Research on formation and properties of adjustable-ring mode (ARM) laser scanning welding of TA1 titanium alloy thin sheet

-

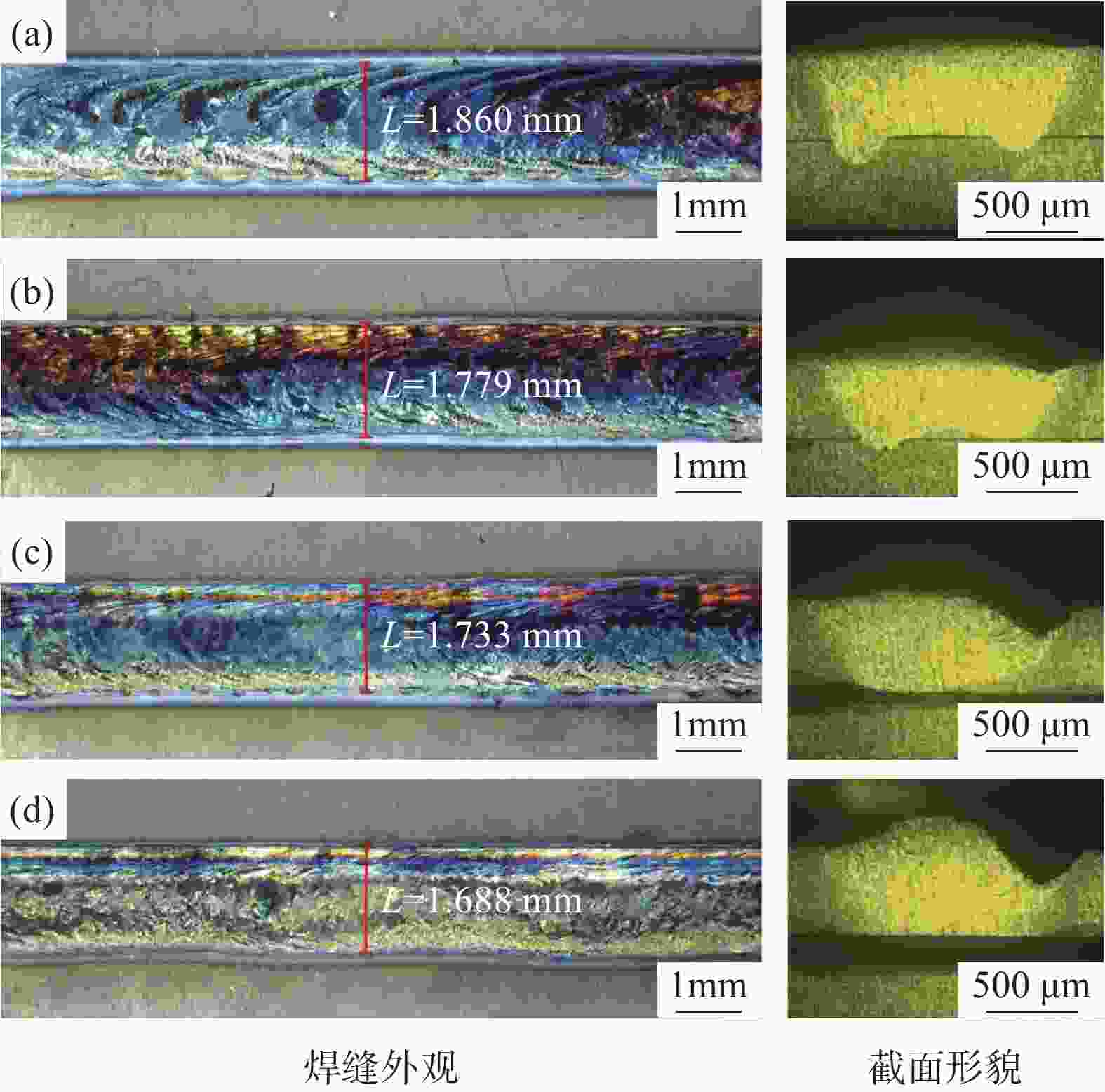

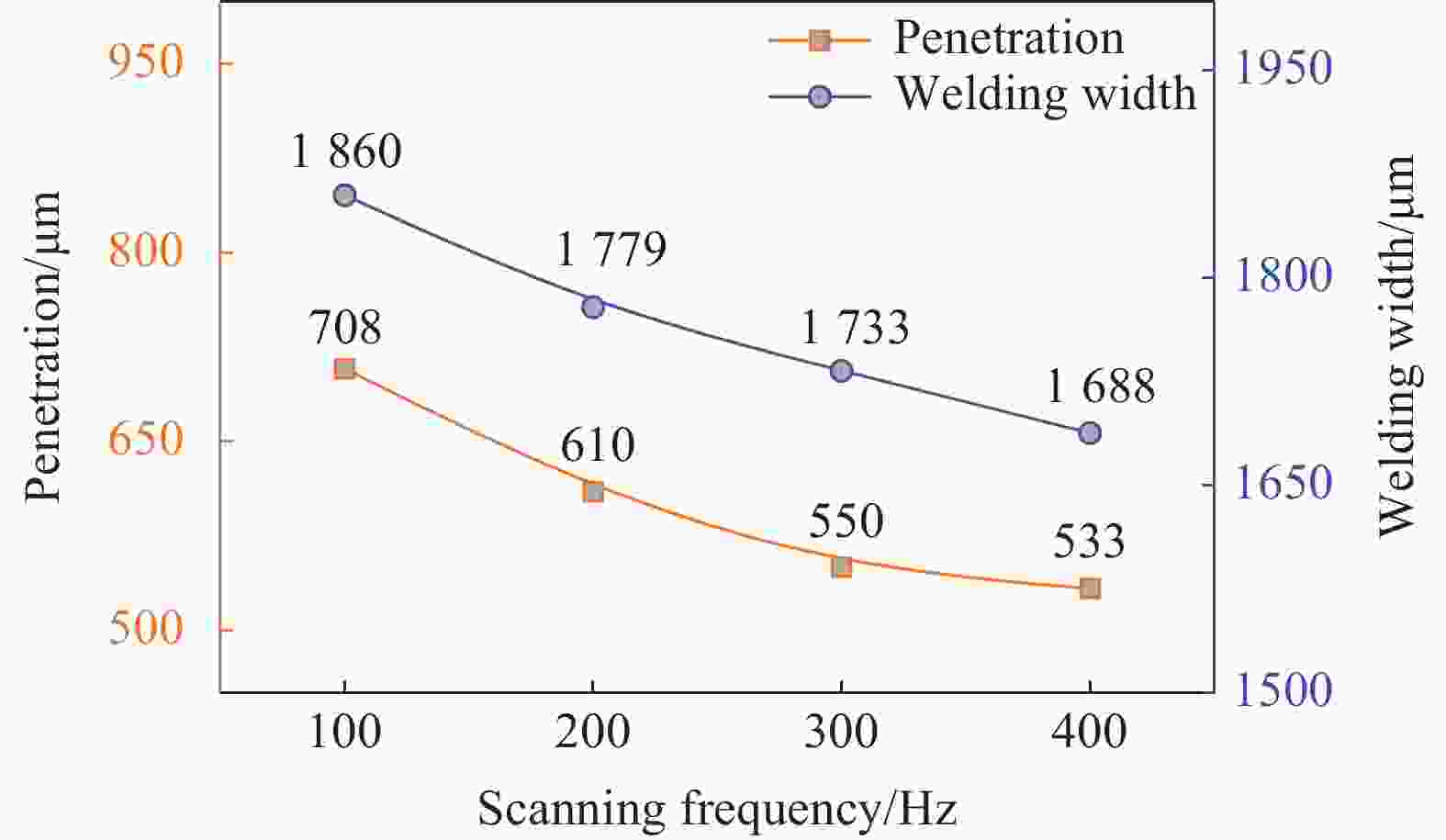

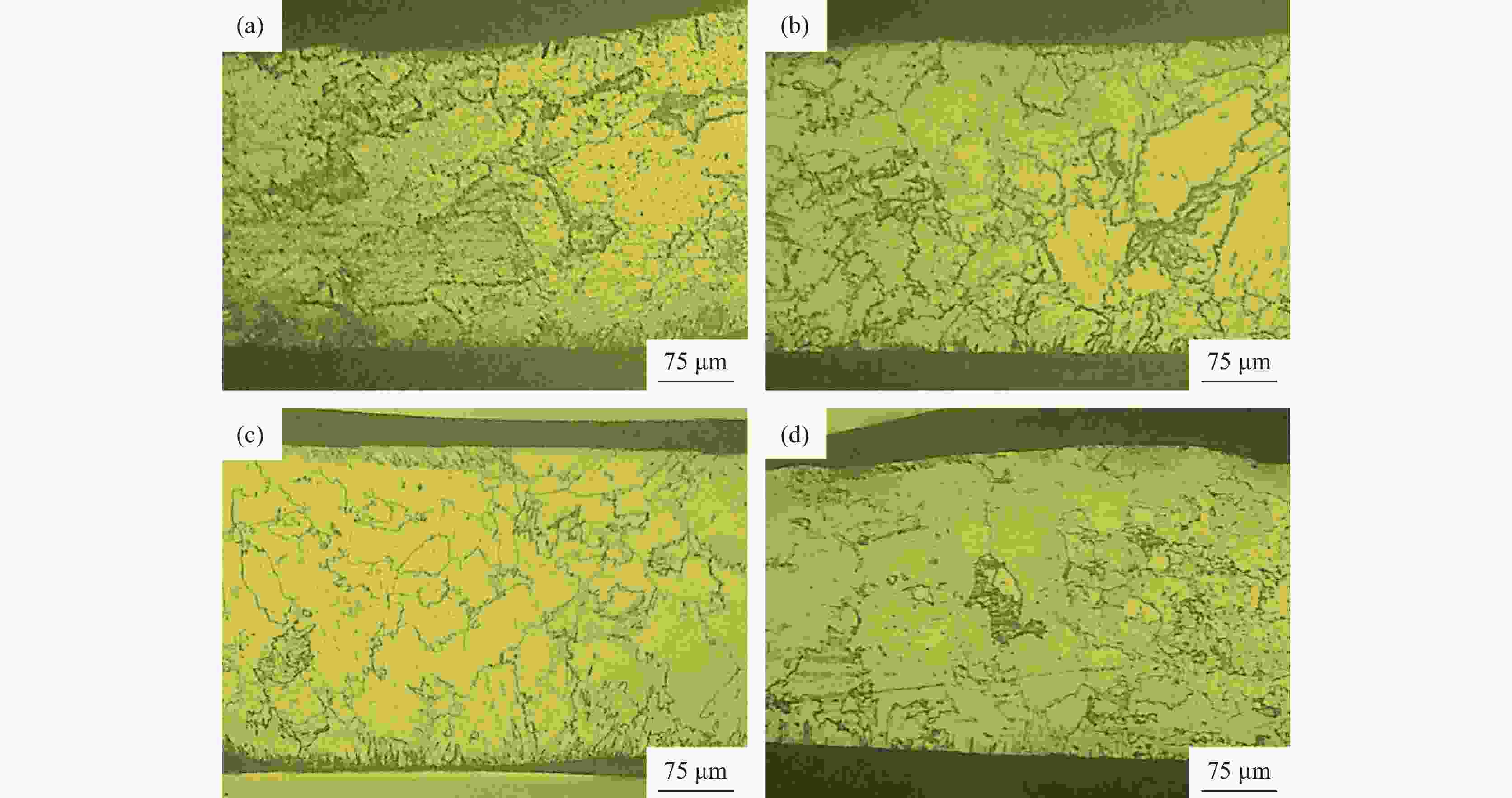

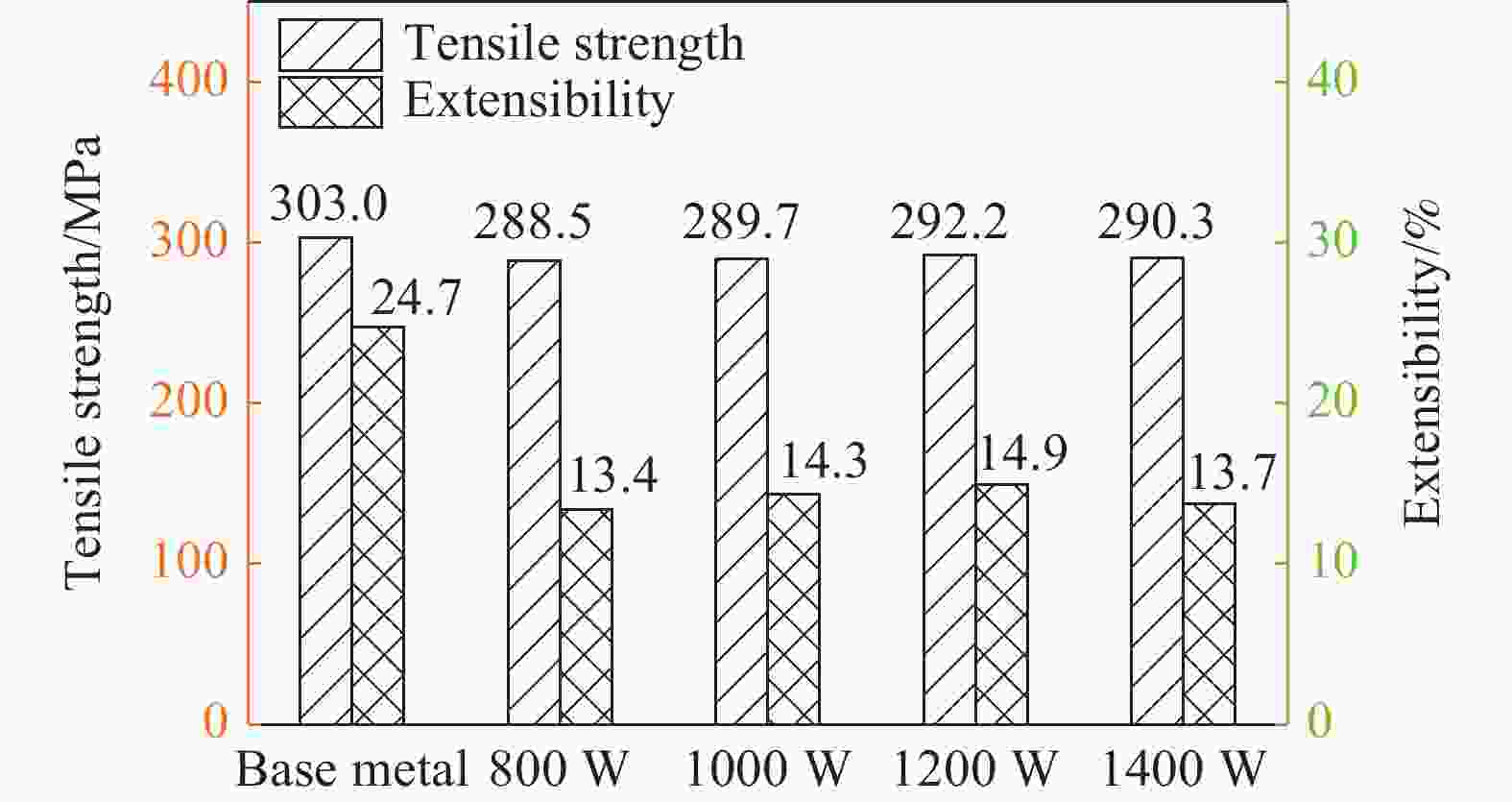

摘要: 针对0.5 mm厚TA1钛合金薄板,采用点环扫描激光的新型焊接方式,研究了工艺参数对焊缝成形与组织性能的影响。采用单因子试验方法,每次仅改变一个参数,固定其它参数不变。各工艺参数不变时的基准数值分别为:中心功率Pz=800 W,外环功率Pw=

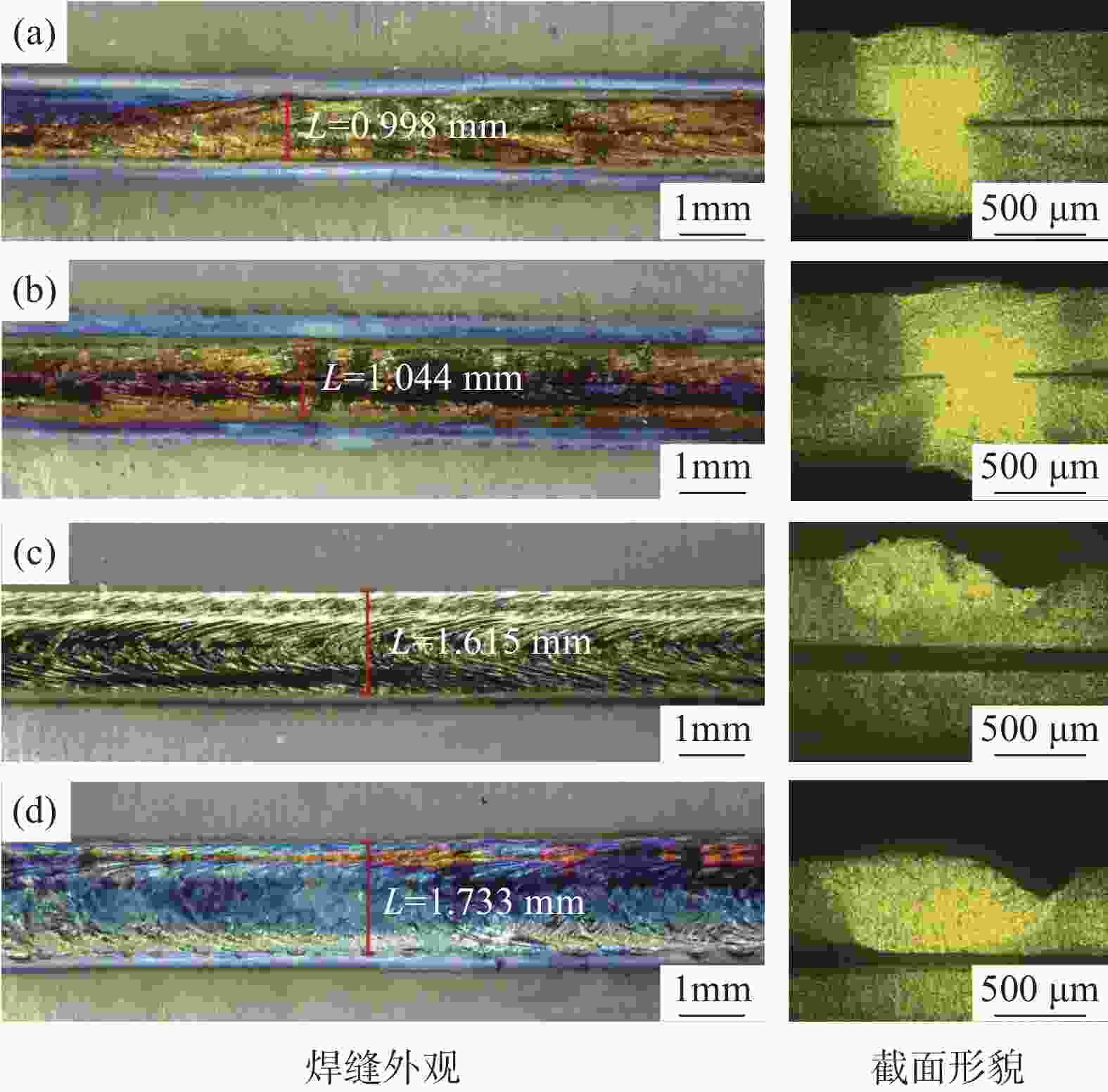

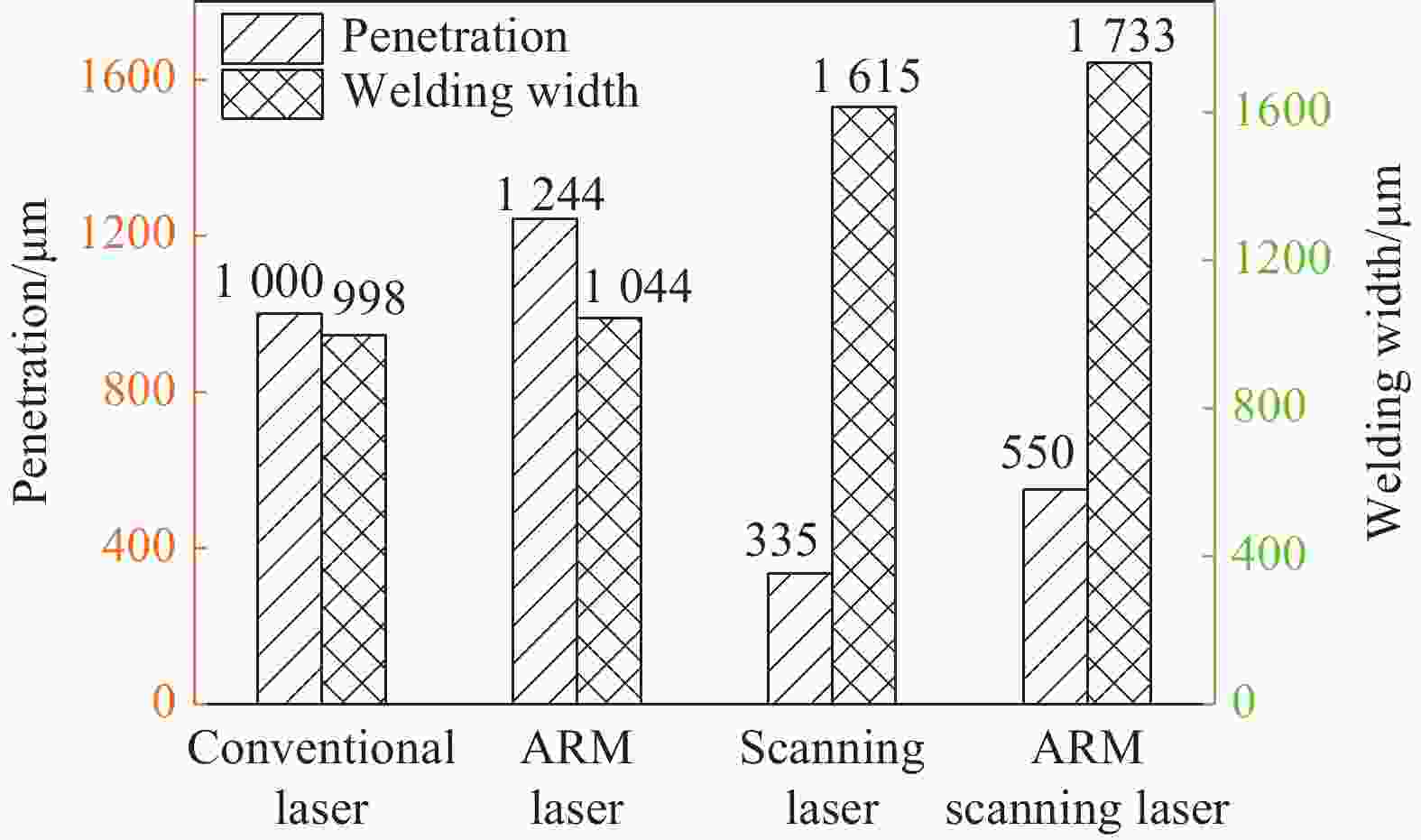

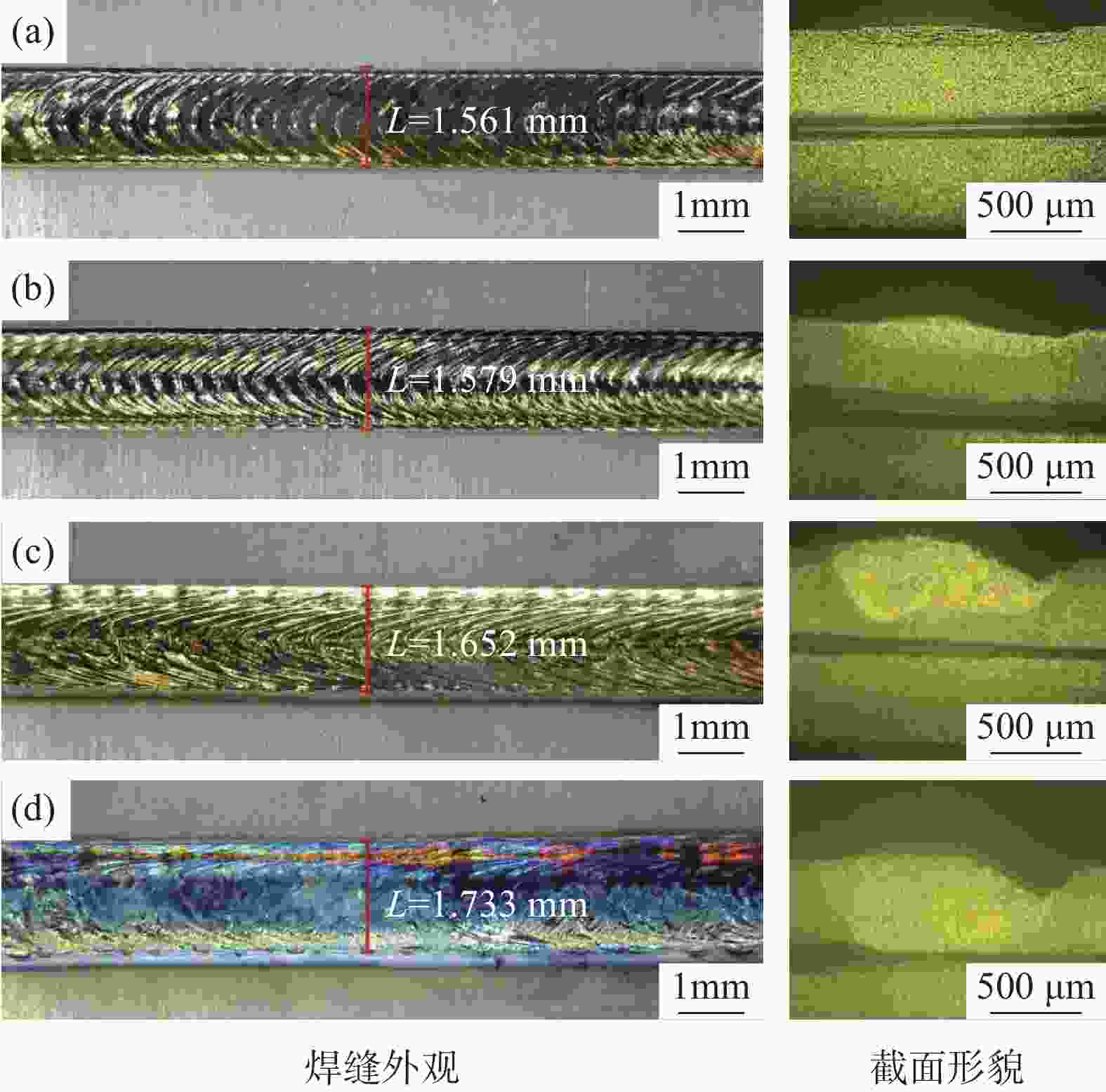

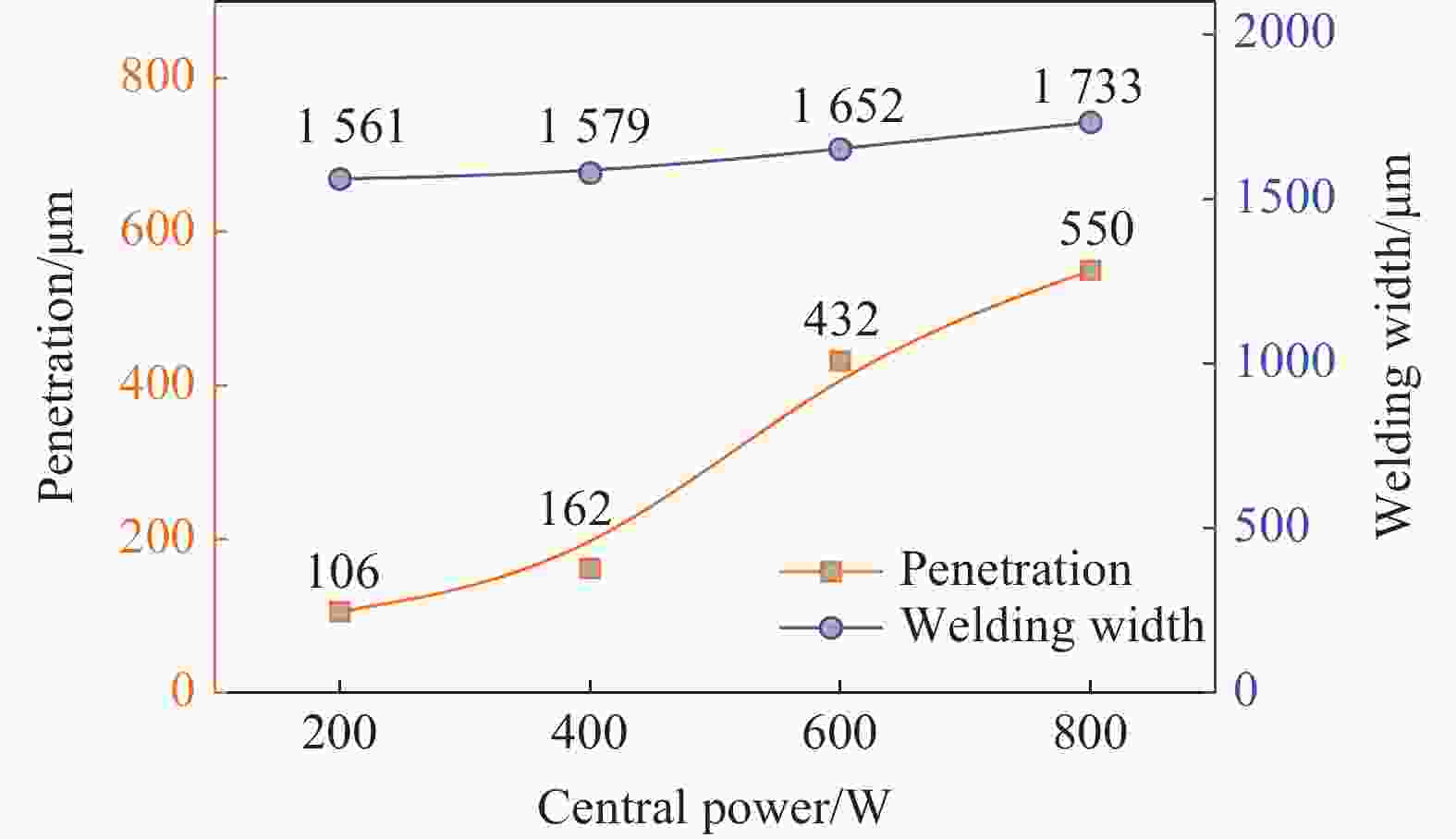

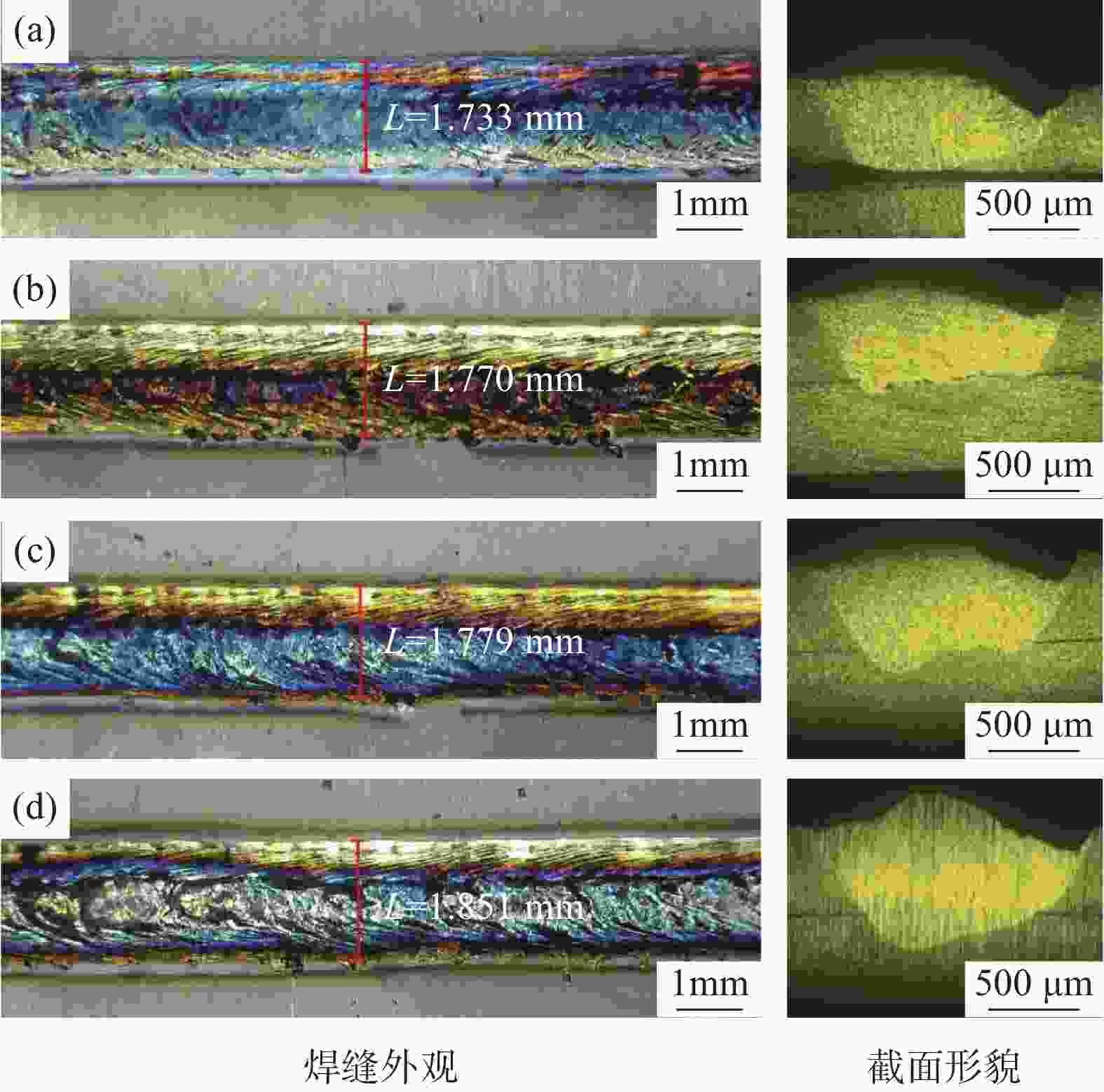

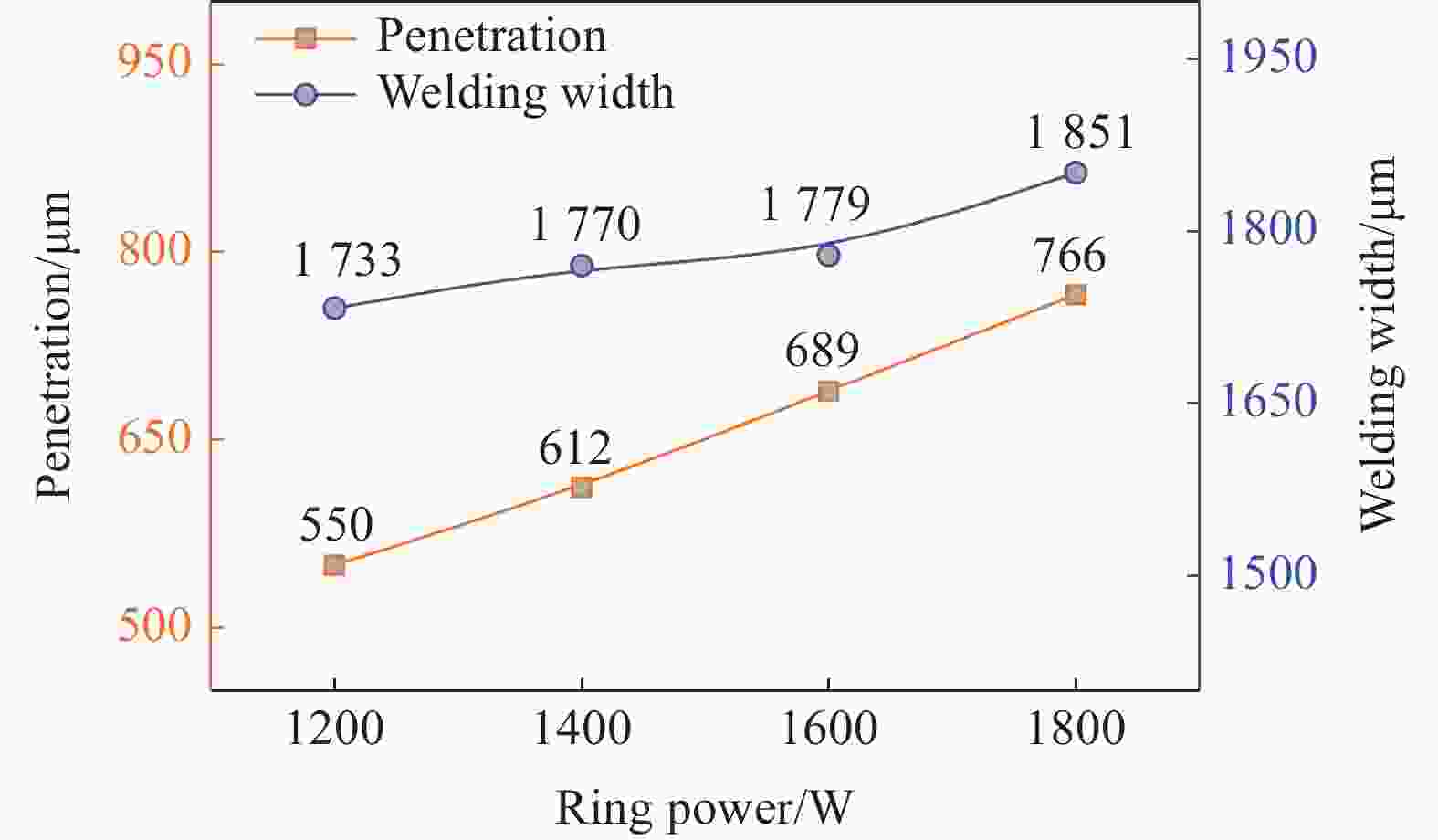

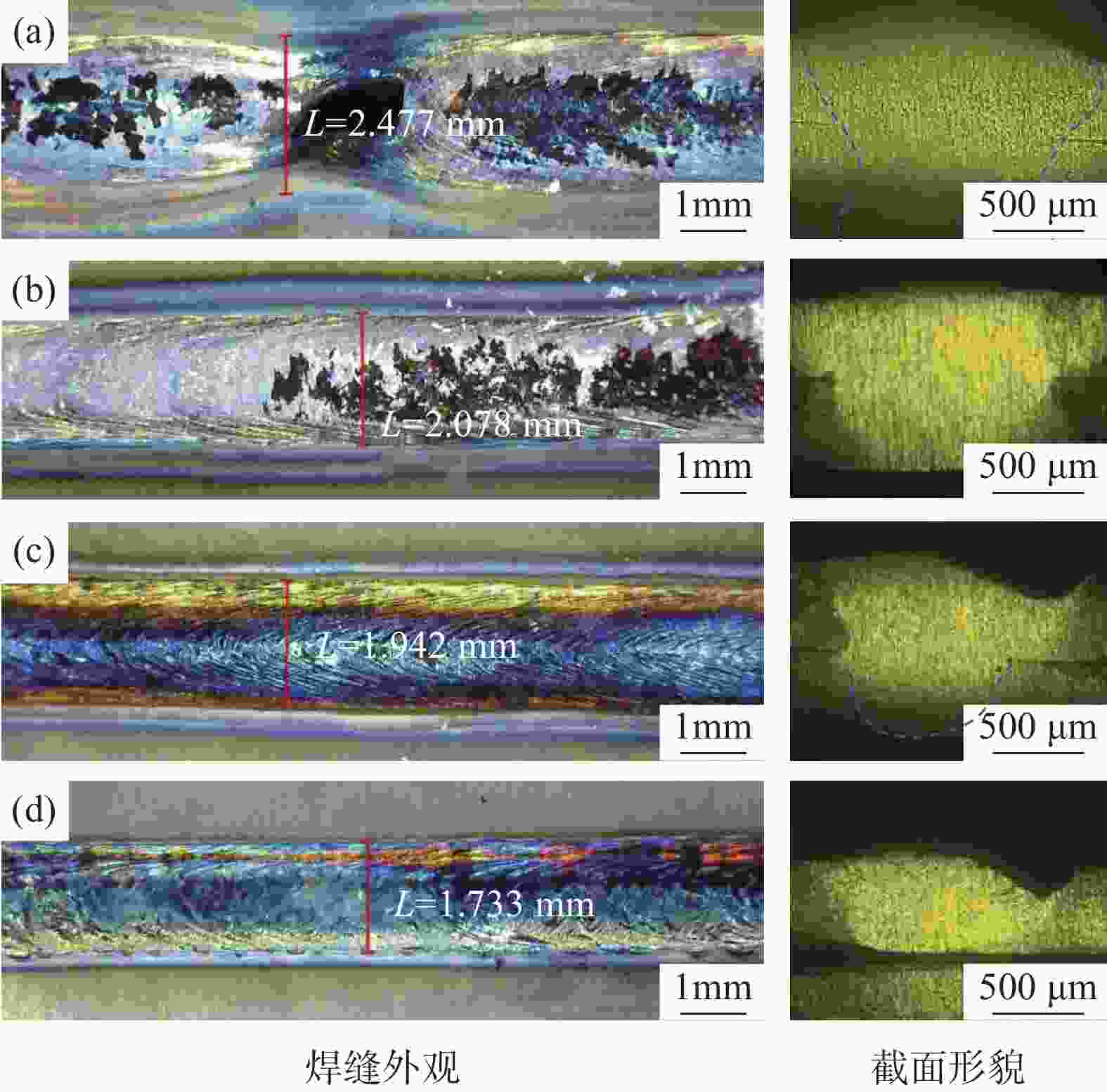

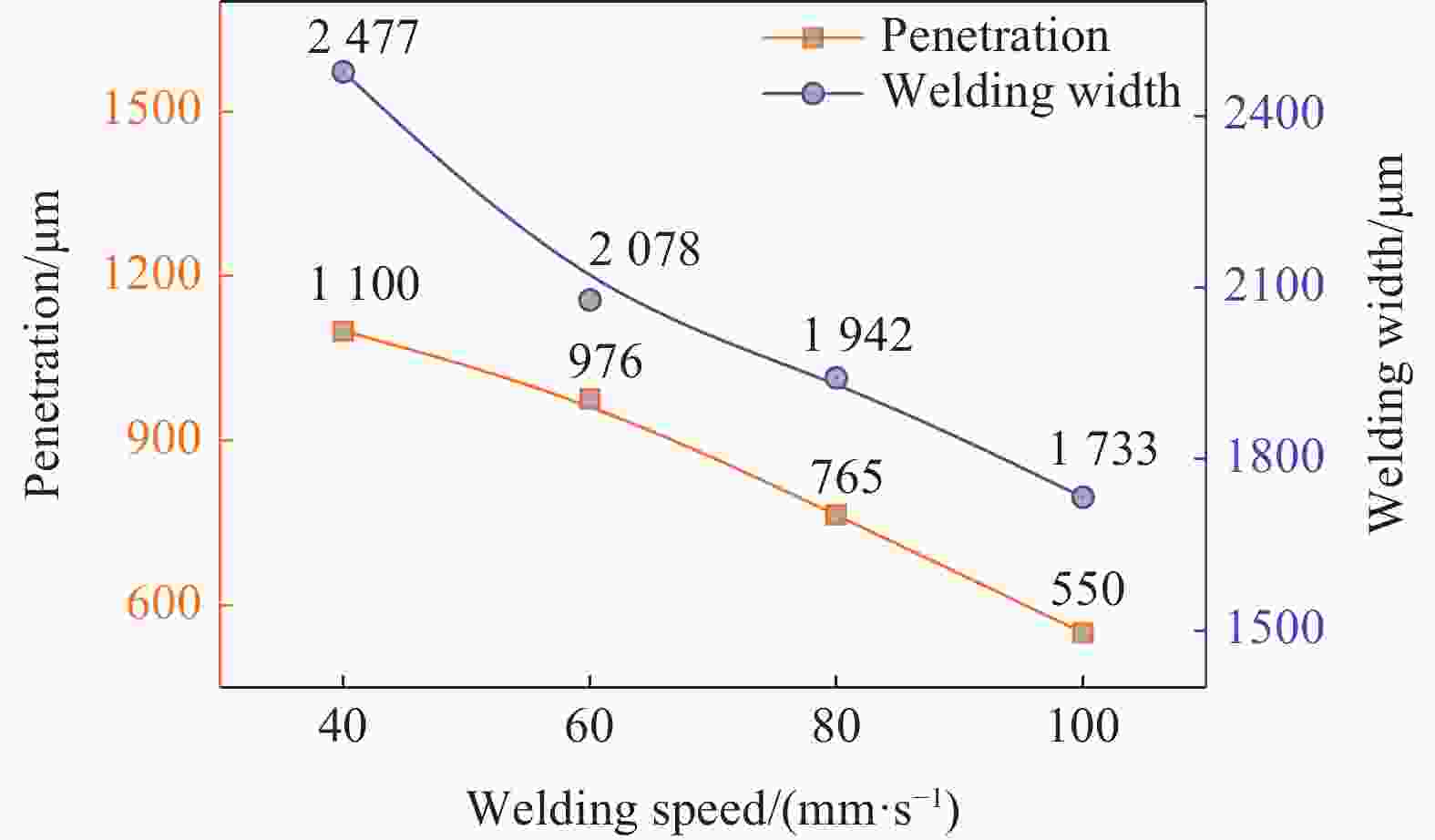

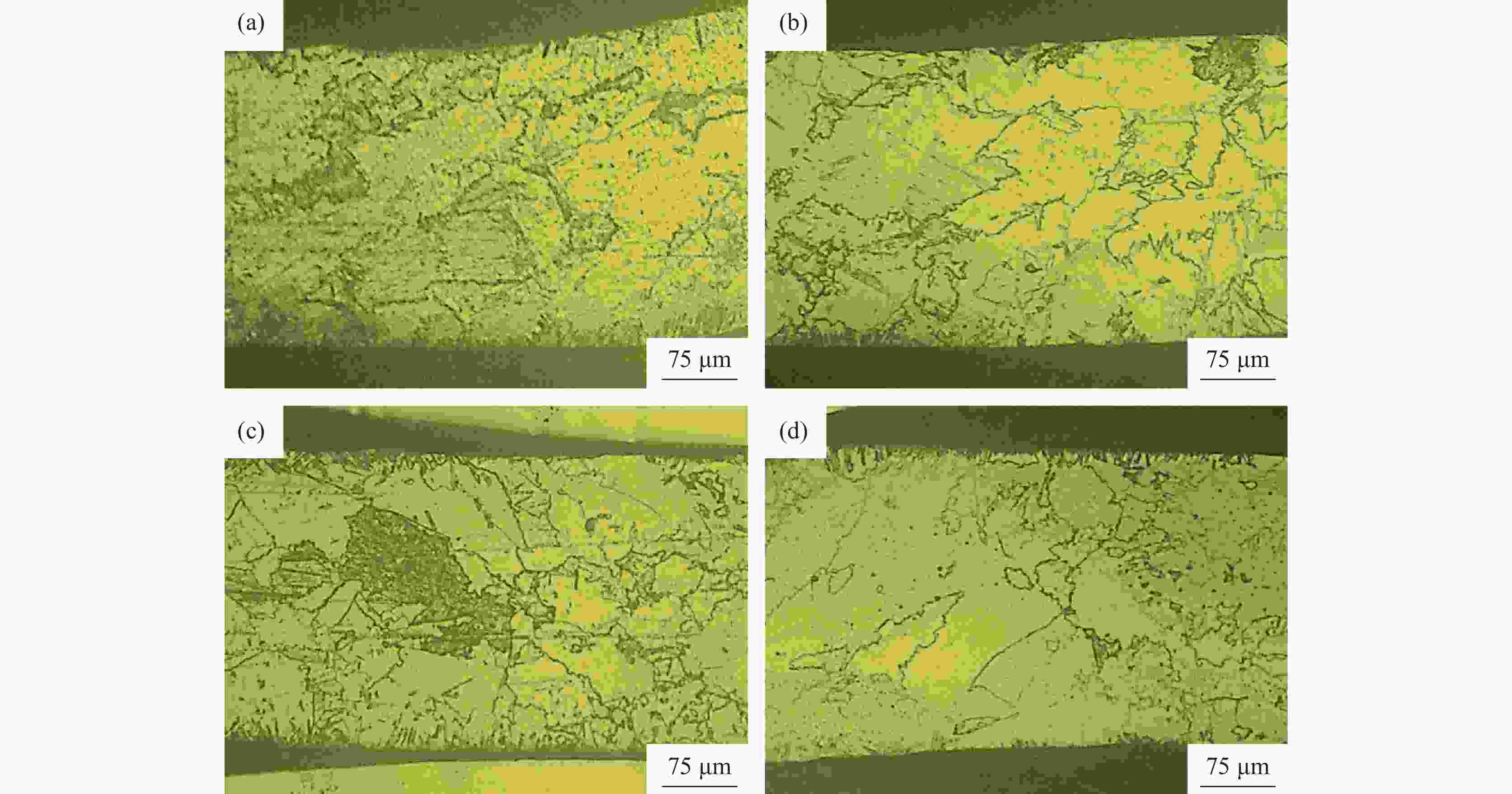

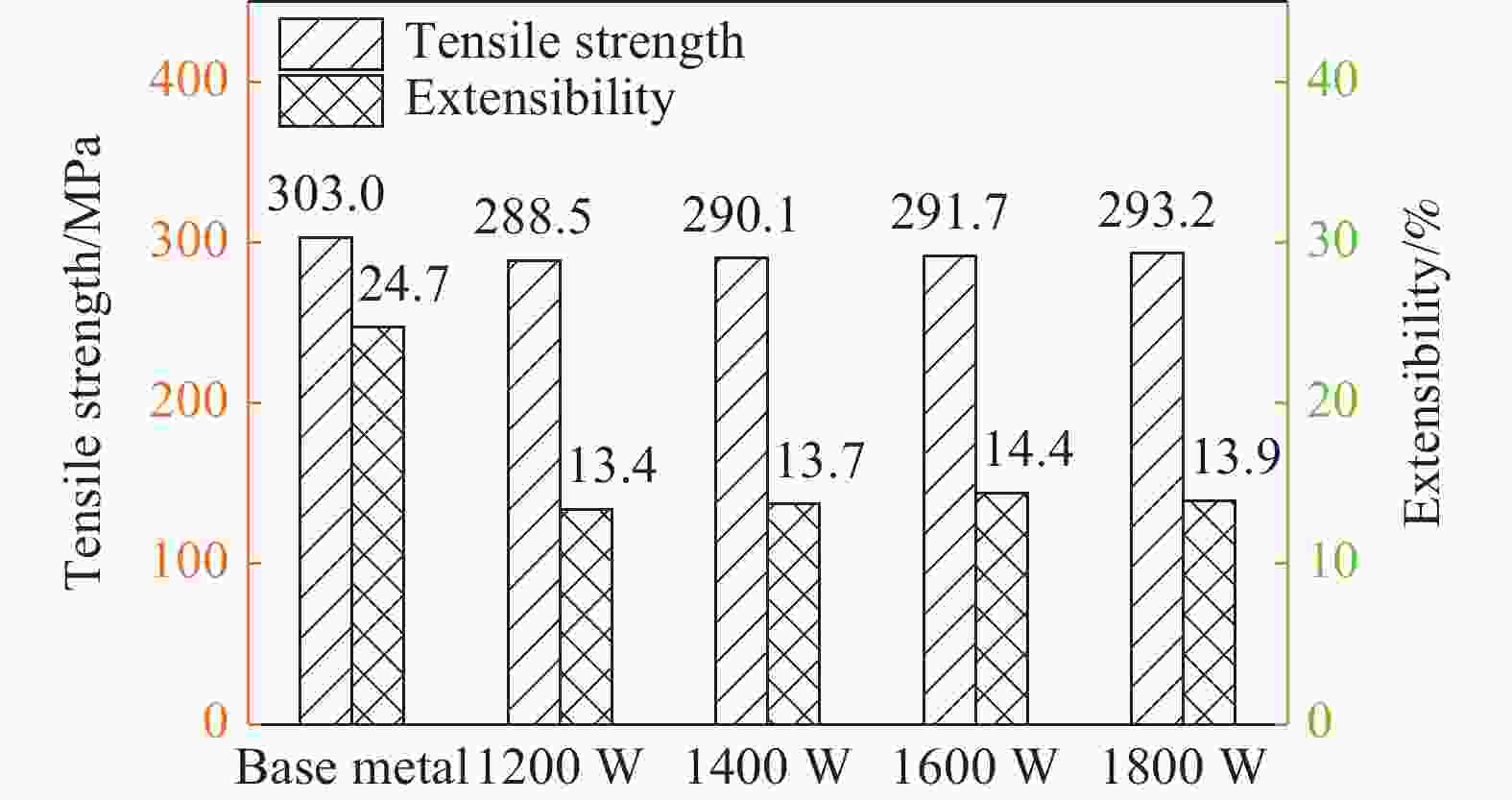

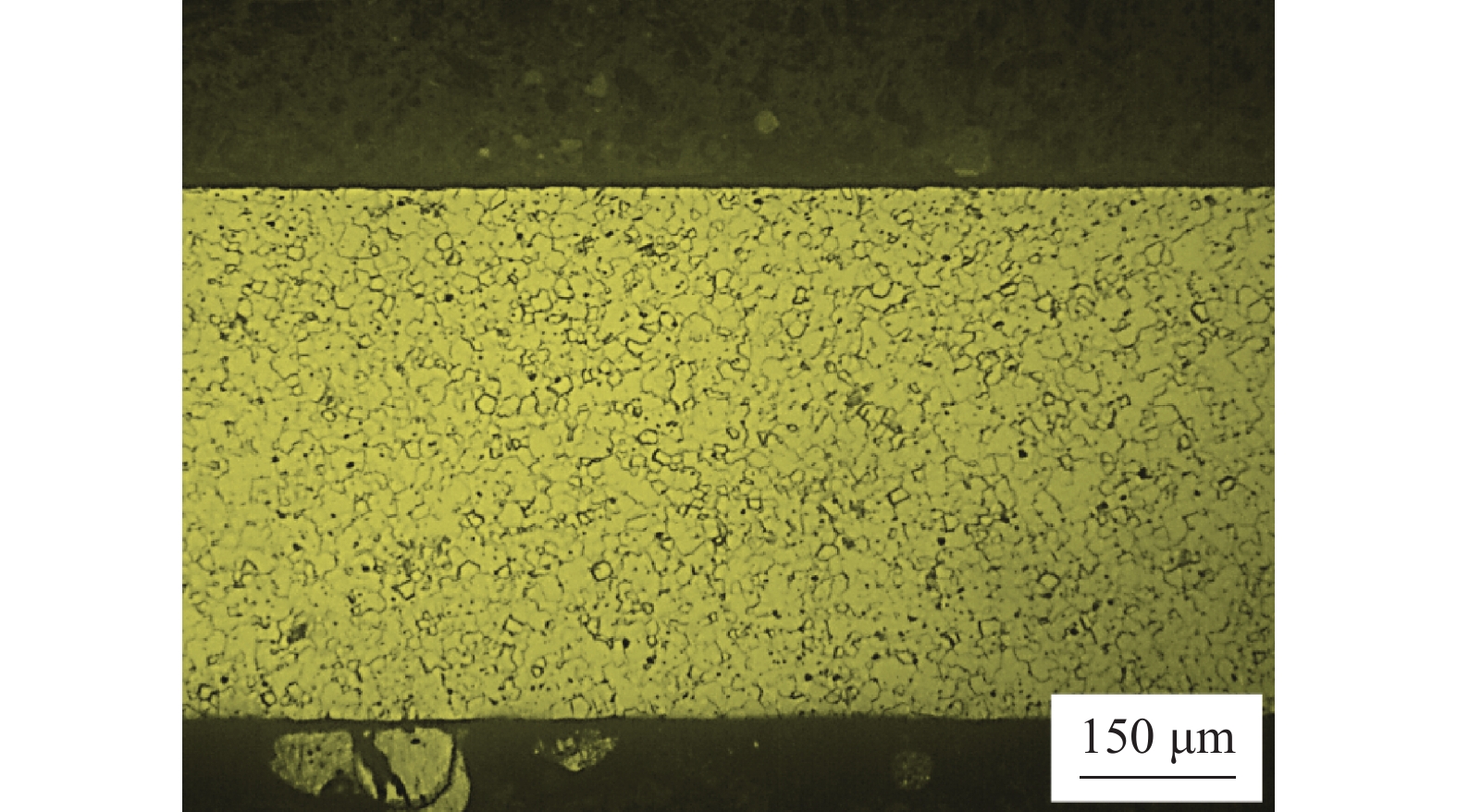

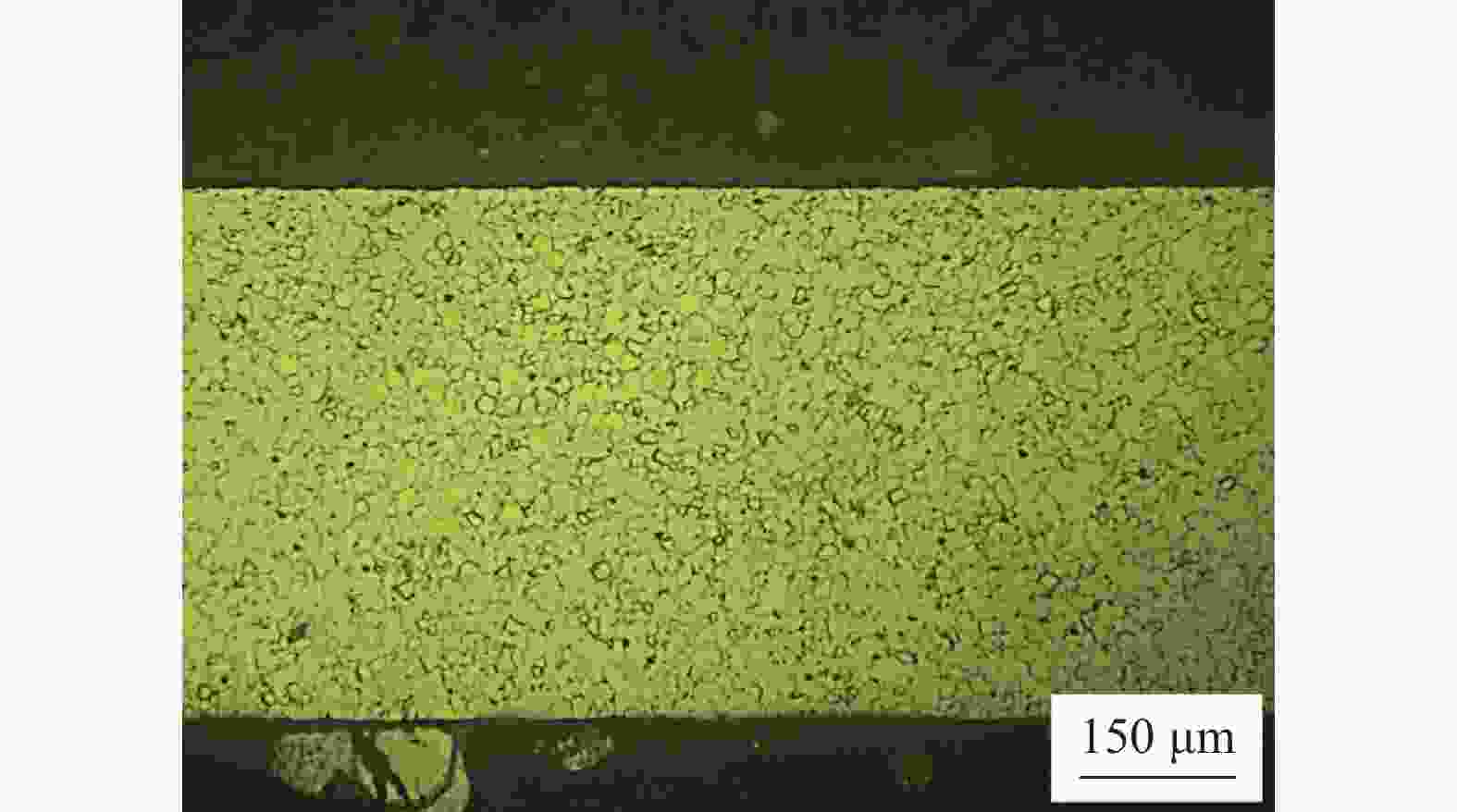

1200 W,焊接速度v=100 mm/s,扫描频率F=300 Hz。改变某一个参数时,其变化范围分别为:中心功率Pz=200~800 W,外环功率Pw=1200 ~1800 W,焊接速度v=40~100 mm/s,扫描频率F=100~400 Hz。研究结果表明:点环扫描激光相比非扫描激光,兼具大熔宽与浅熔深的特点,非常适合薄板焊接;相比普通扫描激光,不仅熔深与熔宽更大,同时焊缝表面成形更光滑、美观,因焊缝余高凸起造成的应力集中也更小。点环扫描激光焊缝显微组织为α相。点环激光的中心功率与外环功率变化对焊缝显微组织、接头抗拉强度与延伸率的影响不显著。焊缝抗拉强度达到母材的95%~96%,延伸率达到母材的54%~60%。Abstract: A new welding method using adjustable-ring mode (ARM) scanning laser was employed to weld 0.5 mm thick TA1 titanium alloy thin sheets. Effects of process parameters on weld formation, microstructure and mechanical properties were studied. A single factor method was adopted in the experiment. One parameter was changed at a time, while other parameters remained unchanged. The values of the process parameters were as follows: the central power Pz=800 W, the ring power Pw=1200 W, the welding speed v=100 mm/s, and the scanning frequency F=300 Hz. When the parameters were changed, the variation ranges are distributed as: the central power Pz=200~800 W, the ring power Pw=1200 ~1800 W, the welding speed v=40~100 mm/s, and the scanning frequency F=100~400 Hz. The results show that compared with non-scanning laser welding, the ARM scanning laser leads to broader bead width and larger penetration, which is highly suitable for thin sheet welding. Compared with conventional scanning laser welding, the ARM scanning laser not only leads to larger bead width and depth, but also produces smoother bead formation and prettier weld appearance, with smaller stress concentration due to lower weld reinforcement. The microstructure of the ARM scanning laser weld metal consists of α phase. The influence of the central power and outer ring power of the ARM laser have insignificant effects on the microstructure, tensile strength and elongation. The tensile strength of the welded joints reaches 95%~96% of the base metal, while the extensibility achieves 54%~60% of the base metal. -

表 1 TA1钛合金化学成分

Table 1. Chemical composition of TA1 titanium alloy

% Materials Ti Fe C N H O Others TA1 Bal. ≤0.20 ≤0.08 ≤0.03 ≤0.015 ≤0.18 ≤0.40 表 2 单因子试验中各工艺参数不变时的基准数值

Table 2. Benchmark values of welding parameters in the single factor experiment

Pz/W Pw/W V/(mm·s−1) F/Hz 800 1200 100 300 -

[1] YU T Y, CHEN S H, LIU K, et al. Two pass laser welding of TC4 titanium alloy and 316L stainless steel with vanadium interlayer[J]. Iron Steel Vanadium Titanium, 2023, 44(2): 92-97. (余腾义, 陈树海, 刘珂, 等. 钒作中间层的TC4钛合金与316L不锈钢双道激光焊接[J]. 钢铁钒钛, 2023, 44(2): 92-97.YU T Y, CHEN S H, LIU K, et al. Two pass laser welding of TC4 titanium alloy and 316L stainless steel with vanadium interlayer[J]. Iron Steel Vanadium Titanium, 2023, 44(2): 92-97. [2] BAI W C, ZHANG X F, ZHU F D. Research on laser welding process optimization of aircraft titanium alloy structure[J]. Metallurgy and Materials, 2023, 43(3): 1-3. (白伟成, 张献逢, 褚福东. 飞机钛合金结构激光焊接工艺优化研究[J]. 冶金与材料, 2023, 43(3): 1-3.BAI W C, ZHANG X F, ZHU F D. Research on laser welding process optimization of aircraft titanium alloy structure[J]. Metallurgy and Materials, 2023, 43(3): 1-3. [3] LU X. Microstructures and defect analysis of TC4 titanium alloy joints by the TIG welding[J]. Iron Steel Vanadium Titanium, 2018, 39(4): 74-79. (陆鑫. TC4钛合金TIG焊接头组织及缺陷分析[J]. 钢铁钒钛, 2018, 39(4): 74-79.LU X. Microstructures and defect analysis of TC4 titanium alloy joints by the TIG welding[J]. Iron Steel Vanadium Titanium, 2018, 39(4): 74-79. [4] SONG X L, AN J R. New handbook of Chinese and foreign metal materials (2nd edition)[M]. Beijing: Chemical Industry Press, 2012: 1246-1247. (宋小龙, 安继儒. 新编中外金属材料手册(第2版)[M]. 北京: 化学工业出版社, 2012: 1246-1247.SONG X L, AN J R. New handbook of Chinese and foreign metal materials (2nd edition)[M]. Beijing: Chemical Industry Press, 2012: 1246-1247. [5] YU H, LI J Z, ZHANG W C, et al. Research progress of weld formation and performance control of thin plate TC4 titanium alloy by laser welding[J]. Iron Steel Vanadium Titanium, 2022, 43(1): 53-66. (于航, 李军兆, 张望成, 等. 薄壁TC4钛合金激光焊缝成型与性能调控研究进展[J]. 钢铁钒钛, 2022, 43(1): 53-66.YU H, LI J Z, ZHANG W C, et al. Research progress of weld formation and performance control of thin plate TC4 titanium alloy by laser welding[J]. Iron Steel Vanadium Titanium, 2022, 43(1): 53-66. [6] WEI Y S, MA Q J, WU P B, et al. Research progress in laser welding technology of tc4 titanium alloy[J]. Electric Welding Machine, 2023, 53(8): 55-66. (魏玉顺, 马青军, 武鹏博, 等. TC4钛合金激光焊接技术研究进展[J]. 电焊机, 2023, 53(8): 55-66.WEI Y S, MA Q J, WU P B, et al. Research progress in laser welding technology of tc4 titanium alloy[J]. Electric Welding Machine, 2023, 53(8): 55-66. [7] FENG J, FAN L M, GENG N T, et al. Research on TIG welding process of high strength titanium alloy[J]. Iron Steel Vanadium Titanium, 2021, 42(6): 158-163. (冯靖, 樊立民, 耿乃涛, 等. 高强钛合金TIG焊接工艺研究[J]. 钢铁钒钛, 2021, 42(6): 158-163.FENG J, FAN L M, GENG N T, et al. Research on TIG welding process of high strength titanium alloy[J]. Iron Steel Vanadium Titanium, 2021, 42(6): 158-163. [8] MENG Y F, FU J W, ZHANG S, et al. Laser-arc hybrid welding of AZ31B magnesium alloy by newly-designed beam oscillating pattern[J]. Journal of Manufacturing Processes, 2023, 93: 208-218. doi: 10.1016/j.jmapro.2023.03.028 [9] LU Y, DENG Y C, SHI L, et al. Numerical simulation of thermal flow dynamics in oscillating laser welding of aluminum alloy[J]. Optics and Laser Technology, 2023, 159: 109003. doi: 10.1016/j.optlastec.2022.109003 [10] CEN L, DU W B, GONG M C, et al. Effect of high-frequency beam oscillation on microstructures and cracks in laser cladding of Al-Cu-Mg alloys[J]. Surface & Coating Technology, 2022, 447: 128852. [11] WANG L, YAO M P, GAO X D, et al. Keyhole stability and surface quality during novel adjustable-ring mode laser (ARM) welding of aluminum alloy[J]. Optics and Laser Technology, 2023, 161: 109202. doi: 10.1016/j.optlastec.2023.109202 [12] WANG Z Y, JIANG M, CHEN X, et al. Mitigating spatters in keyhole-mode laser welding by superimposing additional ring-shaped beam[J]. Optics and Laser Technology, 2024, 168: 109869. doi: 10.1016/j.optlastec.2023.109869 [13] DU Z Y. Welding metallurgy: basic principles[M]. Beijing: Machinery Industry Press, 2018: 189-190. (杜则裕. 焊接冶金学: 基本原理[M]. 北京: 机械工业出版社, 2018: 189-190.DU Z Y. Welding metallurgy: basic principles[M]. Beijing: Machinery Industry Press, 2018: 189-190. [14] LI J H. Metallographic phase map of metallic materials[M]. Beijing: Machinery Industry Press, 2006: 1848-1849. (李炯辉. 金属材料金相图谱[M]. 北京: 机械工业出版社, 2006: 1848-1849.LI J H. Metallographic phase map of metallic materials[M]. Beijing: Machinery Industry Press, 2006: 1848-1849. -

下载:

下载: