Preparation and properties study of ternary composite admixture consisting of silica fume, yellow phosphorus slag, and high titanium blast furnace slag

-

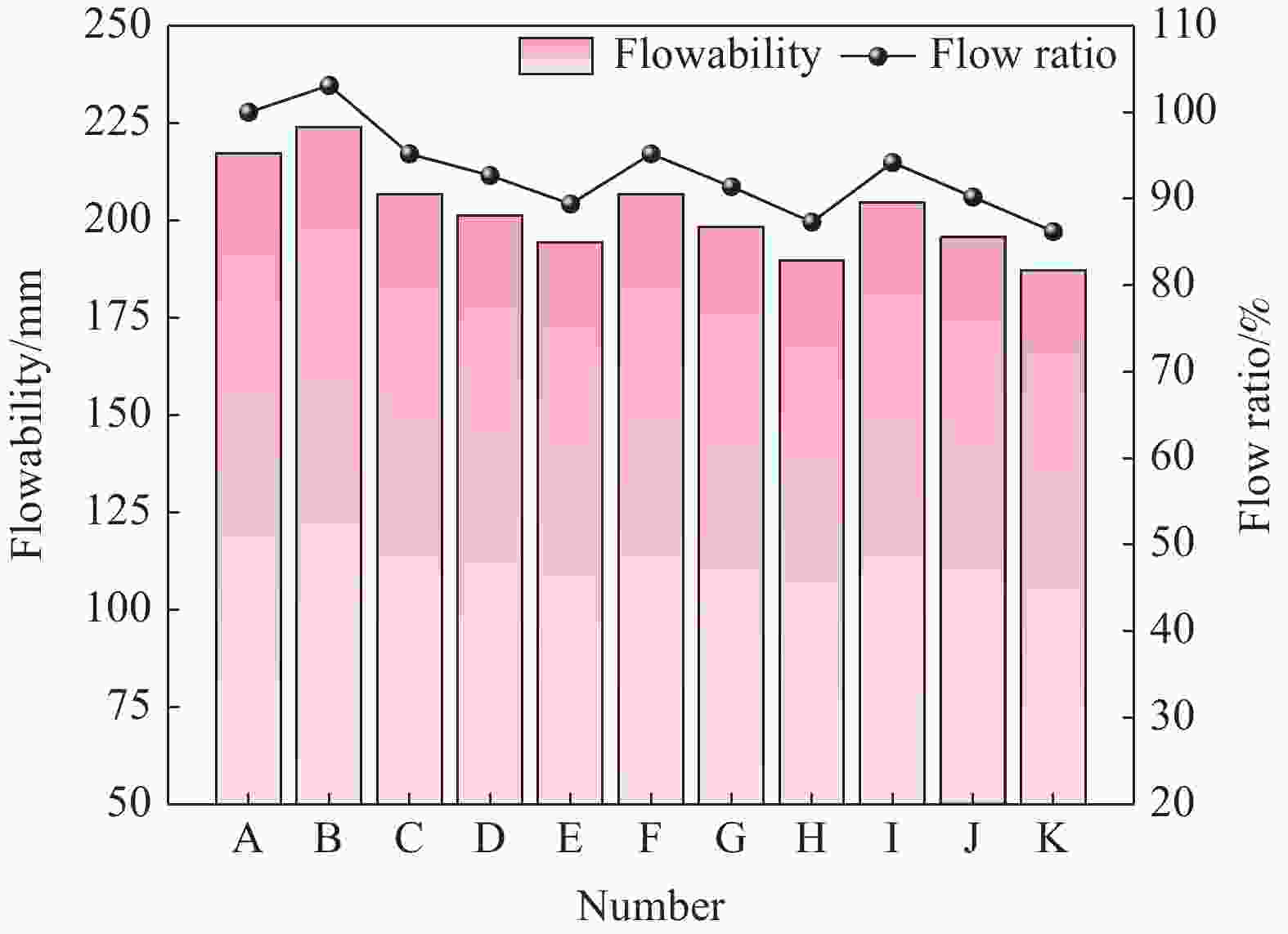

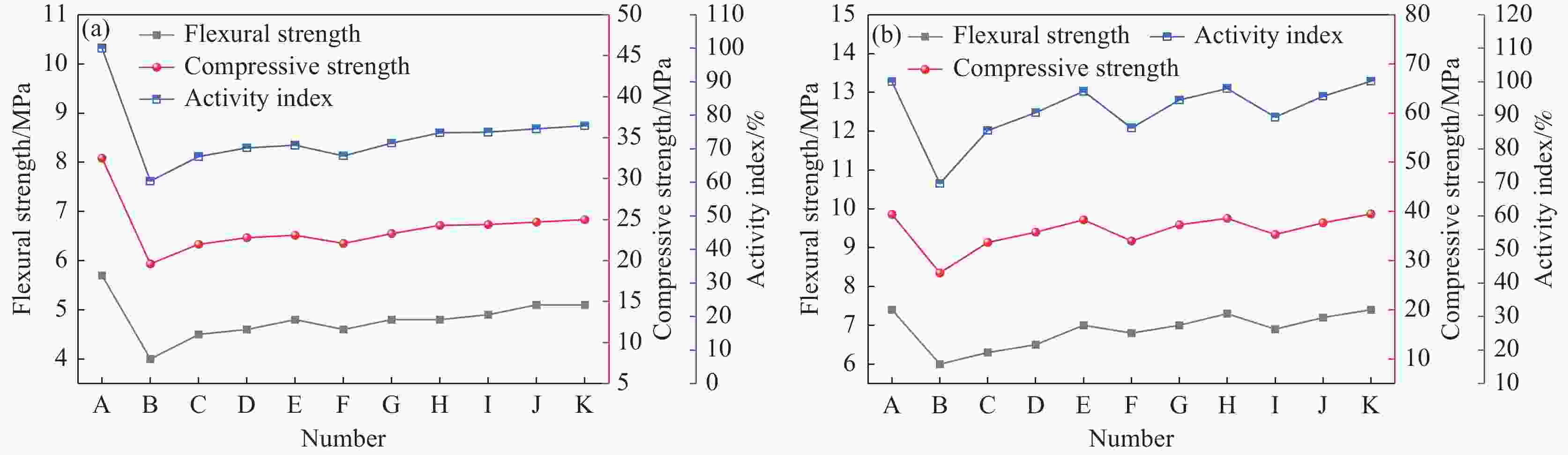

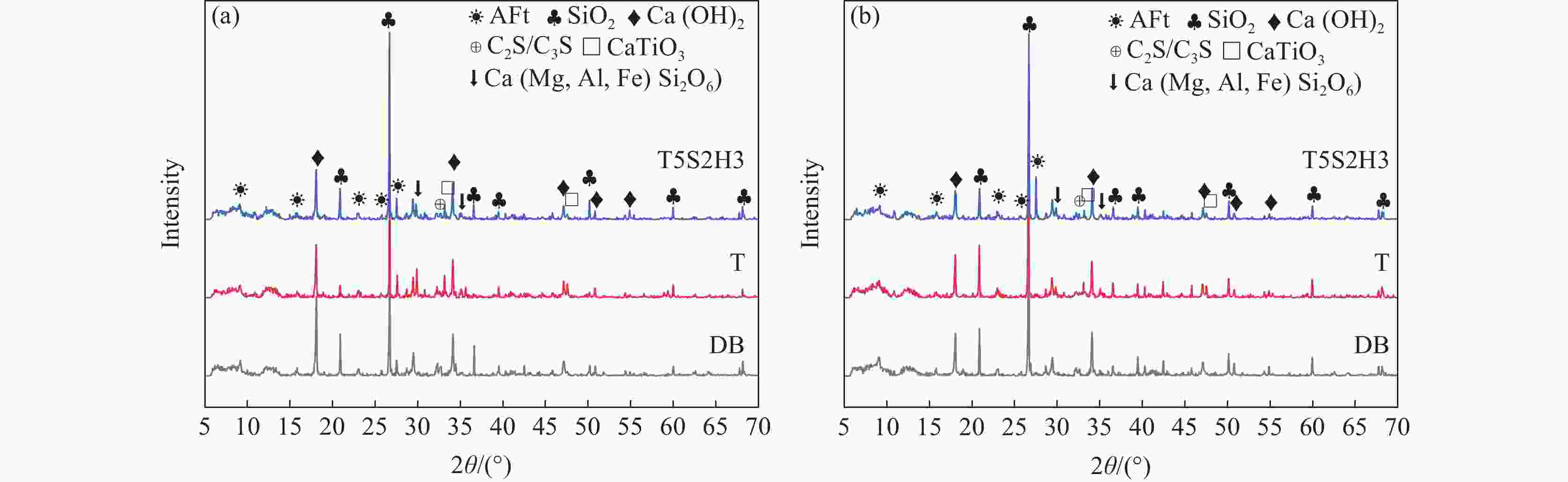

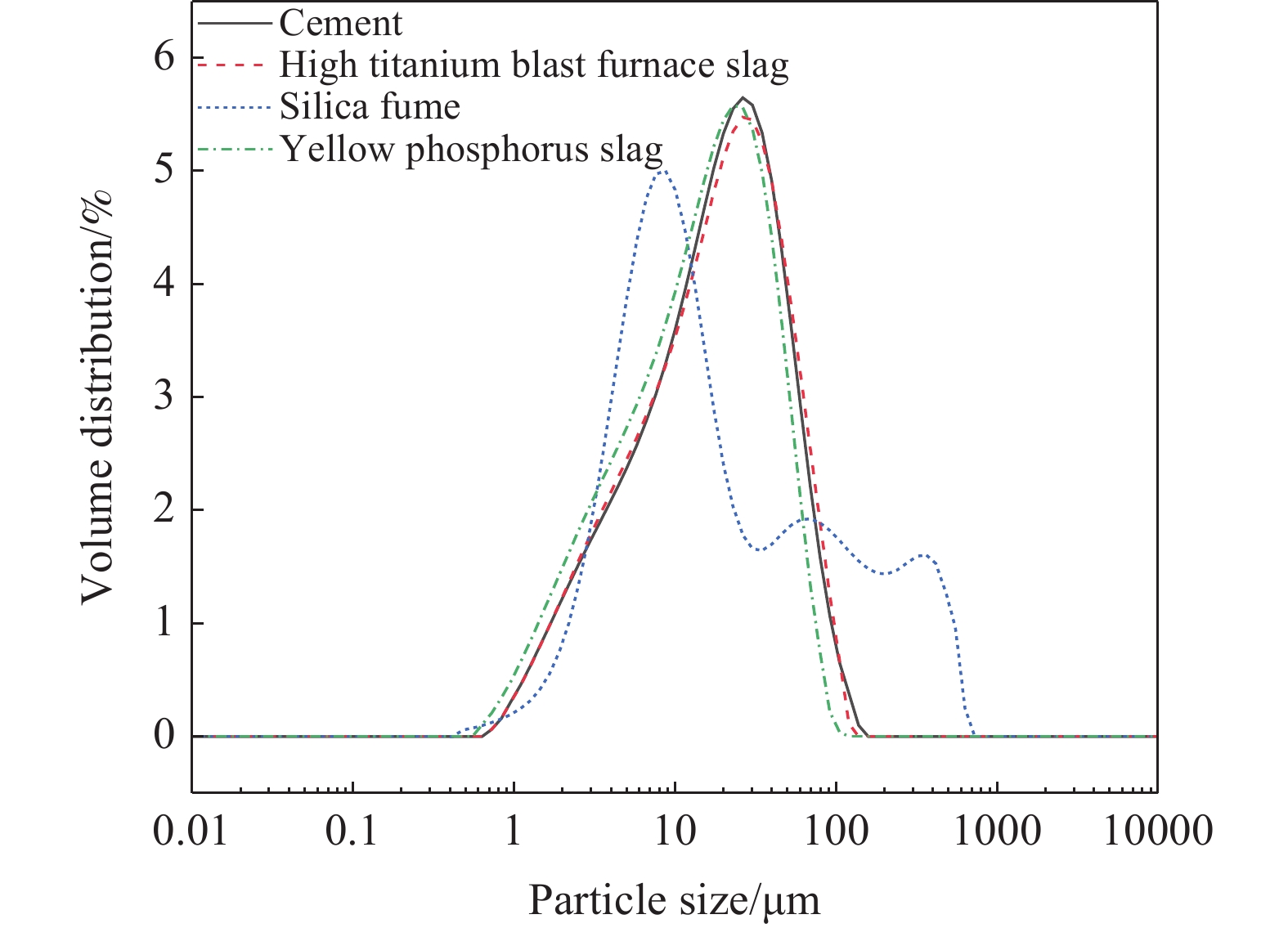

摘要: 高钛型高炉渣活性较低是限制其在混凝土中单独作为掺合料应用的主要因素之一。为解决这一问题,制备了硅灰-黄磷渣-高钛型高炉渣三元复合掺合料,研究其对水泥胶砂流动度比与活性指数的影响。结合XRD、SEM-EDS微观测试手段,分析了不同掺合料对水泥胶砂性能的影响机理。结果表明:随着硅灰-黄磷渣的掺入,水泥胶砂的流动度比会下降,且硅灰的影响大于黄磷渣。三元复合掺合料的活性指数较高钛型高炉渣单独作为掺合料时得到了明显的提升。高钛型高炉渣:硅灰:黄磷渣占比为5:2:3时7 d和28 d龄期的活性指数最优,分别达到了76.9%和100.2%,满足II级掺合料对活性指数的要求。微观测试表明,硅灰-黄磷渣的掺入能消耗片状Ca(OH)2,生成更多絮凝状胶体C-S(A)-H与针棒状AFt的水化产物,形成相互交错、致密的网状结构,从而增强水泥胶砂的强度。Abstract: The low reactivity of high titanium blast furnace slag is one of the main factors limiting its application as a sole admixture in concrete. To address this issue, a ternary composite admixture consisting of silica fume, yellow phosphorus slag, and high titanium blast furnace slag was prepared, and its effects on the flow ratio and activity index of cement mortar were investigated. Combined with microscopic testing methods such as XRD and SEM-EDS, the influence mechanism of different admixtures on the performance of cement mortar was analyzed. The results indicate that the incorporation of silica fume and yellow phosphorus slag leads to a decrease in the flow ratio of cement mortar, with the silica fume having a greater impact than the yellow phosphorus slag. The activity index of the ternary composite admixture is significantly improved compared to when high titanium blast furnace slag is used alone as an admixture. The optimal activity indices at 7 days and 28 days of curing are achieved when the ratio of high-titanium blast furnace slag: silica fume: yellow phosphorus slag is 5:2:3, reaching 76.9% and 100.2%, respectively, which meets the requirements for the activity index of Grade II admixtures. Microscopic testing reveals that the incorporation of silica fume and yellow phosphorus slag consumes flaky Ca(OH)2, generating more flocculent colloidal C-S(A)-H and needle-like AFt hydrates, which form an interlaced and dense network structure, thereby enhancing the strength of cement mortar.

-

表 1 部分原材料主要化学成分及含量

Table 1. The main chemical compositions and content of some raw materials

% Some raw materials CaO SiO2 TiO2 Al2O3 MgO Fe2O3 SO3 K2O Na2O P2O5 F Other Cement 63.09 18.84 1.15 5.07 2.04 3.52 4.42 0.95 0.34 0.15 0.00 0.43 High titanium blast furnace slag 28.43 23.1 21.79 13.56 6.98 1.87 1.56 0.74 0.83 0.02 0.00 1.12 Silica fume 0.90 95.59 0.00 0.40 0.19 0.26 2.03 0.42 0.09 0.08 0.00 0.04 Yellow phosphorus slag 47.58 36.9 0.22 3.63 2.67 0.65 0.74 0.79 0.55 2.86 3.18 0.23 表 2 不同掺合料水泥胶砂样品配合比

Table 2. Mix proportions of cement mortar samples with different admixtures

Number Group Cement/g Admixture/g Standard sand/g Water/mL Admixture type Type of cement mortar High titanium blast furnace slag Silica fume Yellow phosphorus slag A DB 450 0 0 0 1350 225 Admixture-free Comparison mortar B T 315 135 0 0 1350 225 Single-blended admixture Test mortar C T7S1H2 315 94.5 13.5 27 1350 225 Ternary composite admixture D T7S1.5H1.5 315 94.5 20.25 20.25 1350 225 E T7S2H1 315 94.5 27 13.5 1350 225 F T6S1H3 315 81 13.5 40.5 1350 225 G T6S1.5H2.5 315 81 20.25 33.75 1350 225 H T6S2H2 315 81 27 27 1350 225 I T5S1H4 315 67.5 13.5 54 1350 225 J T5S1.5H3.5 315 67.5 20.25 47.25 1350 225 K T5S2H3 315 67.5 27 40.5 1350 225 Note: In the group designations, T represents high-titanium blast furnace slag, S denotes silica fume, and H indicates yellow phosphorus slag. T7S1H2 signifies the proportions of each material in the admixture (e.g., T:S:H = 7:1:2), and other groups follow the same naming convention. -

[1] ZHAO Y, SHEN G H, ZHU L L, et al. Fractal dimension-based fine-scale damage law for uniaxial compression test of 3D printed steel slag cementitious materials[J]. Acta Materiae Compositae Sinica, 2024, 42(4): 1-10. (赵宇, 沈光海, 朱伶俐, 等. 基于分形维数的3D打印钢渣水泥基材料单轴压缩试验的细观破坏规律[J]. 复合材料学报, 2024, 42(4): 1-10.ZHAO Y, SHEN G H, ZHU L L, et al. Fractal dimension-based fine-scale damage law for uniaxial compression test of 3D printed steel slag cementitious materials[J]. Acta Materiae Compositae Sinica, 2024, 42(4): 1-10. [2] SONG Q, YANG Y X, XU S P, et al. Research progress in performance and enhancement of coal gangue concrete[J]. Coal Science and Technology, 2025, 53(2): 402-420. (宋强, 杨玉鑫, 许世鹏, 等. 煤矸石混凝土性能及提升研究进展[J]. 煤炭科学技术, 2025, 53(2): 402-420.SONG Q, YANG Y X, XU S P, et al. Research progress in performance and enhancement of coal gangue concrete[J]. Coal Science and Technology, 2025, 53(2): 402-420. [3] GUO Y, LUO L, LIU T, et al. A review of low-carbon technologies and projects for the global cement industry[J]. Journal of Environmental Sciences, 2024, 136: 682-697. doi: 10.1016/j.jes.2023.01.021 [4] BENHELAL E, SHAMSAEI E, RASHID M I. Challenges against CO2 abatement strategies in cement industry: A review[J]. Journal of Environmental Sciences, 2021, 104: 84-101. doi: 10.1016/j.jes.2020.11.020 [5] ZHENG Y L, JI S, LU C H, et al. Preparation technology and mechanism of cementitious material based on solid waste phosphogypsum[J]. Acta Materiae Compositae Sinica, 2024, 41(3): 1436-1446. (郑玉龙, 嵇帅, 陆春华, 等. 基于固废磷石膏制备胶凝材料的工艺与机制[J]. 复合材料学报, 2024, 41(3): 1436-1446.ZHENG Y L, JI S, LU C H, et al. Preparation technology and mechanism of cementitious material based on solid waste phosphogypsum[J]. Acta Materiae Compositae Sinica, 2024, 41(3): 1436-1446. [6] GU X W, ZHANG Y N, ZHANG W F, et al. Research status and prospect of high value building materials utilization of bulk industrial solid waste[J]. Metal Mine, 2022, 51(1): 1-13. (顾晓薇, 张延年, 张伟峰, 等. 大宗工业固废高值建材化利用研究现状与展望[J]. 金属矿山, 2022, 51(1): 1-13.GU X W, ZHANG Y N, ZHANG W F, et al. Research status and prospect of high value building materials utilization of bulk industrial solid waste[J]. Metal Mine, 2022, 51(1): 1-13. [7] WU J, ZHANG J S, TAN Y Z, et al. Mechanical properties and microscopic mechanism of phosphogypsum-slag-lime solidified sediment[J]. Journal of Basic Science and Engineering, 2024, 32(5): 1360-1373. (吴军, 张金生, 谈云志, 等. 磷石膏-矿渣-石灰固化底泥力学性能及微观机理[J]. 应用基础与工程科学学报, 2024, 32(5): 1360-1373.WU J, ZHANG J S, TAN Y Z, et al. Mechanical properties and microscopic mechanism of phosphogypsum-slag-lime solidified sediment[J]. Journal of Basic Science and Engineering, 2024, 32(5): 1360-1373. [8] LI M Y, ZHANG C, LIANG R, et al. Research progress of blast furnace slag based photocatalytic materials in wastewater treatment[J]. Journal of the Chinese Ceramic Society, 2023, 51(1): 270-282. (李明阳, 张晨, 梁锐, 等. 高炉渣基光催化材料在废水处理领域的研究进展[J]. 硅酸盐学报, 2023, 51(1): 270-282.LI M Y, ZHANG C, LIANG R, et al. Research progress of blast furnace slag based photocatalytic materials in wastewater treatment[J]. Journal of the Chinese Ceramic Society, 2023, 51(1): 270-282. [9] LIU Z, LAI Z Y, LUO X Z, et al. Effect of titanium slag on the properties of magnesium phosphate cement[J]. Construction and Building Materials, 2022, 343. [10] JING J F, GUO Y F, ZHENG F Q, et al. Development status on comprehensive utilization of Ti-bearing blast furnace slag[J]. Metal Mine, 2018, 47(4): 185-191. (景建发, 郭宇峰, 郑富强, 等. 含钛高炉渣综合利用的研究进展[J]. 金属矿山, 2018, 47(4): 185-191.JING J F, GUO Y F, ZHENG F Q, et al. Development status on comprehensive utilization of Ti-bearing blast furnace slag[J]. Metal Mine, 2018, 47(4): 185-191. [11] WANG W, WANG J, LIANG Y H. Feasibility analysis of high-titanium heavy slag as aggregate for asphalt mixture[J]. Iron Steel Vanadium Titanium, 2022, 43(4): 87-93. (王伟, 汪杰, 梁月华. 高钛重矿渣作为集料用于沥青混合料的可行性分析研究[J]. 钢铁钒钛, 2022, 43(4): 87-93.WANG W, WANG J, LIANG Y H. Feasibility analysis of high-titanium heavy slag as aggregate for asphalt mixture[J]. Iron Steel Vanadium Titanium, 2022, 43(4): 87-93. [12] LI X Y, LI J, LU Z Y, et al. Preparation and properties of reactive powder concrete by using titanium slag aggregates[J]. Construction and Building Materials, 2020, 234. [13] TAO M, LU D M, SHI Y, et al. Utilization and life cycle assessment of low activity solid waste as cementitious materials: A case study of titanium slag and granulated blast furnace slag[J]. Science of the Total Environment, 2022, 849: 157797. doi: 10.1016/j.scitotenv.2022.157797 [14] WANG S P, LI J J, YUN X X, et al. Effect of extracted titanium tailing slag on the properties of alkali-activated fly ash-ground blast furnace slag binder[J]. Frontiers in Materials, 2022, 8. [15] WANG J, LIANG Y H. Study on the effect of electric furnace steel slag-fly ash compound admixture on the properties of cement mortar[J]. Iron Steel Vanadium Titanium, 2022, 43(5): 123-128. (汪杰, 梁月华. 电炉钢渣-粉煤灰复合掺合料水泥胶砂性能研究[J]. 钢铁钒钛, 2022, 43(5): 123-128.WANG J, LIANG Y H. Study on the effect of electric furnace steel slag-fly ash compound admixture on the properties of cement mortar[J]. Iron Steel Vanadium Titanium, 2022, 43(5): 123-128. [16] MING Y, WEI Y, LI L, et al. Preparation and properties of ultra-fine mineral admixtures with high activity by steel slag-mineral slag-fly ash[J]. Highway, 2023, 68(5): 289-295. (明阳, 卫煜, 李玲, 等. 钢渣-矿渣-粉煤灰制备高活性超细矿物掺合料及性能研究[J]. 公路, 2023, 68(5): 289-295.MING Y, WEI Y, LI L, et al. Preparation and properties of ultra-fine mineral admixtures with high activity by steel slag-mineral slag-fly ash[J]. Highway, 2023, 68(5): 289-295. [17] LI Y Q, NI Y J, LI F F, et al. Properties of tailings powder-fly ash-cement composite cementitious system[J]. Bulletin of the Chinese Ceramic Society, 2024, 43(1): 236-245. (李永清, 倪勇军, 李芳芳, 等. 尾泥微粉-粉煤灰-水泥复合胶凝体系性能研究[J]. 硅酸盐通报, 2024, 43(1): 236-245.LI Y Q, NI Y J, LI F F, et al. Properties of tailings powder-fly ash-cement composite cementitious system[J]. Bulletin of the Chinese Ceramic Society, 2024, 43(1): 236-245. [18] JIAO D W, SHI C J, YUAN Q, et al. Effect of constituents on rheological properties of fresh concrete-A review[J]. Cement and Concrete Composites, 2017, 83: 146-159. doi: 10.1016/j.cemconcomp.2017.07.016 [19] HARBEC D, ZIDOL A, TAGNIT-HAMOU A, et al. Mechanical and durability properties of high performance glass fume concrete and mortars[J]. Construction and Building Materials, 2017, 134: 142-156. doi: 10.1016/j.conbuildmat.2016.12.018 [20] SHAN Y C, ZHANG L H, LIU L B. Study on the macroscopic properties of phosphorus slag composite cementitious materials based on hydration perspective[J]. Journal of Building Engineering, 2023, 78. [21] CHEN M, SUN Z P, LIU J S. State of the art review on activating techniques and mechanism of phosphorus slag[J]. Materials Reports, 2013, 27(21): 112-116. (陈明, 孙振平, 刘建山. 磷渣活性激发方法及机理研究进展[J]. 材料导报, 2013, 27(21): 112-116.CHEN M, SUN Z P, LIU J S. State of the art review on activating techniques and mechanism of phosphorus slag[J]. Materials Reports, 2013, 27(21): 112-116. [22] LIU X Y, LIU X M, ZHANG Z Q. Recycling and comprehensive utilization of yellow phosphorus slag in building materials: A review[J]. Construction and Building Materials, 2023, 396. -

下载:

下载: