Effect of Ti on the solidification structure and thermal deformation properties of 304B7

-

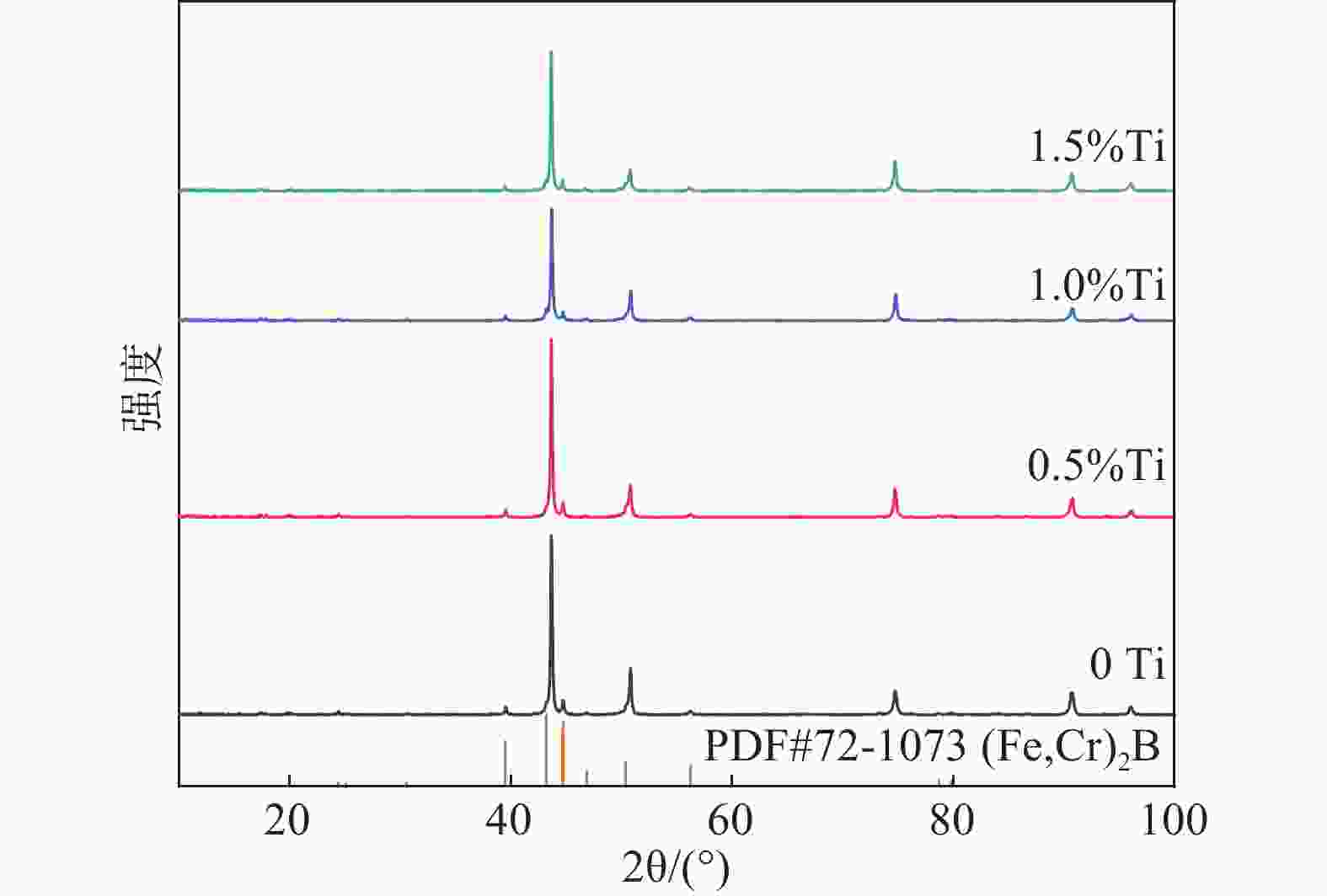

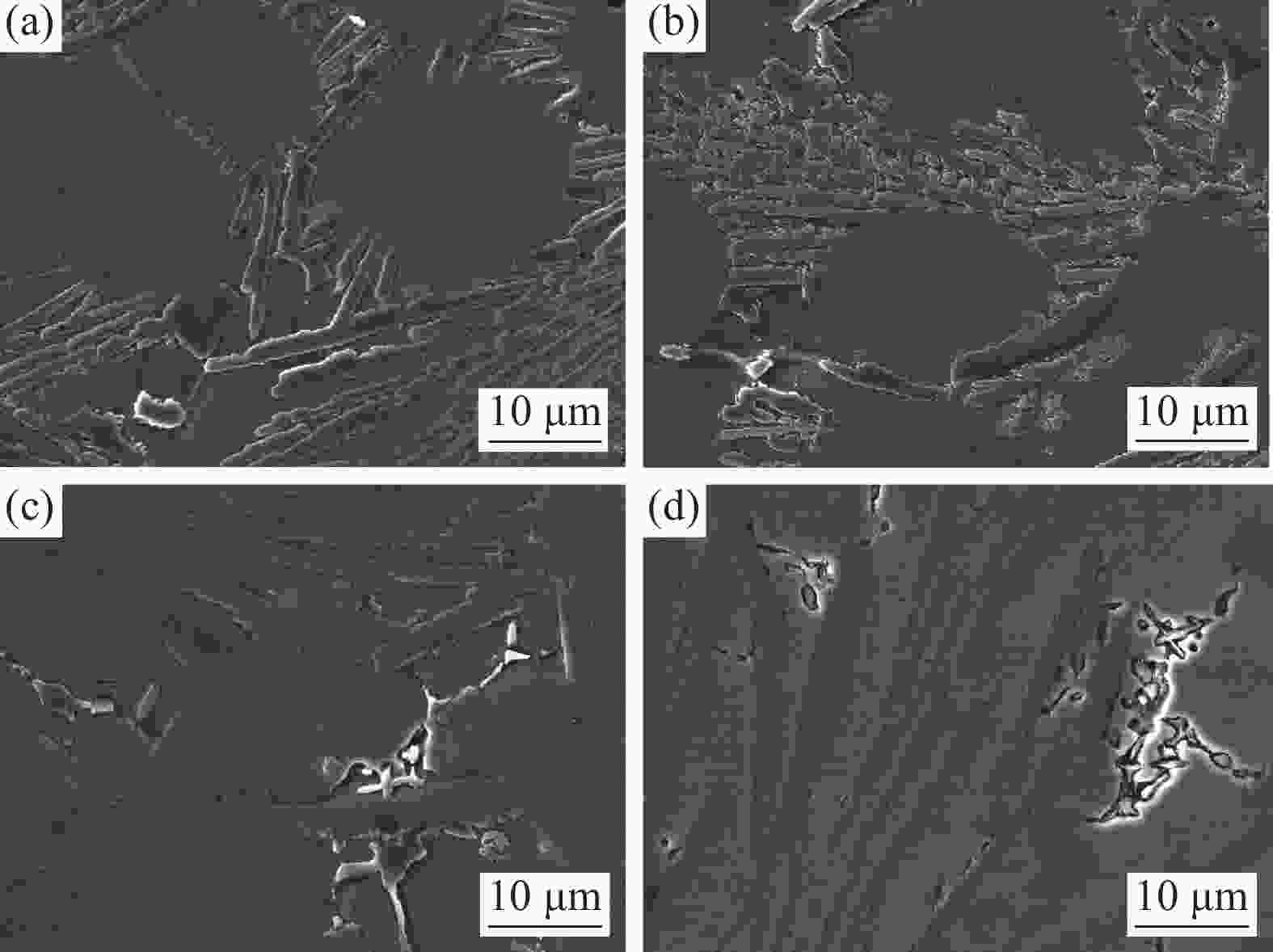

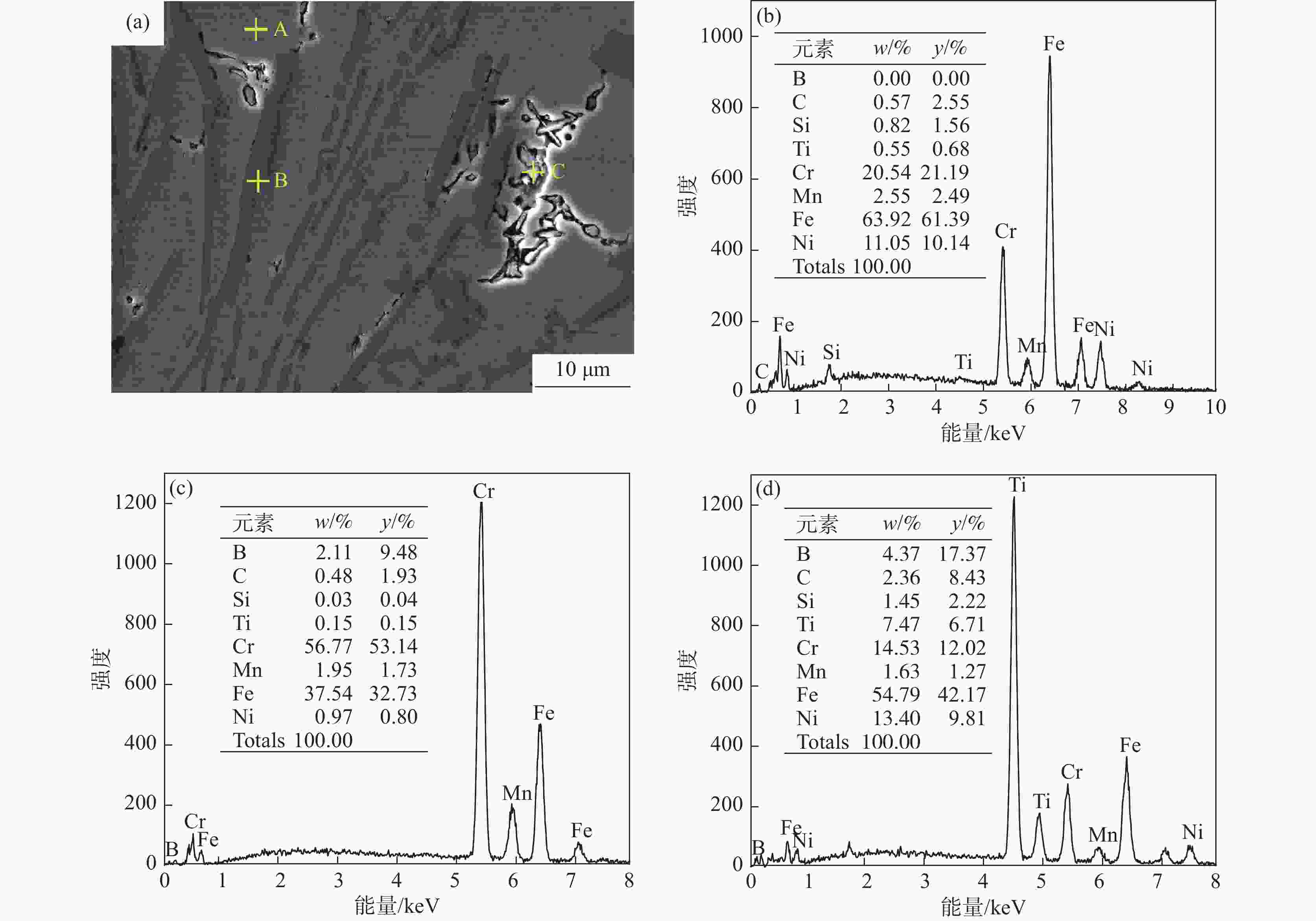

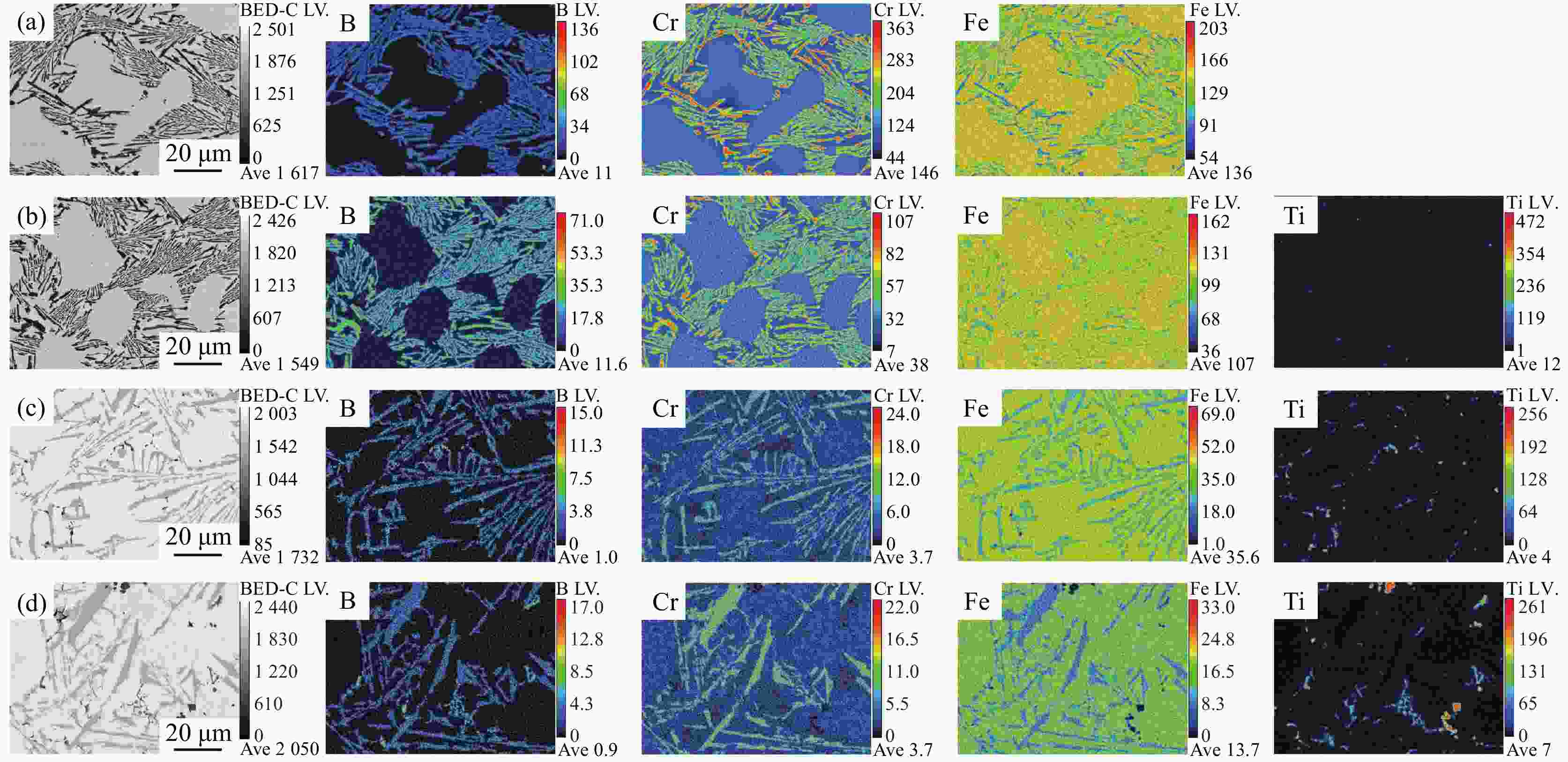

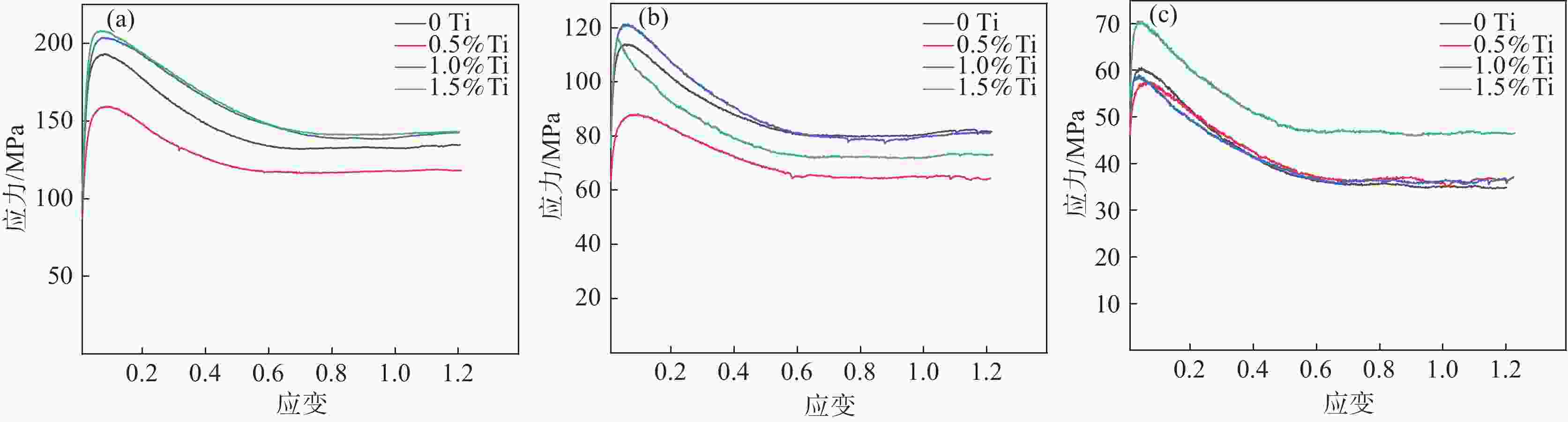

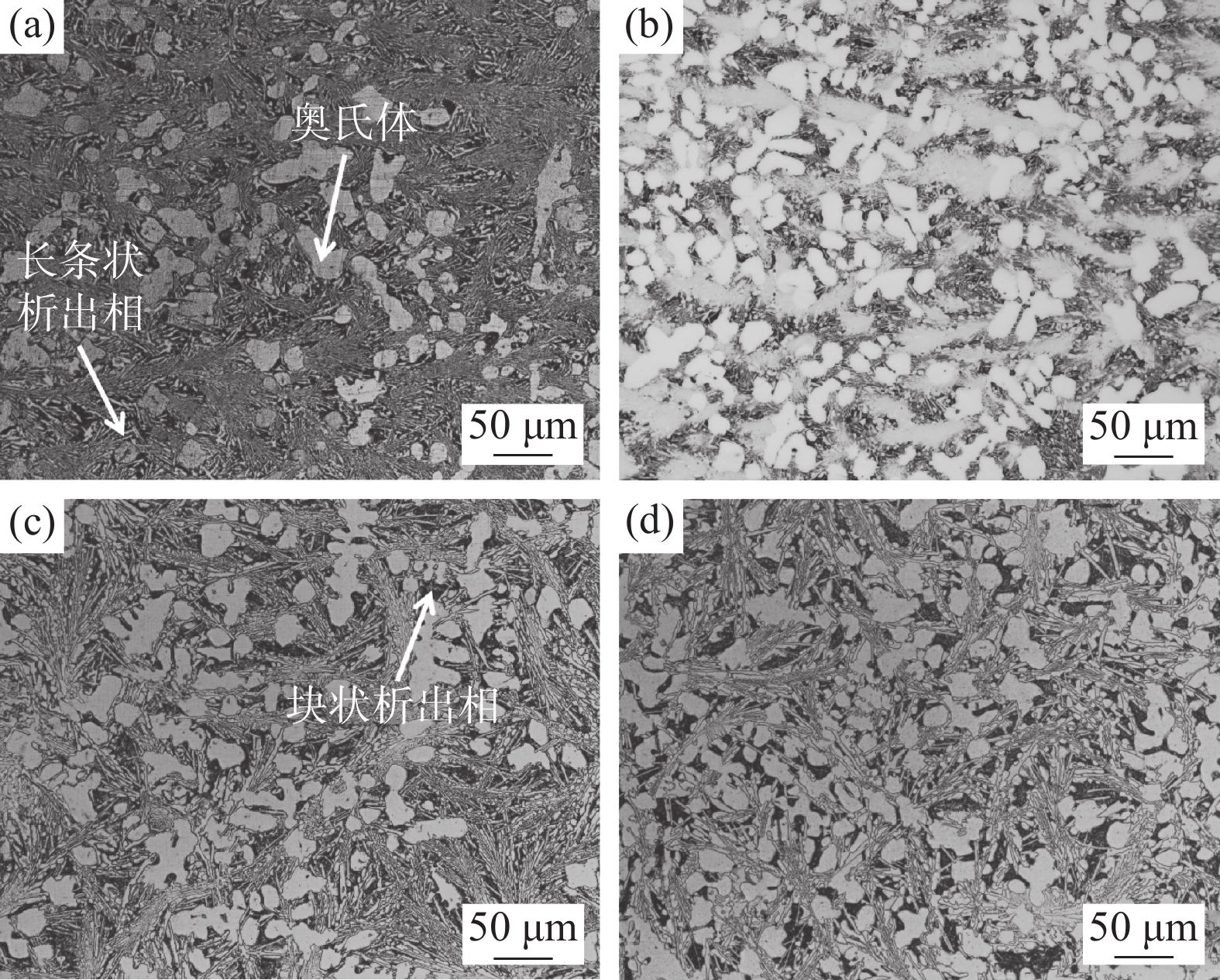

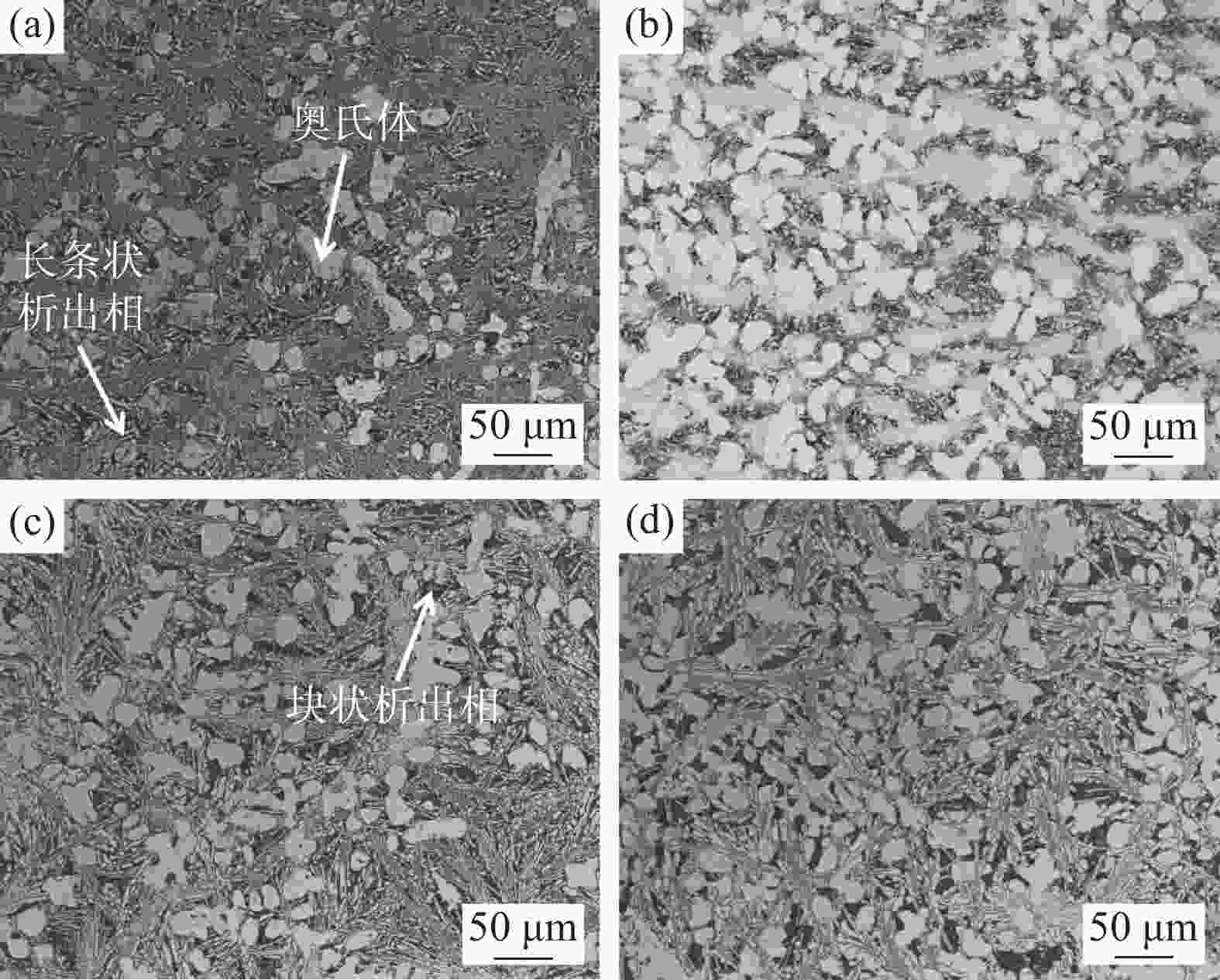

摘要: 以304B7不锈钢为研究对象,添加不同含量的Ti元素熔铸成试验钢,使用热模拟机对其进行热压缩模拟热轧过程。采用光学显微镜、X射线衍射仪、扫描电子显微镜、电子探针对铸态、热压缩后试验钢的物相、显微组织进行分析。结果表明,铸态试验钢中存在大量连续网络状的共晶硼化物,随着Ti的加入,部分硼化物由长条状(Fe,Cr)2B转变为颗粒状TiB2。热压缩后的试验钢奥氏体晶粒沿压缩方向被拉长,硼化物由长条状破碎为短棒状。热压缩温度越高,试验钢变形抗力越小,含0.5%Ti的试验钢热压缩时峰值流变应力相对最小,热加工塑性较好。Abstract: The 304B7 stainless steel was taken as the research object, and different contents of Ti element were added to cast the test steels. The hot compression test was conducted on the test steel using a thermal simulator to simulate the hot rolling process. Optical microscope, X-ray diffractometer, scanning electron microscope, and electron probe were used to analyze the phase composition and microstructure of the as cast and hot compressed test steel. The results indicate that there are a large number of continuous network-like eutectic borides in the as cast test steel. With the addition of Ti, some borides transform from elongated (Fe,Cr)2B to granular TiB2. After hot compression, the austenite grains of the test steel are elongated along the compression direction, and the borides are broken from long strips into short rod-shaped shapes. The higher the hot compression temperature, the lower the deformation resistance of the test steel. The peak flow stress of the test steel containing 0.5% Ti is the relatively smallest during hot compression, indicating better hot workability.

-

Key words:

- Ti /

- 304B7 stainless steel /

- boride /

- thermal deformation

-

表 1 试验钢化学成分

Table 1. Chemical compositions of the test steels

% 编号 C Si Mn Cr Ni B Ti 1 0.025 0.681 1.882 18.817 13.875 1.901 0.000 2 0.021 0.685 1.876 18.759 13.834 1.798 0.542 3 0.029 0.693 1.879 18.925 13.931 1.884 1.093 4 0.026 0.689 1.885 18.853 13.871 1.856 1.531 -

[1] LU W Y, WANG D B, JI B T, et al. Insight into the long-term corrosion evolution of borated stainless steels in the wet storage environment for spent nuclear fuel[J]. Corrosion Science, 2024, 237(1): 112348. [2] A- A C. Standard specification for borated stainless steel plate, sheet, and strip for nuclear application[S]. Annual Book of ASTM Standards, 2000. [3] YU G. Boron-containing stainless steel for thermal neutron shielding[J]. Journal of Iron and Steel Research, 1989(1): 90. [4] TSUBOTA M, OIKAWA M. Boron-bearing stainless steel for thermal neutron shielding[J]. Bulletin of the Iron and Steel Institute of Japan, 2005, 12(10): 25-32. [5] LI Y W, HE X Y, WANG X M, et al. Study on thermal deformation behavior and mechanism of difficult-to-process boron-containing stainless steel[J]. Nuclear Power Engineering, 2022, 43(S2): 67-73. (李永旺, 何雪溢, 王馨敏, 等. 难加工含硼不锈钢热变形行为与机制研究[J]. 核动力工程, 2022, 43(S2): 67-73.LI Y W, HE X Y, WANG X M, et al. Study on thermal deformation behavior and mechanism of difficult-to-process boron-containing stainless steel[J]. Nuclear Power Engineering, 2022, 43(S2): 67-73. [6] FU H G, XIAO Q, KUANG J C, et al. Effect of rare earth and titanium additions on the microstructures and properties of low carbon Fe-B cast steel. Materials Science and Engineering: A , 2007, 466: 160-165. [7] JIANG J. The Effect of Ti on the microstructure of high boron steel[D]. Chengdu: Xihua University, 2009. (蒋军. Ti对高硼钢微观组织结构的影响[D]. 成都: 西华大学, 2009.JIANG J. The Effect of Ti on the microstructure of high boron steel[D]. Chengdu: Xihua University, 2009. [8] HE L, LIU Y, LI J, et al. Effects of hot rolling and titanium content on the microstructure and mechanical properties of high boron Fe-B alloys[J]. Materials and Design, 2012, 36: 88-93. doi: 10.1016/j.matdes.2011.10.043 [9] LIU Y, LI B H, LI J, et al. Effect of titanium on the ductilization of Fe-B alloys with high boron content[J]. Materials and Design, 2010, 64: 1299-1301. [10] ER Q L. Research on spent fuel storage materials (boron containing stainless steel)[D]. Kunming: Kunming University of Science and Technology, 2013. (佴启亮. 乏燃料贮存材料(含硼不锈钢)的研究[D]. 昆明: 昆明理工大学, 2013.ER Q L. Research on spent fuel storage materials (boron containing stainless steel)[D]. Kunming: Kunming University of Science and Technology, 2013. [11] HUANG X M. Study on high boron steel for thermal neutron shielding based on strip casting[D]. Shenyang: Northeastern University, 2017. (黄晓明. 基于薄带连铸技术制备热中子屏蔽用高硼钢的研究[D]. 沈阳: 东北大学, 2017.HUANG X M. Study on high boron steel for thermal neutron shielding based on strip casting[D]. Shenyang: Northeastern University, 2017. [12] YANG H, LIU Y, LI J, et al. Thermodynamic analysis on precipitation behavior of titanium-containing precipitated phases of titanium-alloyed high boron steel[J]. Iron Steel Vanadium Titanium, 2014, 35(1): 41-47. (杨浩, 刘颖, 李军, 等. 钛对高硼钢凝固组织及析出相的热力学分析[J]. 钢铁钒钛, 2014, 35(1): 41-47. doi: 10.7513/j.issn.1004-7638.2014.01.009YANG H, LIU Y, LI J, et al. Thermodynamic analysis on precipitation behavior of titanium-containing precipitated phases of titanium-alloyed high boron steel[J]. Iron Steel Vanadium Titanium, 2014, 35(1): 41-47. doi: 10.7513/j.issn.1004-7638.2014.01.009 [13] YUAN L L. Research on preparative technique of metal composite contained boron for nuclear shielding[D]. Beijing: University of Science and Technology Beijing, 2016. (元琳琳. 核屏蔽用高硼金属复合材料的制备技术基础研究[D]. 北京: 北京科技大学, 2016.YUAN L L. Research on preparative technique of metal composite contained boron for nuclear shielding[D]. Beijing: University of Science and Technology Beijing, 2016. [14] YONG Q L. Second phases in structural steels[M]. Beijing: Metallurgical Industry Press, 2006: 20-24. (雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006: 20-24.YONG Q L. Second phases in structural steels[M]. Beijing: Metallurgical Industry Press, 2006: 20-24. [15] ZHANG Y Y, WANG H, YANG P, et al. Analysis for processing map of Fe-13Cr-4Al alloy[J]. Iron Steel Vanadium Titanium, 2019, 40(4): 152-157, 163. (张毅勇, 王辉, 杨攀, 等. Fe-13Cr-4Al合金的热加工图分析[J]. 钢铁钒钛, 2019, 40(4): 152-157, 163. doi: 10.7513/j.issn.1004-7638.2019.04.028ZHANG Y Y, WANG H, YANG P, et al. Analysis for processing map of Fe-13Cr-4Al alloy[J]. Iron Steel Vanadium Titanium, 2019, 40(4): 152-157, 163. doi: 10.7513/j.issn.1004-7638.2019.04.028 [16] YE M Y, LI J C, QUAN W, et al. Hot compression constitutive equation and hot processing map of 06Cr23Ni13 stainless steel[J]. Transactions of Materials and Heat Treatment, 2024, 45(1): 193-199, 208. (叶梦元, 李俊琛, 权伟, 等. 06Cr23Ni13不锈钢的热压缩本构方程及热加工图[J]. 材料热处理学报, 2024, 45(1): 193-199, 208.YE M Y, LI J C, QUAN W, et al. Hot compression constitutive equation and hot processing map of 06Cr23Ni13 stainless steel[J]. Transactions of Materials and Heat Treatment, 2024, 45(1): 193-199, 208. -

下载:

下载: