Study on the stress-strain behavior of CoCrFeNiCux high-entropy alloy under biaxial tensile state

-

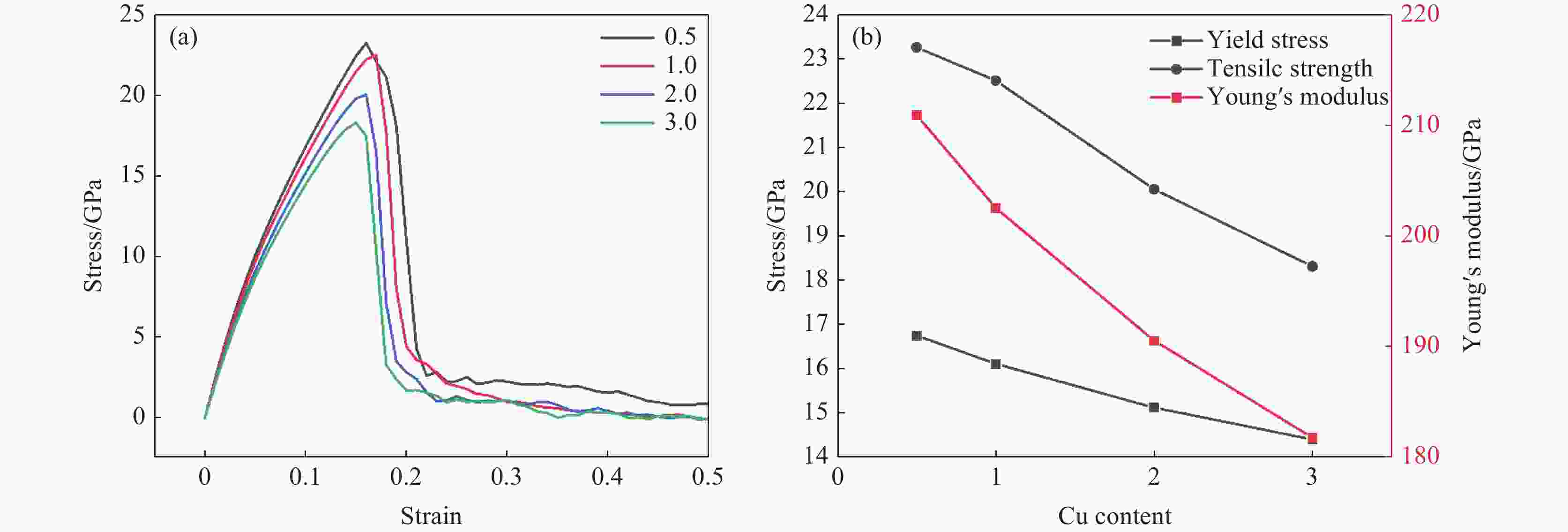

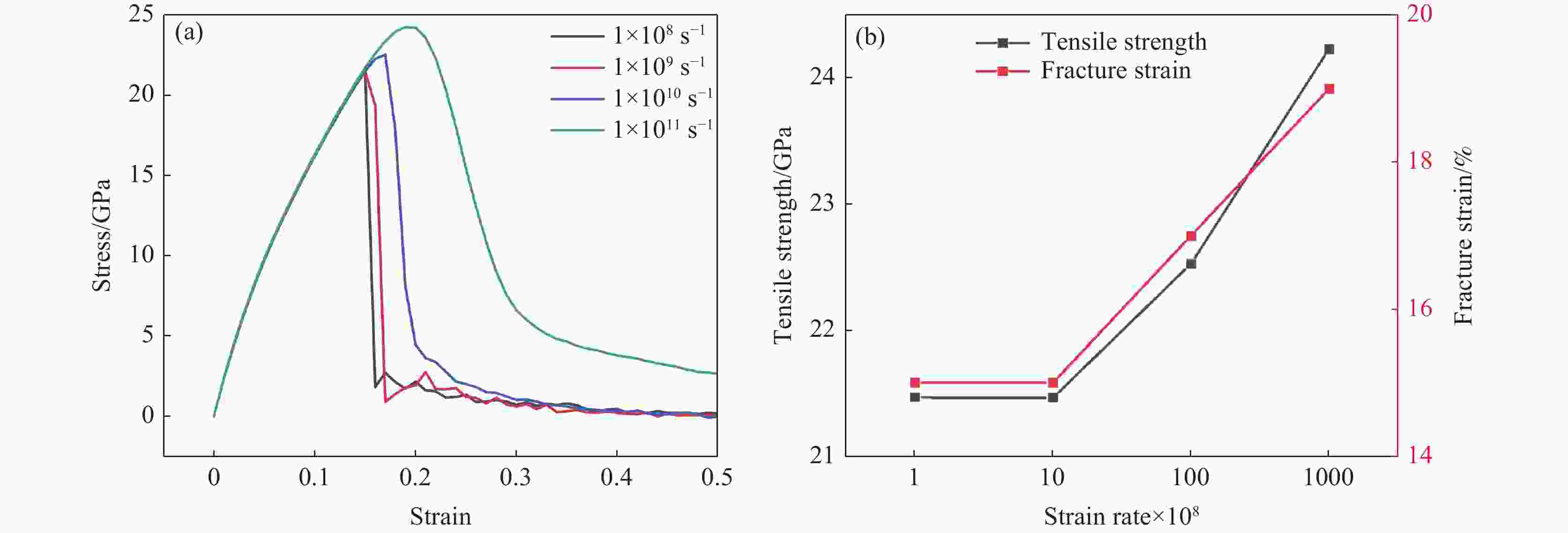

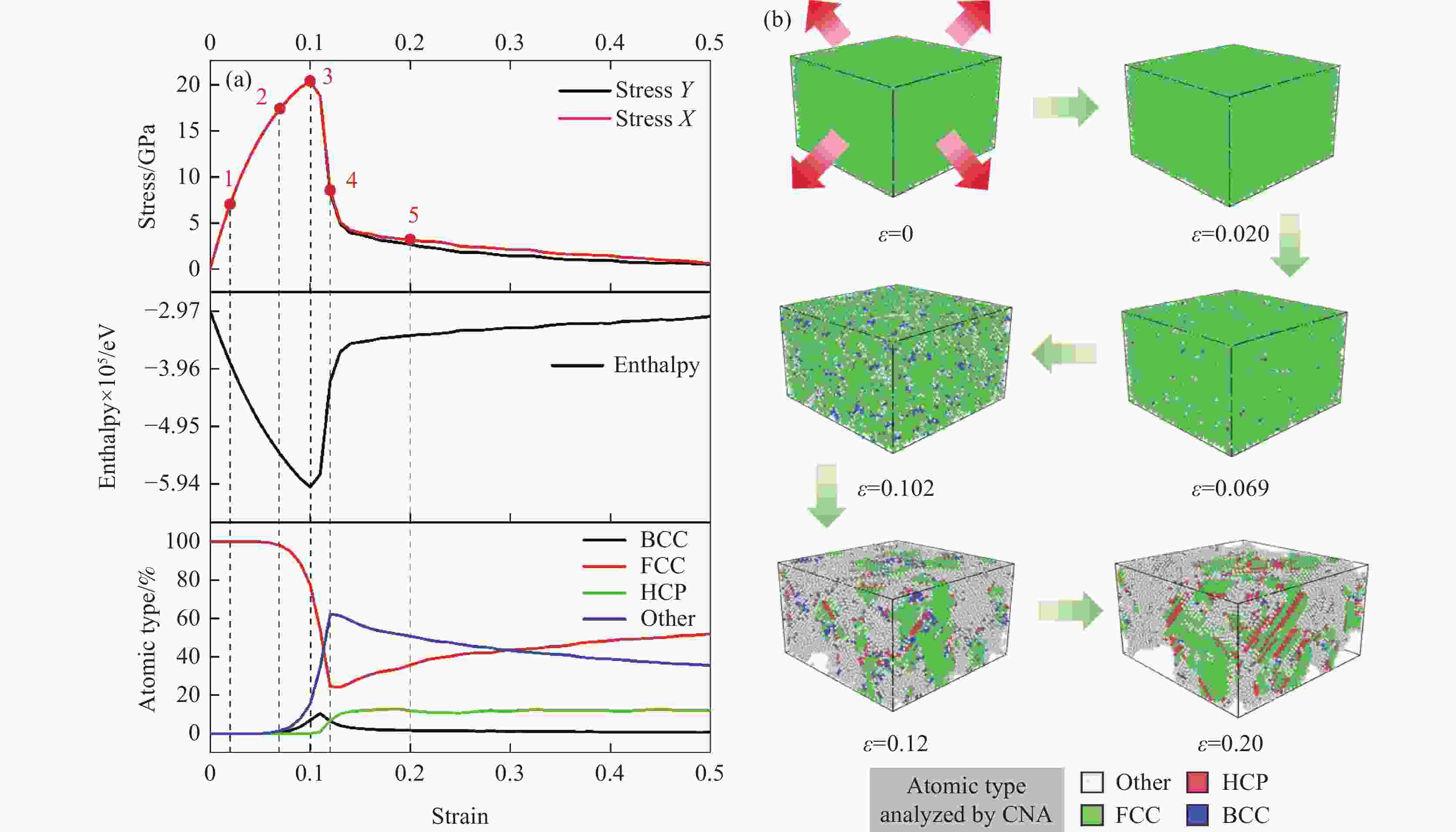

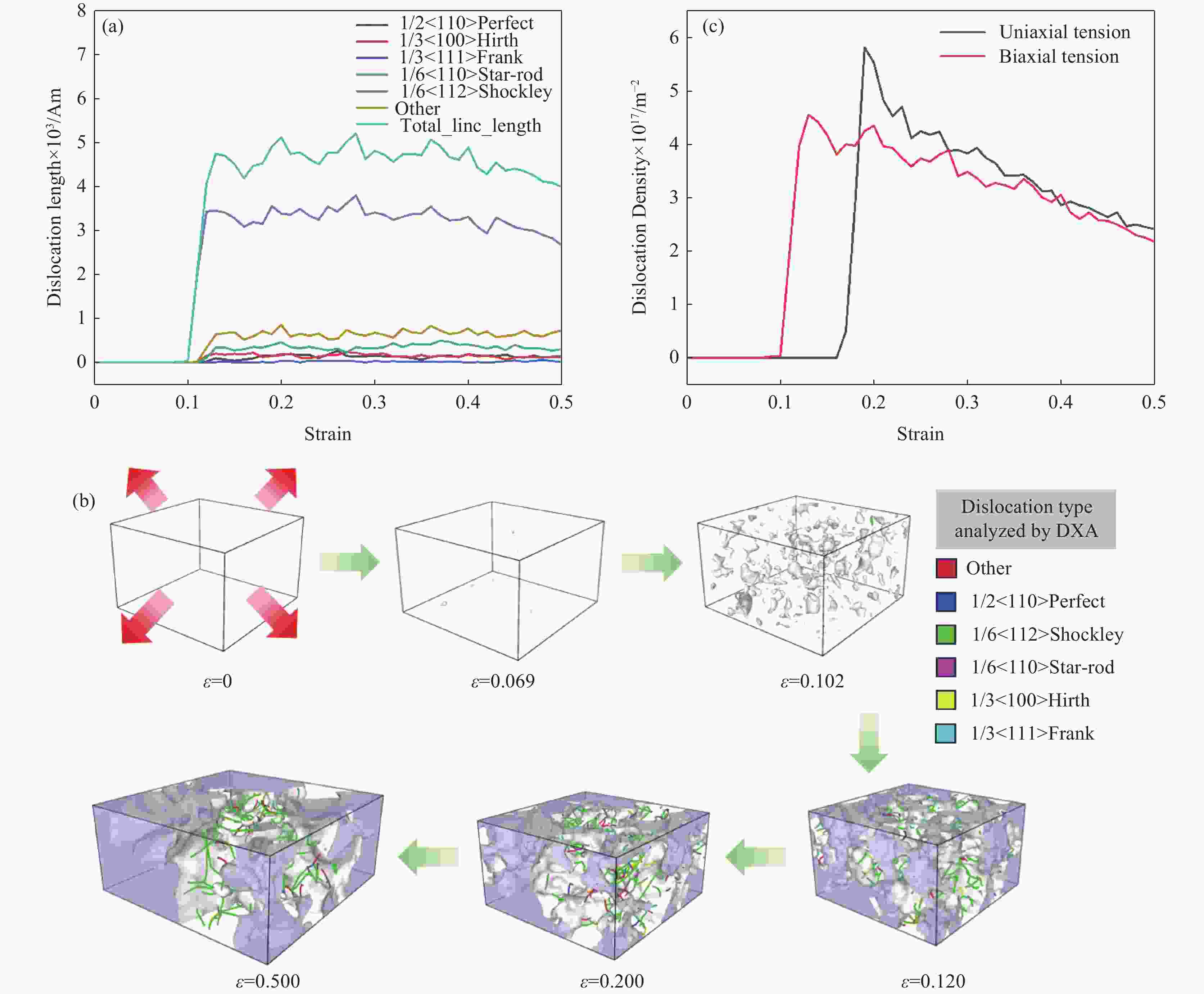

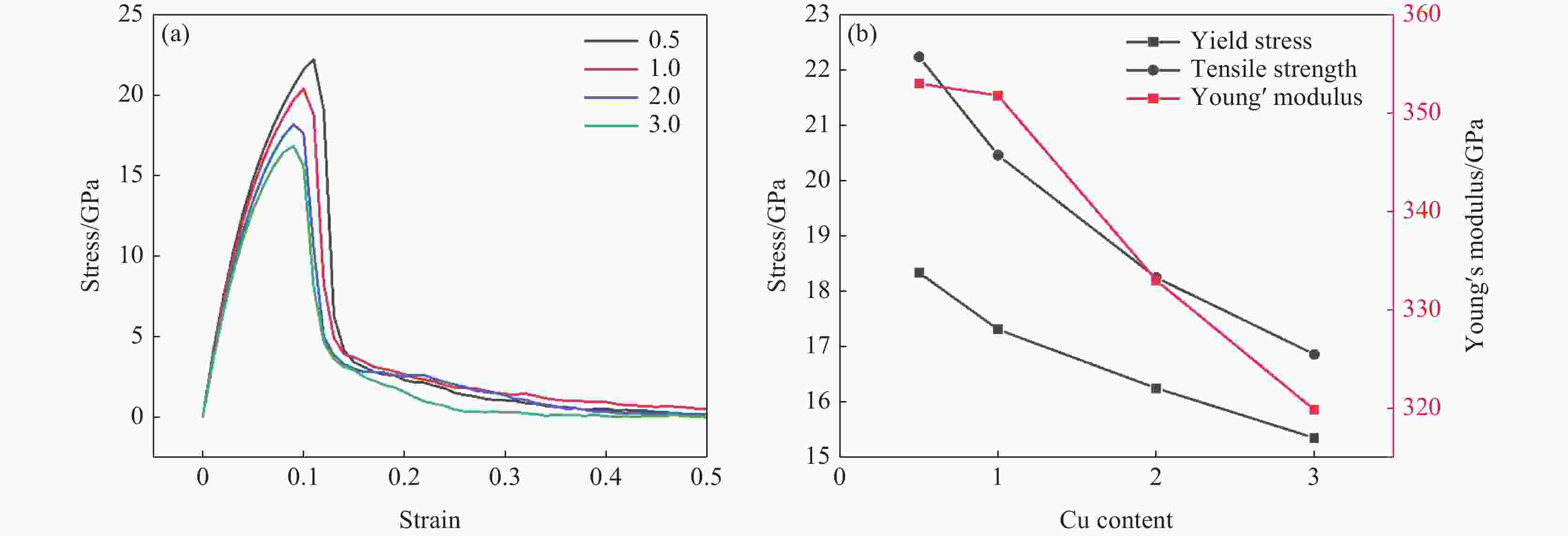

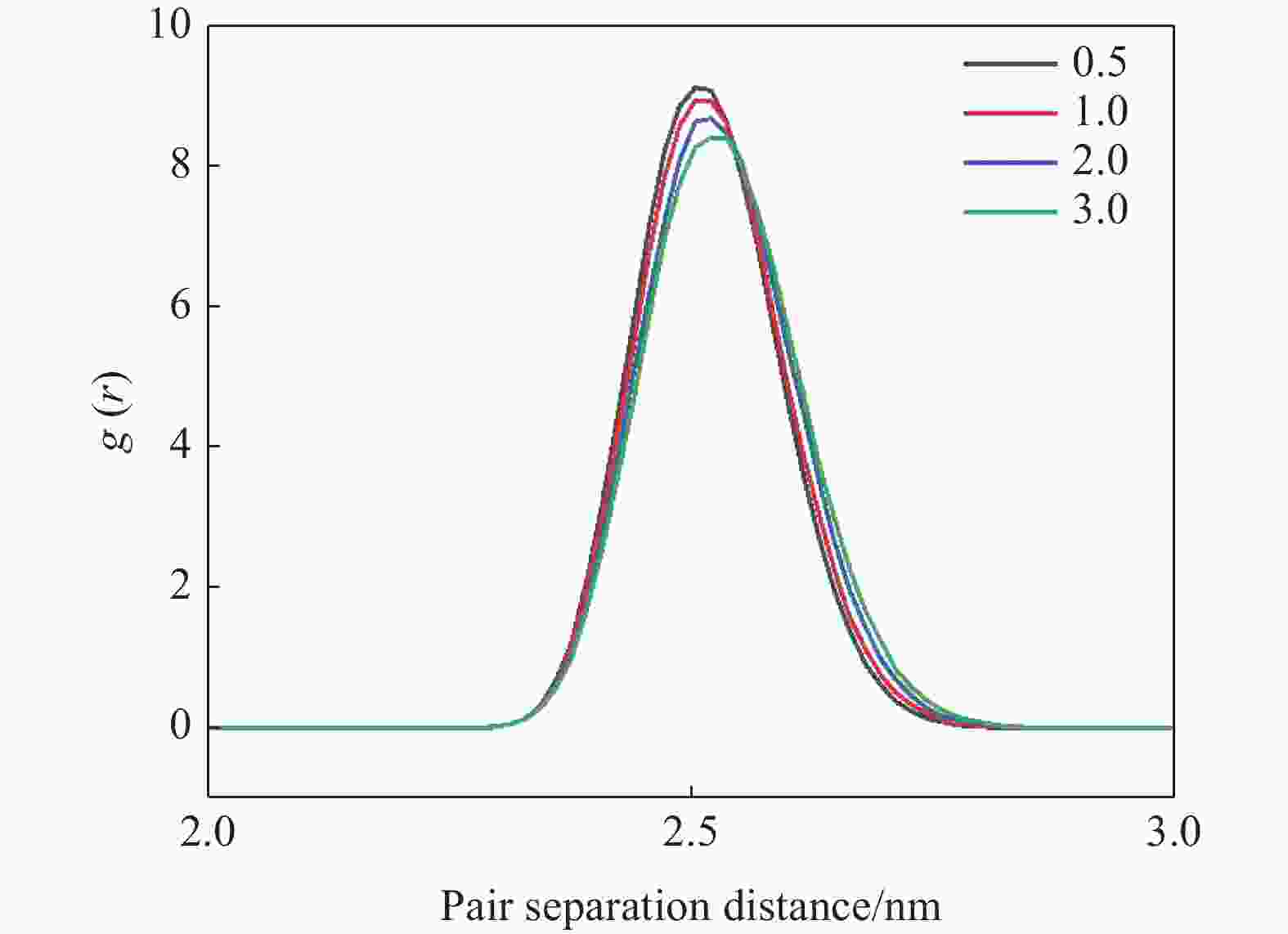

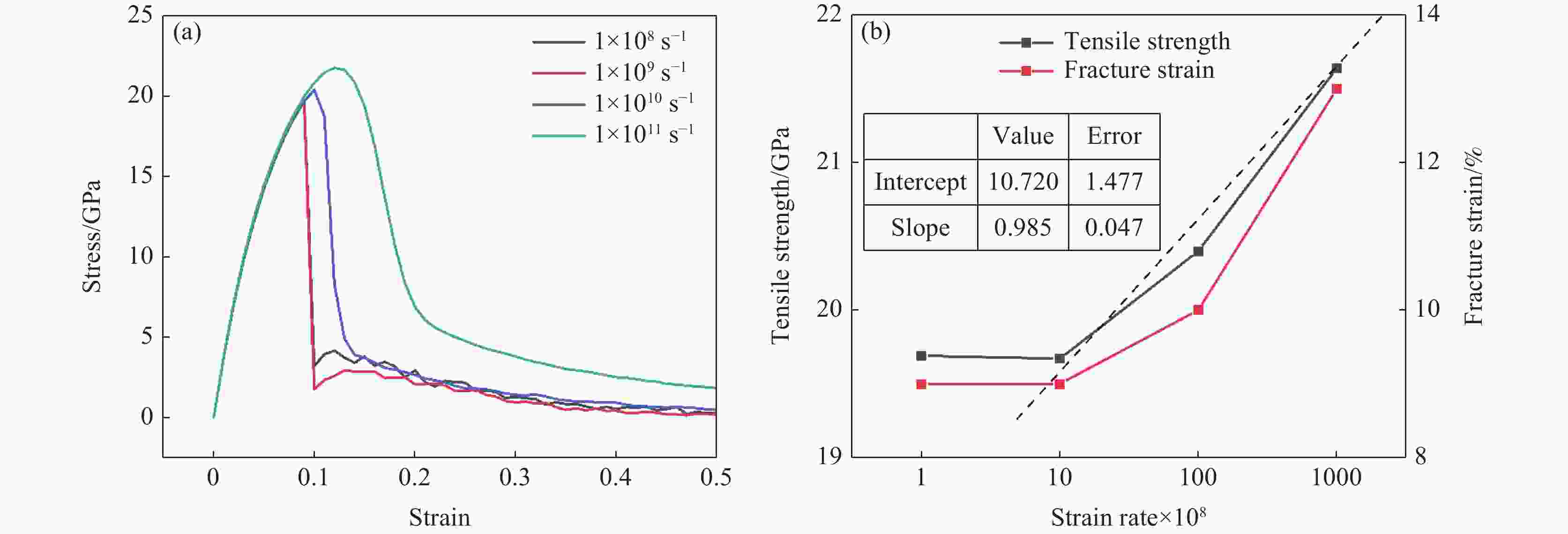

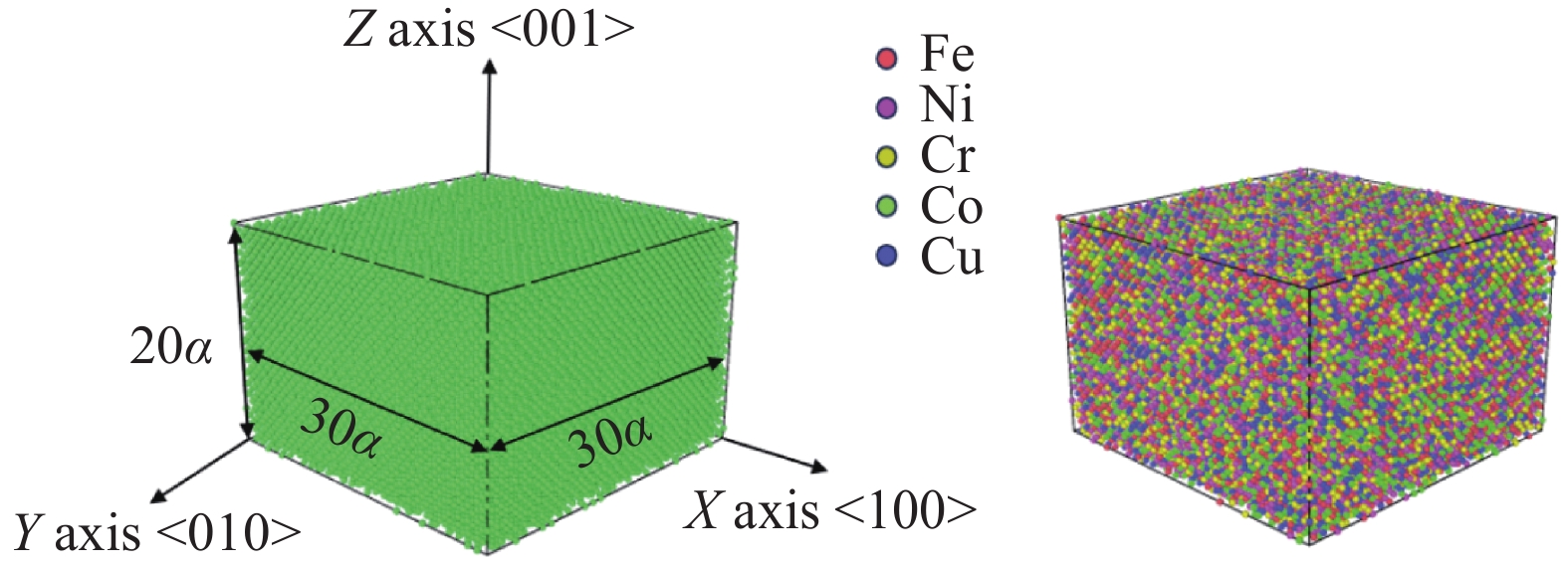

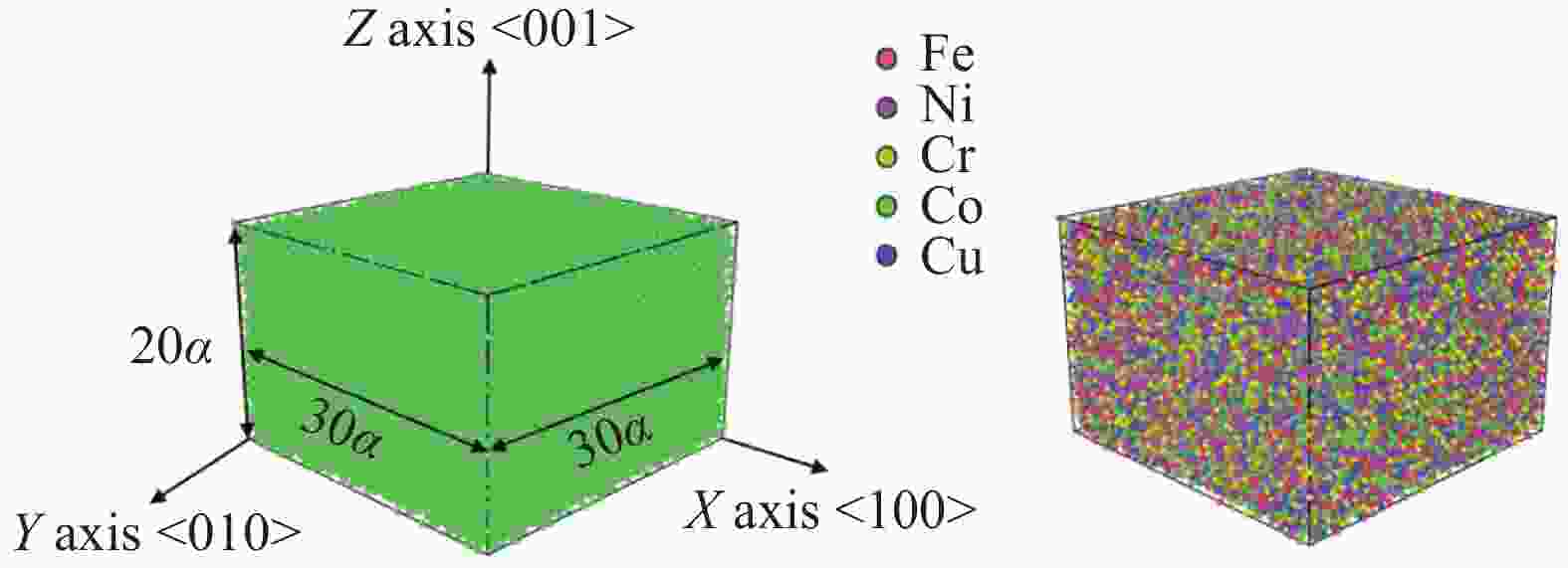

摘要: 采用分子动力学(MD)方法,模拟了CoCrFeNiCux(x=0.5、1.0、2.0和3.0)高熵合金在不同应变速率下的双轴拉伸行为。分析了铜含量和应变率对双轴拉伸应力应变行为及微观变形机理的影响。结果表明,CoCrFeNiCux高熵合金在双轴拉伸过程中,面心立方(FCC)结构和不规则原子结构可以相互转化。随着Cu含量的增加,CoCrFeNiCux高熵合金的杨氏模量、屈服强度和抗拉强度呈下降趋势,而应变率的增加则会提高其抗拉强度和断裂应变。与单轴拉伸相比,两种应力状态下的应力应变行为均表现出应变硬化及应变率强化效应。然而,在双轴载荷作用下,其屈服强度有所提升,但抗拉强度和失效应变均显著降低。此项研究将为该合金的设计和制备提供重要的参考价值。Abstract: Using molecular dynamics (MD) simulations, the biaxial tensile behavior of CoCrFeNiCux (x=0.5, 1.0, 2.0, and 3.0) high-entropy alloys at different strain rates was simulated. The effects of copper content and strain rate on the biaxial tensile stress-strain behavior and the microscopic deformation mechanisms were analyzed. The results indicated that during the biaxial tensile process of CoCrFeNiCux high-entropy alloys, the face-centered cubic (FCC) structure and irregular atomic structure can transform into each other. As the Cu content increases, the Young's modulus, yield strength, and ultimate tensile strength of CoCrFeNiCux high-entropy alloys decrease, while an increase in strain rate enhances their ultimate tensile strength and fracture strain. Compared to the uniaxial tension, the stress-strain behavior under both stress states exhibits the strain hardening and strain rate strengthening effects. However, under biaxial loading, the yield strength increases, while the ultimate tensile strength and failure strain significantly decrease. This study provides important reference value for the design and preparation of this alloy.

-

Key words:

- high-entropy alloy /

- biaxial tension /

- molecular dynamics /

- mechanical properties

-

表 1 CoCrFeNiCu1.0单轴拉伸模拟结果对比

Table 1. Comparison of uniaxial tensile simulation results of CoCrFeNiCu1.0

Mechanical properties Young's modulus/GPa Tensile strength/GPa Fracture strain Simulation results 202.62 22.54 0.17 Comparative results[19] 222.3 22.53 22.53 -

[1] YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299-303. doi: 10.1002/adem.200300567 [2] CANTOR B, CHANG I T H, KNIGHT P, et al. Microstructural development in equiatomic multicomponent alloys[J]. Materials Science and Engineering: A, 2004, 375: 213-218. [3] MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts[J]. Acta Materialia, 2017, 122: 448-511. doi: 10.1016/j.actamat.2016.08.081 [4] MURTY B S, YEH J W, RANGANATHAN S, et al. High-entropy alloys[M]. Elsevier, 2019. [5] YANG Y F, HU F, XIA T, et al. High entropy alloys: a review of preparation techniques, properties and industry applications[J]. Journal of Alloys and Compounds, 2024: 177691. [6] GEORE E P, RAABE D, RITCHIE R O. High-entropy alloys[J]. Nature Reviews Materials, 2019, 4(8): 515-534. doi: 10.1038/s41578-019-0121-4 [7] LI C W, ZHANG Y. Effect of copper content on the microstructure and properties of CoCrFeNi high-entropy alloy[J]. Journal of Precision Forming Engineering, 2022, 14(12): 1-9. (李昌伟, 张勇. 铜含量对CoCrFeNi高熵合金组织结构和性能的影响[J]. 精密成形工程, 2022, 14(12): 1-9. doi: 10.3969/j.issn.1674-6457.2022.12.001LI C W, ZHANG Y. Effect of copper content on the microstructure and properties of CoCrFeNi high-entropy alloy[J]. Journal of Precision Forming Engineering, 2022, 14(12): 1-9. doi: 10.3969/j.issn.1674-6457.2022.12.001 [8] FARKAS D, CARO A. Model interatomic potentials and lattice strain in a high-entropy alloy[J]. Journal of Materials Research, 2018, 33(19): 3218-3225. doi: 10.1557/jmr.2018.245 [9] CAO Y, LIU J F, ZHOU S G, et al. Mechanical properties and microstructural evolution of FeNiCrCoCux high-entropy alloys: A molecular dynamics simulation[J]. Solid State Communications, 2023, 359: 115011. doi: 10.1016/j.ssc.2022.115011 [10] HANNON A, TIERNAN P. A review of planar biaxial tensile test systems for sheet metal[J]. Journal of Materials Processing Technology, 2008, 198(1-3): 1-13. doi: 10.1016/j.jmatprotec.2007.10.015 [11] SUN X L, FAN S M, PENG M J, et al. Classical molecular dynamics simulation of atomic structure transitions in FeSiCuMgAl high-entropy alloys under biaxial stretching[J]. Materials Today Communications, 2024, 40: 109716. doi: 10.1016/j.mtcomm.2024.109716 [12] MENG J K, LIU L, JIANG J T, et al. The role of biaxial stress ratio on the mechanical behavior and deformation mechanisms in HCP α-Ti[J]. Materials Science and Engineering: A, 2023, 862: 144452. doi: 10.1016/j.msea.2022.144452 [13] HU Y X, SHUANG S Y, WANG B, et al. Study on the temperature-dependent tensile behavior of nanocrystalline CrMnFeCoNi high-entropy alloy [J]. Journal of Solid Mechanics, 2020, 41(2): 109-117. (胡远啸, 双思垚, 王冰, 等. CrMnFeCoNi高熵合金纳米晶温度相关的拉伸行为研究[J]. 固体力学学报, 2020, 41(2): 109-117.HU Y X, SHUANG S Y, WANG B, et al. Study on the temperature-dependent tensile behavior of nanocrystalline CrMnFeCoNi high-entropy alloy [J]. Journal of Solid Mechanics, 2020, 41(2): 109-117. [14] STUKOWSKI A. Structure identification methods for atomistic simulations of crystalline materials[J]. Modelling and Simulation in Materials Science and Engineering, 2012, 20(4): 045021. doi: 10.1088/0965-0393/20/4/045021 [15] STUKOWSKI A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool[J]. Modelling and Simulation in Materials Science and Engineering, 2009, 18(1): 015012. [16] STUKOWSKI A, BULATOV V V, ARSENLIS A. Automated identification and indexing of dislocations in crystal interfaces[J]. Modelling and Simulation in Materials Science and Engineering, 2012, 20(8): 085007. doi: 10.1088/0965-0393/20/8/085007 [17] LIU H W. Mechanics of materials [M]. Beijing: Higher Education Press, December 1982. (刘鸿文. 材料力学[M]. 北京: 高等教育出版社, 1982.12.LIU H W. Mechanics of materials [M]. Beijing: Higher Education Press, December 1982. [18] ZHENG H T, CHEN R R, QIN G, et al. Microstructure evolution, Cu segregation and tensile properties of CoCrFeNiCu high entropy alloy during directional solidification[J]. Journal of Materials Science & Technology, 2020, 38: 19-27. [19] WANG Q, GUO J H, CHEN W Q, et al. Molecular dynamics simulations of tensile properties for FeNiCrCoCu high-entropy alloy[J]. Materials Today Communications, 2024, 38: 108187. doi: 10.1016/j.mtcomm.2024.108187 [20] WEISS J, SAVAGE D J, VOGEL S C, et al. Evolution of microstructure and strength of a high entropy alloy undergoing the strain-induced martensitic transformation[J]. Materials Science and Engineering: A, 2023, 887: 145754. doi: 10.1016/j.msea.2023.145754 [21] ZHANG R, QI W J, ZHANG S. Molecular dynamics simulation of tensile mechanical properties of AlxCoCrFeNi[J]. Iron, Steel, Vanadium and Titanium, 2022, 43(6): 173-179. (张荣, 祁文军, 张爽. AlxCoCrFeNi拉伸力学性能的分子动力学模拟[J]. 钢铁钒钛, 2022, 43(6): 173-179. doi: 10.7513/j.issn.1004-7638.2022.06.026ZHANG R, QI W J, ZHANG S. Molecular dynamics simulation of tensile mechanical properties of AlxCoCrFeNi[J]. Iron, Steel, Vanadium and Titanium, 2022, 43(6): 173-179. doi: 10.7513/j.issn.1004-7638.2022.06.026 [22] LI J, FANG Q H, LIU B, et al. Mechanical behaviors of AlCrFeCuNi high-entropy alloys under uniaxial tension via molecular dynamics simulation[J]. RSC Advances, 2016, 6(80): 76409-76419. doi: 10.1039/C6RA16503F [23] LI H Y, GAO L Q, QI L, et al. Biaxial tensile behavior of CoCrFeNi high-entropy alloy under dynamic and proportional loadings[J]. Chinese Journal of Aeronautics, 2024. [24] LIU X R, CHANG L, MA T H, et al. Molecular dynamics simulation of tension and compression deformation behavior in CoCrCuFeNi high-entropy alloy: Effects of temperature and orientation[J]. Materials Today Communications, 2023, 36: 106523. doi: 10.1016/j.mtcomm.2023.106523 [25] ZHANG L M, MA S G, LI Z Q, et al. Molecular dynamics simulation of the mechanical properties of AlxCoCrFeNi high-entropy alloy [J]. Chinese Journal of High Pressure Physics, 2021, 35(5). (张路明, 马胜国, 李志强, 等. AlxCoCrFeNi高熵合金力学性能的分子动力学模拟[J]. 高压物理学报, 2021, 35(5).ZHANG L M, MA S G, LI Z Q, et al. Molecular dynamics simulation of the mechanical properties of AlxCoCrFeNi high-entropy alloy [J]. Chinese Journal of High Pressure Physics, 2021, 35(5). [26] HOGE K G. Influence of strain rate on mechanical properties of 6061-T6 aluminum under uniaxial and biaxial states of stress: Author presents special technique for determining mechanical properties of materials under dynamic tensile loads[J]. Experimental Mechanics, 1966, 6: 204-211. doi: 10.1007/BF02326150 [27] LI M C, JIANG M Q, YANG S J, et al. Effect of strain rate on yielding strength of a Zr-based bulk metallic glass[J]. Materials Science and Engineering: A, 2017, 680: 21-26. doi: 10.1016/j.msea.2016.10.081 -

下载:

下载: