Effect of initial texture on microstructure evolution of Ti-2Al-2.5Zr alloy tubes in multi-pass cold Pilger rolling process

-

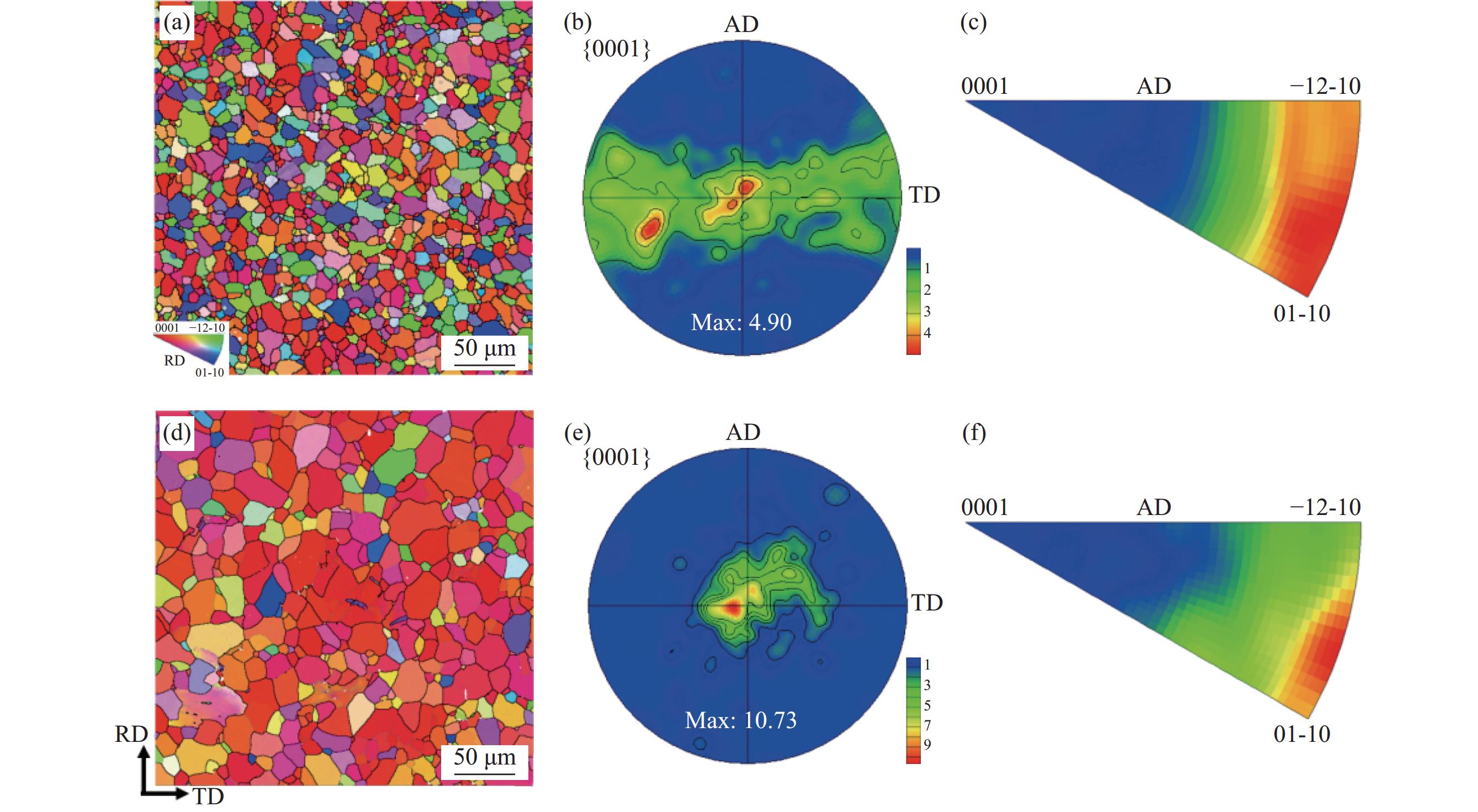

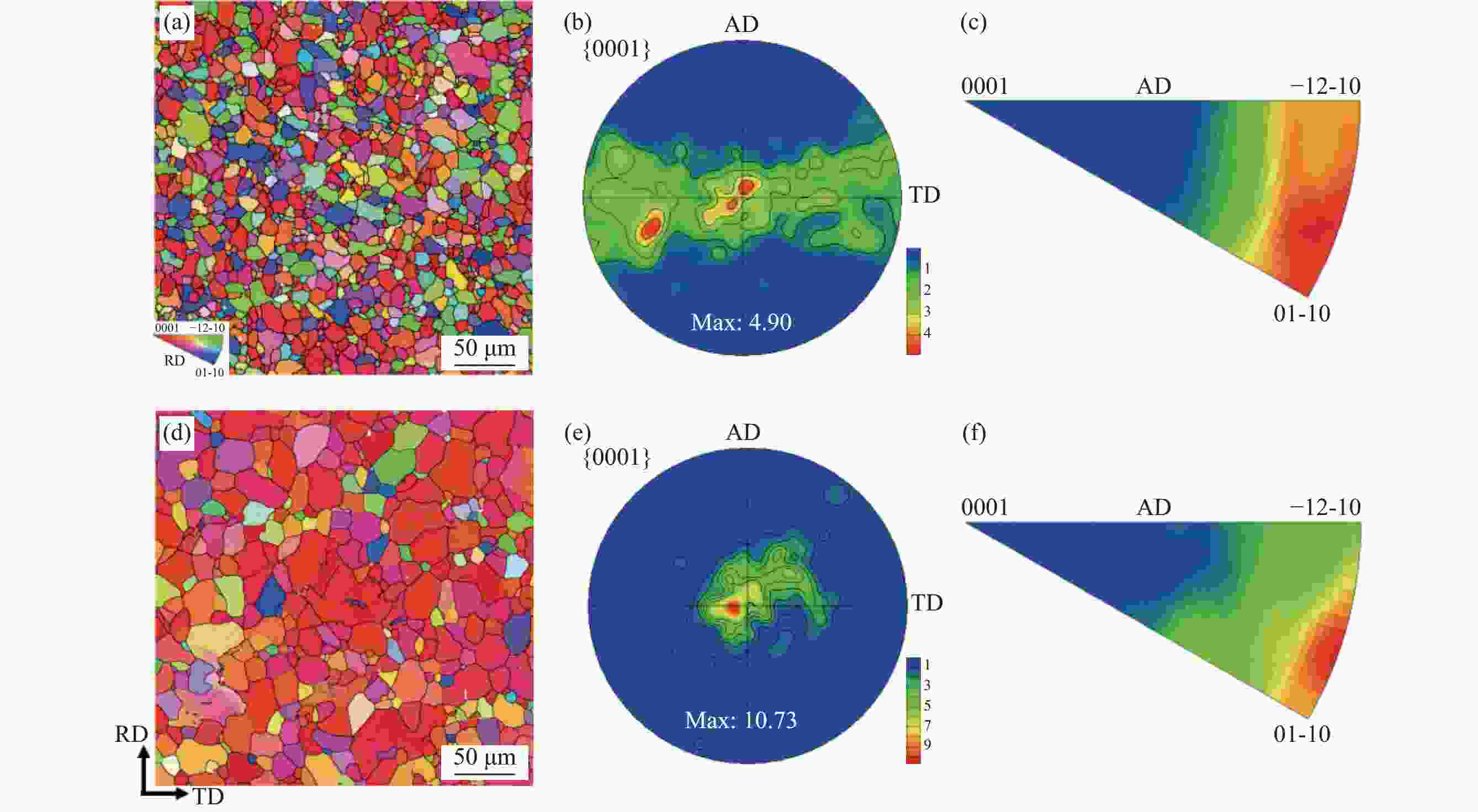

摘要: 皮尔格冷轧是一种良好的难变形管材制造技术,然而,多道次冷轧结合热处理的复杂热力加载历史使得冷轧中管材不均匀变形显著,导致管材微观织构演变规律复杂。文中研究了热轧和精锻工艺制备的Ti-2Al-2.5Zr合金两种不同初始织构坯料在三道次皮尔格冷轧过程中的组织演变及变形机制。通过微观组织分析、极图与反极图表征以及Kearns因子和施密特因子(SF)的计算,研究了不同初始织构坯料对无缝管冷轧过程中组织演变的影响。结果表明,热轧和精锻坯料在三道次冷轧后微观组织的晶粒尺寸接近,均呈现等轴晶粒;冷轧过程中,柱面滑移和锥面<c+a>滑移明显被激活,锥面<c+a>滑移被证实为主要影响冷轧径向晶粒强度的变形机制,Q值的变化导致晶粒c轴在周向(TD)和径向(RD)之间倾转;具有较大初始径向织构强度(fRD)的精锻坯料在冷轧后表现出更强的径向织构。此项研究为优化钛合金管材的织构控制提供了理论依据。

-

关键词:

- Ti-2Al-2.5Zr合金 /

- 皮尔格冷轧 /

- 织构 /

- 变形机制

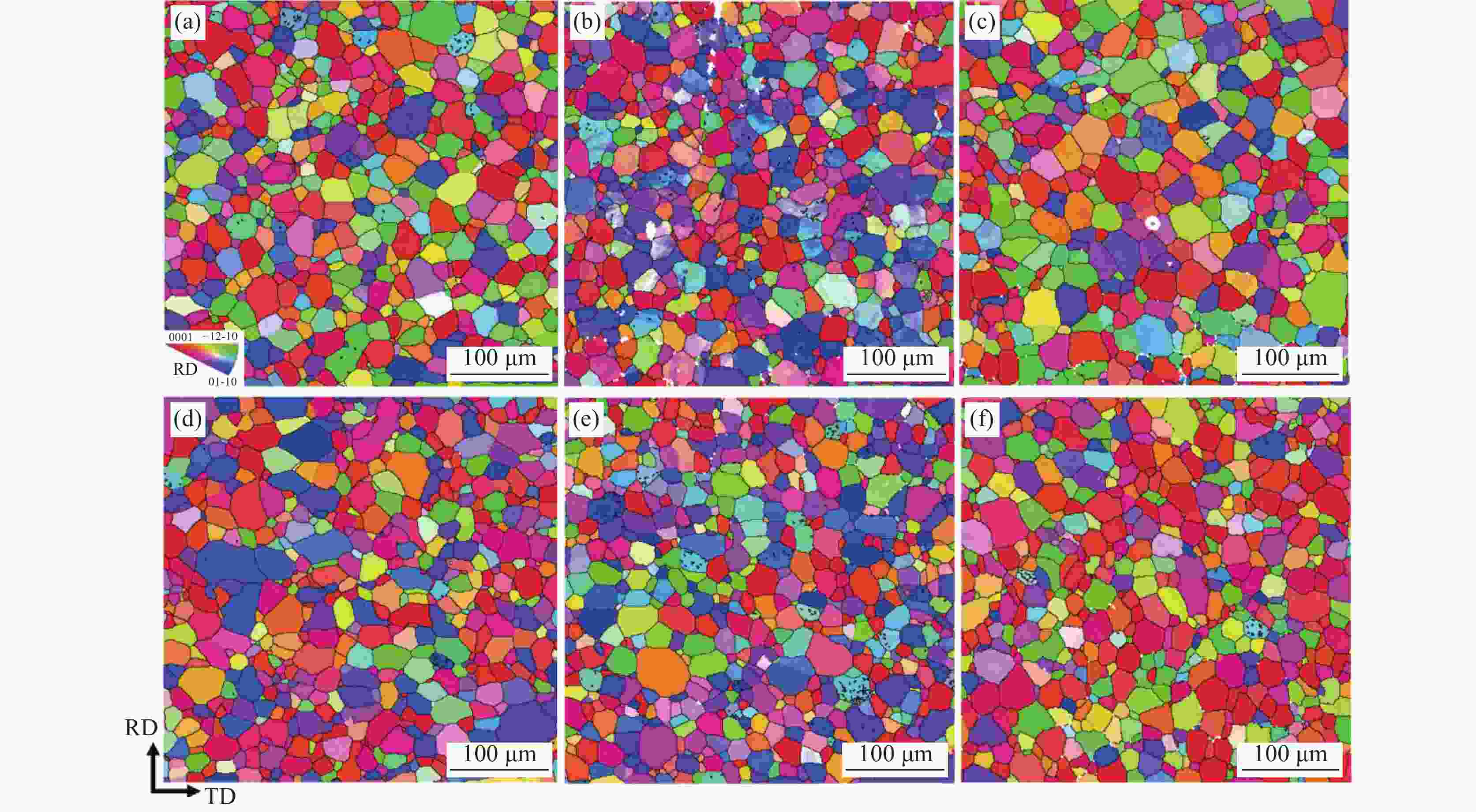

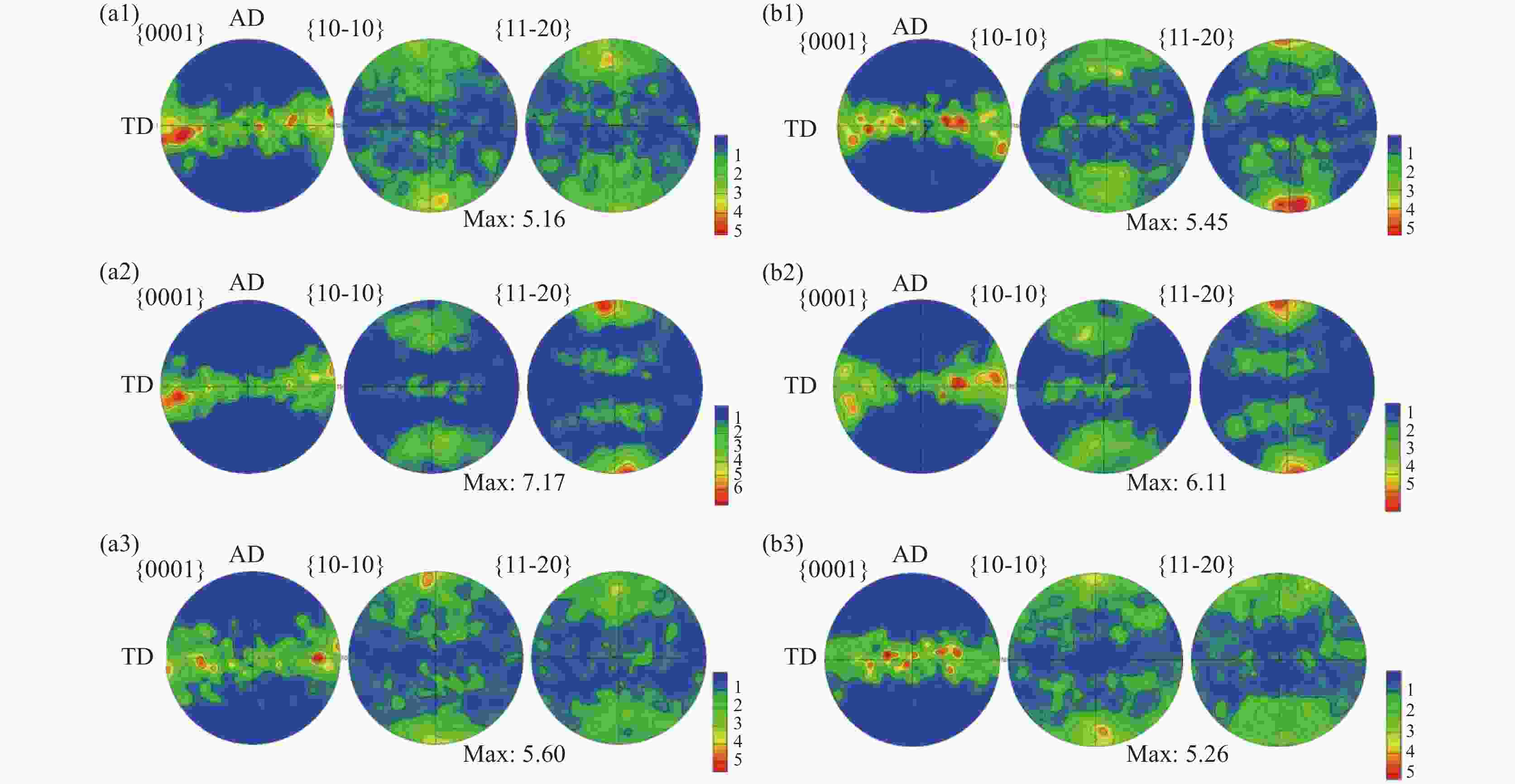

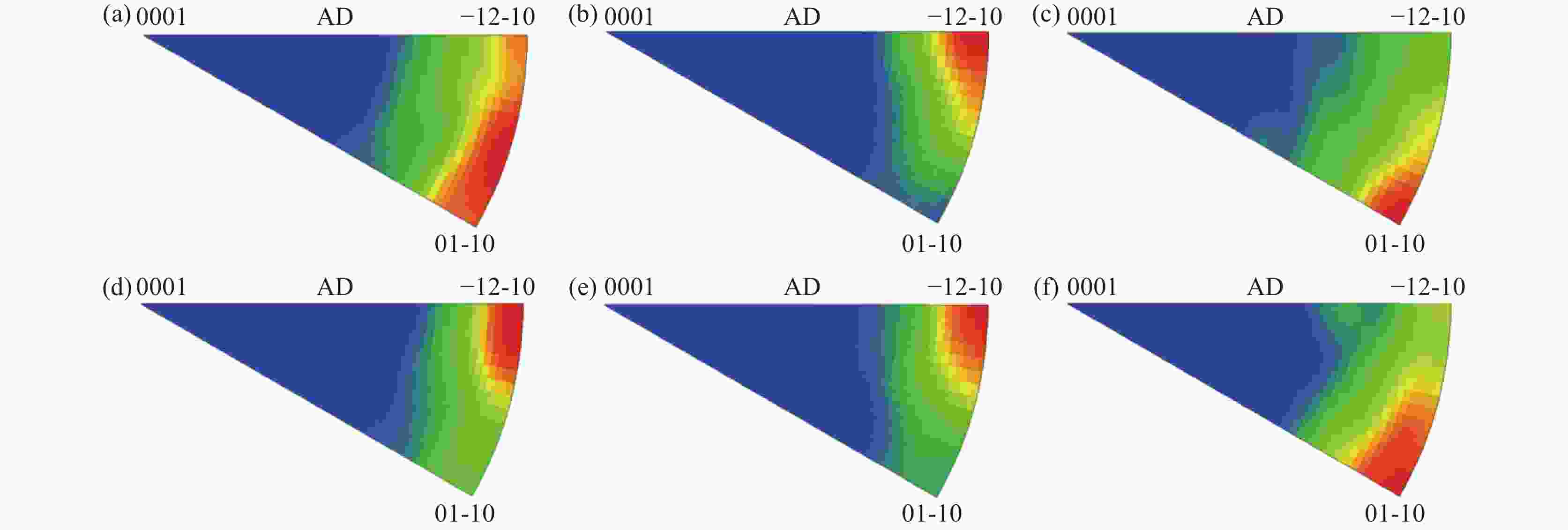

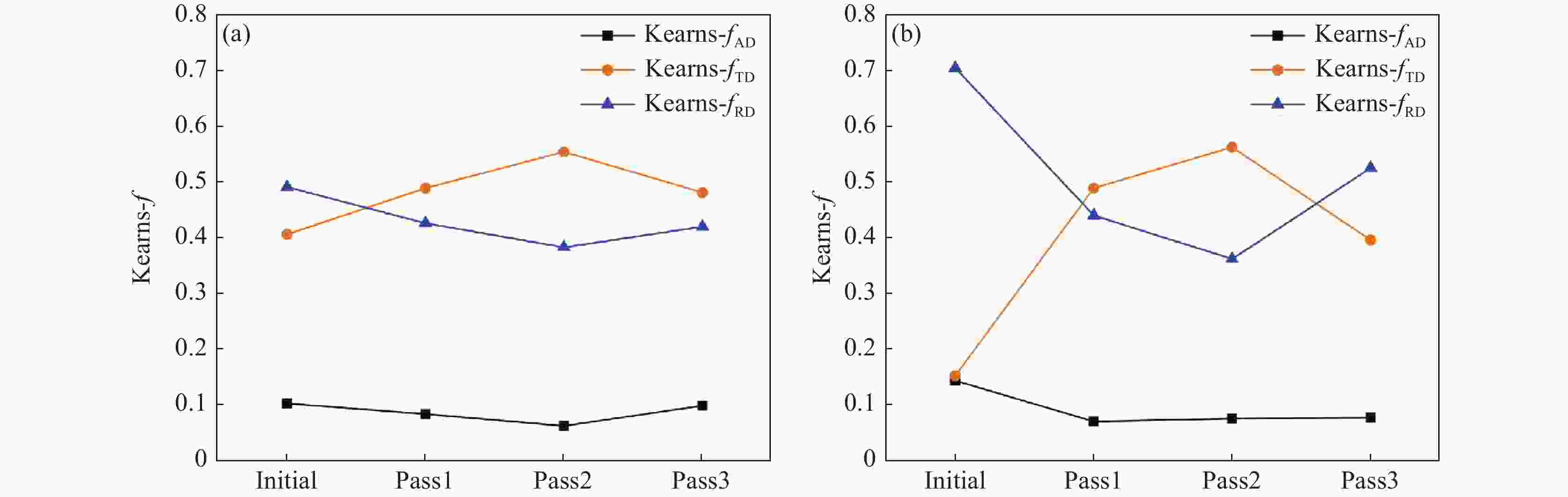

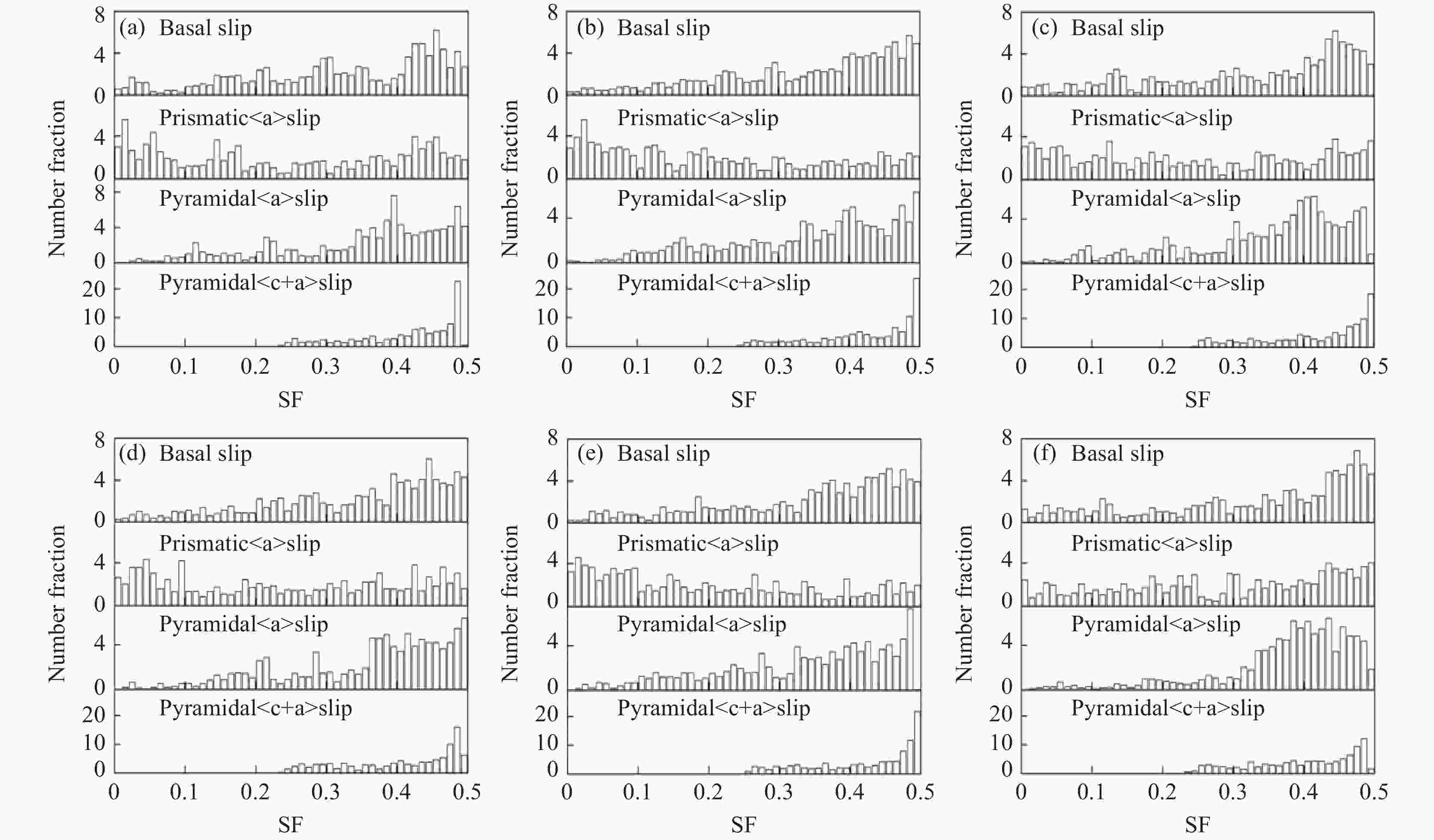

Abstract: Pilger cold rolling is a good technique for manufacturing hard-to-distort tubes. However, the complex thermal loading history of multi-pass cold rolling combined with heat treatment has resulted in significant inhomogeneous tube deformation in cold rolling, leading to complex patterns of tube texture evolution. This study investigated the microstructural evolution and deformation mechanism of two types of Ti-2Al-2.5Zr alloy billets with different initial textures, produced by hot-rolled and precision-forged, during the three-pass Pilger cold rolling process. Through microstructural analysis, pole figures and inverse pole figures characterization, as well as calculations of the Kearns factor and Schmid factor (SF), the influence of different initial textures on the microstructural evolution during the cold rolling of seamless tubes was examined. The results show that after three passes of cold rolling, the grain sizes of the microstructures in both hot-rolled and precision-forged billets are similar, exhibiting equiaxed grains. During the cold rolling process, prismatic slip and pyramidal <c+a> slip are significantly activated, with the pyramidal <c+a> slip being confirmed as the primary deformation mechanism affecting the radial grain intensity in cold rolling. Variations in the Q-value lead to the tilting of the c-axes of the grains between the transverse direction (TD) and the radial direction (RD). The precision-forged billet, which has a higher initial radial texture intensity (fRD), exhibites a stronger radial texture after cold rolling. This study provides a theoretical basis for optimizing texture control of titanium alloy tubes.-

Key words:

- Ti-2Al-2.5Zr alloy /

- Pilger cold rolling /

- texture /

- deformation mechanism

-

表 1 皮尔格冷轧工艺参数

Table 1. Process parameters of Pilger cold rolling

Rolling pass Q value Rolling mill speed/(times·min−1) Feed rate/(mm·time−1) 1 Pass 1.1 80 2.0 2 Pass 0.9 60 1.5 3 Pass 2.5 60 1.0 表 2 不同状态下不同滑移系的平均SF值

Table 2. Average SF values for different slip systems in different states

Basal slip Prismatic

<a> slipPyramidal

<a> slipPyramidal

<c+a> slipRZ-pass1 0.320 0.243 0.350 0.418 RZ-pass2 0.340 0.213 0.342 0.425 RZ-pass3 0.326 0.248 0.348 0.413 JD-pass1 0.336 0.244 0.357 0.400 JD-pass2 0.339 0.208 0.333 0.422 JD-pass3 0.331 0.288 0.376 0.406 -

[1] CHEN G, CHU T S, CUI Y, et al. Effect of surface nanocrystallization on high-cycle fatigue behavior of Ti-2Al-2.5Zr alloy tube[J]. International Journal of Fatigue, 2022, 158: 10673. [2] ABE H, IWAMOTO T, YAMAMOTO Y, et al. Dimensional accuracy of tubes in cold pilgering[J]. Journal of Materials Processing Technology, 2016, 231: 277-287. doi: 10.1016/j.jmatprotec.2016.01.001 [3] HE S T, ZENG W D, ZHAO Z B, et al. Analysis of anisotropy mechanism in relation with slip activity in near α titanium alloy pipe after Pilger cold rolling[J]. Journal of Alloys and Compounds, 2022, 909: 164785. doi: 10.1016/j.jallcom.2022.164785 [4] LI H, WEI D, ZHANG H Q, et al. Texture evolution and controlling of high-strength titanium alloy tube in cold pilgering for properties tailoring[J]. Journal of Materials Processing Technology, 2020, 279: 116520. doi: 10.1016/j.jmatprotec.2019.116520 [5] WU J, WANG L, LIU X, et al. Evolution of microstructure and microtexture in Ti-2Al-2.5Zr during one pass cold pilgering[J]. Rare Metal Materials and Engineering, 2022, 51(4): 1145-1151. [6] LI H, ZHANG H Q, YANG H, et al. Anisotropic and asymmetrical yielding and its evolution in plastic deformation: Titanium tubular materials[J]. International Journal of Plasticity, 2017, 90: 177-211. doi: 10.1016/j.ijplas.2017.01.004 [7] HARVINDER S U, ANDREW H, JANARDHAN S. An EBSD study of texture variation along pilger reduced titanium alloy tubes[J]. Materials Science Forum, 2011, 702-703: 643-646. doi: 10.4028/www.scientific.net/MSF.702-703.643 [8] QI Y, HUI S X, YE W J, et al. Effect of ‘Q’ ratio on texture evolution of Ti-3Al-2.5V alloy tube during rolling[J]. Materials, 2022, 15(3): 817. doi: 10.3390/ma15030817 [9] BIELER T R, EISENLOHR P, ZHANG C, et al. Grain boundaries and interfaces in slip transfer[J]. Current Opinion in Solid State and Materials Science, 2014, 18(4): 212-226. doi: 10.1016/j.cossms.2014.05.003 [10] ZHU X Y, XING Y, JIANG J, et al. Effect of intermediate pass annealing on the microstructures and properties of Ti-3Al-2.5V tubes[J]. Iron Steel Vanadium Titanium, 2023, 44(3): 45-51. (朱小勇, 邢远, 江健, 等. 中间道次退火对Ti-3Al-2.5V管材组织和性能的影响[J]. 钢铁钒钛, 2023, 44(3): 45-51. doi: 10.7513/j.issn.1004-7638.2023.03.007ZHU X Y, XING Y, JIANG J, et al. Effect of intermediate pass annealing on the microstructures and properties of Ti-3Al-2.5V tubes[J]. Iron Steel Vanadium Titanium, 2023, 44(3): 45-51. doi: 10.7513/j.issn.1004-7638.2023.03.007 [11] LIU C Z, GUAN H, TAI Q G, et al. Microstructure, texture and mechanical studies of an inconspicuous shear band formed during hot compression of Ti-6Al-4V alloy[J]. Materials Science and Engineering: A, 2017, 698: 18-26. doi: 10.1016/j.msea.2017.05.041 [12] WEI D, CHEN Y Y, YANG H, et al. An insight into texture evolution and tailoring during multi-pass cold pilgering of high-strength titanium alloy tubular materials[J]. Journal of Alloys and Compounds, 2024, 997: 174835. doi: 10.1016/j.jallcom.2024.174835 [13] FAN Y T, LU L W, LIU J B, et al. Effect of deformation temperature on microstructure and texture of AZ31 magnesium alloy processed by new plastic deformation method[J]. Transactions of Nonferrous Metals Society of China, 2024, 34: 2138-2152. doi: 10.1016/S1003-6326(24)66530-1 [14] XU W L, YU J M, JIA L C, et al. Grain refinement impact on the mechanical properties and wear behavior of Mg-9Gd-3Y-2Zn-0.5Zr alloy after decreasing temperature reciprocating upsetting-extrusion[J]. Journal of Magnesium and Alloys, 2022, 10(12): 3506-3519. doi: 10.1016/j.jma.2021.03.021 -

下载:

下载: