Stacked ensemble learning model-based prediction and optimization of the grade of titanium dioxide in high titanium slag

-

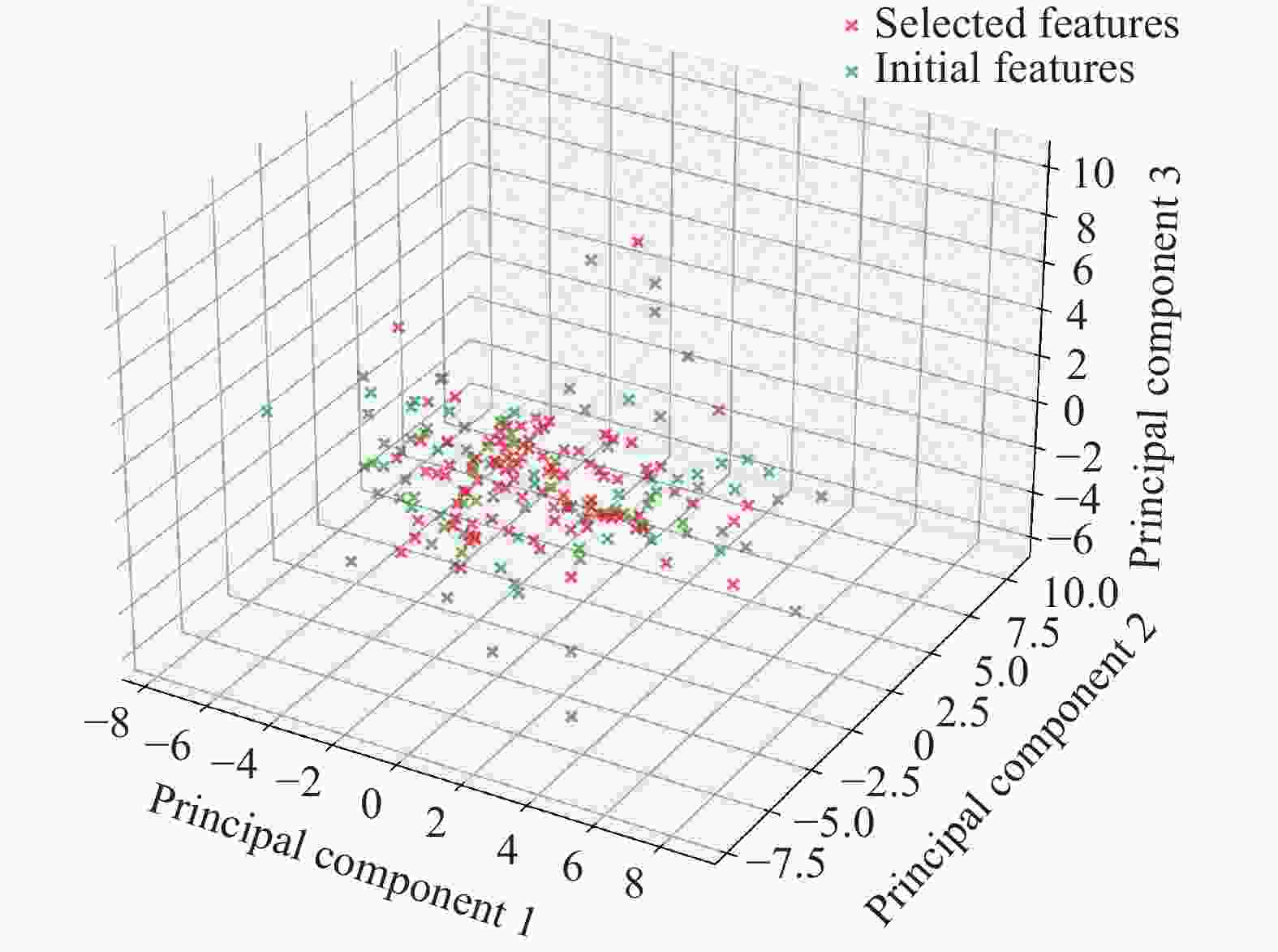

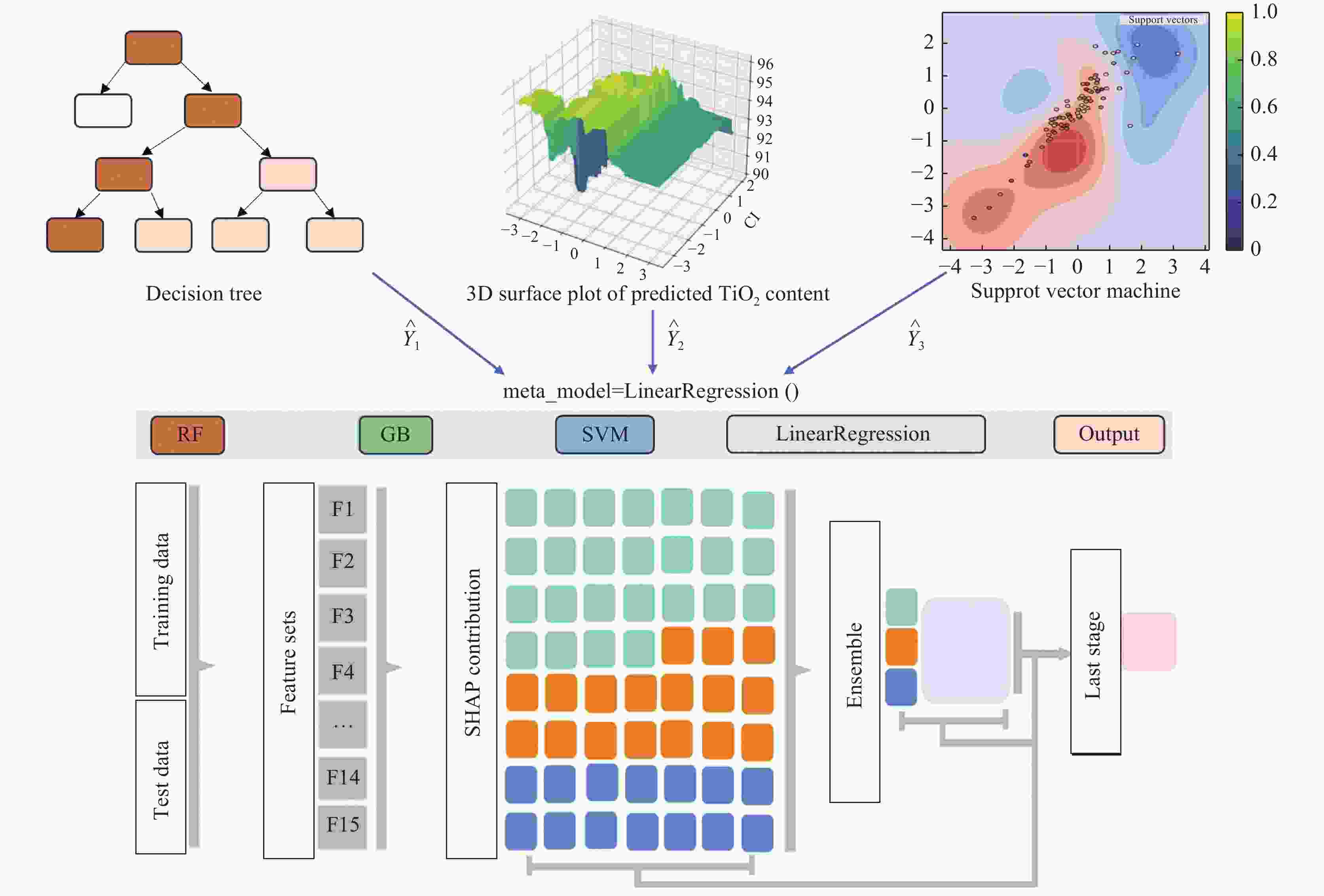

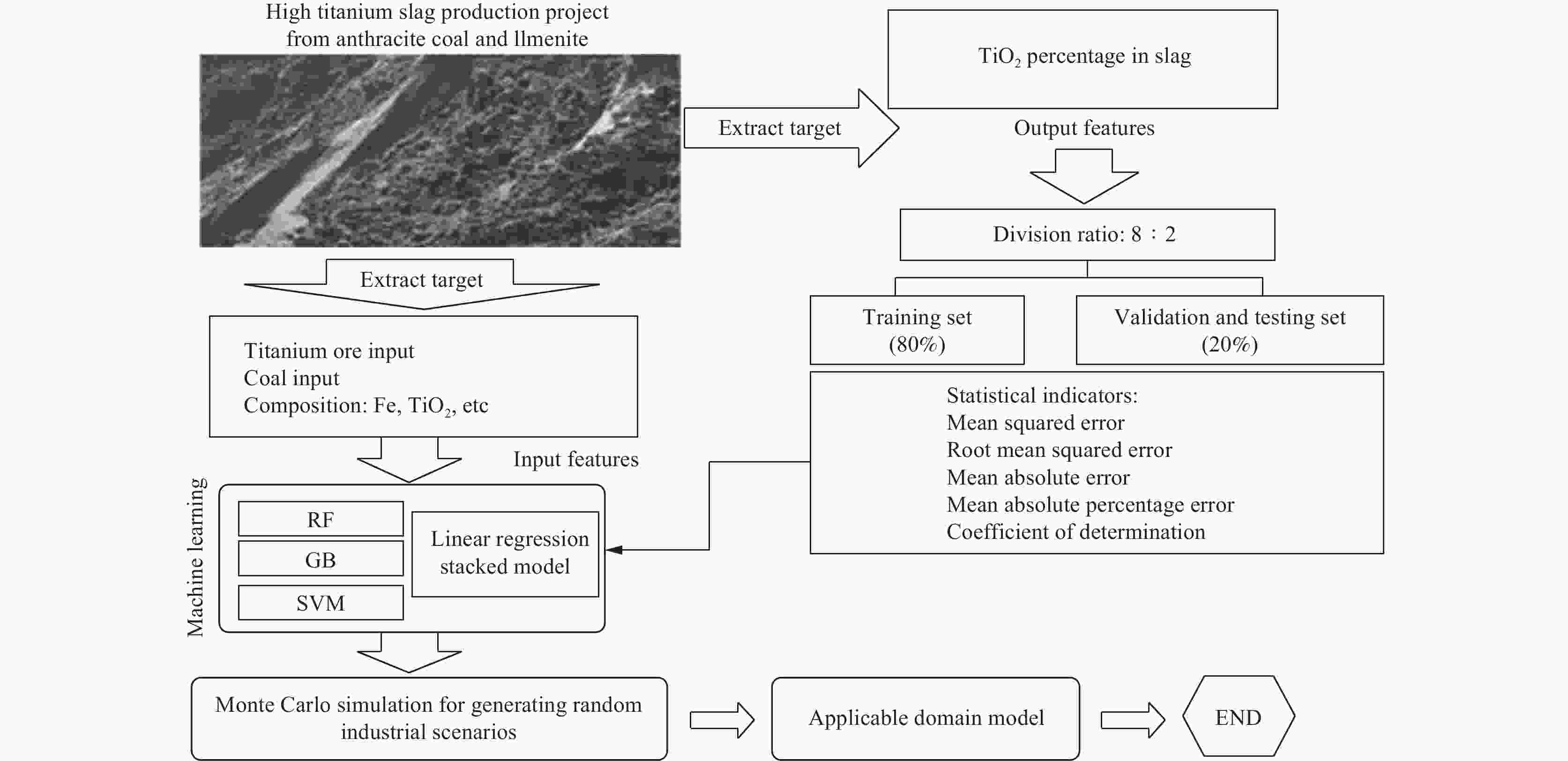

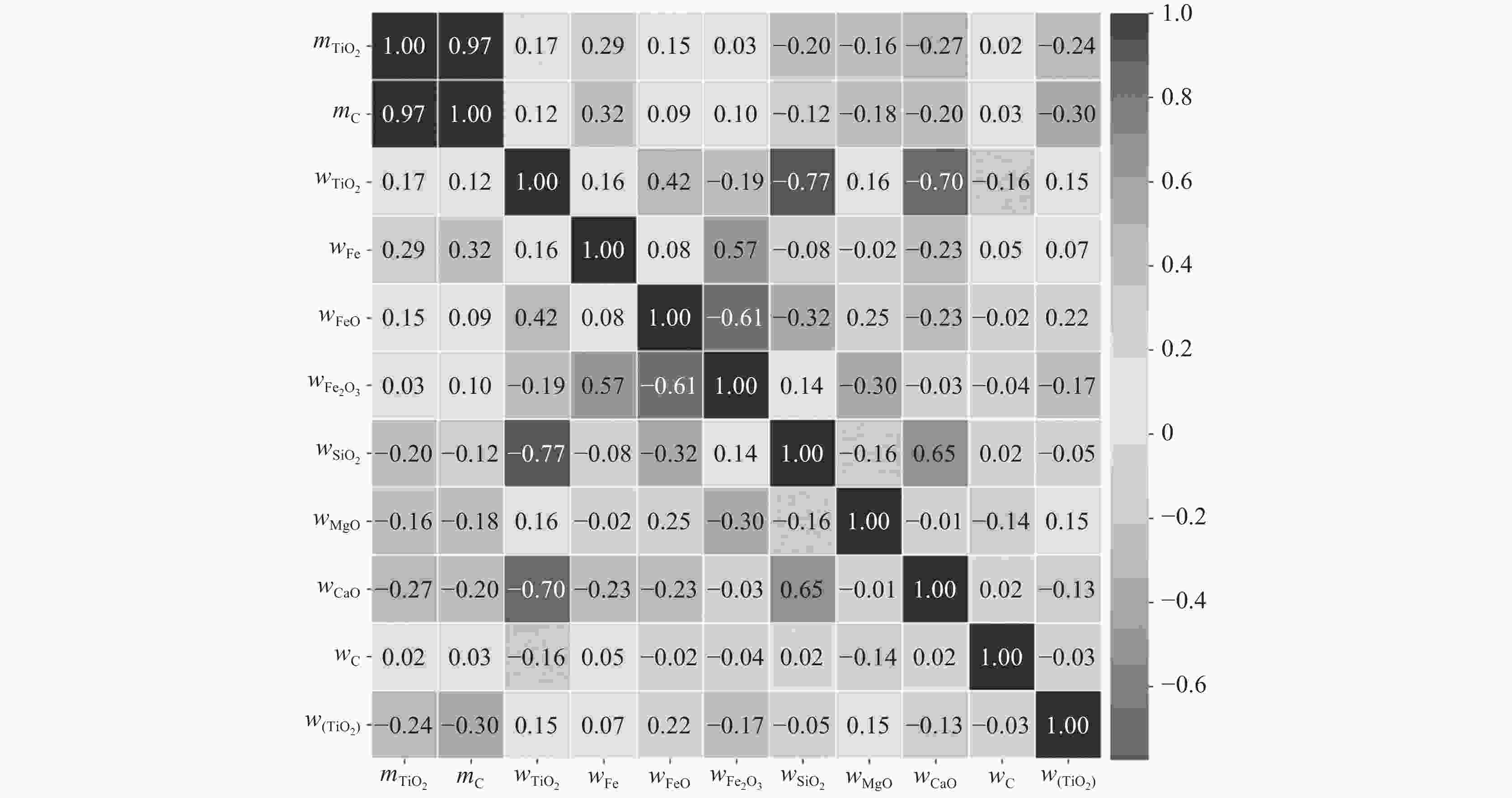

摘要: TiO2是高钛渣的主要成分,广泛应用于涂料、塑料、造纸、化妆品等多个工业领域。提出一种基于堆叠模型的TiO2 品位预测方法,结合随机森林(RF)、梯度提升机(GBM)和支持向量回归(SVR),采用集成学习优化高钛渣中TiO2 品位的预测精度。数据来自冶金厂的原始生产数据,结合数据处理、特征衍生等手段,通过降维技术将特征变量从33个减少到15个,筛选出了更有价值的特征变量。试验结果表明,堆叠回归模型在验证集和测试集上表现优异,R2值为

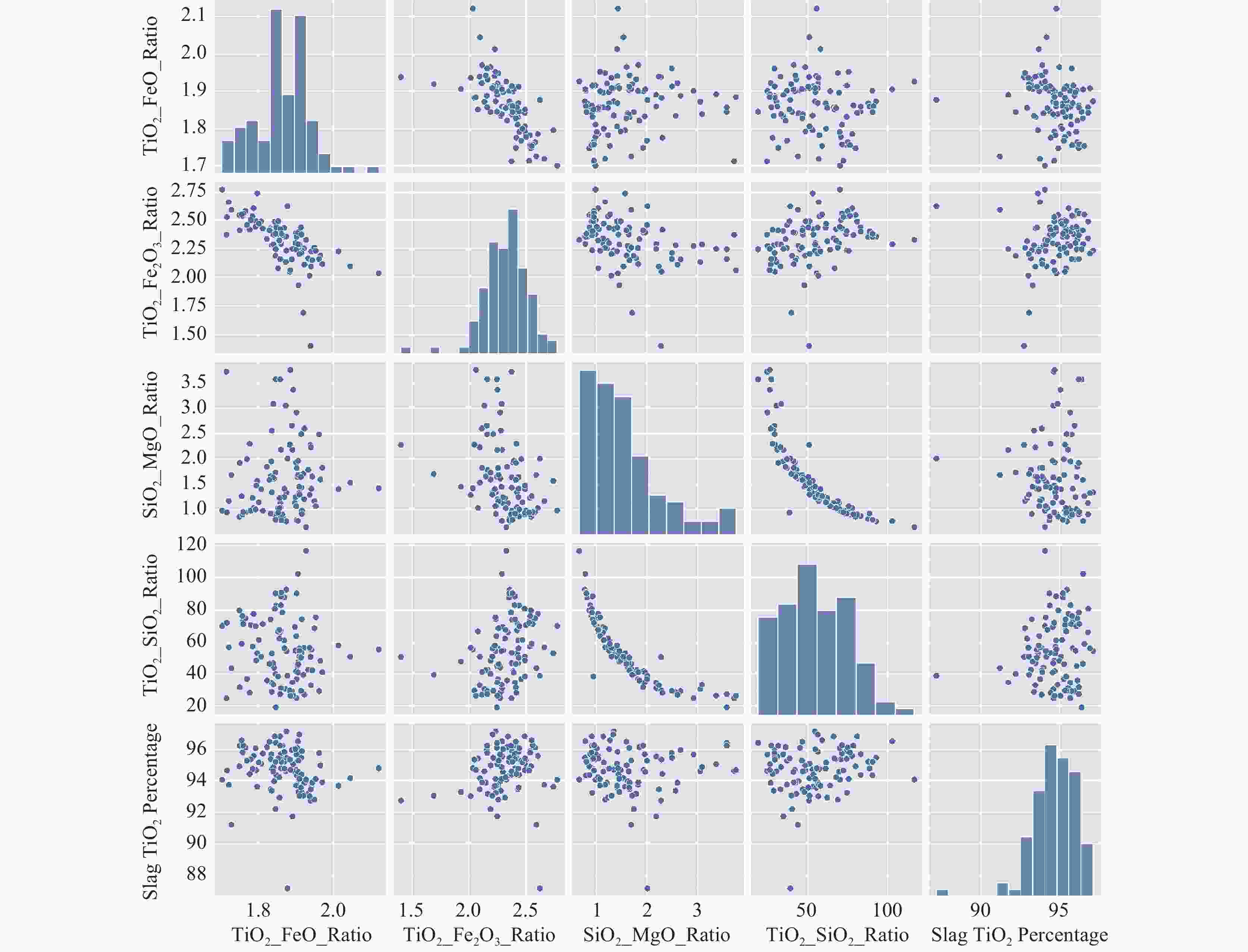

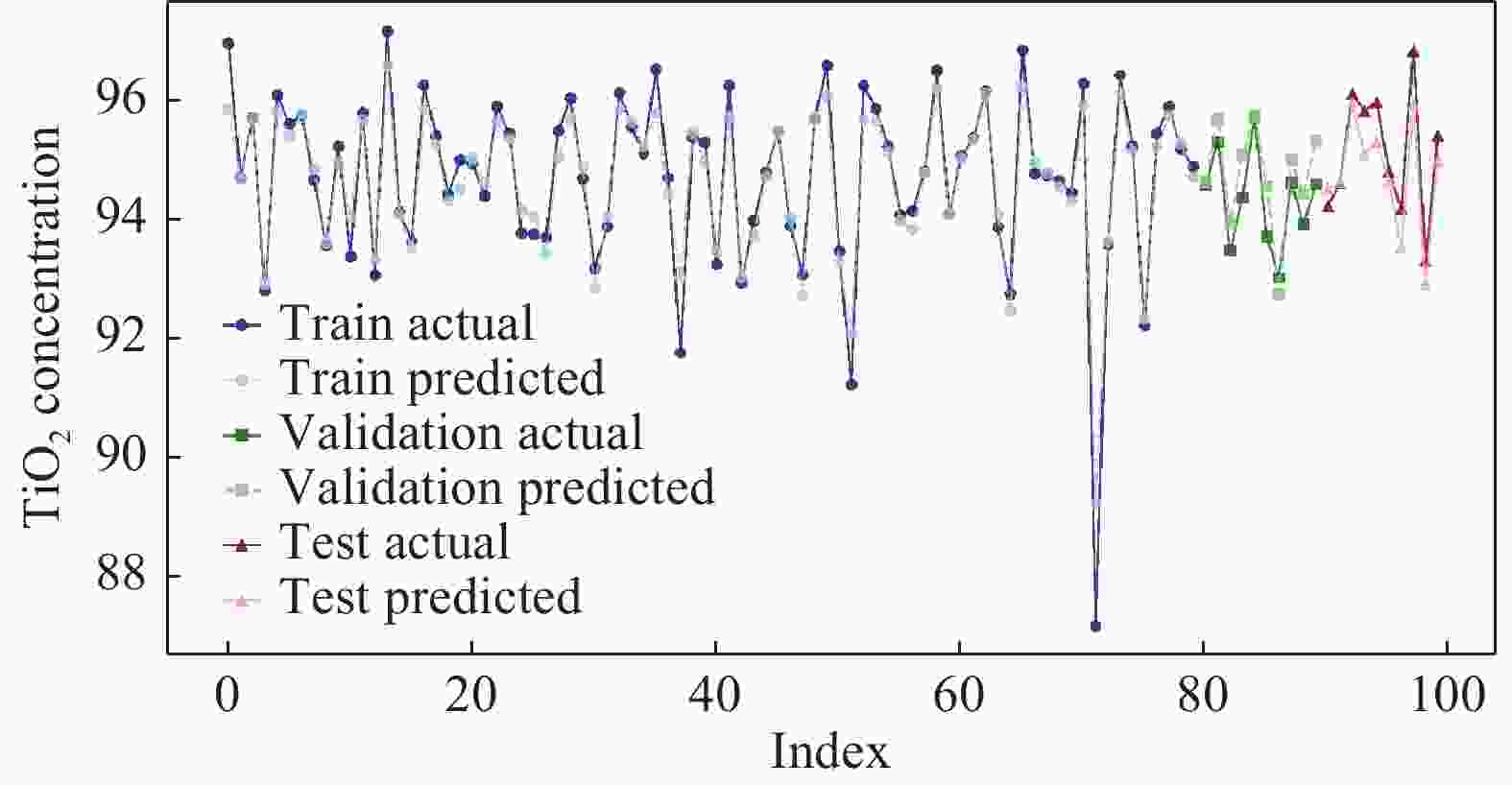

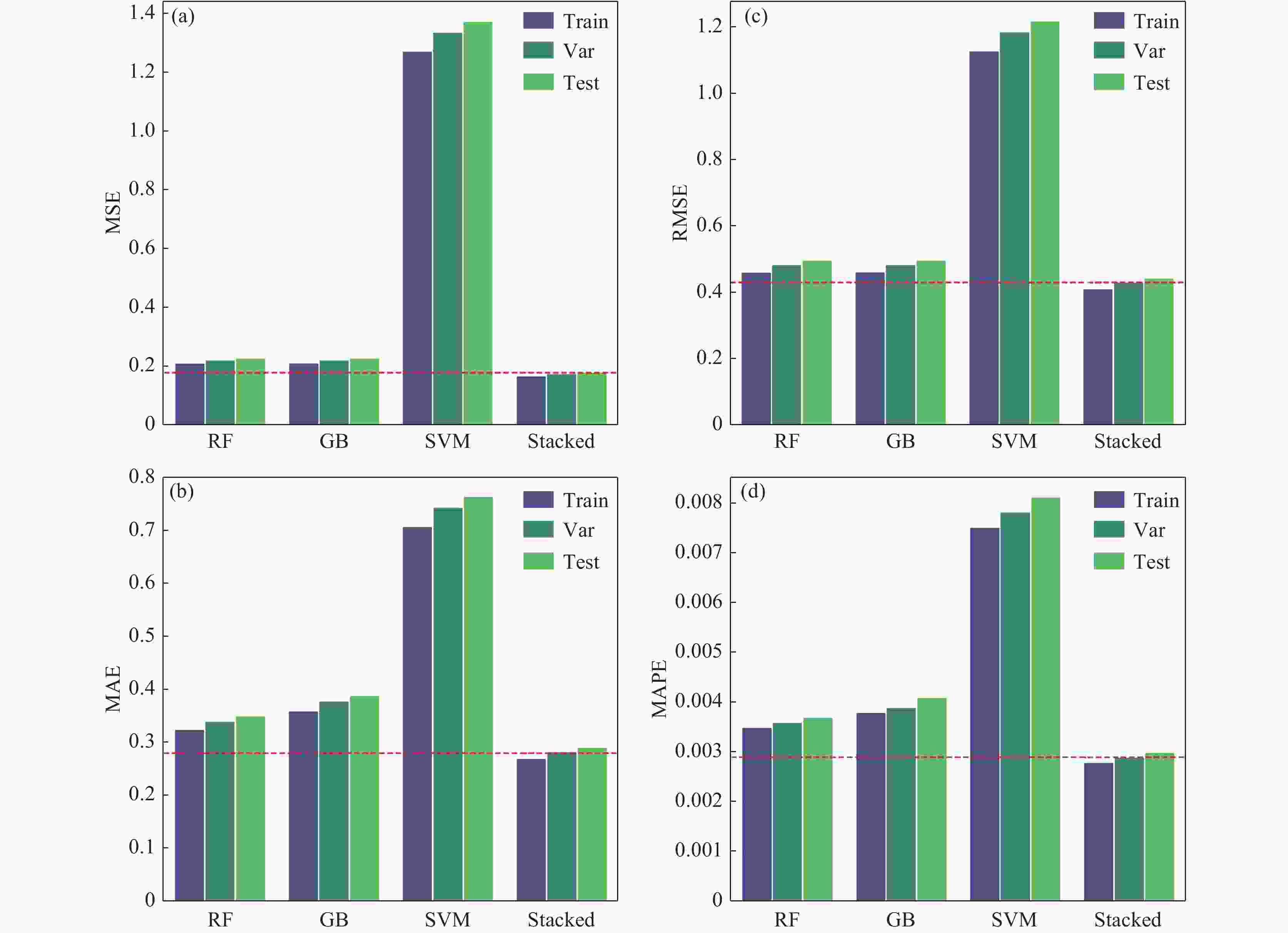

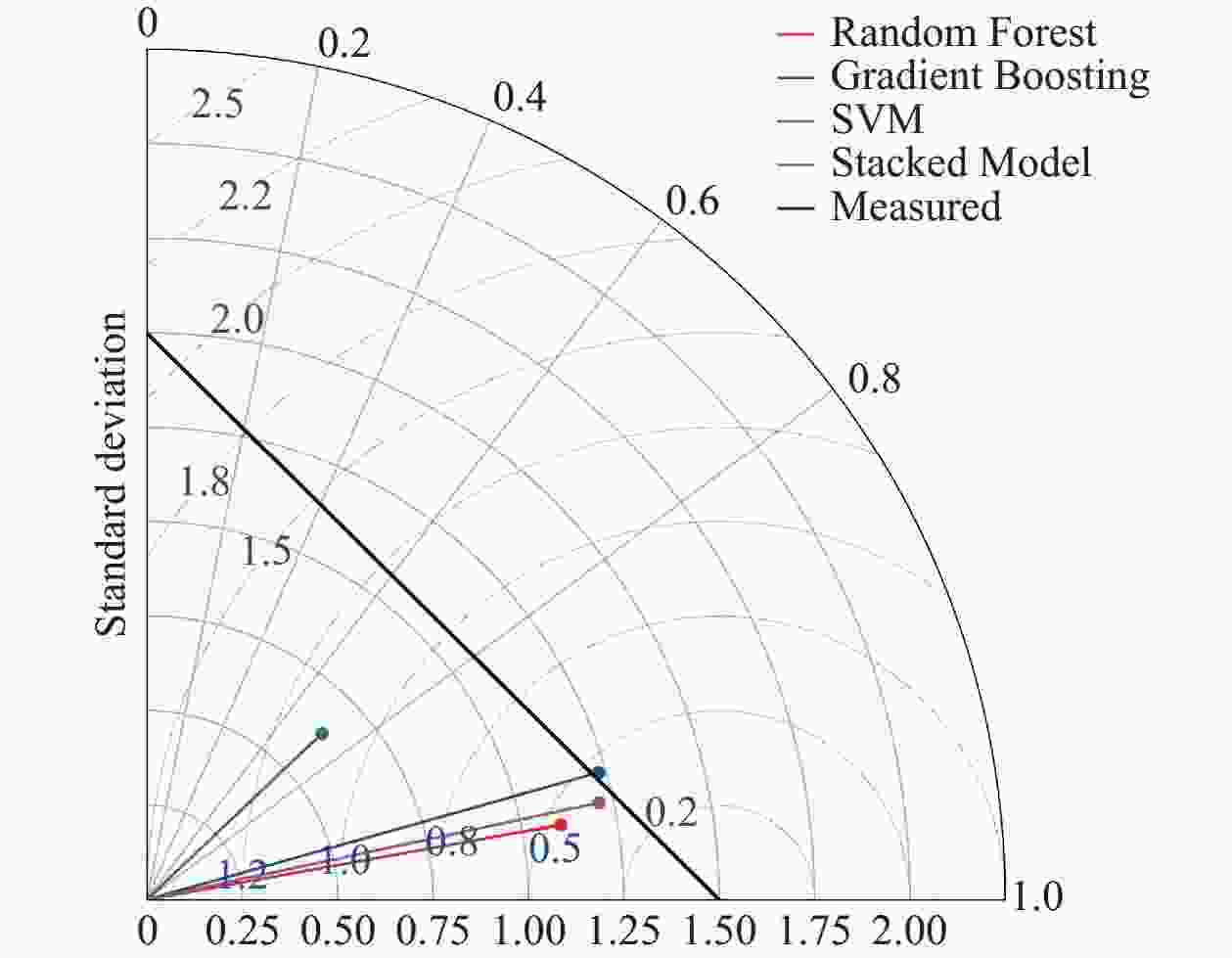

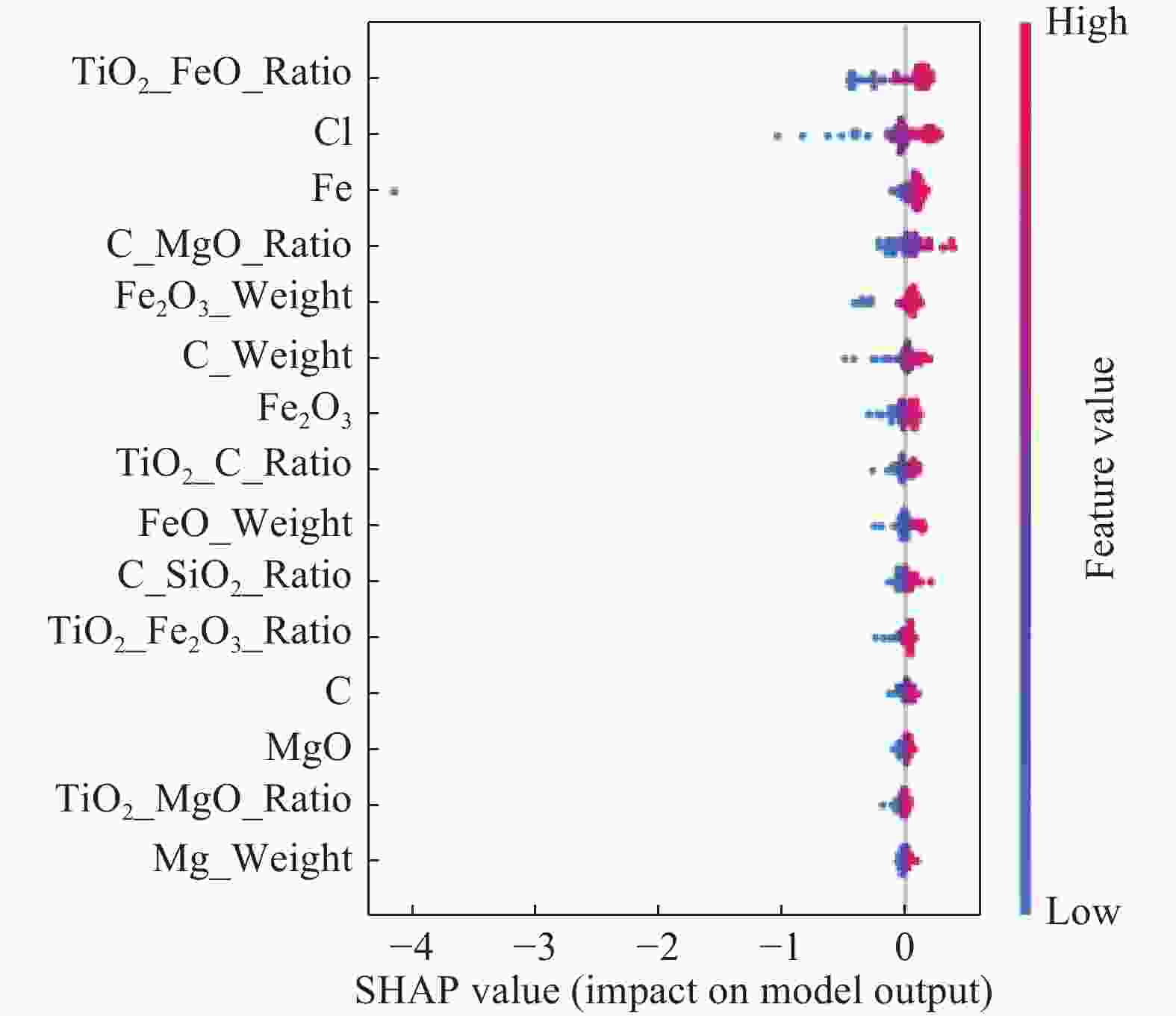

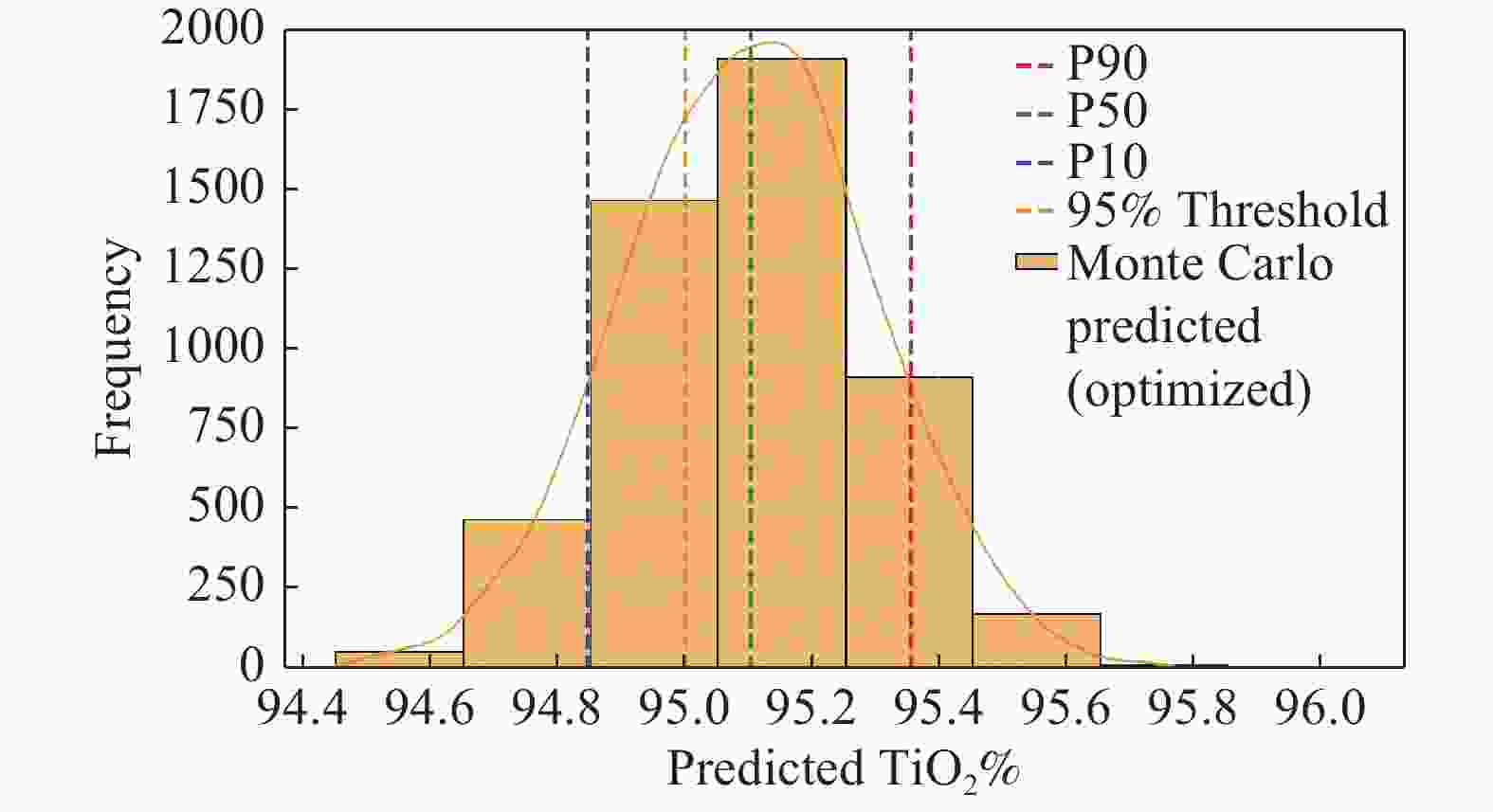

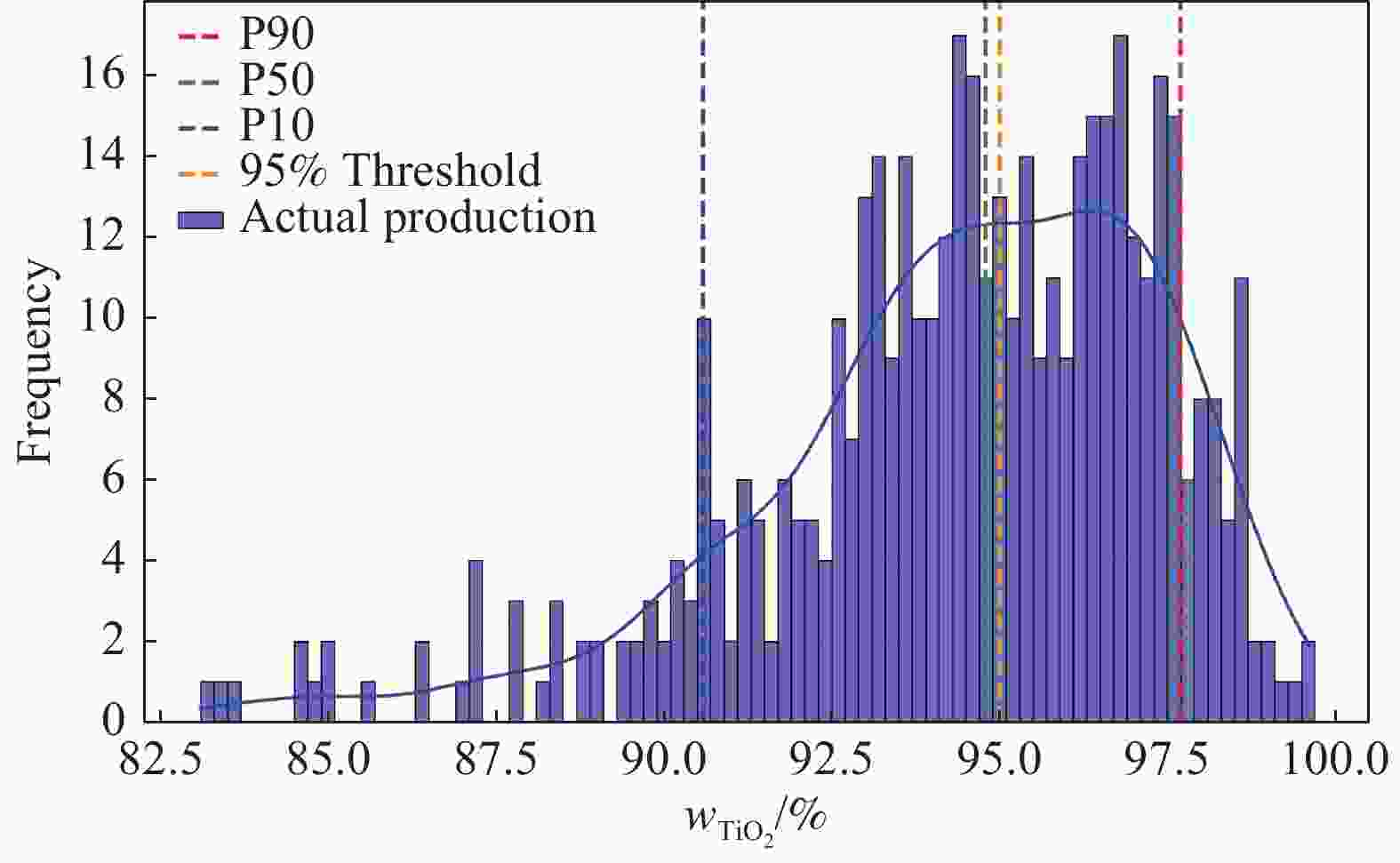

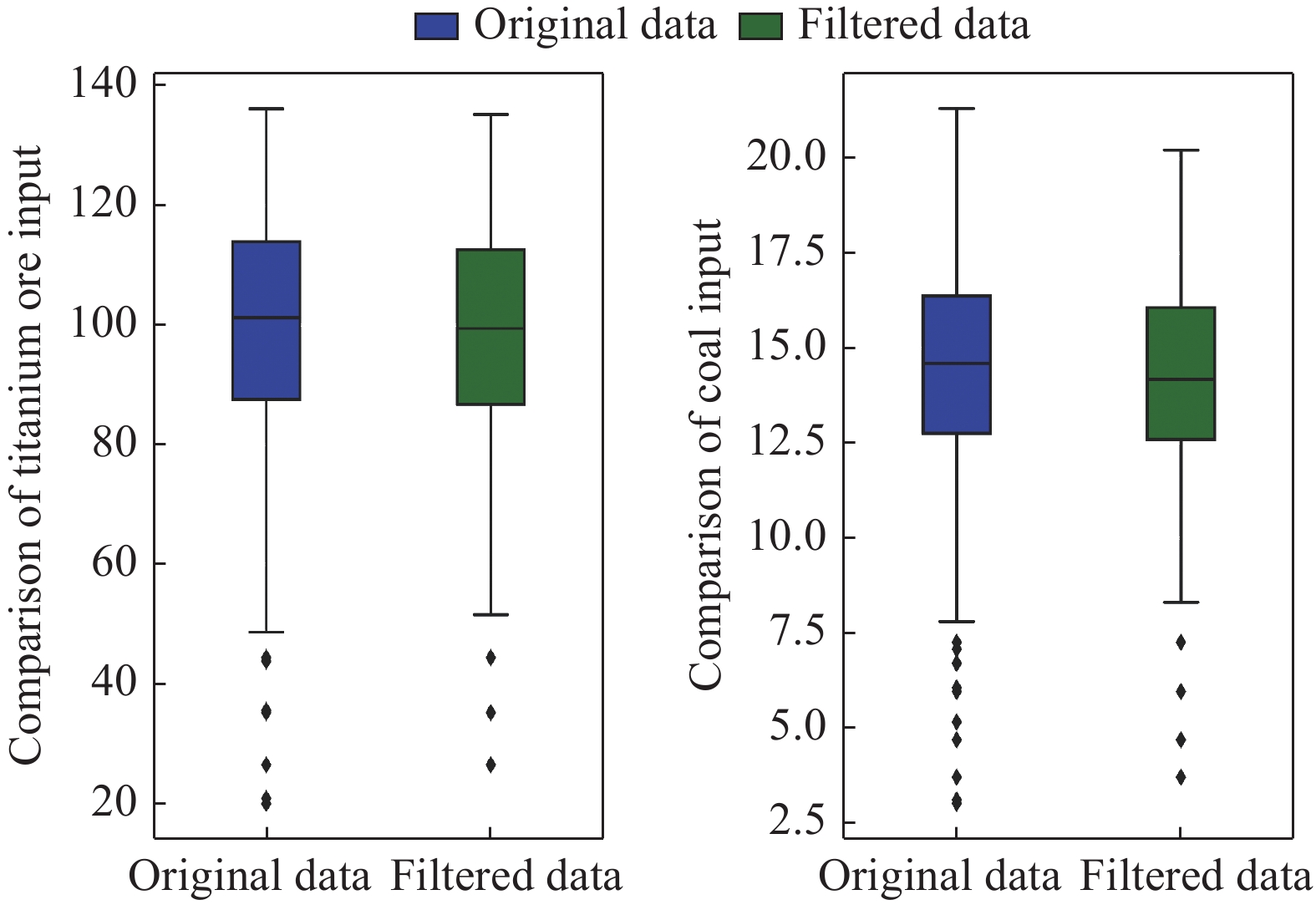

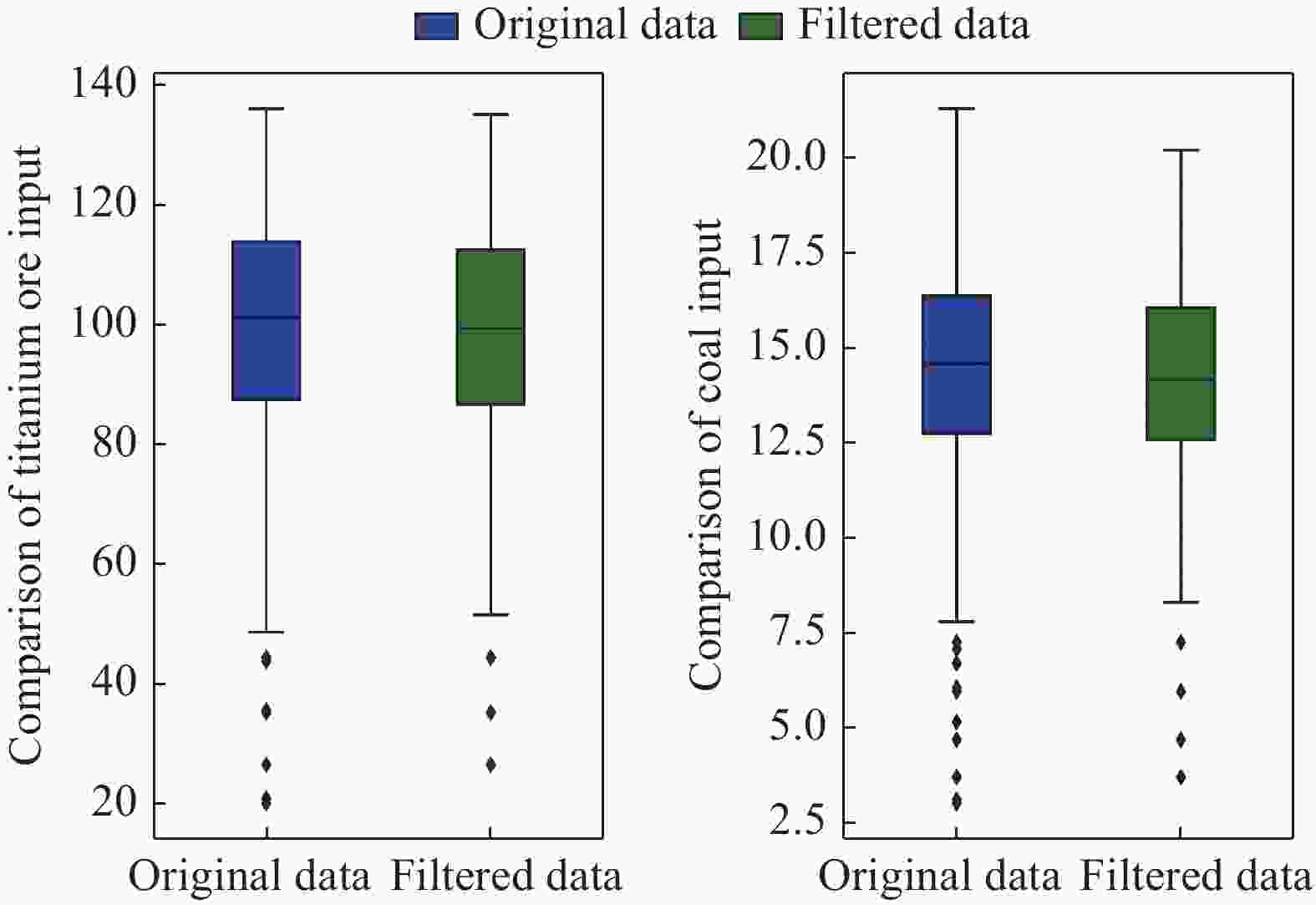

0.9249 ,MAPE值为0.29%和0.30%,MSE值为0.177和0.182,统计表现均优于单一模型。SHAP值分析显示,TiO2 与FeO质量比和C百分比含量等特征变量在一定范围内能够提高TiO2 品位。此外,结合堆叠模型,基于蒙特卡洛试验确定了关键特征变量的最佳范围,如TiO2/FeO比率(1.70至2.12)和TiO2/C比率(0.50至0.58)。该方法避免了传统经验型方法中的配料尝试与能源浪费,有助于节能减排,提升钛渣的生产效率和产品质量。Abstract: Titanium dioxide (TiO2), the primary component of high-titanium slag, is widely used in various industrial fields such as coatings, plastics, papermaking, and cosmetics. This paper proposed a TiO2 grade prediction method based on a stacked model that combines random forest (RF), gradient boosting machine (GBM), and support vector regression (SVR) to optimize the prediction accuracy of TiO2 grade in high-titanium slag through ensemble learning. The dataset was obtained from raw production data in a metallurgical plant. After data processing and feature derivation, dimensionality reduction techniques were applied to reduce the number of feature variables from 33 to 15, thereby identifying the most informative variables. Experimental results demonstrate that the stacked regression model achieves excellent performance on the validation and test sets, with an R2 value of0.9249 , MAPE values of 0.29% and 0.30%, and MSE values of 0.177 and 0.182, respectively—outperforming individual models. SHAP value analysis further revealed that feature variables such as the TiO2/FeO mass ratio and C content positively influence the TiO2 grade within certain ranges. Moreover, by integrating the stacked model with Monte Carlo simulations, the optimal ranges of key feature variables were determined, such as the TiO2/FeO ratio (1.70–2.12) and the TiO2/C ratio (0.50–0.58). This approach avoids the trial-and-error process and energy waste associated with traditional empirical methods, thereby contributing to energy conservation and emission reduction while enhancing the production efficiency and product quality of titanium slag. -

表 1 工业生产性能和指标预测的机器学习建模研究总结

Table 1. Summary of machine learning modeling studies for prediction of industrial production performance and metrics

ML models Target Number of

samplesInput variables Reference ANN, SVM, DT Estimation oil production performance

of LSWI core flooding117 Petrophysical properties, oil viscosity, oil density, residual oil saturation, temperature, brine properties [32] ANN, DT, ERT,

GB, RF, EXBoostEstimation the CO2 foam strength 157 Shear rate, temperature, pressure salinity, surfactant concentration foam quality [33] SVM, XGBoost,

MLP, RFStrip crown 1809 Strip width, slab thickness, exit thickness, entrance temperature, exit temperature, rolling force, rolling speed, strip yield strength, bending force, rolling shifting, roll diameter roll thermal expansion, roll wear [34] Linear SVR, ANN

Gaussian SVRThe hotspot temperature 16 Mould temperature, melt temper-ature, holding time, holding pressure, shot size, switch-over position, injection speed, and cooling time [35] Stacked, BPNN, LSTM Underground reservoir pressure 4000 Spatio-temporal data, Spatial coordinates and time information [36] RFR, KNN, ANN, SVR Tempered martensite hardness 1900 Tempering temperature, C, tempering time, Cr, Si, Mn, Mo, Ni on HV [37] ANN Optimization of water

alternating CO2 gas166 Injection rate, production rate limit, start of depletion,

end of depletion, average pressure[38] PSO-SVM, KNN, RF Crop yield 1200 Weather, soil fertility, water availability, water quality, crop pricing [39] 表 2 机器学习模型优缺点比较

Table 2. Comparison of pros and cons of machine learning models

Methods Pros Cons Liner Regression Simple, easy to implement, highly interpretable Assumes linear relationship between variables, not suitable for nonlinear data, sensitive to outliers Random Forest Generally high accuracy, can handle large amounts of data, reduces the risk of overfitting Larger model size, long training time, lower interpretability Support Vector Machine Effective in handling high-dimensional data, suitable for complex classification problems, insensitive to feature scaling Long training time, difficulty in choosing the appropriate kernel function, sensitive to parameter selection Gradient Boosting High accuracy, robust to outliers, can handle data with complex relationships High computational cost, prone to overfitting, complex parameter tuning, not suitable for high-dimensional sparse data Logistic Regression Suitable for binary classification problems, provides probabilistic output, easy to understand and implement Sets linear boundaries, limited ability to fit complex or nonlinear relationships Stacked Combines the strengths of different models, reduces the bias of a single model, flexible model structure Complex model structure, multiple models such as base models and meta-models need to be trained 表 3 工厂数据统计

Table 3. Statistical parameters of factory raw data

Statistical parameter $ m_{\mathrm{_{TiO_2}}}/{\mathrm{t}} $ $ m_{\mathrm{c}}/ {\mathrm{t}}$ $w_{\mathrm{_{TiO_2}}}/{\text{%}}$ $w_{\rm{_{Fe}}}/{\text{%}}$ $w_{\rm{_{FeO}}}/{\text{%}}$ $w_{_{{\rm{Fe}}_2{\mathrm{O}}_3}}/{\text{%}}$ $w_{_{{\rm{SiO}}_2}}/{\text{%}}$ $w_{{\rm{MgO}}}/{\text{%}}$ $w_{{\rm{CaO}}}/{\text{%}}$ $w_{\rm{C}}/{\text{%}}$ $w_{_{({\mathrm{TiO}}_2)}}/{\text{%}}$ Mean 99.89 14.39 48.51 34.94 25.92 21.13 1.03 0.65 0.04 90.50 94.48 Standard 19.74 2.92 0.73 1.00 1.31 1.82 0.37 0.09 0.04 1.92 2.99 Minimum 20.04 3.02 46.50 31.97 19.68 16.58 0.07 0.03 0.01 83.71 83.09 Maximum 136.08 21.31 49.93 47.33 30.04 34.33 2.54 1.42 0.52 93.40 99.61 Median 101.19 14.6 48.65 34.98 25.86 20.93 0.96 0.66 0.03 91.07 94.79 表 4 超参数调优表

Table 4. Hyperparameter tuning for this study

Model Parameters value RF n_estimators 400 random_state 42 max_depth None min_samples_split 2 GBM learning_rate 0.1 max_depth 6 n_estimators 200 random_state 42 SVM C 1.0 kernel Rbf gamma Scale epsilon 0.1 Stacked Base Estimators RF GB SVM Meta Model Linear Regression -

[1] WANI T U, RATHER A H, KHAN R S, et al. Titanium dioxide functionalized multi-walled carbon nanotubes and silver nanoparticles reinforced polyurethane nanofibers as a novel scaffold for tissue engineering applications[J]. Journal of Industrial and Engineering Chemistry, 2023, 121 : 200-214. [2] AKINNAWO S. Synthesis, modification, applications and challenges of titanium dioxide nanoparticles[J]. Research Journal of Nanoscience and Engineering, 2019, 3(4). [3] LI Y, ZHONG M, HE X, et al. The combined effect of titanium dioxide nanoparticles and cypermethrin on male reproductive toxicity in rats[J]. Environmental Science and Pollution Research, 2023, 30(9) : 22176-22187. [4] HARUNA A, CHONG F K, HO Y C, et al. Preparation and modification methods of defective titanium dioxide-based nanoparticles for photocatalytic wastewater treatment—a comprehensive review[J]. Environmental Science and Pollution Research, 2022, 29: 70706-70745. [5] TIAN C, HUANG S, YANG Y. Influences of hydrolysis temperature and hydrolysis time on titanium white pigment via short sulfate process[J]. Advanced Materials Research, 2012, 602-604: 1255. [6] MIU B A, DINISCHIOTU A. Green synthesized titanium dioxide nanoparticles and their future applications in biomedicine, agriculture and industry[J]. Rev Biol Biomed Sci, 2021, 4(1): 1-21. doi: 10.31178/rbbs.2021.4.1.1 [7] TIWARI P, VERMA M, AMBIKA, et al. Titanium dioxide-based nanoparticles and their applications in water remediation[J]. Journal of Environmental Engineering Science, 2023: 281-304. [8] LÜ X W, LÜ W, ZHANG Y Y, et al. Method for preparing high titanium slag through low temperature reduction and separation of titanium-containing iron ore: Chinese Patent CN106521139A[P]. 2017. (吕学伟, 吕炜, 张颖异, 等.一种低温还原分离含钛铁矿物制备高钛渣的方法 [P]. 中国专利: CN106521139A, 2017.LÜ X W, LÜ W, ZHANG Y Y, et al. Method for preparing high titanium slag through low temperature reduction and separation of titanium-containing iron ore: Chinese Patent CN106521139A[P]. 2017. [9] DONG H G, GUO Y F, JIANG T, et al. Production of synthetic rutile from high Ca and Mg type titanium slag by mineral phase reconstruction process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2642-2647. (董海刚, 郭宇峰, 姜涛, 等.高钙镁型钛渣物相重构法制取人造金红石[J]. 中国有色金属学报, 2012, 22 (9): 2642-2647.DONG H G, GUO Y F, JIANG T, et al. Production of synthetic rutile from high Ca and Mg type titanium slag by mineral phase reconstruction process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2642-2647. [10] KONDORI J, MIAH M I, ZENDEHBOUDI S, et al. Hybrid connectionist models to assess recovery performance of low salinity water injection[J]. Journal of Petroleum Science and Engineering, 2021, 197: 107833. doi: 10.1016/j.petrol.2020.107833 [11] QU Y H. Rapid analysis of TiO2 in blast furnace slag by X-ray fluorescence spectrometry[J]. Metallurgical Analysis, 2003(5): 40-42. (曲月华. X 射线荧光光谱法快速分析高炉渣中 TiO2[J]. 冶金分析, 2003(5): 40-42.QU Y H. Rapid analysis of TiO2 in blast furnace slag by X-ray fluorescence spectrometry[J]. Metallurgical Analysis, 2003(5): 40-42. [12] WU L P, ZENG Y, LIU W, et al. Determination of major and minor elements in high-titanium slag by fusion sample preparation-X-ray fluorescence spectrometry[J]. Multipurpose Utilization of Mineral Resources, 2017, (1): 81-84. (仵利萍, 曾英, 刘卫, 等. 熔融制样 - X 射线荧光光谱法测定高钛渣主次量元素 [J]. 矿产综合利用, 2017, (1): 81-84.WU L P, ZENG Y, LIU W, et al. Determination of major and minor elements in high-titanium slag by fusion sample preparation-X-ray fluorescence spectrometry[J]. Multipurpose Utilization of Mineral Resources, 2017, (1): 81-84. [13] ZHENG M Q, LI B M, CHENG X H. Rapid analysis of mineral phases in titanium ore[J]. Rock and Mineral Analysis, 2010, 29(1): 61-63. (郑民奇, 李邦民, 程秀花. 钛矿石物相的快速分析[J]. 岩矿测试, 2010, 29 (1): 61-63.ZHENG M Q, LI B M, CHENG X H. Rapid analysis of mineral phases in titanium ore[J]. Rock and Mineral Analysis, 2010, 29(1): 61-63. [14] CAO J C, LU M. Industrial water consumption prediction based on improved SSA-SVM with hybrid strategy[J]. Water Resources and Power, 2023, 41(9): 28-31. (曹敬椿, 卢敏. 基于混合策略改进 SSA-SVM 的工业用水量预测[J]. 水电能源科学, 2023, 41 (9): 28-31.CAO J C, LU M. Industrial water consumption prediction based on improved SSA-SVM with hybrid strategy[J]. Water Resources and Power, 2023, 41(9): 28-31. [15] LI H, BU X, LIU X, et al. Evaluation and prediction of blast furnace status based on big data platform of ironmaking and data mining[J]. ISIJ International, 2021, 61(1): 108-118. doi: 10.2355/isijinternational.ISIJINT-2020-249 [16] WANG Y, XU S, BWAR K, et al. Application of machine learning for composite moulding process modelling[J]. Composites Communications, 2024, 48: 101960. doi: 10.1016/j.coco.2024.101960 [17] CAO Y H, CHEN C Y, XU S Z, et al. Machine learning assisted prediction and optimization of mechanical properties for laser powder bed fusion of Ti6Al4V Alloy[J]. Additive Manufacturing, 2024, 91: 104341. doi: 10.1016/j.addma.2024.104341 [18] GUNASEGARAM D R, BARNARD A S, MATTHEWS M J, et al. Machine learning-assisted in-situ adaptive strategies for the control of defects and anomalies in metal additive manufacturing[J]. Additive Manufacturing, 2024, 81: 104013. doi: 10.1016/j.addma.2024.104013 [19] HE Z, ZHANG H, CHENG H, et al. Machine learning guided BCC or FCC phase prediction in high entropy alloys[J]. Journal of Materials Research and Technology, 2024, 29: 3477-3486. doi: 10.1016/j.jmrt.2024.01.257 [20] BAI M, WU X, TANG S, et al. Study on hot deformation behavior and recrystallization mechanism of an Al-6.3Zn-2.5Mg-2.6Cu-0.11Zr alloy based on machine learning[J]. Journal of Alloys and Compounds, 2024, 1000: 175086. doi: 10.1016/j.jallcom.2024.175086 [21] HOSSAIN M A, MIRELES A J, STEWART C M. A machine learning approach for stress-rupture prediction of high temperature austenitic stainless steels[C]. Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition, Rotterdam, Netherlands, June 13-17, 2022: V007T17A029. ASME. [22] NAUTIYAL A, MISHRA A K. Machine learning approach for intelligent prediction of petroleum upstream stuck pipe challenge in oil and gas industry[J]. Environment Development and Sustainability, 2022. [23] SHI Z, DU L, HE X, et al. Prediction model of yield strength of V–N steel hot-rolled plate based on machine learning algorithm[J]. JOM, 2023, 75(5): 1750-1762. doi: 10.1007/s11837-023-05773-y [24] ÁLVARO R O, GERT G, MARTIN S, et al. Optimisation of operator support systems through artificial intelligence for the cast steel industry: a case for optimisation of the oxygen blowing process based on machine learning algorithms[J]. Journal of Manufacturing and Materials Processing, 2022, 6(2): 34-34. doi: 10.3390/jmmp6020034 [25] MIENYE I D, SUN Y. A survey of ensemble learning: concepts, algorithms, applications, and prospects[J]. IEEE Access, 2022, 10 : 99129-99149. [26] LEE C Y, LIU Y Y, TAN B S, et al. Design of hybrid machine learning system for efficient prediction of parameters in metal forming processes[J]. International Journal of Advanced Manufacturing Technology, 2018, 97: 4389-4405. [27] RAMESH G R, RAJU S N C B, NAIDU M S S R. Mathematical modeling and prediction of quality characteristics in CNC turning using machine learning algorithms[J]. Journal of Manufacturing Science and Engineering, 2023, 145(2): 029902. [28] YU M, ZHANG X, HAN Q, et al. Data-Driven method for prediction of residual stress of welding process[J]. Journal of Materials Processing Technology, 2023, 313: 117618. [29] HANY A B, HE W C, ZHANG T J, et al. Process control and optimization for high-quality stainless steel strip production[J]. Computers & Industrial Engineering, 2022, 165: 107896. [30] HE A S, LIU Z L, WANG F Q, et al. Application of artificial intelligence algorithms in predictive maintenance of manufacturing equipment[J]. Journal of Advanced Manufacturing Technology, 2022, 118: 1177-1189. [31] ZHU S M, YOU M L. Discussion on several problems in improving TiO2 grade in high titanium slag production by electric heating method[J]. Iron Steel Vanadium Titanium, 1984, 1: 41-45. [32] RASHIDA S, PEYMAN P, LEI W. Data-Driven analyses of low salinity waterflooding in carbonates[J]. Applied Sciences, 2021, 11(14): 6651-6651. doi: 10.3390/app11146651 [33] ISKANDAROV J, FANOURGAKIS G S, AHMED S, et al. Data-Driven prediction of in situ CO2 foam strength for enhanced oil recovery and carbon sequestration[J]. RSC Advances, 2022, 12: 35703-35711. doi: 10.1039/D2RA05841C [34] WANG Z, HUANG Y, LIU Y, et al. Prediction model of strip crown in hot rolling process based on machine learning and industrial data[J]. Metals, 2023, 13(5): 900. doi: 10.3390/met13050900 [35] KARIMINEJAD M, TORMEY D, O'HARA C, et al. Prediction of hotspots in injection moulding by using simulation, in-mould sensors, and machine learning[C]. 2023 9th International Conference on Control, Decision and Information Technologies (CoDIT), Rome, Italy, 2023: 309-314. [36] CHENG H, HE Y, ZENG P, et al. Deep Learning-based prediction of subsurface oil reservoir pressure using spatio-temporal well-logging data[J]. Advances in Water Resources, 2023: 1265–1275. [37] FIGUEIREDO S G, COSTA A M, GONÇALVES M J M, et al. Artificial intelligence algorithms in process systems engineering[M]. 1st ed. Cham: Springer, 2022. [38] LIU Y, ZHAN L, FANG Z, et al. Study on intelligent diagnosis and prediction of wear status in deep mining equipment under extreme environment[J]. Science Progress, 2023, 106: 009317132312036. [39] SINGH M, KUMAR S, NAIR P S K. Artificial intelligence-based approaches for predicting industrial asset reliability[J]. Materials, 2021, 14(23). [40] CHENG S F, CHENG W C. Application of machine learning algorithms in the predictive maintenance of industrial robots[J]. Procedia CIRP, 2022, 113: 595-600. [41] XIE Y Z, LIU B, ZHANG X L, et al. Predicting the wear life of railway track using machine learning: a case study[J]. Journal of Transportation Engineering, 2023, 149(5): 04023022. doi: 10.1061/JTEPBS.TEENG-7812 [42] GOHAR M A K, JAMIL A S, RAZAK A H. Machine learning approach for predicting energy consumption in mManufacturing industry[J]. Advanced Science Letters, 2023, 29(12): 10760-10766. [43] PRADHAN M M, DUTTA B S, NARAYAN H S. Real-time prediction of industrial equipment health using artificial intelligence and internet of things[J]. Computers & Industrial Engineering, 2022, 164: 107976. [44] ZHUANG S S R, GUO L Y, ZHUANG W D, et al. Application of machine learning for predicting optimal parameters in manufacturing[J]. International Journal of Advanced Manufacturing Technology, 2022, 118(7): 1411-1424. -

下载:

下载: