Research on the rapid evaluation method of weather resistance of titanium dioxide based on photocurrent method

-

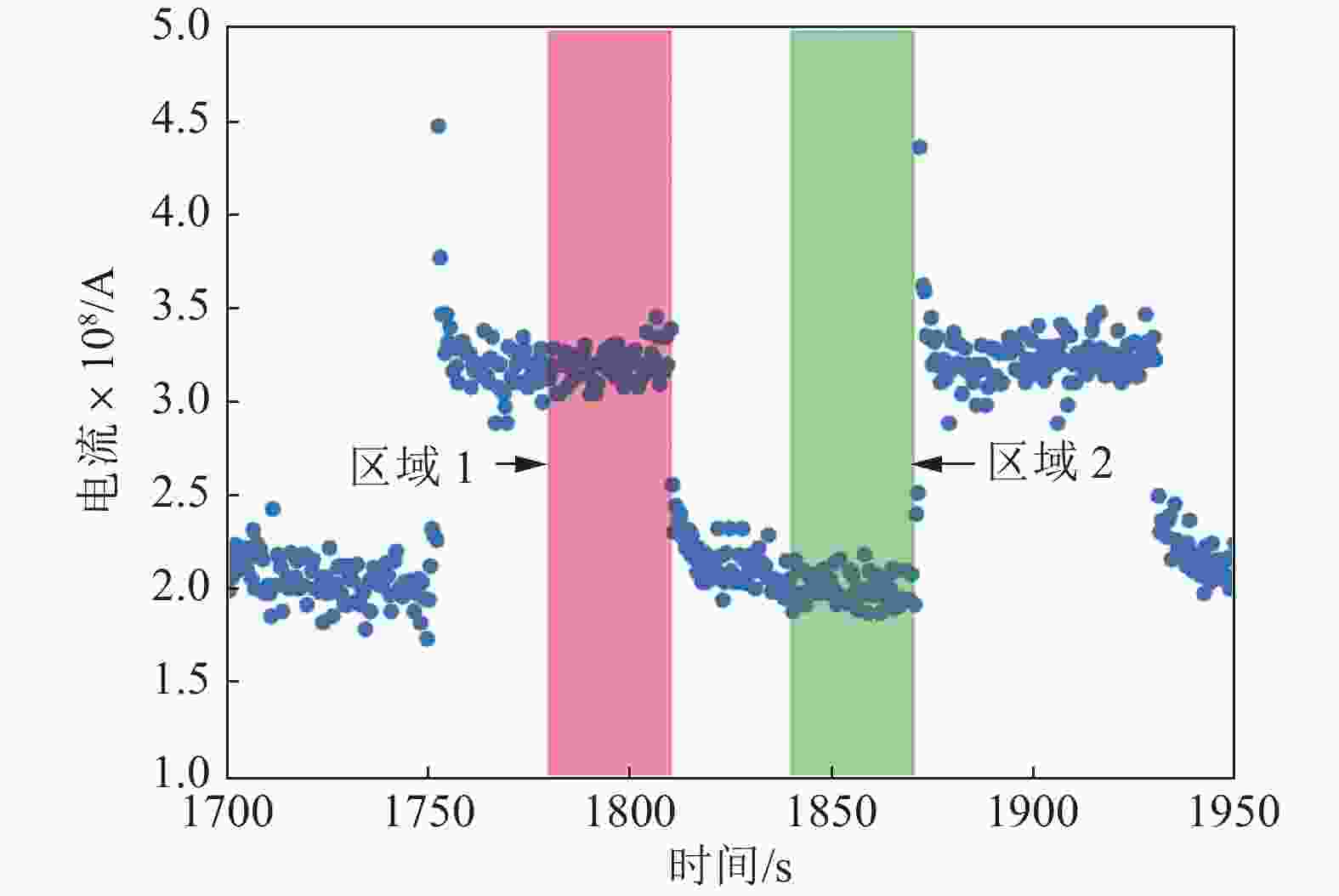

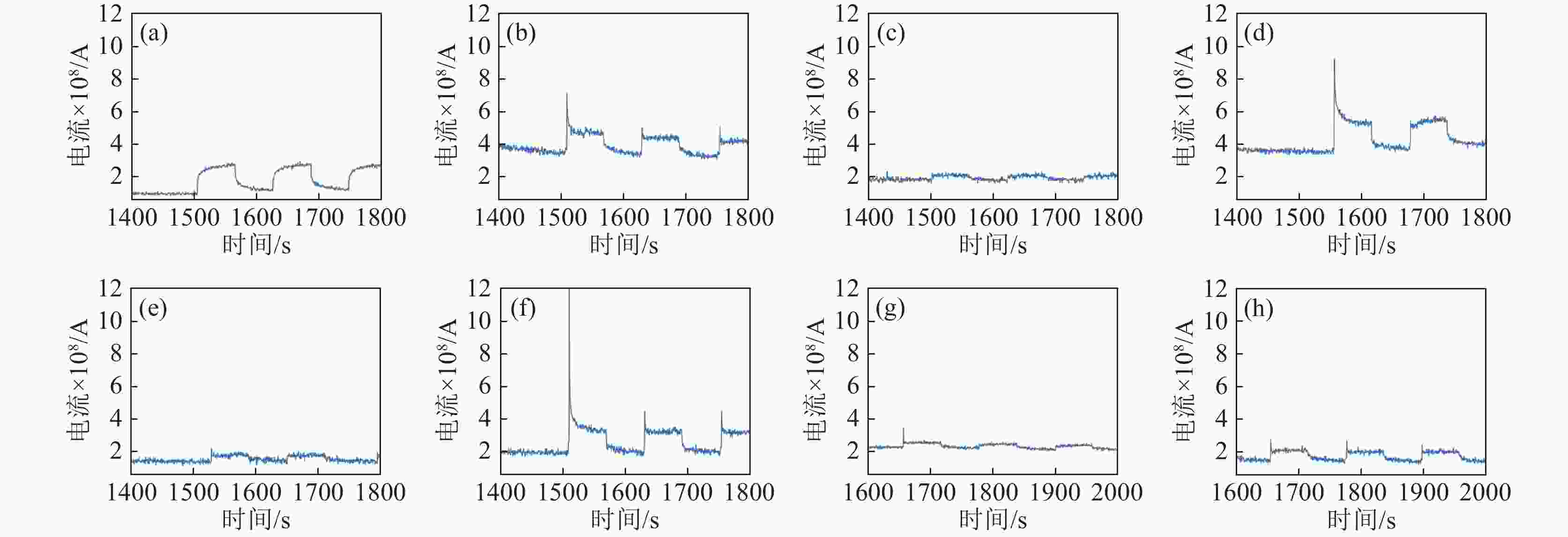

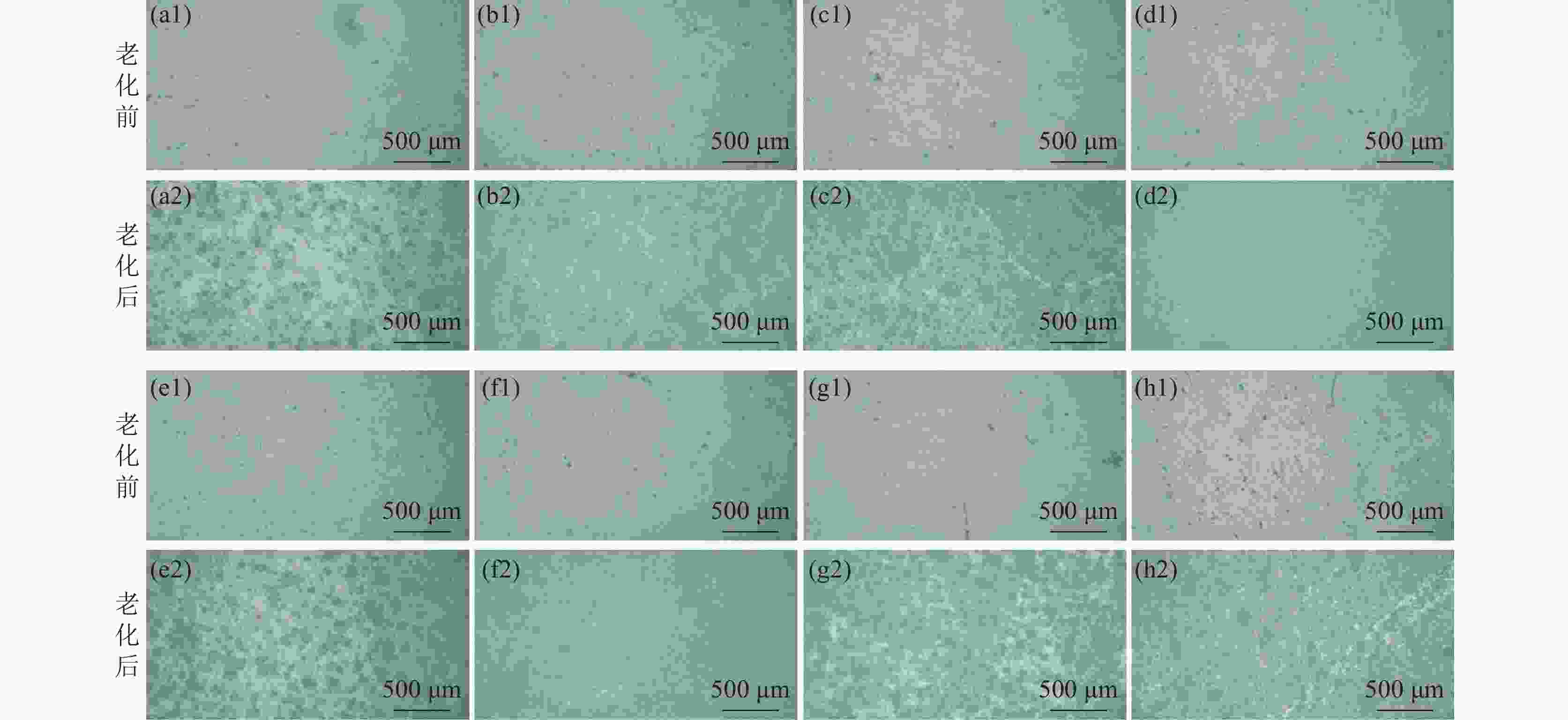

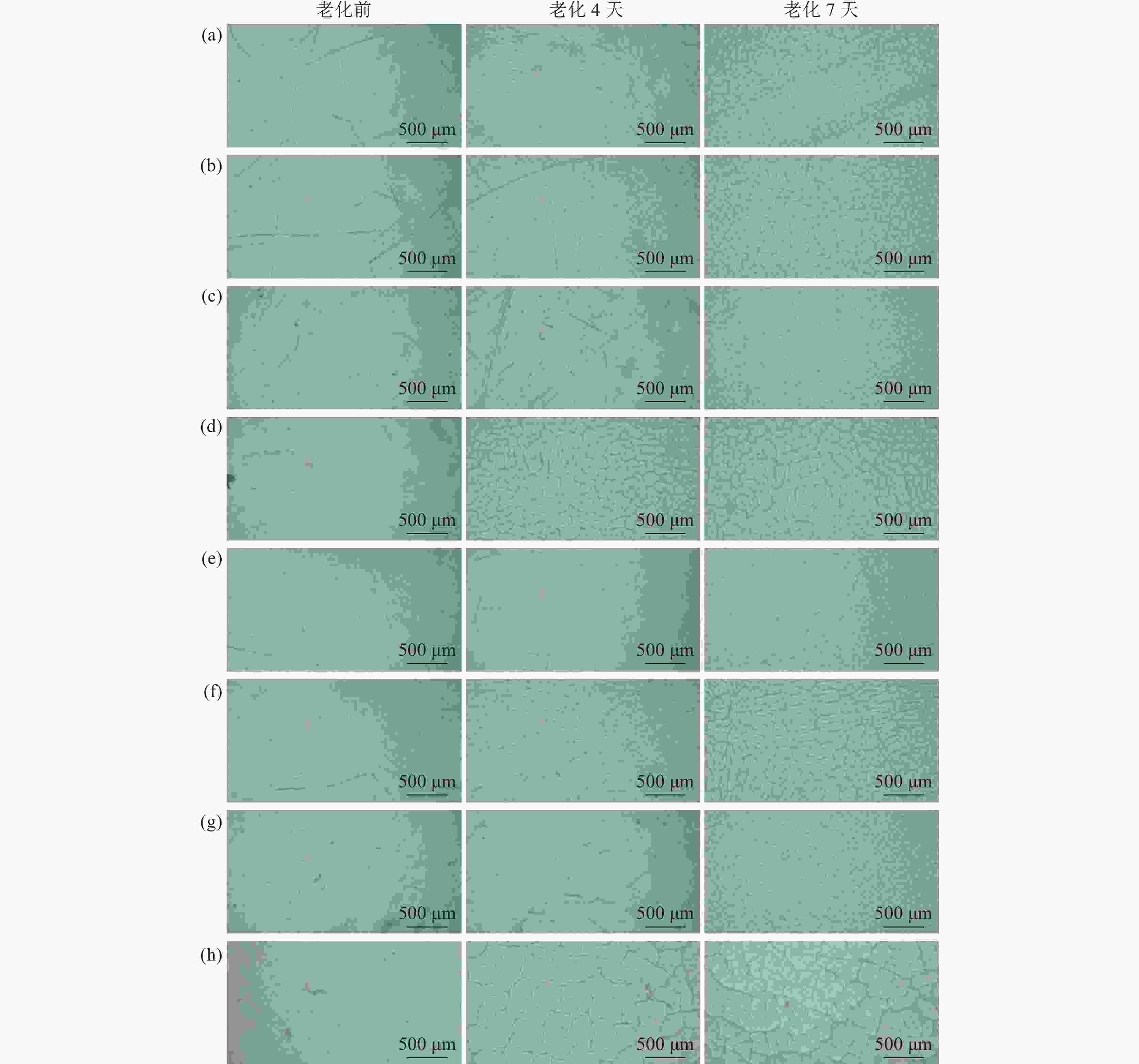

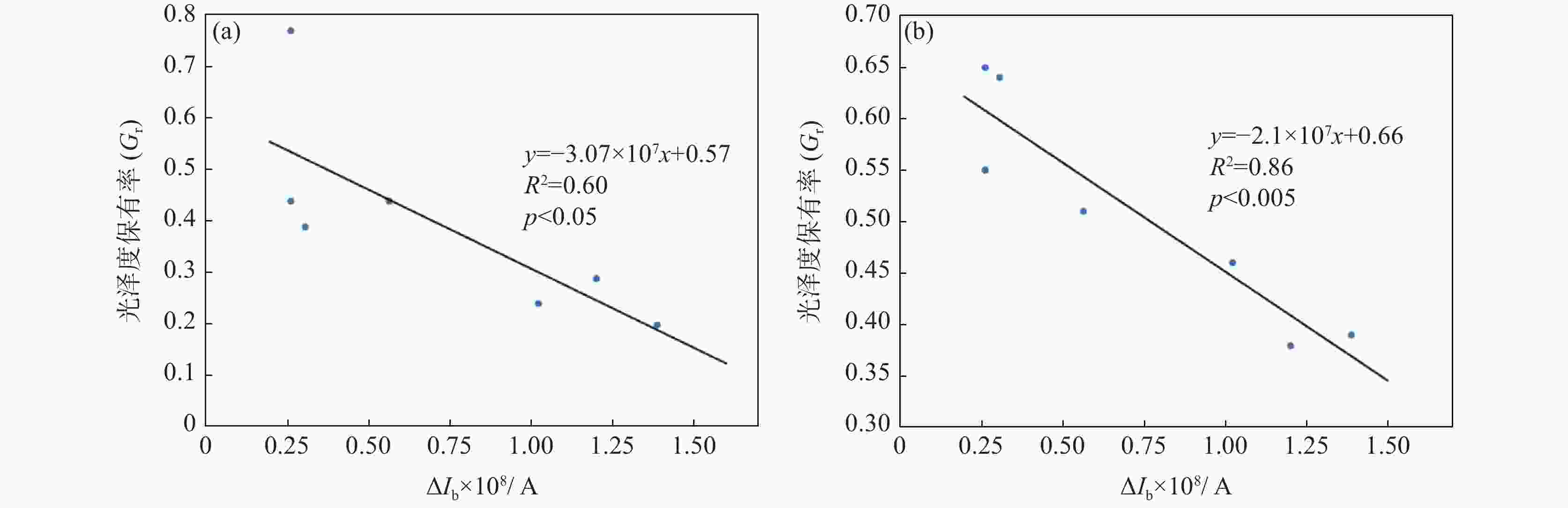

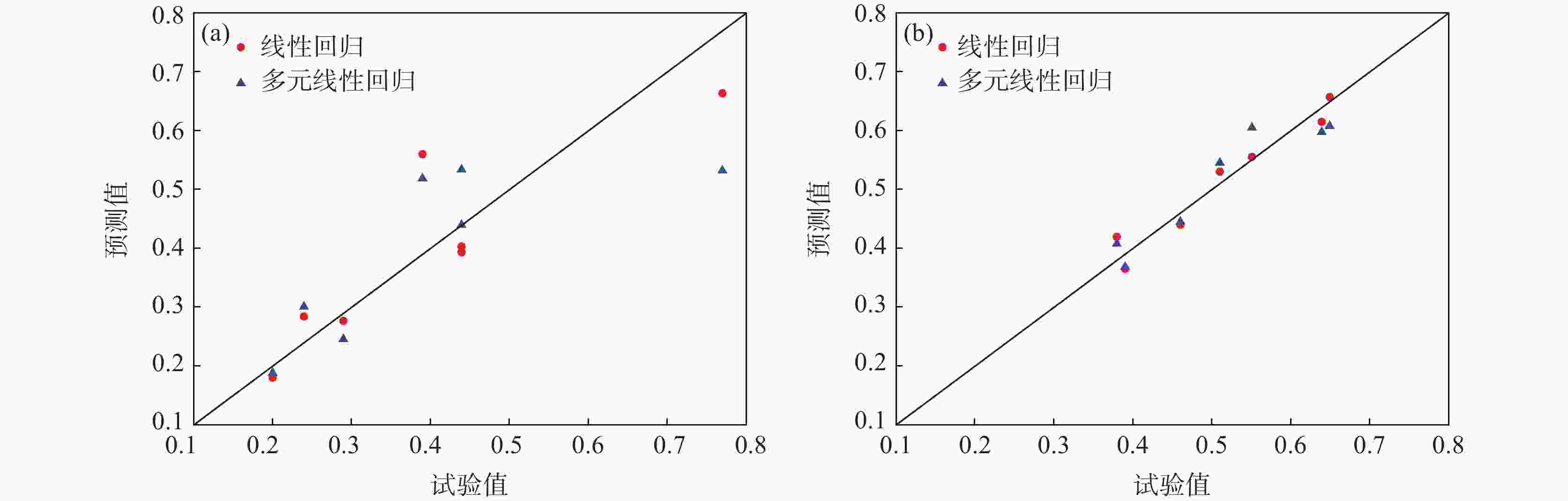

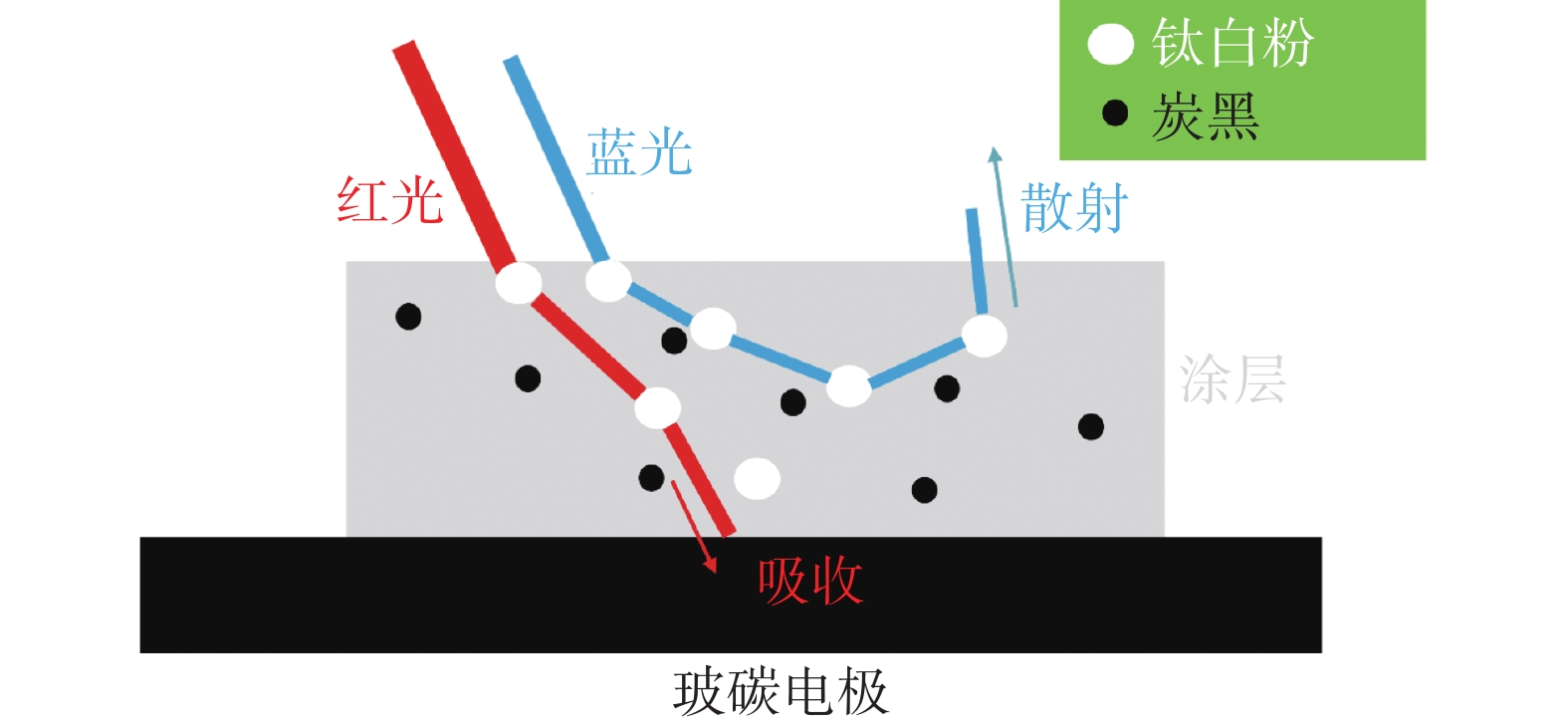

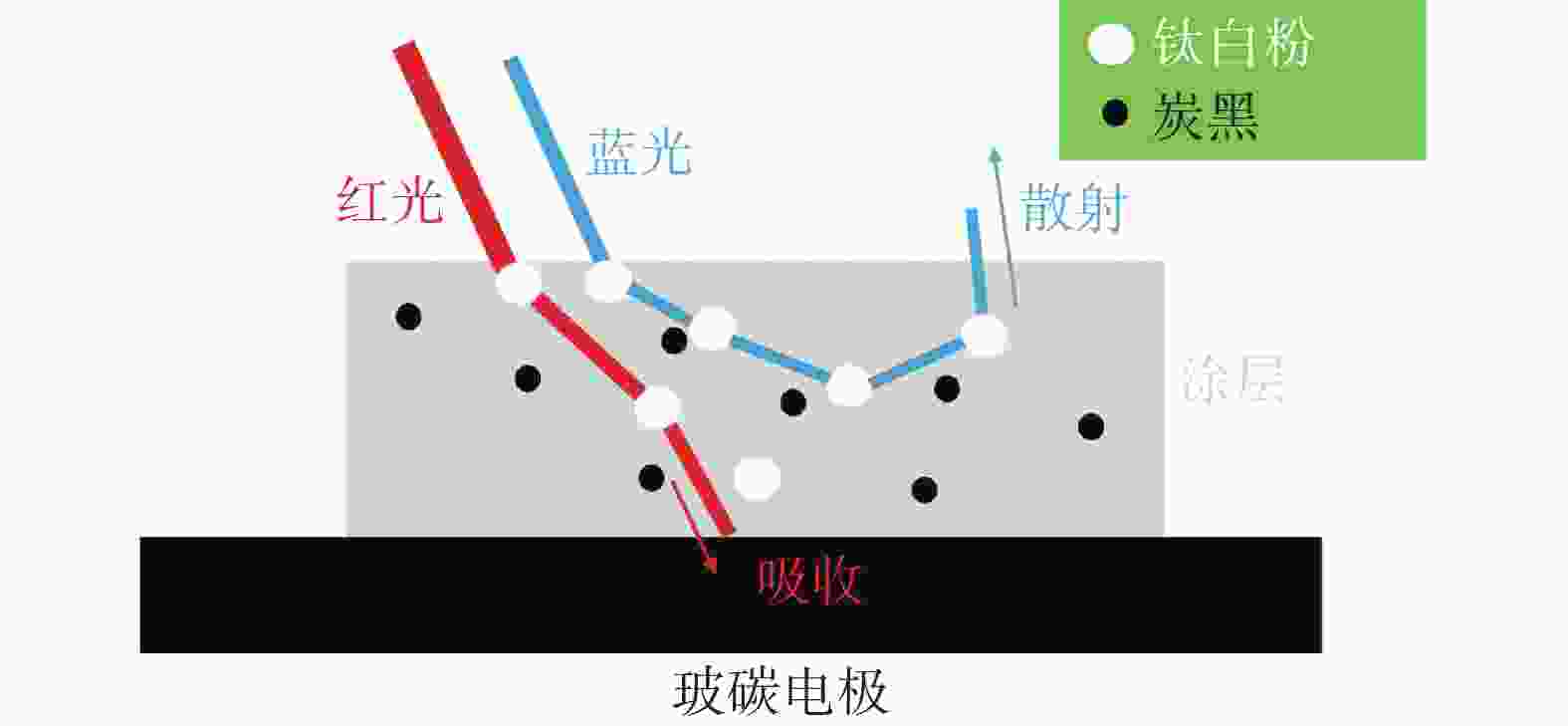

摘要: 钛白粉具有较好的光催化活性,通常需对其进行后处理以抑制光催化活性并提高其耐候性。而评估钛白粉光催化活性对基材耐候性的影响通常耗时较长,难以满足实际生产过程中快速检测以反馈指导工艺调整的需求。基于光电流测试法,融合炭黑底色法,结合不同钛白粉在聚丙烯 (PP) 树脂和聚氯乙烯 (PVC) 树脂体系中的紫外加速老化结果,验证光电流测试方法作为钛白粉在PP、PVC体系中耐候性快速评价手段的实用性。结果表明,以光泽度保有率 (Gr) 作为老化程度的量化指标,通过光电流与分散性参数可较好地定量预测不同钛白粉在PP与PVC体系中的耐候性。可为钛白粉在不同体系中耐候性的快速评价方法开发提供指导,进而为钛白粉工艺优化提供支持。Abstract: Titanium dioxide has relatively high photocatalytic activity, and it is usually necessary to carry out post-treatment to suppress the photocatalytic activity and improve the weather resistance ability. However, the evaluation of the effect of titanium dioxide photocatalytic activity on the weather resistance of the substrate usually takes a long time, and it is difficult to meet the need of rapid detection feedback to guide process adjustment in the actual production process. Based on the photocurrent test method and the carbon black undertone method, combined with the accelerated UV aging results of polypropylene (PP) resin and polyvinyl chloride (PVC) resin systems with addition of different titanium dioxide, the practicability of the photoelectric current testing method as a rapid evaluation means for the weather resistance of titanium dioxide in PP and PVC systems was verified. The results show that, taking the gloss retention rate (Gr) as the quantitative index of aging degree, the photocurrent and dispersion parameters can better quantitatively predict the weather resistance of different titanium dioxide in PP and PVC systems. This technology can provide guidance for the rapid evaluation methods development of weather resistance ability of titanium dioxide in different systems, and then provide support for the optimization of titanium dioxide production process.

-

Key words:

- titanium dioxide /

- weather resistance /

- photocurrent /

- dispersion /

- polypropylene /

- polyvinyl chloride

-

表 1 钛白粉生产及包膜方式

Table 1. Titanium dioxide production and coating method

编号 生产方式 包膜方式 R1 氯化法 铝包膜、疏水改性 RPC1 氯化法 致密铝包膜、疏水改性,聚碳酸酯专用(PC) RPC2 氯化法 致密铝包膜、疏水改性,聚碳酸酯专用 R2 氯化法 铝包膜、疏水改性 RSA 氯化法 致密硅铝包膜、疏水改性 R3 氯化法 铝包膜、疏水改性 R4 氯化法 铝包膜、疏水改性 表 2 聚氯乙烯(PVC)配方

Table 2. Polyvinyl chloride (PVC) formulation

添加剂 试剂来源 份数 PVC 忧悦塑胶 100 邻苯二甲酸二辛脂(简称DOP,增塑剂) 鑫洋化工 40 三盐基硫酸铅(稳定剂) 宏泰化学 3 二盐基亚磷酸铅(稳定剂) 宏泰化学 2 钙锌复合稳定剂 宏泰化学 3 聚乙烯蜡(简称PE蜡,外润滑剂) 宏泰化学 0.5 钛白粉 3 表 3 聚丙烯(PP)配方

Table 3. Polypropylene (PP) formulation

添加剂 试剂来源 份数 PP 浙江石油化工有限公司 100 钛白粉 3 滑石粉 优索样品 20 表 4 有无光照条件下的平衡电流变化∆Ib

Table 4. Variation of balance current ∆Ib with and without irradiation

钛白粉牌号 平衡电流变化∆Ib ×109/A R1 5.66 R4 10.20 RPC1 2.63 R2 13.90 RSA 3.07 R3 12.00 RPC2 2.64 表 5 电极表面CIE Lab测试结果

Table 5. CIE Lab test results of electrode surface

钛白粉牌号 CIE L值 CIE a值 CIE b值 R1 64.71 −0.06 −4.21 R4 61.40 −0.21 −5.31 RPC1 61.14 −0.24 −6.09 R2 60.80 −0.20 −6.05 RSA 65.40 −0.28 −4.86 R3 56.82 −0.06 −6.27 RPC2 64.97 0.68 −2.20 表 6 PVC样品老化后的Gr

Table 6. Gr of PVC samples after aging

钛白粉牌号 PVC的Gr /% R1 44 R4 24 RPC1 77 R2 20 RSA 39 R3 29 RPC2 44 BLANK 21 表 7 PP样品老化后的Gr

Table 7. Gr of PP samples after aging

钛白粉牌号 PP的Gr/% R1 51 R4 46 RPC1 65 R2 39 RSA 64 R3 38 RPC2 55 BLANK 48 表 8 ∆Ib和CIE b值双参数多元线性拟合

Table 8. Two-parameter multivariate linear fitting of ∆Ib and CIE b values

PVC PP 拟合方程 Gr = −4.27×107∆Ib−

0.070b+0.35Gr = −2.6×107∆Ib−

0.027b+0.56R2 0.79 0.95 显著性 Sig.<0.05 Sig.<0.005 -

[1] DIEBOLD M P. Optimizing the benefits of TiO2 in paints[J]. Journal of Coatings Technology and Research, 2019, 17: 1-17. [2] DIEBOLD M P. Effect of TiO2 pigment on gloss retention: A two-component approach[J]. Journal of Coatings Technology and Research, 2009, 6: 32-39. [3] LIU L X, JIANG Z G, LI D X, et al. Research on preparation technology of titanium dioxide for water-based paint[J]. Modern Paint & Finishing, 2018, 21(3): 5-7, 10. (刘立新, 姜志刚, 李冬旭, 等. 水性涂料钛白粉制备工艺研究[J]. 现代涂料与涂装, 2018, 21(3): 5-7, 10.LIU L X, JIANG Z G, LI D X, et al. Research on preparation technology of titanium dioxide for water-based paint[J]. Modern Paint & Finishing, 2018, 21(3): 5-7, 10. [4] DUAN H T, HOU Q L, LI Y L, et al. Study on surface modification of titanium dioxide by zirconia-silicon binary coating[J]. Packaging Journal, 2023, 15(4): 75-80. (段海婷, 侯清麟, 李依林, 等. 钛白粉表面锆-硅二元包膜改性研究[J]. 包装学报, 2023, 15(4): 75-80.DUAN H T, HOU Q L, LI Y L, et al. Study on surface modification of titanium dioxide by zirconia-silicon binary coating[J]. Packaging Journal, 2023, 15(4): 75-80. [5] WU H X, WANG T J, JIN Y. Morphology “phase diagram” of the hydrous alumina coating on TiO2 particles during aqueous precipitation[J]. Industrial & Engineering Chemistry Research, 2006, 45(15): 5274-5278. [6] GAO H, QIAO B, WANG T J, et al. Cerium oxide coating of titanium dioxide pigment to decrease its photocatalytic activity[J]. Industrial & Engineering Chemistry Research, 2014, 53(1): 189-197. [7] WU J C, LU R F, LIU C, et al. Preparation and performance of different aluminum filmson titanium dioxide surface[J]. Iron Steel Vanadium Titanium, 2021, 42(2): 66-72. [8] SHI R, QIAN H J, LU Z Y. Tuning cavitation and crazing in polymer nanocomposite glasses containing bimodal grafted nanoparticles at the nanoparticle/polymer interface[J]. Physical Chemistry Chemical Physics, 2019, 21(13): 7115-7126. doi: 10.1039/C9CP00208A [9] FEDOR G R. Comparison between natural weathering and fluorescent UV exposures: UVA-340 lamp test results[J]. Shanghai Coatings, 2018, 56(6): 37-43. (FEDOR G R. 自然老化试验和荧光紫外曝晒试验的对比: UVA-340灯管曝晒试验结果[J]. 上海涂料, 2018, 56(6): 37-43.FEDOR G R. Comparison between natural weathering and fluorescent UV exposures: UVA-340 lamp test results[J]. Shanghai Coatings, 2018, 56(6): 37-43. [10] WERNER A J. Titanium dioxide pigment coated with silica and alumina: US3437502A[P]. 1968-03-08. [11] DIEBOLD M P, KWOKA R A, MEHR S R, et al. Rapid assessment of TiO2 pigment durability via the acid solubility test[J]. Journal of Coatings Technology and Research, 2004, 1(3): 239-241. doi: 10.1007/s11998-004-0018-y [12] ZHONG C L. Study on inorganic organic coating and weather resistance of rutile titanium dioxide[J]. Shanxi Chemical Industry, 2024, 44(11): 34-36. (钟成林. 金红石型钛白粉无机-有机包覆及耐候性研究[J]. 山西化工, 2024, 44(11): 34-36.ZHONG C L. Study on inorganic organic coating and weather resistance of rutile titanium dioxide[J]. Shanxi Chemical Industry, 2024, 44(11): 34-36. [13] LUO J, WANG L, WANG Z. Evaluation methods of weathering resistance of titanium dioxide and its application performance[J]. Shanghai Coatings, 2023, 61(2): 44-48. (罗蛟, 王玲, 王镇. 钛白粉耐候性评价方法及其应用表现[J]. 上海涂料, 2023, 61(2): 44-48.LUO J, WANG L, WANG Z. Evaluation methods of weathering resistance of titanium dioxide and its application performance[J]. Shanghai Coatings, 2023, 61(2): 44-48. [14] ODLING G, ROBERTSON N. Why is anatase a better photocatalyst than rutile? The importance of free hydroxyl radicals[J]. Chem Sus Chem, 2015, 8(11): 1838-40. doi: 10.1002/cssc.201500298 [15] FUJISHIMA A, HONDA K. Electrochemical photolysis of water at a semiconductor electrode[J]. Nature, 1972, 238(5358): 37-38. doi: 10.1038/238037a0 [16] HE Z J, CUI W, HE T. Photoelectrochemical approach for weatherability assessment of TiO2 pigments[J]. Coating and Protection, 2020, 41(11): 21-25. (贺志娟, 崔伟, 何涛. 钛白粉耐候性的光电化学评价新方法[J]. 涂层与防护, 2020, 41(11): 21-25.HE Z J, CUI W, HE T. Photoelectrochemical approach for weatherability assessment of TiO2 pigments[J]. Coating and Protection, 2020, 41(11): 21-25. [17] CHEMOURS. Polymers, light and the science of TiO2 [EB/OL]. https://www.chemours.cn/-/media/files/tipure/legacy/polymers-light-science-tio2.pdf?rev=ea949113920049298ad4d518211bb314. [18] DIEBOLD M. Prediction of paint chalking rates from early exposure data[J]. Journal of Coatings Technology and Research, 2023, 20(4): 1179-1191. doi: 10.1007/s11998-022-00727-6 [19] KAUSCH H H. Crazing in polymers[C]. 1983. -

下载:

下载: