Analysis of the growth process of crystallized slag rim in 430 stainless steel mold flux

-

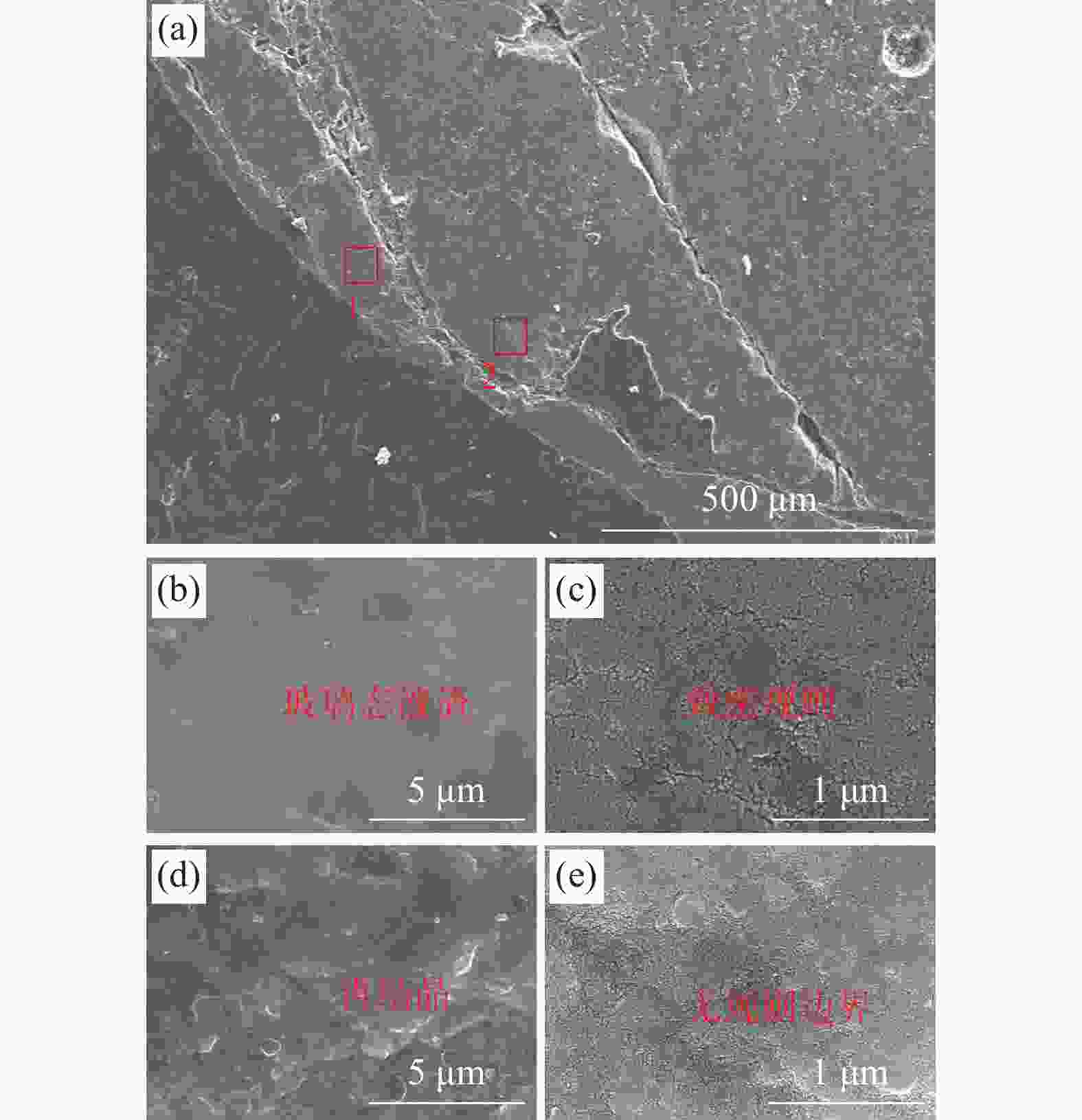

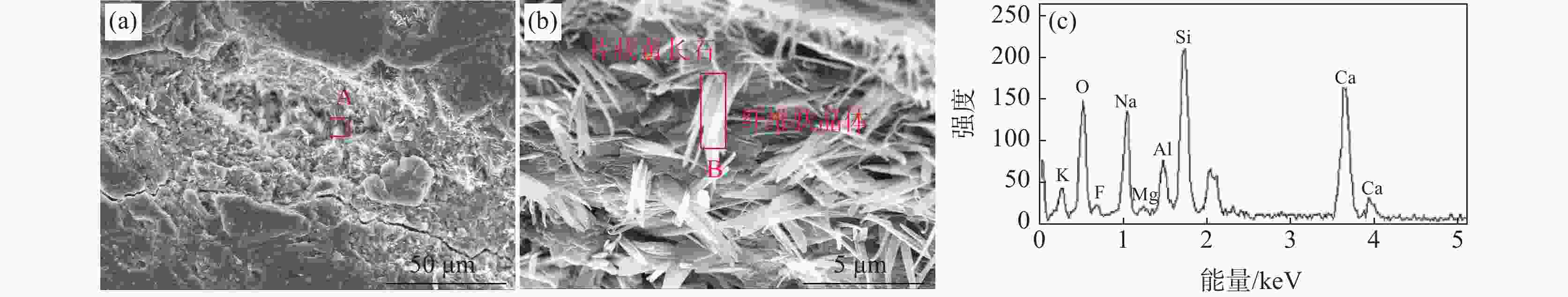

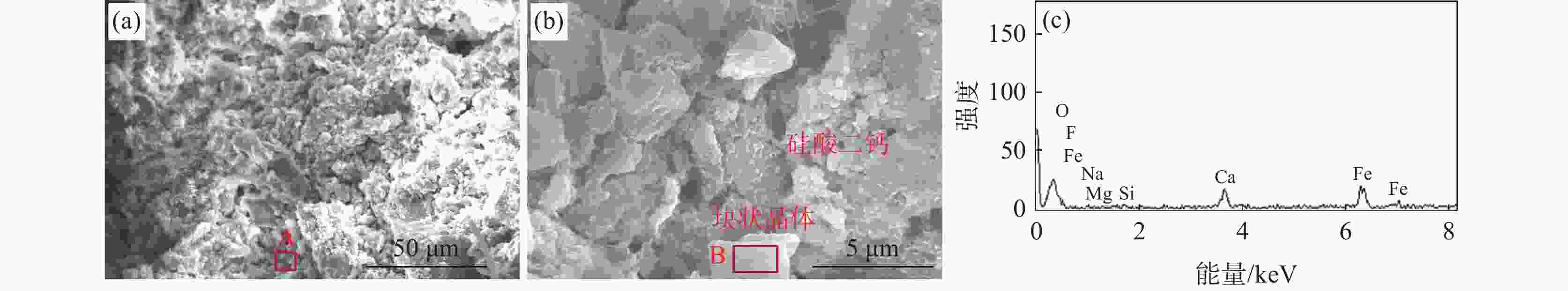

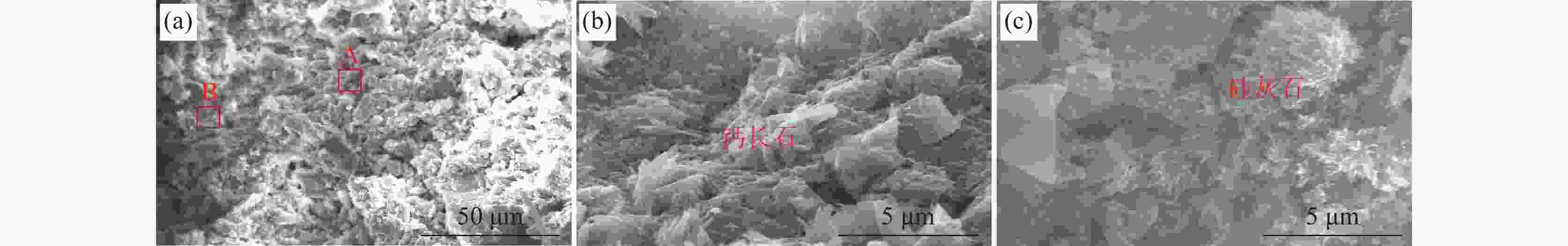

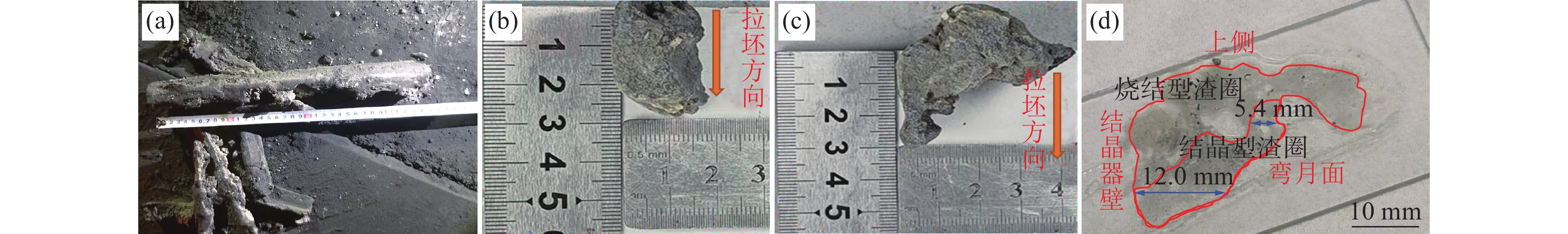

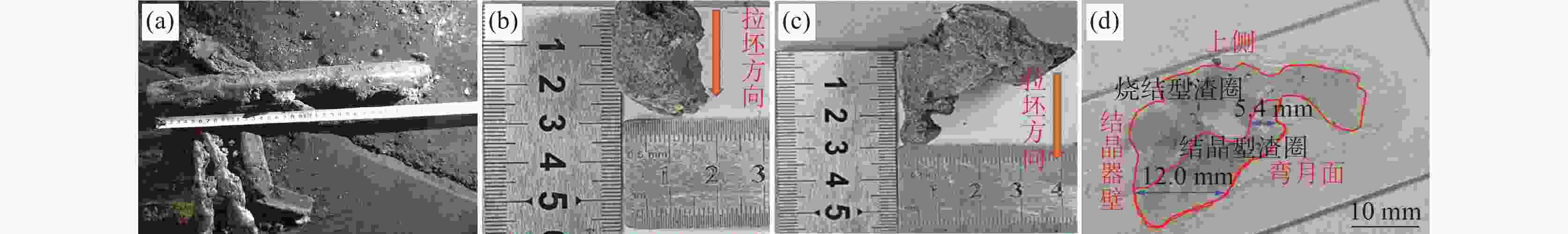

摘要: 某钢厂430不锈钢采用进口保护渣常常形成过大的渣圈,影响铸坯的质量。为了明晰其渣圈长大原因,采用结晶器渣膜热流模拟仪,制取

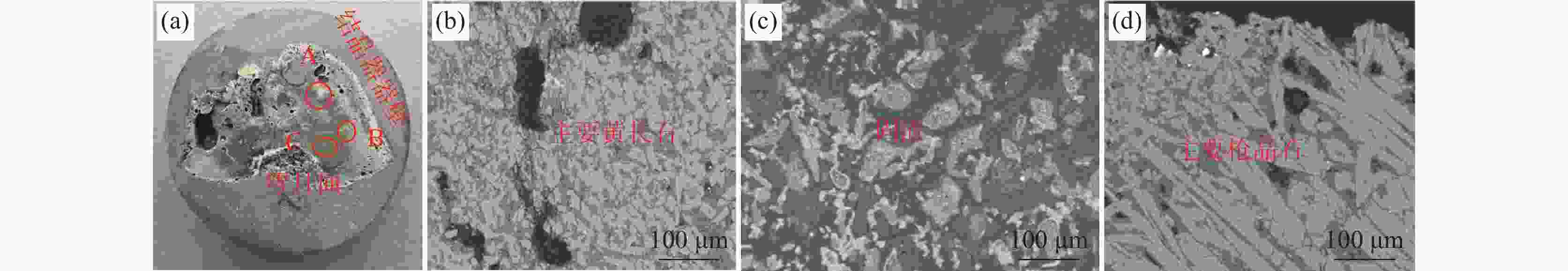

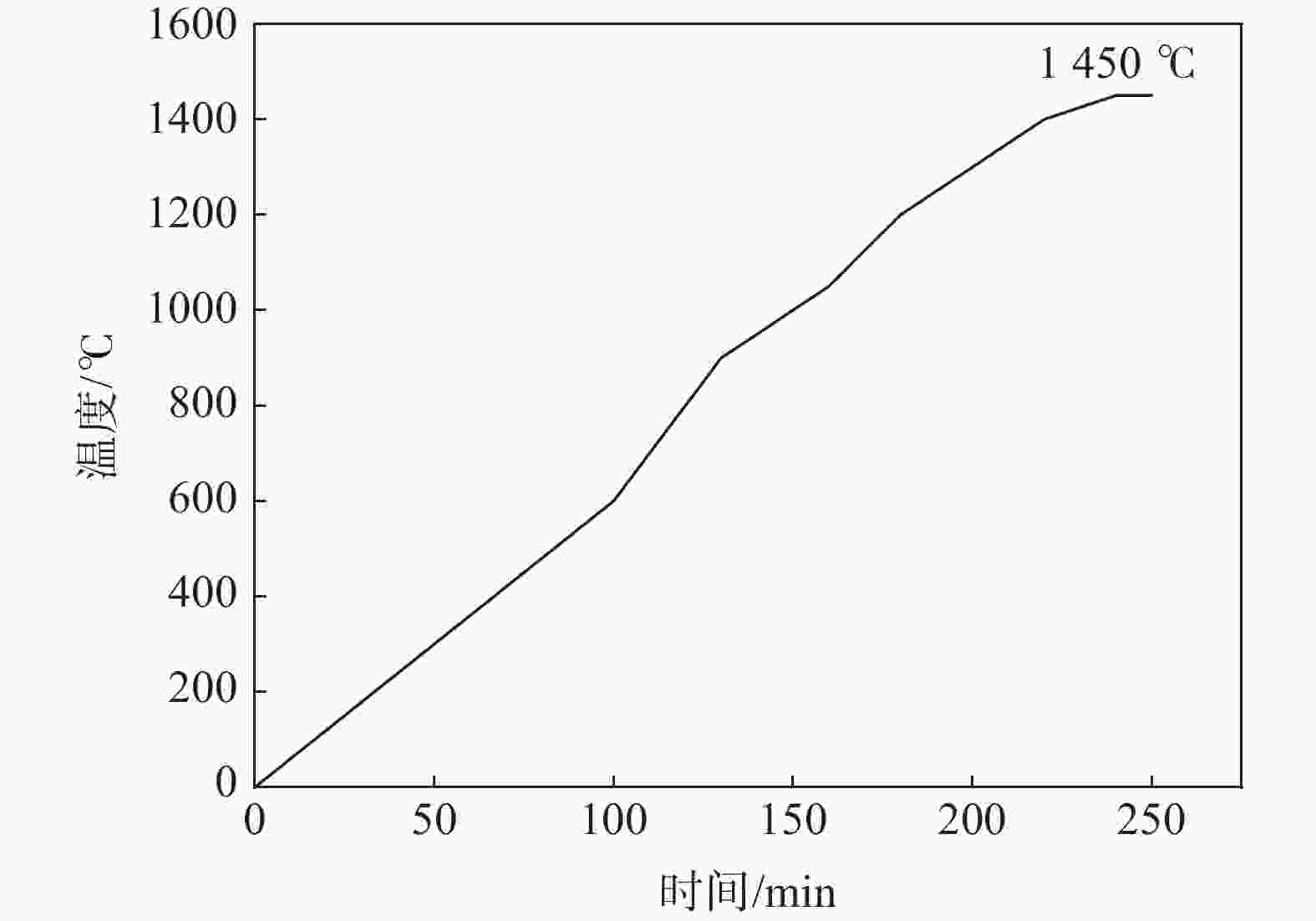

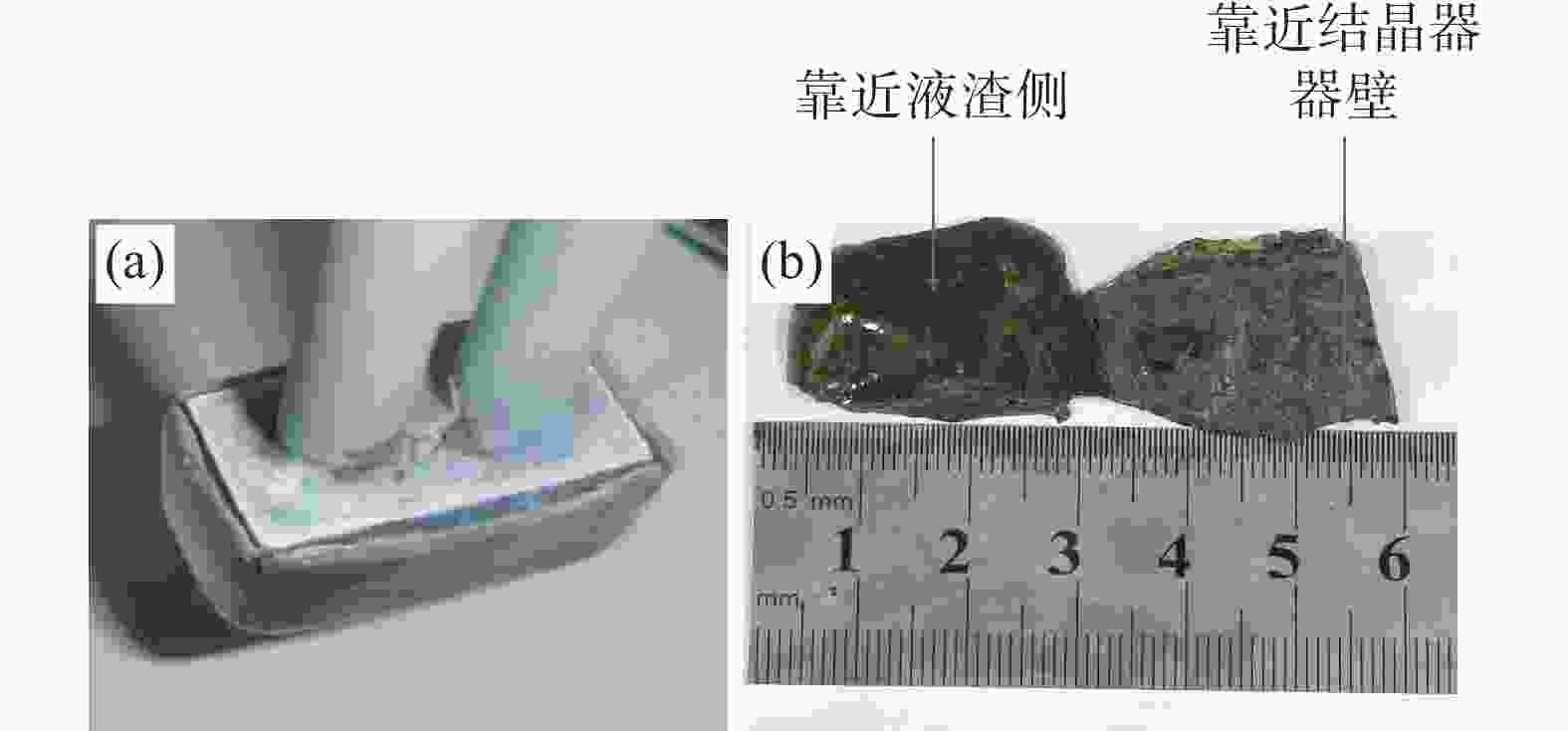

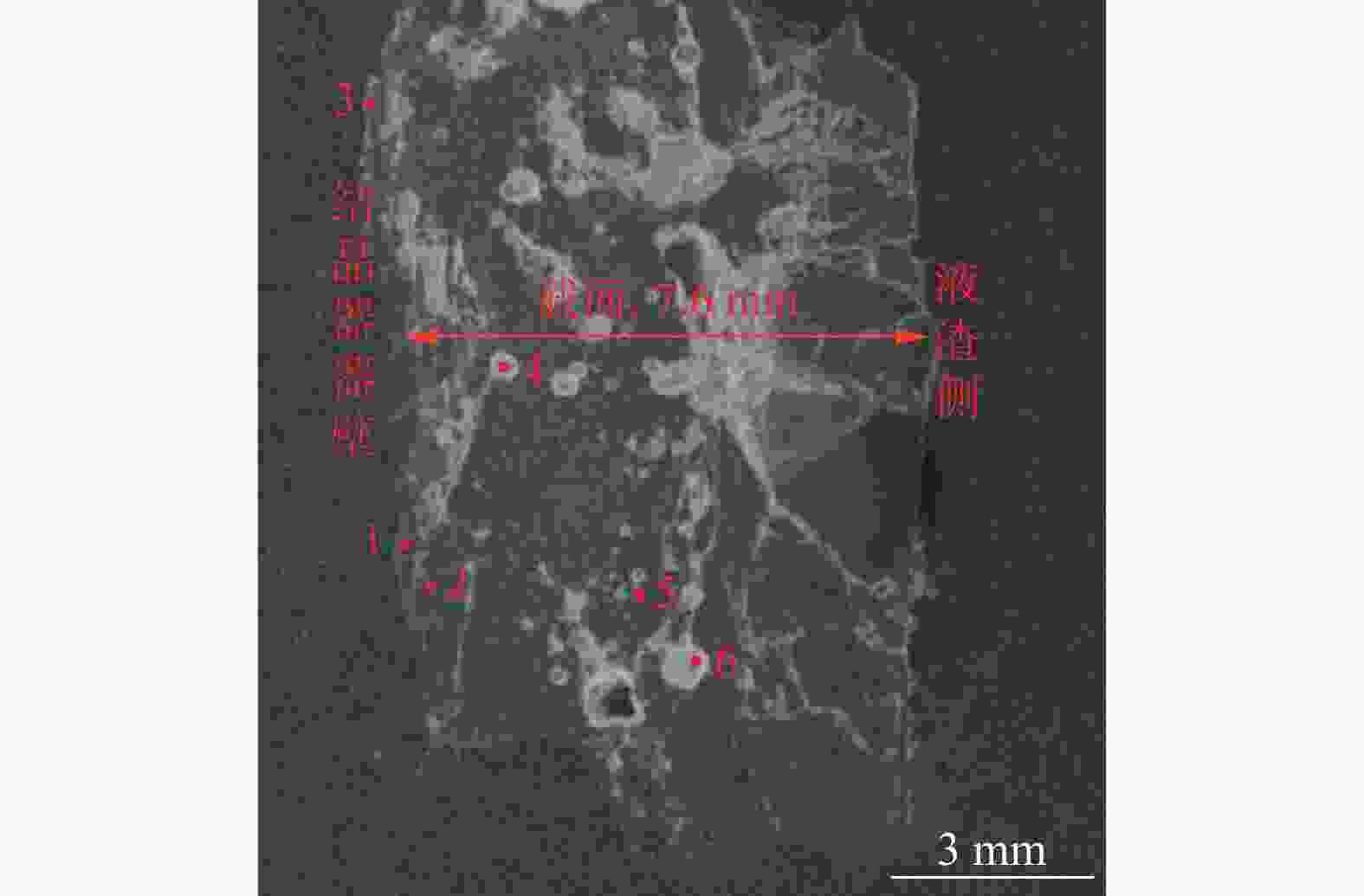

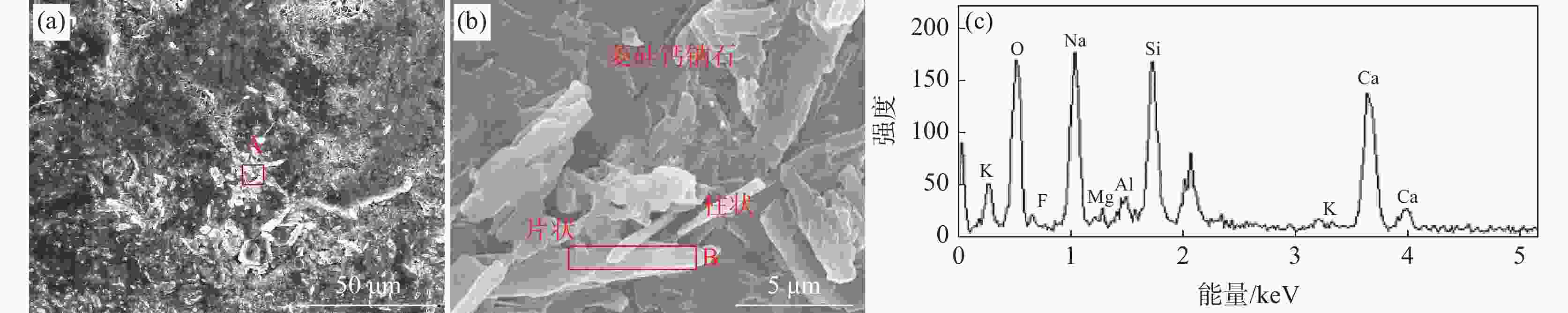

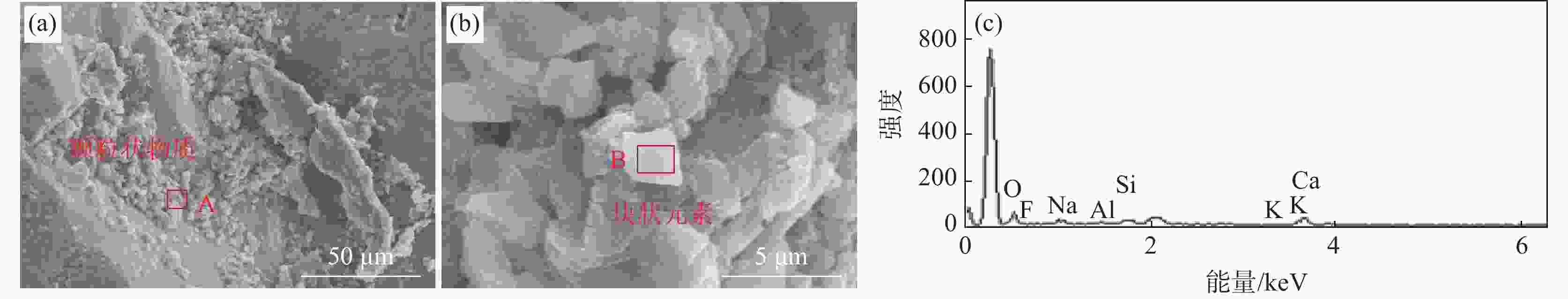

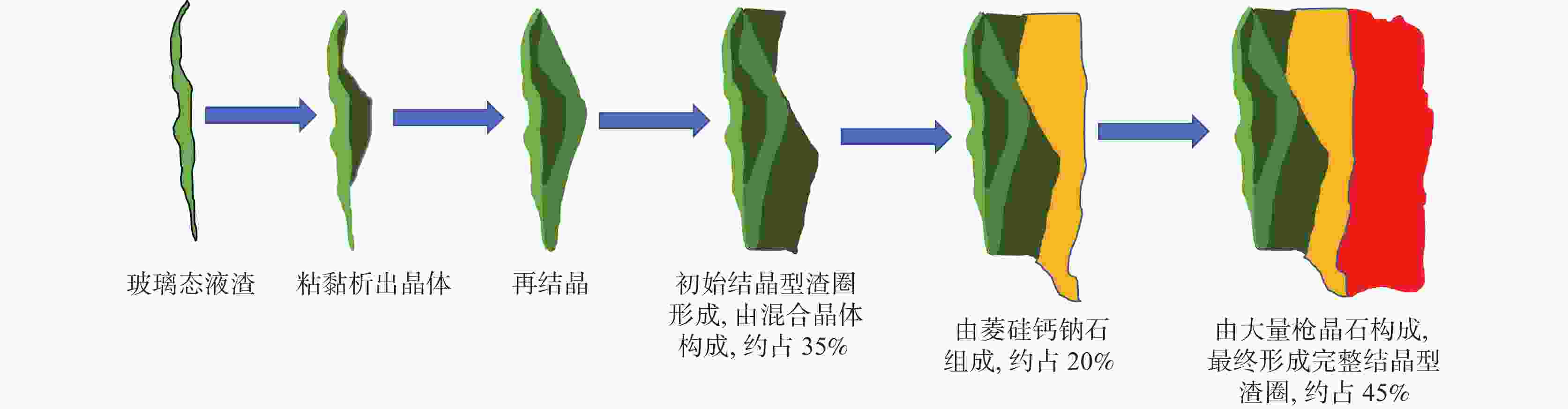

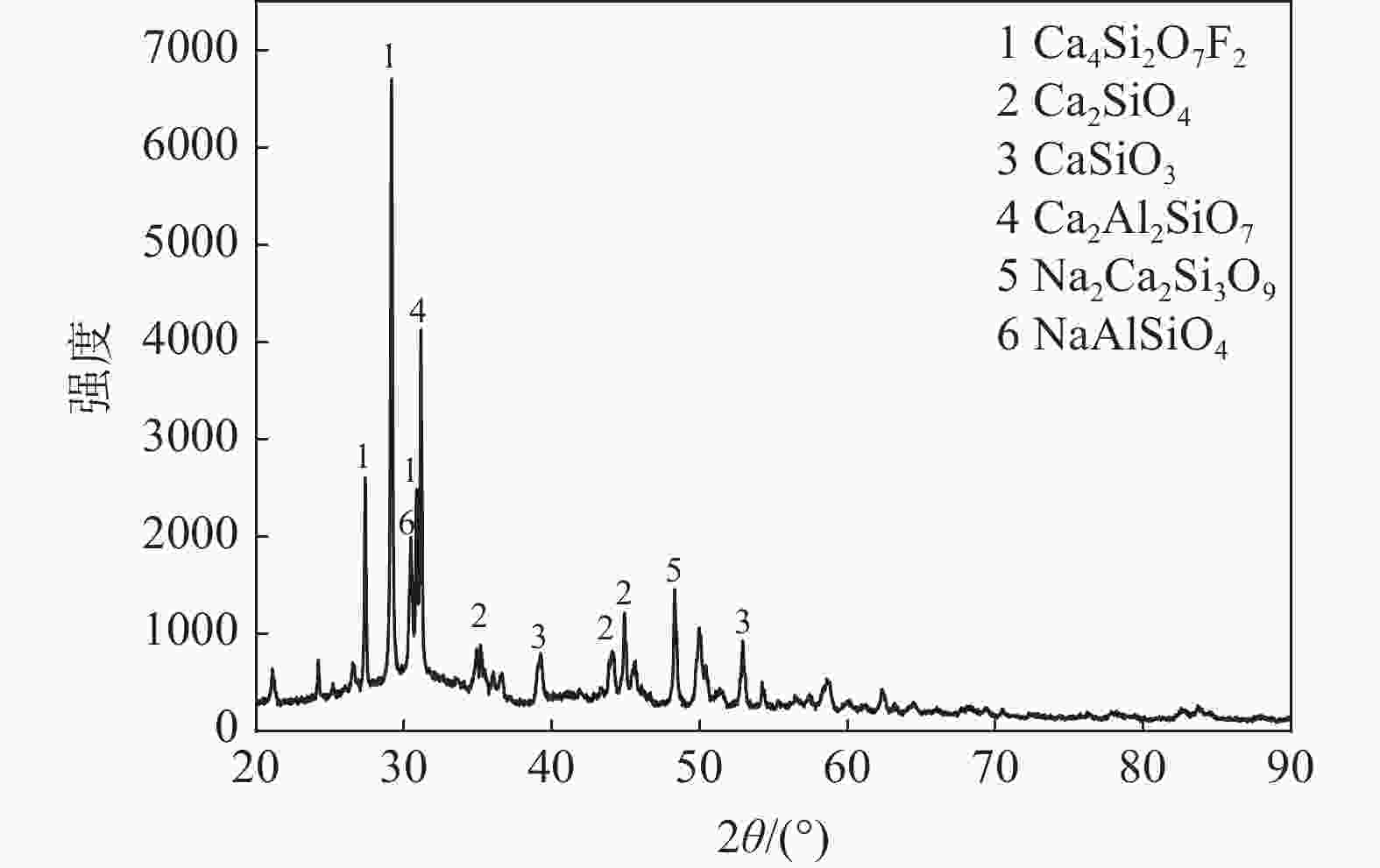

1450 ℃条件下430不锈钢保护渣结晶型渣圈,并利用扫描电镜分析其微观结构,以探究渣圈生长过程。同时,使用Factsage软件进行热力学模拟,并与XRD试验结果对比。结果发现:高熔点的硅酸二钙、硅灰石、黄长石和枪晶石优先析出冷凝在器壁上,形成初始结晶型渣圈,占35%;随后,较低熔点的菱硅钙钠石黏附在此层,占20%;最后,夹杂少量霞石的枪晶石逐渐附着在已形成的渣圈上,占45%。通过对这一过程的分析,揭示了430不锈钢保护渣结晶型渣圈的形成机制,为控制渣圈生长提供了理论依据。Abstract: A certain steel plant using imported mold flux for 430 stainless steel often results in excessively large slag rims that affect the quality of the cast slab. To clarify the reasons for the enlargement of the slag rings, this study employed a slab mold slag film heat flux simulator to create a crystallized slag rim for ultra-low carbon protection slag at1450 °C. SEM microstructural analysis was used to explore the growth process of the slag rim. Additionally, thermodynamic simulations using Factsage were conducted and compared with XRD experimental results. The findings revealed that high-melting-point phases dicalcium silicate, wollastonite, feldspar, and gunite preferentially crystallized and condensed on the mold wall, forming the initial crystallized slag rim (35%). Subsequently, lower-melting-point combeite adhered to this layer (20%). Lastly, cuspidine containing minor nepheline gradually deposited on the existing slag rim (45%).Through the analysis of this process, the study elucidated the formation mechanism of the crystallized slag rims in 430 stainless steel mold flux, providing a theoretical basis for controlling the slag rims growth.-

Key words:

- 430 stainless steel /

- crystalline slag rim /

- microstructure /

- growth mechanism

-

表 1 430不锈钢成分

Table 1. Composition of 430 stainless steel

% C Si Mn P S Cr Ni N 0.030~

0.0400.250~

0.3500.250~

0.500≤0.030 ≤0.005 16.00~

17.00≤0.400 0.030~

0.050表 2 430不锈钢保护渣成分

Table 2. Composition table of ultra-low carbon mold slag

% 成分 碱度 Al2O3 Fe2O3 F MgO Na2O C-total 测验值 1.16 6.30 1.80 5.80 1.00 10.30 2.50 表 3 430不锈钢保护渣降温过程中析出物质

Table 3. Precipitated substances during cooling of 430 stainless steel mold flux

温度/℃ 析出物质成分 1450 ~1315 Slag-liq cooling 1315 ~1167 Ca2SiO4 1167 ~1099 Bredigite+ Ca2SiO4 1099 ~1042 Bredigite + Ca2SiO4 + Ca4Si2F2O7 1042 ~1000 Bredigite + Ca3Si2O7+ Ca4Si2F2O7 1000 ~992Na2CaAl4O8+Bredigite + Ca3Si2O7+ Ca4Si2F2O7 992~921 Combeite + Na2CaAl4O8 + Ca4Si2F2O7 921~829 Combeite + Na2CaAl4O8 + Na2CaSiO4 829~815 Combeite + Na2CaAl4O8 + NaF 815~797 Combeite + Na2CaAl4O8 + NaF + Na2MgSiO4 797~793 Nepheline+Combeite+Na2CaAl4O8+NaF + Na2MgSiO4 793~792 Nepheline + Combeite + NaF+ Na2MgSiO4 + Ca4Si2F2O7 -

[1] ZHAI J, LI H, CHEN F T, et al. Effect of mold flux on edge depression defects of 430 stainless steel billet[J]. China Metallurgy, 2022, 32(5): 102-108. (翟俊, 李欢, 陈法涛, 等. 保护渣对430不锈钢铸坯边部凹陷缺陷的影响[J]. 中国冶金, 2022, 32(5): 102-108.ZHAI J, LI H, CHEN F T, et al. Effect of mold flux on edge depression defects of 430 stainless steel billet[J]. China Metallurgy, 2022, 32(5): 102-108. [2] MA J P, LI H. Effect of mold flux on surface quality of 430 stainless steel billet[J]. Continuous Casting, 2022(4): 29-33. (马骏鹏, 李欢. 保护渣对430不锈钢铸坯表面质量的影响[J]. 连铸, 2022(4): 29-33.MA J P, LI H. Effect of mold flux on surface quality of 430 stainless steel billet[J]. Continuous Casting, 2022(4): 29-33. [3] LEI Z L, ZHANG D D, MEI F, et al. Study on decrease of recarburization of ultra-low-carbon steel with ultra low carbon slag[J]. Continuous Casting, 2018, 43(5): 49-53. (雷志亮, 张东栋, 梅峰, 等. 超低碳保护渣控制钢水增碳的研究[J]. 连铸, 2018, 43(5): 49-53.LEI Z L, ZHANG D D, MEI F, et al. Study on decrease of recarburization of ultra-low-carbon steel with ultra low carbon slag[J]. Continuous Casting, 2018, 43(5): 49-53. [4] MENG X Y, WANG Y, ZHU M Y, et al. Analysis on influences of mold slag rim on channel pressure, oscillation marks and slag consumption[J]. Ansteel Technology, 2015(6): 1-5, 19. (孟祥宇, 汪宇, 朱苗勇, 等. 结晶器渣圈对渣道压力、振痕及渣耗影响的分析[J]. 鞍钢技术, 2015(6): 1-5, 19. doi: 10.3969/j.issn.1006-4613.2015.06.001MENG X Y, WANG Y, ZHU M Y, et al. Analysis on influences of mold slag rim on channel pressure, oscillation marks and slag consumption[J]. Ansteel Technology, 2015(6): 1-5, 19. doi: 10.3969/j.issn.1006-4613.2015.06.001 [5] GRIEVESON P, BAGHA S, MACHINGAWUTA N, et al. Physical properties of casting powders: Part 2 Mineral logical constitution of slags formed by powders[J]. Iron Making and Steel Making, 1998, 15(14): 181-186. [6] KROMHOUT J, A. Mould powders for the hight speed continuous casting of cteel[D]. Delft: Delft University of Tenchnology, 2011. [7] JIANG W B, WEN G H, JIANG J, et al. Research status on mechanism of formation and growth of slag rim and affecting factors[J]. Continuous Casting, 2021(2): 7-13. (蒋文波, 文光华, 江婧, 等. 保护渣渣圈形成长大机理及影响因素研究现状[J]. 连铸, 2021(2): 7-13.JIANG W B, WEN G H, JIANG J, et al. Research status on mechanism of formation and growth of slag rim and affecting factors[J]. Continuous Casting, 2021(2): 7-13. [8] JIANG W B. Formation and control of slag rim in mold for continuous casting[D]. Chongqing: Chongqing University, 2022. (蒋文波. 连铸结晶器保护渣渣圈形成及控制[D]. 重庆: 重庆大学, 2022.JIANG W B. Formation and control of slag rim in mold for continuous casting[D]. Chongqing: Chongqing University, 2022. [9] FENG W M, XUE J H, XING G C, et al. Development of mold flux for continuous casting of Cr13 type martensitic stainless steel square billet[J]. Special Steel, 2023, 44(3): 53-58. (冯为民, 薛井恒, 邢国成, 等. Cr13型马氏体不锈钢方坯连铸保护渣的开发[J]. 特殊钢, 2023, 44(3): 53-58.FENG W M, XUE J H, XING G C, et al. Development of mold flux for continuous casting of Cr13 type martensitic stainless steel square billet[J]. Special Steel, 2023, 44(3): 53-58. [10] GUO W J, ZENG Y N, DI G X, et al. Thin slab protective slag on crystallization behavior[J]. Journal of North China University of Science and Technology, 2024, 46(3): 10-20. (郭文婧, 曾亚南, 邸高翔, 等. 超高速薄板坯保护渣组分对析晶行为影响的热力学研究[J]. 华北理工大学学报, 2024, 46(3): 10-20.GUO W J, ZENG Y N, DI G X, et al. Thin slab protective slag on crystallization behavior[J]. Journal of North China University of Science and Technology, 2024, 46(3): 10-20. [11] DI T C, WANG X J, LIU Z X, et al. Analysis on formation and growth mechanism of 430 stainless steel mold powder slag-bonding rim and control measures[J]. Special Steel, 2022, 43(5): 63-67. (邸天成, 王杏娟, 刘增勋, 等. 430不锈钢用连铸保护渣渣圈形成长大机理分析和控制措施[J]. 特殊钢, 2022, 43(5): 63-67. doi: 10.3969/j.issn.1003-8620.2022.05.013DI T C, WANG X J, LIU Z X, et al. Analysis on formation and growth mechanism of 430 stainless steel mold powder slag-bonding rim and control measures[J]. Special Steel, 2022, 43(5): 63-67. doi: 10.3969/j.issn.1003-8620.2022.05.013 [12] YAN X P. Research on the influence of fluorine and boron on crystallization behavior of continuous casting slag film[D]. Tangshan: North China University of Science and Technology, 2022. (闫晓鹏. 氟及硼对连铸保护渣渣膜析晶行为影响规律研究[D]. 唐山: 华北理工大学, 2022.YAN X P. Research on the influence of fluorine and boron on crystallization behavior of continuous casting slag film[D]. Tangshan: North China University of Science and Technology, 2022. [13] WANG Z C. Heat transfer and lubrication behaviors of slag film for continuous casting of typical steel grades[D]. Changsha: Central South University, 2023. (王子超. 典型钢种连铸保护渣渣膜传热与润滑行为[D]. 长沙: 中南大学, 2023.WANG Z C. Heat transfer and lubrication behaviors of slag film for continuous casting of typical steel grades[D]. Changsha: Central South University, 2023. [14] LI X Y, HE F, ZHAO C B, et al. Study on crystallization behavior and heat transfer performance of CaO-SiO2 based continuous casting protective slag[J]. Wuhan University of Technology News, 2023, 45(12): 28-32, 73. (李晓阳, 何峰, 赵春宝, 等. CaO-SiO2基连铸保护渣的析晶行为与传热性能研究[J]. 武汉理工大学报, 2023, 45(12): 28-32, 73.LI X Y, HE F, ZHAO C B, et al. Study on crystallization behavior and heat transfer performance of CaO-SiO2 based continuous casting protective slag[J]. Wuhan University of Technology News, 2023, 45(12): 28-32, 73. [15] WANG S H, WANG Z H, LI X N, et al. Synthesis of anorthite powder by solid-state method and its application in transparent glaze[J]. Chinese Ceramics, 2024, 60(5): 66-72. (王少华, 王子晗, 李小女, 等. 固相法合成钙长石粉体及其在透明釉中的应用研究[J]. 中国陶瓷, 2024, 60(5): 66-72.WANG S H, WANG Z H, LI X N, et al. Synthesis of anorthite powder by solid-state method and its application in transparent glaze[J]. Chinese Ceramics, 2024, 60(5): 66-72. [16] DU F, WANG Y, LIANG X P, et al. Experimental research on slag film simulation of continuous casting mould fluxes[J]. Journal of Process Engineering, 2009, 9(1): 197-201. (杜方, 王雨, 梁小平, 等. 连铸保护渣渣膜模拟实验研究[J]. 过程工程学报, 2009, 9(1): 197-201. doi: 10.3321/j.issn:1009-606X.2009.z1.041DU F, WANG Y, LIANG X P, et al. Experimental research on slag film simulation of continuous casting mould fluxes[J]. Journal of Process Engineering, 2009, 9(1): 197-201. doi: 10.3321/j.issn:1009-606X.2009.z1.041 [17] WEN Y L. Experimental study on sintering properties and melting speed of continuous casting mould fluxes[D]. Chongqing: Chongqing University, 2016. (温亚磊. 连铸保护渣烧结性能和熔化速度的实验研究[D]. 重庆: 重庆大学, 2016.WEN Y L. Experimental study on sintering properties and melting speed of continuous casting mould fluxes[D]. Chongqing: Chongqing University, 2016. [18] LI Q P, WANG Z, DUAN Z R, et al. Kinetic study of NaF gas formation during mold flux melting based on different fluorides by experimental and computational methods[J]. steel research int. 2024. [19] HAO Z Q, CHEN W Q, CARSTEN L, et al. Study on molten slag layer and slag film of mould flux used in slab casting of stainless steel 1Cr17[J]. Special Steel, 2009, 30(3): 16-18. (郝占全, 陈伟庆, CARSTEN L, 等. 不锈钢1Cr17板坯连铸过程中保护渣液渣层及渣膜的研究[J]. 特殊钢, 2009, 30(3): 16-18. doi: 10.3969/j.issn.1003-8620.2009.03.006HAO Z Q, CHEN W Q, CARSTEN L, et al. Study on molten slag layer and slag film of mould flux used in slab casting of stainless steel 1Cr17[J]. Special Steel, 2009, 30(3): 16-18. doi: 10.3969/j.issn.1003-8620.2009.03.006 -

下载:

下载: