Experimental study on flotation of titanium concentrate from ultrafine iron tailings of a concentration plant

-

摘要: 某厂选钛车间回收工艺为强磁-重选(螺旋)工艺,由于螺旋选矿机对钛铁矿回收粒级的限制,现重选工艺流程对粗粒级钛铁矿回收较好,对细粒级钛铁矿及钛铁矿连生体回收较差,其钛回收率较低,选铁尾矿中钛回收率仅25.3%。为了有效回收钛资源,进行了强磁和浮选条件试验。结果表明,试样经过进一步细磨,再经弱磁除铁后,得到−200目(74 μm)占84%左右的超细粒级选钛试验原料,再采用“两段强磁+浮选”联合流程,最终可获得钛精矿TiO2品位为46.86%、流程精矿总产率为5.93%、流程精矿TiO2总回收率为25.84%的较好指标。Abstract: The titanium recovery process of an investigated plant is high-intensity magnetic gravity separation (spiral). Due to the limitation of the spiral concentrator on the particle size of ilmenite, the recovery of coarse ilmenite is better, and the recovery of fine ilmenite and ilmenite intergrowth is poor. The recovery of titanium in iron tailings is only 25.3%. In order to recover titanium resources effectively, experiments of high-intensity magnetic and flotation conditions were carried out. The results show that after further fine grinding and iron removal by weak magnetic field, the −200 mesh (74 µm) test sample (about 84% in proportion) of ultrafine grade titanium separation raw material was obtained, after the combined process of “two-stage strong magnetic + flotation”, the finally obtained titanium concentrate TiO2 grade is 46.86%, the total yield of process concentrate is 5.93%, and the total recovery of process concentrate TiO2 is 25.84%.

-

Key words:

- ilmenite /

- magnetic separation /

- fine grinding /

- flotation

-

表 1 样品化学多元素分析结果

Table 1. Results of chemical multielement analysis of samples

% TFe TiO2 S P MnO 14.50 10.75 0.124 0.053 0.310 CaO MgO SiO2 Al2O3 Cr2O3 12.33 13.31 35.50 5.14 0.015 表 2 粗精矿试样全粒级筛析结果

Table 2. Results of full size sieving analysis of coarse concentrate sample

粒级/目(mm) 产率/% TiO2品位/% TiO2分布率/% +40 (+0.45) 0.61 4.14 0.24 +60 (+0.28) 6.38 4.92 2.96 +80 (+0.20) 14.17 6.91 9.22 +100 (+0.154) 11.74 9.65 10.67 +120 (+0.125) 17.41 10.00 16.40 +160 (+0.098) 9.72 10.93 10.00 +200 (+0.074) 7.49 9.46 6.67 +320 (+0.045) 19.13 11.38 20.51 +400 (+0.038) 2.02 18.59 3.55 −400 (−0.038) 11.34 18.52 19.78 合计 100.00 10.62 100.00 表 3 样品试样矿物含量及单体解离度测定结果

Table 3. Determination results of mineral content and monomer dissociation degree of samples

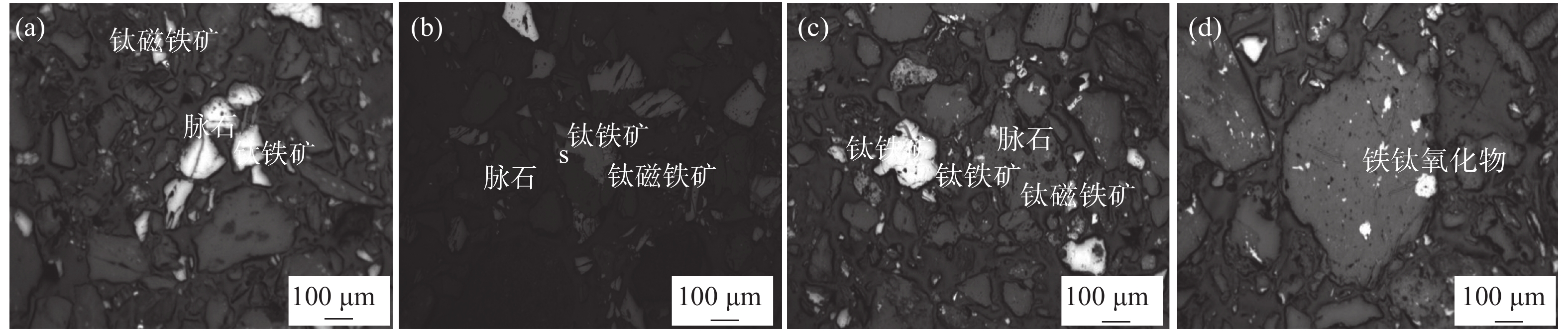

质量分数/% 单体解离度/% 钛磁铁矿 钛铁矿 硫化物 脉石 钛磁铁矿 钛铁矿 硫化物 脉石 10.23 17.95 0.61 71.21 66.52 84.18 70.36 88.72 表 4 粗精矿试样直接强磁精选试验结果

Table 4. Test results of direct high-intensity magnetic separation of coarse concentrate samples

产品 产率/% TiO2品位/% TiO2回收率/% 精矿 66.91 12.55 78.11 尾矿 33.09 7.11 21.89 给矿 100.00 10.75 100.00 表 5 强磁选磁场强度条件试验结果

Table 5. Test results of high-intensity magnetic separation

磁场强度/T 产品 产率/% TiO2品位/% TiO2回收率/% 0.437 精矿 38.65 15.67 60.50 尾矿 61.36 6.44 39.50 给矿 100.00 10.01 100.00 0.533 精矿 39.89 15.47 61.65 尾矿 60.11 6.39 38.35 给矿 100.00 10.01 100.00 0.628 精矿 44.43 14.58 64.71 尾矿 55.57 6.36 35.29 给矿 100.00 10.01 100.00 0.713 精矿 47.98 14.21 68.11 尾矿 52.02 6.14 31.89 给矿 100.00 10.01 100.00 0.852 精矿 49.60 14.18 70.26 尾矿 50.41 5.91 29.74 给矿 100.00 10.01 100.00 表 6 冲程条件试验结果

Table 6. Test results under stroke conditions

冲程/mm 产品 产率/% TiO2品位/% TiO2回收率/% 35 精矿 46.88 14.57 68.23 尾矿 53.13 5.99 31.77 除铁尾 100.00 10.01 100.00 40 精矿 39.89 15.47 61.65 尾矿 60.11 6.39 38.35 除铁尾 100.00 10.01 100.00 45 精矿 35.59 16.10 57.24 尾矿 64.41 6.64 42.76 除铁尾 100.00 10.01 100.00 50 精矿 43.94 14.84 65.13 尾矿 56.07 6.22 34.87 除铁尾 100.00 10.01 100.00 表 7 转环转速条件试验结果

Table 7. Test results under different rotating ring speed

转环转速/(r·min−1) 产品 产率/% TiO2品位/% TiO2回收率/% 2.5 精矿 30.71 17.32 53.13 尾矿 69.30 6.77 46.87 除铁尾 100.00 10.01 100.00 3.0 精矿 34.58 16.37 56.55 尾矿 65.42 6.65 43.45 除铁尾 100.00 10.01 100.00 3.5 精矿 40.09 15.06 60.32 尾矿 59.91 6.63 39.68 除铁尾 100.00 10.01 100.00 4.0 精矿 41.49 14.78 61.25 尾矿 58.52 6.63 38.75 除铁尾 100.00 10.01 100.00 表 8 二段强磁生产试验结果

Table 8. Production results under two-section high-intensity magnetic field

产品 产率/% TiO2品位/% TiO2回收率/% 给矿 100.00 9.98 100.00 二段强精 33.78 16.97 57.43 表 9 三段强磁精选磁场强度条件试验结果

Table 9. Test results under three-section high-intensity magnetic separation

磁场强度/T 产品 产率/% TiO2品位/% TiO2回收率/% 0.533 精矿 76.04 18.65 88.46 0.713 精矿 77.86 18.46 89.66 0.852 精矿 88.94 17.12 94.99 表 10 硫酸用量条件试验结果

Table 10. Effect of sulfuric acid dosage on production

硫酸用量/(g·t−1) 产品 产率/% TiO2品位/% TiO2回收率/% 600 S精 6.18 16.58 5.44 钛粗精 47.47 30.68 77.21 浮尾 46.35 7.06 17.35 给矿 100.00 18.86 100.00 700 S精 5.43 16.38 4.84 钛粗精 39.50 34.38 73.86 浮尾 55.07 7.11 21.30 给矿 100.00 18.39 100.00 800 S精 6.67 16.84 5.95 钛粗精 35.13 38.66 71.92 浮尾 58.21 7.18 22.13 给矿 100.00 18.88 100.00 900 S精 6.85 17.59 6.50 钛粗精 31.13 40.42 67.92 浮尾 62.02 7.64 25.58 给矿 100.00 18.53 100.00 1000 S精 5.03 16.37 4.39 钛粗精 28.32 42.44 64.06 浮尾 66.66 8.88 31.55 给矿 100.00 18.76 100.00 表 11 柴油用量条件试验结果

Table 11. Effect of diesel consumption on production

柴油用量/(g·t−1) 产品 产率/% TiO2品位/% TiO2回收率/% 0 S精 6.67 16.84 5.95 钛粗精 35.13 38.66 71.92 浮尾 58.21 7.18 22.13 给矿 100.00 18.88 100.00 560 S精 5.63 16.32 4.88 钛粗精 38.02 37.68 76.04 浮尾 56.35 6.38 19.08 给矿 100.00 18.84 100.00 700 S精 5.68 16.37 4.90 钛粗精 40.23 37.34 79.19 浮尾 54.09 5.58 15.91 给矿 100.00 18.97 100.00 980 S精 5.93 16.67 5.23 钛粗精 44.88 34.26 81.43 浮尾 49.19 5.12 13.34 给矿 100.00 18.88 100.00 表 13 浮选闭路试验结果

Table 13. Closed-circuit flotation test results

编号 产品 产率/% TiO2品位/% TiO2回收率/% 1 浮选给矿 100.00 18.68 100.00 2 S精 6.05 16.67 5.40 3 脱硫尾矿 93.95 18.81 94.60 4 扫选给矿 78.72 11.32 47.70 5 扫选精矿 5.61 17.96 5.40 6 扫选尾矿 73.10 10.81 42.30 7 粗选给矿 119.75 20.38 130.64 8 粗选精矿 41.03 37.76 82.94 9 精1给矿 53.46 37.98 108.70 10 精1精矿 33.27 43.82 78.05 11 中1 20.18 28.36 30.64 12 精2给矿 34.39 43.71 80.46 13 精2精矿 21.96 46.53 54.70 14 中2 12.43 38.72 25.76 15 钛精矿 20.85 46.86 52.30 16 中3 1.11 40.35 2.40 表 12 捕收剂用量条件试验结果

Table 12. Effect of collector dosage on production

捕收剂用量/(g·t−1) 产品 产率/% TiO2品位/% TiO2回收率/% 2200 S精 5.82 16.12 5.07 钛粗精 32.93 39.87 71.03 浮尾 61.25 7.21 23.89 给矿 100.00 18.48 100.00 2600 S精 5.93 16.23 5.17 钛粗精 36.36 38.67 75.52 浮尾 57.71 6.23 19.31 给矿 100.00 18.62 100.00 3000 S精 5.71 16.37 5.01 钛粗精 39.50 37.14 78.60 浮尾 54.79 5.58 16.38 给矿 100.00 18.66 100.00 3400 S精 6.23 16.69 5.50 钛粗精 42.06 35.82 79.68 浮尾 51.71 5.42 14.82 给矿 100.00 18.91 100.00 3800 S精 5.65 16.08 4.81 钛粗精 45.54 34.06 82.22 浮尾 48.81 5.01 12.96 给矿 100.00 18.86 100.00 -

[1] Xu Lijun, Li Liang, Chen Liuxian, et al. Comprehensive recycling situation and development direction of vanadium-titanium magnetite in Paxi[J]. Sichuan Nonferrous Metals, 2011,(1):1−5. (徐丽君, 李亮, 陈六限, 等. 攀西地区钒钛磁铁矿综合回收利用现状及发展方向[J]. 四川有色金属, 2011,(1):1−5. doi: 10.3969/j.issn.1006-4079.2011.01.001 -

下载:

下载: