Analysis of the causes of cracking of closed impeller blades of centrifugal compressor

-

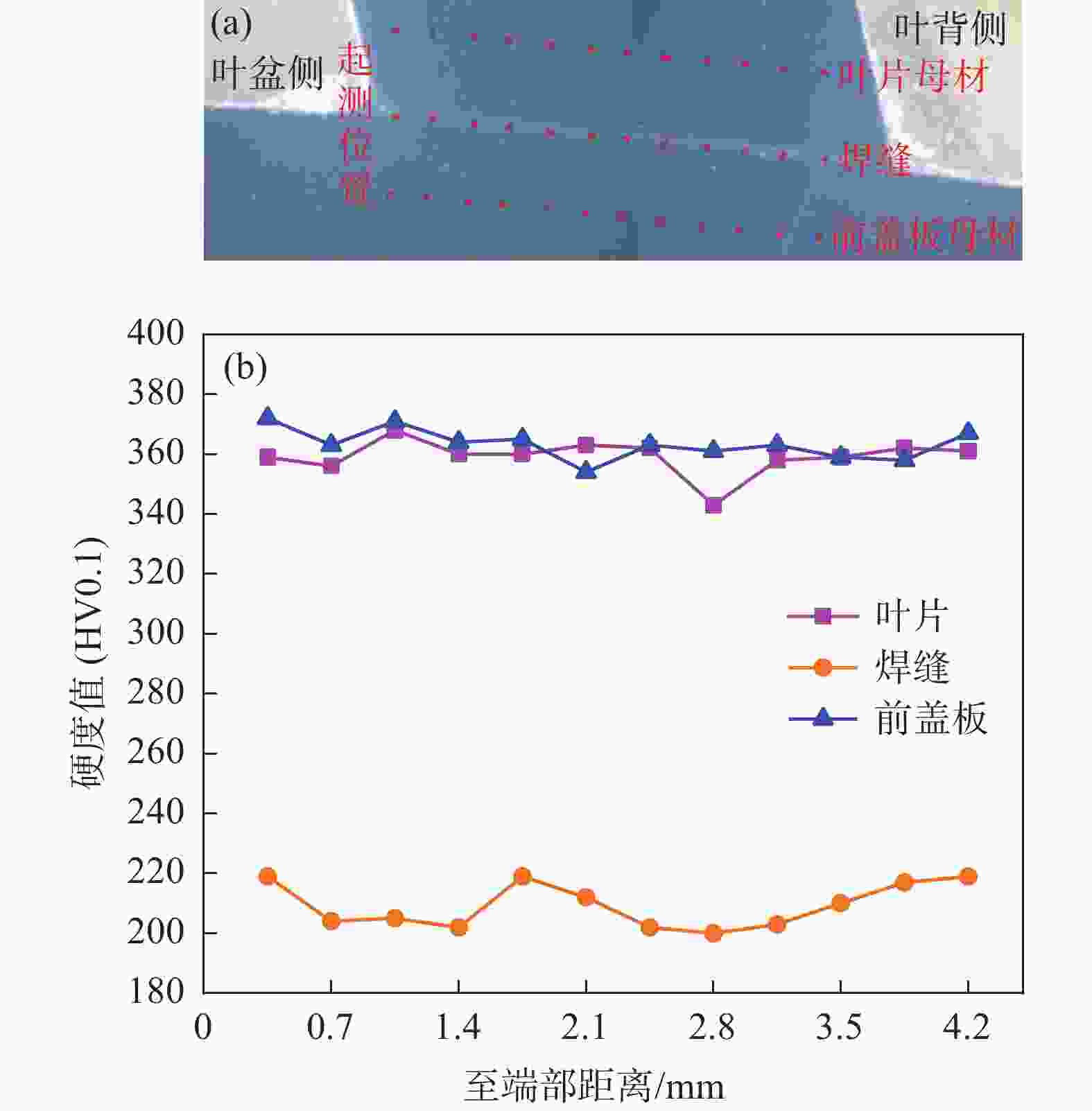

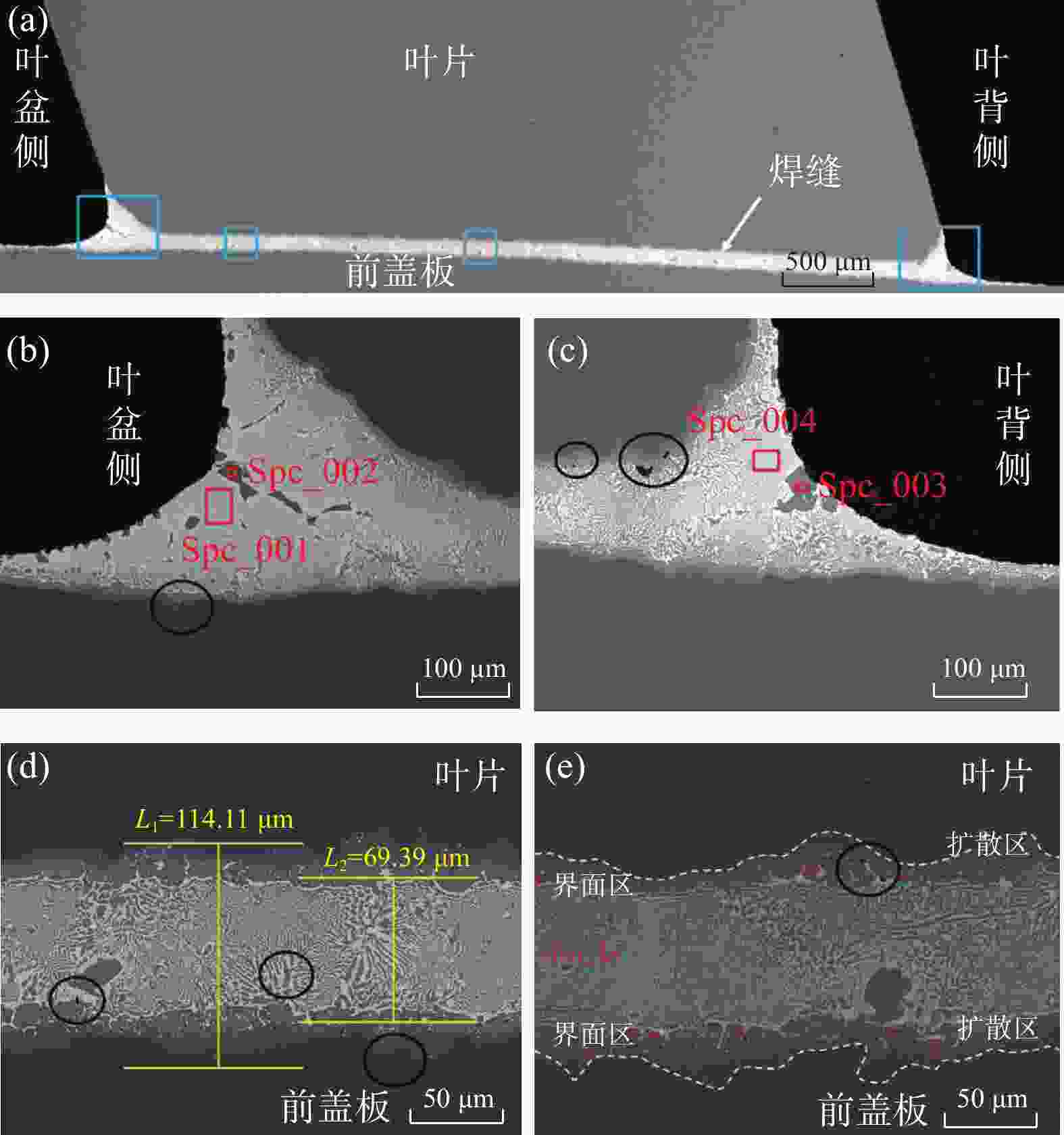

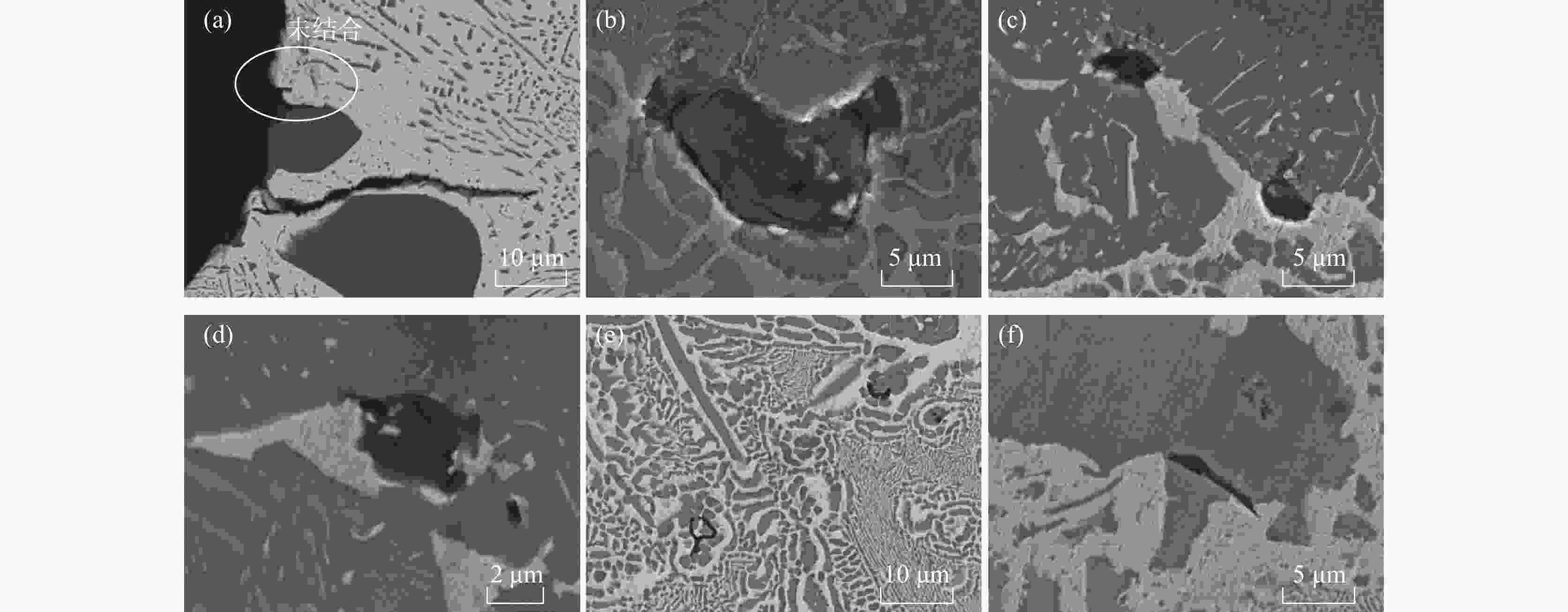

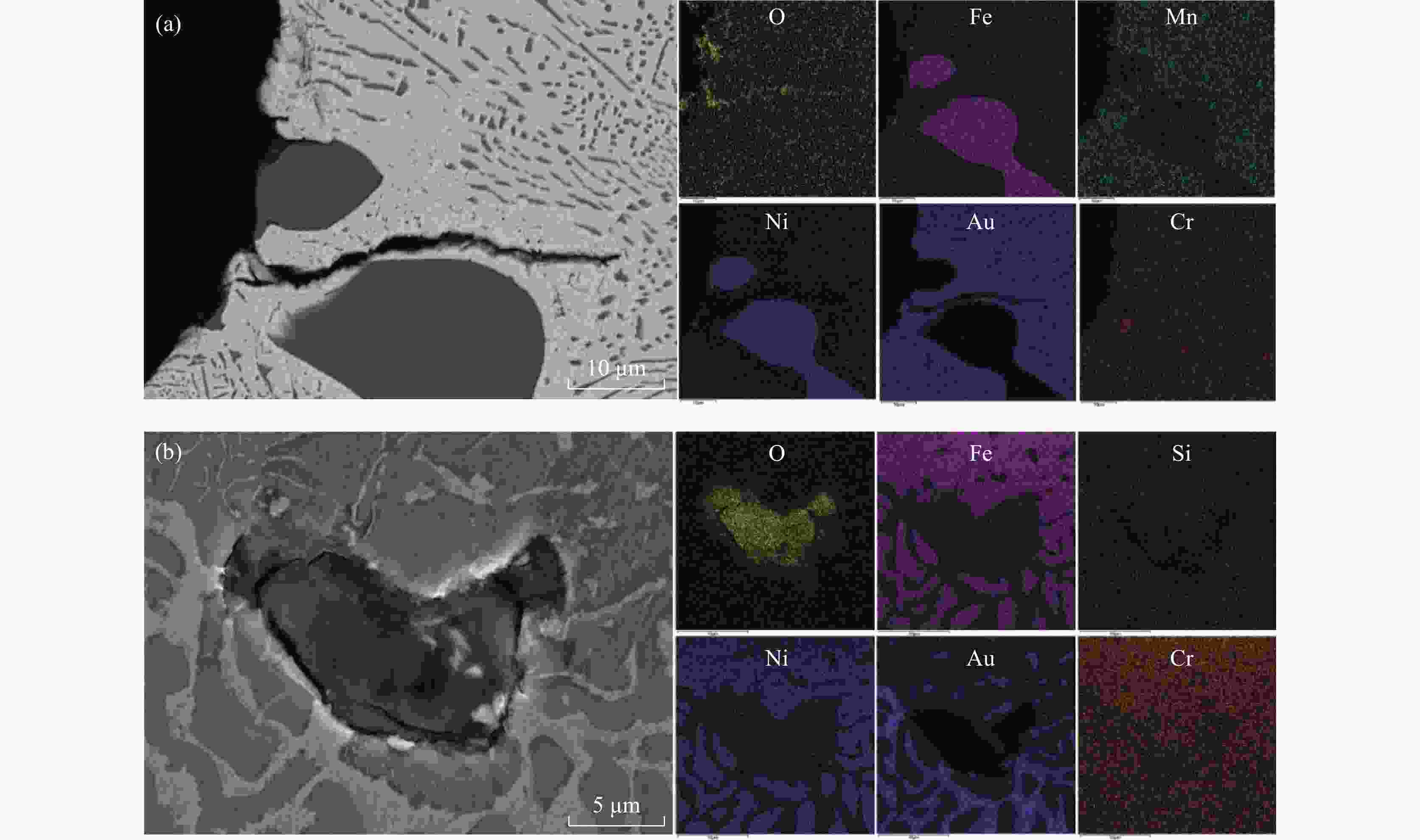

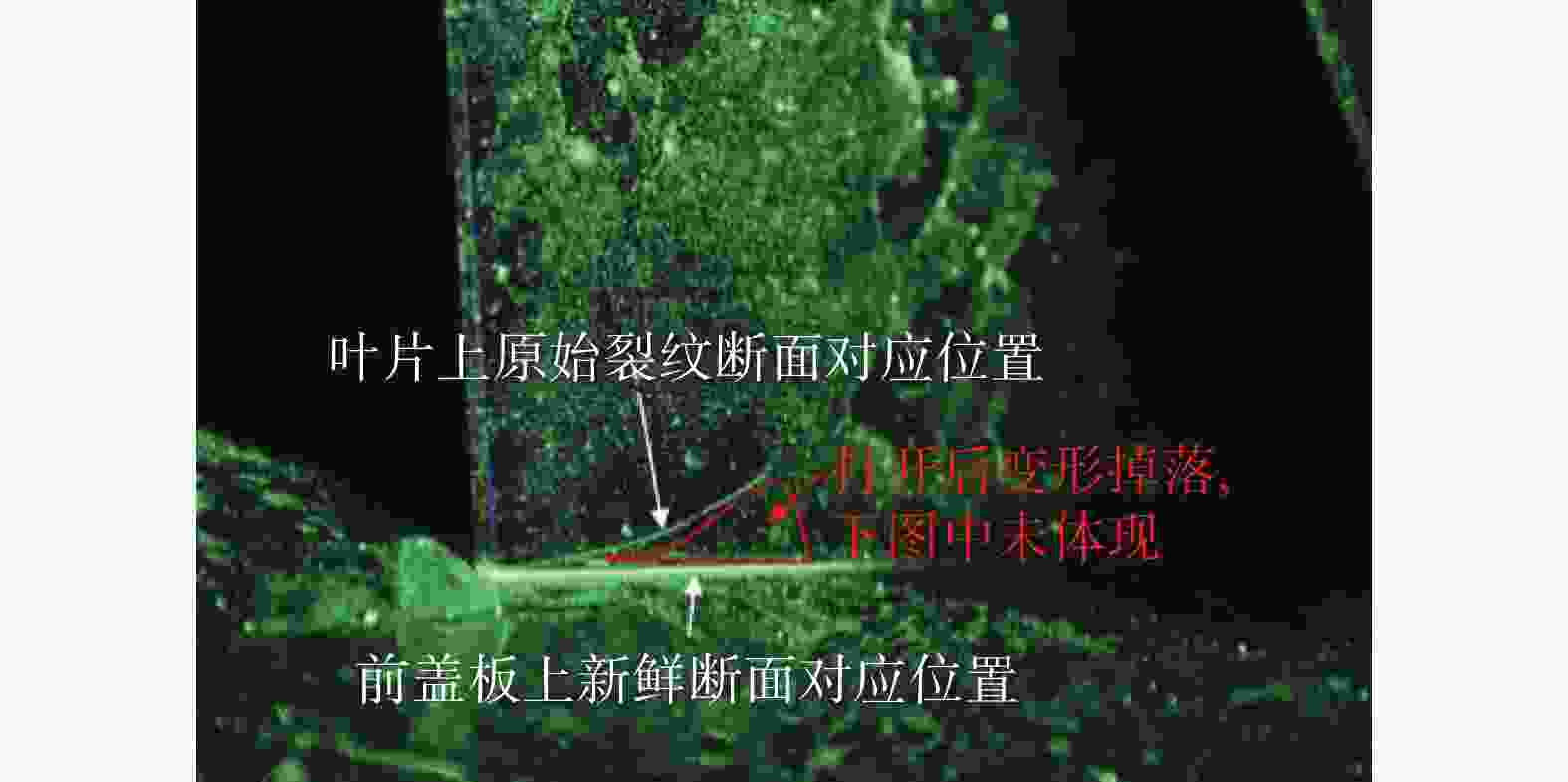

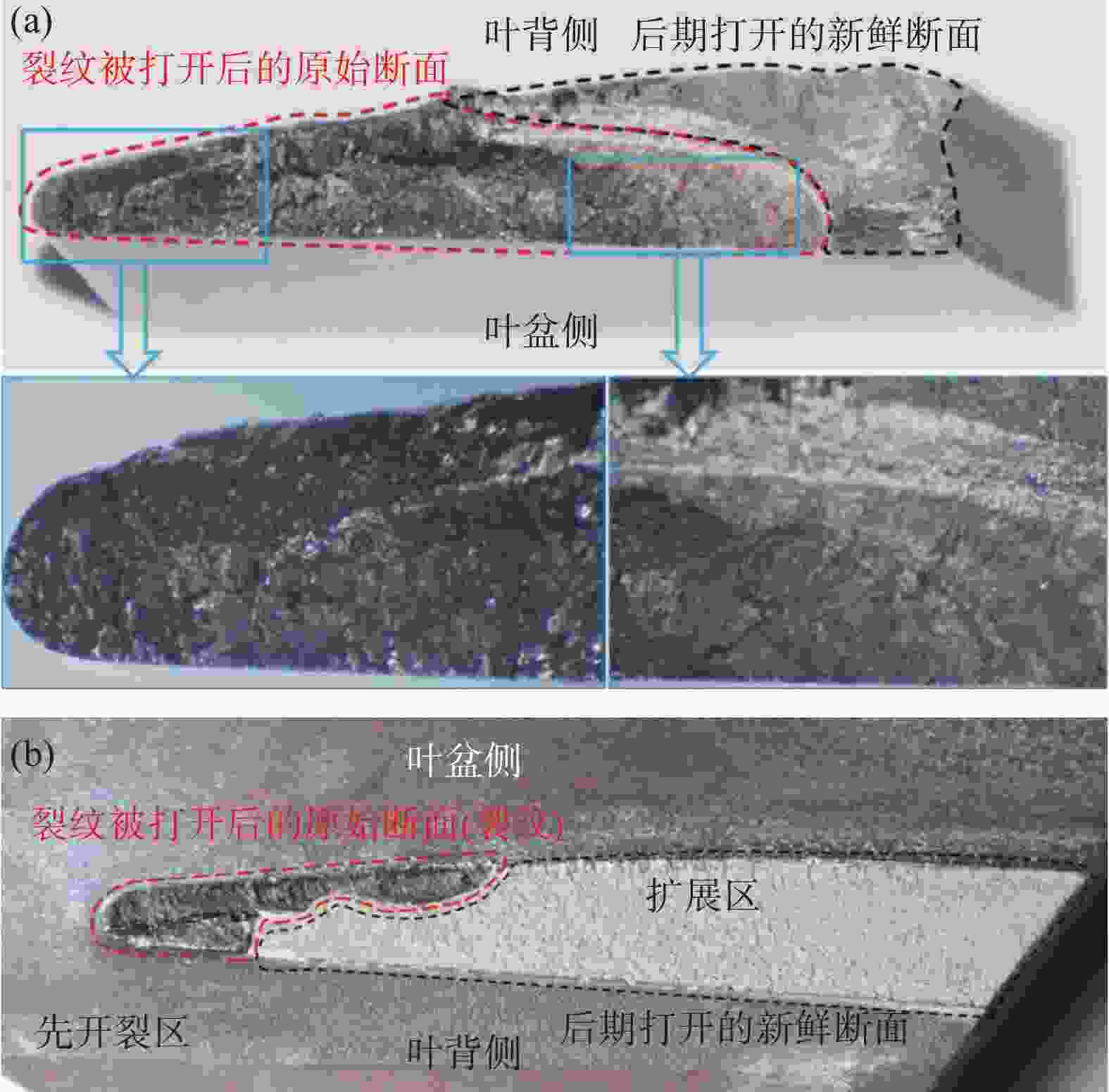

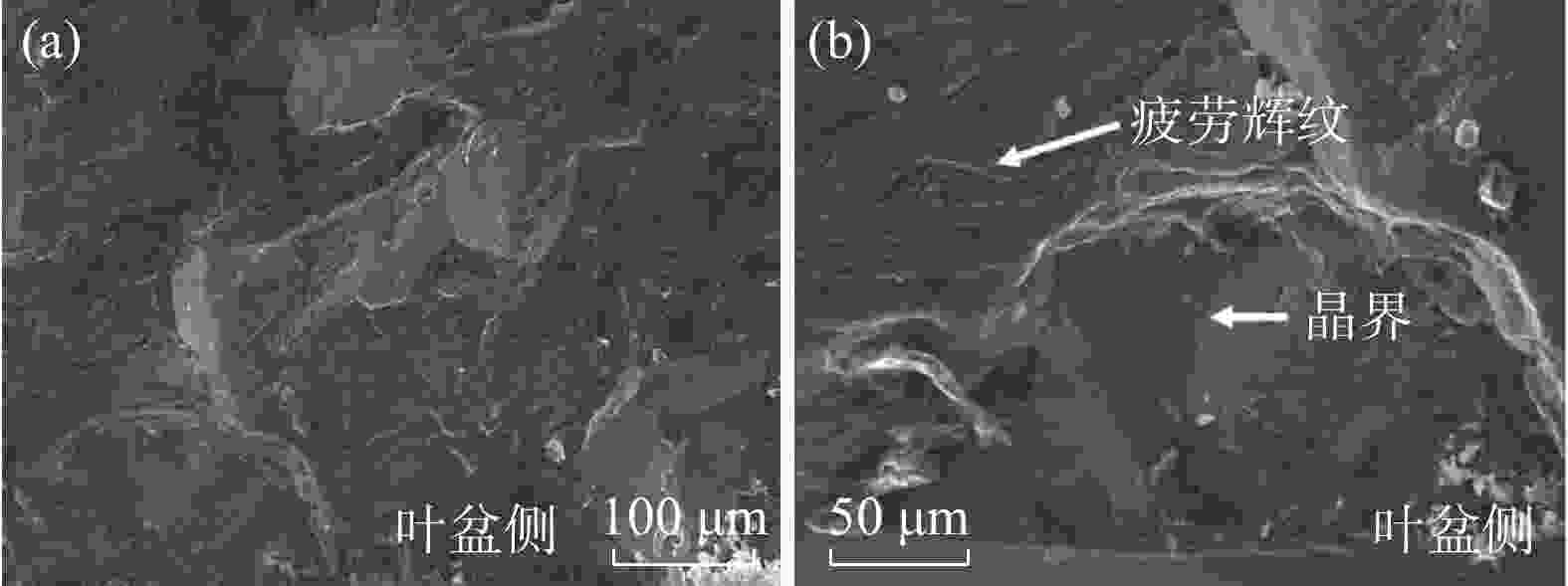

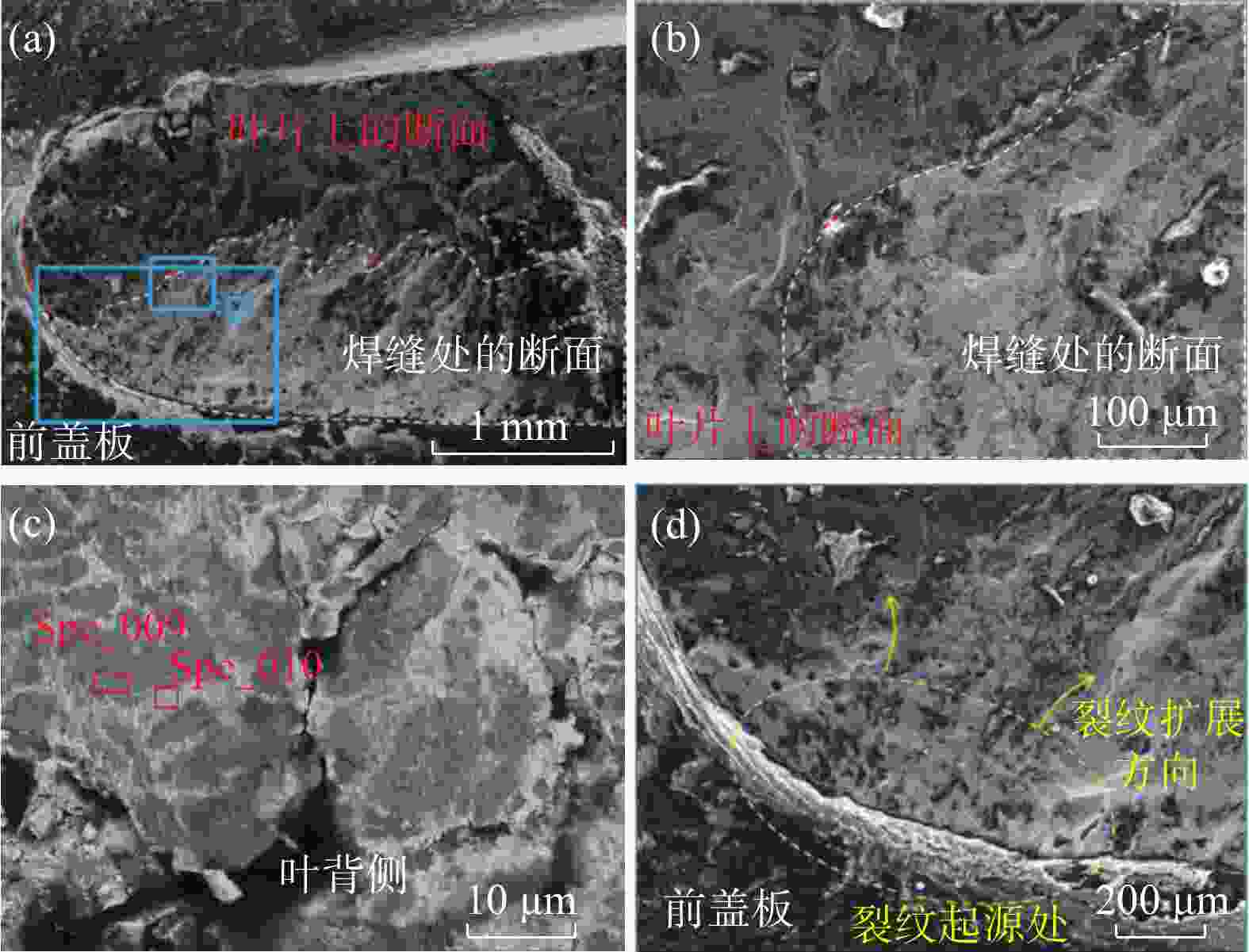

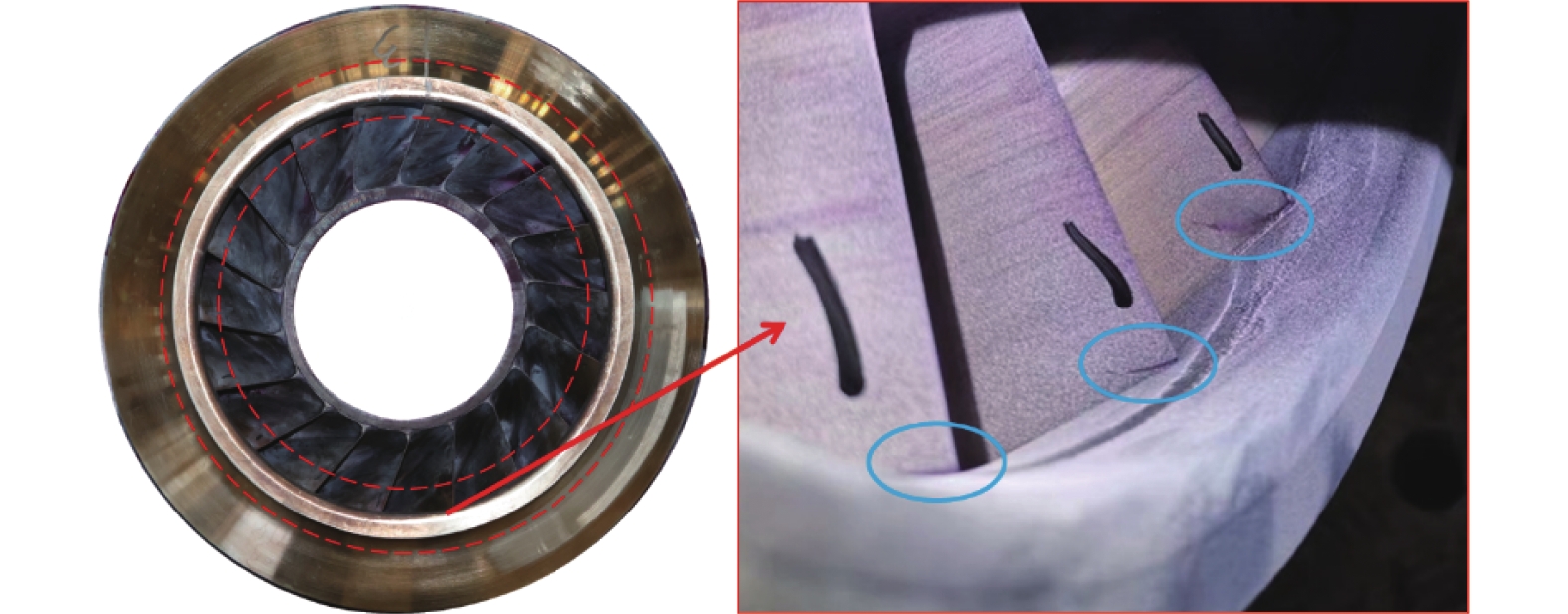

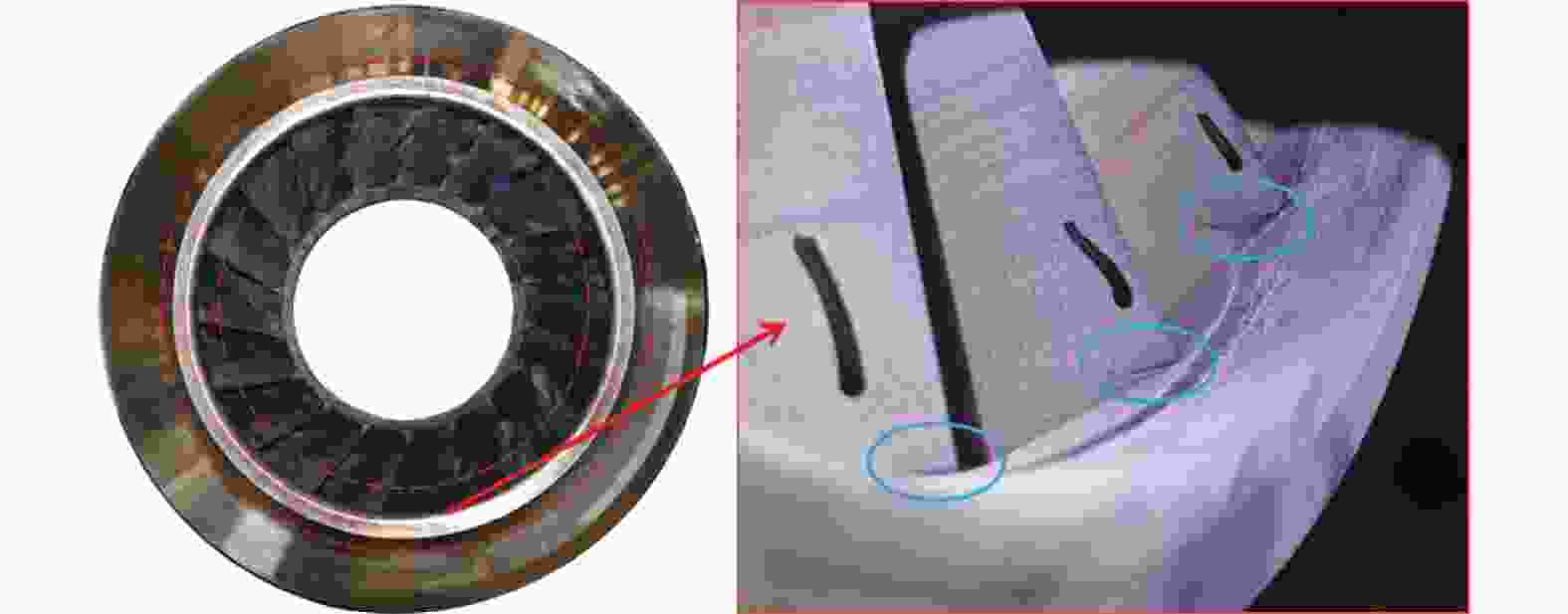

摘要: 某输送天然气所用的离心式压缩机中闭式叶轮在投入生产5年后,对其进行维护保养时发现多处叶片根部产生裂纹。为明确叶片裂纹的产生原因,对失效样品进行化学成分分析、拉伸试验、硬度测试以及金相分析,并选取一处裂纹进行开裂原因分析。结果表明:叶片与前盖板处的钎焊焊缝焊接过程中产生缺陷,叶片焊缝R角位置在运行时于缺陷处生成裂纹,服役时受交变载荷的作用发生疲劳扩展进入叶片,导致叶片发生开裂。因此,针对叶轮制造时的焊接质量以及后续出厂质量验收必须进行严格把控,增加无损检测手段确保产品质量过关,可减少或避免类似情况出现。

-

关键词:

- S41595马氏体型不锈钢 /

- 叶轮叶片 /

- 失效分析 /

- 钎焊

Abstract: After 5 years of production, the closed impeller in a centrifugal compressor used to transport natural gas was found to have cracks in many blade roots during maintenance. In order to clarify the cause of blade cracks, the chemical composition analysis, tensile test, hardness test and metallographic examination of the failed samples were carried out, and one crack was selected for cracking cause analysis. The results showed that defects were generated during the brazing process of the blade and the front cover plate. Cracks were generated at the defect site at the R-angle position of the blade weld during operation, and fatigue propagation occurred into the blade under the action of alternating loads during service, resulting in cracking of the blade. Therefore, the welding quality of the impeller manufacturing and the subsequent factory quality acceptance must be strictly controlled, and non-destructive testing methods must be added to ensure product quality clearance, so as to reduce or avoid this situation.-

Key words:

- S41595 martensitic stainless steel /

- impeller blades /

- failure analysis /

- brazing

-

表 1 叶片和前盖板主要化学成分分析结果

Table 1. Main chemical compositions of the blade and front cover plate

% 分析位置 C Si Mn P S Ni Cr Mo 叶片 0.04 0.53 0.68 0.014 0.004 3.93 12.81 0.58 前盖板 0.04 0.50 0.68 0.017 0.004 4.00 12.84 0.56 GB/T 20878-2007

标准要求≤0.05 ≤0.60 0.50~1.00 ≤0.03 ≤0.03 3.50~5.50 11.50~14.00 0.50~1.00 表 2 拉伸试验结果

Table 2. Tensile test results

Rm/MPa Rp0.2/MPa A/% Z/% 1053 967 20.3 72 表 3 EDS分析结果

Table 3. EDS analysis results

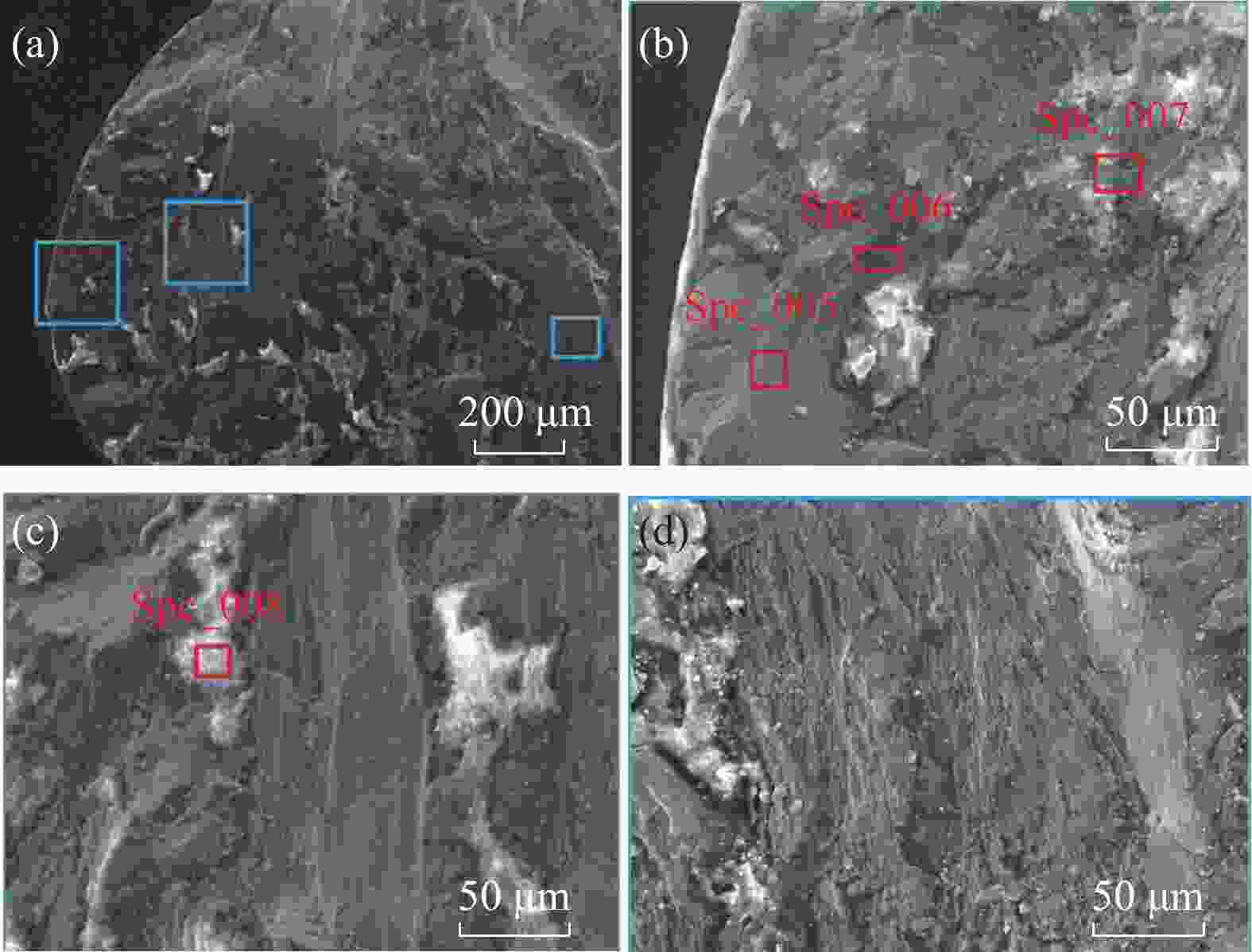

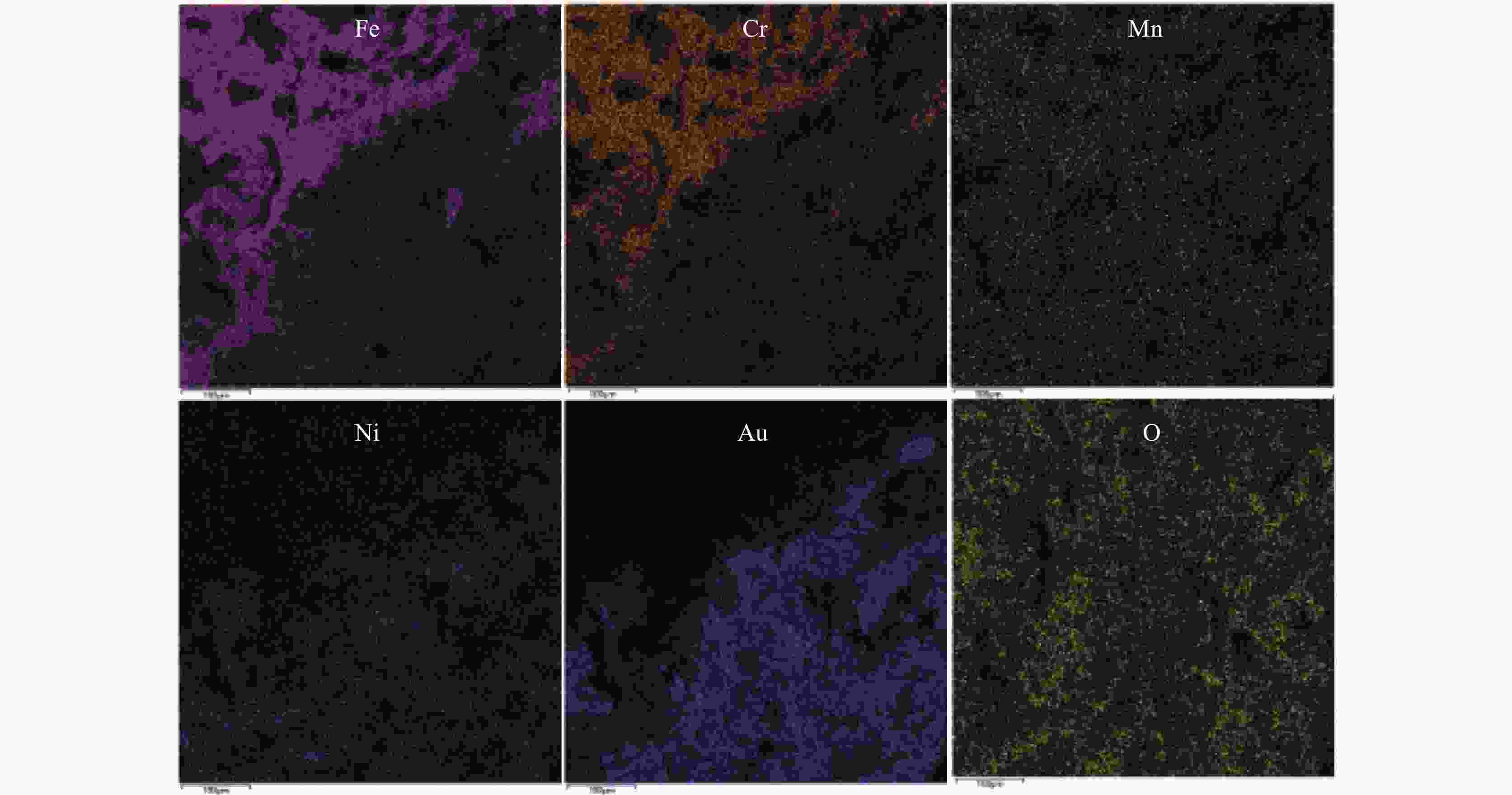

% 分析位置 C O Si Cr Mn Fe Ni Au Spc_001 6.46 1.98 1.88 1.42 7.30 7.77 73.19 Spc_002 4.92 2.75 29.17 52.61 10.55 Spc_003 6.99 1.77 3.57 29.04 44.64 14.01 Spc_004 6.17 1.85 2.00 1.10 10.52 10.01 68.35 表 4 EDS分析结果

Table 4. EDS analysis results

% 分析位置 C O Na Si S Cl K Ti Cr Mn Fe Ni Spc_005 6.39 1.87 0.41 0.58 0.83 12.20 0.69 73.76 3.27 Spc_006 31.08 8.70 0.99 1.30 8.83 0.35 1.00 0.35 6.18 0.44 38.38 1.97 Spc_007 20.30 8.90 1.30 4.25 11.05 0.32 1.34 0.87 4.24 0.63 43.68 2.38 Spc_008 33.33 19.92 2.98 1.61 9.09 3.74 4.91 0.60 1.78 0.35 19.03 1.67 表 5 EDS分析结果

Table 5. EDS analysis results

% 分析位置 C O Cr Mn Fe Ni Au Spc_009 4.56 1.35 3.81 36.48 32.14 21.67 Spc_010 6.02 2.22 2.43 0.57 11.62 8.62 68.52 -

[1] GUO S H. Causes and treatment measures of impeller cracking of circulating hydrogen compressor[J]. Henan Chemical Industry, 2022, 39(4): 33-35. (郭韶华. 循环氢压缩机叶轮开裂原因及处理措施[J]. 河南化工, 2022, 39(4): 33-35. doi: 10.3969/j.issn.1003-3467.2022.4.hnhg202204010GUO S H. Causes and treatment measures of impeller cracking of circulating hydrogen compressor[J]. Henan Chemical Industry, 2022, 39(4): 33-35. doi: 10.3969/j.issn.1003-3467.2022.4.hnhg202204010 [2] SUN J. Study on stress corrosion cracking behavior and mechanism of impeller in centrifugal compressor[D]. Jinan: Shandong University, 2016. (孙蛟. 离心压缩机叶轮应力腐蚀行为和机理的研究[D]. 济南: 山东大学, 2016.SUN J. Study on stress corrosion cracking behavior and mechanism of impeller in centrifugal compressor[D]. Jinan: Shandong University, 2016. [3] MAO P C. Failure analysis of centrifugal compressor impeller[D]. Dalian: Dalian University of Technology, 2016. (毛鹏程. 离心压缩机叶轮断裂失效分析[D]. 大连: 大连理工大学, 2016.MAO P C. Failure analysis of centrifugal compressor impeller[D]. Dalian: Dalian University of Technology, 2016. [4] KLAUS B. On the manufacture of impellers for turbo compressors[R]. turbomachinery and Pump Symposia, 1986: 9-12. [5] WITEK L. Experimental crack propagation and failure analysis of the first stage compressor blade subjected to vibration[J]. Engineering Failure Analysis, 2009, 16(7): 2163-2217. doi: 10.1016/j.engfailanal.2009.02.014 [6] LIU M X, ZHANG H C, LI D L, et al. Analysis of the cause of impeller fracture and failure of a centrifugal compressor[J]. Chinese Journal of Turbomachinery, 2013, 55(5): 80-83. (刘明霞, 张海存, 李德林, 等. 某离心压缩机叶轮断裂失效原因分析[J]. 风机技术, 2013, 55(5): 80-83. doi: 10.3969/j.issn.1006-8155.2013.05.013LIU M X, ZHANG H C, LI D L, et al. Analysis of the cause of impeller fracture and failure of a centrifugal compressor[J]. Chinese Journal of Turbomachinery, 2013, 55(5): 80-83. doi: 10.3969/j.issn.1006-8155.2013.05.013 [7] SONG H B, FEI D, CAO S F, et al. Repair technology for cracking cracks in brazed impellers of centrifugal compressors[J]. Plant Maintenance Engineering, 2015(12): 28-30. (宋慧斌, 费德, 曹尚峰, 等. 离心式压缩机钎焊叶轮钎缝开裂的修复技术[J]. 设备管理与维修, 2015(12): 28-30.SONG H B, FEI D, CAO S F, et al. Repair technology for cracking cracks in brazed impellers of centrifugal compressors[J]. Plant Maintenance Engineering, 2015(12): 28-30. [8] CHEN R, LIU X L, CAI X X, et al. Reason analysis on cracks in centrifugal wheel blade[J]. Physical Testing and Chemical Analysis(Part A: Physical Testing), 2011, 47(1): 60-63. (陈睿, 刘新灵, 蔡显新, 等. 离心叶轮叶片裂纹产生原因分析[J]. 理化检验(物理分册), 2011, 47(1): 60-63.CHEN R, LIU X L, CAI X X, et al. Reason analysis on cracks in centrifugal wheel blade[J]. Physical Testing and Chemical Analysis(Part A: Physical Testing), 2011, 47(1): 60-63. [9] LI P C, LU Q S, WANG K, et al. Brazing process, microstructure and properties of SUS444/SUS304 joints based on Fe-Cr-Ni based brazing filler metal[J]. Welding & Joining, 2023(12): 23-31. (李朋成, 陆青松, 王凯, 等. 基于Fe-Cr-Ni基钎料的SUS444/SUS304接头钎焊工艺及组织与性能[J]. 焊接, 2023(12): 23-31. doi: 10.12073/j.hj.20221123002LI P C, LU Q S, WANG K, et al. Brazing process, microstructure and properties of SUS444/SUS304 joints based on Fe-Cr-Ni based brazing filler metal[J]. Welding & Joining, 2023(12): 23-31. doi: 10.12073/j.hj.20221123002 [10] MENG D M. The techniques of a kind of narrow impeller with curvilinear vane[D]. Shenyang: Northeastern University, 2008. (孟冬梅. 带曲率叶片窄流道叶轮真空钎焊制造工艺技术的研究[D]. 沈阳: 东北大学, 2008.MENG D M. The techniques of a kind of narrow impeller with curvilinear vane[D]. Shenyang: Northeastern University, 2008. [11] XU C, YANG F, SONG Y, et al. Effects of brazing temperature on microstructure and properties of brazed joints of 304 stainless steel[J]. Hot Working Technology, 2016, 45(1): 238-240. (徐创, 杨峰, 宋阳, 等. 钎焊温度对304不锈钢焊缝组织和性能影响[J]. 热加工工艺, 2016, 45(1): 238-240.XU C, YANG F, SONG Y, et al. Effects of brazing temperature on microstructure and properties of brazed joints of 304 stainless steel[J]. Hot Working Technology, 2016, 45(1): 238-240. [12] LIU Y. Influence of heat treatment on microstructure and shear strength of vacuum brazed joints of 6061 aluminum alloy[J]. Hot Working Technology, 2013, 42(19): 209-211,214. (刘勇. 热处理对6061铝合金真空钎焊焊缝组织与性能的影响[J]. 热加工工艺, 2013, 42(19): 209-211,214.LIU Y. Influence of heat treatment on microstructure and shear strength of vacuum brazed joints of 6061 aluminum alloy[J]. Hot Working Technology, 2013, 42(19): 209-211,214. [13] XIE G J, WANG Y, HAN L. Failure analysis of cracked alloy/stainless brazing seam in flange[J]. Aerospace Materials & Technology, 2017, 47(6): 79-82. (谢国君, 王影, 韩露. 铝/钢法兰钎焊焊缝开裂失效分析[J]. 宇航材料工艺, 2017, 47(6): 79-82. doi: 10.12044/j.issn.1007-2330.2017.06.016XIE G J, WANG Y, HAN L. Failure analysis of cracked alloy/stainless brazing seam in flange[J]. Aerospace Materials & Technology, 2017, 47(6): 79-82. doi: 10.12044/j.issn.1007-2330.2017.06.016 [14] LIU H, LI W, ZHANG S H. Technology of merging brazing and heat-treating into one in vacuum for martensitic stainless steel[J]. Journal of Shenyang Institute of Technology, 1999(2): 39-43. (刘红, 李文, 张世航. 马氏体不锈钢真空钎焊与真空热处理一体化工艺[J]. 沈阳工业学院学报, 1999(2): 39-43.LIU H, LI W, ZHANG S H. Technology of merging brazing and heat-treating into one in vacuum for martensitic stainless steel[J]. Journal of Shenyang Institute of Technology, 1999(2): 39-43. [15] ZHANG Q K, ZHONG S J, ZHANG L, et al. Investigation on interfacial reaction behavior of brazed joint of austenitic stainless steel/Cu filler metal[J]. Transactions of the China Welding Institution, 2017, 38(3): 75-78,132. (张青科, 钟素娟, 张雷, 等. 奥氏体不锈钢-铜钎料钎焊界面反应行为分析[J]. 焊接学报, 2017, 38(3): 75-78,132.ZHANG Q K, ZHONG S J, ZHANG L, et al. Investigation on interfacial reaction behavior of brazed joint of austenitic stainless steel/Cu filler metal[J]. Transactions of the China Welding Institution, 2017, 38(3): 75-78,132. [16] ZHANG Q K, PEI Y Y, LONG W M, Investigation on formation mechanisms of brazing cracks at the austenitic stainless steel/filler metal brazing joint interfaces[J]. Acta Metallurgica Sinica, 2013, 49(10): 1177-1184. (张青科, 裴夤崟, 龙伟民. 奥氏体不锈钢钎焊界面裂纹形成机制研究[J]. 金属学报, 2013, 49(10): 1177-1184.ZHANG Q K, PEI Y Y, LONG W M, Investigation on formation mechanisms of brazing cracks at the austenitic stainless steel/filler metal brazing joint interfaces[J]. Acta Metallurgica Sinica, 2013, 49(10): 1177-1184. [17] ZHAO F, CHEN Z S, GAO F, et al. Effect of brazing holding time on microstructure and properties of aluminium radiator vacuum brazing joint[J]. Modern Machinery, 2011(5): 75-77. (赵飞, 陈召松, 高飞, 等. 钎焊保温时间对铝合金散热器真空钎焊焊缝组织和性能的影响[J]. 现代机械, 2011(5): 75-77. doi: 10.3969/j.issn.1002-6886.2011.05.028ZHAO F, CHEN Z S, GAO F, et al. Effect of brazing holding time on microstructure and properties of aluminium radiator vacuum brazing joint[J]. Modern Machinery, 2011(5): 75-77. doi: 10.3969/j.issn.1002-6886.2011.05.028 [18] LIU H Y, LING Z M, SHAN Q C. Effect of soldering temperature on microstructure and properties of AA4045/AA3003 composite layer soldering seam[J]. Hot Working Technology[J], 2010, 39(5): 134-136,140. (刘怀玉, 凌泽民, 单庆成. 钎焊温度对AA4045/AA3003复合层焊缝组织及性能的影响[J]. 热加工工艺, 2010, 39(5): 134-136,140. doi: 10.3969/j.issn.1001-3814.2010.05.042LIU H Y, LING Z M, SHAN Q C. Effect of soldering temperature on microstructure and properties of AA4045/AA3003 composite layer soldering seam[J]. Hot Working Technology[J], 2010, 39(5): 134-136,140. doi: 10.3969/j.issn.1001-3814.2010.05.042 [19] HE F Y. Engine centrifugal impeller fatigue fracture research of split blade[D]. Shanghai: Shanghai Jiao Tong University, 2017. (何风云.发动机离心叶轮分流叶片疲劳断裂研究[D].上海: 上海交通大学, 2017.HE F Y. Engine centrifugal impeller fatigue fracture research of split blade[D]. Shanghai: Shanghai Jiao Tong University, 2017. -

下载:

下载: