Effect of tellurium on sulfide modification and corrosion resistance of 38MnVS non-tempered steel

-

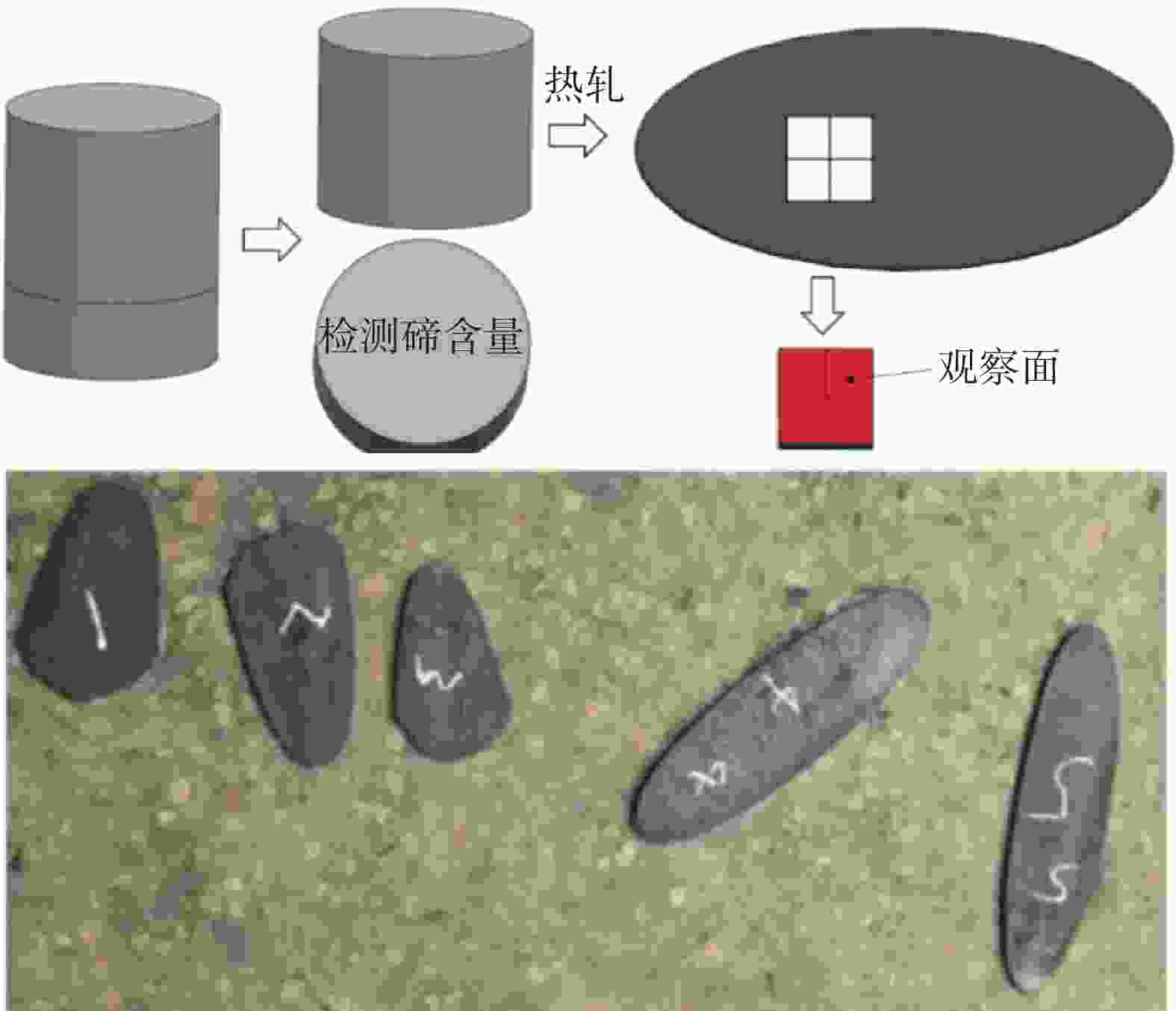

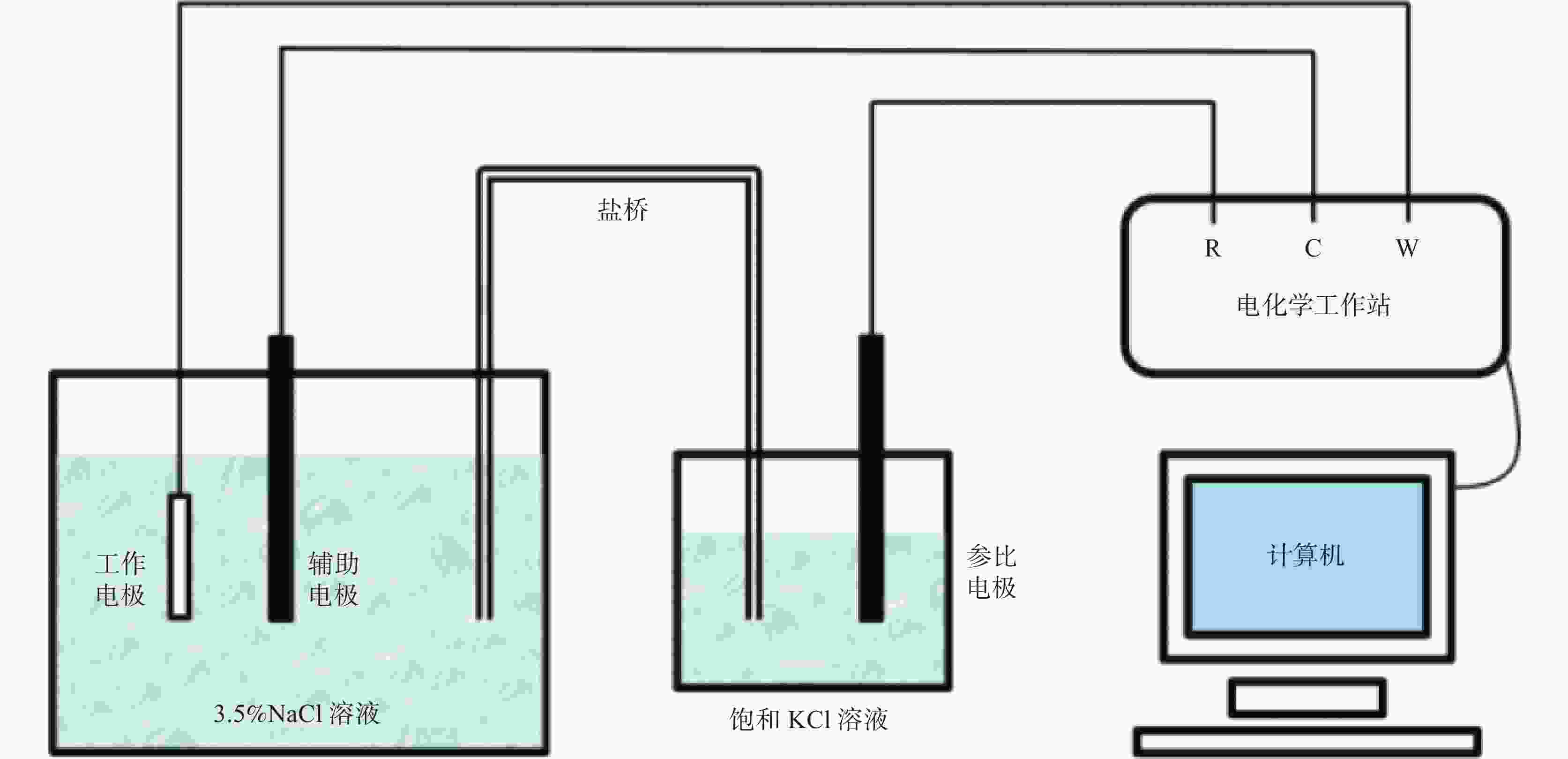

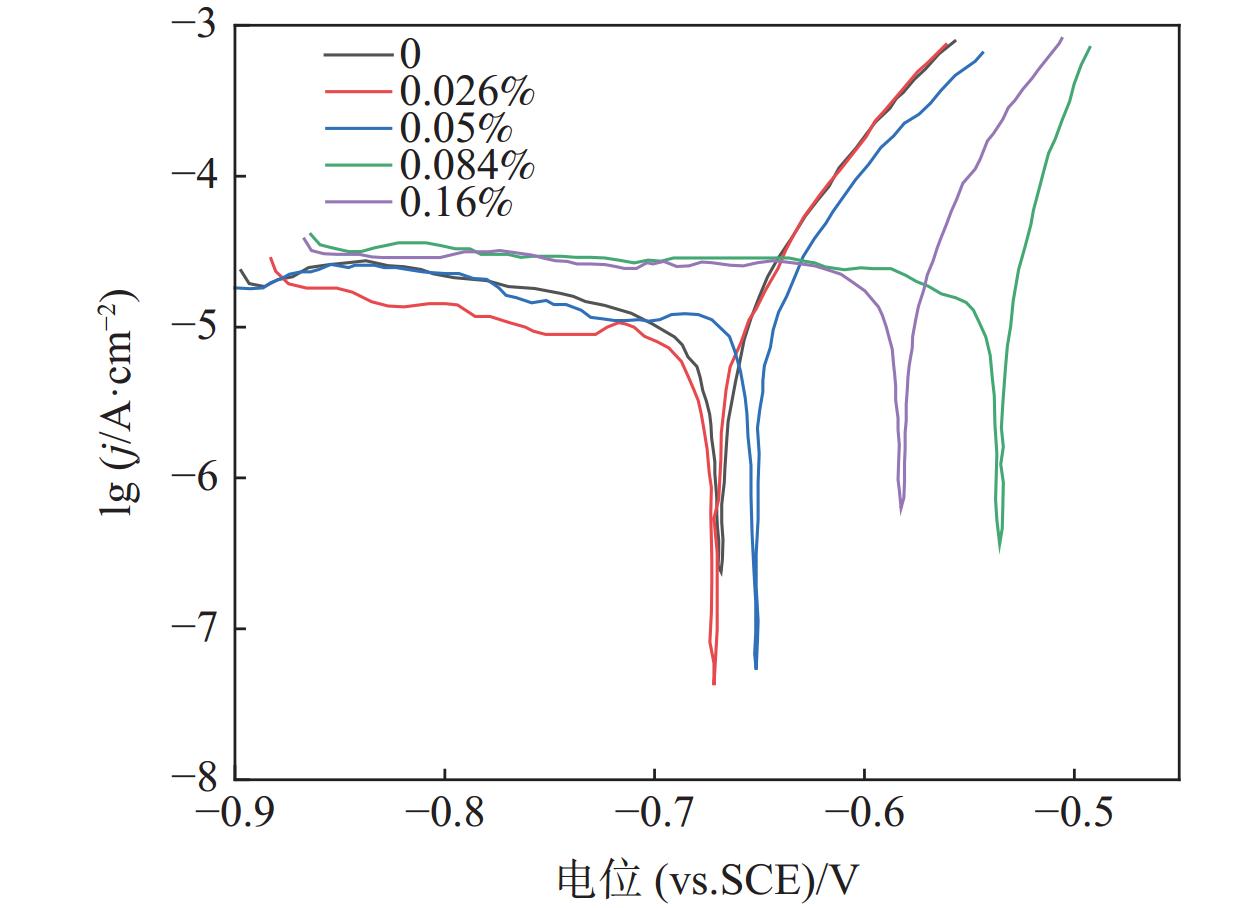

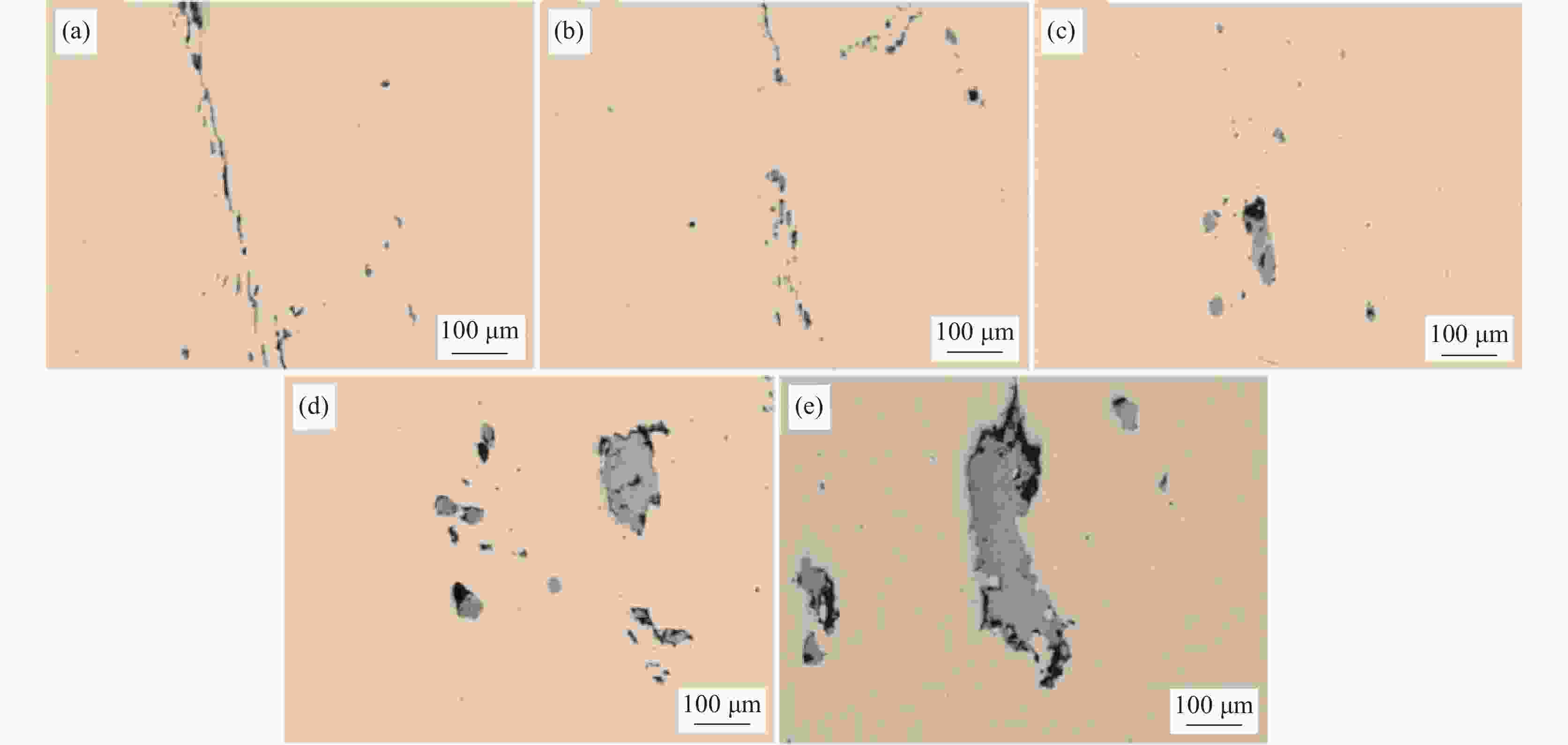

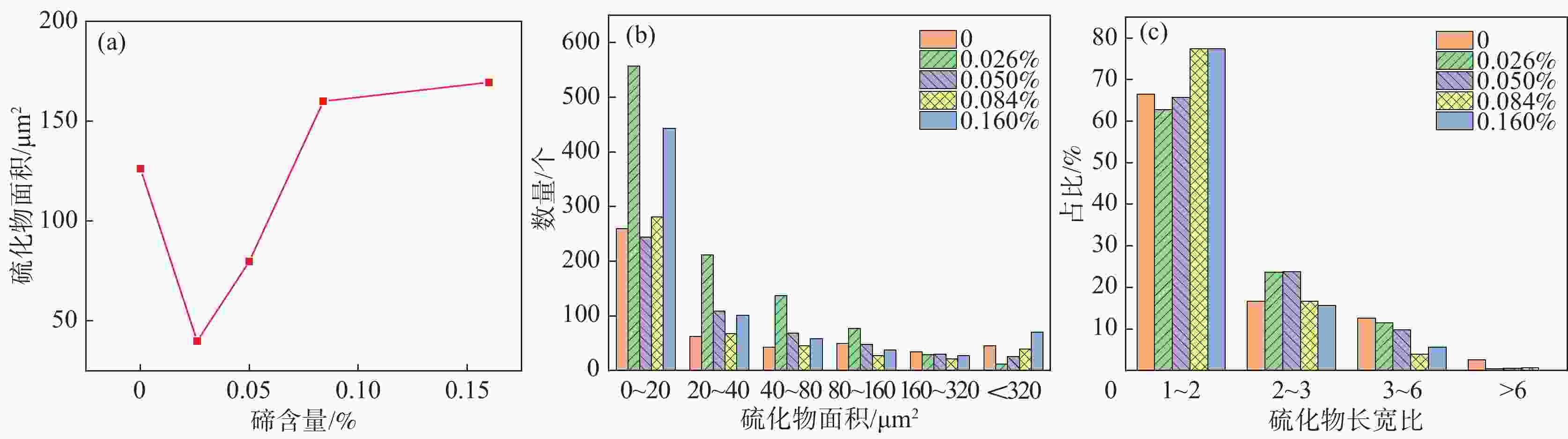

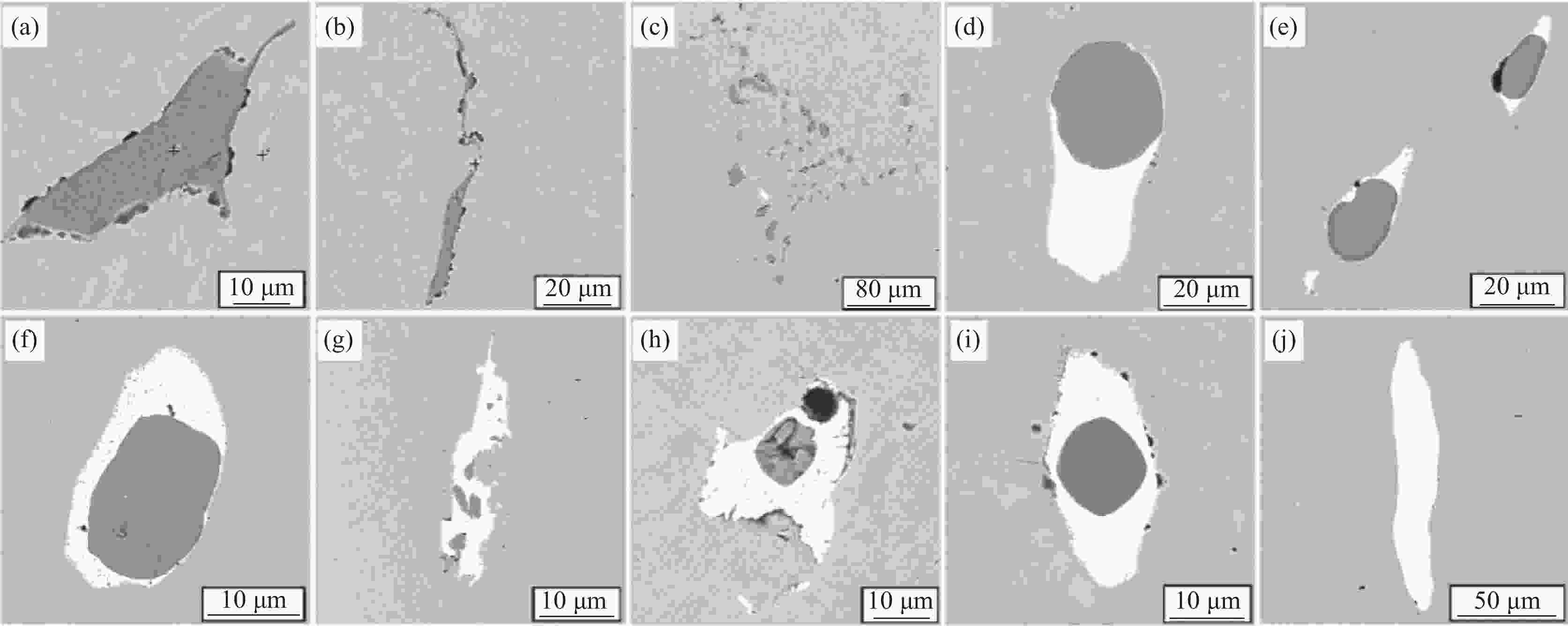

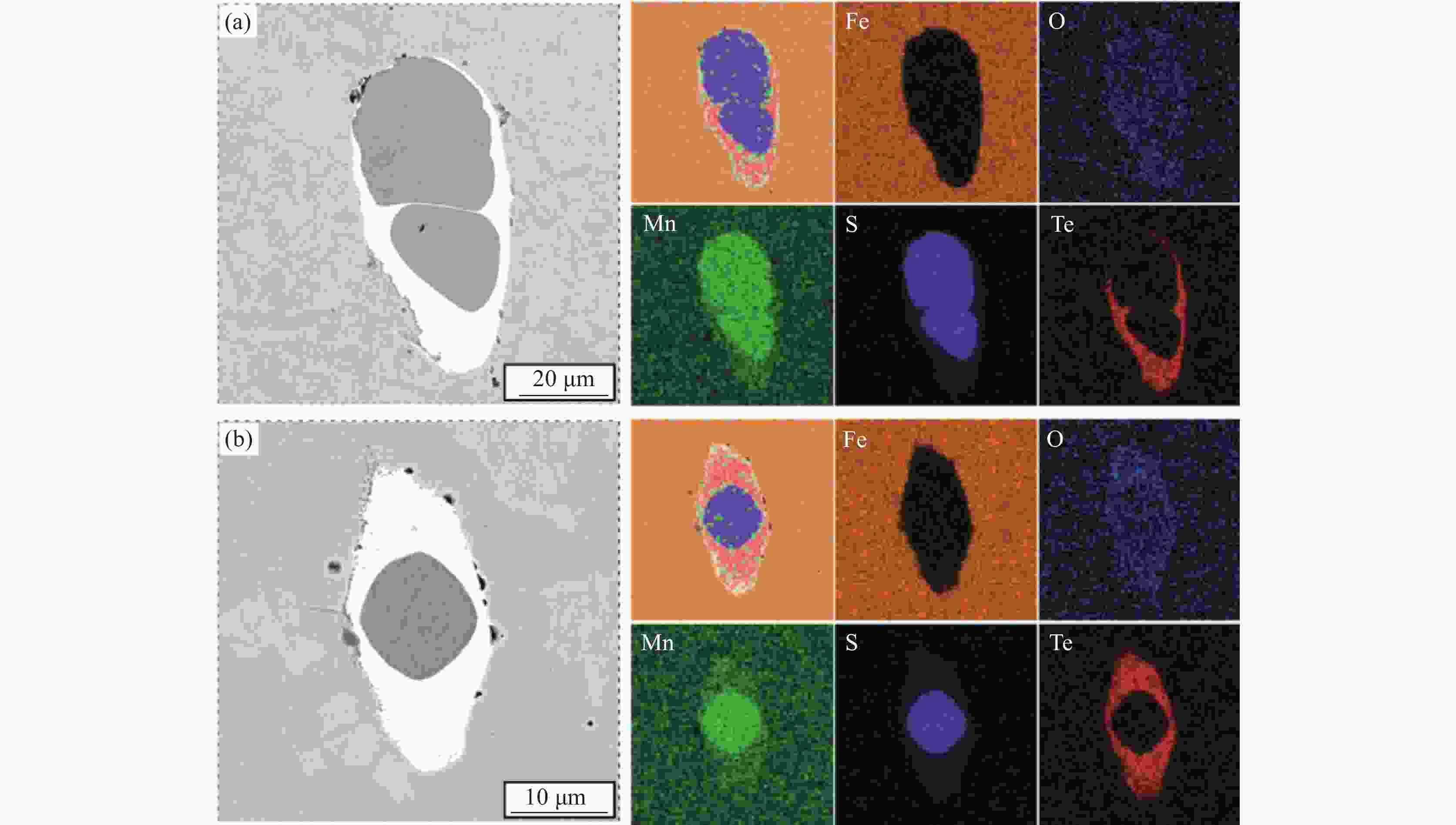

摘要: 开展三电极系统电化学试验,分析碲添加对非调质钢腐蚀性的影响,利用扫描电镜(SEM)和电子探针(EDS)对钢中硫化物进行表征分析,对电化学腐蚀试验结果进行诠释。结果表明:随着钢中碲含量的增加,钢的自腐蚀电位升高,腐蚀倾向减小;少量碲(0.026%)固溶在硫化锰中,钢的腐蚀电流最小,为5.13×10−6 A,耐蚀性能最好。钢中加入碲后,MnTe包裹在MnS周围,导致夹杂物长宽比明显减小,长条状硫化物转变为椭球状,分布更加均匀,有效降低了硫化物周围的应力集中。Abstract: A three-electrode electrochemical test was carried out to investigate the effect of tellurium addition on the corrosion of un-tempered steel, and the sulfide in steel was characterized by scanning electron microscopy (SEM) and electron probe (EDS), and the electrochemical corrosion test results were interpreted. The results show that with the increase of tellurium content, the self-corrosion potential of steel increases and the corrosion tendency decreases. A small amount of tellurium (0.026%) is solid solution in manganese sulfide, and the steel achieve the lowest corrosion current of 5.13×10−6 A and the best corrosion resistance. With tellurium addition in steel, MnTe is surrounded by MnS, resulting in a significant reduction in the aspect ratio of inclusions and a more uniform distribution of long strips of sulfide into ellipsoids, which effectively reduces the stress concentration around the sulfide.

-

Key words:

- non-tempered steel /

- tellurium modification /

- manganese sulfide /

- corrosion resistance

-

表 1 38MnSV化学成分

Table 1. Chemical composition of 38MnSV steel

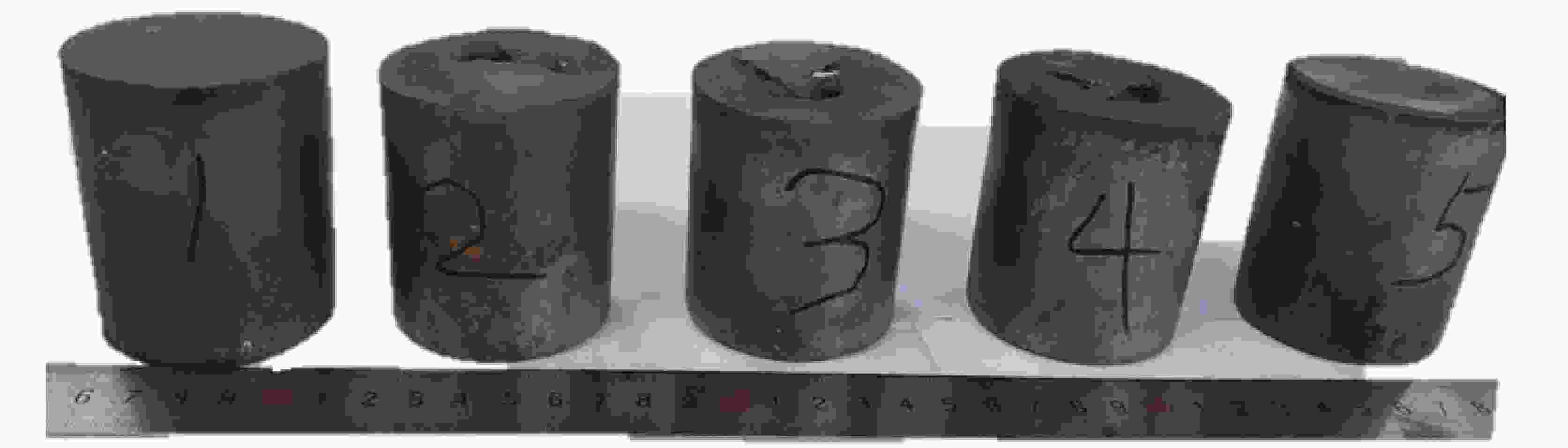

% C Si Mn P S Al Als Ca Cr Mo V Ti Ni Cu 0.37 0.56 1.4 0.01 0.54 0.017 0.016 0.0004 0.17 0.01 0.13 0.012 0.03 0.01 表 2 39MnSV冶炼钢锭中碲含量

Table 2. Tellurium content in smelted ingot of 39MnSV

试样编号 碲含量/% Te/S 1 0 0 2 0.026 0.50 3 0.050 0.96 4 0.084 1.62 5 0.160 3.08 表 3 不同碲含量试样的自腐蚀电位和腐蚀电流

Table 3. Self-corrosion potential and corrosion current of samples with different tellurium contents

碲含量/% 自腐蚀电位/V log( j/A·cm−2) j/(A·cm−2) icorr/A 0 −0.67 −5.01 9.77×10−6 9.77×10−6 0.026 −0.67 −5.29 5.13×10−6 5.13×10−6 0.05 −0.65 −5.15 7.08×10−6 7.08×10−6 0.084 −0.53 −4.67 2.14×10−5 2.14×10−5 0.16 −0.58 −4.59 2.57×10−5 2.57×10−5 -

[1] HANG L R. Corrosion and protection of metals[J]. China Metal Bulletin, 2019(1): 230-231. (韩立荣. 金属的腐蚀与防护[J]. 中国金属通报, 2019(1): 230-231. doi: 10.3969/j.issn.1672-1667.2019.01.149HANG L R. Corrosion and protection of metals[J]. China Metal Bulletin, 2019(1): 230-231. doi: 10.3969/j.issn.1672-1667.2019.01.149 [2] WANG C Y. Damage and protection of metal corrosion[J]. Mechanical Management and Development, 2012(5): 111-112. (王彩云. 金属腐蚀的危害及防护[J]. 机械管理开发, 2012(5): 111-112. doi: 10.3969/j.issn.1003-773X.2012.05.057WANG C Y. Damage and protection of metal corrosion[J]. Mechanical Management and Development, 2012(5): 111-112. doi: 10.3969/j.issn.1003-773X.2012.05.057 [3] WAN W H, DENG X Y. Research on application of 46MnVS5 in connecting rod[J]. Automobile Technology & Material, 2021(3): 20-24. (万文华, 邓向阳. 46MnVS5材料连杆应用研究[J]. 汽车工艺与材料, 2021(3): 20-24.WAN W H, DENG X Y. Research on application of 46MnVS5 in connecting rod[J]. Automobile Technology & Material, 2021(3): 20-24. [4] XIA X J, CAI J B, YE Y H, et al. Failure analysis for fracture of stainless steel adjustable connecting rod[J]. Corrosion & Protection, 2019, 40(6): 453-456. (夏晓健, 蔡建宾, 叶英浩, 等. 不锈钢可调连杆断裂失效分析[J]. 腐蚀与防护, 2019, 40(6): 453-456. doi: 10.11973/fsyfh-201906012XIA X J, CAI J B, YE Y H, et al. Failure analysis for fracture of stainless steel adjustable connecting rod[J]. Corrosion & Protection, 2019, 40(6): 453-456. doi: 10.11973/fsyfh-201906012 [5] LIU C C, ZHANG L F, REN Y, et al. Review on effect of non-metallic inclusions on pitting corrosion resistance of stainless steel[J]. Journal of lron and Steel Research, 2021, 33(10): 1040-1051. (刘城城, 张立峰, 任英, 等. 非金属夹杂物对不锈钢耐点蚀性能影响的综述[J]. 钢铁研究学报, 2021, 33(10): 1040-1051.LIU C C, ZHANG L F, REN Y, et al. Review on effect of non-metallic inclusions on pitting corrosion resistance of stainless steel[J]. Journal of lron and Steel Research, 2021, 33(10): 1040-1051. [6] LIU Z P, LI J, FU J X, et al. Industrial practice of tellurium modified sulfides in the non-quenched and tempered 38MnVS6 steels[J]. Iron Steel Vanadium Titanium, 2023, 44(2): 200-204. (刘增平, 李杰, 付建勋, 等. 38MnVS6非调质钢中硫化物碲改质工业实践[J]. 钢铁钒钛, 2023, 44(2): 200-204.LIU Z P, LI J, FU J X, et al. Industrial practice of tellurium modified sulfides in the non-quenched and tempered 38MnVS6 steels[J]. Iron Steel Vanadium Titanium, 2023, 44(2): 200-204. [7] HU T, ZHONG L M, ZHOU L, et al. The practice of tellurium to control the form of sulfide in non-quenched and tempered steel[J]. Steelmaking, 2022, 38(1): 63-67. (胡涛, 钟亮美, 周蕾, 等. 碲对非调质钢中硫化物形态调控的实践[J]. 炼钢, 2022, 38(1): 63-67. doi: 10.3969/j.issn.1002-1043.2022.1.lg202201011HU T, ZHONG L M, ZHOU L, et al. The practice of tellurium to control the form of sulfide in non-quenched and tempered steel[J]. Steelmaking, 2022, 38(1): 63-67. doi: 10.3969/j.issn.1002-1043.2022.1.lg202201011 [8] SHEN W, LI Z W, TIAN Q R, et al. Modification of sulfide distribution in 46MnVS non-quenched and tempered steel by tellurium[J]. Steelmaking, 2023, 39(2): 56-61, 81. (沈伟, 李志伟, 田钱仁, 等. 碲对46MnVS非调质钢中硫化物分布的改质规律[J]. 炼钢, 2023, 39(2): 56-61, 81. doi: 10.3969/j.issn.1002-1043.2023.2.lg202302009SHEN W, LI Z W, TIAN Q R, et al. Modification of sulfide distribution in 46MnVS non-quenched and tempered steel by tellurium[J]. Steelmaking, 2023, 39(2): 56-61, 81. doi: 10.3969/j.issn.1002-1043.2023.2.lg202302009 [9] SHEN P, YANG Q K, ZHANG D, et al. The effect of tellurium on the formation of MnTe-MnS composite inclusions in non-quenched and tempered steel[J]. Metals, 2018, 8(8): 369. [10] XIE J B, FAN T, SUN H, et al. Enhancement of impurity, machinability and mechanical properties in Te-treated Cr18Ni9 steel[J]. Met. Mater. Int., 2021, 27(6): 1416-1427. doi: 10.1007/s12540-019-00545-3 [11] TORKKELI J, SAUKKONEN T, HANNINEN H, et al. Effect of MnS inclusion dissolution on carbon steel stress corrosion cracking in fuel-grade ethanol[J]. Corros. Sci., 2015, 96: 14-22. doi: 10.1016/j.corsci.2015.03.002 [12] WANG Y F, CHENG G X, WU W, et al. Role of inclusions in the pitting initiation of pipeline steel and the effect of electron irradiation in SEM[J]. Corros. Sci., 2018, 130: 252-260. doi: 10.1016/j.corsci.2017.10.029 [13] DEARDO A J, HUA M J, CHO K G, et al. On strength of microalloyed steels: an interpretive review[J]. Mater. Sci. Technol., 2013, 25(9): 1074-1082. [14] YANG S F, ZHAO M J, FENG J, et al. Induced-pitting behaviors of MnS inclusions in steel[J]. High Tem. Mater. Processes., 2018, 37(9-10): 1007-1016. doi: 10.1515/htmp-2017-0155 [15] KONG D Q, LAI Z H, DONG X M, et al. Effect of inclusions on acid corrosion resistance of free-cutting steel crankshaft[J]. Corros. Prot., 2021, 42(7): 30-33, 47. [16] ZHENG W, XIONG S, LI T Y, et al. Effect of inclusions on pitting susceptibility in low alloy steel[J]. Steelmaking, 2017, 33(5): 31-38, 78. (郑万, 熊珊, 李天佑, 等. 夹杂物对低合金钢点蚀诱发敏感性的影响[J]. 炼钢, 2017, 33(5): 31-38, 78.ZHENG W, XIONG S, LI T Y, et al. Effect of inclusions on pitting susceptibility in low alloy steel[J]. Steelmaking, 2017, 33(5): 31-38, 78. [17] CHEN X Q, KONG X D, YANG S C. Effect of sulfide inclusion on corrosion expansion of low carbon steel[J]. Journal of Chinese Society for corrosion and protection, 2000, 20(2): 65-73. (陈学群, 孔小东, 杨思诚. 硫化物夹杂对低碳钢孔蚀扩展的影响[J]. 中国腐蚀与防护学报, 2000, 20(2): 65-73.CHEN X Q, KONG X D, YANG S C. Effect of sulfide inclusion on corrosion expansion of low carbon steel[J]. Journal of Chinese Society for corrosion and protection, 2000, 20(2): 65-73. [18] ABEYAMA S, NAKAMMA S. An ultra-free machining stainless steel “DSR6F”[J]. J. Jpn. Inst. Met., 2011, 21(5): 363-365. [19] YANG Q K, SHEN P, ZHANG D, et al. Analysis on composition and inclusions of ballpoint pen tip steel[J]. Int. J. Miner. , Metall. Mater., 2018, 25(4): 420-428. doi: 10.1007/s12613-018-1587-6 [20] CHANG K D, WANG P, LIU W P. Development status and application prospect of non-quenched tempered steel[J]. Heat Treat. Met., 2011, 36(3): 80-85. [21] ZHENG J C, HU X J, PAN C, et al. Effects of inclusions on the resistance to pitting corrosion of S32205 duplex stainless steel[J]. Mater. Corros., 2018, 69(5): 572-579. doi: 10.1002/maco.201709723 [22] ATKINSON H V, SHI G, Characterization of inclusions in clean steels: a review including the statistics of extremes methods[J]. Prog. Mater. Sci., 2003, 48(5): 457-520. [23] XU X Y, TIAN L, ZHOU Y, et al. Effect of Nb on corrosion behavior of inner bottom plate of cargo oil tankers[J]. J. Iron Steel Res. Int., 2019, 26(6): 611-620. doi: 10.1007/s42243-018-0180-6 [24] WU W B, YANG S A, SUO D H, et al. Effect of tellurium treatment on the pitting behavior of 38MnVS6 Non-quenched and tempered steel in alkaline environment[J]. Corros. Sci., 2024, 226: 111629. doi: 10.1016/j.corsci.2023.111629 -

下载:

下载: