Effect of hydrostatic pressure on stress corrosion susceptibility of low-cost titanium alloy plates and tubes

-

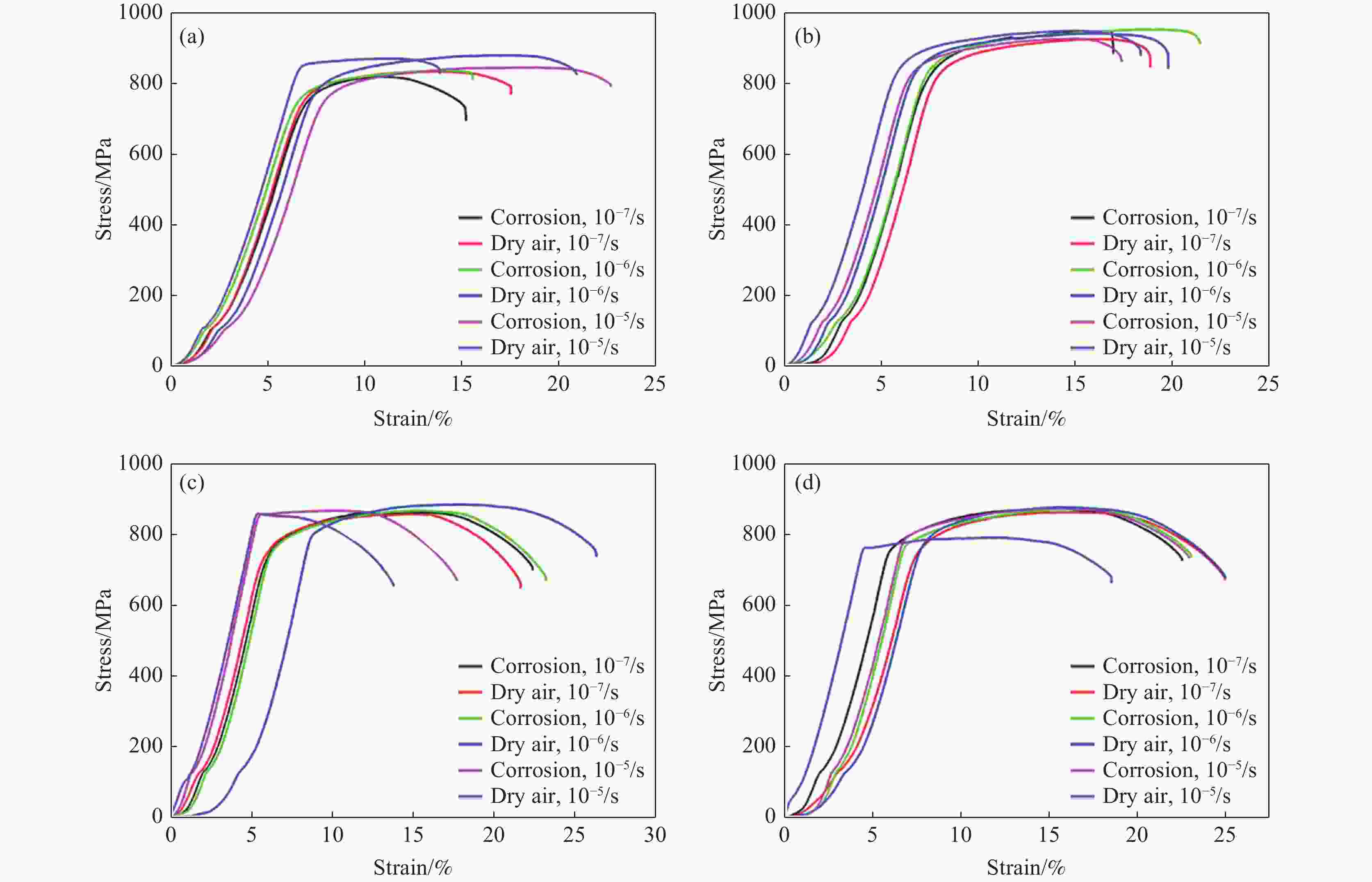

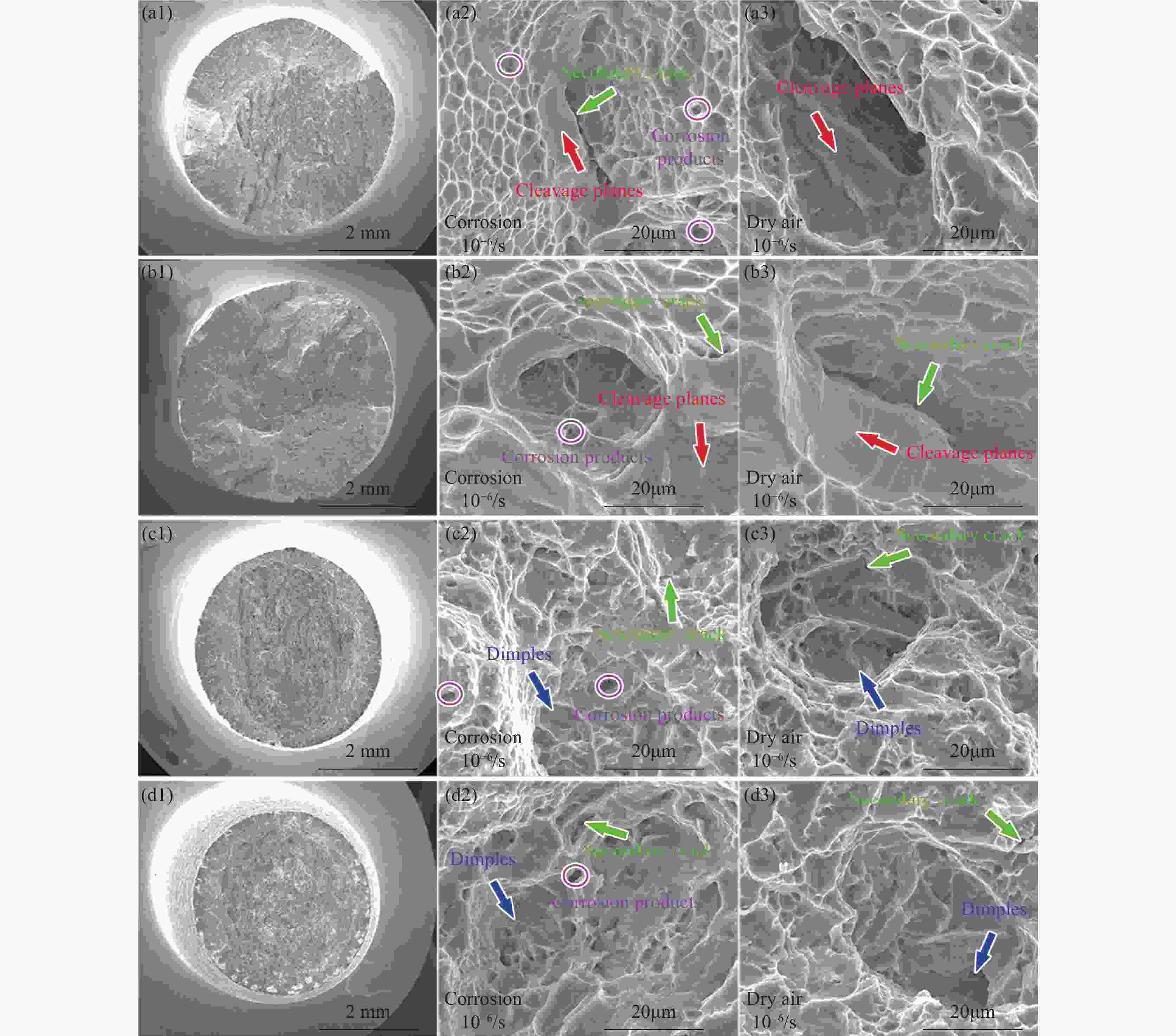

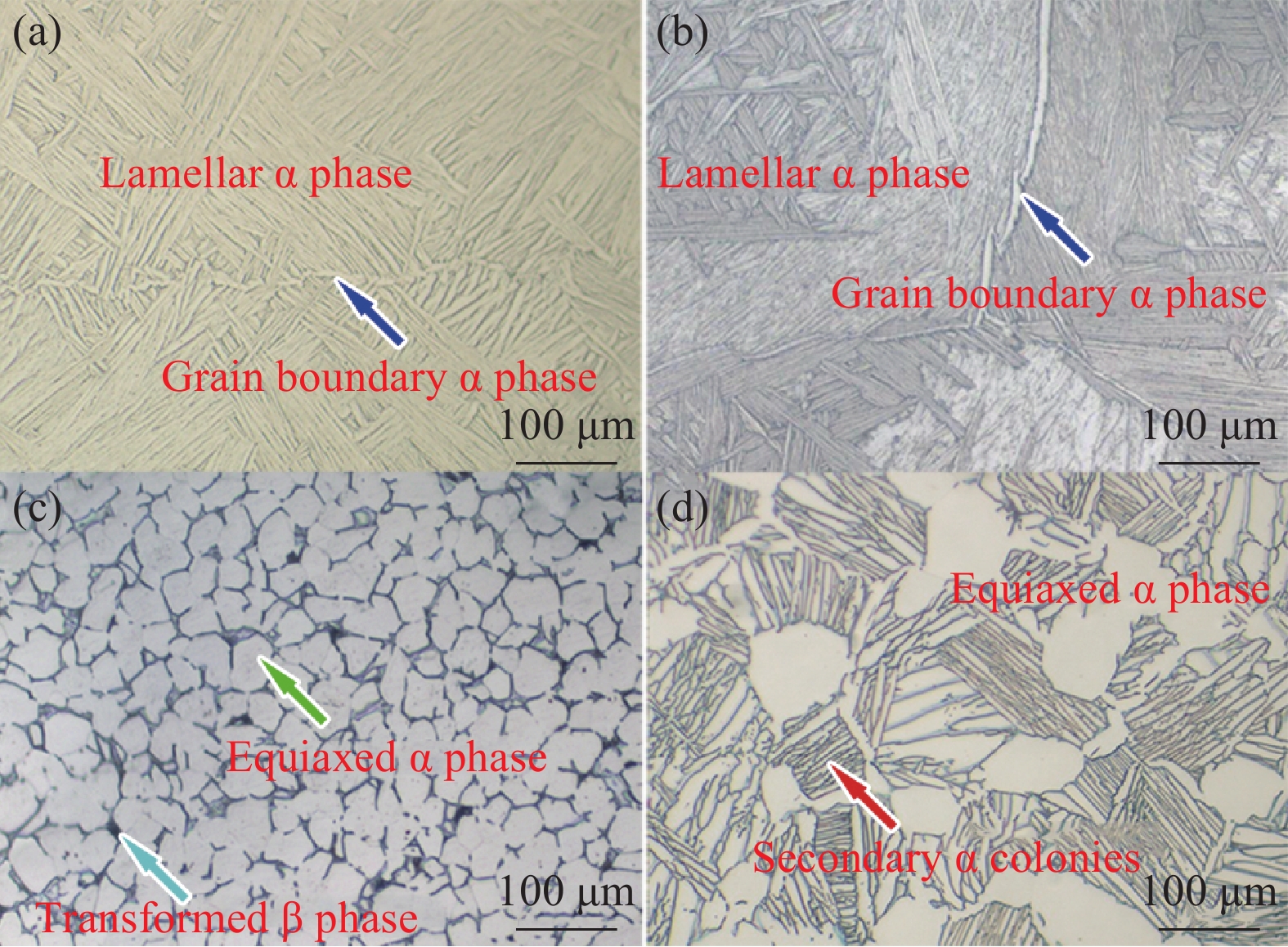

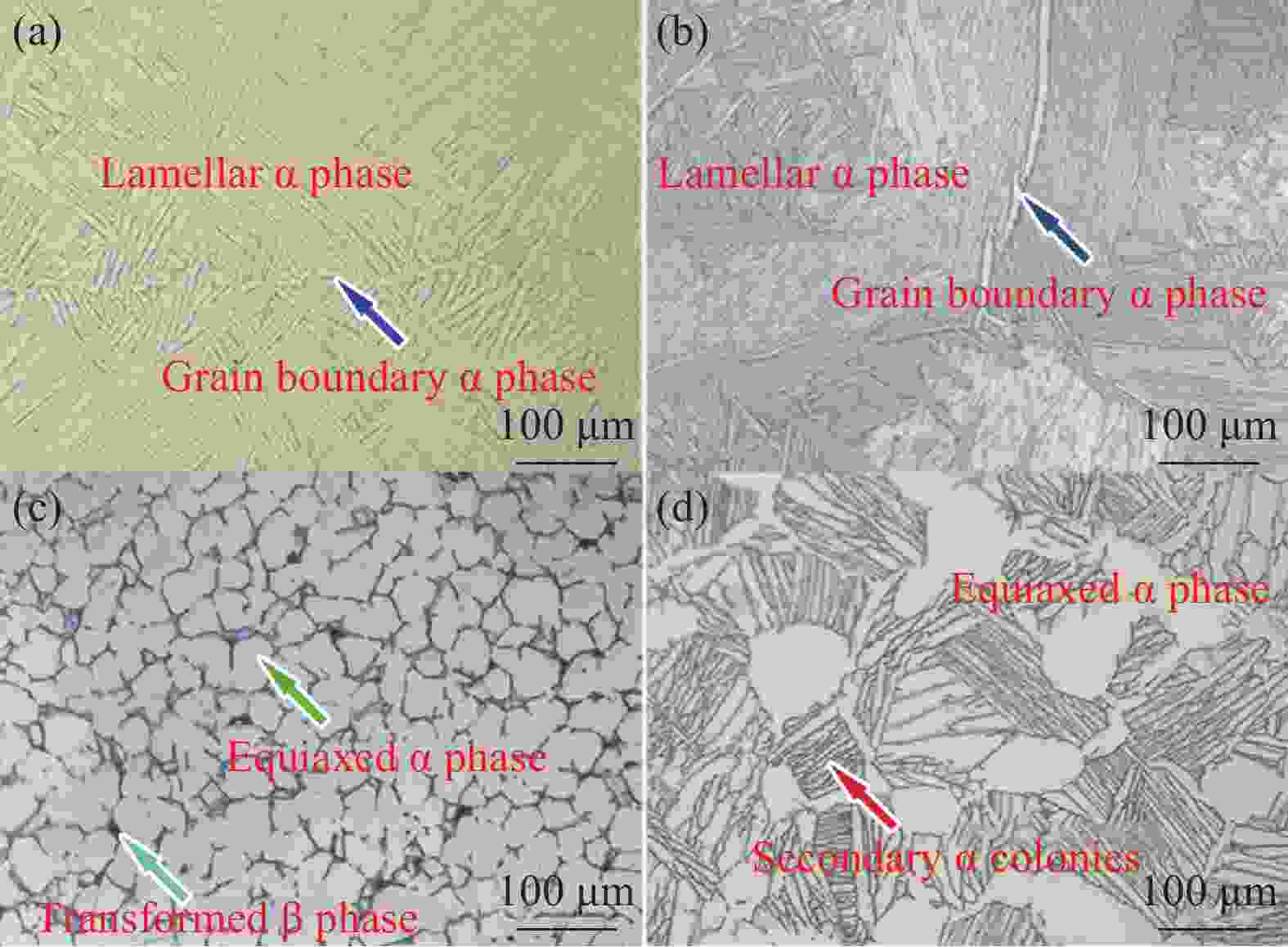

摘要: 采用高压釜测试系统开展低成本Ti6411板材和Ti52管材及船用TC4 ELI和Ti80合金模拟深水环境压力(7.5 MPa)作用下的慢应变拉伸应力腐蚀试验,腐蚀介质为3.5% NaCl溶液和干燥空气,应变速率分别采用10−5、10−6/s和10−7/s,获取拉伸强度、断后延伸率和应力腐蚀敏感性指数(ISSRT)等参数,同时结合OM、SEM等方式观察原始组织与断口形貌,从而阐明低成本钛合金板管材在模拟深水压力作用下的应力腐蚀行为及其失效机制。结果表明:四种钛合金材料的应力腐蚀最佳应变速率在10−5~10−6/s内,其中Ti6411板材在10−5/s和10−6/s两种条件下,ISSRT数值分别为10.0%和9.1%,具有较为明显的应力腐蚀敏感性,而Ti52管材、TC4 ELI和Ti80合金的最大ISSRT值均低于5%,应力腐蚀敏感性不明显。片层状Ti6411板材组织特征易产生应力集中效应,导致准解离断裂,断口表面存在黑色腐蚀产物,氧化膜破裂、选择性阳极溶解和氢脆机制共同主导模拟深水环境应力腐蚀现象,施加的恒定压力活化Cl−,加速穿透氧化膜,从而破坏氧化膜稳定性,增加H含量聚合形成氢气,拉应力加载和内部氢压耦合作用可降低材料耐腐蚀性。Abstract: This paper investigates the stress corrosion cracking (SCC) susceptibility of low-cost Ti6411 plate, Ti52 tube, marine TC4 ELI, and Ti80 alloys under simulated deep-water environment pressure using a high-pressure autoclave testing system. Slow-strain-rate tests (10−5, 10−6/s, and 10−7/s) were exposed to 3.5% NaCl solution and dry air with a hydrostatic pressure of 7.5 MPa. The tensile parameters and stress corrosion susceptibility index (ISSRT) were obtained. Furthermore, the microstructures and fracture features have been observed to elucidate the stress corrosion behavior and failure mechanisms of low-cost titanium alloy plates and tubes using OM and SEM under simulated deep-water pressure. The results indicated that the optimal strain rate is within 10−5/s and 10−6/s. Specifically, the ISSRT values of Ti6411 plate are 10.0% and 9.1% with strain rates of 10−5/s and 10−6/s, respectively. A notable stress corrosion susceptibility was obtained. In contrast, all ISSRT values of Ti52 tube, TC4 ELI, and Ti80 alloys were below 5%, indicating no significant stress corrosion susceptibility. Particularly, Ti6411 plate with lamellar microstructure is sensitive to stress concentration effects and exhibits quasi-cleavage fracture. Some black corrosion products can be observed on the fracture morphologies. It is believed that the corrosion mechanisms were coupled effects of selective anodic dissolution and hydrogen embrittlement. Hydrostatic pressure can promote Cl- to weaken the passive film and increase hydrogen content. As a result, both of the tensile loading and internal hydrogen pressure reduce the corrosion resistance of the titanium alloys.

-

表 1 不同试验条件下钛合金拉伸性能(平均值)

Table 1. Slow-strain-rate tensile properties of titanium alloys under different test conditions (average value)

Materials Conditions×

107/(s−1)Rm(corrosion)/

Rm(Dry air)Am(corrosion)/

Am(Dry air)ISSRT Ti6411 1 98.2 86.9 3.7 10 95.3 74.2 9.1 100 97.0 61.1 10.0 Ti52 1 103.0 89.9 −1.4 10 101.0 108.1 −2.3 100 97.7 94.5 3.2 TC4 ELI 1 100.6 101.8 −1.0 10 98.0 88.2 4.4 100 100.9 136.2 −5.1 Ti80 1 100.7 90.0 1.3 10 98.9 92.0 2.7 100 109.9 123.8 −14 -

[1] ZHANG R Q, ZHAO Q Y, GUO D Z, et al. High impact toughness of CT20 alloy induced by multi-factor coupling[J]. Journal of Materials Science & Technology, 2024, 192: 65-81. [2] LIU X H, WU C, HE W P, et al. Study on strengthening and toughening mechanisms of Ti80 alloy based on microstructure regulation[J]. Development and application of materials, 2024, 39(4): 28-37. (刘向宏, 吴聪, 和卫平, 等. 基于显微组织调控的Ti80合金强韧化机理研究[J]. 材料开发与应用, 2024, 39(4): 28-37.LIU X H, WU C, HE W P, et al. Study on strengthening and toughening mechanisms of Ti80 alloy based on microstructure regulation[J]. Development and application of materials, 2024, 39(4): 28-37. [3] WU D, HAO M Y, ZHANG T L, et al. Heterostructures enhance simultaneously strength and ductility of a commercial titanium alloy[J]. Acta Materialia, 2023, 257: 119182. doi: 10.1016/j.actamat.2023.119182 [4] YANG X W, LIN B, ZHANG H L, et al. Influence of stress on the corrosion behavior of Ti alloys: A review[J]. Journal of Alloys and Compounds, 2024, 985: 173346. doi: 10.1016/j.jallcom.2023.173346 [5] ZHOU J L, LI X G, CHENG X Q, et al. Research progress on corrosion of metallic materials in deep sea environment[J]. Corrosion Science and Protection Technology, 2010, 22(1): 47-51. (周建龙, 李晓刚, 程学群, 等. 深海环境下金属及合金材料腐蚀研究进展[J]. 腐蚀科学与防护技术, 2010, 22(1): 47-51.ZHOU J L, LI X G, CHENG X Q, et al. Research progress on corrosion of metallic materials in deep sea environment[J]. Corrosion Science and Protection Technology, 2010, 22(1): 47-51. [6] LIU H C, FAN L, ZHANG H B, et al. Research progress of stress corrosion cracking of Ti-alloy in deep sea environments[J]. Journal of Chinese Society for Corrosion and Protection, 2022, 42(2): 175-185. (柳皓晨, 范林, 张海兵, 等. 钛合金深海应力腐蚀研究进展[J]. 中国腐蚀与防护学报, 2022, 42(2): 175-185.LIU H C, FAN L, ZHANG H B, et al. Research progress of stress corrosion cracking of Ti-alloy in deep sea environments[J]. Journal of Chinese Society for Corrosion and Protection, 2022, 42(2): 175-185. [7] LIU R, XIE Y S, JIN Y, et al. Stress corrosion cracking of the titanium alloys under hydrostatic pressure resulting from the degradation of passive films[J]. Acta Materialia, 2023, 252: 118946. doi: 10.1016/j.actamat.2023.118946 [8] LIU J, LI X B, WANG J, Effect of hydrostatic pressure on the corrosion behaviors of two low alloy steels[J]. Acta Metallurgica Sinica. 2011, 47(6): 697-705. (刘杰, 李相波, 王佳. 模拟深海压力对2种低合金钢腐蚀行为的影响[J]. 金属学报, 2011, 47(6): 697-705.LIU J, LI X B, WANG J, Effect of hydrostatic pressure on the corrosion behaviors of two low alloy steels[J]. Acta Metallurgica Sinica. 2011, 47(6): 697-705. [9] CHENG H X, LUO H, CHENG J, et al. Optimizing the corrosion resistance of additive manufacturing TC4 titanium alloy in proton exchange membrane water electrolysis anodic environment[J]. International Journal of Hydrogen Energy, 2024, 93: 753-769. doi: 10.1016/j.ijhydene.2024.10.440 [10] YIN Y C, SUN Z J, XUE D, et al. Effect of post heat treatment on the microstructure and properties of as-annealed TC4 ELI alloy[J]. Iron Steel Vanadium Titanium, 2024, 45(3): 55-64. (尹艳超, 孙志杰, 薛达, 等. 后处理对退火态TC4 ELI合金显微组织与性能的影响[J]. 钢铁钒钛, 2024, 45(3): 55-64. doi: 10.7513/j.issn.1004-7638.2024.03.008YIN Y C, SUN Z J, XUE D, et al. Effect of post heat treatment on the microstructure and properties of as-annealed TC4 ELI alloy[J]. Iron Steel Vanadium Titanium, 2024, 45(3): 55-64. doi: 10.7513/j.issn.1004-7638.2024.03.008 [11] DONG Y C, HUANG S, WANG Y Y, et al. Stress corrosion cracking of TC4 ELI alloy with different microstructure in 3.5% NaCl solution[J]. Materials Characterization, 2022, 194: 112357. doi: 10.1016/j.matchar.2022.112357 [12] DING Y, LÜ Y T, CHEN K, et al. Effects of microstructure on the stress corrosion cracking behavior of nickelaluminum bronze alloy in 3.5% NaCl solution[J]. Materials Science & Engineering A, 2018, 733: 361-373. [13] YAN L Y, ZHANG H Y, ZHANG S, et al. Influence of phase composition and stress on the corrosion behavior of metastable β titanium alloy Ti-5Mo-5V-6Cr-3Al in 15 wt% HCl solution[J]. Journal of Alloys and Compounds, 2025, 1010: 177258. doi: 10.1016/j.jallcom.2024.177258 [14] WEN X M, HAO S, LIU S W, et al. Microstructure and corrosion behavior of Ti–10Mo–6Zr–4Sn–3Nb (Ti-B12) alloys as biomedical material in lactic acid-containing Hank’s solution[J]. International Journal of Electrochemical Science, 2025, 20: 100974. doi: 10.1016/j.ijoes.2025.100974 [15] LIU X, ZHANG H Y, WANG S Y, et al. Effect of α phase on stress corrosion behavior of metastable β titanium alloy Ti-5.5Cr-5Al-4Al-3Nb-2Zr in 3.5wt% Nacl solution[J]. Rare Metal Materials and Engineering, 2025, 54(1): 209-217. (刘璇, 张浩宇, 王圣元, 等. α相对亚稳β钛合金Ti-5.5Cr-5Al-4Mo-3Nb-2Zr在 3.5% NaCl溶液中应力腐蚀行为的影响[J]. 稀有金属材料与工程, 2025, 54(1): 209-217. doi: 10.12442/j.issn.1002-185X.20230681LIU X, ZHANG H Y, WANG S Y, et al. Effect of α phase on stress corrosion behavior of metastable β titanium alloy Ti-5.5Cr-5Al-4Al-3Nb-2Zr in 3.5wt% Nacl solution[J]. Rare Metal Materials and Engineering, 2025, 54(1): 209-217. doi: 10.12442/j.issn.1002-185X.20230681 [16] SUN Z J, WANG Y. Research status and prospect of the stress-corrosion of titanium alloys[J]. Development and application of materials, 2020, 35(2): 94-100. (孙志杰, 王洋. 钛合金应力腐蚀研究现状及展望[J]. 材料开发与应用, 2020, 35(2): 94-100.SUN Z J, WANG Y. Research status and prospect of the stress-corrosion of titanium alloys[J]. Development and application of materials, 2020, 35(2): 94-100. -

下载:

下载: