Research on the remaining useful life estimation model of blast furnace tuyere based on image recognition

-

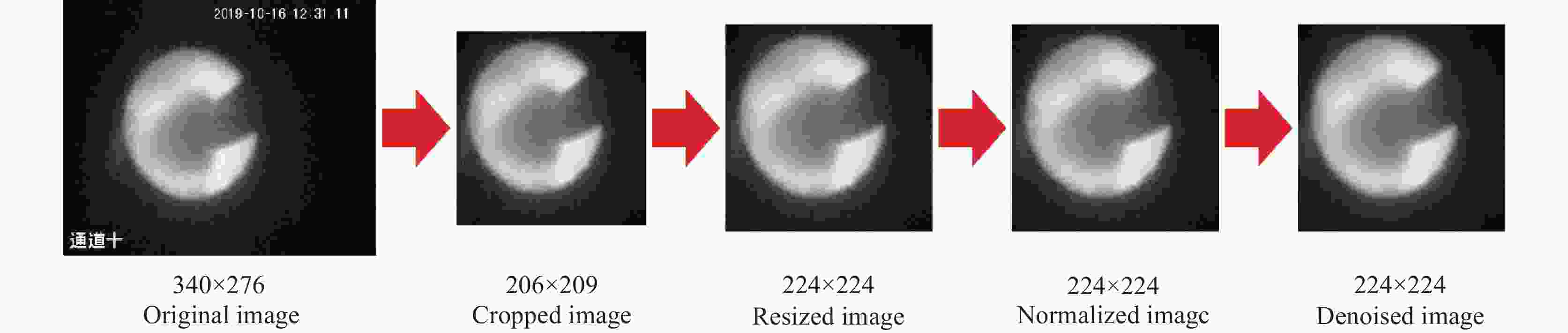

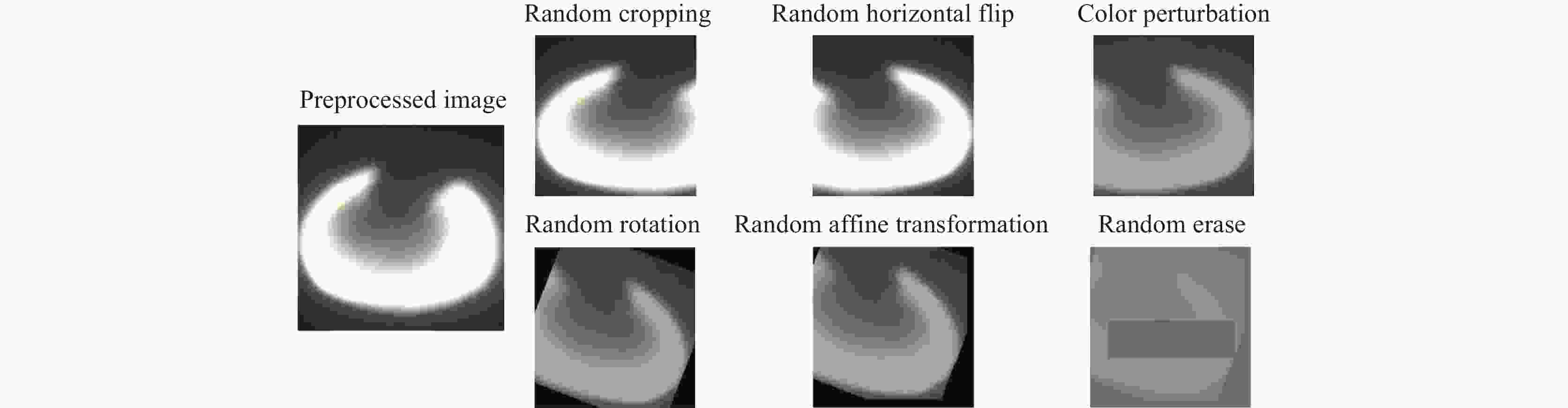

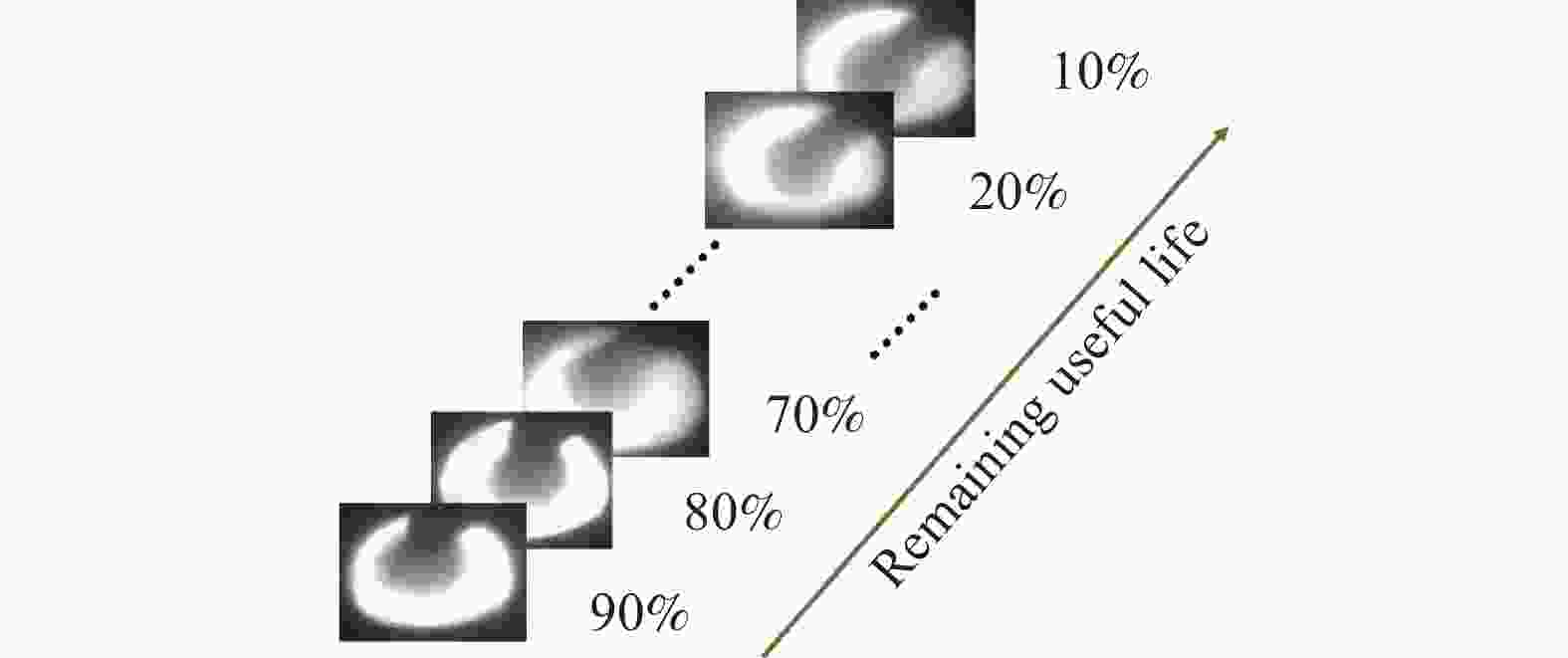

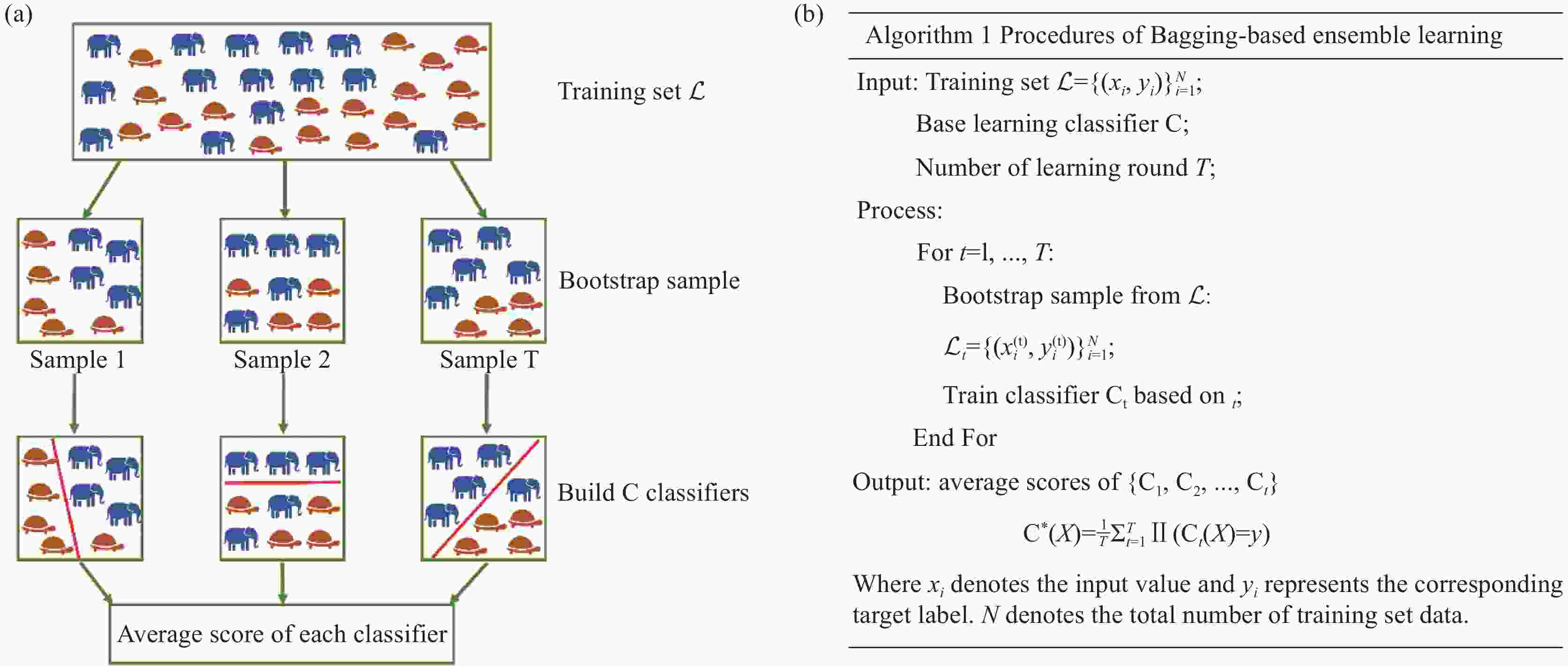

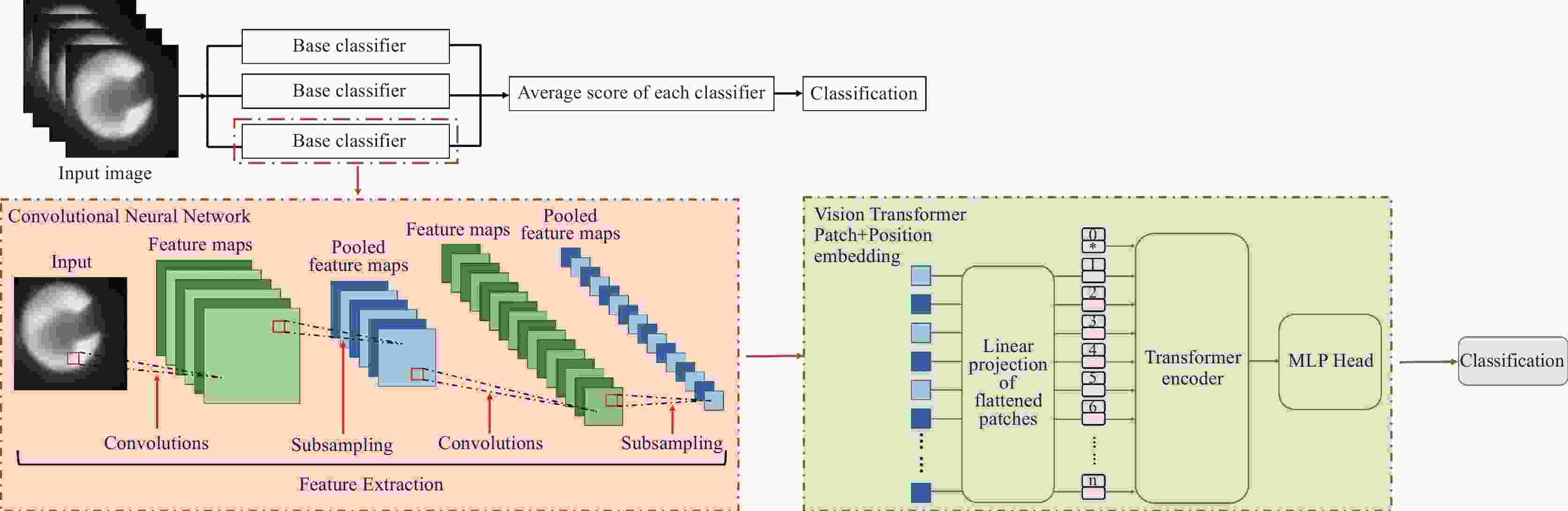

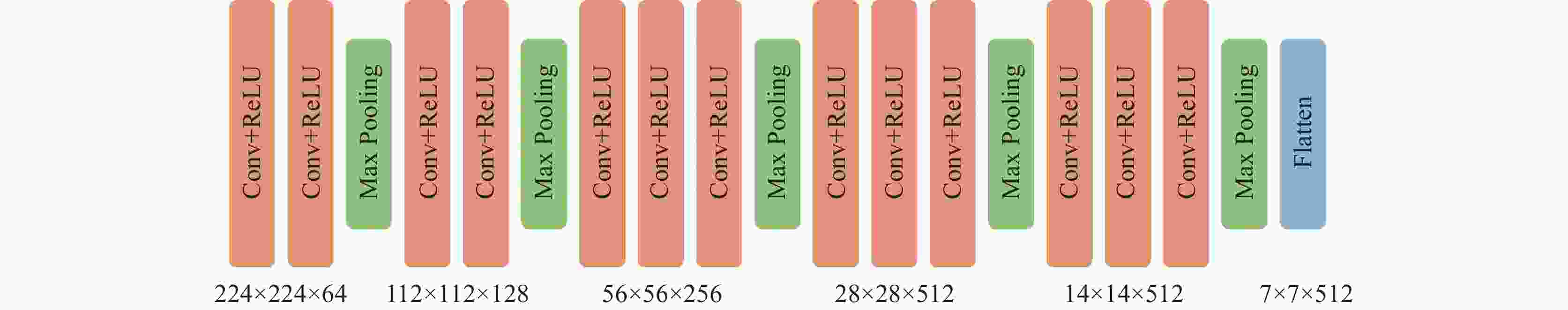

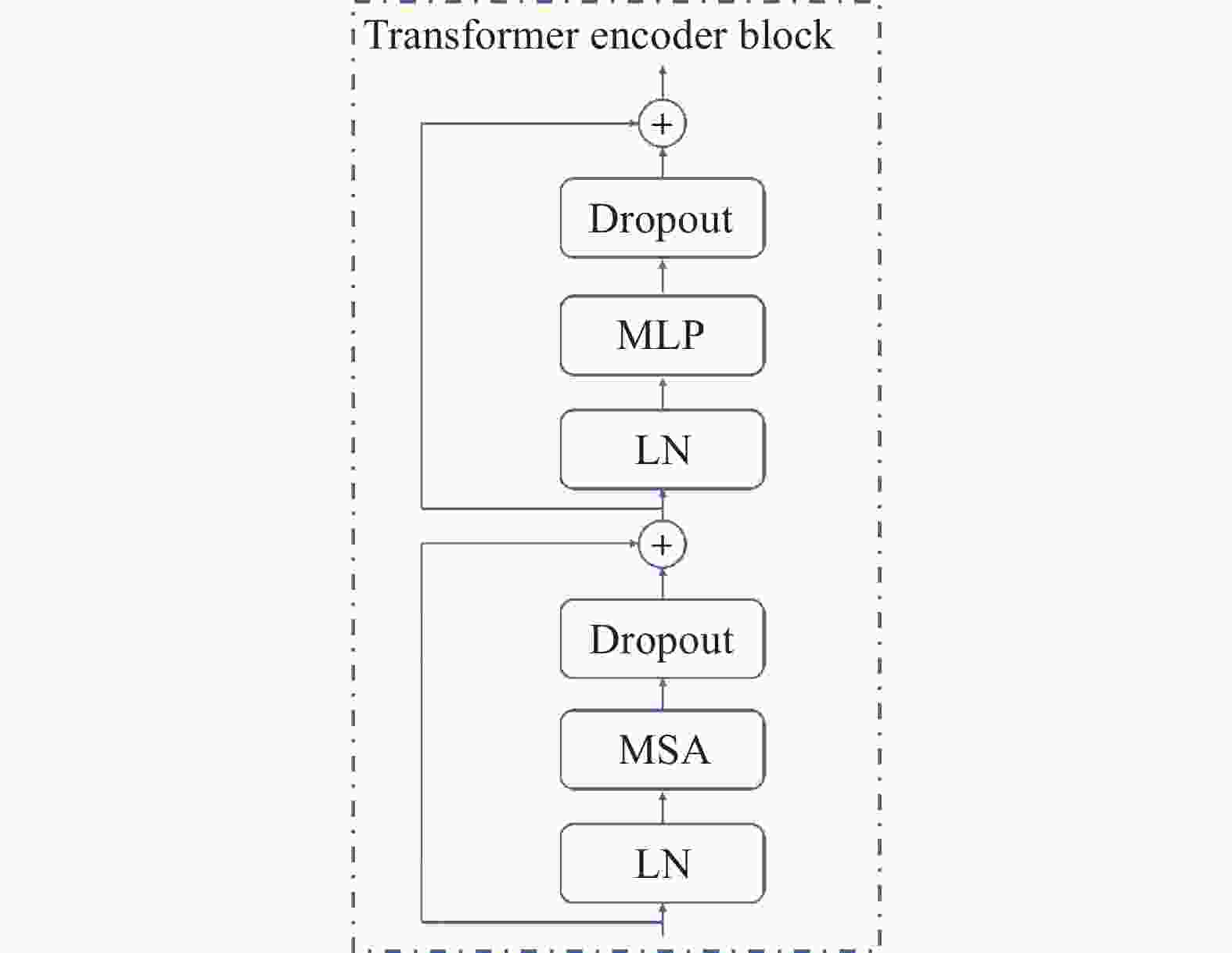

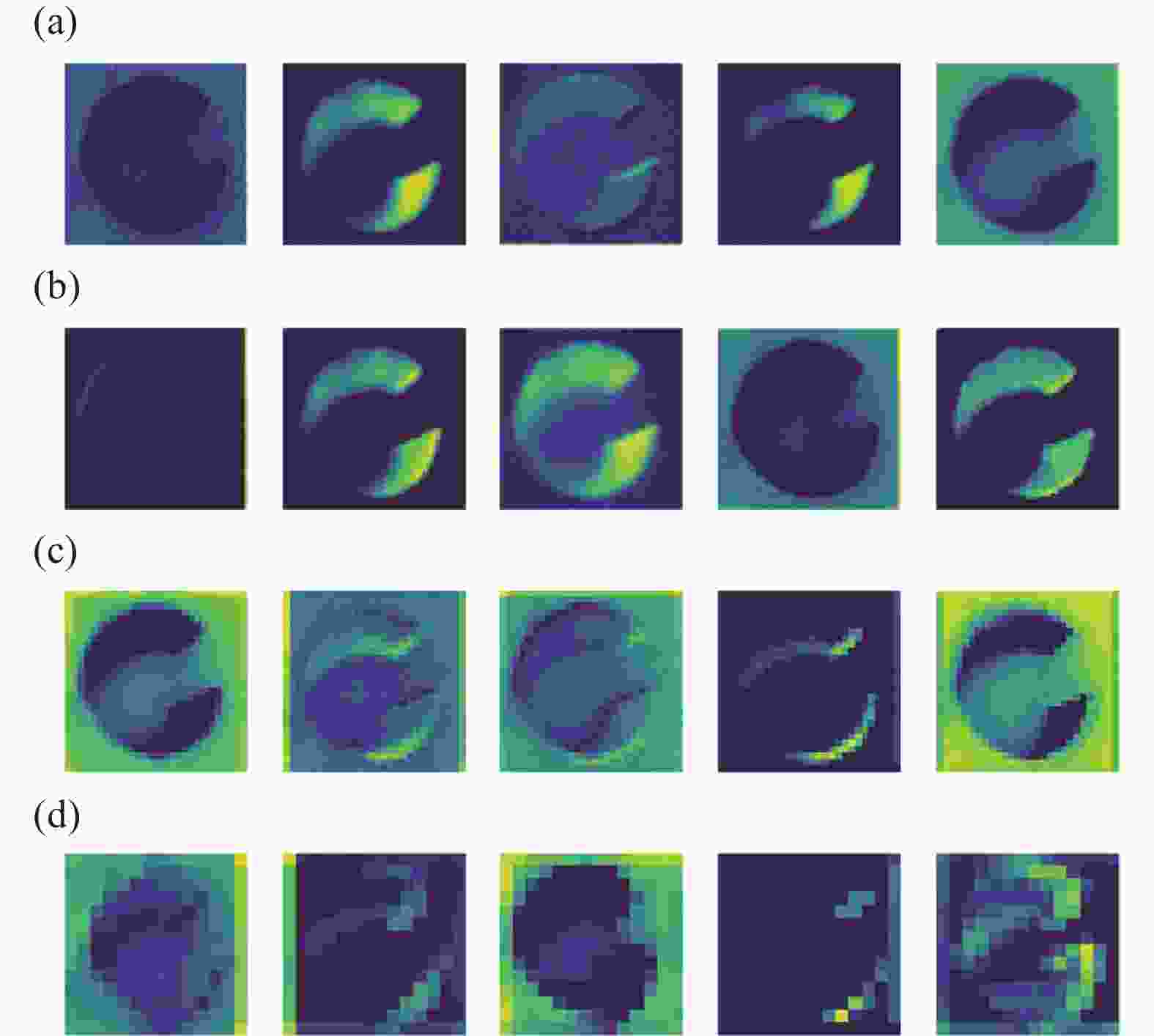

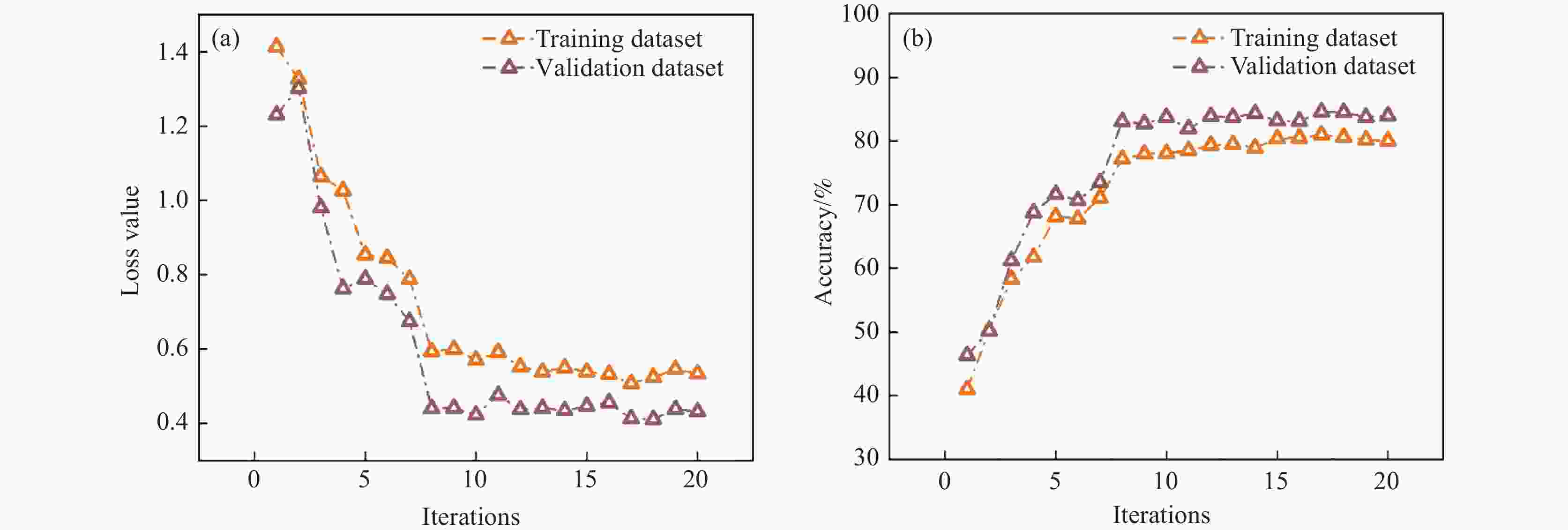

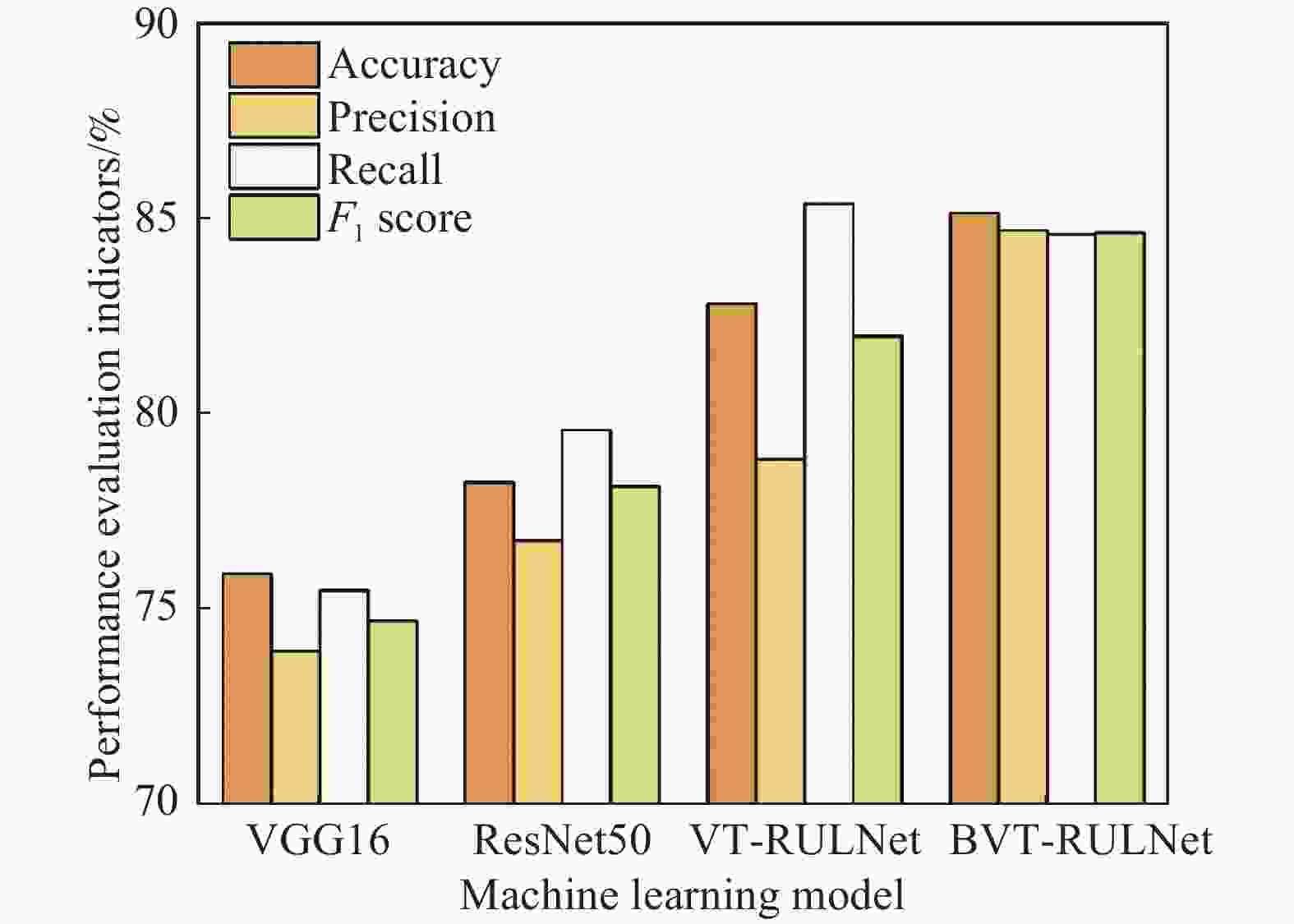

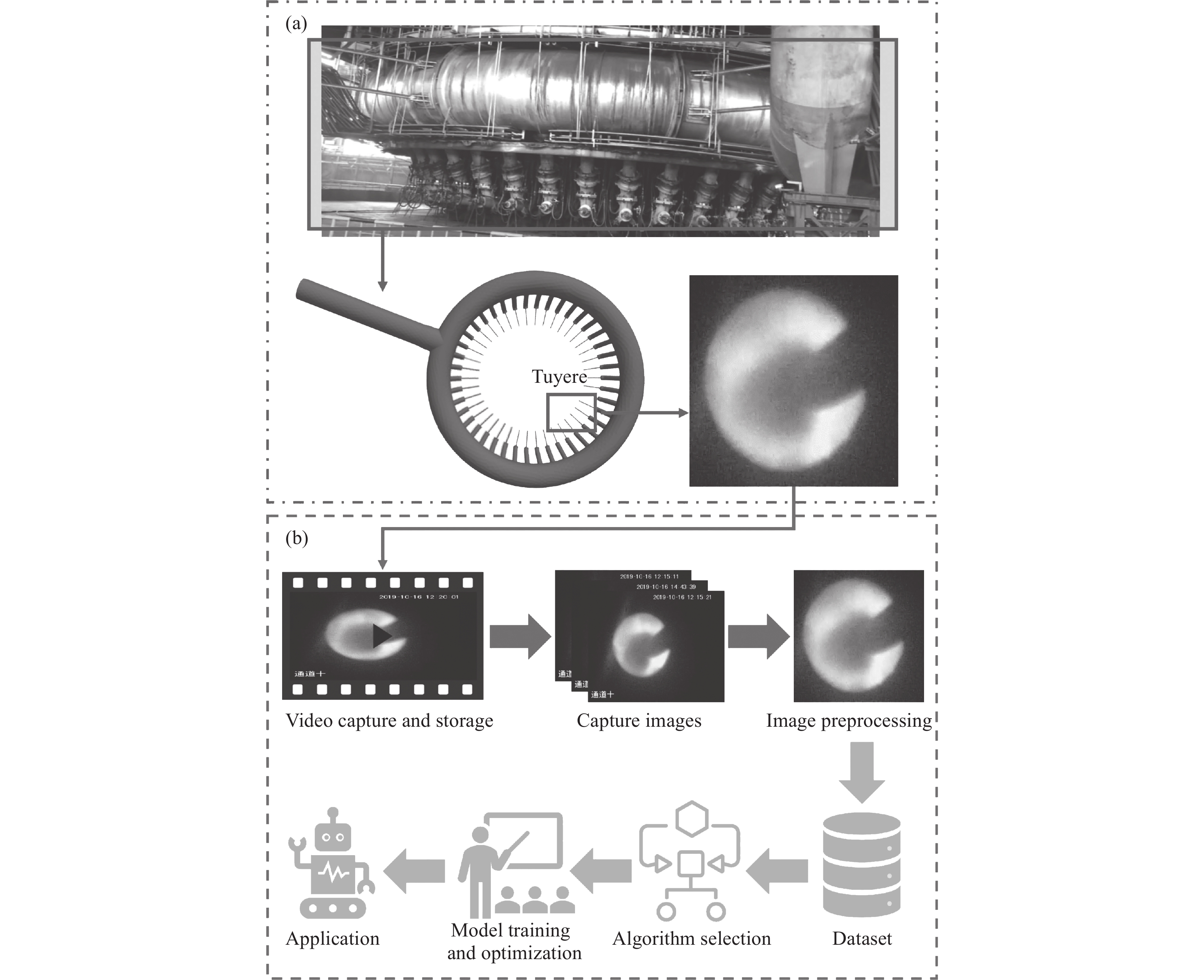

摘要: 高炉风口作为炉内热量的主要来源,其状态检测目前主要依赖人工经验判断,常导致损坏风口更换不及时,造成不必要的停产检修。为解决上述问题,提出了一种专为风口剩余使用寿命(Remaining Useful Life, RUL)预测的机器学习模型BVT-RULNet,该模型采用集成学习(Ensemble Learning, EL)策略,集成三个结构相同的基分类器,每个基分类器均包含一个VGG16卷积神经网络(Convolutional Neural Network, CNN)前端和一个视觉Transformer(Vision Transformer, ViT)模块。在模型训练过程中,采用基于风口完整生命周期图像构建的离散RUL数据集,在测试过程中,则采用独立的测试数据集。结果表明,模型在测试数据集上的评估指标表现优异,准确率、精确率、召回率和F1分数分别达到85.14%、84.70%、84.59%和84.64%,均优于对比模型。因此,BVT-RULNet模型在风口RUL分类识别与预测方面具有较高的准确性和泛化能力,为高炉风口状态智能监测提供了有效的解决方案。Abstract: As the primary source of in-furnace heat, the condition detection of blast furnace tuyeres mainly relies on manual experience currently. This practice often leads to delayed replacement of damaged tuyeres and unnecessary shutdown maintenance. To address the above issues, this paper proposes a machine learning model named BVT-RULNet, specifically designed to predict the Remaining Useful Life (RUL) of tuyeres. The model employs an Ensemble Learning (EL) strategy that integrates three base classifiers with identical architectures. Each base classifier consists of a VGG16 Convolutional Neural Network (CNN) frontend and a Vision Transformer (ViT) module. During model training, a discrete RUL dataset constructed based on the images covering the complete life cycle of the tuyere was used, and an independent test dataset was used during the evaluation process. Results show that the model achieves excellent metrics on the test set, with accuracy, precision, recall, and F1 score reaching 85.14%, 84.70%, 84.59%, and 84.64%, respectively, all outperforming the comparison models. Therefore, BVT-RULNet model demonstrates high accuracy and strong generalization for tuyere RUL classification and prediction, providing an effective solution for intelligent monitoring of blast furnace tuyere condition.

-

表 1 混淆矩阵

Table 1. Confusion matrix

Actual condition Predicted condition Positive Negative Positive TP FN Negative FP TN -

[1] WANG G, LIAO Z H, HU Z W, et al. Influence of the residual iron on the erosion of carbon bricks in a 4000 m3 blast furnace hearth: From the measured properties to the proposed mechanisms[J]. Metallurgical and Materials Transactions B, 2022: 53, 931-937.[2] YU X B, SHEN Y S. Transient state modeling of industry-scale ironmaking blast furnaces[J]. Chemical Engineering Science, 2022, 248: 117185. doi: 10.1016/j.ces.2021.117185 [3] ZHENG K, ZHAO P, HU P, et al. Study on the effects of oxygen enrichment modes on the tuyere raceway states of blast furnace[J]. Iron Steel Vanadium Titanium, 2024, 45(6): 108-118. (郑魁, 赵鹏, 胡鹏, 等. 富氧方式对高炉风口回旋区状态的影响研究[J]. 钢铁钒钛, 2024, 45(6): 108-118.ZHENG K, ZHAO P, HU P, et al. Study on the effects of oxygen enrichment modes on the tuyere raceway states of blast furnace[J]. Iron Steel Vanadium Titanium, 2024, 45(6): 108-118. [4] ZHANG J, WANG R, HU R, et al. Failure mode and mechanism of a blast furnace tuyere[J]. Engineering Failure Analysis, 2022, 137: 106294. doi: 10.1016/j.engfailanal.2022.106294 [5] HUANG C C, BORN S, KLAASSEN M, et al. Comprehensive numerical modeling of raceways in blast furnaces[J]. Chemical Engineering Science, 2024, 289: 119857. doi: 10.1016/j.ces.2024.119857 [6] MA S W, QIU G B, LÜ X W, et al. Theoretical research on the effects of oxygen enrichment and pulverized coal injection on performance of tuyere raceway zone in blast furnace[J]. Iron Steel Vanadium Titanium, 2012, 33(4): 62-67. (马世伟, 邱贵宝, 吕学伟, 等. 富氧喷煤对高炉风口回旋区特征影响的理论研究[J]. 钢铁钒钛, 2012, 33(4): 62-67.MA S W, QIU G B, LÜ X W, et al. Theoretical research on the effects of oxygen enrichment and pulverized coal injection on performance of tuyere raceway zone in blast furnace[J]. Iron Steel Vanadium Titanium, 2012, 33(4): 62-67. [7] ZHOU D D, CHENG S S, ZHANG R X, et al. Study of the combustion behaviour and temperature of pulverised coal in a tuyere zone of blast furnace[J]. Ironmaking & Steelmaking, 2018, 45(7): 665-671. [8] LI G S, HUANG P Y, CHENG P, et al. Analysis of the failure mechanism of a blast furnace tuyere sleeve with protective coating[J]. Engineering Failure Analysis, 2023, 153: 107537. doi: 10.1016/j.engfailanal.2023.107537 [9] WANG H Y, ZHANG J L, LIU Z J, et al. Damage mechanism of blast furnace tuyere by zinc[J]. Ironmaking & Steelmaking, 2018, 45(6): 560-565. [10] CHAI Y F, ZHANG J L, NING X J, et al. Mechanism research on melting loss of coppery tuyere small sleeve in blast furnace[J]. High Temperature Materials and Processes, 2016, 35(1): 73-80. doi: 10.1515/htmp-2014-0149 [11] LEI M, DU P, ZHU H, et al. Influence of blasting conditioning parameters on tuyere life of shagang's 5800 m3 BF[J]. Ironmaking, 2022, 41(3): 22-26. (雷鸣, 杜屏, 朱华, 等. 沙钢5800 m3高炉下部调剂参数对风口寿命的影响[J]. 炼铁, 2022, 41(3): 22-26.LEI M, DU P, ZHU H, et al. Influence of blasting conditioning parameters on tuyere life of shagang's5800 m3 BF[J]. Ironmaking, 2022, 41(3): 22-26.[12] GUGULOTHU N, TV V, MALHOTRA P, et al. Predicting remaining useful life using time series embeddings based on recurrent neural networks[J]. arXiv preprint arXiv: 1709, 0107, 3: 2017. [13] WANG Y D, ZHAO Y F, ADDEPALLI S. Remaining useful life prediction using deep learning approaches: a review[J]. Procedia Manufacturing, 2020, 49: 81-88. doi: 10.1016/j.promfg.2020.06.015 [14] SI X S, WANG W B, HU C H, et al. Remaining useful life estimation – a review on the statistical data driven approaches[J]. European Journal of Operational Research, 2011, 213(1): 1-14. doi: 10.1016/j.ejor.2010.11.018 [15] PUTTINGER S, STOCKER H. Improving blast furnace raceway blockage detection. Part 1: classification of blockage events and processing framework[J]. ISIJ International, 2019, 59(3): 466-473. doi: 10.2355/isijinternational.ISIJINT-2018-530 [16] PUTTINGER S, STOCKER H. Improving blast furnace raceway blockage detection. Part 2: signal processing of hot blast pressure data[J]. ISIJ International, 2019, 59(3): 474-480. doi: 10.2355/isijinternational.ISIJINT-2018-531 [17] PUTTINGER S, STOCKER H. Improving blast furnace raceway blockage detection. Part 3: visual detection based on tuyere camera images[J]. ISIJ International, 2019, 59(3): 481-488. doi: 10.2355/isijinternational.ISIJINT-2018-532 [18] O’SHEA K, NASH R. An introduction to convolutional neural networks[J/OL]. arXiv preprint arXiv: 2015. https://arxiv.org/abs/1511.08458. [19] LI Q, WANG Z J, WANG S, et al. A deep learning–based diagnosis model driven by tuyere images big data for iron‐making blast furnaces[J]. Steel Research International, 2022, 93(8): 2100826. doi: 10.1002/srin.202100826 [20] WANG R H, LI Z Y, YANG L Z, et al. Application of efficient channel attention residual mechanism in blast furnace tuyere image anomaly detection[J]. Applied Sciences, 2022, 12(15): 7823. doi: 10.3390/app12157823 [21] SONG C, LI Z Y, LI Y M, et al. Research on blast furnace tuyere image anomaly detection, based on the local channel attention residual mechanism[J]. Applied Sciences, 2023, 13(2): 802. doi: 10.3390/app13020802 [22] ZHOU B, YE H, ZHANG H F, et al. Process monitoring of iron-making process in a blast furnace with PCA-based methods[J]. Control Engineering Practice, 2016, 47: 1-14. doi: 10.1016/j.conengprac.2015.11.006 [23] CUI G M, JIANG Z G, LIU P L, et al. Prediction of blast furnace temperature based on multi-information fusion of image and data[C]// 2018 Chinese Automation Congress (CAC). Xi’an: 2018: 2317-2322. [24] LIU B N, WU M H. Intelligent modeling of tuyere raceway of blast furnace[C]// 2021 33rd Chinese Control and Decision Conference (CCDC). Kunming: 2021: 5466-5471. [25] LIU Y R, ZHANG H M, SHEN Y S. A data-driven approach for the quick prediction of in-furnace phenomena of pulverized coal combustion in an ironmaking blast furnace[J]. Chemical Engineering Science, 2022, 260: 117945. doi: 10.1016/j.ces.2022.117945 [26] ZHOU D D, XU K, BAI J Y, et al. On-line detecting the tuyere coke size and temperature distribution of raceway zone in a working blast furnace[J]. Fuel, 2022, 316: 123349. doi: 10.1016/j.fuel.2022.123349 [27] WANG Y T, HUANG P, YANG G. A visual PCI blockage detection in blast furnace raceway[J]. ISIJ International, 2020, 60(3): 519-527. doi: 10.2355/isijinternational.ISIJINT-2019-367 [28] DONG X B, YU Z W, CAO W M, et al. A survey on ensemble learning[J]. Frontiers of Computer Science, 2020, 14(2): 241-258. doi: 10.1007/s11704-019-8208-z [29] DOSOVITSKIY A, BEYER L, KOLESNIKOV A, et al. An image is worth 16 x16 words: transformers for image recognition at scale[J]. arXiv preprint arXiv: 2010, 1192, 9: 2020. [30] PATRO S, SAHU K. Normalization: a preprocessing stage[J]. arXiv preprint arXiv: 1503, 0646, 2: 2015. [31] KUMAR B. Image denoising based on gaussian/bilateral filter and its method noise thresholding[J]. Image and Video Processing, 2013, 7: 1159-1172. doi: 10.1007/s11760-012-0372-7 [32] GUO Y Y, WANG X, XIAO P C, et al. An ensemble learning framework for convolutional neural network based on multiple classifiers[J]. Soft Computing, 2020, 24(5): 3727-3735. doi: 10.1007/s00500-019-04141-w [33] BREIMAN L. Bagging predictors[J]. Machine Learning, 1996, 24(2): 123-140. doi: 10.1023/A:1018054314350 [34] MASCARENHAS S, AGARWAL M. A comparison between VGG16, VGG19 and ResNet50 architecture frameworks for image classification[C]// 2021 International Conference on Disruptive Technologies for Multi-Disciplinary Research and Applications (CENTCON). Bengaluru: 2021: 96-99. [35] NEWTON D, YOUSEFIAN F, PASUPATHY R. Stochastic gradient descent: recent trends[J]. Recent Advances in Optimization and Modeling of Contemporary Problems, 2018, 193-220. [36] ZHANG Z L, SABUNCU M. Generalized cross entropy loss for training deep neural networks with noisy labels[C]// 2018 32nd Conference on Neural Information Processing Systems (NeurIPS), Montréal: 2018:31. -

下载:

下载: