Research on the prediction model of hot metal temperature in vanadium-titanium magnetite blast furnace based on deep learning

-

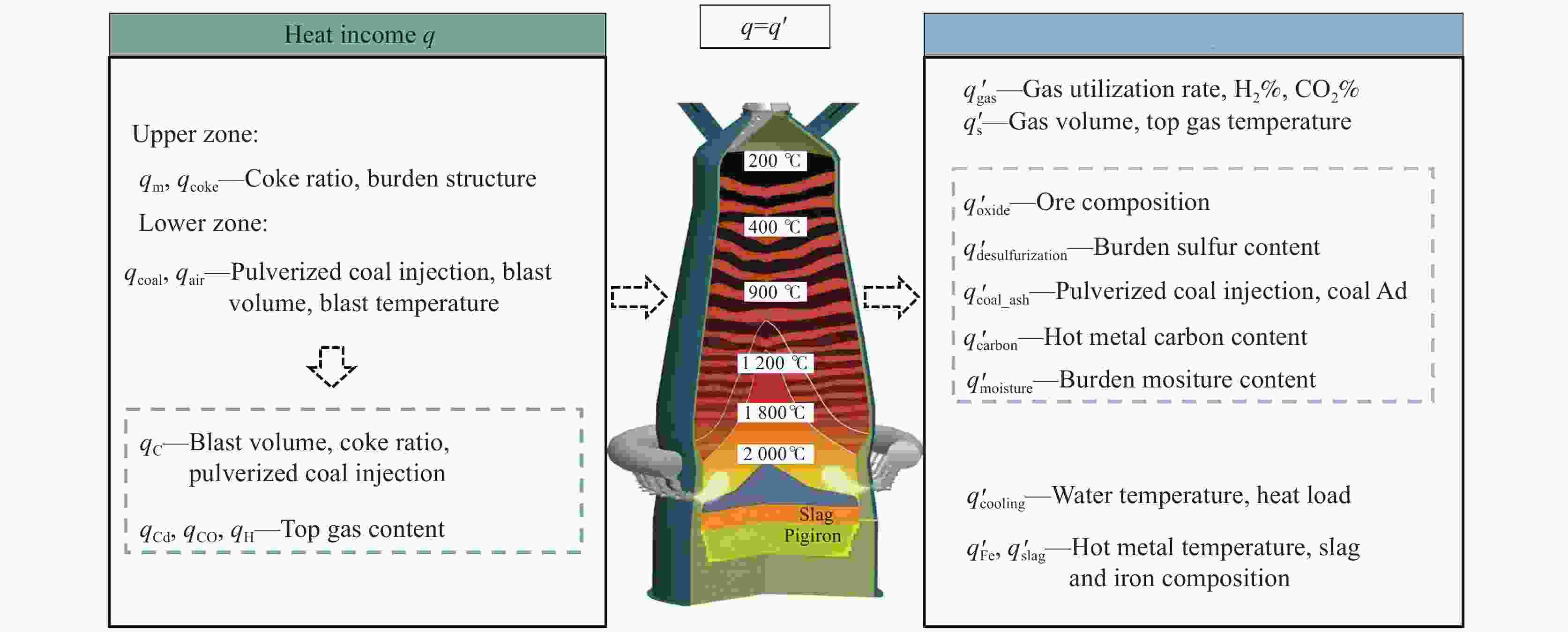

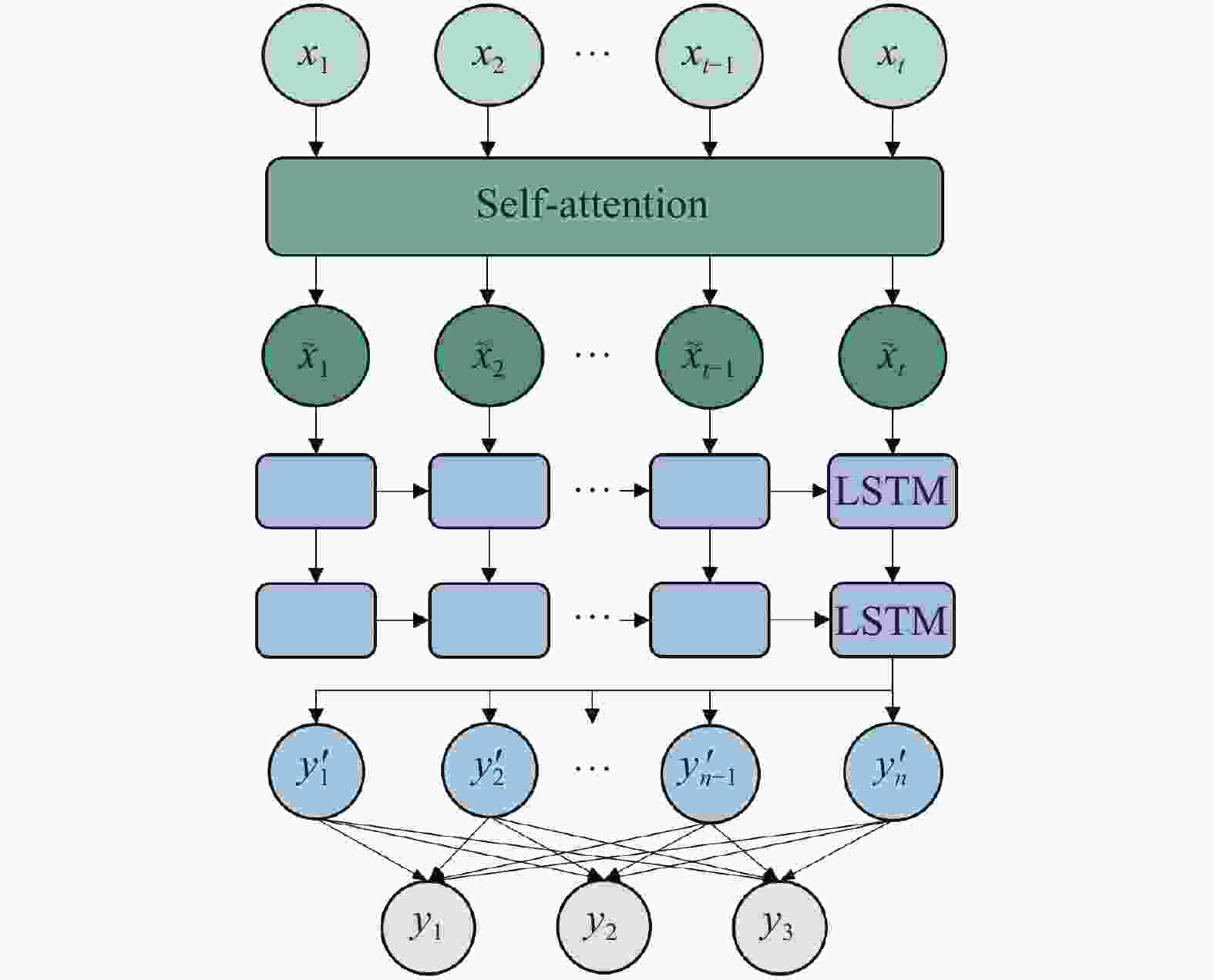

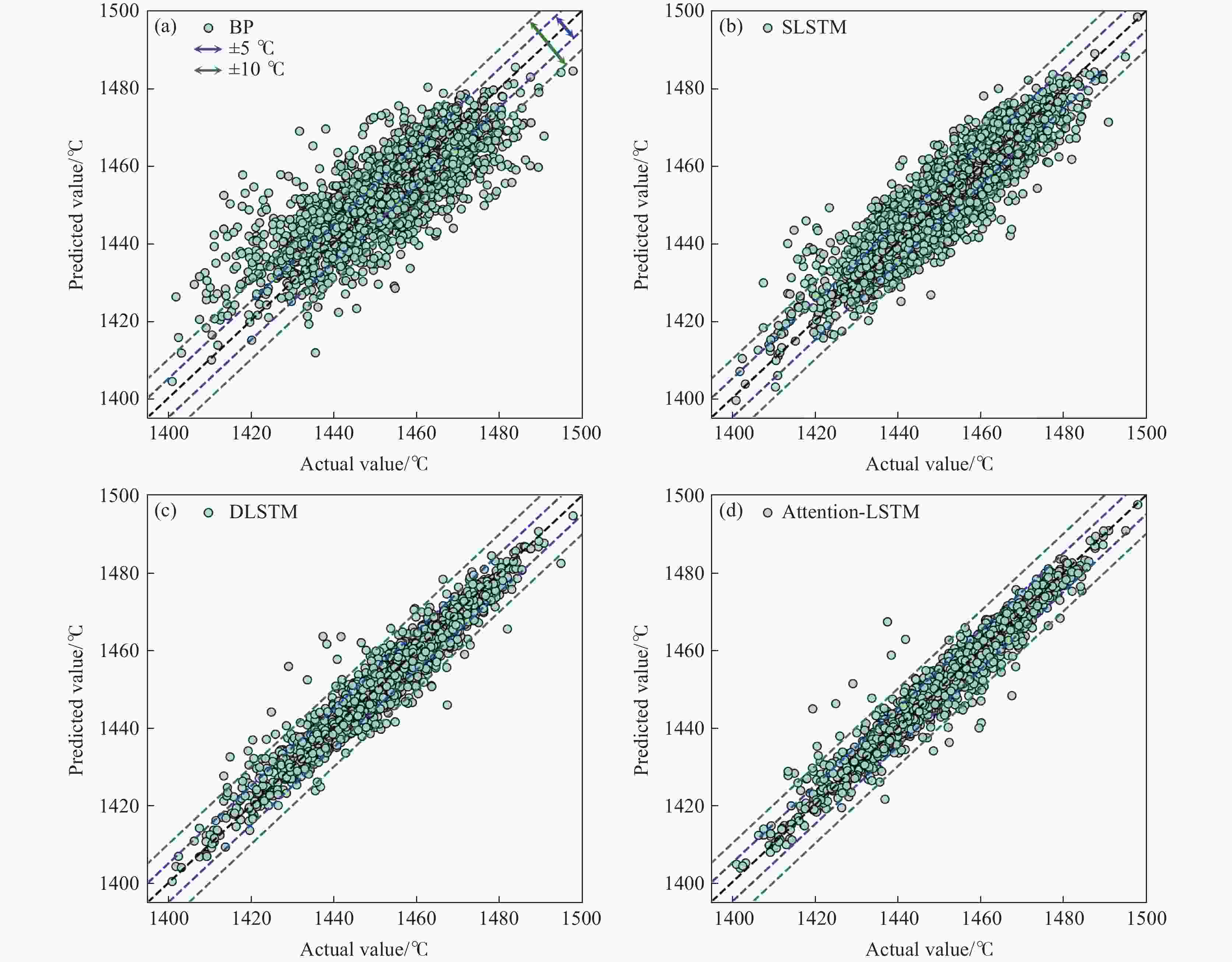

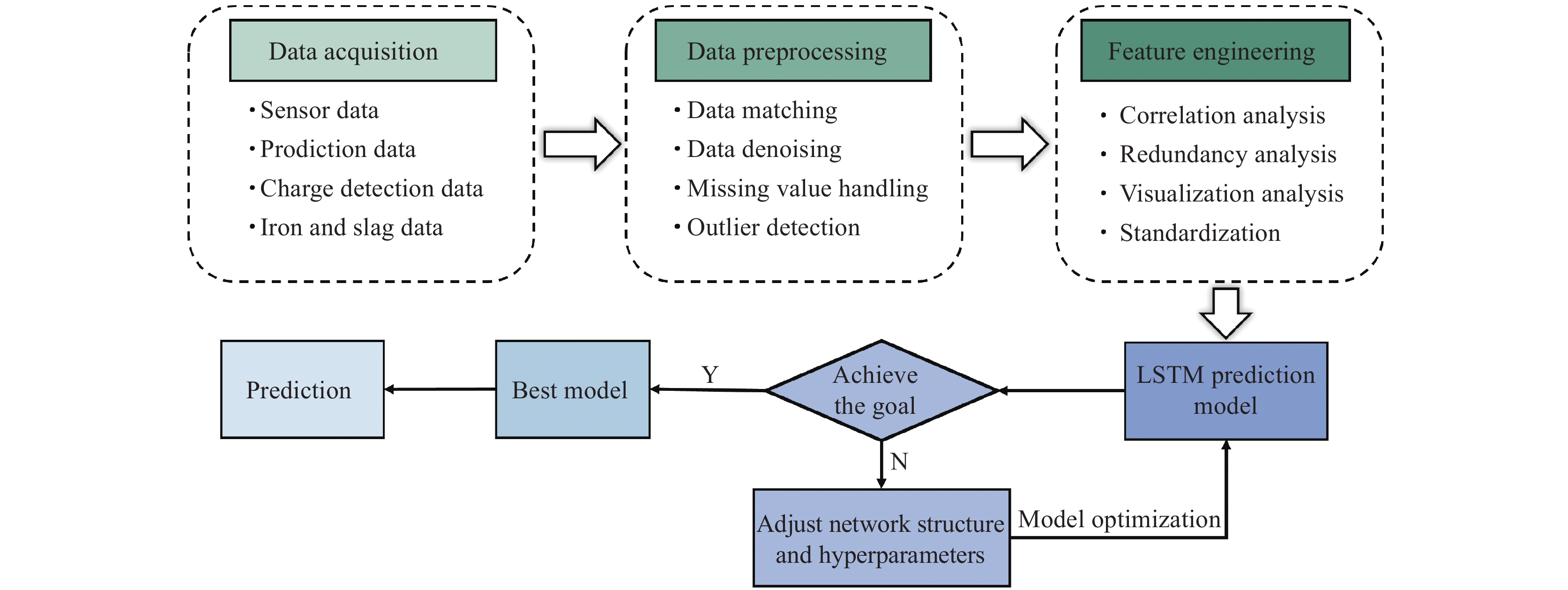

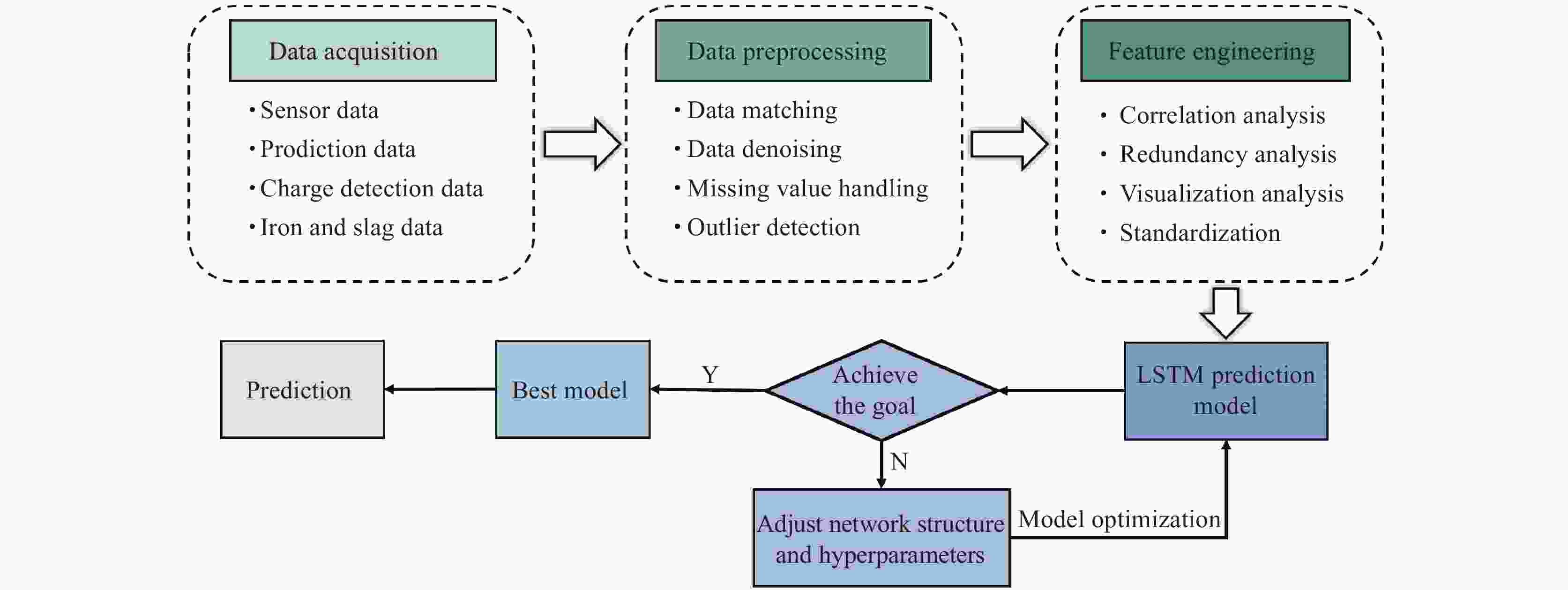

摘要: 准确及时地掌握铁水温度对保证钒钛磁铁矿高炉冶炼平稳顺行和提高铁水质量十分重要。基于长期生产现场数据,融合领域知识和数据驱动方法,构建了基于注意力机制和LSTM的铁水温度预测模型。首先,结合冶炼经验、规则与数据分析技术构建钒钛磁铁矿高炉冶炼过程特征矩阵,并通过降维技术将特征维度减少至28维,降低了预测复杂度。其次,将不同时间窗口的历史操作数据作为输入,构建基于LSTM架构的多时间步预测模型,并引入深度学习中的注意力机制提升关键特征的权重,以提高预测精度。结果表明,该模型在命中率(±5 ℃)达到92.5%,初步实现了钒钛磁铁矿高炉铁水温度高精度预测,为高炉炉况判断和操作优化提供了重要参考。Abstract: Accurate and timely prediction of hot metal temperature (HMT) is crucial for ensuring stable operation and improving hot metal quality in vanadium-titanium magnetite blast furnaces. Leveraging long-term field data, an HMT prediction model was developed for blast furnaces by integrating domain knowledge with data-driven strategies and combining an attention mechanism with long short-term memory neural networks (LSTM). Firstly, a feature matrix of the vanadium-titanium magnetite blast furnace smelting process was constructed by integrating smelting experience, rules, and data analysis techniques. Dimensionality reduction techniques were applied to reduce the feature dimension to 28, effectively reducing the prediction complexity. Secondly, we constructed a multi-time-step prediction model based on the LSTM architecture, using historical operation data from different time windows as inputs. By introducing an attention mechanism from deep learning to capture the importance of input features, the model's prediction accuracy was further improved. The results show that the model achieved a hit rate of 92.5% within a ±5 ℃ error range, realizing high-precision online prediction of hot metal temperatures in vanadium-titanium magnetite blast furnaces. This model provides an important reference for condition judgment and operation evaluation of blast furnaces.

-

图 6 LSTM神经网络结构[25]

Figure 6. LSTM neural network architecture

表 1 Attention-LSTM模型主要参数设置

Table 1. Main parameter settings of Attention-LSTM

Parameter Setting range Time window 1 ~ 30 LSTM layers 2 Neurons per layers 64 Self-Attention layers 1 Input parameter numbers 28 Output parameter numbers 1 ~ 3 Learning rate 0.001 Batch size 32 Iterations 500 表 2 不同模型性能结果对比

Table 2. Comparison of performance results of different models

Model R2 RMSE/℃ H/% ±5 ℃ ±10 ℃ BP 0.634 8.343 50.316 80.702 SLSTM 0.821 5.824 66.211 91.614 DLSTM 0.936 3.485 88.702 98.421 Attention-LSTM 0.948 3.146 92.526 98.842 -

[1] BAI C G, LÜ X W, QIU G B, et al. Research progress on high efficiency metallurgy and clean extraction of vanadium-titanium magnetite ore in Panxi area[J]. The Chinese Journal of Process Engineering, 2022, 22(10): 1390-1399. (白晨光, 吕学伟, 邱贵宝, 等. 攀西钒钛磁铁矿资源高效冶金及清洁提取研究进展[J]. 过程工程学报, 2022, 22(10): 1390-1399. doi: 10.12034/j.issn.1009-606X.222302BAI C G, LÜ X W, QIU G B, et al. Research progress on high efficiency metallurgy and clean extraction of vanadium-titanium magnetite ore in Panxi area[J]. The Chinese Journal of Process Engineering, 2022, 22(10): 1390-1399. doi: 10.12034/j.issn.1009-606X.222302 [2] ZHENG K, WANG W, GAN X, et al. Research on theoretical combustion temperature control of V-Ti magnetite blast furnace smelting[J]. Iron Steel Vanadium Titanium, 2024, 45(5): 130-138. (郑魁, 王炜, 干显, 等. 钒钛磁铁矿高炉冶炼理论燃烧温度控制研究[J]. 钢铁钒钛, 2024, 45(5): 130-138.ZHENG K, WANG W, GAN X, et al. Research on theoretical combustion temperature control of V-Ti magnetite blast furnace smelting[J]. Iron Steel Vanadium Titanium, 2024, 45(5): 130-138. [3] HE Y Y, LIU Q C, YANG J, et al. Experimental investigation on fluidity of hot metal bearing titanium[J]. Iron Steel Vanadium Titanium, 2010, 31(2): 10-14. (贺媛媛, 刘清才, 杨剑, 等. 含钛铁水流动性能研究[J]. 钢铁钒钛, 2010, 31(2): 10-14.HE Y Y, LIU Q C, YANG J, et al. Experimental investigation on fluidity of hot metal bearing titanium[J]. Iron Steel Vanadium Titanium, 2010, 31(2): 10-14. [4] HOU P, YU W Z, BAI C G, et al. Viscous flow properties and influencing factors of vanadium-titanium magnetite smelting iron[J]. lron and Steel, 2022, 57(1): 57-65. (侯飘, 余文轴, 白晨光, 等. 钒钛磁铁矿冶炼铁水的黏流性能及其影响因素[J]. 钢铁, 2022, 57(1): 57-65.HOU P, YU W Z, BAI C G, et al. Viscous flow properties and influencing factors of vanadium-titanium magnetite smelting iron[J]. lron and Steel, 2022, 57(1): 57-65. [5] PAN D, JIANG Z H, XU C, et al. Research progress of measurement methods of molten iron temperature in blast furnace[J]. Chinese Journal of Scientific Instrument, 2023, 44(12): 280-296. (潘冬, 蒋朝辉, 许川, 等. 高炉铁水温度检测方法的研究进展[J]. 仪器仪表学报, 2023, 44(12): 280-296.PAN D, JIANG Z H, XU C, et al. Research progress of measurement methods of molten iron temperature in blast furnace[J]. Chinese Journal of Scientific Instrument, 2023, 44(12): 280-296. [6] CHU M S, WANG H T, LIU Z G, et al. Research progress on mathematical modeling of blast furnace ironmaking process[J]. Iron and Steel, 2014, 49(11): 1-8. (储满生, 王宏涛, 柳政根, 等. 高炉炼铁过程数学模拟的研究进展[J]. 钢铁, 2014, 49(11): 1-8.CHU M S, WANG H T, LIU Z G, et al. Research progress on mathematical modeling of blast furnace ironmaking process[J]. Iron and Steel, 2014, 49(11): 1-8. [7] ZUO H B, ZHANG J L, YANG T J. Research and application on heat transfer model of hearth including phase-change heat transfer[J]. The Chinese Journal of Process Engineering, 2008(S1): 123-129. (左海滨, 张建良, 杨天钧. 考虑相变传热的炉缸传热模型的研究与应用[J]. 过程工程学报, 2008(S1): 123-129. doi: 10.3321/j.issn:1009-606X.2008.z1.027ZUO H B, ZHANG J L, YANG T J. Research and application on heat transfer model of hearth including phase-change heat transfer[J]. The Chinese Journal of Process Engineering, 2008(S1): 123-129. doi: 10.3321/j.issn:1009-606X.2008.z1.027 [8] LIN W K, RAO J T, LI Z L. Burden structure model analysis and production practice of smelting V-Ti ore in blast furnace[J]. Sichuan Metallurgy, 2022, 44(4): 12-16. (林文康, 饶家庭, 李志霖. 高炉冶炼钒钛矿炉料结构模型分析及生产实践[J]. 四川冶金, 2022, 44(4): 12-16.LIN W K, RAO J T, LI Z L. Burden structure model analysis and production practice of smelting V-Ti ore in blast furnace[J]. Sichuan Metallurgy, 2022, 44(4): 12-16. [9] LI H W, LI X, LIU X J, et al. Evaluation model for comprehensive operation condition of vanadium and titanium blast furnace based on big data mining[J]. Iron & Steel, 2023, 58(10): 51-66. (李红玮, 李欣, 刘小杰, 等. 基于大数据挖掘的钒钛高炉综合运行状态评价模型[J]. 钢铁, 2023, 58(10): 51-66.LI H W, LI X, LIU X J, et al. Evaluation model for comprehensive operation condition of vanadium and titanium blast furnace based on big data mining[J]. Iron & Steel, 2023, 58(10): 51-66. [10] LIU X J, WEN L Y X, ZHANG Y J, et al. Prediction model of blast furnace hearth activity based ontheoretical analysis and intelligent algorithm[J]. China Metallurgy, 2024, 34(2): 83-95. (刘小杰, 温梁亦欣, 张玉洁, 等. 基于理论分析和智能算法的高炉炉缸活性预测模型[J]. 中国冶金, 2024, 34(2): 83-95.LIU X J, WEN L Y X, ZHANG Y J, et al. Prediction model of blast furnace hearth activity based ontheoretical analysis and intelligent algorithm[J]. China Metallurgy, 2024, 34(2): 83-95. [11] ALOM M Z, TAHA T M, YAKOPCIC C, et al. The history began from alexnet: A comprehensive survey on deep learning approaches[J]. ArXiv Preprint ArXiv: 1803, 0116, 4: 2018. [12] SILVER D, HUANG A, MADDISON C J, et al. Mastering the game of Go with deep neural networks and tree search[J]. Nature, 2016, 529(7587): 484-489. doi: 10.1038/nature16961 [13] JUMPER J, EVANS R, PRITZEL A, et al. Highly accurate protein structure prediction with AlphaFold[J]. Nature, 2021, 596(7873): 583-589. doi: 10.1038/s41586-021-03819-2 [14] JIA W, WANG H, CHEN M, et al. Pushing the limit of molecular dynamics with ab initio accuracy to 100 million atoms with machine learning[C]. SC20: International Conference for High Performance Computing, Networking, Storage and Analysis, 2020: 1-14. [15] WANG Z Y, JIANG D W, WANG X D, et al. Prediction of blast furnace hot metal temperature based on support vector regression and extreme learning machine[J]. Chinese Journal of Engineering, 2021, 43(4): 569-576. (王振阳, 江德文, 王新东, 等. 基于支持向量回归与极限学习机的高炉铁水温度预测[J]. 工程科学学报, 2021, 43(4): 569-576.WANG Z Y, JIANG D W, WANG X D, et al. Prediction of blast furnace hot metal temperature based on support vector regression and extreme learning machine[J]. Chinese Journal of Engineering, 2021, 43(4): 569-576. [16] LI Y, ZHANG S, YIN Y, et al. A soft sensing scheme of gas utilization ratio prediction for blast furnace via Improved extreme learning machine[J]. Neural Processing Letters, 2018, 50(2): 1191-1213. [17] CUI Z, YANG A, WANG L, et al. Dynamic prediction model of silicon content in molten iron based on comprehensive characterization of furnace temperature[J]. Metals, 2022, 12(9): 1403. doi: 10.3390/met12091403 [18] ZHANG X L, YU K, ZHANG S N, et al. Prediction method of blast furnace hearth thermal state by introducing time series of water temperature difference[J]. China Measurement & Test, 2022, 48(6): 74-79. (张小乐, 于凯, 张胜男, 等. 引入水温差时间序列的高炉炉缸热状态预测方法[J]. 中国测试, 2022, 48(6): 74-79.ZHANG X L, YU K, ZHANG S N, et al. Prediction method of blast furnace hearth thermal state by introducing time series of water temperature difference[J]. China Measurement & Test, 2022, 48(6): 74-79. [19] ZHANG X, KANO M, MATSUZAKI S. Ensemble pattern trees for predicting hot metal temperature in blast furnace[J]. Computers & Chemical Engineering, 2019, 121: 442-449. [20] CARDOSO W, DI FELICE R. A novel committee machine to predict the quantity of impurities in hot metal produced in blast furnace[J]. Computers & Chemical Engineering, 2022, 163. [21] CARDOSO W, DI FELICE R, BAPTISTA R C. Artificial neural network for predicting silicon content in the hot metal produced in a blast furnace fueled by metallurgical coke[J]. Materials Research, 2022, 25. [22] GU Z Y, LÜ D H, LI X L, et al. Fusion prediction of blast furnace temperature based on combination of knowledge and data[J]. China Measurement & Test, 2024, 50(3): 19-28. (古志远, 吕东澔, 李向丽, 等. 基于知识与数据相结合的高炉炉温融合预测[J]. 中国测试, 2024, 50(3): 19-28.GU Z Y, LÜ D H, LI X L, et al. Fusion prediction of blast furnace temperature based on combination of knowledge and data[J]. China Measurement & Test, 2024, 50(3): 19-28. [23] SONG J, XING X, PANG Z, et al. Prediction of silicon content in the hot metal of a blast furnace based on FPA-BP model[J]. Metals, 2023, 13(5): 918. doi: 10.3390/met13050918 [24] LIU X, ZHANG Y, LI X, et al. Control of silicon content in blast furnace iron based on GRA-LSTM-BAS prediction methods[J]. Ironmaking & Steelmaking: Processes, Products and Applications, 2024, 51 (2): 127-138. [25] HOCHREITER S, SCHMIDHUBER J. Long short-term memory[J]. Neural Computation, 1997, 9(8): 1735-1780. doi: 10.1162/neco.1997.9.8.1735 [26] SHI Q, TANG J, CHU M. Process metallurgy and data-driven prediction and feedback of blast furnace heat indicators[J]. International Journal of Minerals, Metallurgy and Materials, 2024, 31(6): 1228-1240. doi: 10.1007/s12613-023-2693-7 [27] SHI Q, TANG J, CHU M. Key issues and progress of industrial big data-based intelligent blast furnace ironmaking technology[J]. International Journal of Minerals, Metallurgy and Materials, 2023, 30(9): 1651-1666. doi: 10.1007/s12613-023-2636-3 [28] HUA J M, ZHANG L L. Influence and control over blast furnace smelting by blast kinetic energy[J]. Ironmaking, 2005(4): 5-8. (华建明, 张龙来. 鼓风动能对高炉冶炼的影响及控制[J]. 炼铁, 2005(4): 5-8.HUA J M, ZHANG L L. Influence and control over blast furnace smelting by blast kinetic energy[J]. Ironmaking, 2005(4): 5-8. [29] LIN A C, QIU G B, ZHANG X L, et al. Development and application of comprehensive diagnosticc ontrol model for blast furnace production[J]. Iron and Steel, 2022, 57(12): 41-56. (林安川, 邱贵宝, 张晓雷, 等. 高炉生产综合诊控模型研发及应用[J]. 钢铁, 2022, 57(12): 41-56.LIN A C, QIU G B, ZHANG X L, et al. Development and application of comprehensive diagnosticc ontrol model for blast furnace production[J]. Iron and Steel, 2022, 57(12): 41-56. [30] ZHANG Z W, CHE X R, ZHANG H B. Establishment and validation of multi-objective optimization model of blast furnace[J]. The Chinese Journal of Process Engineering, 2017, 17(1): 178-182. (张宗旺, 车晓锐, 张宏博. 高炉多目标优化模型的建立及验证[J]. 过程工程学报, 2017, 17(1): 178-182.ZHANG Z W, CHE X R, ZHANG H B. Establishment and validation of multi-objective optimization model of blast furnace[J]. The Chinese Journal of Process Engineering, 2017, 17(1): 178-182. [31] RESHEF D N, RESHEF Y A, FINUCANE H K, et al. Detecting novel associations in large data sets[J]. Science, 2011, 334(6062): 1518-1524. doi: 10.1126/science.1205438 [32] HU J, GAO C H. Thermal state prediction of blast furnace based on multi-task learning[J]. China Metallurgy, 2023, 33(7): 81-90. (胡进, 郜传厚. 基于多任务学习的高炉热状态预测[J]. 中国冶金, 2023, 33(7): 81-90.HU J, GAO C H. Thermal state prediction of blast furnace based on multi-task learning[J]. China Metallurgy, 2023, 33(7): 81-90. [33] ZENG A, CHEN M, ZHANG L, et al. Are transformers effective for time series forecasting?[C]. Proceedings of The AAAI Conference on Artificial Intelligence, 2023: 11121-11128. [34] VASWANI A, SHAZEER N, PARMAR N, et al. Attention is all you need[J]. Advances in Neural Information Processing Systems, 2017, 30. -

下载:

下载: