Na2CO3-enhanced vacuum carbothermal reduction for titanium enrichment from ilmenite concentrate

-

摘要: 钒钛磁铁矿经二次选矿可获得TiO2品位45%~50%的钛精矿,其中钛以与铁形成复杂氧化物的形式存在,且Ca、Mg、Al等杂质含量较高。针对目前常用的电炉熔炼法存在富集率低、污染废物产生量大及能源消耗较高等问题,采用理论计算与真空碳热还原试验相结合的方法,探究Na2CO3 作为添加剂对钛精矿的还原及钛富集行为的影响。结果表明:在

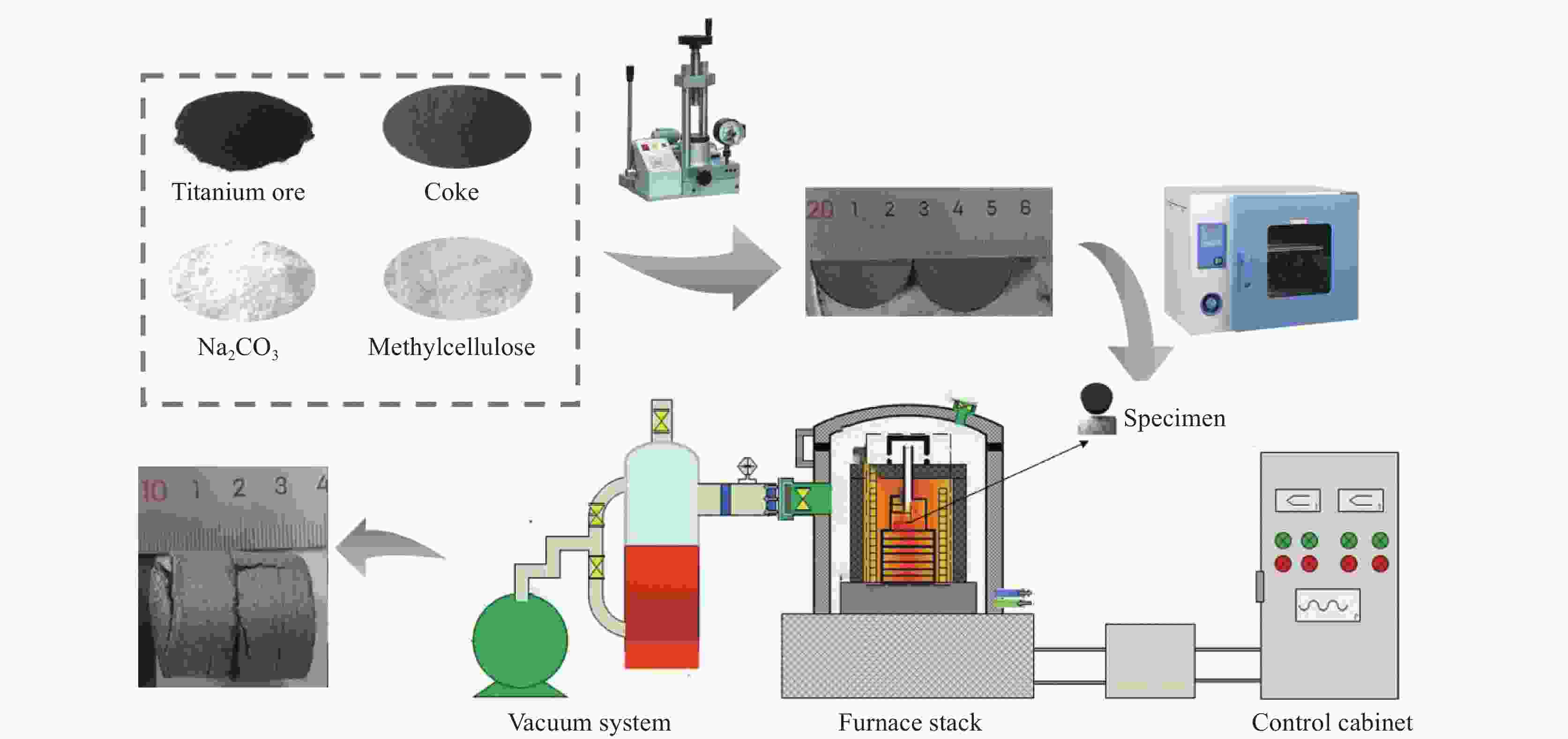

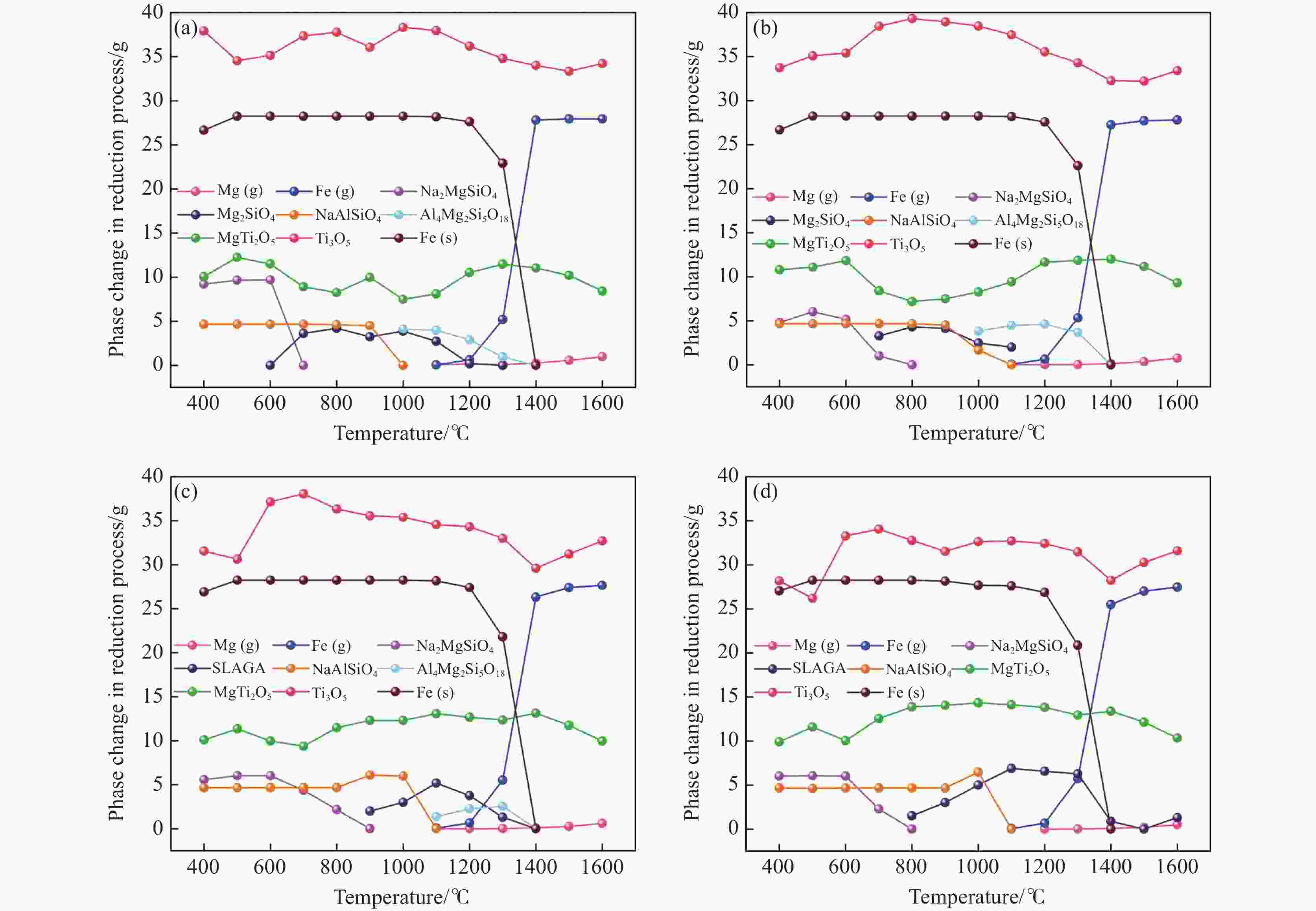

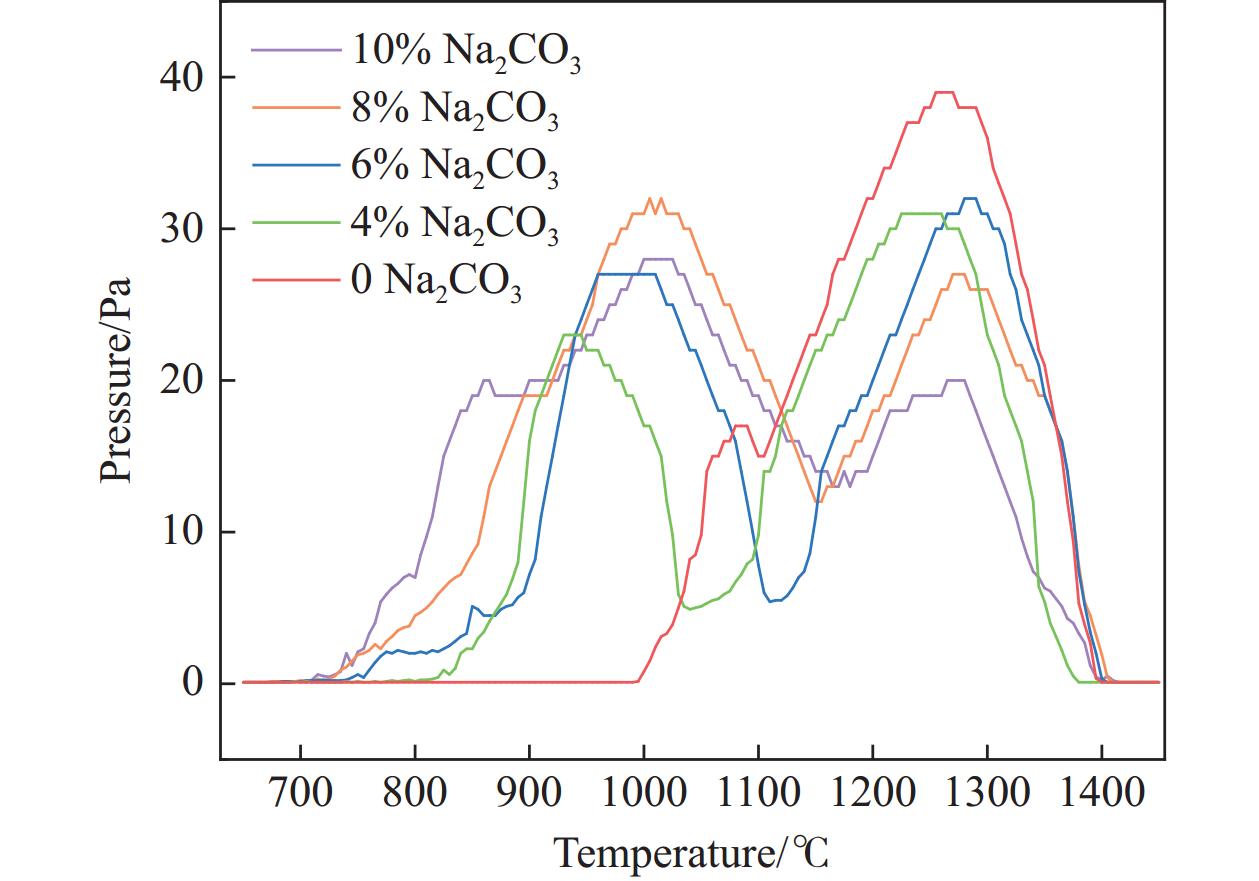

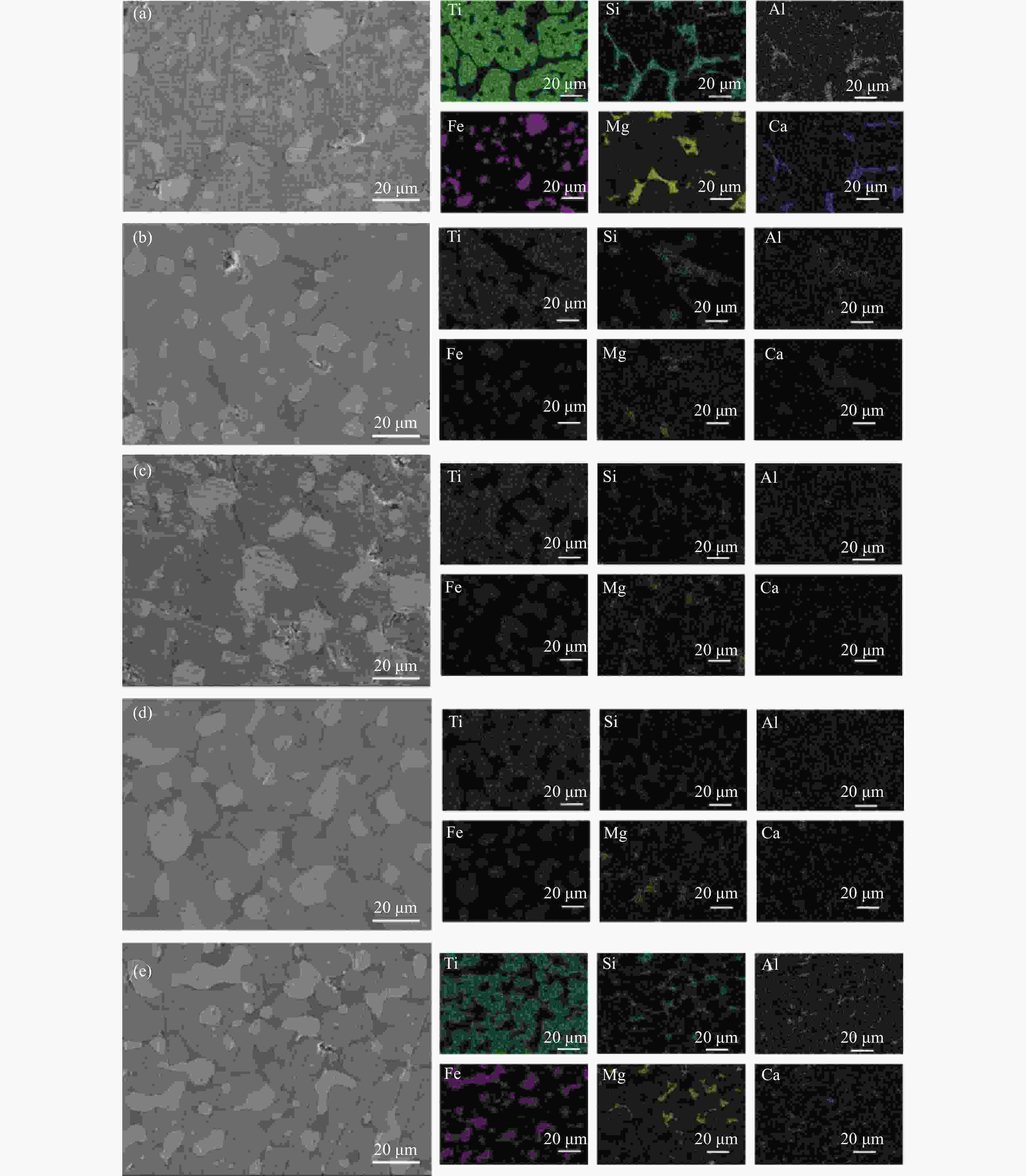

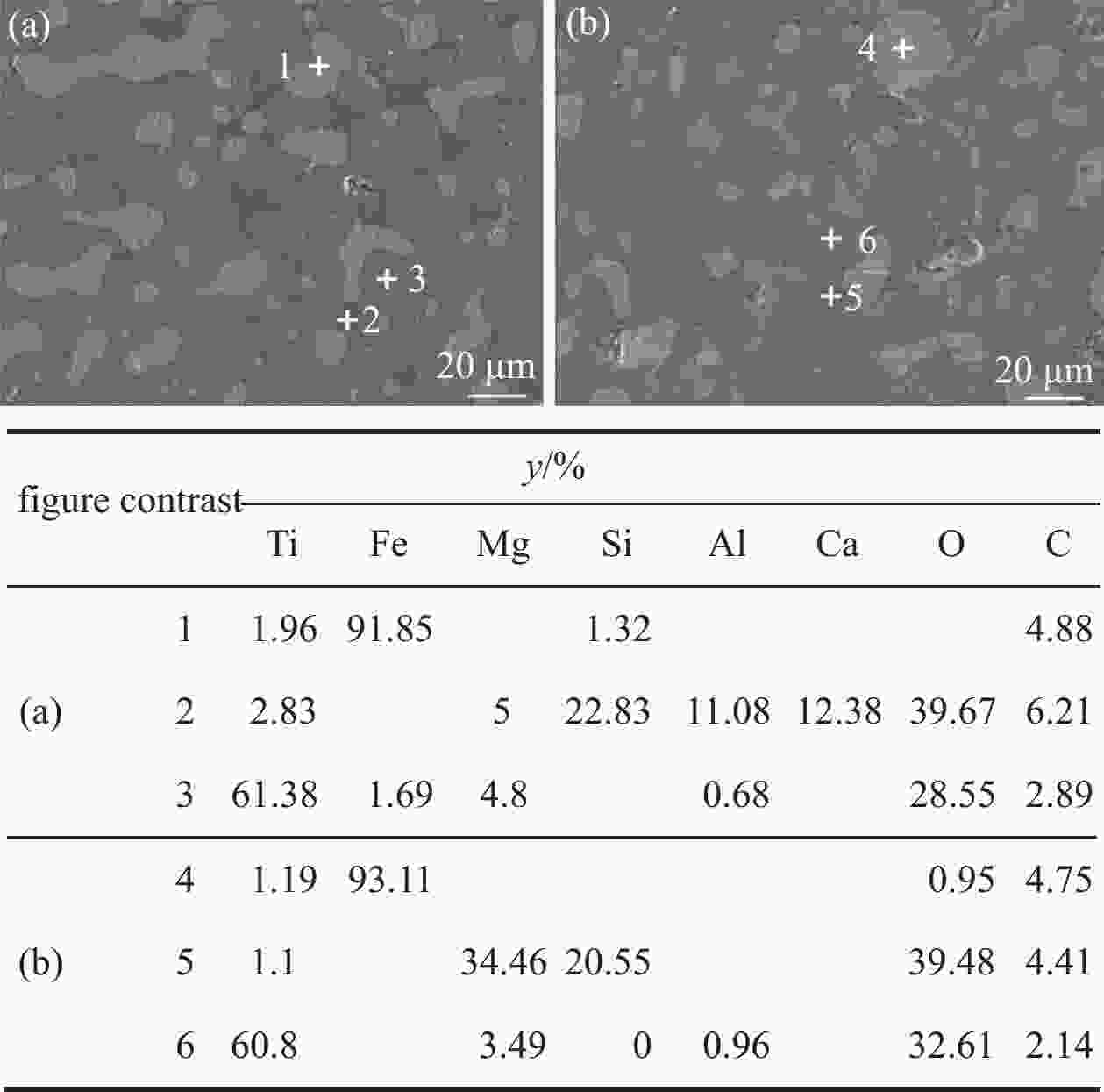

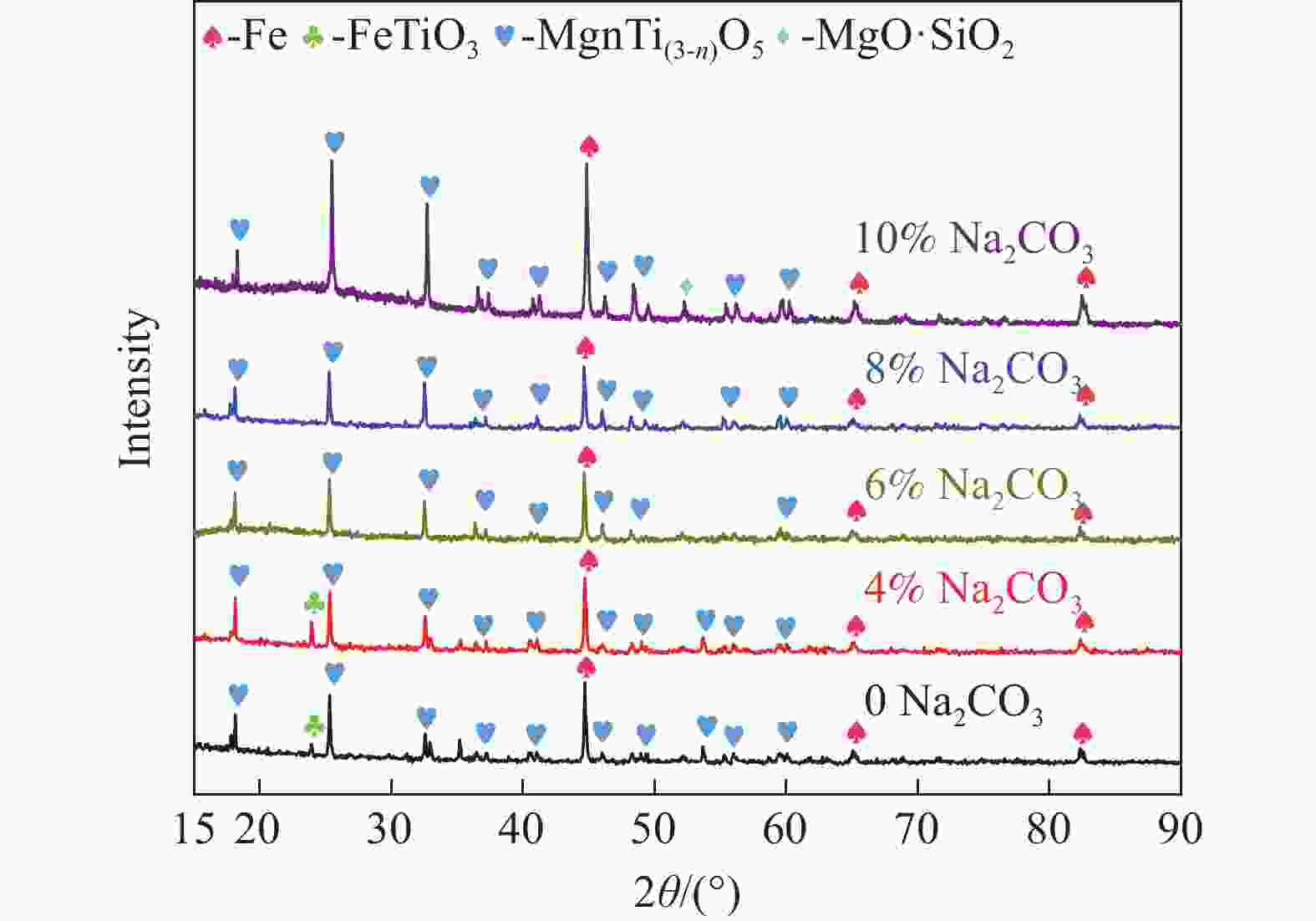

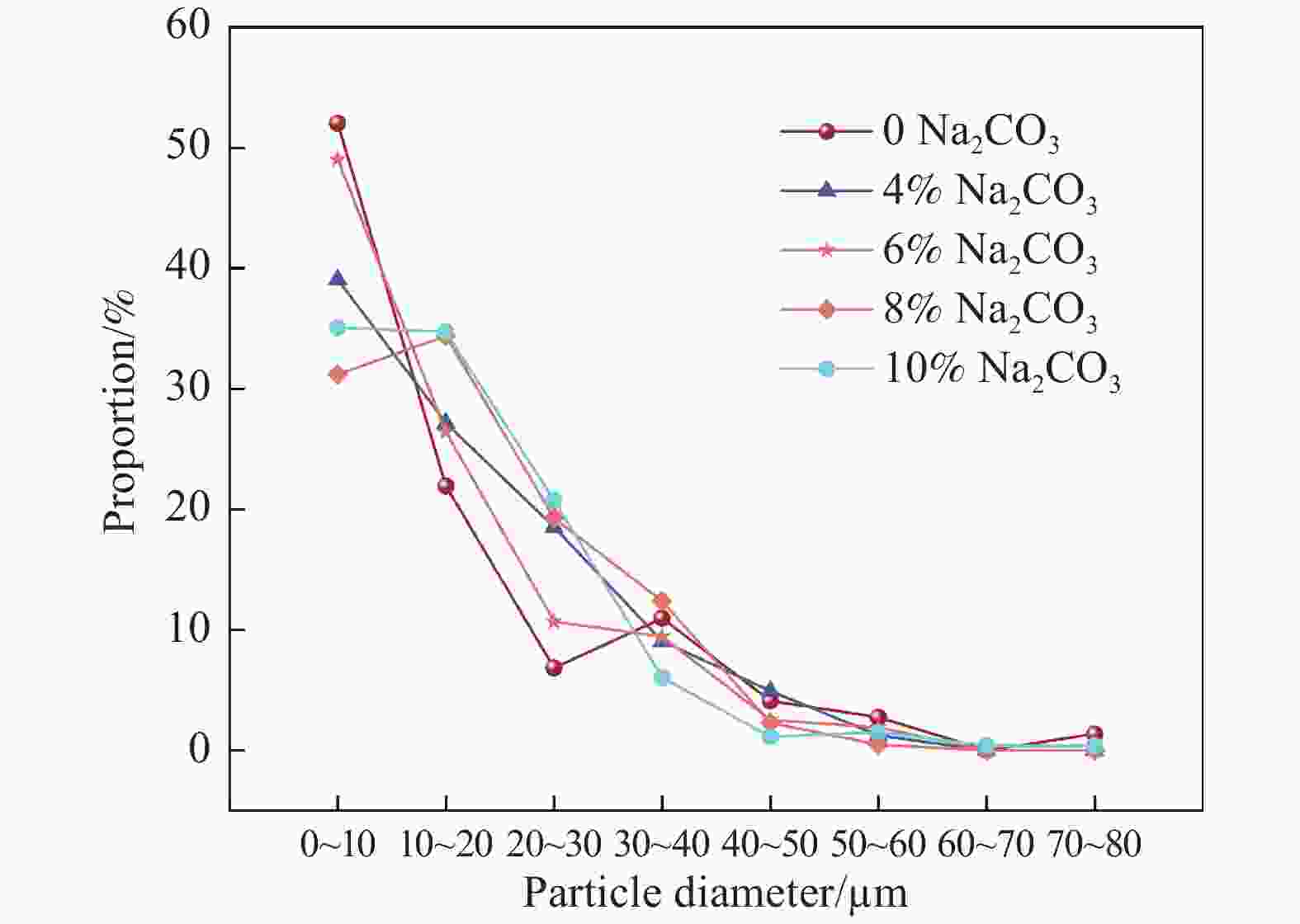

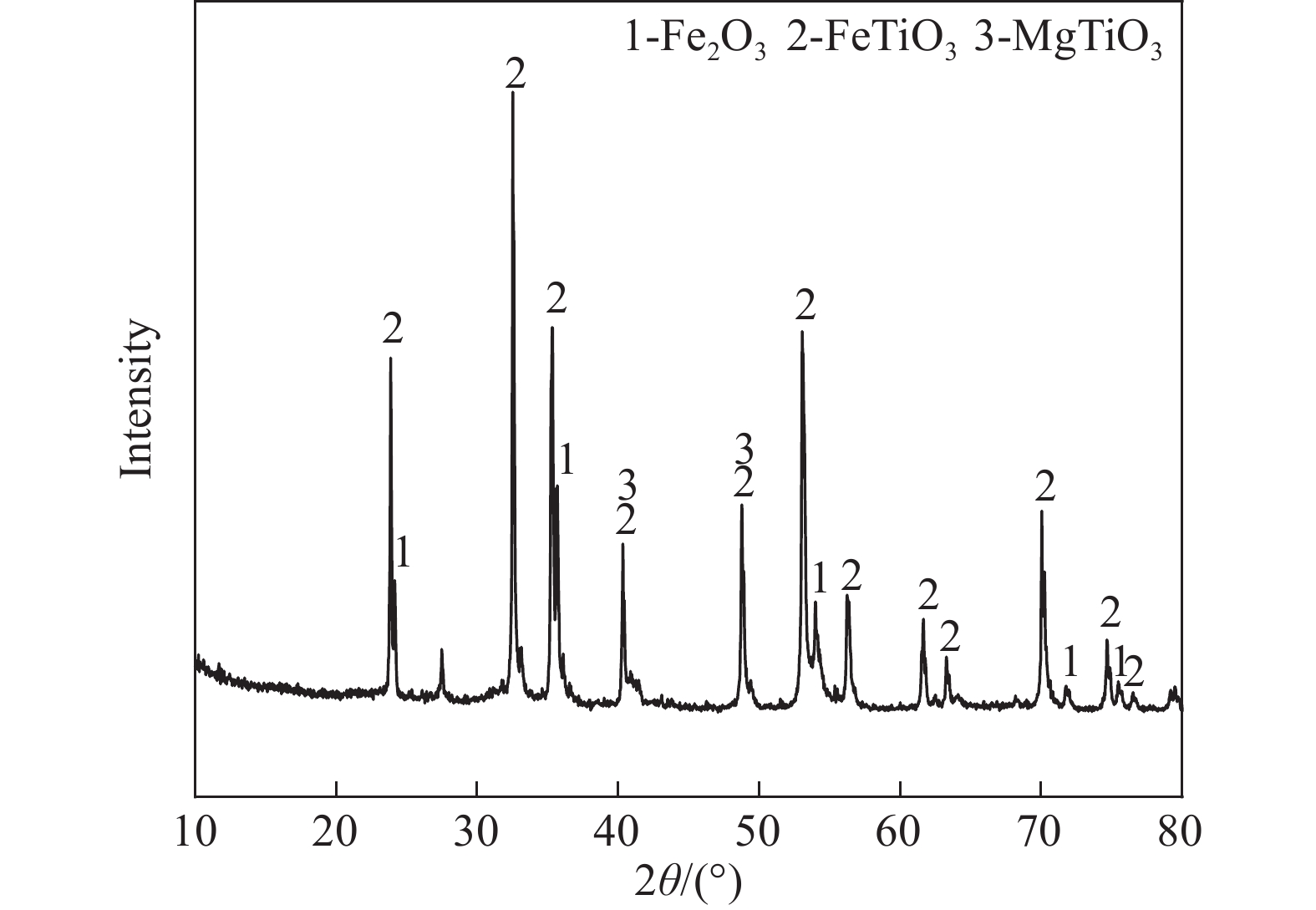

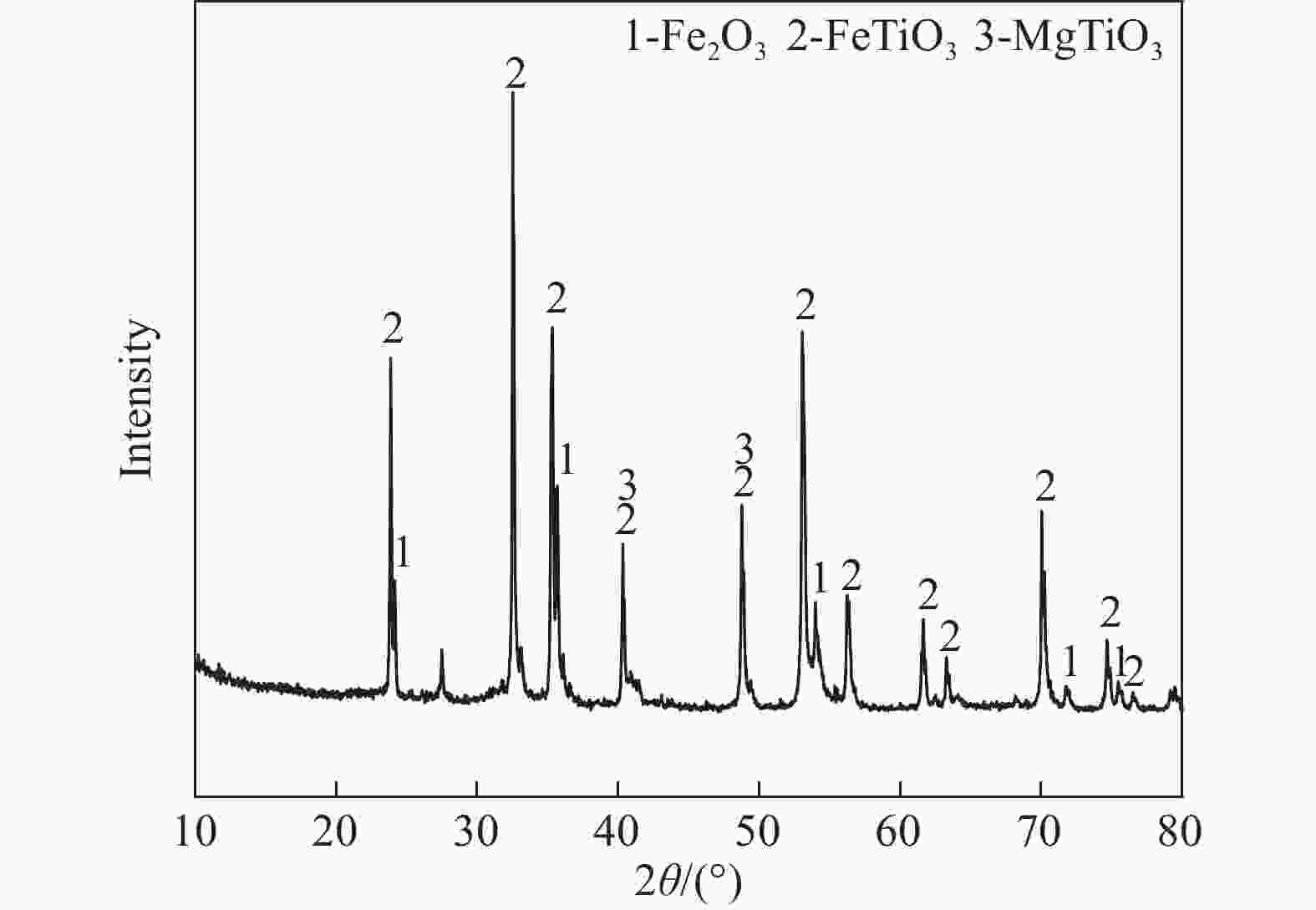

1450 ℃还原温度、12%配碳量及 10% Na2CO3添加量条件下,体系可显著提高Si、Mg、Al、Ca等杂质的聚集效果,同时促进FeTiO3的还原以及Fe颗粒粗化。为后续磁选分离Fe以及盐酸浸出富集Ti提供了创新技术路线。Abstract: Vanadium-titanium magnetite ore can yield a titanium concentrate with a TiO2 grade of 45%–50% through secondary beneficiation, where Ti predominantly exists in complex oxide phases associated with Fe, containing elevated levels of impurities such as Ca, Mg, and Al. To resolve the prevalent issues of low enrichment efficiency, excessive generation of polluting waste, and high energy consumption in conventional electric furnace smelting methods, this study integrates theoretical calculations with vacuum carbothermal reduction experiments to investigate the influence of Na2CO3 as an additive on the reduction behavior of titanium concentrate and titanium enrichment. Results demonstrate that under optimized conditions-reduction temperature of 1450 ºC, carbon dosage of 12%, and 10% Na2CO3 addition, the system significantly enhances the aggregation efficiency of impurities (Si, Mg, Al, Ca), promotes the reduction of FeTiO3, and facilitates the coarsening of metallic Fe particles. This methodology establishes an innovative technical approach for subsequent magnetic separation of Fe and hydrochloric acid leaching-based Ti enrichment processes.-

Key words:

- titanium concentrate /

- vacuum carbothermal reduction /

- thermodynamics /

- Na2CO3

-

表 1 钛精矿化学成分

Table 1. Chemical composition of titanium concentrate

% TiO2 Fe2O3 MgO SiO2 Al2O3 CaO Na2O SO3 45.826 40.395 5.677 4.205 1.667 0.828 0.15 0.426 表 2 焦炭化学成分

Table 2. Chemical composition of coke

% S P Solid carbon Volatile matter Ash Ash Fe2O3 CaO Al2O3 MgO SiO2 0.65 0.12 83.66 2.22 14.12 8.91 6.01 22.26 2.16 47.79 -

[1] XIA Y, WANG G, REN G Y, et al. Market analysis and development of TiO2 industry in 2023[J]. Coating and protection, 2024, 45(10): 35-42. (夏渊, 王岗, 任广义, 等. 2023年钛白粉行业状况与市场运行分析[J]. 涂层与防护, 2024, 45(10): 35-42.XIA Y, WANG G, REN G Y, et al. Market analysis and development of TiO2 industry in 2023[J]. Coating and protection, 2024, 45(10): 35-42. [2] HUANG R, LÜ X W, ZHANG K, et al. Carbothermic reduction and vacuum smelting of Panzhihua ilmenit concentrate[J]. Journal of Central South University (Natural Science Edition), 2014, 45(3): 684-689. (黄润, 吕学伟, 张凯, 等. 攀枝花钛精矿碳热还原-真空冶炼工艺[J]. 中南大学学报(自然科学版), 2014, 45(3): 684-689.HUANG R, LÜ X W, ZHANG K, et al. Carbothermic reduction and vacuum smelting of Panzhihua ilmenit concentrate[J]. Journal of Central South University (Natural Science Edition), 2014, 45(3): 684-689. [3] HUANG R, LÜ X D, WU Q H, et al. Vacuum carbothermal solid phase reduction of Panzhihua ilmenit concentrate[J]. Journal of Chongqing University, 2019, 42(4): 56-62. (黄润, 吕晓东, 武庆慧, 等. 攀枝花钛精矿真空碳热固相还原[J]. 重庆大学学报, 2019, 42(4): 56-62. doi: 10.11835/j.issn.1000-582X.2019.04.007HUANG R, LÜ X D, WU Q H, et al. Vacuum carbothermal solid phase reduction of Panzhihua ilmenit concentrate[J]. Journal of Chongqing University, 2019, 42(4): 56-62. doi: 10.11835/j.issn.1000-582X.2019.04.007 [4] TONG S, AI L Q, HONG L K, et al. Reduction of Chengde vanadium titanium magnetite concentrate by microwave enhanced Ar–H2 atmosphere[J]. International Journal of Hydrogen Energy, 2024, 49: 42-48. doi: 10.1016/j.ijhydene.2023.06.219 [5] DENG G Z. titanium metallurgy[M]. Beijing : Metallurgical Industry Press, 2010. (邓国珠. 钛冶金[M]. 北京: 冶金工业出版社, 2010.DENG G Z. titanium metallurgy[M]. Beijing : Metallurgical Industry Press, 2010. [6] LÜ X D. Study on the preparation of high-quality titanium-rich materials from ilmenite by combined beneficiation and metallurgy process[D]. Chongqing: Chongqing University, 2023. (吕晓东. 钛铁矿选冶联合工艺制备高品质富钛料研究[D]. 重庆: 重庆大学, 2023.LÜ X D. Study on the preparation of high-quality titanium-rich materials from ilmenite by combined beneficiation and metallurgy process[D]. Chongqing: Chongqing University, 2023. [7] WU Q Z. Reseach on kinetics of vacuum carbothermalreduction of low-grade phosphate rock[D]. Guizhou: Guizhou University, 2021. (伍秦至. 真空碳热还原中低品位磷矿的动力学研究[D]. 贵州: 贵州大学, 2021.WU Q Z. Reseach on kinetics of vacuum carbothermalreduction of low-grade phosphate rock[D]. Guizhou: Guizhou University, 2021. [8] WU Q H. Process optimization and mechanism study of vacuum carbothermic reduction of medium-low grade phosphate rock [D]. Guizhou: Guizhou University, 2021. (武庆慧. 真空碳热还原中低品位磷矿的工艺优化及机理研究[D]. 贵州: 贵州大学, 2021.WU Q H. Process optimization and mechanism study of vacuum carbothermic reduction of medium-low grade phosphate rock [D]. Guizhou: Guizhou University, 2021. [9] WANG L Z, JIANG C L, ZHU J X, et al. Occurrence state of titanium in vanadium-titanium magnetite ore from Panxi region[J]. Mining and Metallurgy Engineering, 2024, 44(5): 84-88. (王利珍, 姜楚灵, 朱家祥, 等. 攀西某钒钛磁铁矿中钛的赋存状态研究[J]. 矿冶工程, 2024, 44(5): 84-88. doi: 10.3969/j.issn.0253-6099.2024.05.017WANG L Z, JIANG C L, ZHU J X, et al. Occurrence state of titanium in vanadium-titanium magnetite ore from Panxi region[J]. Mining and Metallurgy Engineering, 2024, 44(5): 84-88. doi: 10.3969/j.issn.0253-6099.2024.05.017 [10] YUE Y H, HUANG R, LIU P S, et al. Vacuum carbothermal reduction experiment for ilmenite concentrate from Panzhihua[J]. China Metallurgy, 2016, 26(7): 21-25. (岳跃辉, 黄润, 刘鹏胜, 等. 攀枝花钛精矿的真空碳热还原试验[J]. 中国冶金, 2016, 26(7): 21-25.YUE Y H, HUANG R, LIU P S, et al. Vacuum carbothermal reduction experiment for ilmenite concentrate from Panzhihua[J]. China Metallurgy, 2016, 26(7): 21-25. [11] CHONG X X, LUAN W L, WANG F X, et al. Overview of the current situation of global titanium resources and the trend of titanium consumption in China[J]. Mineral protection and utilization, 2020, 40(2): 162-170. (崇霄霄, 栾文楼, 王丰翔, 等. 全球钛资源现状概述及我国钛消费趋势[J]. 矿产保护与利用, 2020, 40(2): 162-170.CHONG X X, LUAN W L, WANG F X, et al. Overview of the current situation of global titanium resources and the trend of titanium consumption in China[J]. Mineral protection and utilization, 2020, 40(2): 162-170. [12] YUE Y H. Experimental study on vacuum carbon thermal reductionof ilmenite concentrate[D]. Guizhou: Guizhou University, 2017. (岳跃辉. 钛精矿的真空碳热还原实验研究[D]. 贵州: 贵州大学, 2017.YUE Y H. Experimental study on vacuum carbon thermal reductionof ilmenite concentrate[D]. Guizhou: Guizhou University, 2017. [13] LIU J, CHENG G, LIU J, et al. Oxidation kinetics of a low-grade vanadiferous titanomagnetite concentrate with high titanium[J]. Journal of Physics, 2022, 230: 6-12. [14] QIAO L N. X-ray fluorescence spectrometric analysis of titanium ores and concentrates[J]. China Metals Bulletin, 2024(8): 74-76. (乔丽娜. 钛矿石与钛精矿X射线荧光光谱分析研究[J]. 中国金属通报, 2024(8): 74-76. doi: 10.3969/j.issn.1672-1667.2024.15.025QIAO L N. X-ray fluorescence spectrometric analysis of titanium ores and concentrates[J]. China Metals Bulletin, 2024(8): 74-76. doi: 10.3969/j.issn.1672-1667.2024.15.025 [15] LÜ X D. Kinetic study on vacuum carbothermic reduction of titanium concentrate[D]. Guizhou: Guizhou University, 2019. (吕晓东. 真空碳热还原钛精矿的动力学研究[D]. 贵州: 贵州大学, 2019.LÜ X D. Kinetic study on vacuum carbothermic reduction of titanium concentrate[D]. Guizhou: Guizhou University, 2019. [16] ZHAO S F. Study on the reduction and volatilization mechanism of iron in the process of vacuum carbothermic reduction of Fe-Ti-O system[D]. Guizhou: Guizhou University, 2022. (赵世翻. 真空碳热还原Fe-Ti-O体系过程中铁的还原与挥发机理研究[D]. 贵州: 贵州大学, 2022.ZHAO S F. Study on the reduction and volatilization mechanism of iron in the process of vacuum carbothermic reduction of Fe-Ti-O system[D]. Guizhou: Guizhou University, 2022. [17] XIAO J. Effective extraction of titanium and iron from coarse anatase concentrate[J]. JOM, 74(10): 3833-3842. [18] SHI Q. A novel process for direct reduction of titanium concentrate pellets in a gas-based shaft furnace[J]. Journal of Sustainable Metallurgy, 2023: 1620-1623. [19] WANG S W, TANG J, ZHANG C D, et al. Research on ore blending of vanadium-titanium magnetite based on hydrogen-based shaft furnace reduction & electric furnace me lting separation[C]/ / Proceedings of the 12 th Annual Youth Academic Conference of the Chinese Academy of Metallurgy and the First Salon of Young Metallurgical Scientists on " Carbon Neutralization " (I). China Metallurgical Society, Youth Working Committee of China Metallurgical Society, 2024: 7. (王世伟, 唐珏, 张彩东, 等. 基于氢基竖炉还原-电炉熔分的钒钛磁铁矿配矿研究[C]//第十二届中国金属学会青年学术年会暨首届〝碳中和〞冶金青年科学家沙龙论文集(一). 中国金属学会、中国金属学会青年工作委员会, 2024: 7.WANG S W, TANG J, ZHANG C D, et al. Research on ore blending of vanadium-titanium magnetite based on hydrogen-based shaft furnace reduction & electric furnace me lting separation[C]/ / Proceedings of the 12 th Annual Youth Academic Conference of the Chinese Academy of Metallurgy and the First Salon of Young Metallurgical Scientists on " Carbon Neutralization " (I). China Metallurgical Society, Youth Working Committee of China Metallurgical Society, 2024: 7. [20] LIAO Q, YI L, CHENG J G, et al. Study on beneficiation technology of titanium recovery from iron tailings[J]. Hunan Nonferrous Metals, 2024, 40(5): 13-16. (廖乾, 易峦, 程建国, 等. 某铁尾矿回收钛选矿工艺研究[J]. 湖南有色金属, 2024, 40(5): 13-16. doi: 10.3969/j.issn.1003-5540.2024.05.004LIAO Q, YI L, CHENG J G, et al. Study on beneficiation technology of titanium recovery from iron tailings[J]. Hunan Nonferrous Metals, 2024, 40(5): 13-16. doi: 10.3969/j.issn.1003-5540.2024.05.004 [21] LÜ C. A new technique for preparation of high-grade titanium slag from titanomagnetite concentrate by reduction–melting–magnetic separation processing[J]. JOM, 69(10): 1801-1805. [22] LÜ W, BAI C, LÜ X, et al. Carbothermic reduction of ilmenite concentrate in semi-molten state by adding sodium sulfate[J]. Powder Technology, 2018, 340: 354-361. doi: 10.1016/j.powtec.2018.09.043 [23] JING J, GUO Y, WANG S, et al. Recent progress in electric furnace titanium slag processing and utilization: A review[J]. Crystals, 2022, 12(7): 958-978. doi: 10.3390/cryst12070958 [24] KIM J, AZIMI G. Technospheric mining of niobium and titanium from electric arc furnace slag[J]. Hydrometallurgy, 2020, 191: 105203. doi: 10.1016/j.hydromet.2019.105203 [25] LÜ X D, CHEN D, XIN Y T, et al. Effect of sodium carbonate addition on carbothermic reduction of ilmenite concentrate[J]. Transactions of Nonferrous Metals Society of China, 2022, 32(3): 1010-1018. (吕晓东, 陈丹, 辛云涛, 等. 添加剂Na2CO3对钛精矿碳热还原的影响(英文)[J]. Transactions of Nonferrous Metals Society of China, 2022, 32(3): 1010-1018. doi: 10.1016/S1003-6326(22)65850-3LÜ X D, CHEN D, XIN Y T, et al. Effect of sodium carbonate addition on carbothermic reduction of ilmenite concentrate[J]. Transactions of Nonferrous Metals Society of China, 2022, 32(3): 1010-1018. doi: 10.1016/S1003-6326(22)65850-3 [26] EL-TAWIL SZ, MORSI IM, YEHIA A, et al. Alkali reductive roasting of ilmenite ore[J]. Canadian Metallurgical Quarterly, 1996, 35(1): 31-37. doi: 10.1179/cmq.1996.35.1.31 [27] ZHAO W, CHU M, WANG H, et al. Reduction behavior of vanadium-titanium magnetite carbon composite hot briquette in blast furnace process[J]. Powder Technology, 2019, 342: 214-223. doi: 10.1016/j.powtec.2018.09.069 -

下载:

下载: