Experimental study on flotation of titanium concentrate from ultrafine iron tailings of a concentration plant

-

摘要: 某厂选钛车间回收工艺为强磁-重选(螺旋)工艺,由于螺旋选矿机对钛铁矿回收粒级的限制,现重选工艺流程对粗粒级钛铁矿回收较好,对细粒级钛铁矿及钛铁矿连生体回收较差,其钛回收率较低,选铁尾矿中钛回收率仅25.3%。为了有效回收钛资源,进行了强磁和浮选条件试验。结果表明,试样经过进一步细磨,再经弱磁除铁后,得到−200目(74 μm)占84%左右的超细粒级选钛试验原料,再采用“两段强磁+浮选”联合流程,最终可获得钛精矿TiO2品位为46.86%、流程精矿总产率为5.93%、流程精矿TiO2总回收率为25.84%的较好指标。Abstract: The titanium recovery process of an investigated plant is high-intensity magnetic gravity separation (spiral). Due to the limitation of the spiral concentrator on the particle size of ilmenite, the recovery of coarse ilmenite is better, and the recovery of fine ilmenite and ilmenite intergrowth is poor. The recovery of titanium in iron tailings is only 25.3%. In order to recover titanium resources effectively, experiments of high-intensity magnetic and flotation conditions were carried out. The results show that after further fine grinding and iron removal by weak magnetic field, the −200 mesh (74 µm) test sample (about 84% in proportion) of ultrafine grade titanium separation raw material was obtained, after the combined process of “two-stage strong magnetic + flotation”, the finally obtained titanium concentrate TiO2 grade is 46.86%, the total yield of process concentrate is 5.93%, and the total recovery of process concentrate TiO2 is 25.84%.

-

Key words:

- ilmenite /

- magnetic separation /

- fine grinding /

- flotation

-

0. 引言

攀西地区钒钛磁铁矿资源,已经探明的储量约100亿t,集中分布在攀枝花、白马、红格、太和四大矿区。钒钛磁铁矿共生有铁、钒、钛三种主要有益元素,伴生的有益元素含量大部分达到了综合利用指标,如何提高有用成分,尤其是钛的回收率,是值得思考的问题[1]。

某厂选钛车间回收工艺为强磁-重选(螺旋)工艺,由于螺旋选矿机对钛铁矿回收粒级的限制,现重选对粗粒级钛铁矿回收较好,对细粒级钛铁矿及钛铁矿连生体回收较差,其钛回收率较低,仅25.3%。

超细粒级钛铁矿的回收技术,特别是对矿物组分复杂,品位较低(TiO2<10%)的原生钛铁矿−0.045 mm粒级的选别回收一直是难题。由于超细粒级钛铁矿与其主要脉石组分钛辉石在比重、磁性、可浮性等方面差别很小,因此采用单一的重选、磁选、电选和浮选的选别技术难以获得好的效果,必须采用以浮选为主的联合流程才能获得比较好的结果。超细粒级钛铁矿浮选是技术含量高、选别难度大的选矿回收技术。其难度在于:①钛铁矿属氧化矿类型,其可浮性一般,与钛辉石等脉石矿物的可浮性差别不大,而对钛精矿质量要求又很高;②超细粒矿物质量小、比表面大,由此导致浮选矿浆体系的各种化学性质错综复杂,浮选环境恶化,最终导致浮选分离效果差、药剂用量大;③超细粒级钛铁矿原料矿物组成复杂、粒度特性多变。因此对浮选技术,特别是对浮选捕收剂的性能提出了很高要求。

为提高钛资源的综合利用率,针对其矿物特点和通过大量试验数据对比,提出通过对原料再磨矿,从而增加−0.074 mm粒级的矿物含量,达到矿物单体解离,经过弱磁、强磁后再进入浮选机进行浮选的技术方案。重点对某厂选铁尾矿中的超细粒级钛铁矿进行强磁选及浮选试验研究,以验证回收方案,为后续的浮选法回收磁尾中超细粒钛铁矿的生产线建设提供技术支撑。对红格矿区乃至攀西地区超细粒级回收都具有借鉴意义。

1. 矿物成分及研究方法

1.1 试样制备

试验用矿石结构与攀密选钛厂类似,均为橄辉岩难选矿。矿石中钛铁矿被脉石网状、选择性交代现象及钛铁矿边缘石化现象比较严重,对钛精矿的品质、回收指标有较大的影响。钛铁矿中还有绿泥石、白钛石等少量微细粒包裹体,这些包裹体因太细而不能与钛铁矿解离。研究采用浮选法进行选钛。

本次试验采用选铁后尾矿经强磁粗选后的粗精矿300 kg为试验原料,试验前对样品进行充分混匀,再进行相关选钛试验研究。

样品化学多元素分析结果见表1。从表1可以看出:该矿可回收利用的矿物主要为铁和钛,TFe含量14.50%、TiO2含量10.75%;脉石矿物主要以钙、镁、铝和硅的氧化物为主;有害元素硫和磷的含量不高。

表 1 样品化学多元素分析结果Table 1. Results of chemical multielement analysis of samples% TFe TiO2 S P MnO 14.50 10.75 0.124 0.053 0.310 CaO MgO SiO2 Al2O3 Cr2O3 12.33 13.31 35.50 5.14 0.015 经过缩分制备200 g矿样进行全粒级筛析,结果见表2。

表 2 粗精矿试样全粒级筛析结果Table 2. Results of full size sieving analysis of coarse concentrate sample粒级/目(mm) 产率/% TiO2品位/% TiO2分布率/% +40 (+0.45) 0.61 4.14 0.24 +60 (+0.28) 6.38 4.92 2.96 +80 (+0.20) 14.17 6.91 9.22 +100 (+0.154) 11.74 9.65 10.67 +120 (+0.125) 17.41 10.00 16.40 +160 (+0.098) 9.72 10.93 10.00 +200 (+0.074) 7.49 9.46 6.67 +320 (+0.045) 19.13 11.38 20.51 +400 (+0.038) 2.02 18.59 3.55 −400 (−0.038) 11.34 18.52 19.78 合计 100.00 10.62 100.00 从表2可知:该试验矿样−200目(0.074 mm)含量为32.49%,粒度相对较粗,TiO2粒级分布情况:80目(0.20 mm)以上粒级TiO2品位相对较低,均小于7%,且分布较少,为12.42%;80目(0.20 mm)至320目(0.045 mm)粒级TiO2品位相当,为10%左右,TiO2分布率达到64.25%;400目(0.038 mm)及以下粒级TiO2品位达到18%以上,分布率为23.33%。说明要想提高该矿TiO2品位,必须细磨.

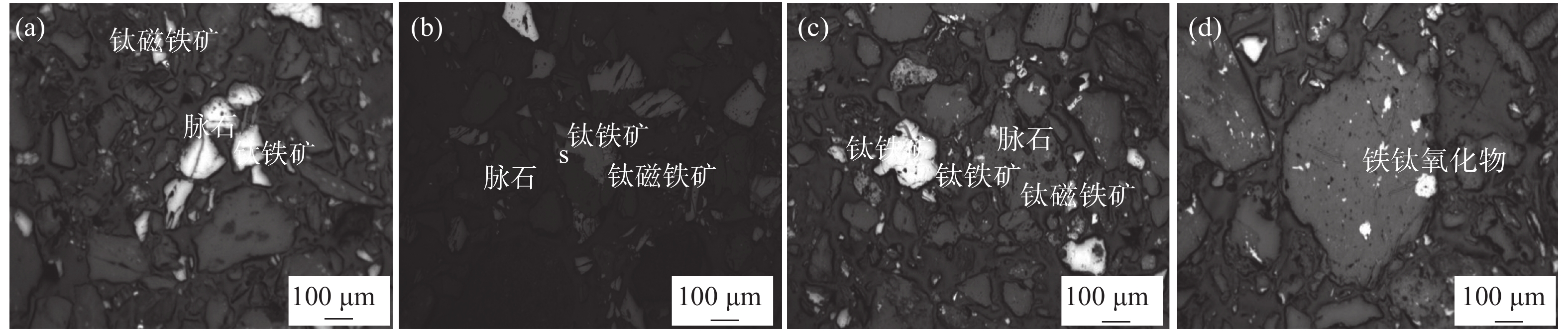

为了解试验矿样的矿物组成及嵌布特征,将该矿制成光片进行镜下鉴定,其矿物含量及单体解离度见表3。

试样中钛铁矿的矿物含量为17.95%,钛铁矿的单体解离度为84.18%。具体如下:

钛磁铁矿:嵌布粒度0.01~0.28 mm;少量的粒状单体钛磁铁矿(见图1a);与钛铁矿、脉石形成三项连生体(见图1b);部分呈小粒状浸染、稀疏浸染嵌布在脉石中(见图1c、图1d)。

表 3 样品试样矿物含量及单体解离度测定结果Table 3. Determination results of mineral content and monomer dissociation degree of samples质量分数/% 单体解离度/% 钛磁铁矿 钛铁矿 硫化物 脉石 钛磁铁矿 钛铁矿 硫化物 脉石 10.23 17.95 0.61 71.21 66.52 84.18 70.36 88.72 钛铁矿:以粒状为主,嵌布粒度0.01~0.30 mm;部分钛铁矿被脉石网状交代。

脉石:以粒状为主,嵌布粒度0.01~0.67 mm;与其他工艺矿物都有连生。

1.2 试验设备

所用试验设备主要有:江西恒诚选矿设备有限公司生产的XPM—Φ120 X3三头研磨机、南昌通用化验制样机厂生产的240X90锥形球磨机型、江西恒诚选矿设备有限公司生产的XCGS—50型磁选管、江西恒诚选矿设备有限公司生产的SCRS型鼓型湿式弱磁选机、吉林省探矿机械厂生产的XFD—1.5L型单槽式浮选机、山东华特磁电科技股份有限公司生产的LHGC—100F型周期式脉动高梯度磁选机、标准套筛等。

1.3 试验方法

本项目技术路线主要是:原料—隔渣—弱磁—浓缩分级—粗粒(重选:螺旋一粗三扫三精磨矿分级)—细粒(强磁一粗一扫一精)—弱磁—浓缩—浮选(一粗二扫四精)—钛精矿。

2. 试验研究

2.1 磨矿细度条件试验

根据原矿镜鉴和全粒级筛析的结果,要想获得较高品位的钛精矿,对粗粒级物料必须进一步细磨。由于后续流程还须进行浮选,矿石过磨后易造成泥化,恶化浮选效果,因此合理的磨矿细度(指−74 μm含量)非常重要。

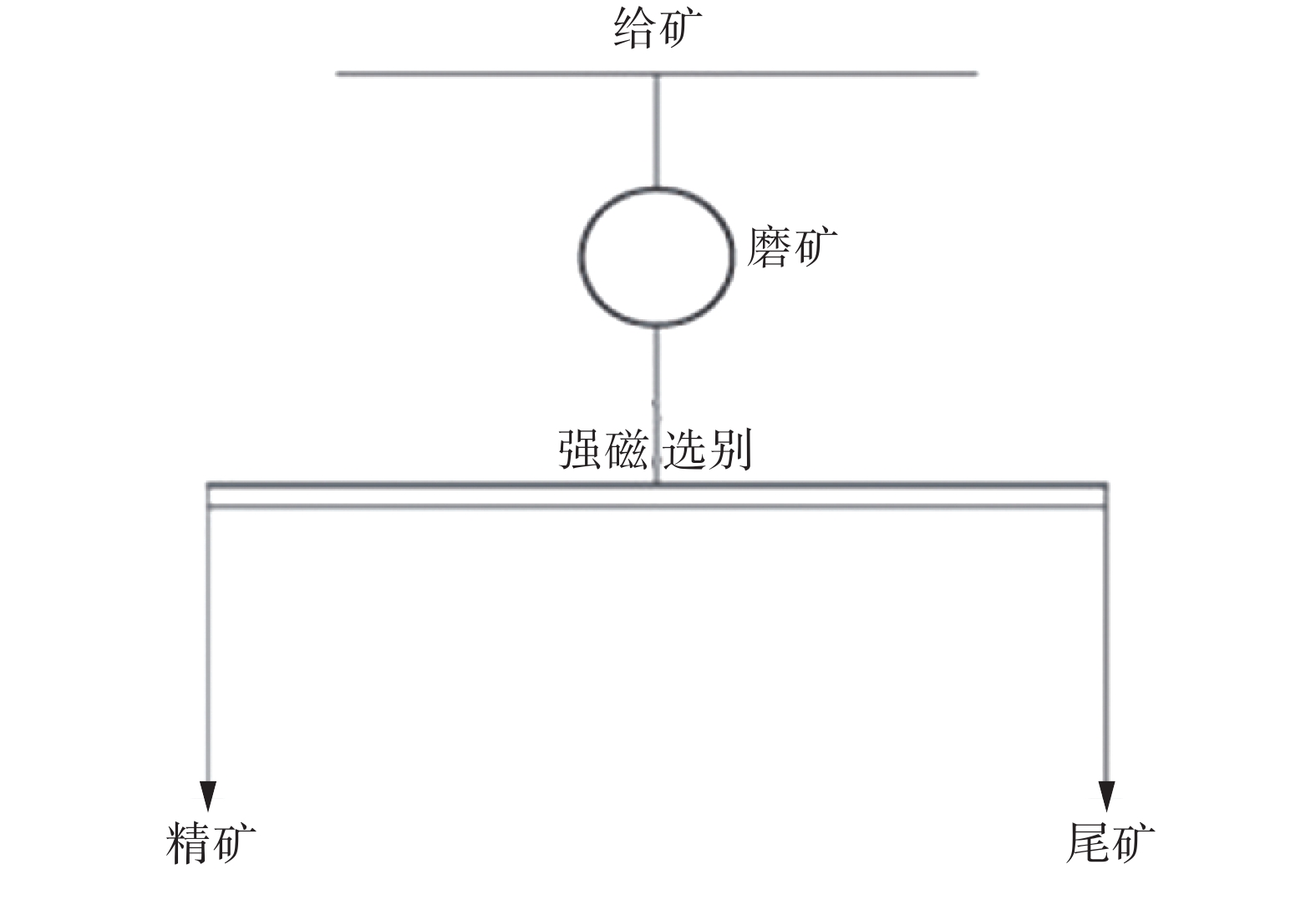

为确定合理的磨矿细度,将试样全磨成不同细度产品,再将各细度样品分别进行强磁选试验。采用SLon-500脉动高梯度磁选机,选择强磁选参数:背景磁场强度0.7 T、脉动冲程35 mm、转环转速3 r/min、冲次300次/min。试验流程如图2所示,磨矿细度与TiO2品位、TiO2回收率的关系如图3所示。

从图3得知:随着磨矿细度的增加,精矿TiO2品位呈上升趋势,回收率则呈下降趋势。综合各项指标,考虑后续浮选的细度要求,确定试样合理的磨矿细度为84%左右。

2.2 强磁精选试验

为探索粗精矿直接强磁精选的选别指标情况,采用SLon-500脉动高梯度磁选机将试样直接进行二段强磁精选选别,强磁选运行参数为:磁场强度0.53 T、冲程35 mm、转环转速3 r/min、冲次300次/min。粗精矿直接强磁精选试验选别结果见表4。

表 4 粗精矿试样直接强磁精选试验结果Table 4. Test results of direct high-intensity magnetic separation of coarse concentrate samples产品 产率/% TiO2品位/% TiO2回收率/% 精矿 66.91 12.55 78.11 尾矿 33.09 7.11 21.89 给矿 100.00 10.75 100.00 从表4结果可知:试样直接二段强磁精选选别,采用较低的0.53 T的磁场强度,精矿中TiO2品位仅提高约2个百分点,且强磁尾矿TiO2品位较高,达到7.11%。选别效果不理想,说明强磁精矿连生体较多,精矿品位提升不大,与镜鉴结果相一致。

2.2.1 二段强磁精选磁场强度条件试验

为探寻二段强磁选较佳的磁场强度,将磨至−74 μm含量84%的试验原料,进行了不同磁场强度的强磁选条件试验,采用SLon-500脉动高梯度磁选机,强磁选参数为:磁场强度为变量、脉动冲程40 mm、转环转速3 r/min、冲次300次/min。试验流程如图4所示,试验结果见表5。

从表5结果可知:随着磁场强度的提高,精矿TiO2品位呈下降趋势,而精矿产率和回收率则呈上升趋势,尾矿TiO2品位基本在6%左右。从提高精矿TiO2品位和回收率的角度考虑,二段强磁选的磁场强度0.533 T。

表 5 强磁选磁场强度条件试验结果Table 5. Test results of high-intensity magnetic separation磁场强度/T 产品 产率/% TiO2品位/% TiO2回收率/% 0.437 精矿 38.65 15.67 60.50 尾矿 61.36 6.44 39.50 给矿 100.00 10.01 100.00 0.533 精矿 39.89 15.47 61.65 尾矿 60.11 6.39 38.35 给矿 100.00 10.01 100.00 0.628 精矿 44.43 14.58 64.71 尾矿 55.57 6.36 35.29 给矿 100.00 10.01 100.00 0.713 精矿 47.98 14.21 68.11 尾矿 52.02 6.14 31.89 给矿 100.00 10.01 100.00 0.852 精矿 49.60 14.18 70.26 尾矿 50.41 5.91 29.74 给矿 100.00 10.01 100.00 2.2.2 粗精矿强磁精选冲程条件试验

为探寻二段强磁选较佳的冲程,将磨至−74 μm含量84%的除铁尾矿进行了冲程条件试验,采用SLon-500脉动高梯度磁选机,选择强磁选参数:磁场强度0.533 T、冲程变量、转环转速3 r/min、冲次300次/min。试验结果见表6。

从表6结果得知:随着强磁选机冲程的提高,精矿TiO2品位呈上升趋势,而精矿产率和回收率则呈下降趋势,但当冲程达到设备的冲程极限50 mm时,与上述规律相反。由于二段精选强磁在兼顾钛回收率的情况下重点是要提高精矿品位,综合各项指标,二段强磁选用较佳的冲程45 mm。

2.2.3 强磁精选转环转速条件试验

为探寻二段强磁精选较佳的转环转速,将磨至−74 μm含量84%的除铁尾矿进行了转环转速条件试验,采用SLon-500脉动高梯度磁选机,选择强磁选参数:磁场强度0.533 T、冲程45 mm、冲次300次/min。试验结果见表7。

表 6 冲程条件试验结果Table 6. Test results under stroke conditions冲程/mm 产品 产率/% TiO2品位/% TiO2回收率/% 35 精矿 46.88 14.57 68.23 尾矿 53.13 5.99 31.77 除铁尾 100.00 10.01 100.00 40 精矿 39.89 15.47 61.65 尾矿 60.11 6.39 38.35 除铁尾 100.00 10.01 100.00 45 精矿 35.59 16.10 57.24 尾矿 64.41 6.64 42.76 除铁尾 100.00 10.01 100.00 50 精矿 43.94 14.84 65.13 尾矿 56.07 6.22 34.87 除铁尾 100.00 10.01 100.00 表 7 转环转速条件试验结果Table 7. Test results under different rotating ring speed转环转速/(r·min−1) 产品 产率/% TiO2品位/% TiO2回收率/% 2.5 精矿 30.71 17.32 53.13 尾矿 69.30 6.77 46.87 除铁尾 100.00 10.01 100.00 3.0 精矿 34.58 16.37 56.55 尾矿 65.42 6.65 43.45 除铁尾 100.00 10.01 100.00 3.5 精矿 40.09 15.06 60.32 尾矿 59.91 6.63 39.68 除铁尾 100.00 10.01 100.00 4.0 精矿 41.49 14.78 61.25 尾矿 58.52 6.63 38.75 除铁尾 100.00 10.01 100.00 从表7结果得知:随着强磁机转环转速的提高,精矿TiO2品位呈下降趋势,而精矿产率和回收率则呈上升趋势。综合各项指标,二段强磁选用较佳的转环转速3 r/min。

2.2.4 二段强磁最佳条件运行试验

根据上述条件试验确定的参数(磁场强度一段0.533 T、转环转速3 r/min、冲程45 mm、冲次300次/min),进行二段强磁选最佳条件运行试验,试验结果见表8。

表 8 二段强磁生产试验结果Table 8. Production results under two-section high-intensity magnetic field产品 产率/% TiO2品位/% TiO2回收率/% 给矿 100.00 9.98 100.00 二段强精 33.78 16.97 57.43 从表8结果得知:将试样进行二段强磁生产,可获得产率33.78%、TiO2品位16.97%、TiO2回收率57.43%的强磁精矿。

2.2.5 三段强磁试验

为探索试样经过三段强磁选后TiO2品位的提升幅度,将上述二段强磁生产获得的混合强磁精矿进行三段磁场强度条件试验,采用SLon-500脉动高梯度磁选机,选择三段强磁选参数:磁场强度变量、冲程45 mm、转环转速3 r/min、冲次300次/min。试验结果见表9。

表 9 三段强磁精选磁场强度条件试验结果Table 9. Test results under three-section high-intensity magnetic separation磁场强度/T 产品 产率/% TiO2品位/% TiO2回收率/% 0.533 精矿 76.04 18.65 88.46 0.713 精矿 77.86 18.46 89.66 0.852 精矿 88.94 17.12 94.99 从表9结果得知:随着磁场强度的提高,精矿TiO2品位呈下降趋势。为确保三段强磁精矿有相对较高的TiO2品位,综合各项指标,三段强磁选用最佳背景磁场强度为0.533 T。

2.3 浮选试验研究

试样经强磁选初步提升TiO2品位到18.00%左右后,为探索浮选进一步精选的最佳指标,对粗精矿选别出的含TiO2品位18.00%左右的精矿进行了相关浮选试验研究。

2.3.1 浮选研究

将粗精矿经磁选后产出的强磁精矿,进行相关浮选试验研究,以探索出浮选法回收强磁精矿的最佳条件,浮选实验室试验流程采用目前常用的“浮硫+浮钛(一粗三精流程)”常规流程,浮钛捕收剂采用湖北石首市荆江选矿药剂有限责任公司生产的MOH,pH值调整剂为硫酸。

2.3.2 浮钛粗选硫酸条件试验

结合攀西地区钛铁矿浮选药剂制度,通过初步探索试验,初步确定以捕收剂用量为3000 g/t,进行硫酸条件试验。考虑到该浮选给矿粒度较细,进行硫酸条件试验时,浮钛粗选中暂不添加柴油,条件试验流程及加药制度如图5所示,试验结果见表10。

表 10 硫酸用量条件试验结果Table 10. Effect of sulfuric acid dosage on production硫酸用量/(g·t−1) 产品 产率/% TiO2品位/% TiO2回收率/% 600 S精 6.18 16.58 5.44 钛粗精 47.47 30.68 77.21 浮尾 46.35 7.06 17.35 给矿 100.00 18.86 100.00 700 S精 5.43 16.38 4.84 钛粗精 39.50 34.38 73.86 浮尾 55.07 7.11 21.30 给矿 100.00 18.39 100.00 800 S精 6.67 16.84 5.95 钛粗精 35.13 38.66 71.92 浮尾 58.21 7.18 22.13 给矿 100.00 18.88 100.00 900 S精 6.85 17.59 6.50 钛粗精 31.13 40.42 67.92 浮尾 62.02 7.64 25.58 给矿 100.00 18.53 100.00 1000 S精 5.03 16.37 4.39 钛粗精 28.32 42.44 64.06 浮尾 66.66 8.88 31.55 给矿 100.00 18.76 100.00 从表10结果得知:随着硫酸用量的增加,钛粗精产率和回收率呈下降趋势,但钛粗精的TiO2品位则呈上升趋势;浮选尾矿在低硫酸用量时为7%,高硫酸用量时接近9%。由于该作业段为浮钛粗选段试验,要充分兼顾粗选精矿TiO2品位和回收率,以利于下步精选,确定浮钛粗选最佳硫酸用量为800 g/t。

2.3.3 柴油条件试验

从硫酸用量条件试验结果可知,浮选尾矿TiO2品位较高。为探索添加柴油是否能降低尾矿TiO2品位,在硫酸用量800 g/t和捕收剂用量3000 g/t的条件下,进行柴油用量条件试验,试验流程及加药制度如图6所示,试验结果见表11。

表 11 柴油用量条件试验结果Table 11. Effect of diesel consumption on production柴油用量/(g·t−1) 产品 产率/% TiO2品位/% TiO2回收率/% 0 S精 6.67 16.84 5.95 钛粗精 35.13 38.66 71.92 浮尾 58.21 7.18 22.13 给矿 100.00 18.88 100.00 560 S精 5.63 16.32 4.88 钛粗精 38.02 37.68 76.04 浮尾 56.35 6.38 19.08 给矿 100.00 18.84 100.00 700 S精 5.68 16.37 4.90 钛粗精 40.23 37.34 79.19 浮尾 54.09 5.58 15.91 给矿 100.00 18.97 100.00 980 S精 5.93 16.67 5.23 钛粗精 44.88 34.26 81.43 浮尾 49.19 5.12 13.34 给矿 100.00 18.88 100.00 从表11结果得知:随着柴油用量的增加,钛粗精产率和回收率呈上升趋势,但钛粗精的TiO2品位则呈下降趋势,尾矿TiO2品位也呈下降趋势。说明添加柴油对降低尾矿TiO2品位有效果。综合各项指标,确定浮钛粗选柴油用量700 g/t。

2.3.4 捕收剂条件试验

在硫酸用量800 g/t和柴油用量700 g/t的条件下,进行了MOH捕收剂的用量条件试验,试验流程及加药制度如图7所示,试验结果见表12。

从表12结果得知:随着捕收剂用量的增加,钛粗精产率和回收率呈上升趋势,但钛粗精和尾矿的TiO2品位则呈下降趋势。综合各项指标,利于下步精选,确定浮钛粗选捕收剂最佳用量为3000 g/t。

2.3.5 浮选闭路试验

闭路试验结果见表13。

表 13 浮选闭路试验结果Table 13. Closed-circuit flotation test results编号 产品 产率/% TiO2品位/% TiO2回收率/% 1 浮选给矿 100.00 18.68 100.00 2 S精 6.05 16.67 5.40 3 脱硫尾矿 93.95 18.81 94.60 4 扫选给矿 78.72 11.32 47.70 5 扫选精矿 5.61 17.96 5.40 6 扫选尾矿 73.10 10.81 42.30 7 粗选给矿 119.75 20.38 130.64 8 粗选精矿 41.03 37.76 82.94 9 精1给矿 53.46 37.98 108.70 10 精1精矿 33.27 43.82 78.05 11 中1 20.18 28.36 30.64 12 精2给矿 34.39 43.71 80.46 13 精2精矿 21.96 46.53 54.70 14 中2 12.43 38.72 25.76 15 钛精矿 20.85 46.86 52.30 16 中3 1.11 40.35 2.40 从表13得知:粗精矿再经过磨矿和两段强磁精选所得到的三段强磁精矿采用“浮硫+浮钛(一粗三精)” 闭路浮选流程,可获得钛精矿TiO2品位46.86%、产率20.85%、TiO2回收率52.30%的浮选闭路流程指标。

2.4 粗精矿选钛数质量流程

试样经过进一步细磨,再经弱磁除铁所得的试验矿样,采用“两段强磁+浮选”,最终获得的试验数质量流程如图8所示。

试样经过进一步细磨,再经弱磁除铁后,所得的试验矿样为−74 μm占84%左右的超细粒级选钛试验原料,再采用“两段强磁+浮选”联合流程,最终可获得钛精矿TiO2品位为46.86%、流程精矿总产率为5.93%、流程精矿TiO2总回收率为25.84%的较好指标。

表 12 捕收剂用量条件试验结果Table 12. Effect of collector dosage on production捕收剂用量/(g·t−1) 产品 产率/% TiO2品位/% TiO2回收率/% 2200 S精 5.82 16.12 5.07 钛粗精 32.93 39.87 71.03 浮尾 61.25 7.21 23.89 给矿 100.00 18.48 100.00 2600 S精 5.93 16.23 5.17 钛粗精 36.36 38.67 75.52 浮尾 57.71 6.23 19.31 给矿 100.00 18.62 100.00 3000 S精 5.71 16.37 5.01 钛粗精 39.50 37.14 78.60 浮尾 54.79 5.58 16.38 给矿 100.00 18.66 100.00 3400 S精 6.23 16.69 5.50 钛粗精 42.06 35.82 79.68 浮尾 51.71 5.42 14.82 给矿 100.00 18.91 100.00 3800 S精 5.65 16.08 4.81 钛粗精 45.54 34.06 82.22 浮尾 48.81 5.01 12.96 给矿 100.00 18.86 100.00 3. 结论

1)要获得相对较高的TiO2品位,试验矿样必须细磨,−74 μm含量达到84%左右。

2)为减少试样细磨后磁铁矿对精矿质量的影响,需进行多段弱磁除铁。

3)试样经过进一步细磨,再经弱磁除铁后,所得的试验矿样为−74 μm占84%左右的超细粒级选钛试验原料,再采用“两段强磁+浮选”联合流程,最终可获得钛精矿TiO2品位为46.86%、流程精矿总产率为5.93%、流程精矿TiO2总回收率为25.84%的较好指标。

-

表 1 样品化学多元素分析结果

Table 1. Results of chemical multielement analysis of samples

% TFe TiO2 S P MnO 14.50 10.75 0.124 0.053 0.310 CaO MgO SiO2 Al2O3 Cr2O3 12.33 13.31 35.50 5.14 0.015 表 2 粗精矿试样全粒级筛析结果

Table 2. Results of full size sieving analysis of coarse concentrate sample

粒级/目(mm) 产率/% TiO2品位/% TiO2分布率/% +40 (+0.45) 0.61 4.14 0.24 +60 (+0.28) 6.38 4.92 2.96 +80 (+0.20) 14.17 6.91 9.22 +100 (+0.154) 11.74 9.65 10.67 +120 (+0.125) 17.41 10.00 16.40 +160 (+0.098) 9.72 10.93 10.00 +200 (+0.074) 7.49 9.46 6.67 +320 (+0.045) 19.13 11.38 20.51 +400 (+0.038) 2.02 18.59 3.55 −400 (−0.038) 11.34 18.52 19.78 合计 100.00 10.62 100.00 表 3 样品试样矿物含量及单体解离度测定结果

Table 3. Determination results of mineral content and monomer dissociation degree of samples

质量分数/% 单体解离度/% 钛磁铁矿 钛铁矿 硫化物 脉石 钛磁铁矿 钛铁矿 硫化物 脉石 10.23 17.95 0.61 71.21 66.52 84.18 70.36 88.72 表 4 粗精矿试样直接强磁精选试验结果

Table 4. Test results of direct high-intensity magnetic separation of coarse concentrate samples

产品 产率/% TiO2品位/% TiO2回收率/% 精矿 66.91 12.55 78.11 尾矿 33.09 7.11 21.89 给矿 100.00 10.75 100.00 表 5 强磁选磁场强度条件试验结果

Table 5. Test results of high-intensity magnetic separation

磁场强度/T 产品 产率/% TiO2品位/% TiO2回收率/% 0.437 精矿 38.65 15.67 60.50 尾矿 61.36 6.44 39.50 给矿 100.00 10.01 100.00 0.533 精矿 39.89 15.47 61.65 尾矿 60.11 6.39 38.35 给矿 100.00 10.01 100.00 0.628 精矿 44.43 14.58 64.71 尾矿 55.57 6.36 35.29 给矿 100.00 10.01 100.00 0.713 精矿 47.98 14.21 68.11 尾矿 52.02 6.14 31.89 给矿 100.00 10.01 100.00 0.852 精矿 49.60 14.18 70.26 尾矿 50.41 5.91 29.74 给矿 100.00 10.01 100.00 表 6 冲程条件试验结果

Table 6. Test results under stroke conditions

冲程/mm 产品 产率/% TiO2品位/% TiO2回收率/% 35 精矿 46.88 14.57 68.23 尾矿 53.13 5.99 31.77 除铁尾 100.00 10.01 100.00 40 精矿 39.89 15.47 61.65 尾矿 60.11 6.39 38.35 除铁尾 100.00 10.01 100.00 45 精矿 35.59 16.10 57.24 尾矿 64.41 6.64 42.76 除铁尾 100.00 10.01 100.00 50 精矿 43.94 14.84 65.13 尾矿 56.07 6.22 34.87 除铁尾 100.00 10.01 100.00 表 7 转环转速条件试验结果

Table 7. Test results under different rotating ring speed

转环转速/(r·min−1) 产品 产率/% TiO2品位/% TiO2回收率/% 2.5 精矿 30.71 17.32 53.13 尾矿 69.30 6.77 46.87 除铁尾 100.00 10.01 100.00 3.0 精矿 34.58 16.37 56.55 尾矿 65.42 6.65 43.45 除铁尾 100.00 10.01 100.00 3.5 精矿 40.09 15.06 60.32 尾矿 59.91 6.63 39.68 除铁尾 100.00 10.01 100.00 4.0 精矿 41.49 14.78 61.25 尾矿 58.52 6.63 38.75 除铁尾 100.00 10.01 100.00 表 8 二段强磁生产试验结果

Table 8. Production results under two-section high-intensity magnetic field

产品 产率/% TiO2品位/% TiO2回收率/% 给矿 100.00 9.98 100.00 二段强精 33.78 16.97 57.43 表 9 三段强磁精选磁场强度条件试验结果

Table 9. Test results under three-section high-intensity magnetic separation

磁场强度/T 产品 产率/% TiO2品位/% TiO2回收率/% 0.533 精矿 76.04 18.65 88.46 0.713 精矿 77.86 18.46 89.66 0.852 精矿 88.94 17.12 94.99 表 10 硫酸用量条件试验结果

Table 10. Effect of sulfuric acid dosage on production

硫酸用量/(g·t−1) 产品 产率/% TiO2品位/% TiO2回收率/% 600 S精 6.18 16.58 5.44 钛粗精 47.47 30.68 77.21 浮尾 46.35 7.06 17.35 给矿 100.00 18.86 100.00 700 S精 5.43 16.38 4.84 钛粗精 39.50 34.38 73.86 浮尾 55.07 7.11 21.30 给矿 100.00 18.39 100.00 800 S精 6.67 16.84 5.95 钛粗精 35.13 38.66 71.92 浮尾 58.21 7.18 22.13 给矿 100.00 18.88 100.00 900 S精 6.85 17.59 6.50 钛粗精 31.13 40.42 67.92 浮尾 62.02 7.64 25.58 给矿 100.00 18.53 100.00 1000 S精 5.03 16.37 4.39 钛粗精 28.32 42.44 64.06 浮尾 66.66 8.88 31.55 给矿 100.00 18.76 100.00 表 11 柴油用量条件试验结果

Table 11. Effect of diesel consumption on production

柴油用量/(g·t−1) 产品 产率/% TiO2品位/% TiO2回收率/% 0 S精 6.67 16.84 5.95 钛粗精 35.13 38.66 71.92 浮尾 58.21 7.18 22.13 给矿 100.00 18.88 100.00 560 S精 5.63 16.32 4.88 钛粗精 38.02 37.68 76.04 浮尾 56.35 6.38 19.08 给矿 100.00 18.84 100.00 700 S精 5.68 16.37 4.90 钛粗精 40.23 37.34 79.19 浮尾 54.09 5.58 15.91 给矿 100.00 18.97 100.00 980 S精 5.93 16.67 5.23 钛粗精 44.88 34.26 81.43 浮尾 49.19 5.12 13.34 给矿 100.00 18.88 100.00 表 13 浮选闭路试验结果

Table 13. Closed-circuit flotation test results

编号 产品 产率/% TiO2品位/% TiO2回收率/% 1 浮选给矿 100.00 18.68 100.00 2 S精 6.05 16.67 5.40 3 脱硫尾矿 93.95 18.81 94.60 4 扫选给矿 78.72 11.32 47.70 5 扫选精矿 5.61 17.96 5.40 6 扫选尾矿 73.10 10.81 42.30 7 粗选给矿 119.75 20.38 130.64 8 粗选精矿 41.03 37.76 82.94 9 精1给矿 53.46 37.98 108.70 10 精1精矿 33.27 43.82 78.05 11 中1 20.18 28.36 30.64 12 精2给矿 34.39 43.71 80.46 13 精2精矿 21.96 46.53 54.70 14 中2 12.43 38.72 25.76 15 钛精矿 20.85 46.86 52.30 16 中3 1.11 40.35 2.40 表 12 捕收剂用量条件试验结果

Table 12. Effect of collector dosage on production

捕收剂用量/(g·t−1) 产品 产率/% TiO2品位/% TiO2回收率/% 2200 S精 5.82 16.12 5.07 钛粗精 32.93 39.87 71.03 浮尾 61.25 7.21 23.89 给矿 100.00 18.48 100.00 2600 S精 5.93 16.23 5.17 钛粗精 36.36 38.67 75.52 浮尾 57.71 6.23 19.31 给矿 100.00 18.62 100.00 3000 S精 5.71 16.37 5.01 钛粗精 39.50 37.14 78.60 浮尾 54.79 5.58 16.38 给矿 100.00 18.66 100.00 3400 S精 6.23 16.69 5.50 钛粗精 42.06 35.82 79.68 浮尾 51.71 5.42 14.82 给矿 100.00 18.91 100.00 3800 S精 5.65 16.08 4.81 钛粗精 45.54 34.06 82.22 浮尾 48.81 5.01 12.96 给矿 100.00 18.86 100.00 -

[1] Xu Lijun, Li Liang, Chen Liuxian, et al. Comprehensive recycling situation and development direction of vanadium-titanium magnetite in Paxi[J]. Sichuan Nonferrous Metals, 2011,(1):1−5. (徐丽君, 李亮, 陈六限, 等. 攀西地区钒钛磁铁矿综合回收利用现状及发展方向[J]. 四川有色金属, 2011,(1):1−5. doi: 10.3969/j.issn.1006-4079.2011.01.001 -

下载:

下载:

下载:

下载: