Effects of EMS on the dendritic structure and homogeneity of rail steel

-

摘要: 为提升重轨钢均质性和致密性,通过试验对比分析连铸电磁搅拌对大方坯重轨钢凝固组织及均质性的影响。结果表明:无电磁搅拌工艺条件下,铸坯凝固组织无明显分区,枝晶组织致密且铸坯窄面至距离窄面80 mm区域的均质性较好,但铸坯中心偏析严重;通过取消结晶器电磁搅拌(M-EMS)并采用凝固末端电磁搅拌(F-EMS)有利于重轨钢均质性和致密性协同提升,试验铸坯中心偏析可以得到补充控制,铸坯轧制钢轨的中心偏析控制良好,轨头Mn元素偏析度极差达到0.098,致密度达到0.9764。Abstract: In order to optimize the homogeneity and compactness of rail steel, the effects of continuous casting electromagnetic stirring on the dendritic structure and homogeneity of rail steel was analyzed by industrial experiments. The results show that blooms produced without electromagnetic stirring have no obvious dendritic structure partition, the dendritic structure tends to be more compact and the homogeneity is better for the area in which from narrow surface to 80 mm below, while central segregation tends to be worse. The F-EMS is more suitable both for optimizing homogeneity and compactness than M-EMS. Central segregation control of experiment blooms could be make up, Central segregation of rails rolled from the experiment blooms is well, and the same as rail head, range value of segregation degree for Mn is 0.098, value of compactness degree is 0.9764.

-

Key words:

- continuous casting /

- rail steel /

- electromagnetic stirring /

- dendritic structure /

- homogeneity /

- compactness

-

0. 引言

钢轨服役环境随着铁路运输的不断发展变得多样且复杂,其性能要求不断提高[1,2]。一般而言,铸坯内部的宏观偏析及微观偏析均会对铸件、轧材产品的性能产生不利影响[3-7],尤其使产品的韧性、塑性和抗腐蚀性能下降。研究表明,高碳钢铸坯中心的C、Mn元素偏析会导致碳化物和马氏体沉淀;中心偏析会引起钢轨呈“S”型断裂;Mn、S元素的偏析聚集会促进MnS非金属夹杂的析出。因此,减轻铸坯偏析对轧材质量的提升具有重要意义。铸坯偏析与凝固演变关系密切,尤其晶间偏析与凝固组织的枝晶臂间距有重要联系,大量研究及实践结果表明,连铸电磁搅拌是铸坯偏析及凝固组织控制的重要技术手段[8-13]。笔者基于国内某厂连铸机的装备条件,试验研究连铸电磁搅拌对大方坯重轨钢凝固组织及均质性的影响,在此基础上探讨性提出新的连铸电磁搅拌工艺技术思路,并进一步开展对比试验进行验证。

1. 结晶器电磁搅拌工艺初步试验

1.1 试验工艺

为探讨结晶器电磁搅拌强度对重轨钢凝固组织及均质性的影响,开展了结晶器电磁搅拌工艺对比试验,试验工艺分为:强搅拌、弱搅拌及无搅拌。各工艺的实际磁场强度(最强位置点)测定结果如表1所示。

表 1 不同试验工艺对应的实际磁场强度Table 1. Actual magnetic flux density corresponding to the testing processesT 试验工艺 实际磁场强度×10−4 强搅拌 350~400 弱搅拌 200~250 无搅拌 0 1.2 试验结果

1)结晶器电磁搅拌强度对铸坯凝固组织的影响

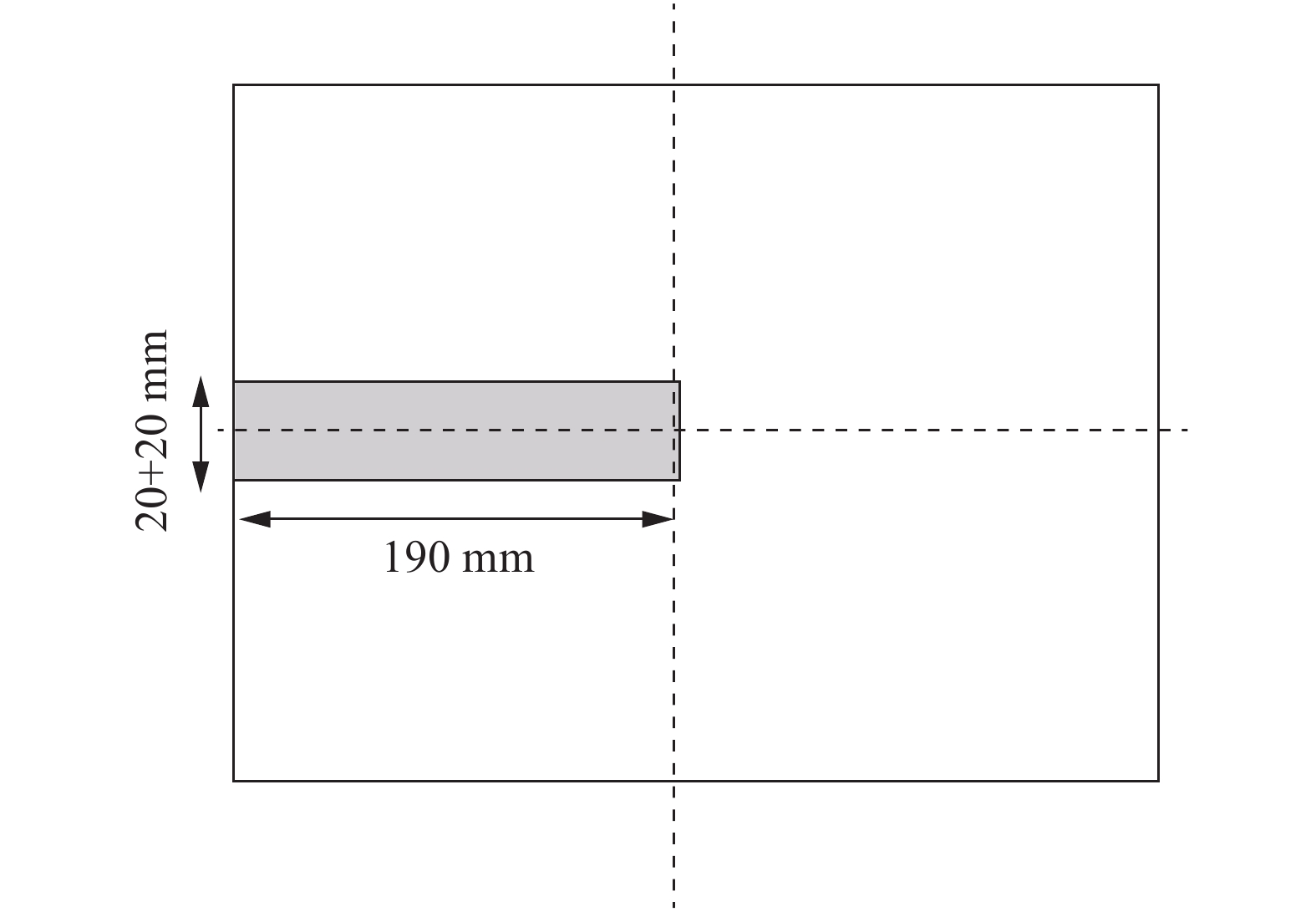

按图1所示位置进行代表区域取样,对试样进行凝固组织腐蚀检验。

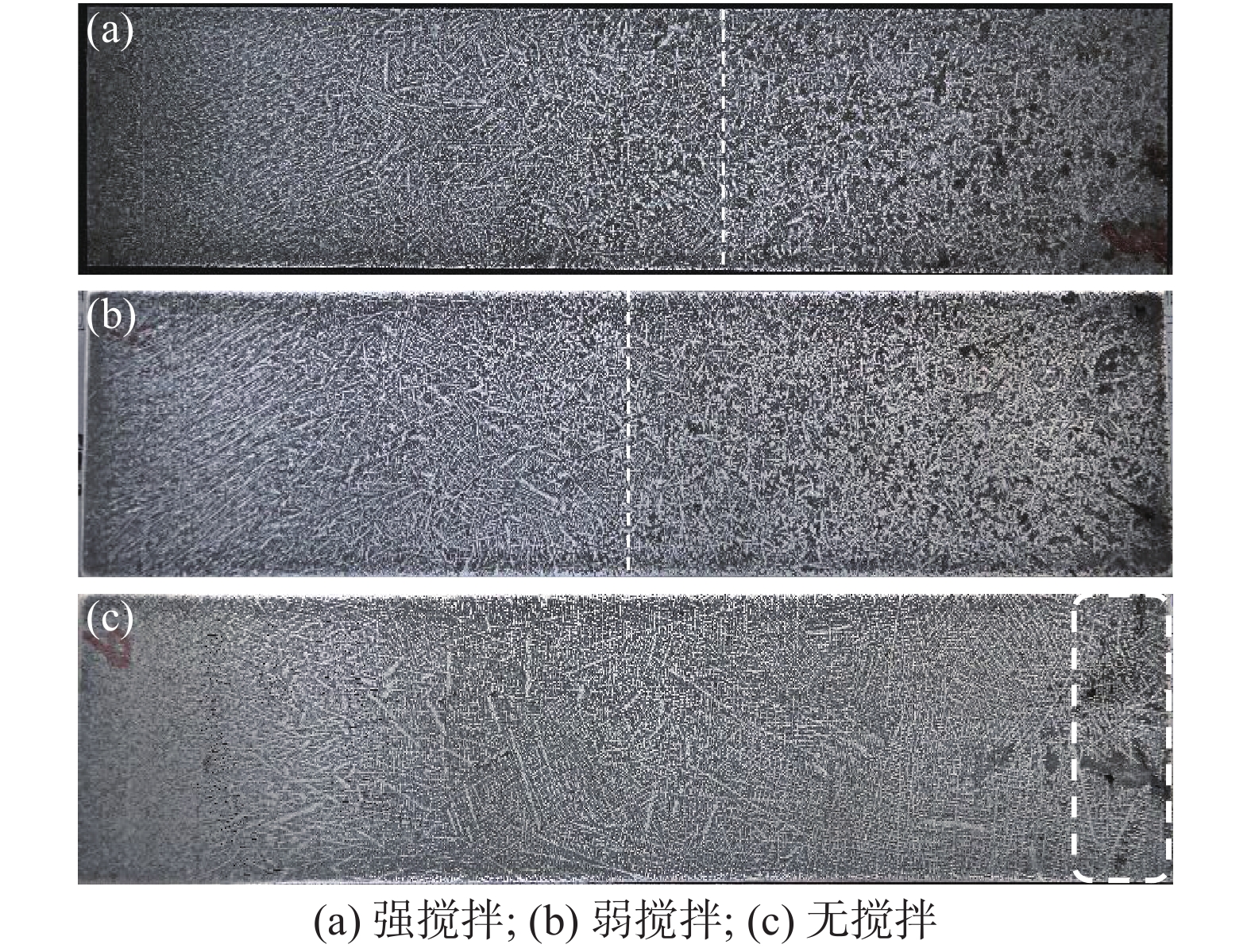

不同搅拌强度工艺试验铸坯代表区域典型凝固组织照片如图2所示。由图2可以看出,随着搅拌强度增强,铸坯等轴晶区面积增加,中心偏析趋于弥散化,无搅拌时铸坯柱状晶发达,晶干轮廓清晰,晶干细且致密,但铸坯中心存在聚集偏析。

2)结晶器电磁搅拌强度对均质性的影响

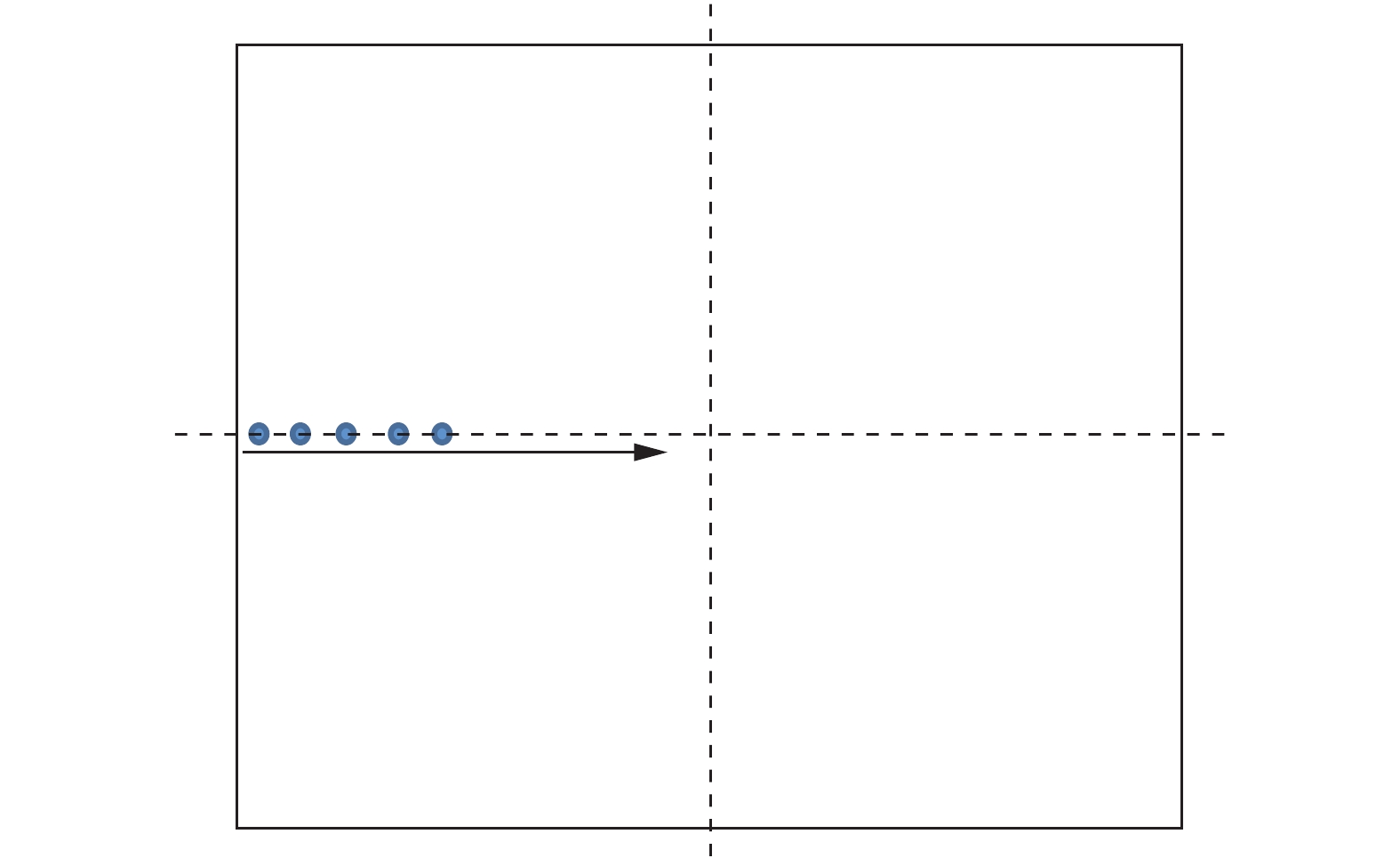

对试验铸坯按图3所示,取样尺寸为Φ5 mm。

试验铸坯横断面C元素偏析度演变分布如图4所示。由图4可知,随着搅拌强度减弱,结晶器电磁搅拌直接作用带(距离窄面20 mm区域)与作用延续区(距离窄面50~80 mm)的负正偏析交替趋于平缓,区域均质性改善,但铸坯中心偏析趋于严重。

由上述结果可知,结晶器电磁搅拌强度提升可以有效提高铸坯等轴晶比例,强搅拌条件下重轨钢铸坯柱状晶尖端截止于距离窄面约45 mm处,等轴晶比例极高;此外,结晶器电磁搅拌强度提升可有效降低中心偏析度,无电磁搅拌工艺条件下,铸坯中心偏析严重。

对于重轨钢而言,轨头区域的均质性对其实用性能影响巨大。铸坯等轴晶较为发达则轧制成钢轨后等轴晶区将延伸至轨头中下部。过于发达的等轴晶由于晶粒长大充分,晶内溶质元素原子扩散充分并在晶间发生聚集,最终呈严重的晶间偏析,尺度为半宏观尺度,这样的偏析常因化学检验取样尺度偏大而与晶干发生中和,最终导致无法通过检验结果直观显现而被忽略。但严重的中心偏析同样影响钢轨质量,铸坯表现为中心偏析线超标,焊接组织异常等问题。

1.3 改进思路

由上述分析可知,全面提升重轨钢均质性需要由单一的中心偏析控制向铸坯中心区域均质性控制转变。结晶器电磁搅拌不宜于重轨钢均质性的全面提升控制,主要由于结晶器电磁搅拌一方面造成轨头中上部区域显著的负正偏析交替,局部均质性恶化;其次,搅拌促使中心区域钢液过早产生晶核,局部凝固时间延长,晶间偏析加剧。因此,提出“取消结晶器电磁搅拌的基础上采用凝固末端电磁搅拌”的工艺制度,以实现重轨均质性协同提升控制。

2. 电磁搅拌工艺验证试验

连铸电磁搅拌工艺验证的试验方案设计如表2所示,工艺1为目标工艺试验组,即无结晶器电磁搅拌(M-EMS)而采用凝固末端电磁搅拌(F-EMS);工艺2与工艺3作为对比工艺,其中工艺2为单一结晶器电磁搅拌,工艺3为结晶器电磁搅拌与凝固末端电磁搅拌组合工艺。

2.1 铸坯凝固组织控制对比

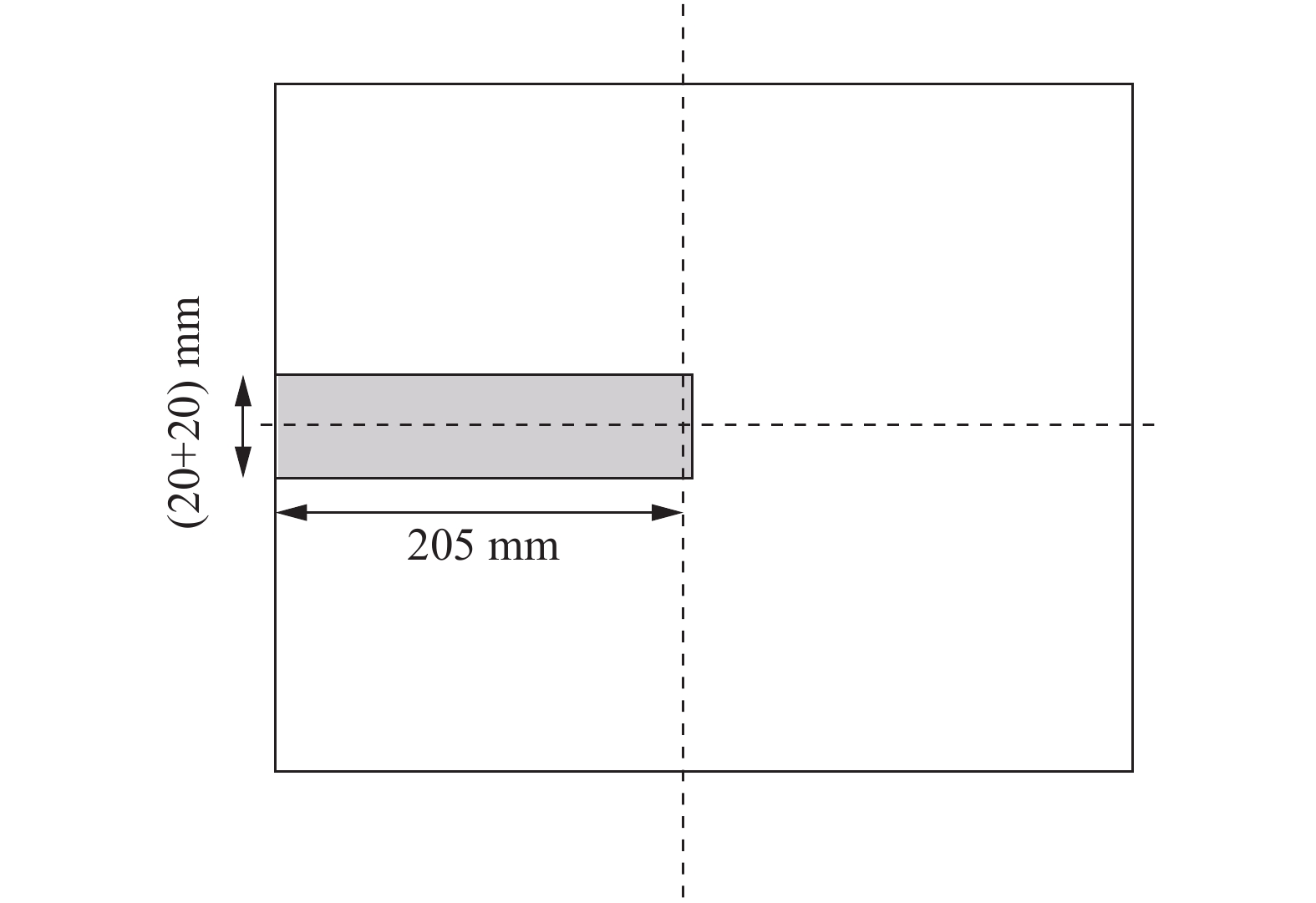

对试验铸坯按图5所示位置进行代表区域凝固组织检验对比。

表 2 连铸电磁搅拌工艺验证试验方案Table 2. Test program of processes verification for continuous casting electro-magnetic stirring试验工艺 结晶器电磁搅拌

(M-EMS)凝固末端电磁搅拌

(F-EMS)工艺1 无 有 工艺2 有 无 工艺3 有 有 不同连铸电磁搅拌试验铸坯代表区域凝固组织检验实物照片如图6所示。由图6可知,工艺2试验铸坯柱状晶截止于距窄面45 mm处,等轴晶区位于距窄面(上侧)105 mm至中心的区域,而距窄面45~105 mm区域为混晶(晶粒晶干细,晶干组织清晰且致密)区,等轴晶区可见较大尺寸晶间偏析;铸坯凝固组织与图2中结晶器电磁搅拌强搅拌工艺试验铸坯相似,即存在明显的等轴晶(晶粒短但粗,晶干不清晰)特征区。

与工艺2相比,工艺1试验铸坯凝固组织分区不明显,即凝固组织过渡平缓无明显等轴晶特征的凝固组织,凝固组织晶干清晰,细而致密,无类似等轴晶区的明显的弥散偏析;工艺3与工艺2的试验铸坯凝固组织无明显区别,但工艺3试验铸坯等轴晶区的弥散偏析略显轻微。

2.2 铸坯均质性对比

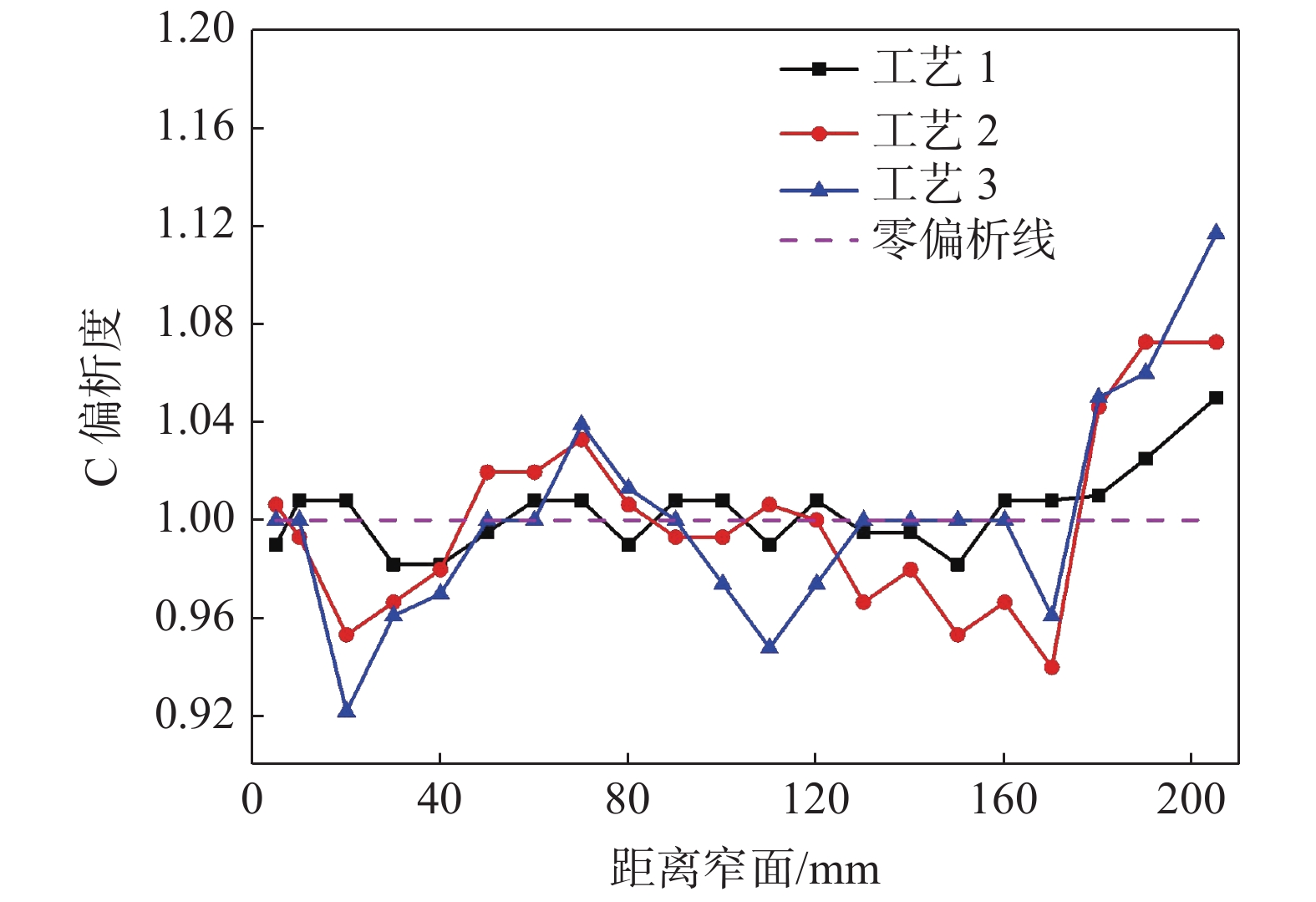

对试验铸坯采用Φ5 mm钻头按图3所示取样并进行横断面均质性对比,结果如图7所示。由图7可知,与工艺1相比,工艺3试验铸坯在距离铸坯表面20 mm处出现C元素偏析度波谷,负偏析严重,后续区域逐渐过渡到正偏析,在距窄面70 mm到达峰值,随着位置向中心推移,偏析度逐渐向负偏析过渡,在110 mm处达到第二个波谷,随后向正偏析演变,铸坯全断面C元素偏析度正负偏析交替明显。而工艺1试验铸坯的横断面C元素偏析度基本在零偏析线附近小幅波动,即均质性较好。工艺2与工艺3的C元素偏析度曲线对比可知,工艺2试验铸坯在距窄面130~170 mm区域负偏析比工艺3更严重,即凝固末端电磁搅拌对铸坯中心区域均质性的改善有利。

2.3 钢轨金属原位检验

对试验铸坯轧制钢轨轨头区域进行金属原位扫描统计,实物检验区域如图8所示。

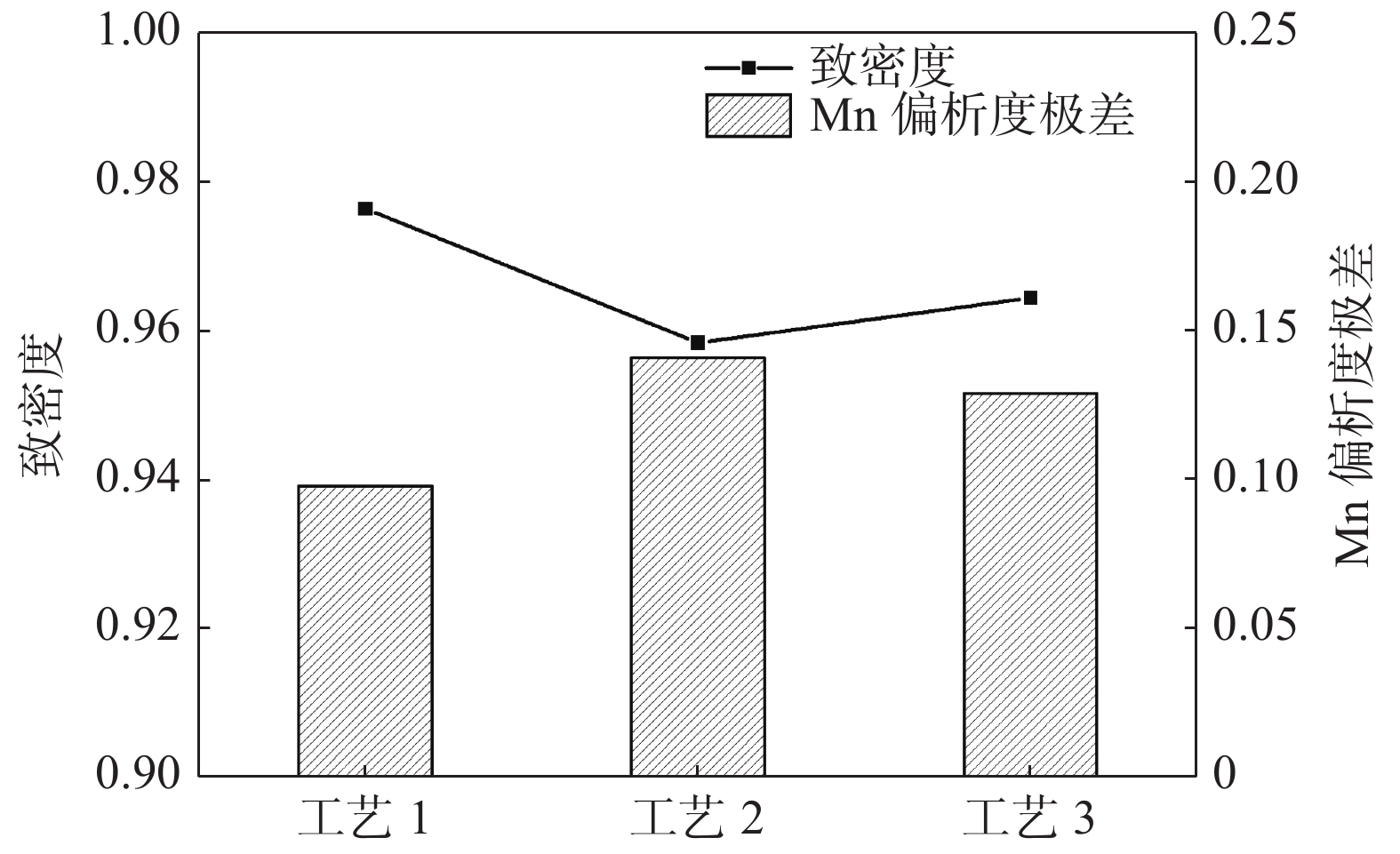

试验铸坯轧制钢轨轨头金属原位扫描检验结果统计对比如图9所示。由图9可知,工艺1试验铸坯轧制钢轨轨头区域致密度最高,Mn元素偏析度极差最低,即该工艺生产的铸坯轧制钢轨轨头致密性与均质性控制最优。工艺2与工艺3试验铸坯轧制钢轨轨头区域的致密度则无明显差异,工艺3试验铸坯轧制钢轨轨头均质性略好,结果与铸坯检验结果吻合,即凝固末端电磁搅拌对中心(弥散)偏析有改善作用。

2.4 目标工艺和无电磁搅拌工艺的钢轨腐蚀对比

酸洗腐蚀低倍对比检验图2中无搅拌工艺及目标工艺试验铸坯轧制的钢轨,结果如图10所示。

由图10可以看出,二者存在共同点,即无结晶器电磁搅拌时,凝固组织分区不明显,柱状晶发达且无显著等轴晶,晶粒组织晶干清晰,细而致密;二者差别在于目标工艺试验铸坯在取消结晶器电磁搅拌后通过凝固末端电磁搅拌弥补了中心偏析控制不利的短板。

3. 结论

1)结晶器电磁搅拌提高等轴晶率并不能切实提升大方坯重轨钢均质性,反而降低心部钢液的局部凝固速度,加剧弥散偏析。

2)取消结晶器电磁搅拌后,铸坯柱状晶发达,中心区域无典型等轴晶特征凝固组织,凝固组织晶干更清晰且细而致密,但铸坯中心点偏析严重,轧制后钢轨轨腰中心偏析线连续且较长。

3)凝固末端电磁搅拌可弥补取消结晶器电磁搅拌后铸坯中心偏析严重的短板,对大方坯重轨钢铸坯均质且致密控制有利。

-

表 1 不同试验工艺对应的实际磁场强度

Table 1. Actual magnetic flux density corresponding to the testing processes

T 试验工艺 实际磁场强度×10−4 强搅拌 350~400 弱搅拌 200~250 无搅拌 0 表 2 连铸电磁搅拌工艺验证试验方案

Table 2. Test program of processes verification for continuous casting electro-magnetic stirring

试验工艺 结晶器电磁搅拌

(M-EMS)凝固末端电磁搅拌

(F-EMS)工艺1 无 有 工艺2 有 无 工艺3 有 有 -

[1] Guo Xiaoyang. Research on the development trend of railway transportation in China[J]. Co-operative Economy & Science, 2012,(2):10−12. (郭晓阳. 我国铁路运输发展趋势研究[J]. 合作经济与科技, 2012,(2):10−12. doi: 10.3969/j.issn.1672-190X.2012.02.005 [2] (李春龙. 包钢高速铁路重轨钢生产工艺及质量水平[C]// 2008年全国炼钢——连铸生产技术会议文集.中国金属学会, 2008: 12.)Li Chunlong. Production technology and quality level of heavy rail steel for high-speed railway of Baotou steel[C]// Proceedings of Steel Making and Continuous Casting Technology Conference. Chinese Society for Metals, 2008: 12. [3] Li Pin, Wang Lei, Zhou Qingfeng. Formation reasons and countermeasures of cementite network in the center of 82B wire rods[J]. Journal of Iron and Steel Research, 2014,26(9):33−36. (李平, 王雷, 周青峰. 82B中心网状渗碳体产生原因及改善方法[J]. 钢铁研究学报, 2014,26(9):33−36. [4] (纪元. 连铸还偏析及其铸轧遗传性研究[D]. 北京: 北京科技大学, 2018.)Ji Yuan. Segregation of billet castings and its heredity effect on the hot-rolled products[D]. Beijing:University of Science and Technology Beijing, 2018. [5] Zong Nanfu, Zhang Hui, Liu Yang, et al. Causes and harms of defects in solidification structure and segregation of continuous casting bearing steel[J]. Bearing, 2018,(6):62−67. (宗男夫, 张慧, 刘洋, 等. 连铸轴承钢偏析和凝固组织缺陷的成因及其危害[J]. 轴承, 2018,(6):62−67. [6] Song Yancheng, Liu Jigang. Analyze of the effects of segregation on the performance of billets[J]. Modern Metallurgy, 2019,47(2):7−10. (宋延成, 刘吉刚. 偏析对于连铸坯性能的影响分析[J]. 现代冶金, 2019,47(2):7−10. [7] Chen Yuhui, Song Yancheng. Analyze of the effects of segregation on the mechanical capacity of slab[J]. Modern Metallurgy, 2018,46(5):13−15. (陈玉辉, 宋延成. 连铸坯偏析对钢板机械性能的影响分析[J]. 现代冶金, 2018,46(5):13−15. doi: 10.3969/j.issn.1005-6068.2018.05.004 [8] (廖建国. 热溶质对流对连铸坯宏观偏析影响分析[N]. 世界金属导报, 2019-03-12(B02).)Liao Jianguo. Analyze of the effects of hot solute convection on the macro-segregation of bloom[N]. World metal guide report, 2019-03-12(B02). [9] Chen Liang. Study on macro-segregation control of continuous casting billet in gear steel 20CrMnTiH[J]. Iron Steel Vanadium Titanium, 2019,40(4):110−115. (陈亮. 小方坯连铸20CrMnTiH齿轮钢宏观偏析控制[J]. 钢铁钒钛, 2019,40(4):110−115. [10] Wang Baofeng, Li Jianchao. Application of electromagnetic stirring technology in continuous casting[J]. Angang Technology, 2009,(1):1−5. (王宝峰, 李建超. 电磁搅拌技术在连铸生产中的应用[J]. 鞍钢技术, 2009,(1):1−5. doi: 10.3969/j.issn.1006-4613.2009.01.001 [11] Limoges J, Beitelman L, Bai Jing. The effect of secondary cooling intensity and mole electromagnetic stirring carbon segregation and solidification structure of high carbon steel[J]. Tianjin Metallurgy, 2002,(4):40−45. (J·里摩吉斯, L·贝特尔曼, 白静. 二次冷却和结晶器电磁搅拌对高碳钢碳偏析及其凝固结构的影响[J]. 天津冶金, 2002,(4):40−45. doi: 10.3969/j.issn.1006-110X.2002.04.014 [12] Xu Ruijun, Yan Huicheng, Wu Qinming, et al. Effect of M-EMS on carbon segregation of gear steel round bar rolled from rectangular bloom[J]. Iron Steel Vanadium Titanium, 2012,33(02):56−61. (徐瑞军, 颜慧成, 吴清明, 等. 结晶器电磁搅拌对矩形坯轧制大规格齿轮钢圆钢碳偏析行为的影响[J]. 钢铁钒钛, 2012,33(02):56−61. [13] Cao Hongfu. Effect of multiple electro-magnetic stirring on carbon segregation in continuous casting low carbon steel[J]. Special steel, 2010,31(2):38−39. (曹红福. 连铸复合电磁搅拌对低碳钢碳偏析的影响[J]. 特殊钢, 2010,31(2):38−39. doi: 10.3969/j.issn.1003-8620.2010.02.012 期刊类型引用(4)

1. 陈亮,汤群伟,王璞,陈刚,扈凯,李伟涛,张家泉. M-EMS对45钢矩形坯铸态组织和溶质分布均匀性的影响. 连铸. 2024(02): 45-49 .  百度学术

百度学术2. 年义,李家乐,张立强. 连铸智能化发展现状与展望. 连铸. 2024(03): 2-11 .  百度学术

百度学术3. 任春节,冷永磊,尹修刚,任立坤,邢伟,张英男,刘福斌,姜周华. ?800 mm大断面连铸圆坯凝固传热和凝固组织模拟. 连铸. 2024(06): 21-30 .  百度学术

百度学术4. 李向川,杨吉春,白国君,樊志明. 稀土元素对重轨钢的影响及改善工艺探究. 中国铸造装备与技术. 2021(06): 80-84 .  百度学术

百度学术其他类型引用(2)

-

下载:

下载:

下载:

下载:

百度学术

百度学术