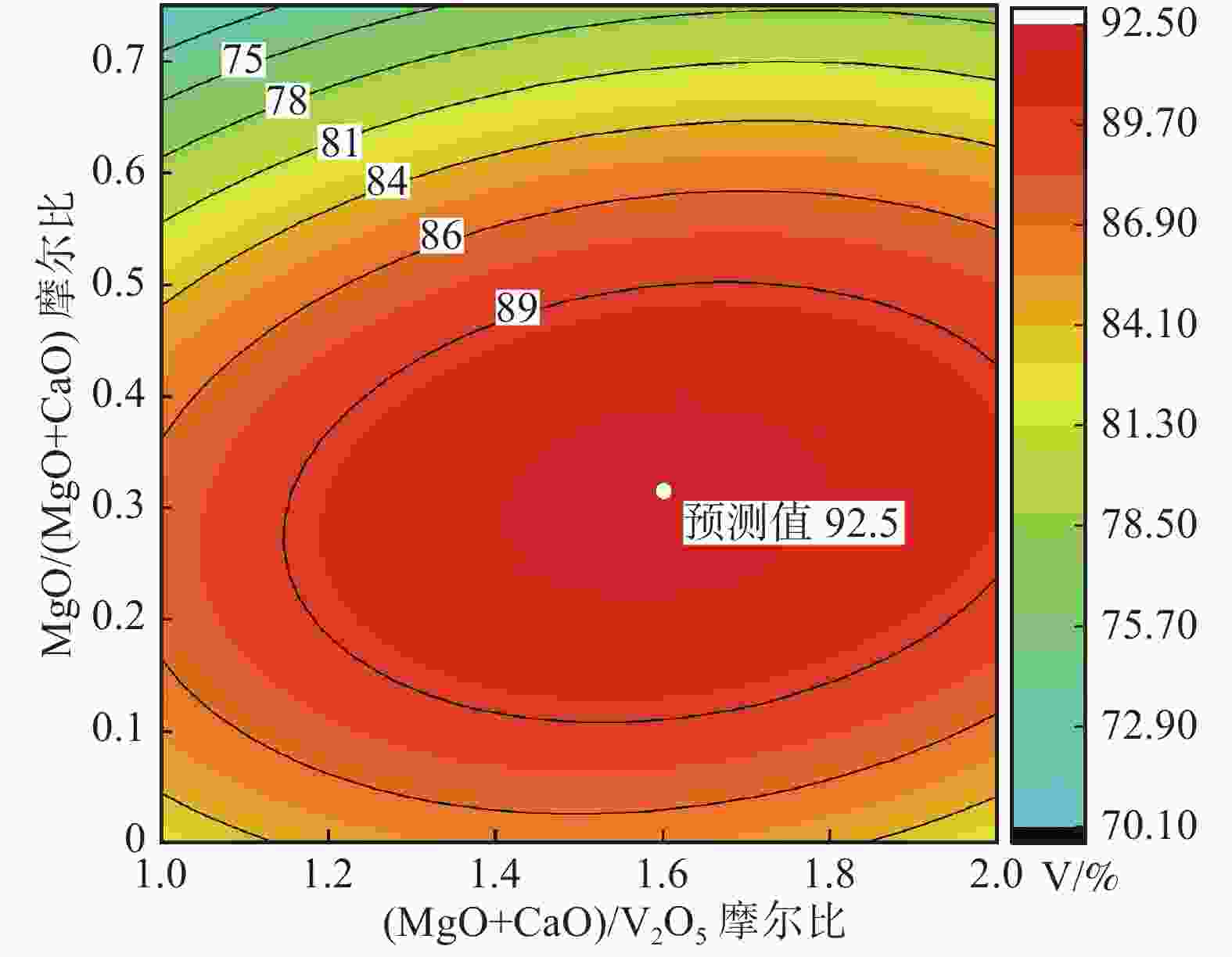

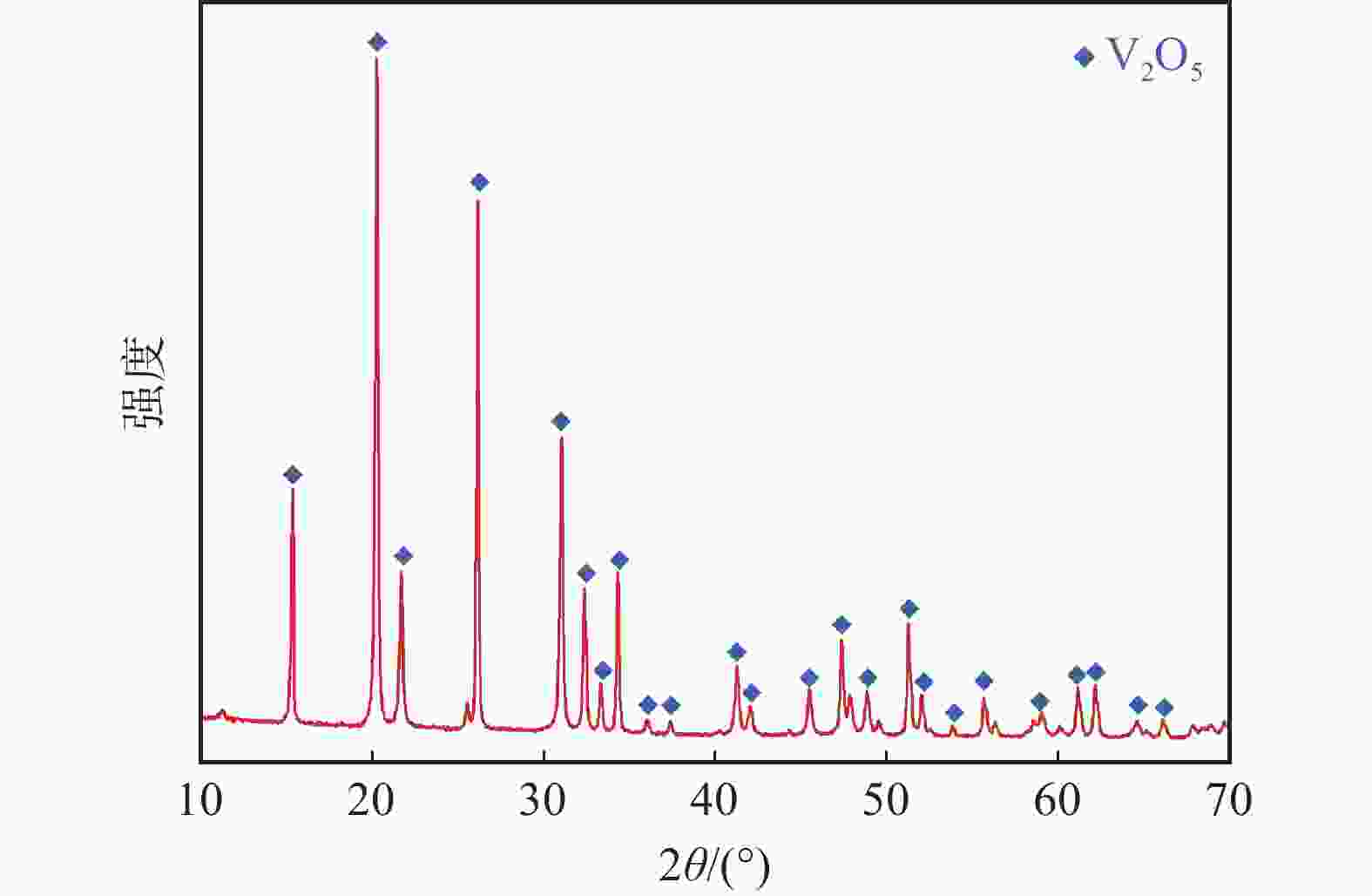

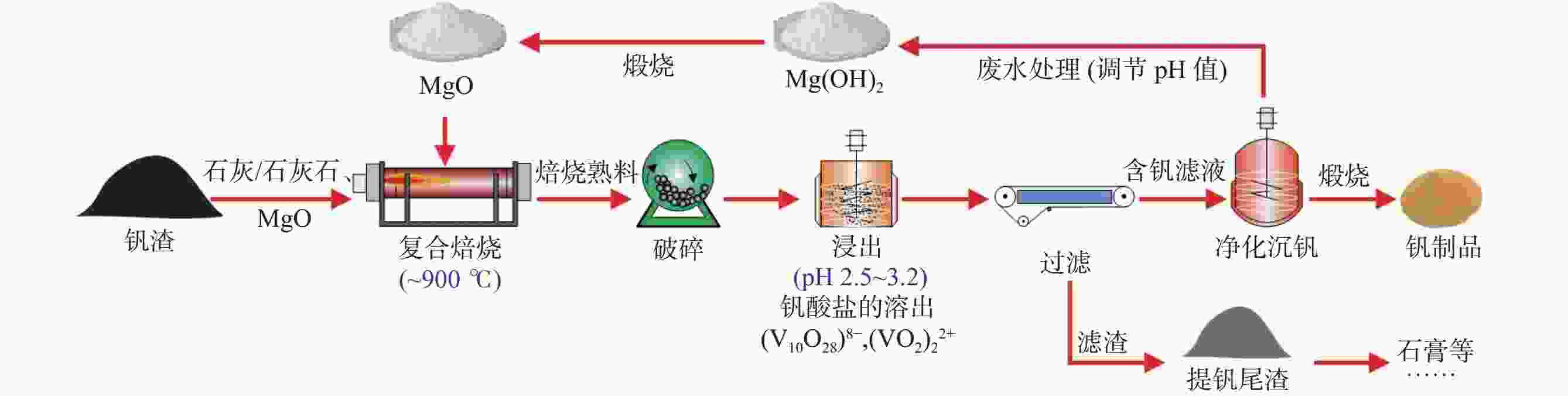

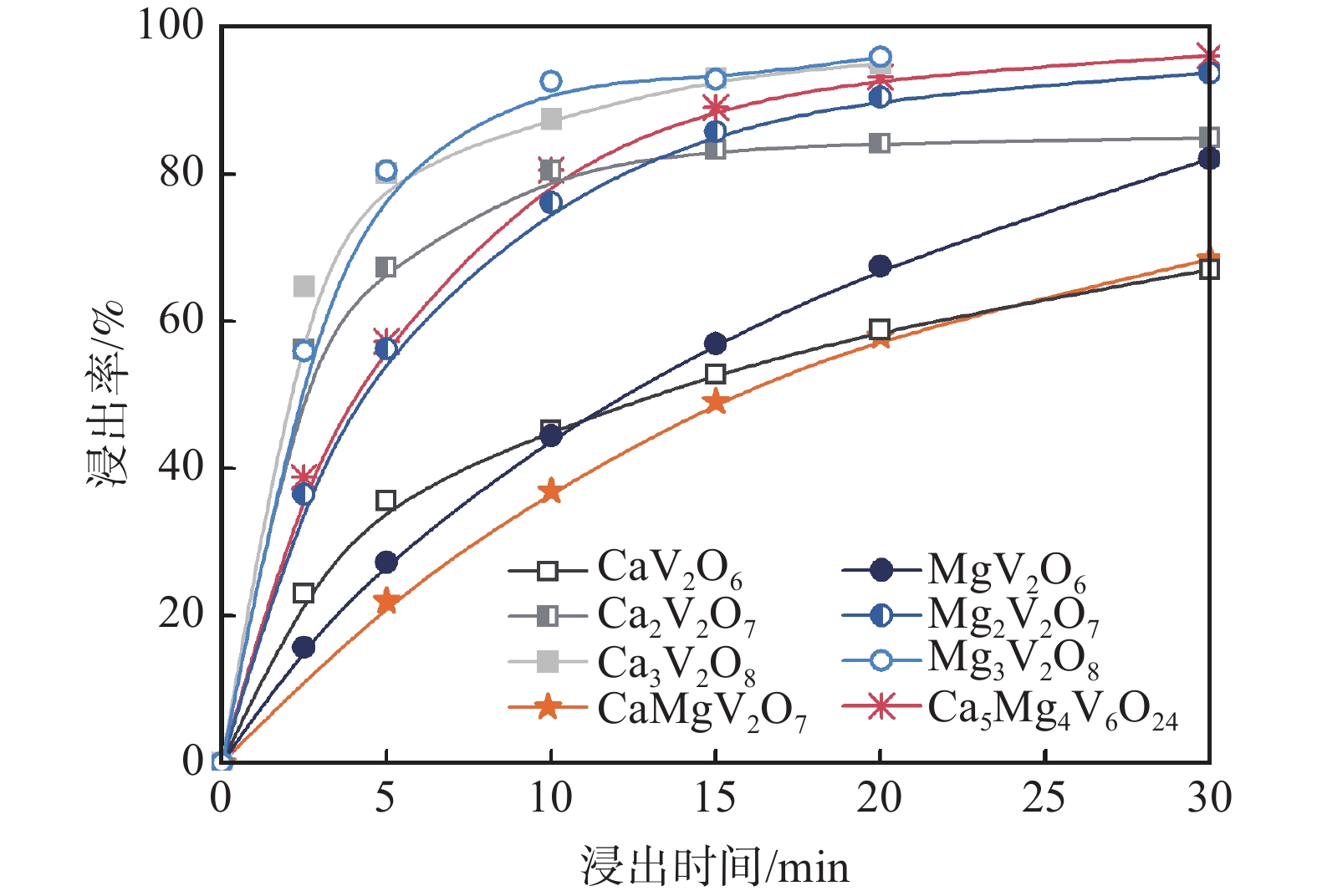

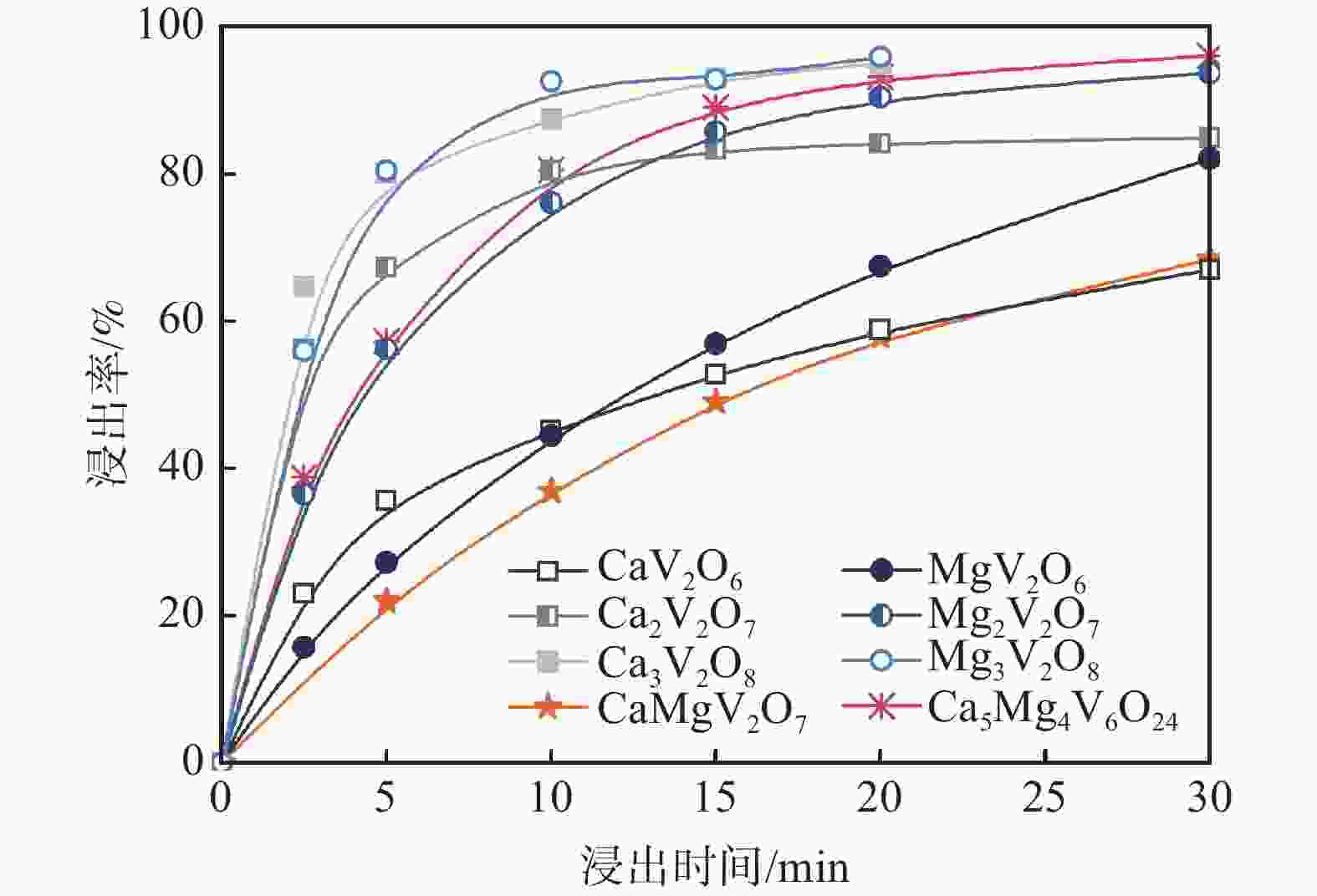

摘要: 钙化工艺是一种相对清洁的钒渣提钒技术,但在钒收率、产品指标等方面仍有进一步提升空间。笔者团队原创性开发的钙镁复合提钒工艺通过离子协同效应,同时实现了钒回收率提升、杂质溶出率降低和尾渣减量的效果。文中阐述了钙镁复合对钒渣提钒工艺全流程的综合影响,钙镁复合焙烧后钒渣焙烧熟料中的主要含钒物相由Ca2V2O7、Mn2V2O7转变为Ca2V2O7、Mn2V2O7、Mg2V2O7和Ca5Mg4V6O24;复合焙烧产物酸浸后钒浸出率提升约5%,Ca、P等杂质元素溶出率降低;钒浸出液铵盐沉钒率达99.5%,氧化钒产品纯度达99.8%;沉钒废水经石灰中和处理后可完全回用,且不影响原工艺顺行。Abstract: The calcification process is a relatively clean vanadium extraction technology from vanadium slag, but there is still room for further improvement in vanadium yield and product index. The calcium-magnesium composite vanadium extraction process originally developed by our team has achieved the effect of improving vanadium recovery rate, reducing impurity dissolution rate and tailings reduction through ion synergistic effect. In this paper, the comprehensive influence of calcium-magnesium composite on the whole process of vanadium extraction from vanadium slag is expounded. After calcium-magnesium composite roasting, the main vanadium-containing phases in the roasting clinker of vanadium slag are changed from Ca2V2O7 and Mn2V2O7 to Ca2V2O7, Mn2V2O7, Mg2V2O7 and Ca5Mg4V6O24. After acid leaching, the leaching rate of vanadium was increased by about 5%, and the dissolution rate of impurity elements such as Ca and P decreased. The vanadium precipitation rate of ammonium salt in vanadium leaching solution was 99.5%, and the purity of vanadium oxide product was 99.8%. The vanadium precipitation wastewater can be completely reused after lime neutralization treatment without affecting the smooth operation of the original process.

-

Key words:

- vanadium slag /

- calcium-magnesium composite roasting /

- vanadium extraction /

- recovery

-

表 1 钒渣主要组成成分

Table 1. The main components of vanadium slag

% V2O5 TFe SiO2 TiO2 MgO Al2O3 MnO CaO Cr2O3 15.29 31.00 14.50 14.38 2.92 3.47 7.32 2.57 1.43 表 2 不同MgO/(CaO+MgO)摩尔比下杂质元素的浸出浓度

Table 2. Leaching concentrations of impurity elements at different MgO/(CaO+MgO) molar ratios

mg/L MgO/(CaO+MgO) V Cr P Mn Fe Mg 0 14265 8.925 9.52 3614 23.95 627.7 1/6 16074 6.828 0.854 4523 16.50 894.8 1/3 16074 6.259 1.849 5049 17.78 1344 1/2 16501 5.121 1.707 5604 18.92 1507 表 3 不同MgO/(CaO+MgO)摩尔比下浸出尾渣化学成分

Table 3. Chemical composition of the leaching residue with different MgO/(CaO+MgO) mole ratio

% MgO/

(CaO+MgO)Mg Al Mn P S Ca Ti V Cr Si Fe O 渣率 0 0.42 0.38 3.81 0.09 7.25 6.68 6.21 0.71 1.29 4.04 30.53 6.21 93.7 1/6 0.63 0.38 3.39 0.1 6.01 6.04 6.38 0.62 1.28 4.52 31.76 6.38 90.6 1/3 0.91 0.38 3.28 0.1 5.86 5.1 6.84 0.64 1.33 4.79 32.58 6.84 89.4 1/2 1.83 0.38 3.18 0.09 5.31 4.35 6.85 0.64 1.39 4.91 33.07 6.15 88.5 表 4 铵盐沉钒废水中元素浓度及沉钒率

Table 4. Element concentration and vanadium precipitation rate in vanadium precipitation wastewater by ammonium salt

MgO/(CaO+MgO) 元素浓度/(mg·L−1) 沉钒率/% V Cr P Fe Si Mn Mg 0 73.0 0.10 0.10 1.10 27.6 2220 370 99.24 1/6 57.0 1.58 0.38 0.48 13.5 3217 602 99.50 1/3 62.5 0.58 0.41 1.28 8.55 3488 840 99.45 1/2 67.5 0.60 0.55 1.80 6.05 3528 767 99.42 表 5 氧化钒产品化学成分

Table 5. Chemical composition of vanadium oxide products

% 工艺 V2O5 Mg Si Al P Mn Ti Cr Ca Fe 钙化 99.5 0.003 0.0037 <0.001 0.008 0.168 0.037 0.011 0.070 0.081 钙镁复合 99.8 0.003 <0.001 <0.001 0.002 0.009 0.013 0.009 0.002 0.002 表 6 废水循环次数对钒渣浸出的影响

Table 6. Effect of wastewater recirculation on the leaching of vanadium slag

循环次数 元素浓度/(mg·L−1) 钒浸出率/% V Cr P Mn Mg 1 13532 4.160 27.54 3073 800.1 91.85 2 15167 4.253 26.89 3555 855.6 91.45 3 15795 4.371 27.21 3397 832.2 90.98 4 15993 4.635 28.80 3550 897.8 91.76 -

[1] WU Y, CHEN D H, LIU W H, et al. 2022 Global vanadium industry development report[J]. Iron Steel Vanadium Titanium, 2023, 44(6): 1-8. (吴优, 陈东辉, 刘武汉, 等. 2022年全球钒工业发展报告[J]. 钢铁钒钛, 2023, 44(6): 1-8.WU Y, CHEN D H, LIU W H, et al. 2022 Global vanadium industry development report[J]. Iron Steel Vanadium Titanium, 2023, 44(6): 1-8. [2] LIANG X Y, YE G H, ZHU S Q, et al. Research progress of vanadium extraction process from vanadium-titanium magnetite[J]. Rare Metals, 2023, 47(6): 893-907. (梁雪崟, 叶国华, 朱思琴, 等. 钒钛磁铁矿提钒工艺的研究进展[J]. 稀有金属, 2023, 47(6): 893-907.LIANG X Y, YE G H, ZHU S Q, et al. Research progress of vanadium extraction process from vanadium-titanium magnetite[J]. Rare Metals, 2023, 47(6): 893-907. [3] CHEN H S. Study on the process of extracting V2O5 from vanadium slag by lime roasting[J]. Iron Steel Vanadium Titanium, 1992(6): 1-9. (陈厚生. 钒渣石灰焙烧法提取V2O5工艺研究[J]. 钢铁钒钛, 1992(6): 1-9.CHEN H S. Study on the process of extracting V2O5 from vanadium slag by lime roasting[J]. Iron Steel Vanadium Titanium, 1992(6): 1-9. [4] HUANG Q Y, XIANG J Y, PEI G S, et al. Mechanical activation enhanced vanadium slag calcification vanadium extraction process[J]. Chinese Journal of Nonferrous Metals, 2020, 30(4): 858-865. (黄青云, 向俊一, 裴贵尚, 等. 机械活化强化钒渣钙化提钒工艺[J]. 中国有色金属学报, 2020, 30(4): 858-865. doi: 10.11817/j.ysxb.1004.0609.2020-35745HUANG Q Y, XIANG J Y, PEI G S, et al. Mechanical activation enhanced vanadium slag calcification vanadium extraction process[J]. Chinese Journal of Nonferrous Metals, 2020, 30(4): 858-865. doi: 10.11817/j.ysxb.1004.0609.2020-35745 [5] FU N X, ZHANG L, LIU W H, et al. Mechanism analysis of phase transformation process of vanadium slag calcification roasting[J]. Chinese Journal of Nonferrous Metals, 2018, 28(2): 377-386. (付念新, 张林, 刘武汉, 等. 钒渣钙化焙烧相变过程的机理分析[J]. 中国有色金属学报, 2018, 28(2): 377-386.FU N X, ZHANG L, LIU W H, et al. Mechanism analysis of phase transformation process of vanadium slag calcification roasting[J]. Chinese Journal of Nonferrous Metals, 2018, 28(2): 377-386. [6] WANG C Q, LIU W H, LIU H Q, et al. Vanadium slag calcification roasting sintering phenomenon research[J]. Iron Steel Vanadium Titanium, 2013, 34(6): 6-11. (王春琼, 刘武汉, 刘恢前, 等. 钒渣钙化焙烧烧结现象研究[J]. 钢铁钒钛, 2013, 34(6): 6-11.WANG C Q, LIU W H, LIU H Q, et al. Vanadium slag calcification roasting sintering phenomenon research[J]. Iron Steel Vanadium Titanium, 2013, 34(6): 6-11. [7] YIN D F, PENG Y, SUN Z H, et al. Study on the influence factors of vanadium slag calcification roasting and process thermal analysis[J]. Metal Mine, 2012, 41(4): 91-94. (尹丹凤, 彭毅, 孙朝晖, 等. 攀钢钒渣钙化焙烧影响因素研究及过程热分析[J]. 金属矿山, 2012, 41(4): 91-94.YIN D F, PENG Y, SUN Z H, et al. Study on the influence factors of vanadium slag calcification roasting and process thermal analysis[J]. Metal Mine, 2012, 41(4): 91-94. [8] FAN K, LI Z C, LI Z S, et al. Effects of different calcification agents on acid leaching of vanadium from high vanadium slag[J]. Journal of Chongqing University (Natural Science Edition), 2015(5): 151-156. (范坤, 李曾超, 李子申, 等. 不同钙化剂对高钒渣酸浸提钒的影响[J]. 重庆大学学报(自然科学版), 2015(5): 151-156.FAN K, LI Z C, LI Z S, et al. Effects of different calcification agents on acid leaching of vanadium from high vanadium slag[J]. Journal of Chongqing University (Natural Science Edition), 2015(5): 151-156. [9] ZHANG J H, ZHANG W, ZHANG L, et al. Effect of acid leaching on vanadium leaching rate in calcification roasting process[J]. Journal of Northeastern University (Natural Science Edition), 2014, 35(11): 1574-1578. (张菊花, 张伟, 张力, 等. 酸浸对钙化焙烧提钒工艺钒浸出率的影响[J]. 东北大学学报(自然科学版), 2014, 35(11): 1574-1578.ZHANG J H, ZHANG W, ZHANG L, et al. Effect of acid leaching on vanadium leaching rate in calcification roasting process[J]. Journal of Northeastern University (Natural Science Edition), 2014, 35(11): 1574-1578. [10] ZHAO Y, LI H Y, YIN X C, et al. Leaching kinetics of calcification roasted vanadium slag with high CaO content by sulfuric acid[J]. International Journal of Mineral Processing, 2014, 133: 105-111. doi: 10.1016/j.minpro.2014.10.011 [11] XIANG J Y, HUANG Q Y, LÜ X W, et al. Effect of mechanical activation treatment on the recovery of vanadium from converter slag[J]. Metallurgical and Materials Transactions B, 2017, 48(5): 2759-2767. doi: 10.1007/s11663-017-1033-6 [12] YANG Y, MAO H H, MALIN S. An assessment of the Ca-V-O system[J]. Calphad, 2017, 56: 29-40. doi: 10.1016/j.calphad.2016.11.005 [13] JIANG T, WEN J, ZHOU M, et al. Phase evolutions, microstructure and reaction mechanism during calcification roasting of high chromium vanadium slag[J]. Journal of Alloys and Compounds, 2018, 742: 402-412. doi: 10.1016/j.jallcom.2018.01.201 [14] TAYLOR P R, SHUEY S A, VIDAL E E, et al. Extractive metallurgy of vanadium-containing titaniferous magnetite ores: A review[J]. Minerals and Metallurgical Processing, 2006, 23: 80-86. [15] CAO Z M, WANG N, XIE W, et al. Critical evaluation and thermodynamic assessment of the MgO-V2O5 and CaO-V2O5 systems in air[J]. Calphad, 2017, 56: 72-79. doi: 10.1016/j.calphad.2016.12.001 [16] YANG S Z. Vanadium Metallurgy[M]. Metallurgical Industry Press, 2010. (杨守志. 钒冶金[M]. 冶金工业出版社, 2010.YANG S Z. Vanadium Metallurgy[M]. Metallurgical Industry Press, 2010. [17] JI C L, ZHAN Q L, ZENG G Y. Solubility of magnesium vanadate in water-basic research on vanadium extraction with non-sodium salt additives[J]. Non-ferrous Metals, 1984(1): 60-66. (冀春霖, 詹庆霖, 曾桂仪. 钒酸镁盐在水中的溶解度-非钠盐添加剂提钒的基础研究[J]. 有色金属, 1984(1): 60-66.JI C L, ZHAN Q L, ZENG G Y. Solubility of magnesium vanadate in water-basic research on vanadium extraction with non-sodium salt additives[J]. Non-ferrous Metals, 1984(1): 60-66. [18] ZHANG L, ZHANG T, FU N X, et al. Calcification roasting thermal analysis and phase transformation mechanism analysis of vanadium slag[J]. China Nonferrous Metallurgy, 2024, 53(4): 142-148. (张林, 张涛, 付念新, 等. 钒渣钙化焙烧热分析及物相转变机理分析[J]. 中国有色冶金, 2024, 53(4): 142-148.ZHANG L, ZHANG T, FU N X, et al. Calcification roasting thermal analysis and phase transformation mechanism analysis of vanadium slag[J]. China Nonferrous Metallurgy, 2024, 53(4): 142-148. [19] LU X, BAI L, RAO H, et al. Oxidation behavior of ferrovanadium spinel particles in air: isothermal kinetic and reaction mechanism[J]. Journal of Central South University, 2024, 31(9): 3090-3102. doi: 10.1007/s11771-024-5754-9 [20] WEN J, JIANG T, LI F F, et al. Conversion mechanism of calcium vanadate and manganese vanadate in a simplified CaO-V2O5-MnO2 system for calcification roasting of vanadium slag[J/OL]. Transactions of Nonferrous Metals Society of China, 1-19[2025-03-15]. https://link.cnki.net/urlid/43.1239.TG.20240807.1348.015. [21] WANG X. Vanadium slag calcium magnesium composite roasting-acid leaching vanadium process research [D]. Chongqing: Chongqing University, 2022. (王鑫. 钒渣钙镁复合焙烧—酸浸提钒工艺研究[D]. 重庆: 重庆大学, 2022.WANG X. Vanadium slag calcium magnesium composite roasting-acid leaching vanadium process research [D]. Chongqing: Chongqing University, 2022. -

下载:

下载: