Study on modification of vanadium-titanium tailings and preparation of tailings-based cementing materials

-

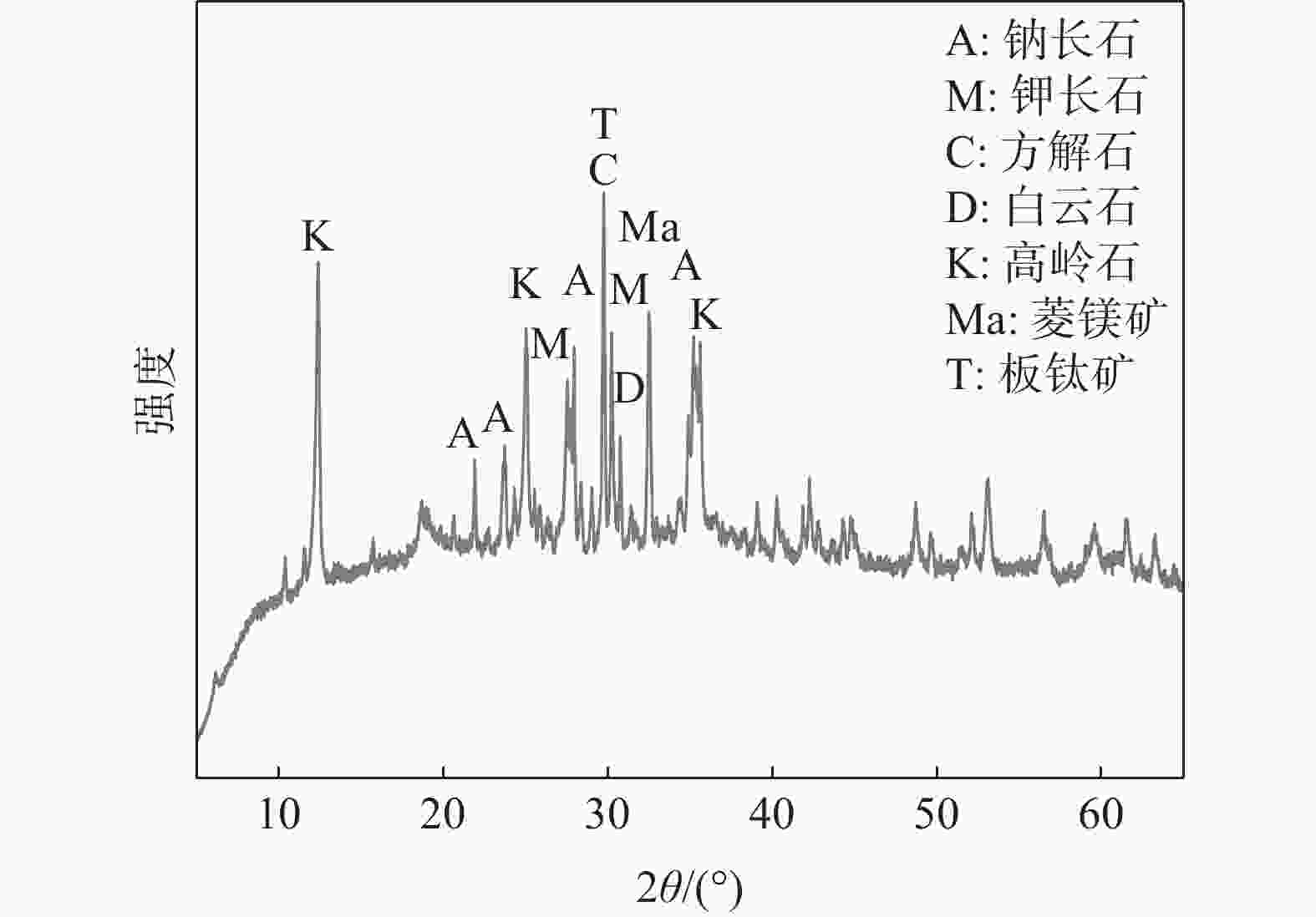

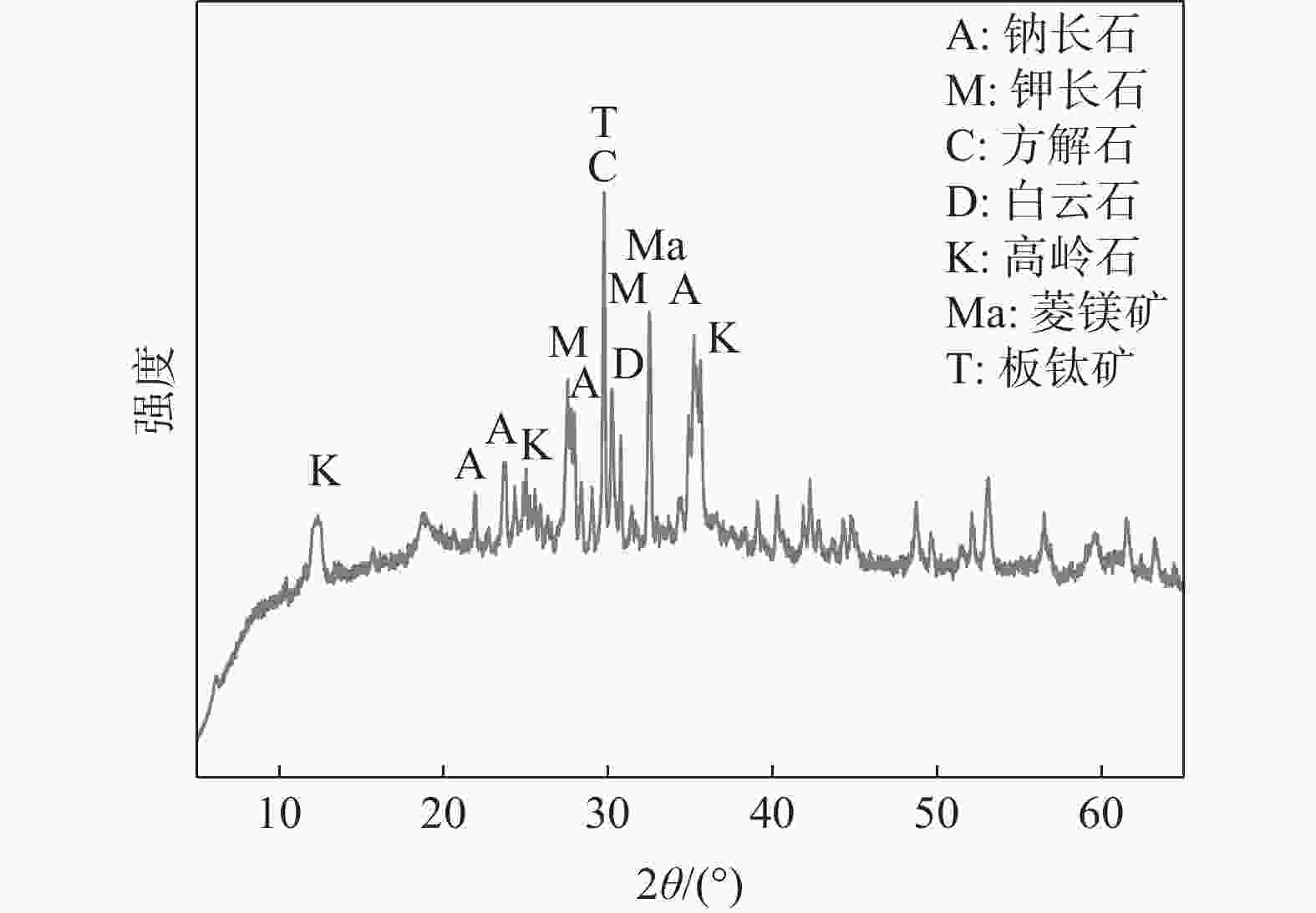

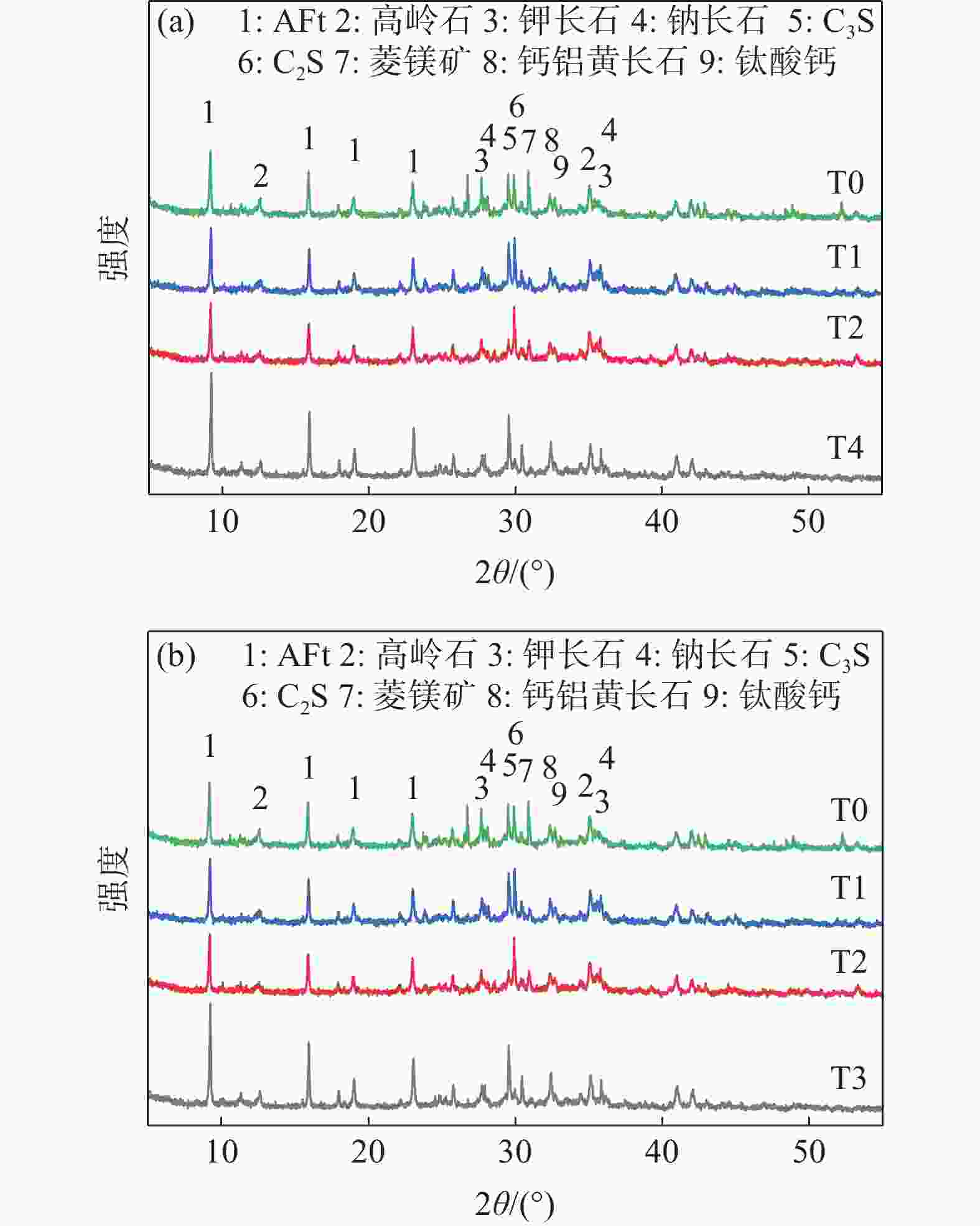

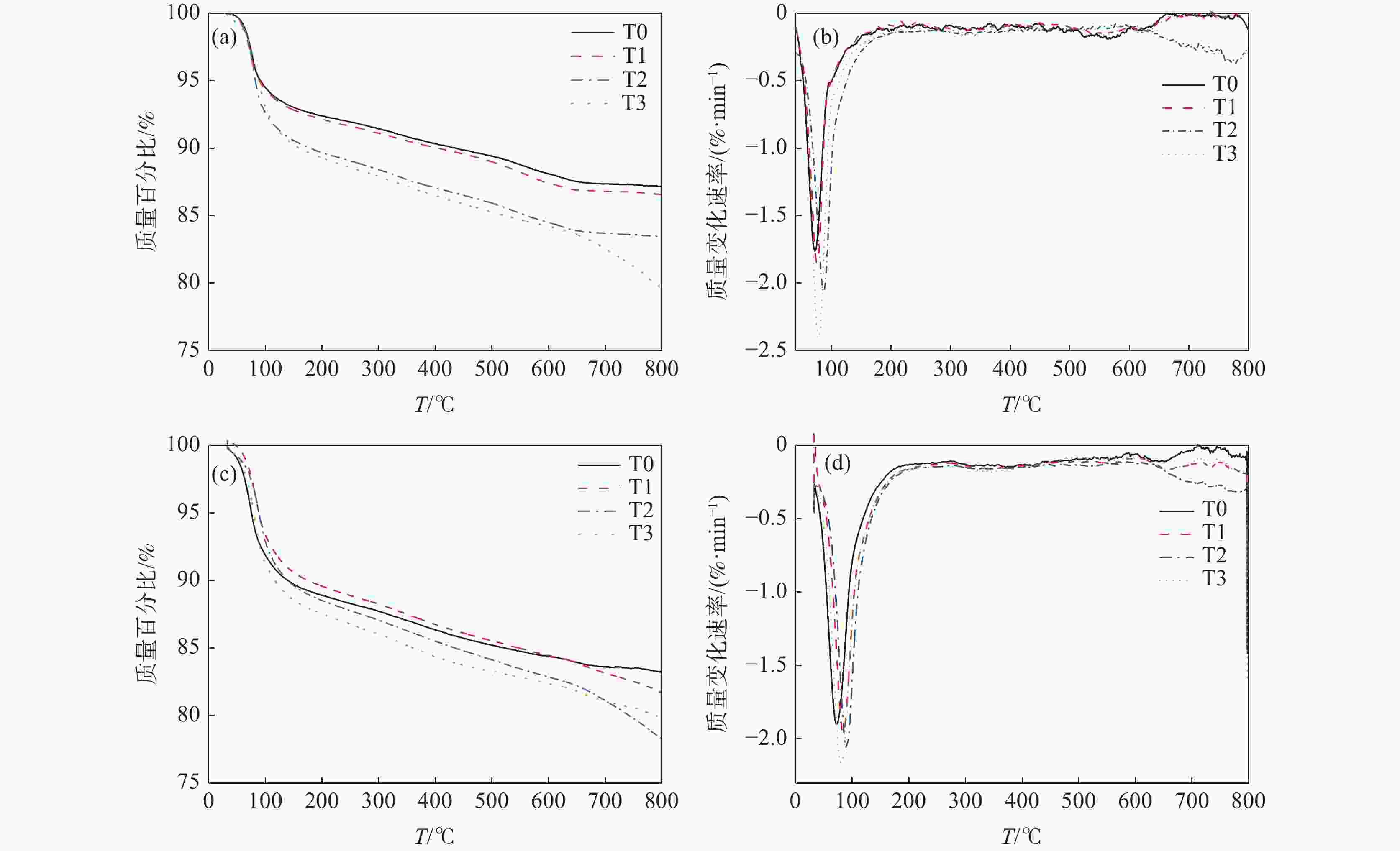

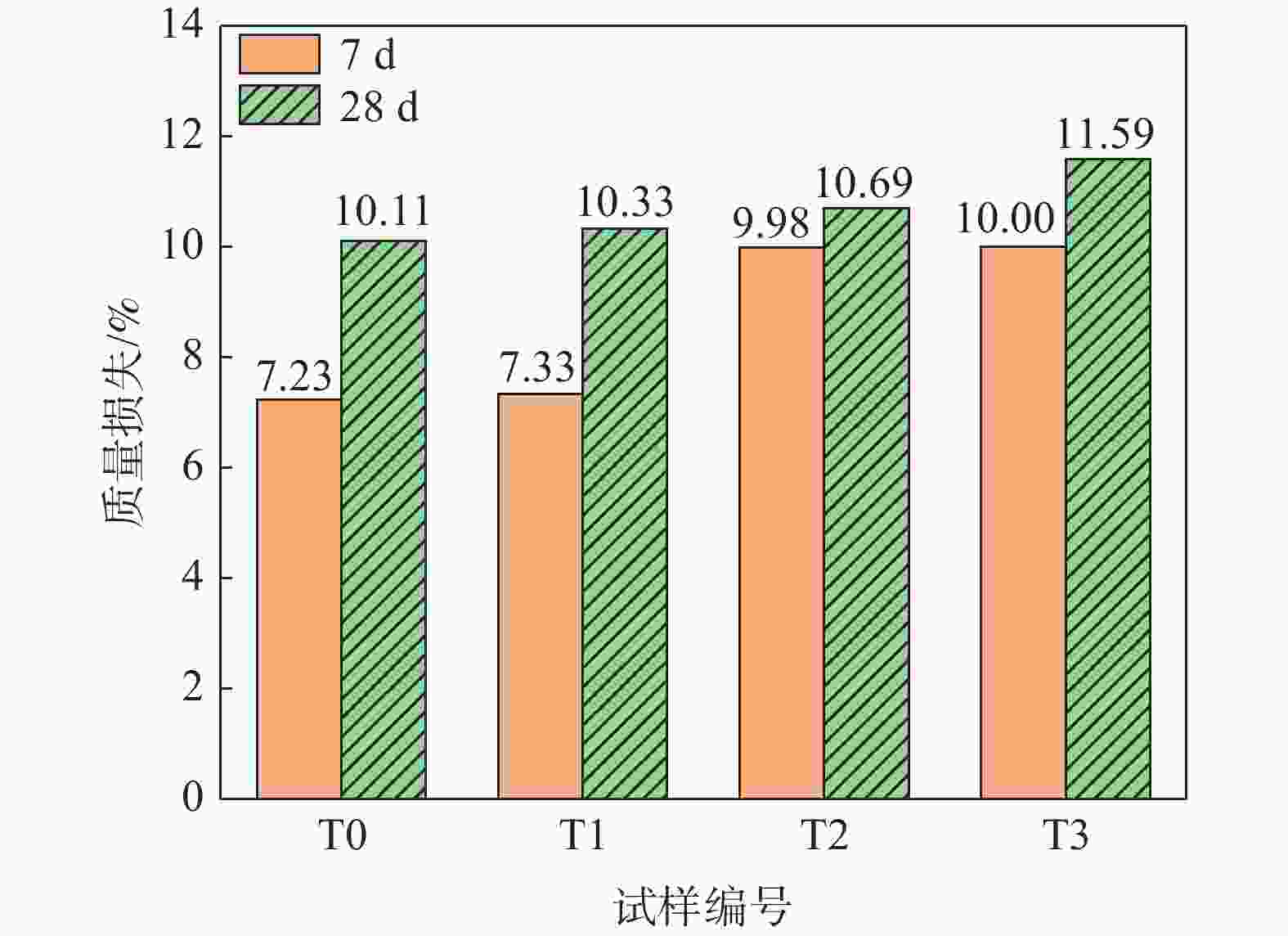

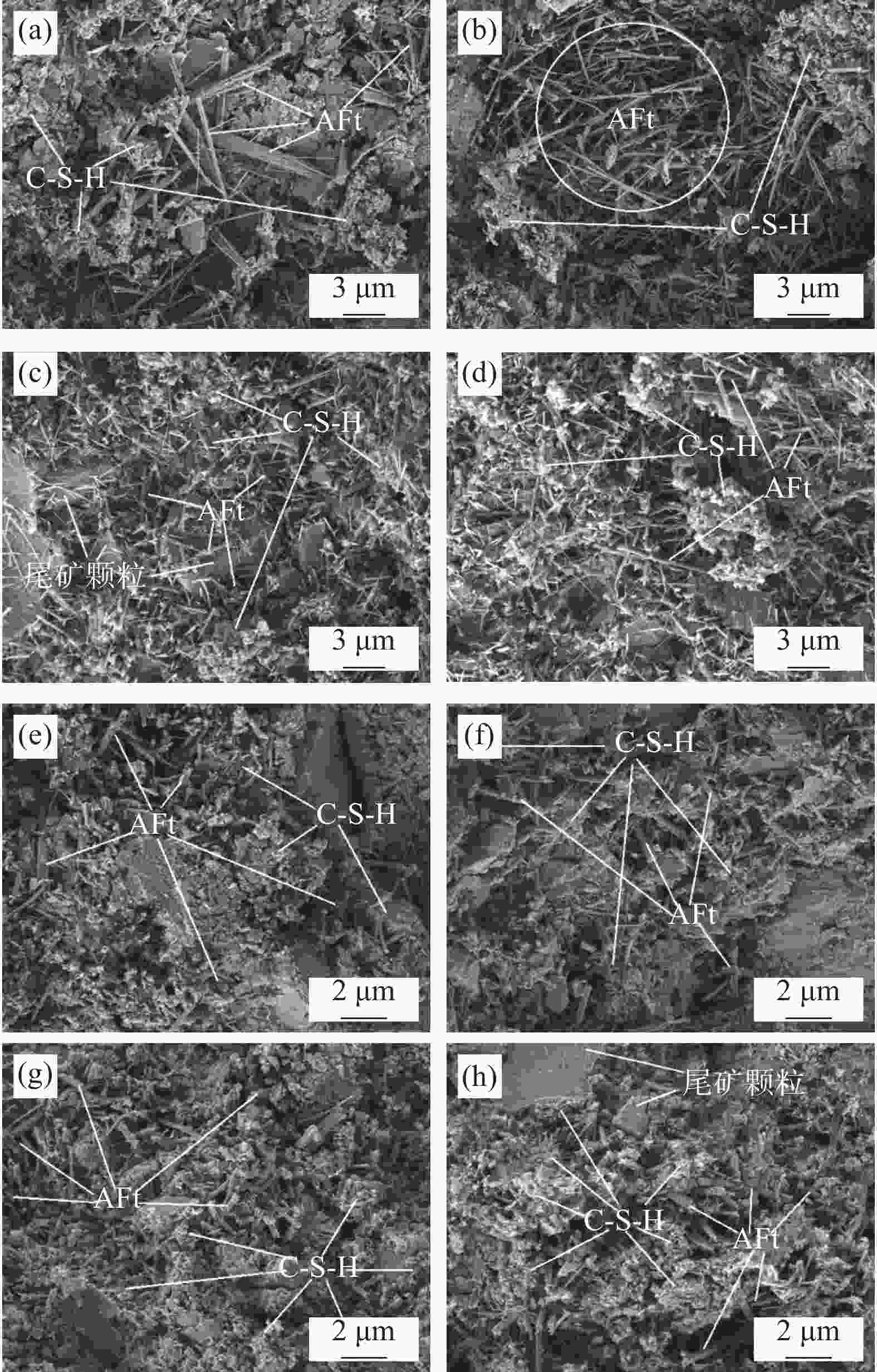

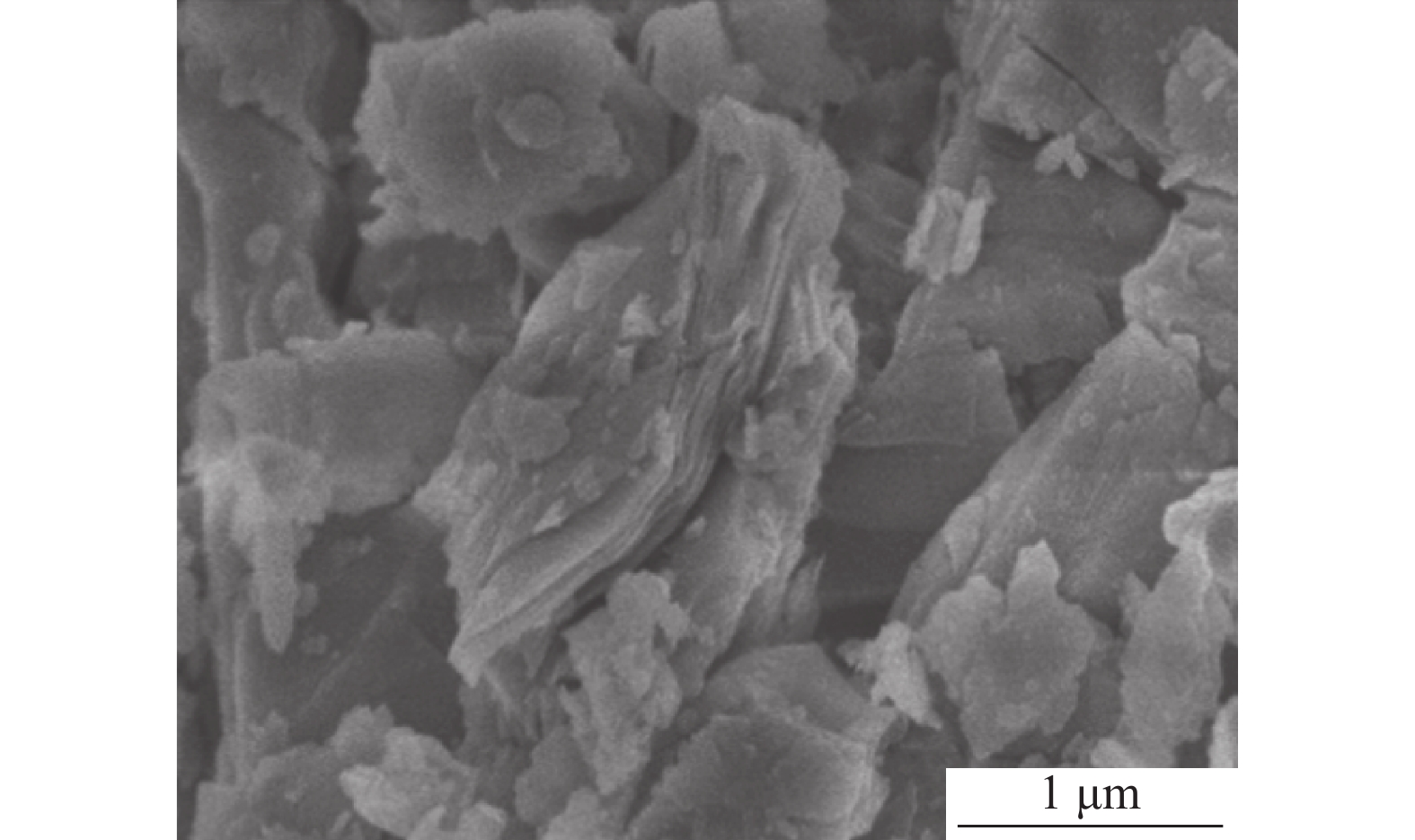

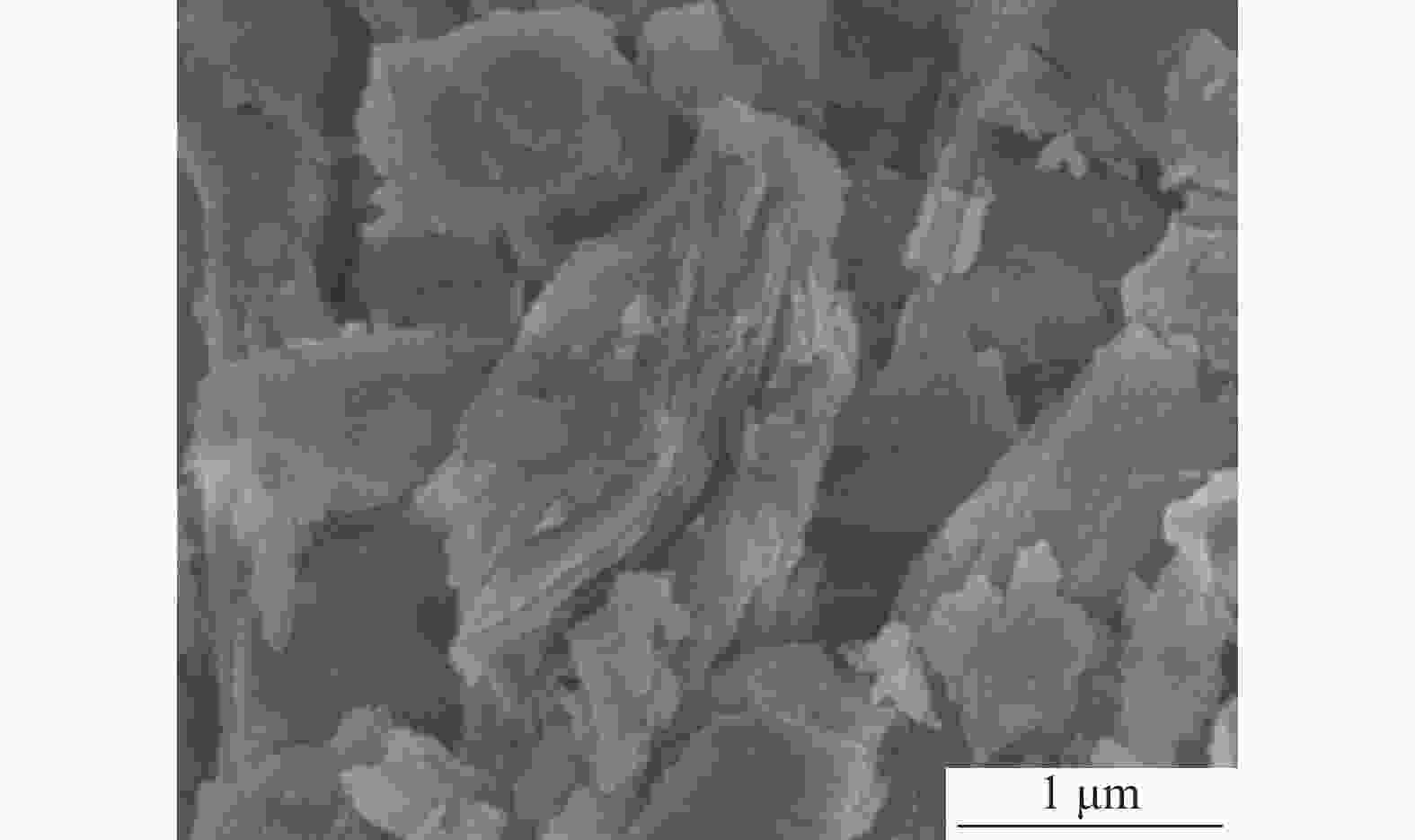

摘要: 以攀西地区钒钛尾矿为原材料,通过物理和复合化学改性技术激发其潜在的胶凝活性,进而制备钒钛尾矿基胶凝材料。通过对所制备材料的微观性能进行分析,探讨胶凝材料体系的水化产物、微观结构的演变过程。结果表明,经机械力活化与化学复合改性处理后,钒钛尾矿养护28 d活性指数显著提升,由原始的60%提升至84%。当条件为钒钛尾矿45%、提钛渣20%、钙质材料5%、硫质材料15%和水泥熟料15%时,所制备的钒钛尾矿基胶凝材料展现出良好的力学性能,养护28 d抗压强度达到33.1 MPa,与32.5级水泥相当,表明该材料在非结构工程领域具有潜在的应用前景。Abstract: This study utilized vanadium-titanium tailings from the Panxi region as raw materials, aiming to activate their potential cementitious activity through physical and composite chemical modification techniques, thereby preparing vanadium-titanium tailings-based cementitious materials. By analyzing the micro-properties of the prepared materials, the hydration products and the evolution of microstructures within the cementitious material system were explored. The research results indicate that after treatment with mechanical activation and composite chemical modification, the 28-day activity index of the vanadium-titanium tailings significantly increases from the original 60% to 84%. When the composition is 45% vanadium-titanium tailings, 20% titanium slag, 5% calcium material, 15% sulfur material, and 15% cement clinker, the prepared vanadium-titanium tailings-based cementitious material exhibits good mechanical properties with a 28-day compressive strength of 33.1 MPa, which is comparable to that of 32.5-grade cement. This indicates that the material has potential application prospects in non-structural engineering field.

-

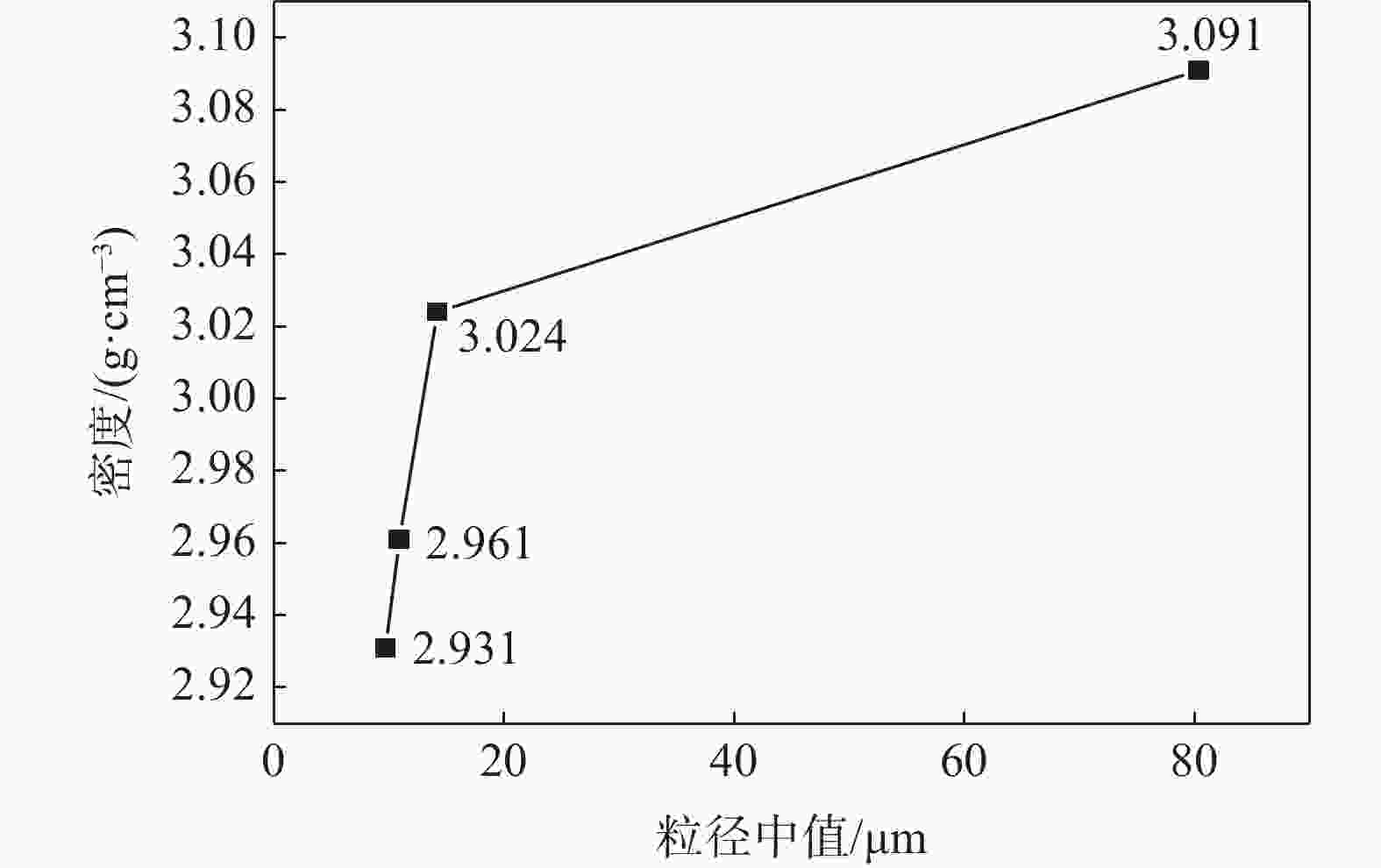

表 1 钒钛尾矿的主要物理性能

Table 1. Main physical properties of vanadium-titanium tailings

密度/

(g·cm−3)比表面积/

(m2·kg−1)45 μm筛

余量/%80 μm筛

余量/%需水量

比/%活性指数/% 3 d 7 d 28 d 3.09 160 80.4 64.4 92 53 55 55 表 2 钒钛尾矿的主要化学成分

Table 2. Main chemical components of vanadium-titanium tailings

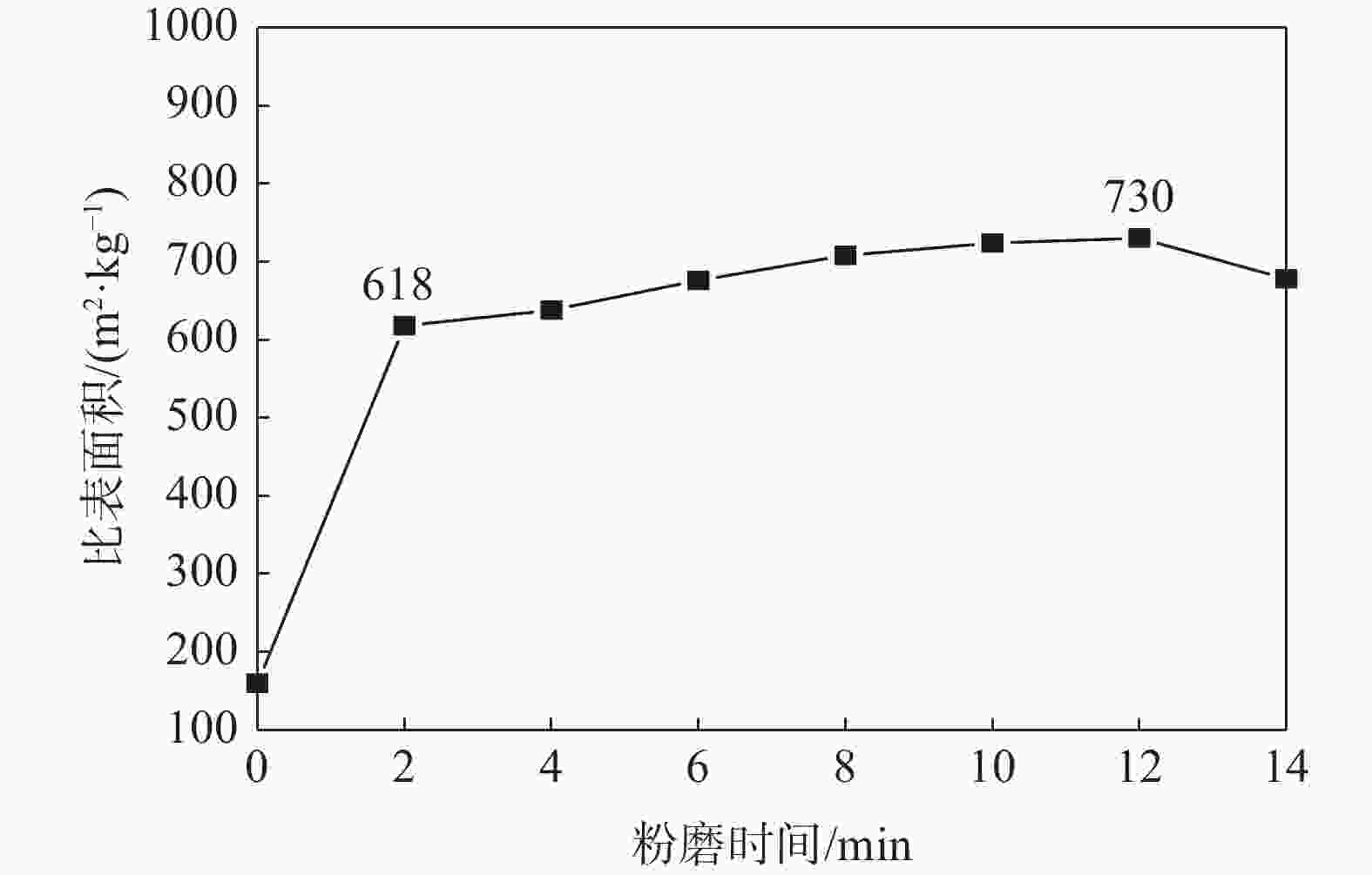

% SiO2 Al2O3 MgO CaO Fe2O3 K2O TiO2 34.6 12.9 10.4 12.7 19.1 0.2 6.6 表 3 粉磨后钒钛尾矿的火山灰活性技术指标

Table 3. Pozzolanic activity technical indicators of the ground vanadium-titanium tailings

粉磨时间/min 比表面积/(m2·kg−1) 需水量比/% 活性指数/% 3 d 7 d 28 d 0(原状) 160 92 53 55 55 2 618 96 59 60 60 12 730 98 60 69 69 表 4 钒钛尾矿改性方案及活性指数测试结果

Table 4. Modification scheme and activity index test results of vanadium-titanium tailings

名称 粉磨时间/min 比表面积/(m2·kg−1) 尾矿掺量/% 提钛渣掺量/% 硫质材料掺量/% 钙质材料掺量/% 水泥熟料/% 活性指数/% 3 d 7 d 28 d MC1 2 618 30.0 70.0 59 60 60 MC2 12 730 30.0 70.0 60 69 69 CC1 2 618 25.5 4.5 70.0 53 56 73 CC2 12 730 13.5 8.25 4.5 3.75 70.0 81 87 84 表 5 钒钛尾矿基胶凝材料配比方案及强度结果

Table 5. Ratio scheme and strength results of vanadium-titanium tailings-based cementing materials

试样

编号粉磨时间/min 钒钛尾矿 尾矿掺量/% 提钛渣

掺量/%钙质材料

掺量/%硫质材料

掺量/%水泥熟料

掺量/%抗压强度/MPa D50/μm 3 d 7 d 28 d T0 0 189 45 20 5 15 15 9.7 11.8 18.7 T1 3 14.2 45 20 5 15 15 11.5 13.2 19.6 T2 8 10.9 45 20 5 15 15 13.6 14.9 20.8 T3 12 9.7 45 20 5 15 15 15.0 19.1 33.1 -

[1] GUO L J, LIU G S, MA Q H, et al. Research progress on the application of filling mining technology in metal mines[J]. Journal of China Coal Society, 2022, 47(12): 4182-4200. (郭利杰, 刘光生, 马青海, 等. 金属矿山充填采矿技术应用研究进展[J]. 煤炭学报, 2022, 47(12): 4182-4200.GUO L J, LIU G S, MA Q H, et al. Research progress on the application of filling mining technology in metal mines[J]. Journal of China Coal Society, 2022, 47(12): 4182-4200. [2] CHEN Y N, LIANG L M. Development and research on low-cost cementitious filling materials[J]. Nonferrous Metals: Mining Section, 2004(5): 12-13,16. (陈云嫩, 梁礼明. 低成本充填胶凝材料的开发研究[J]. 有色金属: 矿山部分, 2004(5): 12-13,16.CHEN Y N, LIANG L M. Development and research on low-cost cementitious filling materials[J]. Nonferrous Metals: Mining Section, 2004(5): 12-13,16. [3] ZHANG X T. Experimental study on expansive filling materials[D]. Shenyang: Northeastern University, 2014. (张雄天. 膨胀充填材料的试验研究[D]. 沈阳: 东北大学, 2014.ZHANG X T. Experimental study on expansive filling materials[D]. Shenyang: Northeastern University, 2014. [4] WEI Z A, YIN G Z, LI G Z, et al. Reinforced terraced fields method for fine tailings disposal[J]. Minerals Engineering, 2009, 22(12): 1053-1059. doi: 10.1016/j.mineng.2009.03.014 [5] Ministry of Emergency Management. Interpretation of the "Work plan for preventing and defusing the safety risks of tailings ponds" [EB/OL]. Beijing: Ministry of Emergency Management, (2021-03-02) [2022-07-05]. (应急管理部. 《防范化解尾矿库安全风险工作方案》解读[EB/OL]. 北京: 应急管理部, (2021-03-02)[2022-07-05].Ministry of Emergency Management. Interpretation of the "Work plan for preventing and defusing the safety risks of tailings ponds" [EB/OL]. Beijing: Ministry of Emergency Management, (2021-03-02) [2022-07-05]. [6] ZUCCHERATTE A C V, FREIRE C B, LAMEIRAS F S. Synthetic gravel for concrete obtained from sandy iron oretailing and recycled polyethyltherephtalate[J]. Construction and Building Materials, 2017, 151: 859-865. doi: 10.1016/j.conbuildmat.2017.06.133 [7] QIN Y. Influence of iron tailings sand on the mechanical properties and microstructure of foam concrete[J]. China Measurement & Test, 2022, 48(6): 134-142. (秦毅. 铁尾矿砂对泡沫混凝土力学性质和微观结构的影响[J]. 中国测试, 2022, 48(6): 134-142.QIN Y. Influence of iron tailings sand on the mechanical properties and microstructure of foam concrete[J]. China Measurement & Test, 2022, 48(6): 134-142. [8] WANG S C. Experimental study on the development of a new type of cementitious material based on phosphogypsum-slag in Jinchuan No. 2 mine[D]. Baotou: Inner Mongolia University of Science and Technology, 2015. (王世昌. 金川二矿磷石膏—矿渣基新型胶凝材料开发试验研究[D]. 包头: 内蒙古科技大学, 2015.WANG S C. Experimental study on the development of a new type of cementitious material based on phosphogypsum-slag in Jinchuan No. 2 mine[D]. Baotou: Inner Mongolia University of Science and Technology, 2015. [9] ZHANG L, LÜ G Z. Application and prospect of filling materials in filling mining methods of metal mines[J]. Modern Mining, 2010(1): 20-22. (张璐, 吕广忠. 金属矿山充填采矿法中充填材料的应用及展望[J]. 现代矿业, 2010(1): 20-22. doi: 10.3969/j.issn.1674-6082.2010.01.005ZHANG L, LÜ G Z. Application and prospect of filling materials in filling mining methods of metal mines[J]. Modern Mining, 2010(1): 20-22. doi: 10.3969/j.issn.1674-6082.2010.01.005 [10] HOU Y F. Effect of iron tailing sand and natural sand on concrete properties[J]. Key Engineering Materials, 2014, 3019: 599. [11] LIU B, MENG H N, PAN G H, et al. Relationship between the fineness and specific surface area of iron tailing powder and its effect on compressive strength and drying shrinkage of cement composites[J]. Construction and Building Materials, 2022, 357. [12] LATIF S A, RAHMAN M S A, SIKIRU O. Sorptivity of concrete containing iron ore tailings[J]. Romanian Journal of Materials, 2017, 47(3): 336-344. [13] TAO Y P, LAI T M. Research on the mechanical and durability properties of recycled concrete with iron tailings sand[J]. Journal of Functional Materials, 2023, 54(3): 3143-3148. (陶亚平, 赖天文. 铁尾矿砂再生混凝土的力学及耐久性能研究[J]. 功能材料, 2023, 54(3): 3143-3148. doi: 10.3969/j.issn.1001-9731.2023.03.020TAO Y P, LAI T M. Research on the mechanical and durability properties of recycled concrete with iron tailings sand[J]. Journal of Functional Materials, 2023, 54(3): 3143-3148. doi: 10.3969/j.issn.1001-9731.2023.03.020 [14] ZHU Q, YUAN Y X, CHEN J H. Research on the high-temperature resistance of recycled aggregate concrete withiron tailing sand[J]. Construction and Building Materials, 2022, 327: 126889. doi: 10.1016/j.conbuildmat.2022.126889 [15] TAN M Y, LÜ X J, JIANG M F. Research status of mine tailings used as cement admixture[J]. Concrete, 2015, (9): 84-86. (谭明洋, 吕宪俊, 姜梅芬. 尾矿作水泥混合材的研究现状[J]. 混凝土, 2015, (9): 84-86.TAN M Y, LÜ X J, JIANG M F. Research status of mine tailings used as cement admixture[J]. Concrete, 2015, (9): 84-86. [16] LI J C, WU T Y. Relationship between the microstructure of tungsten carbide powder and process parameters[J]. Journal of Central South University (Science and Technology), 1986(4): 54-61,115. (李健纯, 吴惕言. 碳化钨粉末的微观结构与工艺参数的关系[J]. 中南大学学报(自然科学版), 1986(4): 54-61,115.LI J C, WU T Y. Relationship between the microstructure of tungsten carbide powder and process parameters[J]. Journal of Central South University (Science and Technology), 1986(4): 54-61,115. [17] WANG B H, WANG H D. Feasibility study on the manufacture of ultrafine powder by mechanical crushing method[J]. Journal of Wuhan University of Technology, 1996, 18(4): 127-128. (王炳华, 王怀德. 机械粉碎法制造超微粉的可行性探讨[J]. 武汉工业大学学报, 1996, 18(4): 127-128.WANG B H, WANG H D. Feasibility study on the manufacture of ultrafine powder by mechanical crushing method[J]. Journal of Wuhan University of Technology, 1996, 18(4): 127-128. [18] XIAO L N, ZHU J L. Study on the hydration characteristics of copper tailings powder-based composite cementitious materials[J]. Non-Metallic Mines, 2020, 43(2): 61-63. (肖莉娜, 朱街禄. 铜尾矿粉基复合胶凝材料水化特性研究[J]. 非金属矿, 2020, 43(2): 61-63. doi: 10.3969/j.issn.1000-8098.2020.02.016XIAO L N, ZHU J L. Study on the hydration characteristics of copper tailings powder-based composite cementitious materials[J]. Non-Metallic Mines, 2020, 43(2): 61-63. doi: 10.3969/j.issn.1000-8098.2020.02.016 [19] WANG S X. Research on the preparation and properties of iron tailings composite cementitious materials[D]. Handan: Hebei University of Engineering, 2024. (王绍熙. 铁尾矿复合胶凝材料的制备及性能研究[D]. 邯郸: 河北工程大学, 2024.WANG S X. Research on the preparation and properties of iron tailings composite cementitious materials[D]. Handan: Hebei University of Engineering, 2024. [20] CHEN J L. Research on the preparation of composite cementitious materials from steel solid wastes and their application in concrete[D]. Handan: Hebei University of Engineering, 2024. (陈敬亮, 土木工程. 钢铁固废制备复合胶凝材料及其混凝土的研究[D]. 邯郸: 河北工程大学, 2024.CHEN J L. Research on the preparation of composite cementitious materials from steel solid wastes and their application in concrete[D]. Handan: Hebei University of Engineering, 2024. [21] WANG C L, MA J T, YANG F H, et al. Preparation and properties of vanadium-titanium iron tailings compositecementitious materials[J]. Iron Steel Vanadium Titanium, 2023, 44(1): 98-105. (王长龙, 马锦涛, 杨丰豪, 等. 钒钛铁尾矿复合胶凝材料的制备及性能[J]. 钢铁钒钛, 2023, 44(1): 98-105. doi: 10.7513/j.issn.1004-7638.2023.01.017WANG C L, MA J T, YANG F H, et al. Preparation and properties of vanadium-titanium iron tailings compositecementitious materials[J]. Iron Steel Vanadium Titanium, 2023, 44(1): 98-105. doi: 10.7513/j.issn.1004-7638.2023.01.017 -

下载:

下载: