Effect of Ta on microstructure and corrosion resistance of TA23 alloy

-

摘要: 利用金相显微镜、X射线衍射仪、显微硬度仪和电化学工作站研究了微量Ta元素对TA23合金显微组织、物相、维氏硬度及腐蚀性能的影响。结果表明,加入Ta元素之后,初生α相比例有不同程度的增大,且次生α相比例明显减少;对含Ta双态组织TA23合金进行X射线衍射谱分析发现没有出现新的衍射峰,即合金中无新相生成。当合金中Ta含量为0.5%时,(10-11)α的峰强度明显增高,织构更明显;通过显微硬度测试发现双态组织TA23合金的硬度出现下降,这主要是Ta元素加入后,合金中塑性较好的初生α相比例增大导致。对双态组织TA23合金进行动电位极化曲线测试,发现加入微量Ta元素之后合金的自腐蚀电位增高,自腐蚀电流密度下降,耐腐蚀性能提高,Ta元素的加入降低了钛合金的阳极活性。当Ta含量为0.5%时,初生α晶粒尺寸增大,减少了腐蚀原电池的形成,提高了钛合金在海水中的耐腐蚀性能。Abstract: The effect of Ta element on the microstructure, phase compositions, microhardness and corrosion resistance of TA23 alloy was investigated by means of optical microscopy, X-ray diffraction, Vickers hardness tester and electrochemical workstation. The results show that the proportion of primary α phase increases to some extent and the proportion of secondary α phase decreases obviously in the alloy with Ta added. The X-ray diffraction indicates that there is no new phase identified in the alloy after addition of Ta. At 0.5% of Ta in the alloy, the peak intensity of (10-11) α increases significantly. The microhardness of TA23 decreases slowly as the Ta content increases, which is attributed to the increase of soft α phase in the alloy with Ta added. The potentiodynamic polarization curves suggest that after addition of Ta element, the corrosion resistance of TA23 alloy is improved. When the Ta content is 0.5%, the size of primary α phase increases, which reduces the formation of corrosion battery and improves the corrosion resistance of titanium alloy in seawater.

-

Key words:

- TA23 /

- microstructure /

- microhardness /

- potentiodynamic polarization curve /

- corrosion resistance

-

0. 引言

钛合金相对于传统钢材具有密度小、比强度高、耐腐蚀、无磁性、抗冲击震动等优良特质,被称作“海洋金属”,是一种理想的船用金属材料[1-3]。双态组织钛合金因其混合了初生等轴α相与晶间针状β相,兼备了等轴组织和魏氏组织的优点,表现出良好的综合性能,在工程方面应用最为广泛[4-5]。我国近年来研发了一系列船用钛合金如:TA23、Ti91、TA5、TC11等,其中TA23(Ti-6Al-3Nb-2Zr-1Mo)的综合性能比较优秀,应用十分广泛[6]。大量研究表明,在钛合金中加入Ta,可以显著提高合金的抗腐蚀性能,并且对钛钽合金在强酸介质中的腐蚀性能展开了研究[7-8]。同时有研究表明,在钛合金中加入Ta虽然可以提高其腐蚀性能,但是会造成力学性能的恶化,无法广泛在船舶领域推广[9]。因此,有必要研究在钛合金中Ta的适宜加入量以及对合金在海水中的耐腐蚀性能,以拓展钽钛合金在船舶等领域的应用与发展。为此,笔者系统研究不同Ta含量对TA23合金微观组织、显微硬度和化学腐蚀性能的影响,旨在优化TA23合金的力学和腐蚀性能匹配性,为其在船舶领域的推广应用提供理论依据。

1. 试验材料及方法

TA23合金的名义成分为Ti-6Al-3Nb-2Zr-1Mo。本试验在TA23合金的基础上加入了不同含量的Ta元素,制备出不同Ta含量的TA23合金,其化学成分如表1所示。

表 1 合金化学成分Table 1. Chemical compositions of different samples% Al Zr Nb Mo Ta TA23 6.38 2.00 3.11 1.06 0 TA23-0.2%Ta 6.38 2.10 3.36 1.19 0.2 TA23-0.5%Ta 6.25 2.06 3.41 1.15 0.5 利用OLYMPUS-BX51M显微镜对不同Ta含量TA23合金的金相显微组织进行观察,金相试样采用机械抛光制备,腐蚀剂采用3%HF+7%HNO3+90%H2O,腐蚀10~15 s后立即水冲并吹干。利用UIV-X射线衍射仪(XRD)对三种不同Ta含量TA23合金的物相进行分析。使用HV-1000IS维氏显微硬度计对试样的维氏硬度进行测试,试验力选取300 N,保荷时间10 s,每个试样分别选取5个不同区域进行测试并取其平均值。

电化学测试仪器采用上海华辰CHI760e电化学工作站,试样保留有效工作面积为1 cm2,通过杜邦线试样背面连接,其余面采用环氧树脂密封。测试前依次通过240#、600#、1000#、1500#砂纸打磨,并使用酒精清洗工作面,在室温下人工模拟海水3.5%NaCl溶液中浸泡30 min并吹干,保存待用。动电位极化曲线测试采用三电极体系,Pt电极作为辅助电极、饱和甘汞电极为参比电极(SCE)、待测试样作为工作电极。测试温度为(23±3)℃,扫描范围选择−2~3 V,扫描速率采用0.01 V/s,并在测量下一试样之前更换溶液。

2. 结果与分析

2.1 金相形貌

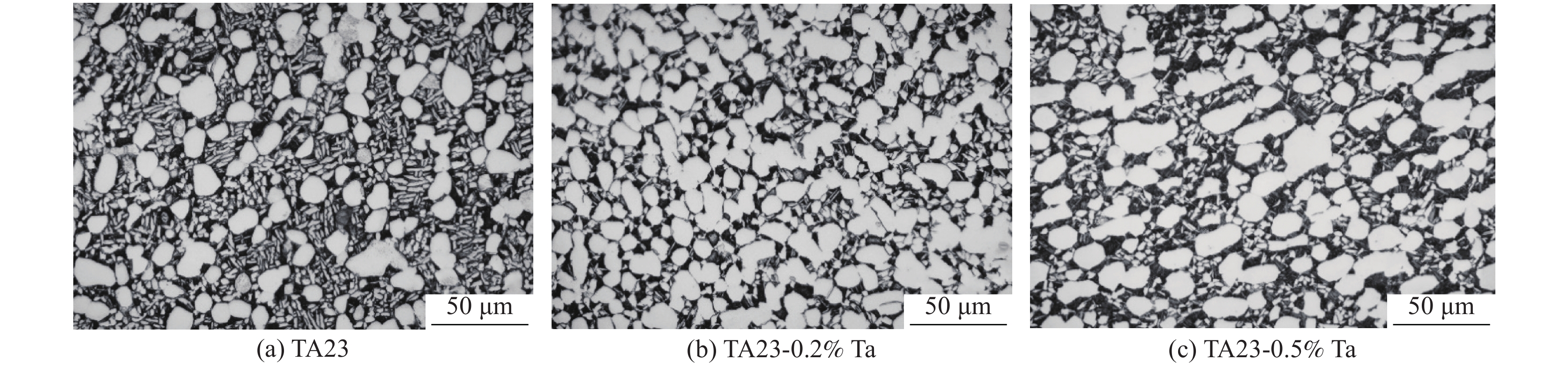

图1分别为Ta含量为0%、0.2%和0.5%的三种双态组织TA23合金的金相组织照片。通过对金相组织分析可知,在相同的热加工和热处理条件下,TA23中初生α相的比例为35.5%,TA23-0.2%Ta中初生α相的比例为53.8%,明显高于TA23。TA23-0.5%Ta中初生α相的比例有所下降,为44.4%。加入微量Ta元素后,次生α相被“吞并”,其比例相对TA23均有所减少。进一步观察发现TA23-0.5%Ta的初生α相晶粒尺寸相较于TA23与TA23-0.2%Ta稍有增大,且TA23中次生α相大多为扁平的条状,增加微量Ta元素后则与之前有所不同,其次生α相多为块状且数量明显减少。

2.2 XRD

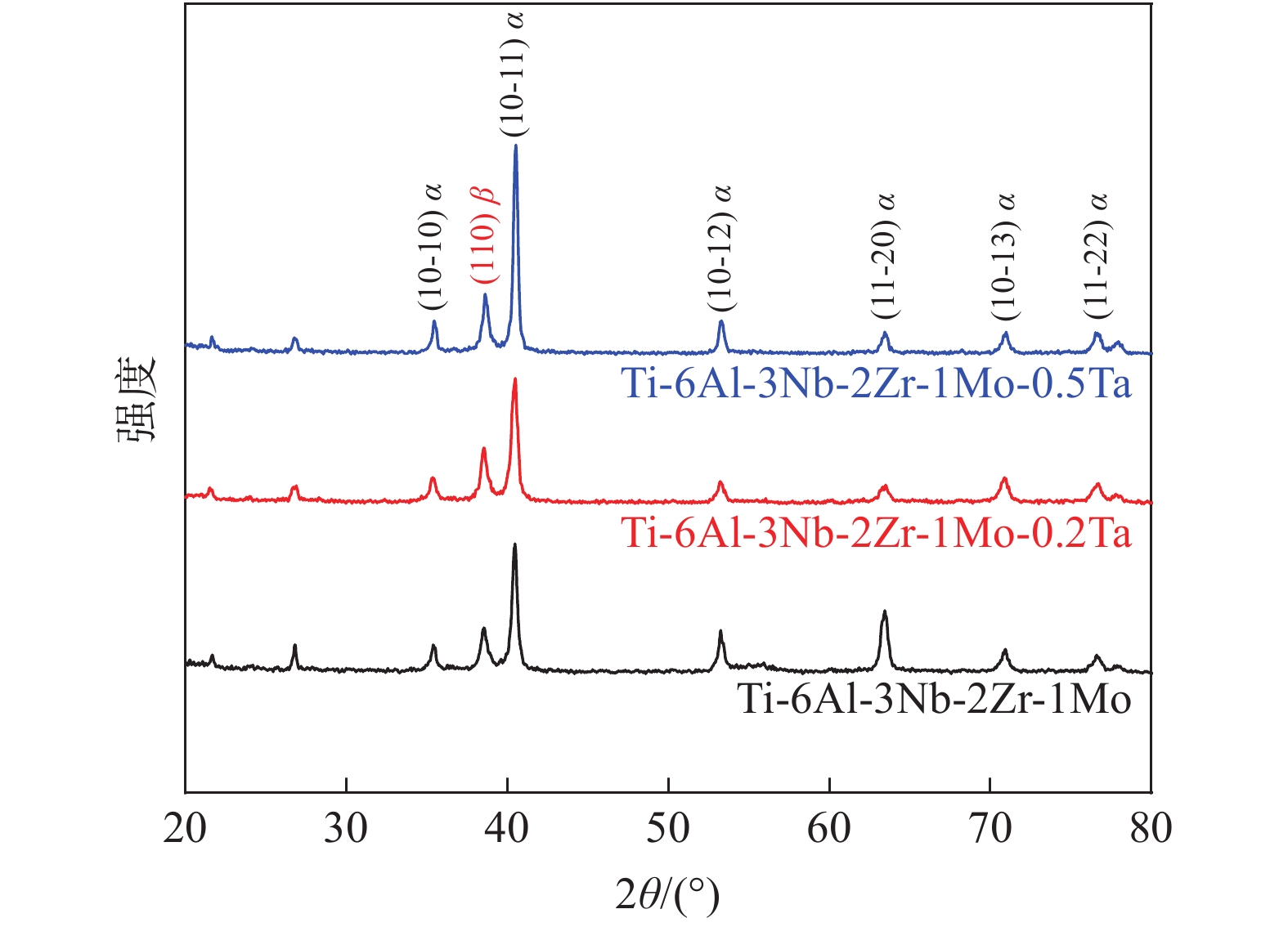

不同Ta含量双态组织TA23合金X射线衍射图谱如图2所示。可以看到,随着Ta含量的增加,X射线衍射谱中并没有出现新的衍射峰,说明在双态组织TA23合金中加入少量Ta元素之后,无新相生成。其次,通过观察可以发现,当Ta含量增加到0.5%时,(10-11) α的峰强度明显增强,(10-11)取向的初生α晶粒明显增多,其(10-11)织构越来越明显。TA23的X射线衍射谱中(11-20)α的峰明显高于TA23-0.2%Ta与TA23-0.5%Ta,TA23的次生α相的比例最高,与显微组织分析结论一致。

2.3 显微硬度测试

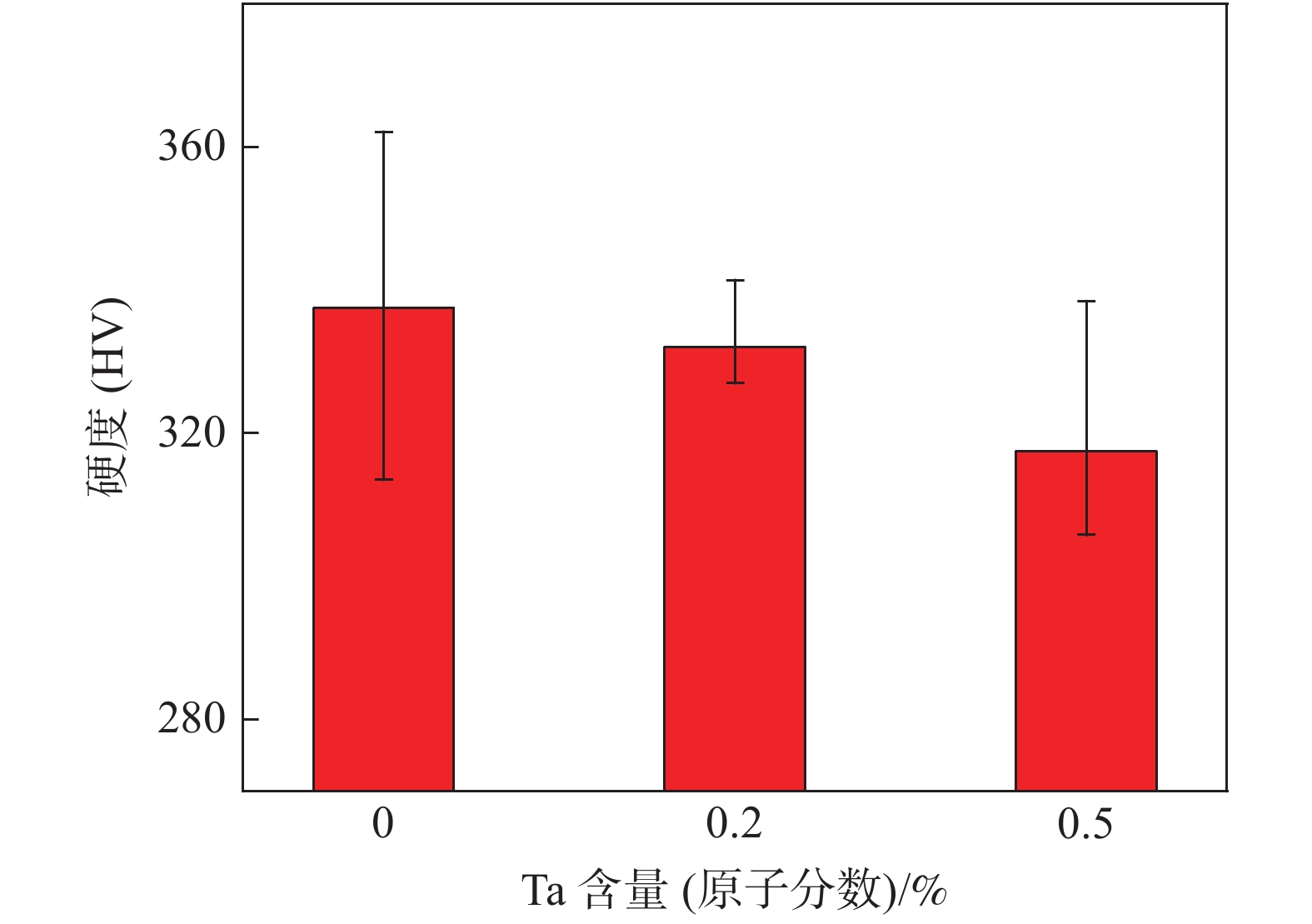

图3为不同Ta含量双态组织TA23合金的显微硬度。可以看到,合金中不加入Ta元素时硬度(HV)最高,为337.5。随着Ta元素含量的增加,显微硬度出现降低,当Ta元素含量达到0.5%时,显微硬度达到最小,为317.5。总体来说,随着双态组织TA23合金中Ta含量的增加,其显微硬度出现了细微的下降。造成这种现象的原因是钛合金中初生α相晶粒滑移面较多更容易变形,因此相对于β相,初生α相较软,塑性较好[10]。而结合显微组织观察可以发现,相对于TA23,TA23-0.2%Ta与TA23-0.5%Ta中塑性较好的初生α相比例明显增多,因此TA23-0.2%Ta与TA23-0.5%Ta的显微硬度相对TA23均有所下降。而TA23-0.2%Ta中初生α相的晶粒尺寸明显小于TA23-0.5%Ta,根据hall-petch公式:

$$ {\sigma _y} = {\sigma _0} + \frac{{{{{k}}_{{y}}}}}{{\sqrt d }} $$ 其中:σy为材料屈服极限; σ0为移动单个位错时产生的晶格摩擦阻力;ky为常数;d为平均晶粒直径。

TA23-0.2%Ta相对TA23-0.5%Ta晶粒尺寸较小,由于细晶强化的作用,导致TA23-0.2%Ta的初生α相比例虽然高于TA23-0.5%Ta,但其显微硬度仍然高于TA23-0.5%Ta。其次,由于TA23-0.2%Ta相界比例相对较高,更容易阻碍位错的开动,也一定程度上提高了TA23-0.2%Ta的显微硬度[11]。

2.4 耐腐蚀性能

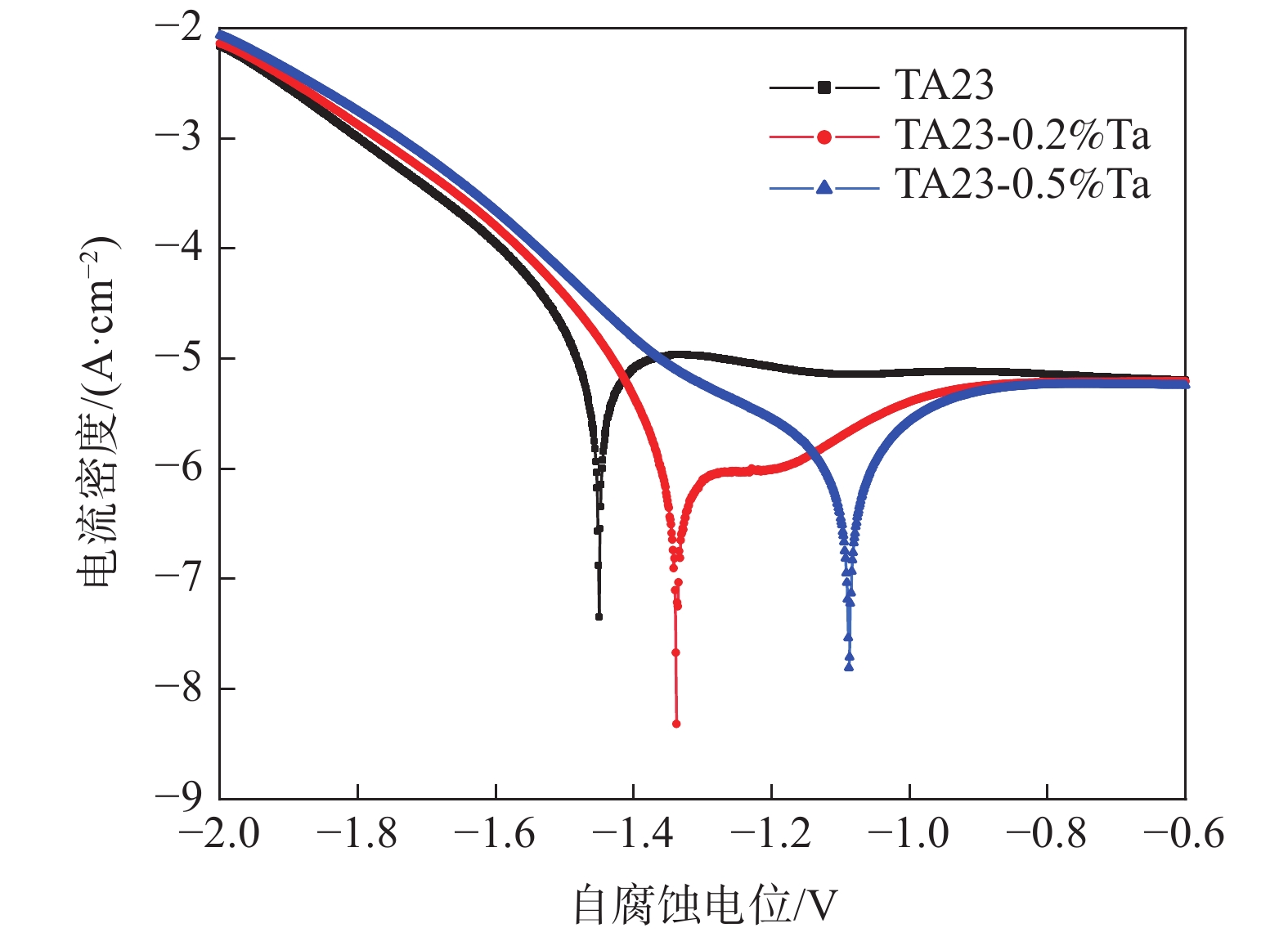

图4为不同Ta含量双态组织TA23合金在3.5%NaCl溶液中的动电位极化曲线。可以看到,随着Ta含量的增加,钛合金的自腐蚀电位不断右移,当Ta含量增加到0.5%时,试样的自腐蚀电位最高,约为−1.09 V。Ta元素含量的增加,一定程度上提高了双态组织TA23合金的自腐蚀电位,从而提高了钛合金腐蚀的难易程度。

进一步观察发现,在TA23-0.2%Ta极化曲线阳极区−1.3 V左右试样发生钝化,随着电位的升高,在−1.2 V左右时自腐蚀电流密度上升,最终在−0.9 V左右时趋于稳定,而TA23与TA23-0.5%Ta并未出现类活化再钝化过程[12]。通过对动电位极化曲线Tafel区进行拟合,自腐蚀电位与自腐蚀电流密度如表2所示。可以发现,随着Ta含量的增加,试样的自腐蚀电流密度越来越小,TA23-0.5%Ta的自腐蚀电流密度最小,约为1.43×10−6 A/cm2,说明其腐蚀速度最慢,TA23-0.5%Ta的耐腐蚀性最强[13],这也与自腐蚀电位规律一致。

表 2 不同Ta含量双态TA23合金在人工模拟海水溶液中的电化学参数Table 2. Electrochemical parameters of polarization curves of the TA23 alloys in simulated seawaterφcorr(vs SCE)/V Jcorr/(A·cm−2) TA23 −1.46 1.119×10−5 TA23-0.2%Ta −1.34 1.49×10−6 TA23-0.5%Ta −1.09 1.43×10−6 综上所述,加入微量Ta元素后,双态组织TA23合金自腐蚀电位增大、自腐蚀电流密度下降,其耐腐蚀性能增强。可能的原因是Ta元素作为易钝化合金元素,在双态组织TA23合金中加入易钝化元素能够使钛合金的阳极活性降低,提高其钝化能力,降低了自腐蚀电流密度[14]。其次,晶界处因杂质原子偏聚而存在电位差,易形成腐蚀原电池,结合显微组织分析,Ta含量达到0.5%时,初生α相晶粒尺寸偏大,使其晶界密度减少,减少了腐蚀原电池的数量,从而使其耐腐蚀性能进一步提高[15-16]。

3. 结论

1)不同Ta含量双态组织TA23初生α相比例有所不同;加入Ta元素之后,次生α相由扁平的条状变为块状且数量有所减少,结合XRD测试结果可知,加入Ta元素后双态组织TA23合金中并无新相生成。

2)通过显微硬度测试发现,TA23-0.2%Ta、TA23-0.5%Ta中塑性较好的初生α相比例大于TA23,因此显微硬度出现细微下降。而TA23-0.2%Ta虽然初生α相比例高于TA23-0.5%Ta,但TA23-0.2%Ta中初生α相晶粒尺寸相对较小,由于细晶强化的作用导致TA23-0.2%Ta的硬度略微高于TA23-0.5%Ta。

3)在双态组织TA23合金中加入微量易钝化的Ta元素之后,降低了钛合金的阳极活性,且当Ta含量达到0.5%时,初生α相晶粒尺寸增大,减少了腐蚀原电池的形成,增加了钛合金在海水中的耐腐蚀性。

-

表 1 合金化学成分

Table 1. Chemical compositions of different samples

% Al Zr Nb Mo Ta TA23 6.38 2.00 3.11 1.06 0 TA23-0.2%Ta 6.38 2.10 3.36 1.19 0.2 TA23-0.5%Ta 6.25 2.06 3.41 1.15 0.5 表 2 不同Ta含量双态TA23合金在人工模拟海水溶液中的电化学参数

Table 2. Electrochemical parameters of polarization curves of the TA23 alloys in simulated seawater

φcorr(vs SCE)/V Jcorr/(A·cm−2) TA23 −1.46 1.119×10−5 TA23-0.2%Ta −1.34 1.49×10−6 TA23-0.5%Ta −1.09 1.43×10−6 -

[1] Huang Xiaoyan, Liu Bo, Li Xue. Applications of titanium alloys in warship building[J]. Southern Metals, 2005,(6):11. (黄晓艳, 刘波, 李雪. 钛合金在舰船上的应用[J]. 南方金属, 2005,(6):11. [2] Chen Fenglin, Ge Keke, Hou Chunming. Progress in welding technology of titanium alloy for naval vessels[J]. Electric Welding Machine, 2019,49(8):60−65. (陈凤林, 葛可可, 侯春明. 舰船用钛合金焊接技术进展[J]. 电焊机, 2019,49(8):60−65. [3] Jiang Peng, Wang Qi, Zhang Binbin, et al. Application of titanium alloy materials for the pressure-resistant structure of deep diving equipment[J]. Strategic Study of CAE, 2019,21(6):104. (蒋鹏, 王启, 张斌斌, 等. 深海装备耐压结构用钛合金材料应用研究[J]. 中国工程科学, 2019,21(6):104. [4] (赵永庆. 钛合金相变及热处理[M]. 长沙: 中南大学出版社, 2012: 12−14.)Zhao Yongqing. Phase transformation and heat treatment of titanium alloys[M]. Changsha: Central South University Press, 2012: 12−14. [5] (张仕林. (α+β)钛合金电子束焊接接头显微组织及力学性能研究[D]. 合肥: 中国科学技术大学, 2019.)Zhang Shilin. Microstructures and mechanical properties of electron beam welded (α+β) titanium alloy[D]. Hefei: University of Science and Technology of China, 2019. [6] (陈才敏. 耐蚀Ti-Al-Nb-Zr-Mo合金的成分优化及组织性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.)Chen Caimin. Study on composition optimization and microstructures and properties of corrosion resistant Ti-Al-Nb-Zr-Mo alloy[D]. Haerbin: Harbin Institute of Technology, 2018. [7] Xu Xiaoxiao, Qiu Shaoyu. Research progress in the application of titanium alloy to nuclear fuel reprocessing facility[J]. Materials Reports, 2005,19(11):57−59. (徐潇潇, 邱绍宇. Ti合金在核燃料后处理设备中的应用研究进展[J]. 材料导报, 2005,19(11):57−59. doi: 10.3321/j.issn:1005-023X.2005.11.016 [8] Souza K, Robin A. Preparation and characterization of Ti-Ta alloys for application in corrosive media[J]. Mater Lett, 2003,57:3010. doi: 10.1016/S0167-577X(02)01422-2 [9] (杨帆. 钛钽合金的组织结构与腐蚀行为研究[D]. 西安: 西安建筑科技大学, 2015.)Yang Fan. Research on microstructure and corrosion behavior of Ti-Ta alloys[D]. Xi’an: Xi’an University of Architecture and Technology, 2015. [10] Yan Qian, Shu Xinzhu, Zhu Feixia, et al. A comparative study on quasistatic mechanical properties of four kinds of typical microstructure of TC11 titanium alloy at room temperature[J]. Journal of Yunnan University (Natural Sciences Edition), 2016,38(1):99−104. (颜茜, 舒鑫柱, 祝菲霞, 等. TC11钛合金4种典型组织静态力学性能对比研究[J]. 云南大学学报(自然科学版), 2016,38(1):99−104. [11] Lv Zhidan, Feng Hong, Zhang Shuzhi, et al. Effect of C addition on microstructure and mechanical properties of near beta titanium alloy[J]. Titanium Industry Progress, 2019,36(5):21. (吕智丹, 冯弘, 张树志, 等. C元素添加对近β钛合金显微组织及力学性能的影响[J]. 钛工业进展, 2019,36(5):21. [12] He Yafeng, Lu Wenzhuang, Yu Weimin. Electrochemical corrosion behaviors of titanium alloy in different solutions[J]. Journal of South China University of Technology (Natural Science Edition), 2017,45(6):126. (何亚峰, 卢文壮, 于为民. 钛合金在不同溶液中的电化学腐蚀行为[J]. 华南理工大学学报(自然科学版), 2017,45(6):126. [13] (崔昌兴. 硫酸体系钛阳极氧化特性及影响因素研究[D]. 昆明: 昆明理工大学, 2017.)Cui Changxing. Study on the anodizing characteristics and influencing factors of titanium in sulfuric acid system[D]. Kunming: Kunming University of Science and Technology, 2017. [14] Dupuis Jennifer, Chenon M, Faure S, et al. Mechanical properties and corrosion resistance of some titanium alloys in marine environment[C]//EDP Sciences, 2013: 01009. [15] Cui Qiang, Yi Danqing, Wang Hongxuan, et al. Effects of grain size and secondary phase on corrosion behavior and electrochemical performance of Mg-3Al-5Pb-1Ga-Y sacrificial anode[J]. Journal of Rare Earths, 2019,37:1341−1350. doi: 10.1016/j.jre.2018.11.012 [16] Xia L D, Ji Y Z, Liu W B, et al. Radiation induced grain boundary segregation in ferritic/martensitic steels[J]. Nuclear Engineering and Technology, 2020,52(1):148−154. doi: 10.1016/j.net.2019.07.009 期刊类型引用(3)

1. 戴全春,王楠,戴国庆. 典型元素微合金化对钛合金组织与性能影响研究进展. 钛工业进展. 2024(06): 39-49 .  百度学术

百度学术2. 荣宇航,朱杰,吴金平,谢龙飞,李兰云. Ti-3Ta-xNb合金在沸腾硝酸中的电化学腐蚀研究. 钛工业进展. 2023(02): 25-29 .  百度学术

百度学术3. 何苗霞,燕迟,黄帅,王楚,董月成,李峰,常辉. 油气钻采用低成本近α钛合金力学与腐蚀性能研究. 石油管材与仪器. 2023(04): 32-36+42 .  百度学术

百度学术其他类型引用(1)

-

下载:

下载:

下载:

下载:

百度学术

百度学术