Numerical simulation of the influence of vertical traveling wave magnetic field on the behavior of molten steel flow and steel slag interface fluctuation in a continuous casting slab mold

-

摘要: 在绿色低碳发展趋势下,当代冶金工业追求高速高效连铸以促进可持续发展。鉴于此,提出一种立式行波磁场控流技术,旨在优化和控制金属液流动行为,克服现存技术局限,为连铸过程的绿色低碳转型提供理论依据和技术支持。研究过程以

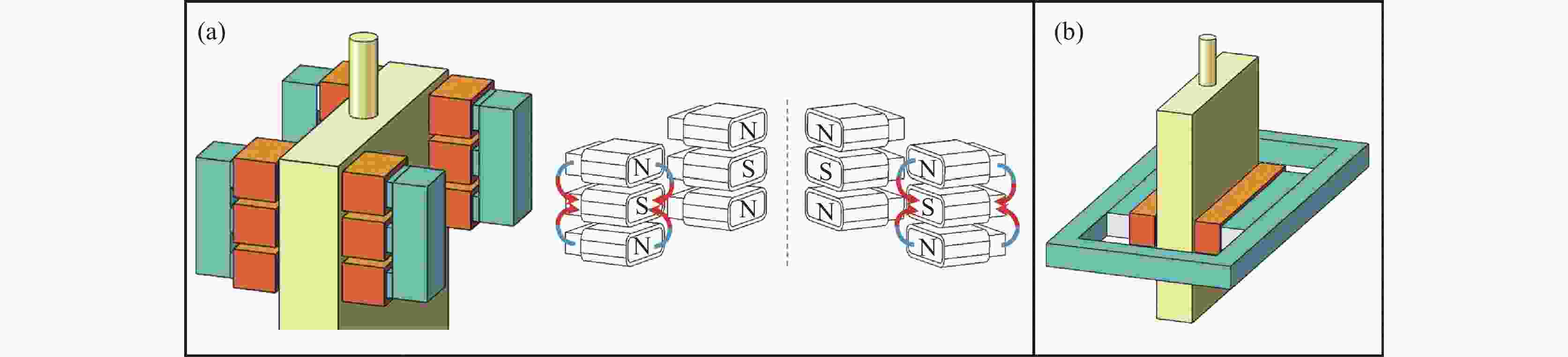

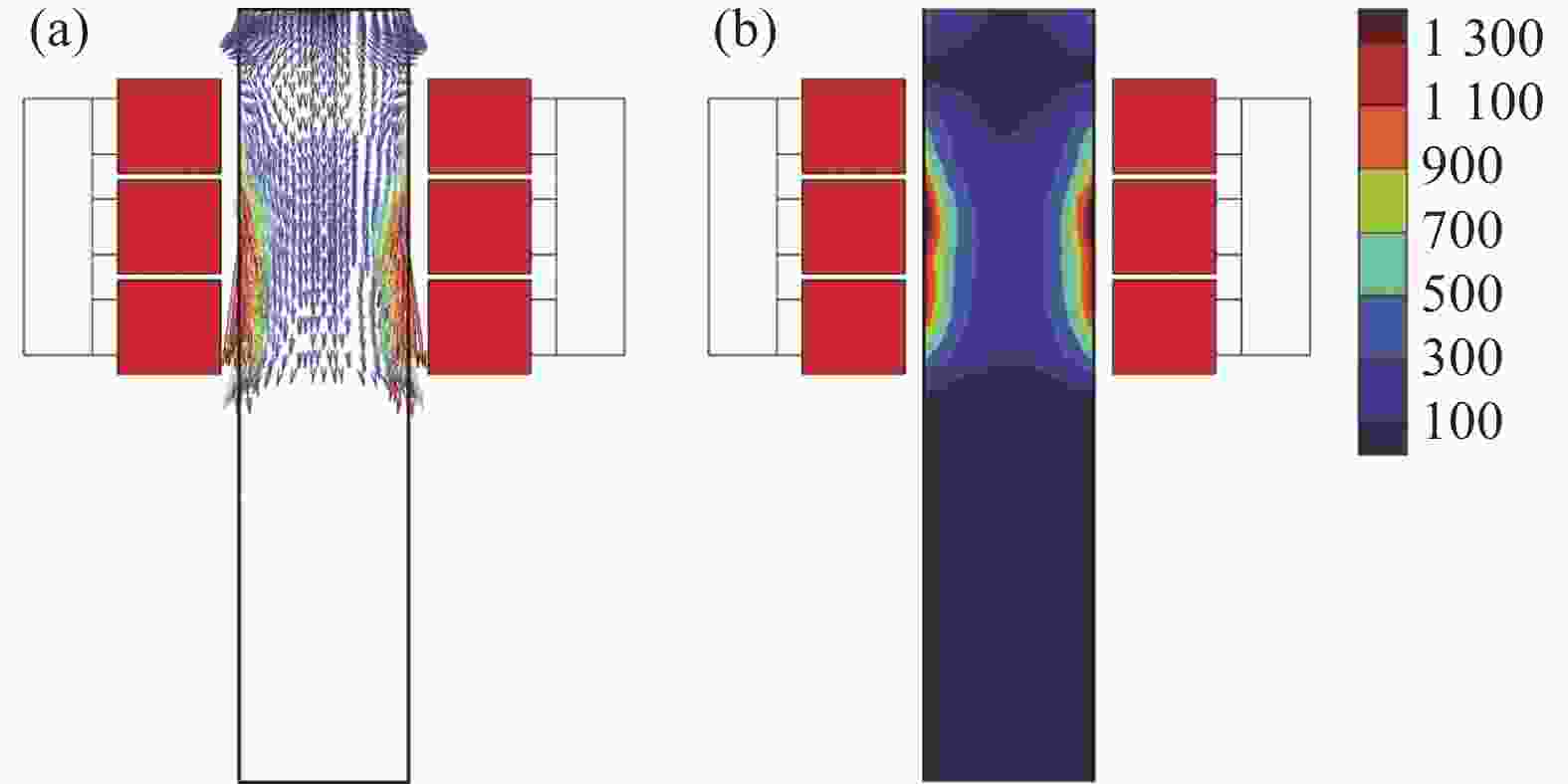

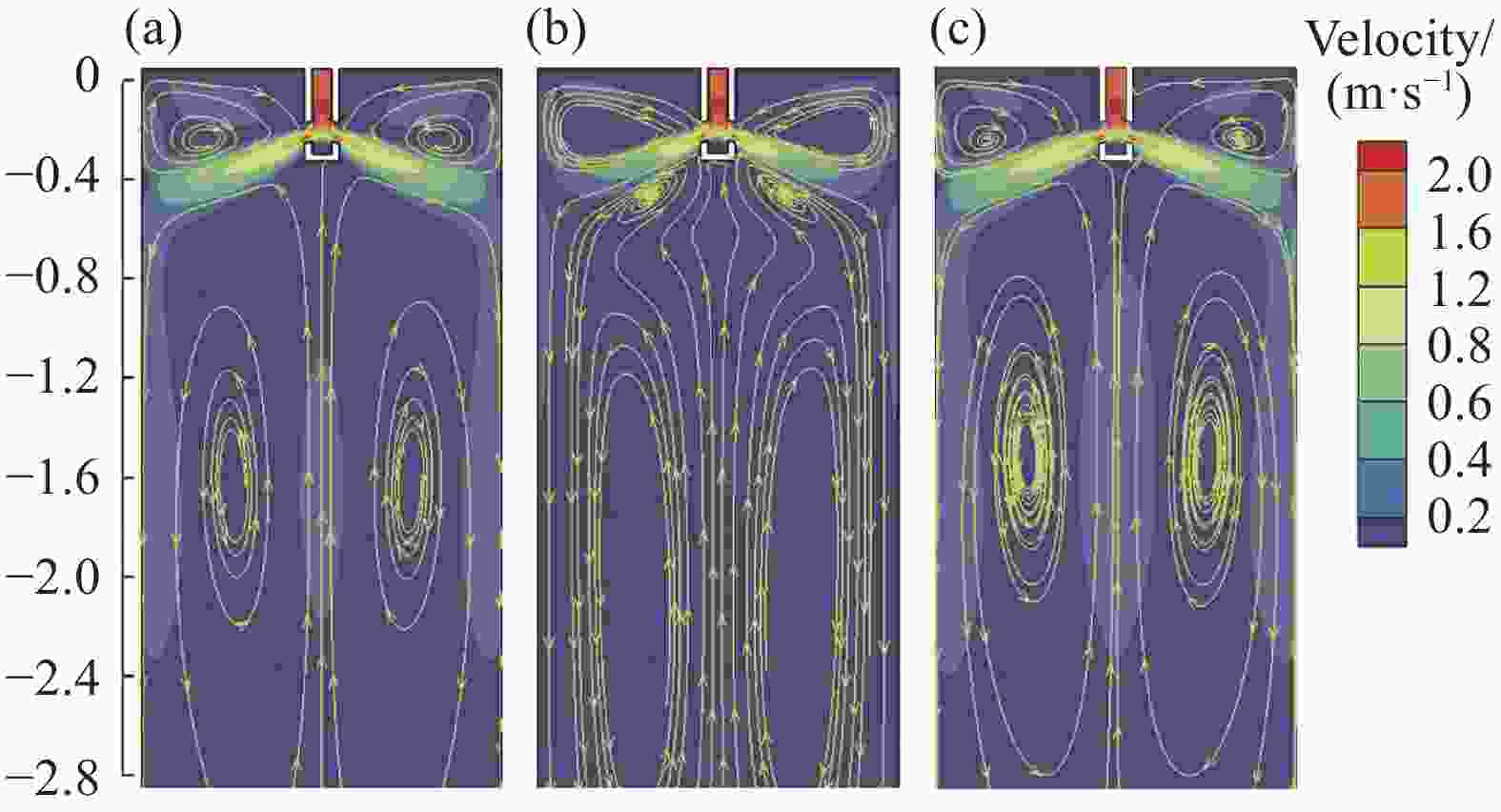

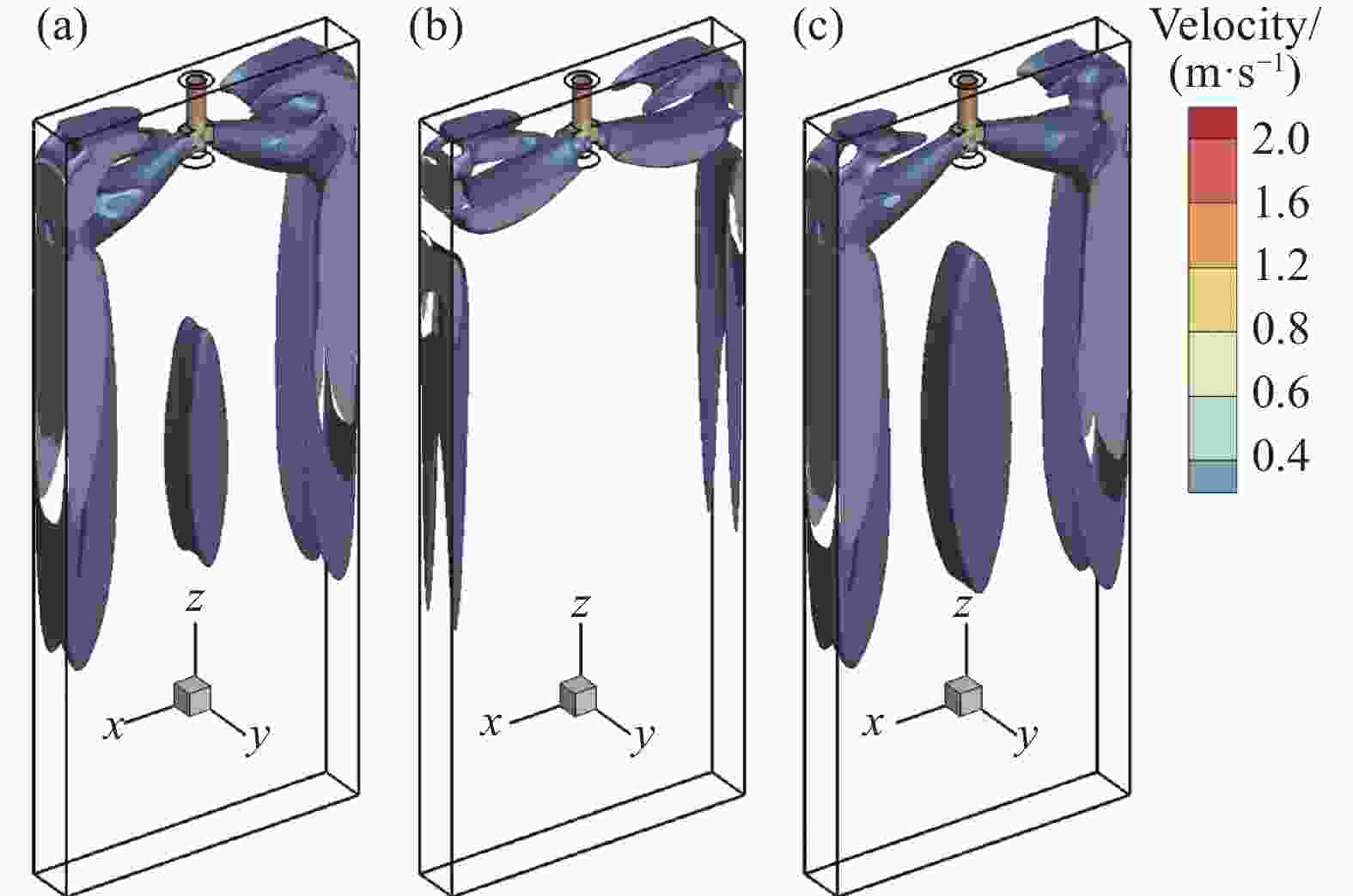

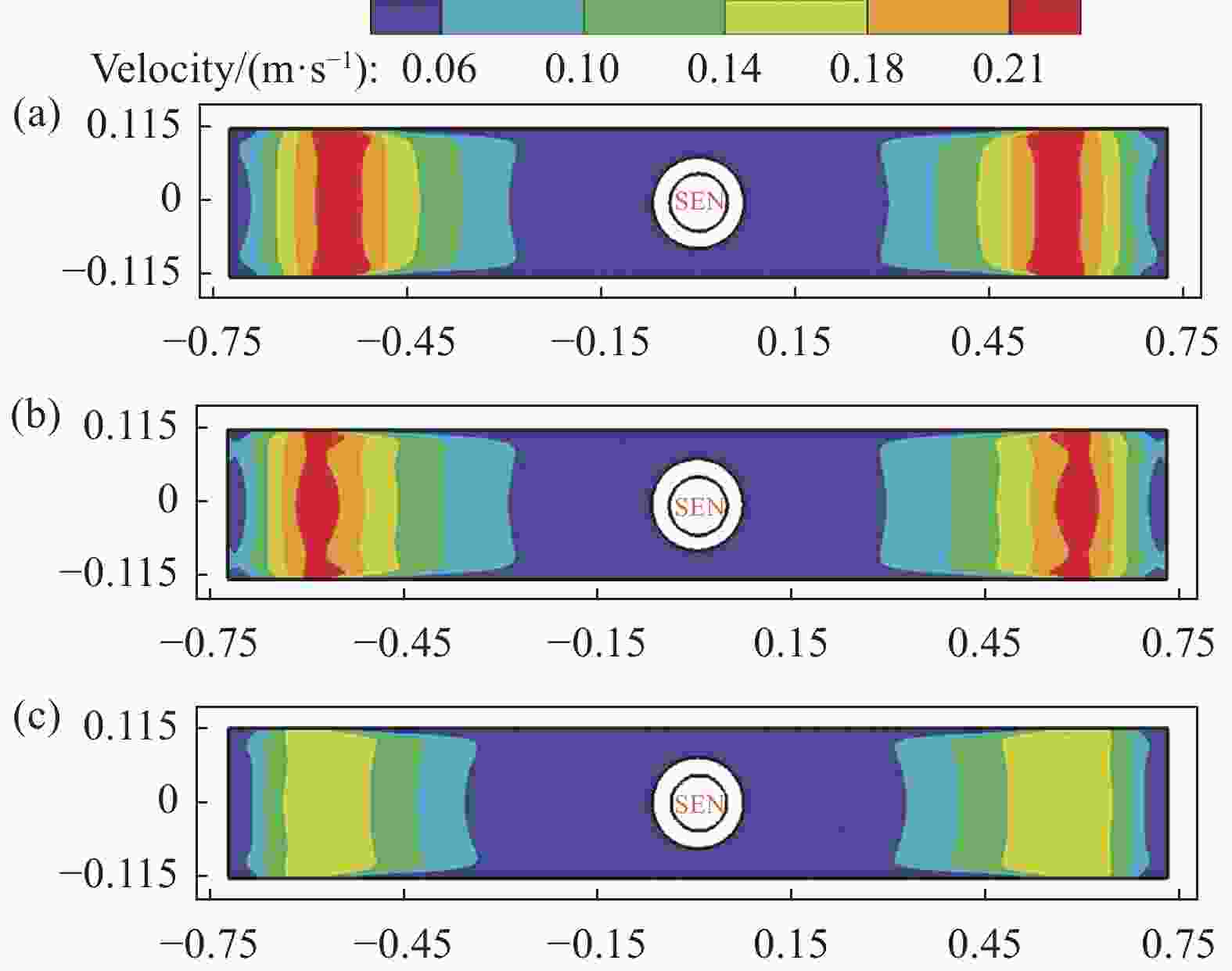

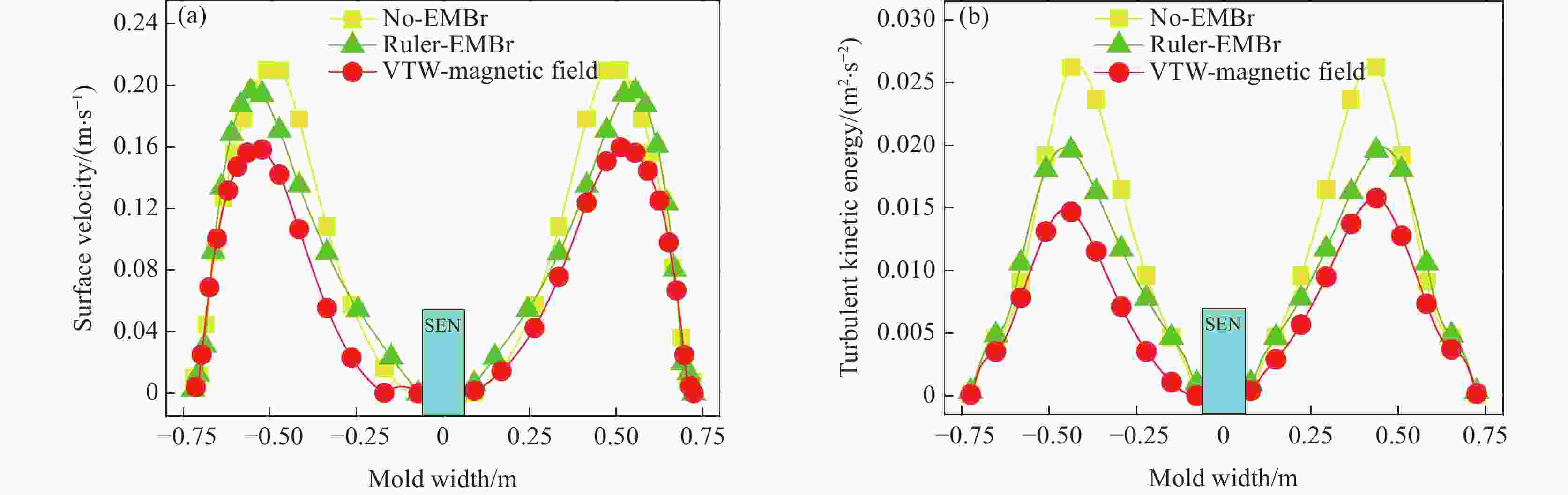

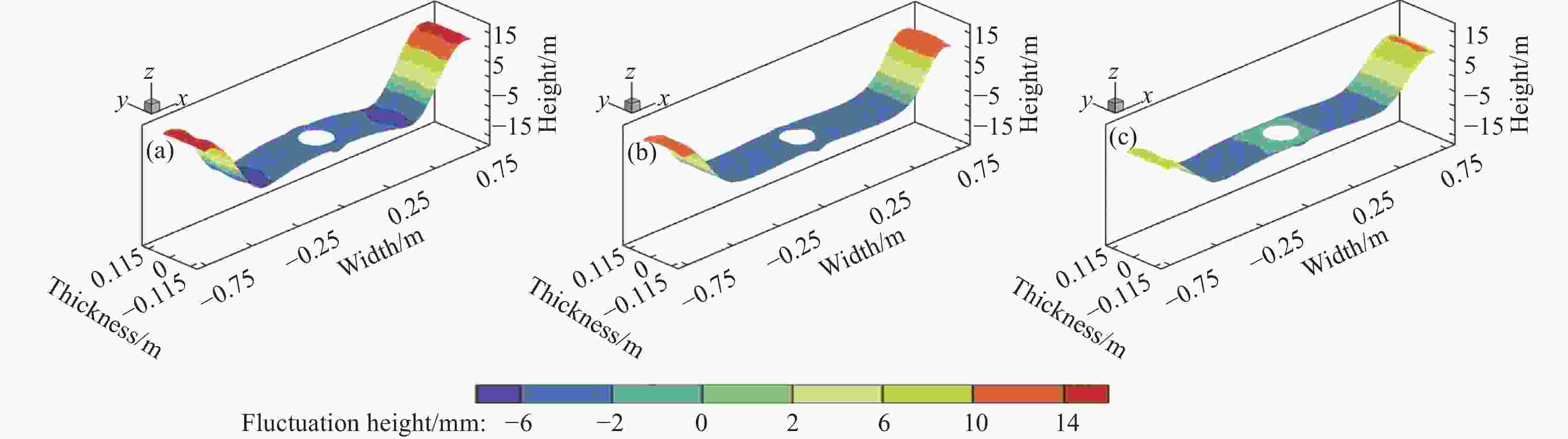

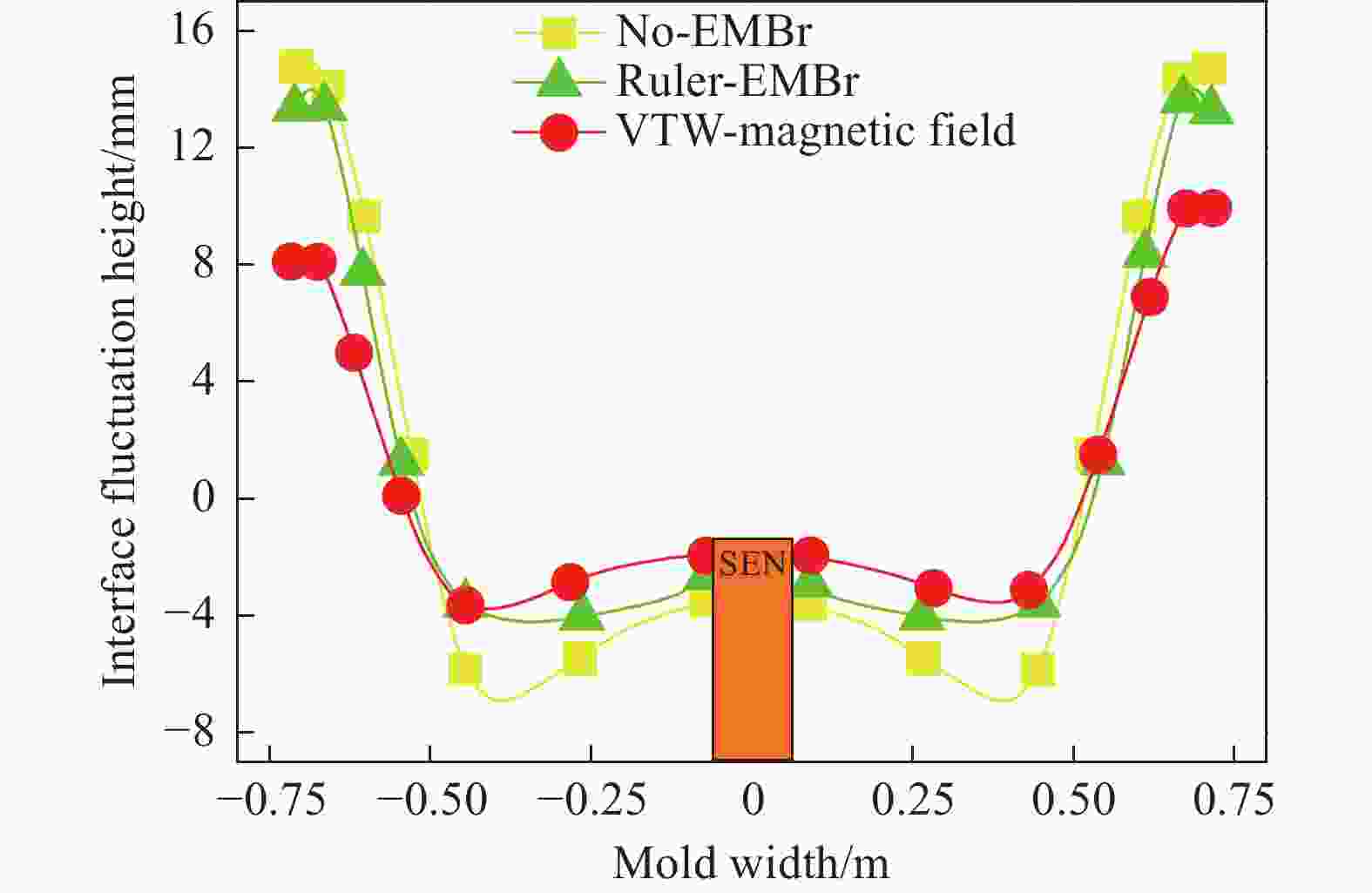

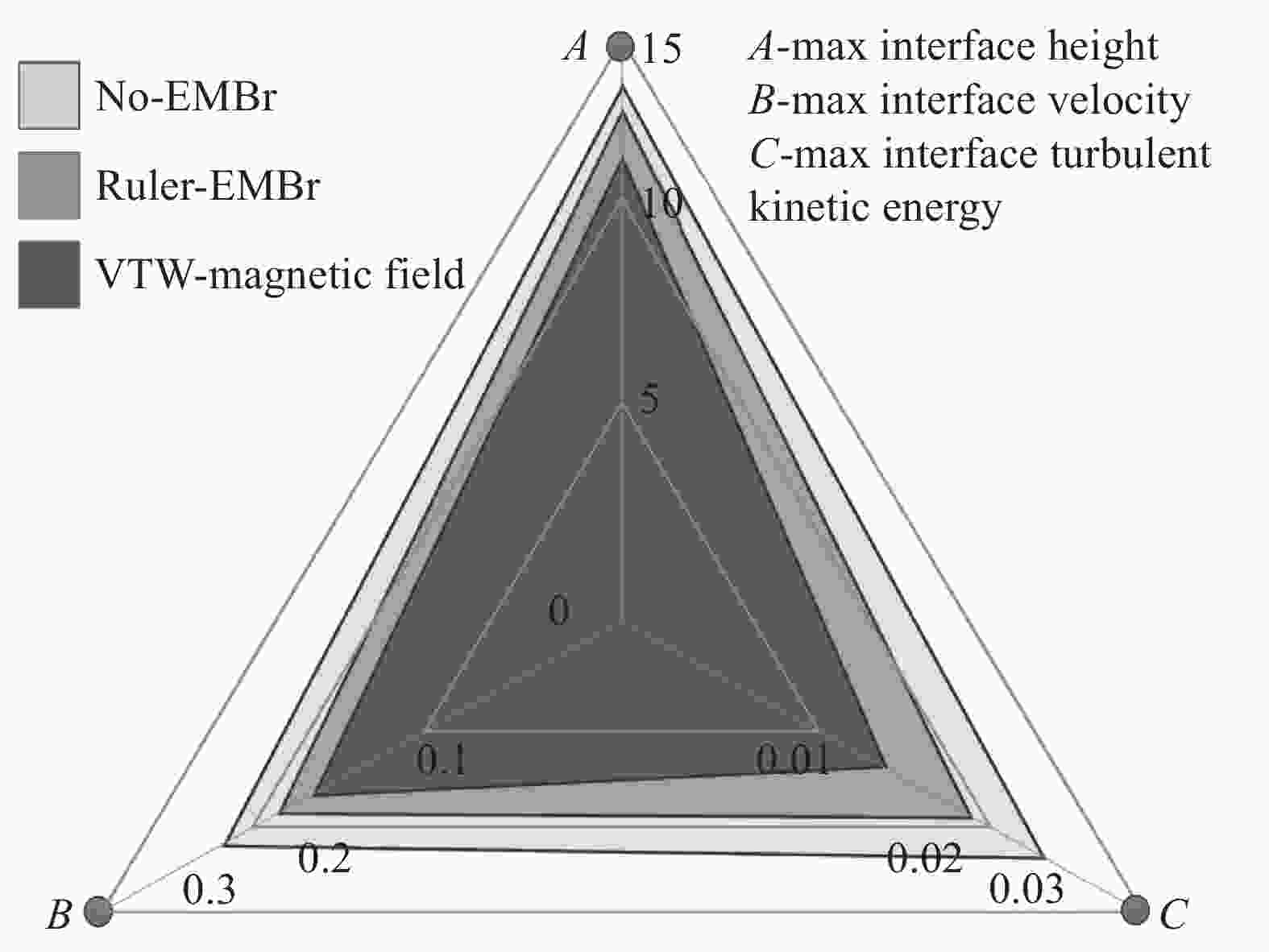

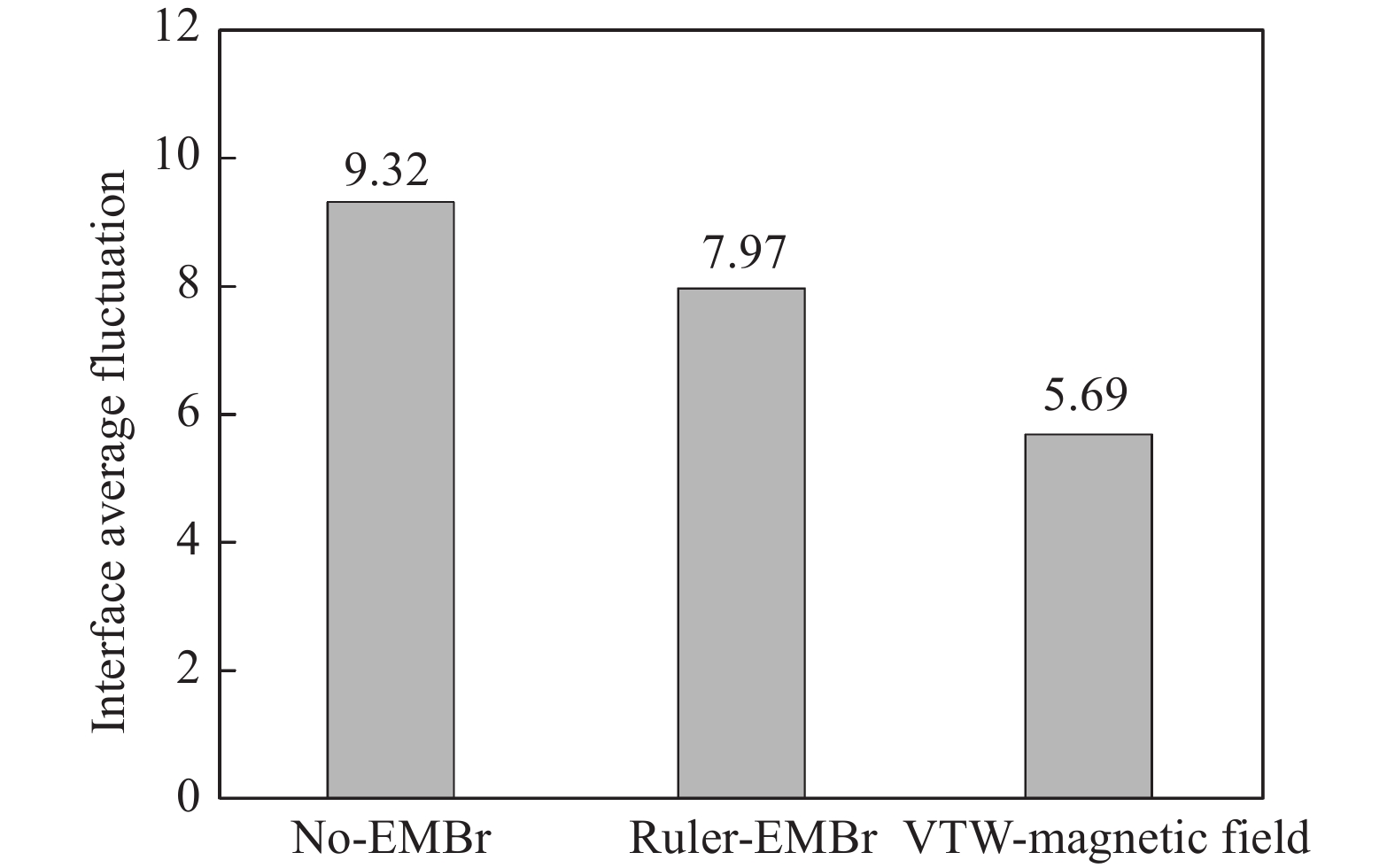

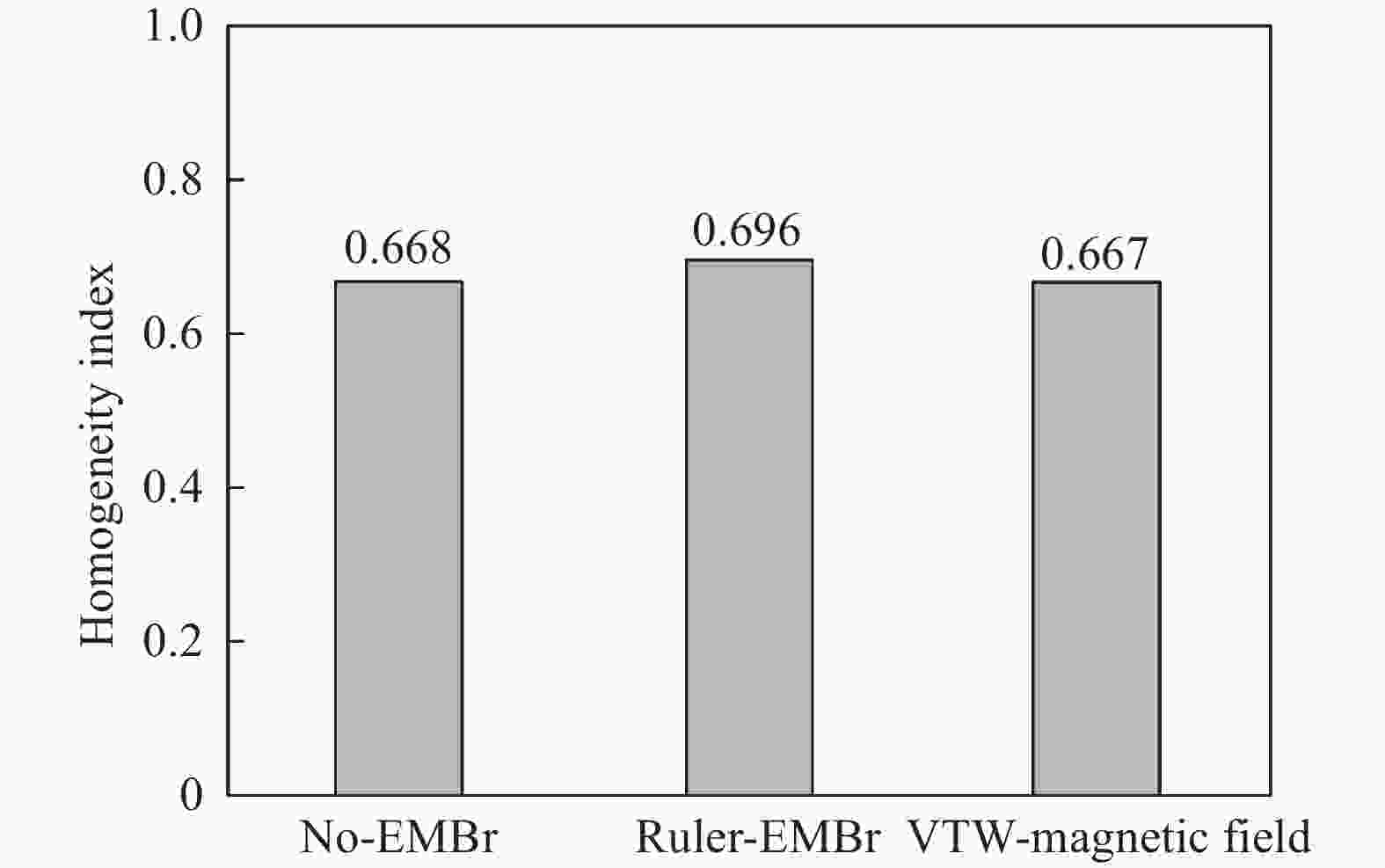

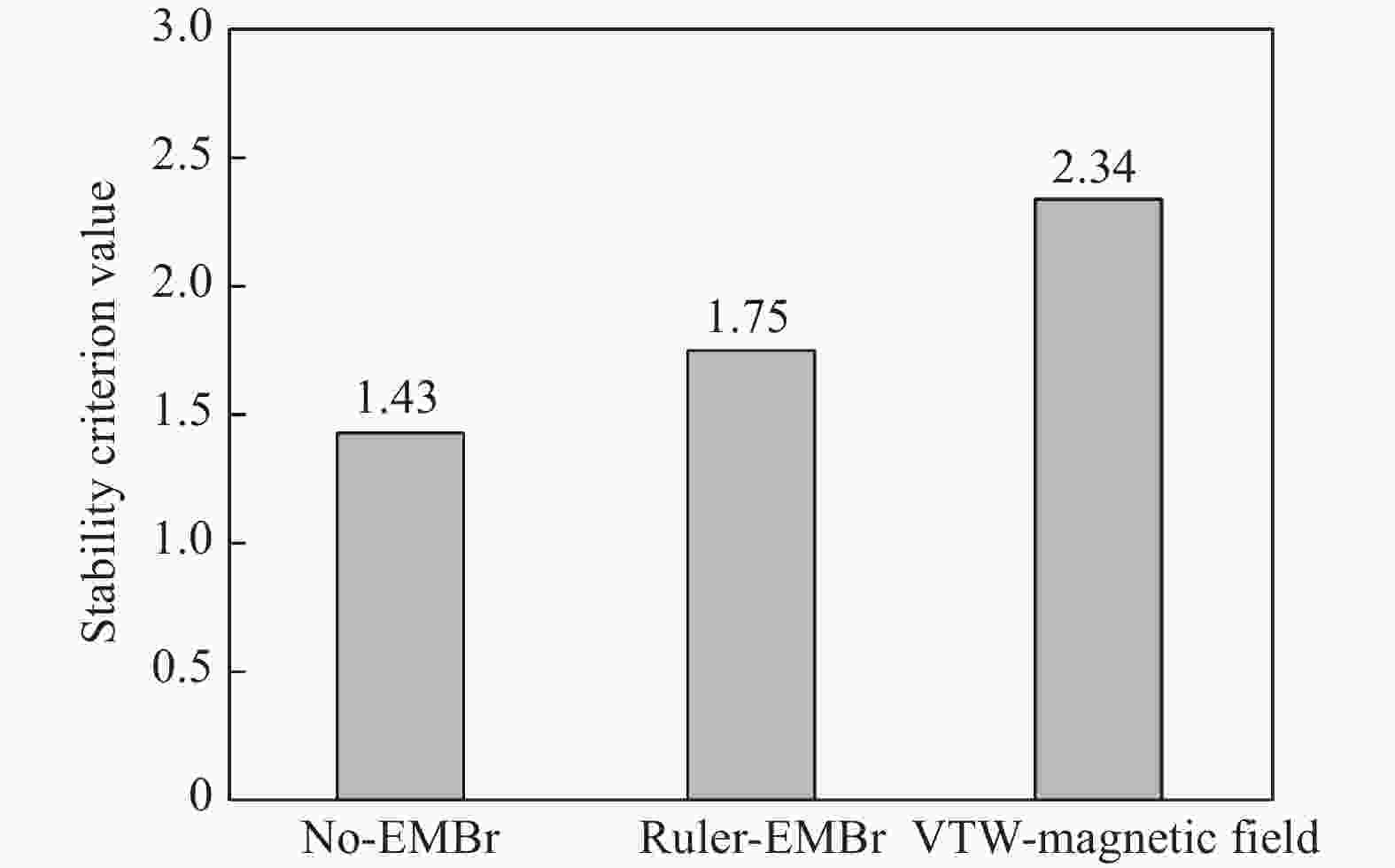

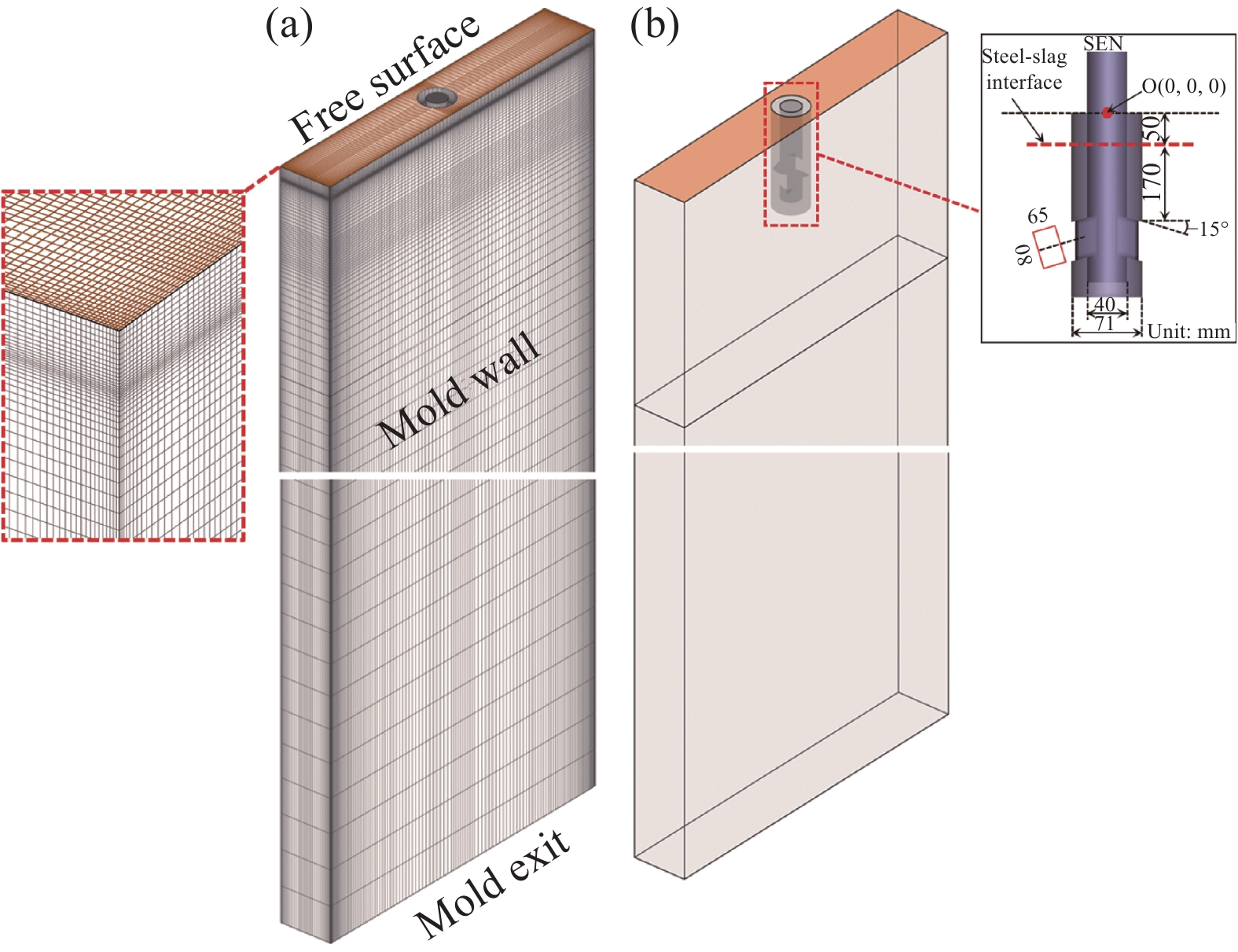

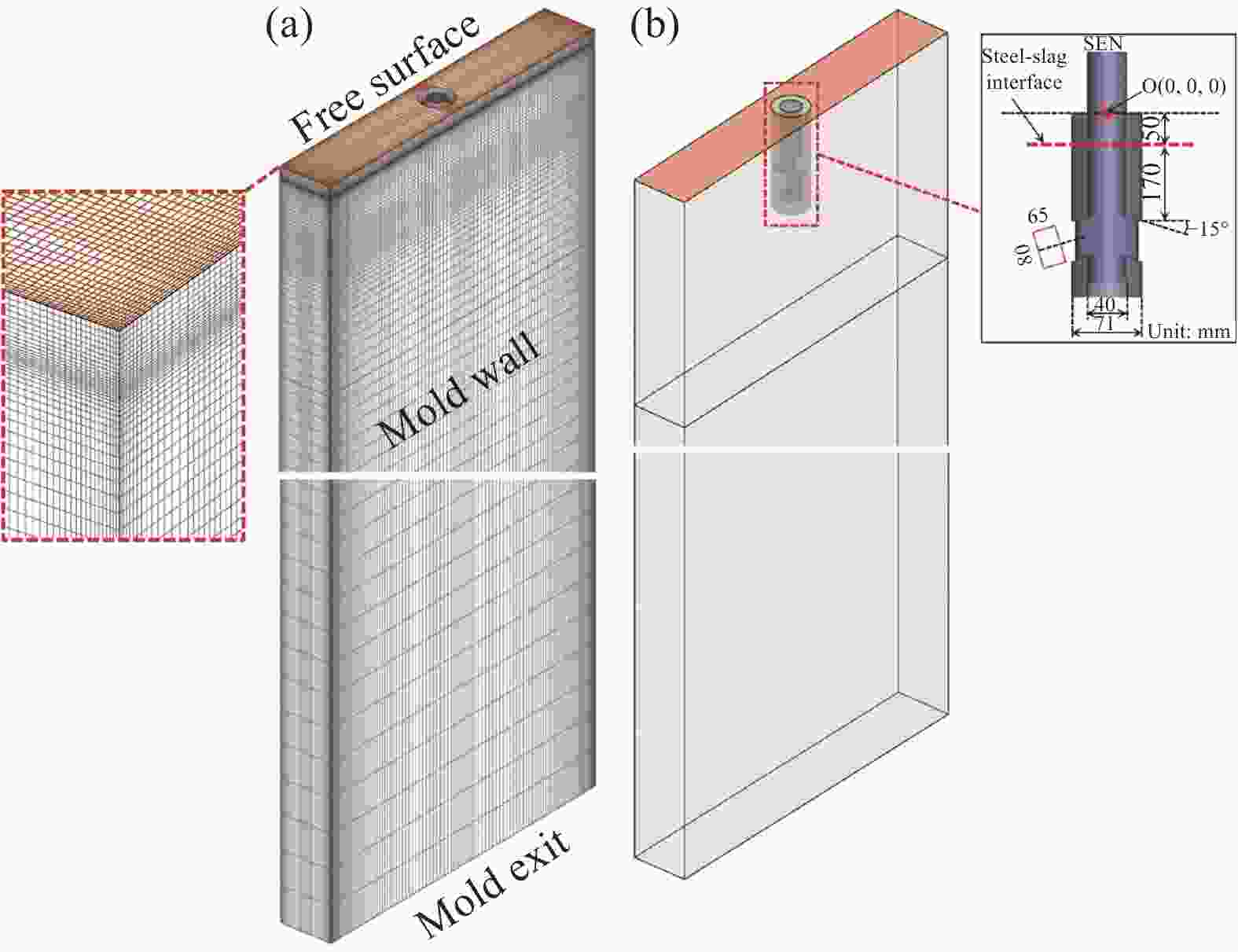

1450 mm×230 mm断面连铸板坯结晶器为对象,首先建立结晶器电磁连铸过程三维多物理场耦合数学模型,其次模拟研究无磁场、立式行波磁场及全幅一段水平直流磁场作用下板坯连铸结晶器内金属液流动与渣金界面行为,最后对比评价两种磁场形式对结晶器内钢液流动控制效果的影响。结果表明,无磁场作用时,渣金界面最大高度为22.3 mm;当全幅一段电磁制动器施加的电流为1350 A时,渣金界面最大高度降至18.6 mm;而当立式行波磁场减速器施加的电流仅为600 A时,渣金界面最大高度显著降至13.9 mm。可见,相较于全幅一段电磁制动器,立式行波磁场控流器能以更低能耗实现对结晶器内上回流区钢液流动的有效控制,从而稳定渣金界面波动,防止表面卷渣。Abstract: With the trend of green and low carbon development, the contemporary metallurgical industry pursues high-speed and high-efficiency continuous casting to promote sustainable development. In view of this, a vertical traveling wave magnetic field flow control technology is proposed to optimize and control the flow behavior of liquid metal during continuous casting and overcome the existing technical limitations. The proposed flow control technology can provide theoretical basis and technical support for the green and low-carbon transformation of continuous casting process. In the current research, a1450 mm × 230 mm continuous casting slab mold is taken as a research object. Firstly, a three-dimensional multi-physical field coupling mathematical model is established for describing the electromagnetic continuous casting process. Secondly, the behaviors of molten steel flow and the steel-slag interface within the slab continuous casting mold under conditions of free magnetic field, vertical traveling wave magnetic field, and single ruler horizontal direct current magnetic field are simulated and investigated. Finally, the effects of these two magnetic field forms on the flow control of molten steel in the mold are compared and evaluated. The results indicate that, in the absence of the magnetic field, the maximum height of the steel-slag interface is 22.3 mm. When applied the current via the single ruler horizontal electromagnetic brake is1350 A, the maximum height decreases to 18.6 mm. In comparison, when the vertical traveling wave magnetic field reducer applies a current of only 600 A, the maximum height of the steel-slag interface is significantly decreased to 13.9 mm. Based on the results, it can be concluded that the vertical traveling wave magnetic field reducer has more significant flow control advantages than the single ruler horizontal electromagnetic brake with lower energy consumption. The directional electromagnetic force generated by the vertical traveling wave magnetic field can effectively suppress the flow of molten steel in the upper recirculation zone of the mold and stabilize the fluctuation of the steel-slag interface.-

Key words:

- mold /

- traveling wave magnetic field /

- electromagnetic braking /

- steel-slag interface

-

表 1 板坯结晶器计算参数

Slab cross section/mm × mm Mold effective height/mm Computational domain/mm SEN exit cross section/mm 1450 ×230800 4000 65×80 SEN depth/mm Nozzle cavity/mm Casting speed/(m∙min‒1) Steel density/(kg∙m‒3) 170 80 1.8 7020 Steel viscosity/(Pa∙s) Steel conductivity/(S∙m‒1) Steel permeability/(H∙m‒1) Liquid steel density/(kg∙m‒3) 0.0062 7.14×105 1.26×106 3500 Surface tension/(N∙m‒1) Traveling wave magnetic field current/A Traveling wave magnetic field frequency/Hz Direct current magnetic field/A 1.2 600 3 1350 -

[1] ZHU M Y. A study of transport phenomena and key technologies for high-speed continuous casting of steel[J]. Iron and Steel, 2021, 56(7): 1-12. (朱苗勇. 高拉速连铸过程传输行为特征及关键技术探析[J]. 钢铁, 2021, 56(7): 1-12.ZHU M Y. A study of transport phenomena and key technologies for high-speed continuous casting of steel[J]. Iron and Steel, 2021, 56(7): 1-12. [2] ZHU M Y. Some considerations for new generation of high-efficiency continuous casting technology development[J]. Iron and Steel, 2019, 54(8): 21-36. (朱苗勇. 新一代高效连铸技术发展思考[J]. 钢铁, 2019, 54(8): 21-36.ZHU M Y. Some considerations for new generation of high-efficiency continuous casting technology development[J]. Iron and Steel, 2019, 54(8): 21-36. [3] ZHU M Y, LOU W T. Numerical simulation of multiphase flow and reaction kinetics during steelmaking process[J]. Journal of Materials and Metallurgy, 2022, 22(1): 1-19. (朱苗勇, 娄文涛. 炼钢过程多相流及其反应动力学数值模拟研究[J]. 材料与冶金学报, 2022, 22(1): 1-19.ZHU M Y, LOU W T. Numerical simulation of multiphase flow and reaction kinetics during steelmaking process[J]. Journal of Materials and Metallurgy, 2022, 22(1): 1-19. [4] REN Z M, LEI Z S, LI C J, et al. New study and development on electromagnetic field technology in metallurgical processes[J]. Acta Metallurgica Sinica, 2020, 56(4): 583-600. (任忠鸣, 雷作胜, 李传军, 等. 电磁冶金技术研究新进展[J]. 金属学报, 2020, 56(4): 583-600. doi: 10.11900/0412.1961.2019.00373REN Z M, LEI Z S, LI C J, et al. New study and development on electromagnetic field technology in metallurgical processes[J]. Acta Metallurgica Sinica, 2020, 56(4): 583-600. doi: 10.11900/0412.1961.2019.00373 [5] XU L, PEI Q W, LI Y, et al. Investigation of multiphase transport behaviors in a FTSR mold during electromagnetic continuous casting process[J]. Iron Steel Vanadium Titanium, 2023, 44(4): 125-134. (许琳, 裴群武, 李阳, 等. 电磁连铸过程FTSR结晶器多相传输行为的研究[J]. 钢铁钒钛, 2023, 44(4): 125-134. doi: 10.7513/j.issn.1004-7638.2023.04.019XU L, PEI Q W, LI Y, et al. Investigation of multiphase transport behaviors in a FTSR mold during electromagnetic continuous casting process[J]. Iron Steel Vanadium Titanium, 2023, 44(4): 125-134. doi: 10.7513/j.issn.1004-7638.2023.04.019 [6] VAKHRUSHEV A, KARIMI-SIBAKI E, BOHACEK J, et al. Impact of submerged entry nozzle (SEN) immersion depth on meniscus flow in continuous casting mold under electromagnetic brake (EMBr)[J]. Metals, 2023, 13(3): 444-464. doi: 10.3390/met13030444 [7] CUI H N, SUN J K, ZHANG J S, et al. Large eddy simulation of novel EMBr effect on flow pattern in thin slab casting mold with multi-port SEN and ultra-high casting speed[J]. J. Manuf. Process., 2025, 133(3): 448-465. [8] WEI Z J, WANG T, FENG C, et al. Modeling and simulation of multi-phase and multi-physical fields for slab continuous casting mold under ruler electromagnetic braking[J]. Metall. Mater. Trans. B, 2024, 55(4): 2194-2208. doi: 10.1007/s11663-024-03085-3 [9] LIU Z Q, LI B K, XIAO L J, et al. Modeling progress of high-temperature melt multiphase flow in continuous casting mold[J]. Acta Metallurgica Sinica, 2022, 58(10): 1236-1252. (刘中秋, 李宝宽, 肖丽俊, 等. 连铸结晶器内高温熔体多相流模型化研究进展[J]. 金属学报, 2022, 58(10): 1236-1252. doi: 10.11900/0412.1961.2022.00175LIU Z Q, LI B K, XIAO L J, et al. Modeling progress of high-temperature melt multiphase flow in continuous casting mold[J]. Acta Metallurgica Sinica, 2022, 58(10): 1236-1252. doi: 10.11900/0412.1961.2022.00175 [10] LUO S, YANG Y W, WANG W L, et al. Development of electromagnetic flow control technology for high speed casting mold[J]. Journal of Materials and Metallurgy, 2023, 22(1): 1-22. (罗森, 杨宇威, 王卫领, 等. 高拉速连铸结晶器电磁控流技术发展[J]. 材料与冶金学报, 2023, 22(1): 1-22.LUO S, YANG Y W, WANG W L, et al. Development of electromagnetic flow control technology for high speed casting mold[J]. Journal of Materials and Metallurgy, 2023, 22(1): 1-22. [11] VILA A, LINDLBAUER F, ZHANG Z, et al. Simulation and optimization of electromagnetic stirring and braking in slab continuous casting mold[J]. Berg Huettenmaenn Monatsh, 2025, 170(1): 37-44. doi: 10.1007/s00501-024-01539-4 [12] XIAO H, WANG P, ZHU J L, et al. Effect of deceleration mode of traveling wave magnetic field on the liquid steel transportation behavior in the mold of slab casting[J]. Journal of Mechanical Engineering, 2023, 59(18): 219-227. (肖红, 王璞, 朱晶亮, 等. 行波磁场减速模式对板坯连铸结晶器内传输行为的影响[J]. 机械工程学报, 2023, 59(18): 219-227. doi: 10.3901/JME.2023.18.219XIAO H, WANG P, ZHU J L, et al. Effect of deceleration mode of traveling wave magnetic field on the liquid steel transportation behavior in the mold of slab casting[J]. Journal of Mechanical Engineering, 2023, 59(18): 219-227. doi: 10.3901/JME.2023.18.219 [13] HE J G, DENG A Y, XU X J, et al. Effect of electromagnetic stirring position on liquid steel flow and liquid level fluctuation in continuous casting mold for wide thick slab[J]. Continuous Casting, 2022, 4: 50-58. (何建国, 邓安元, 许秀杰, 等. 电磁搅拌宽厚板结晶器内钢液流动和液面波动[J]. 连铸, 2022, 4: 50-58.HE J G, DENG A Y, XU X J, et al. Effect of electromagnetic stirring position on liquid steel flow and liquid level fluctuation in continuous casting mold for wide thick slab[J]. Continuous Casting, 2022, 4: 50-58. [14] XIE X X, LUO S, CHEN Y, et al. Effect of electromagnetic stirring on flow, solidification and liquid level fluctuations in slab mold[J]. Continuous Casting, 2025, 44(2): 7-14. (解晓晓, 罗森, 陈耀, 等. 电磁搅拌对板坯结晶器内钢液流动、凝固和液面波动的影响[J]. 连铸, 2025, 44(2): 7-14.XIE X X, LUO S, CHEN Y, et al. Effect of electromagnetic stirring on flow, solidification and liquid level fluctuations in slab mold[J]. Continuous Casting, 2025, 44(2): 7-14. [15] SUN X H, LI B, LU H B, et al. Steel slag interface behavior under multifunction electromagnetic driving in a continuous casting slab mold[J]. Metals, 2019, 9(9): 983-999. doi: 10.3390/met9090983 [16] LI B, LU H B, ZHONG Y B, et al. Numerical simulation for the influence of EMS position on fluid flow and inclusion removal in a slab continuous casting mold[J]. ISIJ Int., 2020, 60(6): 1204-1212. doi: 10.2355/isijinternational.ISIJINT-2019-666 [17] LIU G L, LU H B, LI B, et al. Influence of M-EMS on fluid flow and initial solidification in slab continuous casting[J]. Materials, 2021, 14(13): 3681-3697. doi: 10.3390/ma14133681 [18] XU L, PEI Q W, LI N, et al. Study on the effect of multi area controllable electromagnetic braking on behavior of non-uniform molten steel flow and steel-slag interface in the mold[J]. Iron Steel Vanadium Titanium, 2025, 46(1): 112-123. (许琳, 裴群武, 李楠, 等. 多区域独立可控电磁制动对结晶器内钢液非均匀流动与渣金界面行为影响的研究[J]. 钢铁钒钛, 2025, 46(1): 112-123. doi: 10.7513/j.issn.1004-7638.2025.01.017XU L, PEI Q W, LI N, et al. Study on the effect of multi area controllable electromagnetic braking on behavior of non-uniform molten steel flow and steel-slag interface in the mold[J]. Iron Steel Vanadium Titanium, 2025, 46(1): 112-123. doi: 10.7513/j.issn.1004-7638.2025.01.017 [19] XU L, WANG E G, KARCHER C, et al. Numerical simulation of the effects of horizontal and vertical EMBr on jet flow and mold level fluctuation in continuous casting[J]. Metall. Mater. Trans. B, 2018, 49(5): 2779-2793. doi: 10.1007/s11663-018-1342-4 [20] XU L, KARCHER C, WANG E G. Numerical simulation of melt flow, heat transfer and solidification in CSP continuous casting mold with vertical-combined electromagnetic braking[J]. Metall. Mater. Trans. B, 2023, 54(4): 1646-1664. doi: 10.1007/s11663-023-02784-7 [21] XU L, HAN Z F, KARCHER C, et al. Melt flow, heat transfer and solidification in a flexible thin slab continuous casting mold with vertical-combined electromagnetic braking[J]. J. Iron Steel Res. Int., 2024, 31(2): 401-415. doi: 10.1007/s42243-023-01062-9 [22] ZHANG A H, MA D Z, JIAN W W, et al. Numerical simulation of argon blowing behavior inside an independent adjustable combination electromagnetic brake mold[J]. Continuous Casting, 2024, 4: 38-46. (张安昊, 马丹竹, 建伟伟, 等. 独立可调式组合电磁制动结晶器内吹氩行为数值模拟[J]. 连铸, 2024, 4: 38-46.ZHANG A H, MA D Z, JIAN W W, et al. Numerical simulation of argon blowing behavior inside an independent adjustable combination electromagnetic brake mold[J]. Continuous Casting, 2024, 4: 38-46. -

下载:

下载: