Research on hot deformation behaviors of short-time high temperature titanium alloy

-

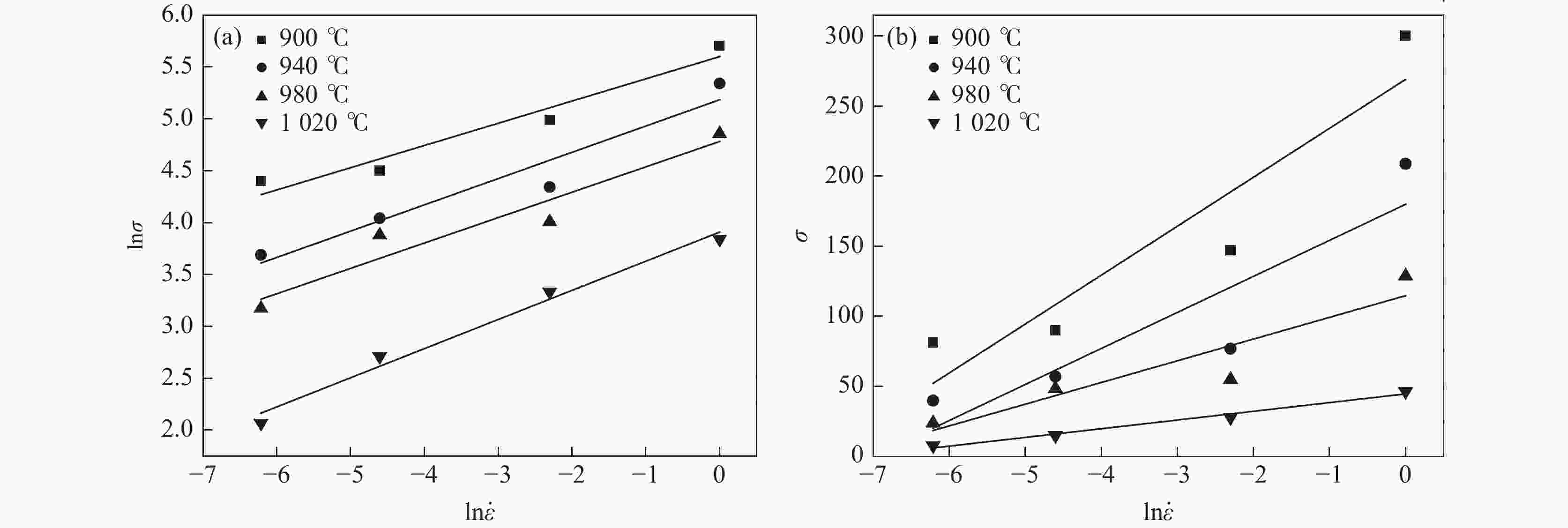

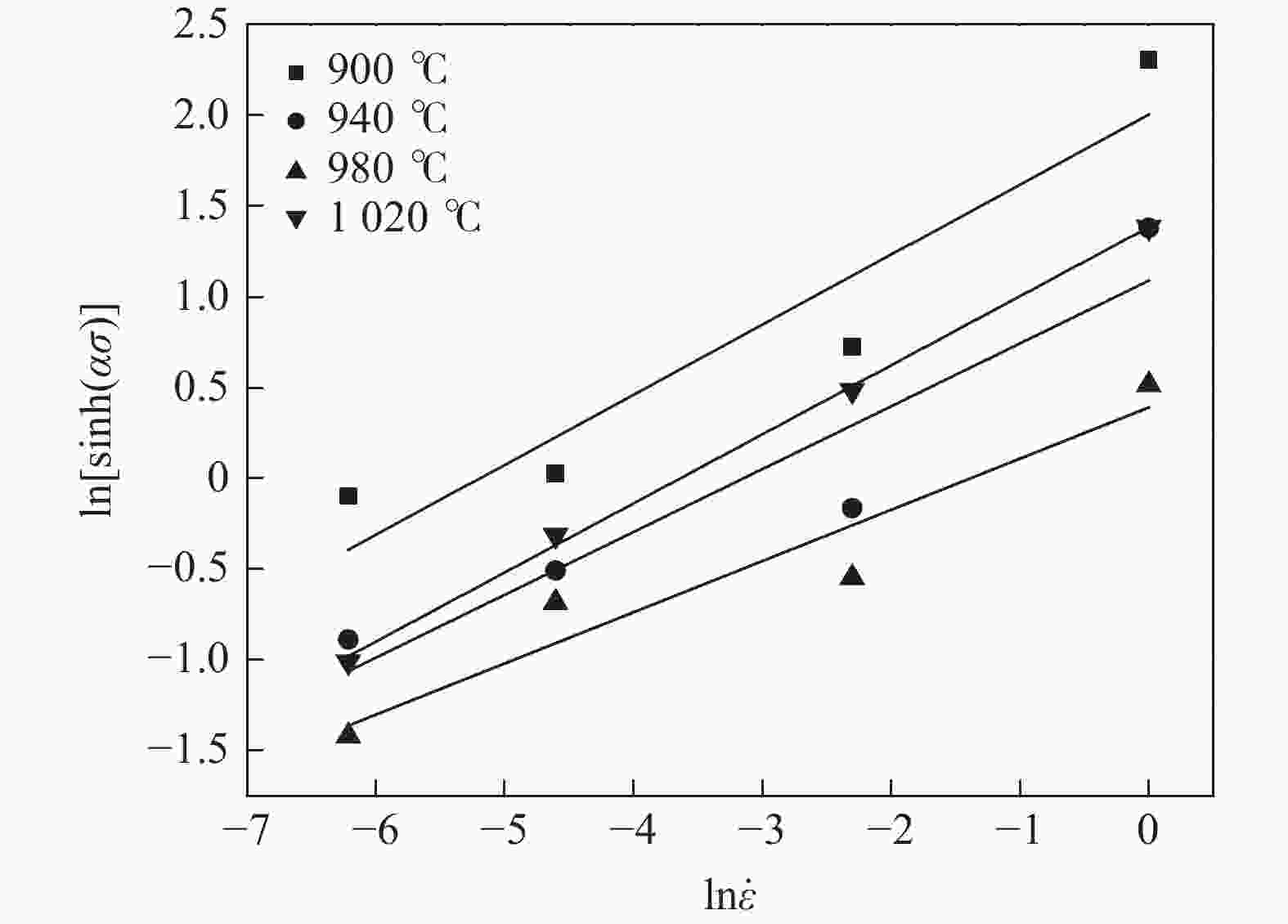

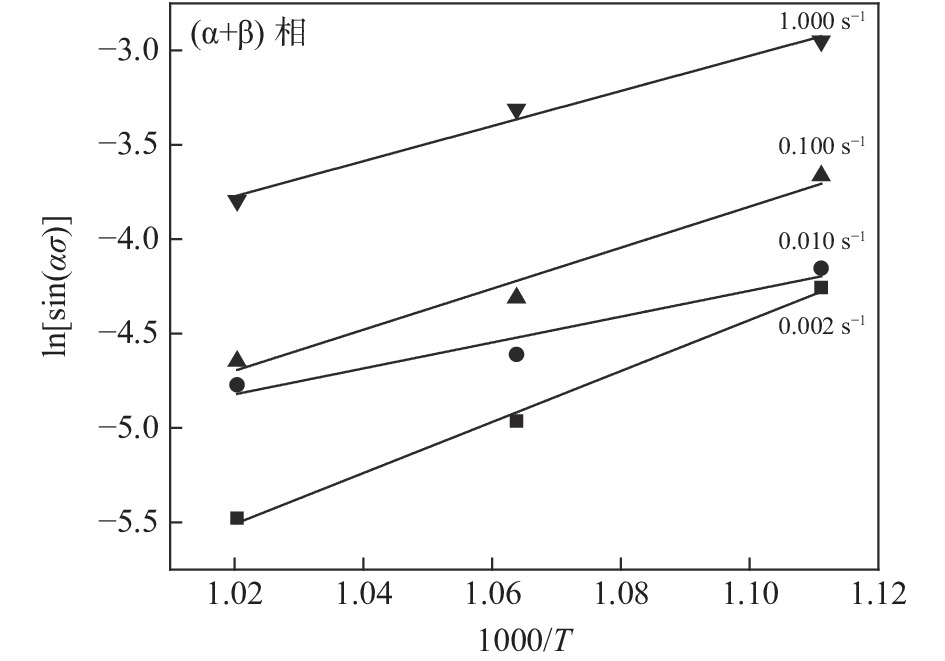

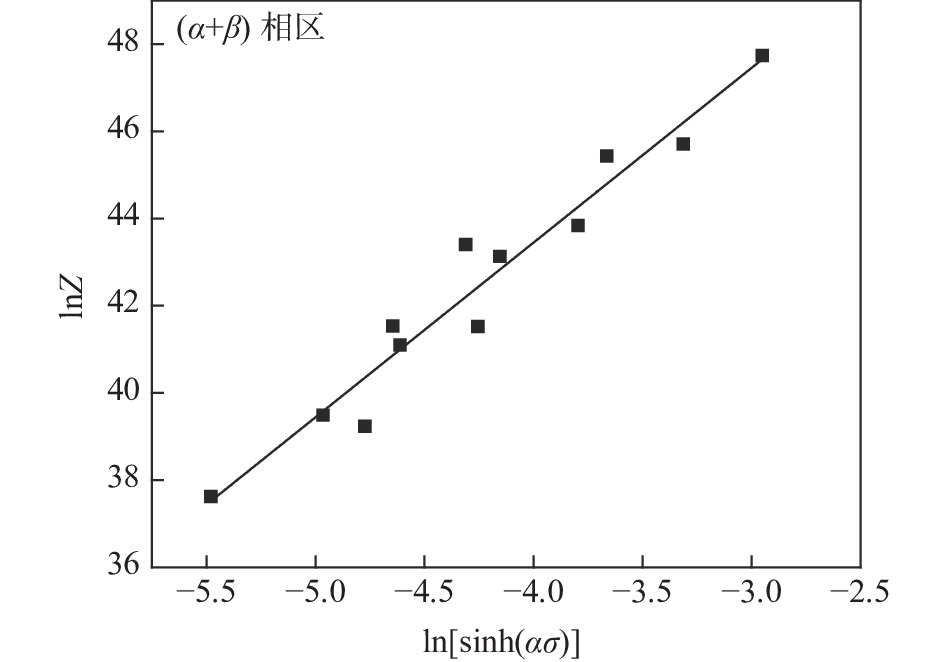

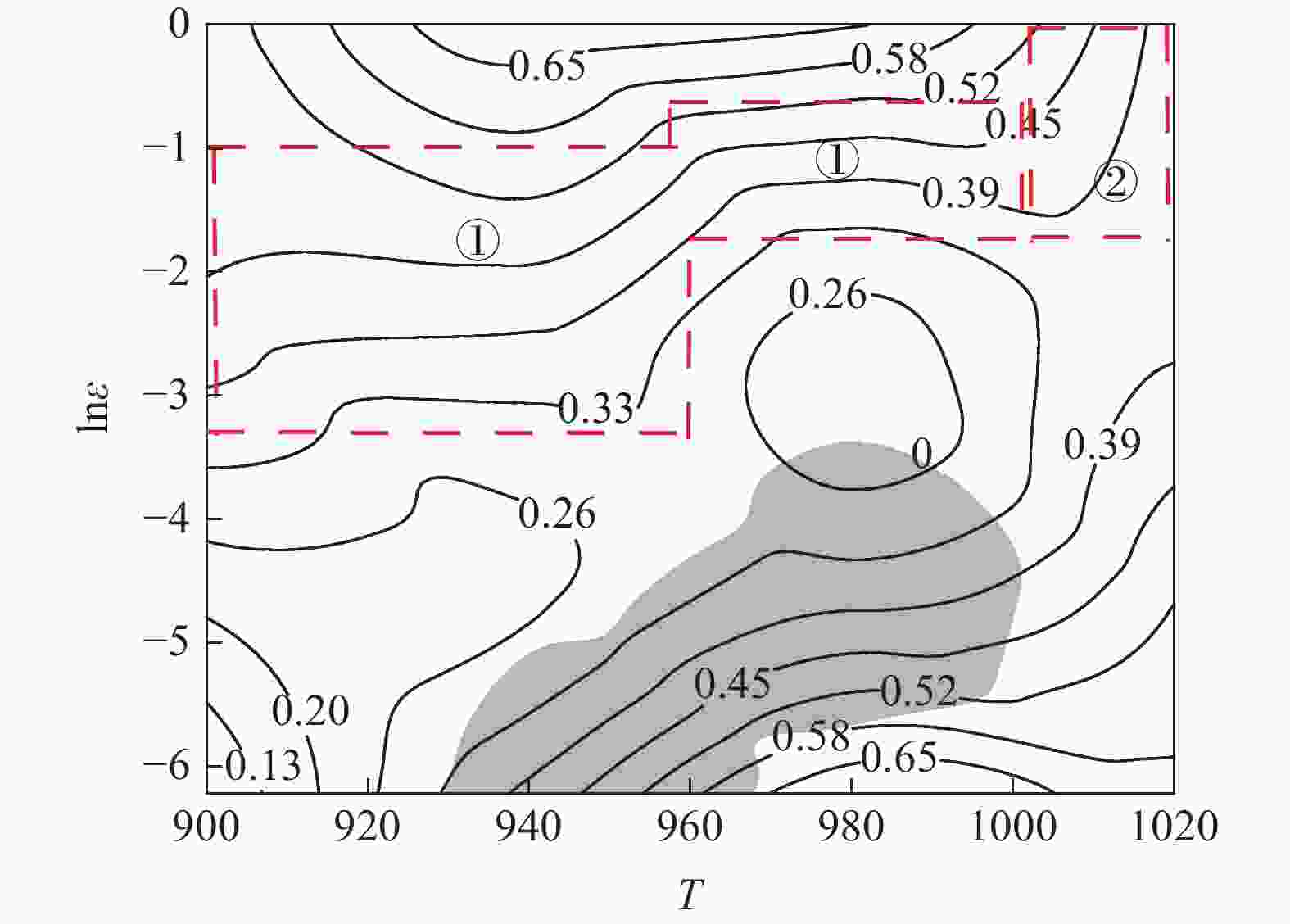

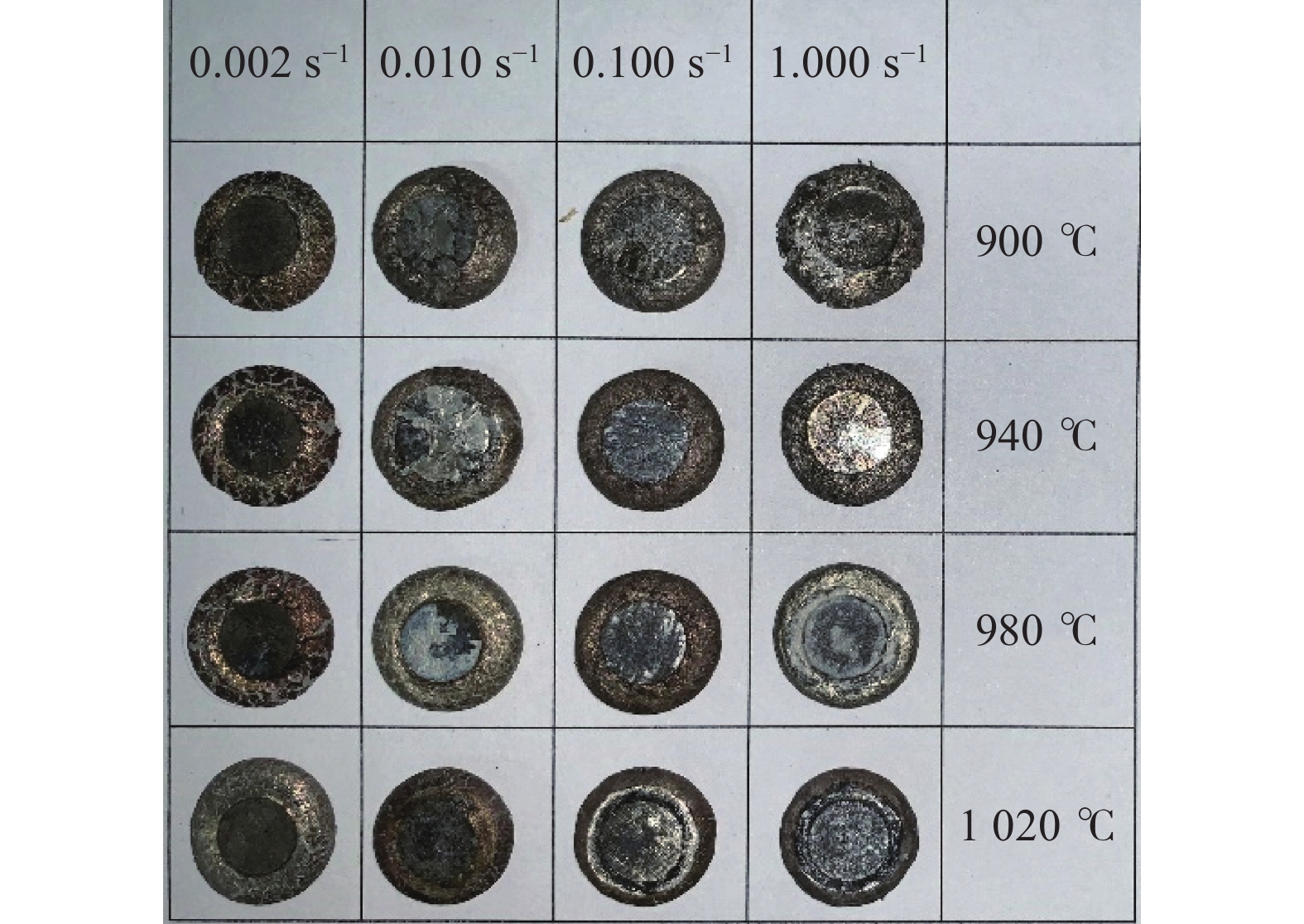

摘要: 采用热模拟试验机对铸态Ti-6Al-4Sn-8Zr-0.8Mo-1.5Nb-1W-0.25Si短时高温钛合金进行热模拟试验,研究了其高温变形行为。试验结果表明:该高温钛合金热变形对温度和变形速率敏感,随着应变速率降低和变形温度升高,真应力显著降低。利用高温压缩应力应变数据绘制了热加工图,分析结果显示:(α+β)相区的900~960 ℃、0.035~0.368 s−1和960~1010 ℃、0.165~0.577 s−1;β相区的1010~1020 ℃、0.165~1 s−1为最适合加工的区域。经计算,(α+β)两相区的热变形激活能为316.229 kJ/mol,并构建了该相区内的本构方程。Abstract: The thermal simulation test was carried out and high temperature deformation behavior of the as-cast Ti-6Al-4Sn-8Zr-0.8Mo-1.5Nb-1W-0.25Si short-time high temperature titanium alloy was studied. The experimental results show that the deformation of Ti-6Al-4Sn-8Zr-0.8Mo-1.5Nb-1W-0.25Si alloy is sensitive to the deformation temperature and deformation rate, and the true stress decreases significantly with the decrease of strain rate and the increase of deformation temperature. The hot working diagram was plotted using the high temperature compression stress-strain data. The analysis results demonstrate that 900-960 ℃, 0.035-0.368 s−1 and 960-1 010 ℃, 0.165-0.577 s−1 in the (α+β) phase region as well as 1010-1020 ℃, 0.165-1 s−1 of β phase region are the most suitable regions for hot processing. The thermal deformation activation energy of (α+β) two-phase region is calculated to be 316.229 kJ/mol, and the constitutive equation of the region is established as well.

-

表 1 合金流变峰值应力σp

Table 1. Peak rheological stress of the alloy σp

应变速率/s−1 σp/MPa 900 ℃ 940 ℃ 980 ℃ 1020 ℃ 1 300 208.7 128.7 46.52 0.1 146.95 76.96 55 28.04 0.01 90 56.96 48.48 15.04 0.002 81.3 40 23.91 7.91 表 2 峰值应力下的各参数值

Table 2. The parameters value of the peak stress

温度/℃ n1 β α 900 (ɑ+β)相区 4.671 0.029 940 3.949 0.039 980 4.089 0.065 平均值 4.236 0.044 0.010 1020 β相区 3.562 0.161 平均值 3.562 0.161 0.045 -

[1] Zhao Yongqing. Study on high temperature titanium alloy[J]. Titanium Industry Progress, 2001,(1):33−39. (赵永庆. 高温钛合金研究[J]. 钛工业进展, 2001,(1):33−39. doi: 10.3969/j.issn.1009-9964.2001.01.013 [2] Ren Pengli. Application and development prospect of high temperature titanium alloy[J]. Advanced Materials Industry, 2014,(3):56−58. (任朋立. 高温钛合金的应用及其发展前景[J]. 新材料产业, 2014,(3):56−58. doi: 10.3969/j.issn.1008-892X.2014.03.014 [3] 叶园. Zr 含量对650 ℃短时高温钛合金显微组织和力学性能的影响[D]. 哈尔滨: 哈尔滨工业大学, 2020: 61.Ye Yuan. Effect of Zr content on microstructure and mechanical properties of high temperature titanium alloys for short-term used at 650 ℃[D]. Harbin: Harbin Institute of Technology, 2020: 61. ) [4] 郑壮壮. 纳米 Y2O3 增强高温钛合金热变形行为及板材组织性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2019: 71.Zheng Zhuangzhuang. Study on thermal deformation behavior and microstructure and properties of sheet of high temperature titanium alloy reinforced by nano-Y2O3[D]. Harbin: Harbin Institute of Technology, 2019: 71. [5] Wang Zhenling, Yu Yucheng, Li Ruizhi, et al. Microstructure and high temperature tensile properties of (TiC+TiB) reinforced titanium matrix composites by vacuum induction suspension melting[J]. Iron Steel Vanadium Titnaium, 2021,45(5):54−61. (王振玲, 于玉城, 李睿智, 等. 真空感应悬浮熔炼(TiC+TiB)增强钛基复合材料组织及高温拉伸性能研究[J]. 钢铁钒钛, 2021,45(5):54−61. [6] Zeng W D, Shu Y, Zhang X M. Hot workability and microstructure evolution of highly β stabilised Ti-25V-15Cr-0.3Si alloy[J]. Materials Science and Technology, 2008,24:1222−1229. doi: 10.1179/174328407X185884 [7] Huang L J, Geng L, Li A B, et al. Characteristics of hot compression behavior of Ti-6.5A1-3.5Mo-1.5Zr-0.3Si alloy with an equiaxed microstructure[J]. Materials Science and Engineering A, 2009,505:136−143. doi: 10.1016/j.msea.2008.12.041 [8] Jonas J J, Sellars C M, Tegart W J M. Strength and structure under hot-working. conditions[J]. Metallurgical Reviews, 1969,14(1):1−24. doi: 10.1179/mtlr.1969.14.1.1 [9] Quan G Z, Wen H R, Jia P, et al. Construction of processing maps based on expanded data by BP-ANN and identification of optical deforming parameters for Ti-6Al-4V alloy[J]. Int. J. Precis. Eng. Manuf., 2016,17(2):171−180. doi: 10.1007/s12541-016-0022-z [10] Wang Y, Liu D L, Lay C C. A correlation between tensile flow stress and Zenner-Hollomon factor in TiAl alloys at high temperatures[J]. Journal of Materials Science Letters, 2000,19:1185−1188. doi: 10.1023/A:1006723629430 [11] Prasad Y V R K. Author’s reply: Dynamic materials model: Basis and principles[J]. Metallurgical and Materials Transactions A, 1996,27:235−236. doi: 10.1007/BF02647765 -

下载:

下载: