Research on the leaching characteristics of Ca, Mg, Al elements in high titanium blast furnace slag

-

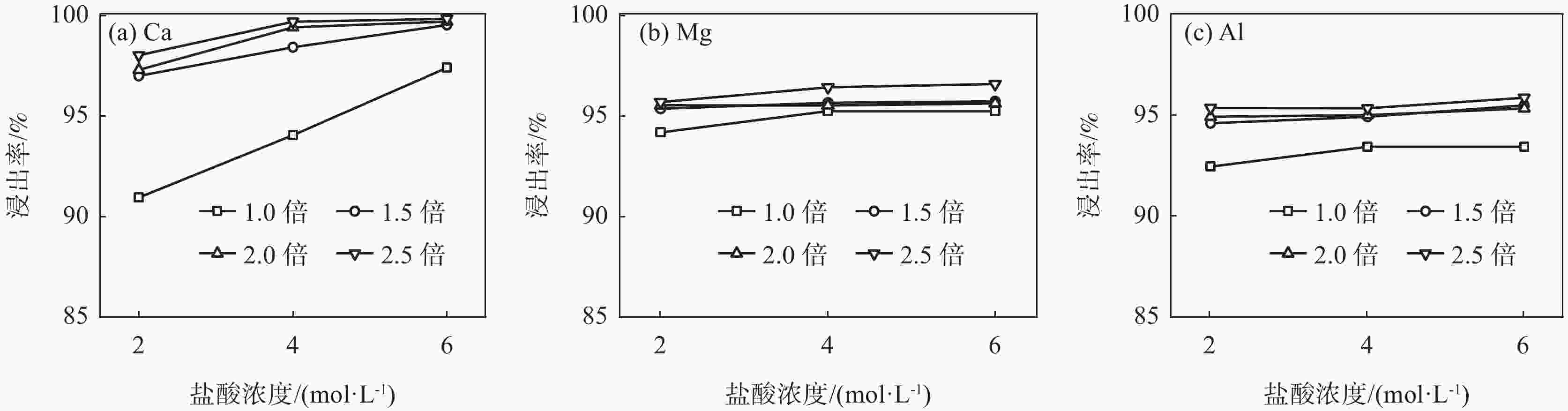

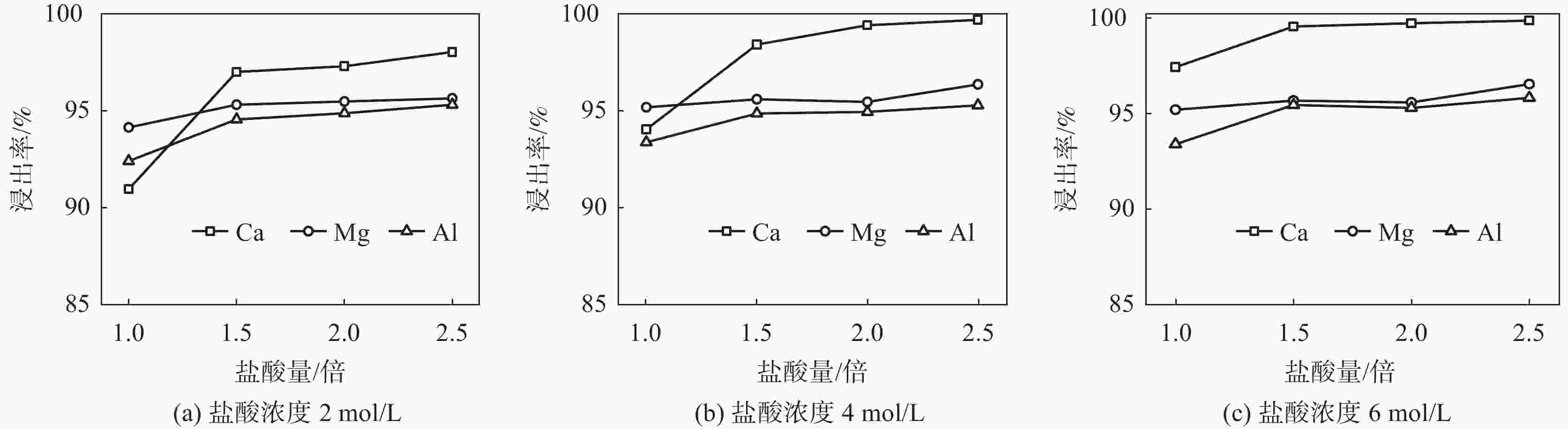

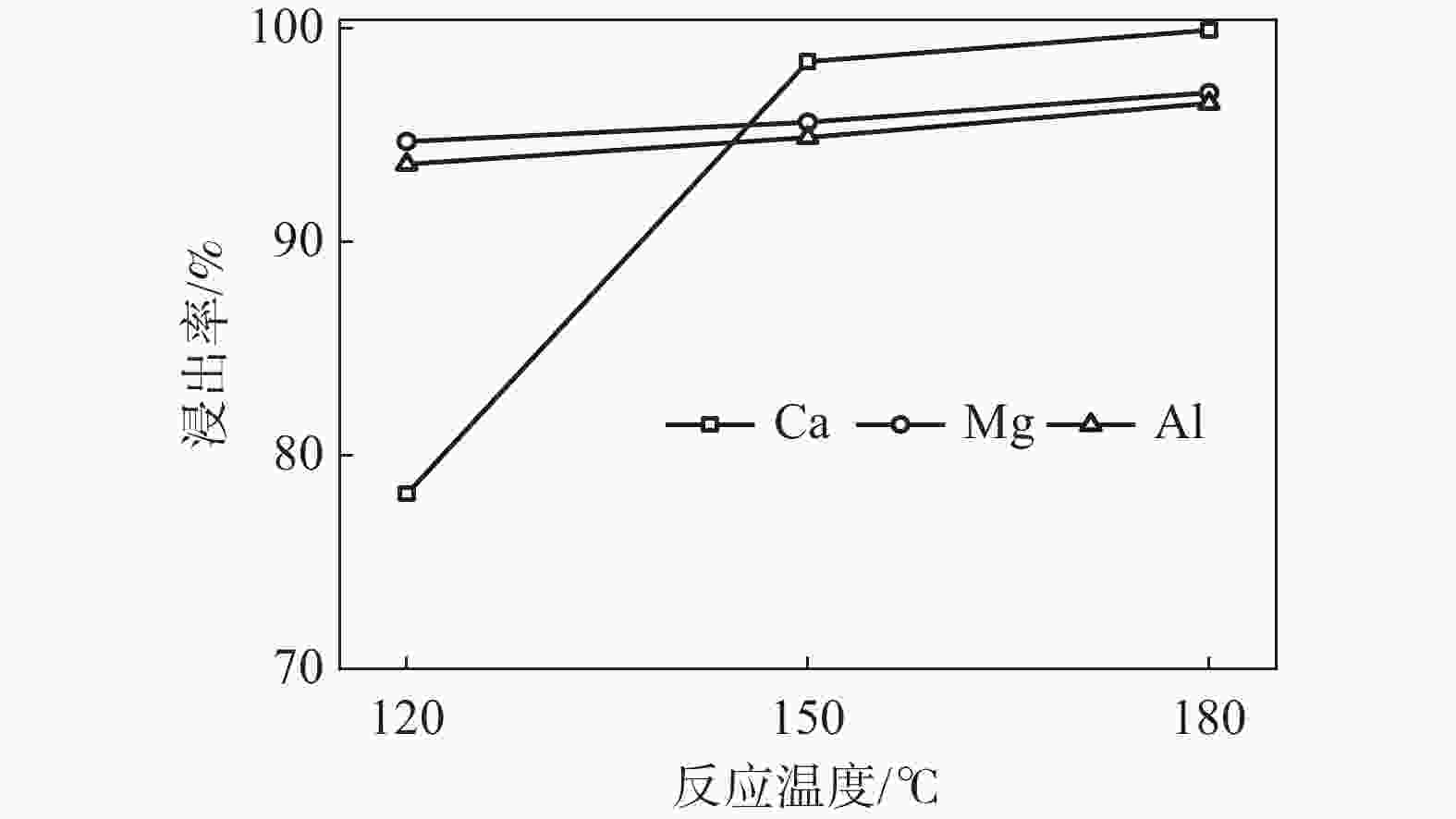

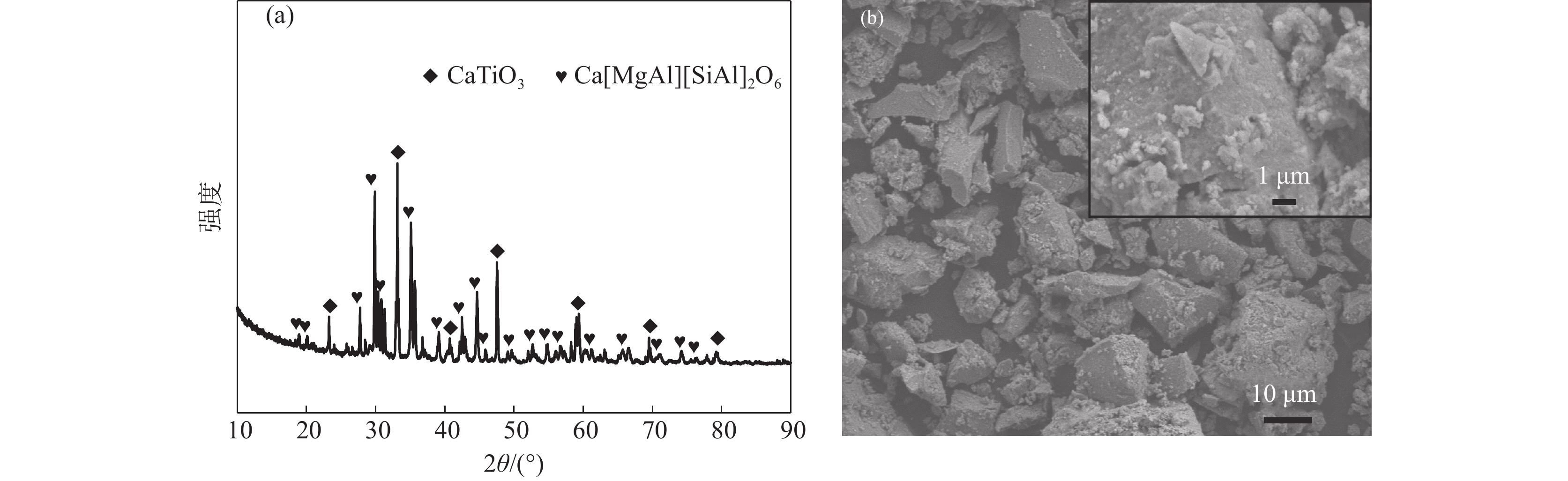

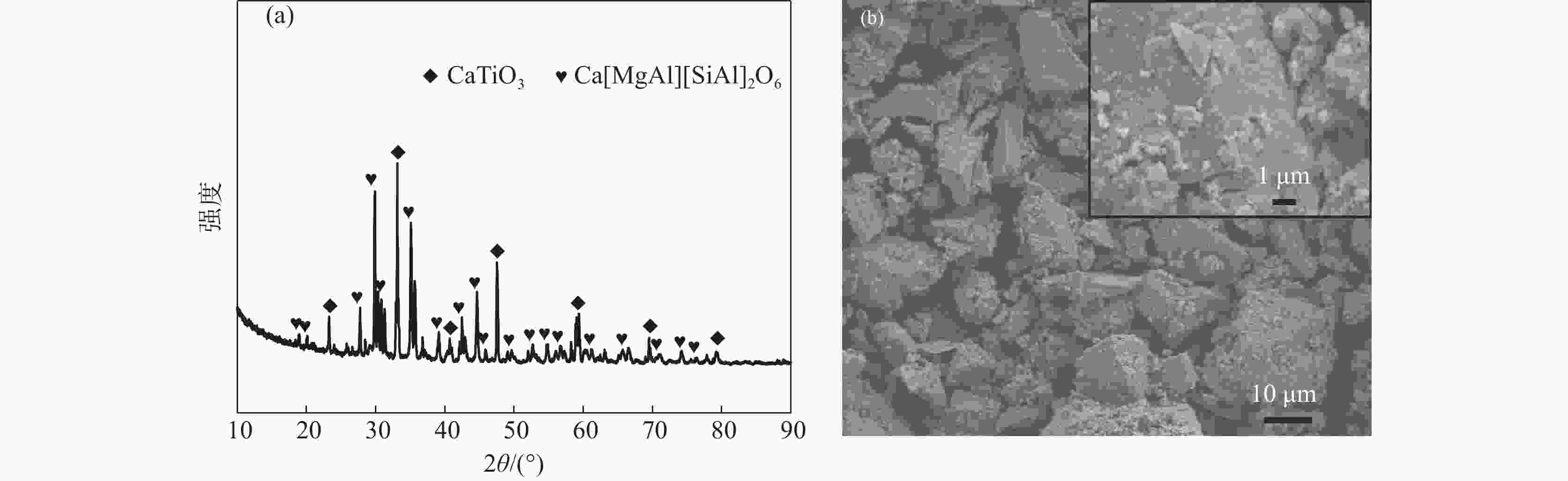

摘要: 为了充分利用高钛型高炉渣中的价值元素,通过对其理化性质进行分析,提出采用盐酸水热浸出的方式分离出高钛型高炉渣中Ca、Mg元素,重点考察了反应条件参数对高钛型高炉渣中元素浸出特性的影响。试验结果显示,随着盐酸浓度、盐酸量、反应温度和反应时间的增加,高钛型高炉渣中Ca、Mg、Al元素浸出率均呈上升趋势。其中,Mg、Al元素浸出率在高于95%后基本保持稳定,而Ca元素浸出率最高可接近100%。在盐酸浓度为4 mol/L、盐酸量为理论计算可完全溶解高钛型高炉渣中Ca、Mg、Al元素的1.5倍、反应温度为150 ℃、反应时间为10 h的条件下,可使高钛型高炉渣中Ca、Mg元素完全解离,浸出残渣中MgO、CaO含量均在1%以下,而TiO2、SiO2、Al2O3总含量则高于95%,可满足制备多孔吸附材料的要求。该研究成果有望为高钛型高炉渣的资源化高效利用提供数据支撑。Abstract: To make full use of the valuable elements in high titanium blast furnace slag, the physical and chemical properties were analyzed. The method of hydrochloric acid hydrothermal leaching was proposed to separate Ca and Mg elements from high titanium blast furnace slag. And the influence of reaction condition parameters on the leaching characteristics of elements in high titanium blast furnace slag was studied. The results reveal that with the increase of hydrochloric acid concentration, hydrochloric acid amount, reaction temperature and reaction time, the leaching efficiency of Ca, Mg and Al elements in high titanium blast furnace slag all increase. Among them, the leaching efficiency of Mg and Al remain stable when they are higher than 95%, while the leaching efficiency of Ca can raise to nearly 100%. The Ca and Mg elements in high titanium blast furnace slag can be entirely dissociated when the concentration of hydrochloric acid is 4 mol/L, the amount of hydrochloric acid is 1.5 times of theoretical acid amount required for the entire dissolution of Ca, Mg and Al elements in high titanium blast furnace slag, the reaction temperature is 150 ℃, the reaction time is 10 h. Meanwhile, the amounts of both MgO and CaO in the leaching residue are all below 1%, and the aggregate amounts of TiO2, SiO2 and Al2O3 are higher than 95%, which can fulfill the requirements of preparing porous adsorption materials. The results of this research are anticipated to provide data support for the efficient utilization of high titanium blast furnace slag.

-

表 1 高钛型高炉渣的主要化学组成

Table 1. Main chemical composition of high titanium blast furnace slag

% MgO Al2O3 SiO2 SO3 K2O CaO TiO2 MnO Fe2O3 8.44 13.49 22.84 1.55 0.71 28.36 20.46 0.80 1.74 -

[1] Gao Yang, Gui Yongliang, Song Chunyan, et al. Current situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019,(1):6−10. (高洋, 贵永亮, 宋春燕, 等. 高钛高炉渣综合利用现状及展望[J]. 矿产综合利用, 2019,(1):6−10.Gao Yang, Gui Yongliang, Song Chunyan, et al. Current situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019 (1): 6-10. [2] Cai Yongfeng, Song Ningning, Yang Yunfei, et al. Recent progress of efficient utilization of titanium-bearing blast furnace slag[J]. International Journal of Minerals Metallurgy and Materials, 2022,29(1):22−31. doi: 10.1007/s12613-021-2323-1 [3] Li Xinghua, Pu Jiangtao. The latest developments of integrated utilization on Panzhihua high titanium-bearing BF slag[J]. Iron Steel Vanadium Titanium, 2011,32(2):10−14. (李兴华, 蒲江涛. 攀枝花高钛型高炉渣综合利用研究最新进展[J]. 钢铁钒钛, 2011,32(2):10−14. doi: 10.7513/j.issn.1004-7638.2011.02.003Li Xinghua, Pu Jiangtao. The latest developments of integrated utilization on Panzhihua high titanium-bearing BF slag[J]. Iron Steel Vanadium Titanium, 2011, 32(2): 10-14. doi: 10.7513/j.issn.1004-7638.2011.02.003 [4] Xu Renze, Zhang Jianliang, Chang Zhiyu, et al. Research progress of selective enrichment and precipitation of titanium in high titanium blast furnace slag[J]. Iron Steel Vanadium Titanium, 2017,38(6):6−12. (许仁泽, 张建良, 常治宇, 等. 高钛型高炉渣中钛组分选择性富集与析出研究进展[J]. 钢铁钒钛, 2017,38(6):6−12.Xu Renze, Zhang Jianliang, Chang Zhiyu, et al. Research progress of selective enrichment and precipitation of titanium in high titanium blast furnace slag[J]. Iron Steel Vanadium Titanium, 2017, 38(6): 6-12. ) [5] Shi Junjie, Qiu Yuchao, Yu Bin, et al. Titanium extraction from titania-bearing blast furnace slag: A review[J]. JOM, 2022,74(2):654−667. doi: 10.1007/s11837-021-05040-y [6] Deng Yong, Zhen Changliang, Li Junguo, et al. Titanium enrichment process of titanium bearing blast furnace slag and utilization of titanium resources[J]. China Metallurgy, 2022,32(8):25−31. (邓勇, 甄常亮, 李俊国, 等. 含钛高炉渣钛富集工艺及钛资源利用[J]. 中国冶金, 2022,32(8):25−31.Deng Yong, Zhen Changliang, Li Junguo, et al. Titanium enrichment process of titanium bearing blast furnace slag and utilization of titanium resources[J]. China Metallurgy, 2022, 32(8): 25-31. [7] Li Youqi, Ke Changming, Gan Lin, et al. Development and application of refining desulfurizing agent based on Panzhihua Iron and Steel Co. blast furnace slag extracted titanium[J]. Iron Steel Vanadium Titanium, 2008,29(4):26−31. (李有奇, 柯昌明, 甘霖, 等. 基于攀钢含钛高炉渣提钛尾渣的精炼脱硫剂研究[J]. 钢铁钒钛, 2008,29(4):26−31.Li Youqi, Ke Changming, Gan Lin, et al. Development and application of refining desulfurizing agent based on Panzhihua Iron and Steel Co. blast furnace slag extracted titanium[J]. Iron Steel Vanadium Titanium, 2008, 29(4): 26-31. [8] Wang Peng, Han Bingqiang, Ke Changming, et al. Study on the performance of corundum castables binded by high titanium blast furnace after extracting titanium[J]. Iron Steel Vanadium Titanium, 2016,37(4):76−82. (汪朋, 韩兵强, 柯昌明, 等. 以高钛型高炉渣提钛后尾渣为结合剂的刚玉浇注料性能研究[J]. 钢铁钒钛, 2016,37(4):76−82.Wang Peng, Han Bingqiang, Ke Changming, et al. Study on the performance of corundum castables binded by high titanium blast furnace after extracting titanium[J]. Iron Steel Vanadium Titanium, 2016, 37(4): 76-82. [9] Chu Guanrun, Wang Lin, Liu Weizao, et al. Indirect mineral carbonation of chlorinated tailing derived from Ti-bearing blast-furnace slag coupled with simultaneous dechlorination and recovery of multiple value-added products[J]. Greenhouse Gases-Science and Technology, 2019,9(1):52−66. doi: 10.1002/ghg.1832 [10] Wang Huaibin, Fan Fuzhong, Hao Jianzhang, et al. Action mechanism of high titanium BF slag in concrete[J]. Iron Steel Vanadium Titanium, 2004,25(3):48−53. (王怀斌, 范付忠, 郝建璋, 等. 高钛高炉渣在混凝土中的作用机理[J]. 钢铁钒钛, 2004,25(3):48−53.Wang Huaibin, Fan Fuzhong, Hao Jianzhang, et al. Action mechanismof high titaniumbf slag in concrete[J]. Iron Steel Vanadium Titanium, 2004, 25 (3): 48-53. [11] Zhou Chunli. Experimental study on high-titanium blast furnace slag heat-resistant concrete[J]. Bulletin of the Chinese Ceramic Society, 2018,37(10):3119−3123. (周春利. 高钛型高炉渣耐热混凝土试验研究[J]. 硅酸盐通报, 2018,37(10):3119−3123.Zhou Chunli. Experimental study on high-titanium blast furnace slag heat-resistant concrete[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(10): 3119-3123. [12] Ao Jinqing, Hao Jianzhang, Wang Huaibin, et al. Development of slag brick with high content of Ti-bearing slag[J]. Iron Steel Vanadium Titanium, 2007,28(2):57−62. (敖进清, 郝建璋, 王怀斌, 等. 大掺量高钛型高炉渣实心砖的研制[J]. 钢铁钒钛, 2007,28(2):57−62.Ao Jinqing, Hao Jianzhang, Wang Huaibin, et al. Development of slag brick with high content of Ti-bearing slag[J]. Iron Steel Vanadium Titanium, 2007, 28(2): 57-62. [13] Tian Jian, Feng Keqin, Yan Zidi, et al. Comparative study on preparation of foam glass-ceramics from slow-cooling and water-quenched high titanium blast furnace slag[J]. Iron Steel Vanadium Titanium, 2020,41(5):96−101. (田坚, 冯可芹, 严子迪, 等. 缓冷与水淬高钛型高炉渣制备微晶泡沫玻璃的对比研究[J]. 钢铁钒钛, 2020,41(5):96−101.Tian Jian, Feng Keqin, Yan Zidi, et al. Comparative study on preparation of foam glass-ceramics from slow-cooling and water-quenched high titanium blast furnace slag[J]. Iron Steel Vanadium Titanium, 2020, 41(5): 96-101. [14] Li Jiahao, Liang Zongyu, Yang He, et al. Foamed ceramics prepared by titanium-bearing blast furnace slag with borax as flux agent[J]. Bulletin of the Chinese Ceramic Society, 2021,40(12):4077−4083. (李嘉昊, 梁宗宇, 杨合, 等. 以硼砂为助熔剂使用含钛高炉渣制备发泡陶瓷[J]. 硅酸盐通报, 2021,40(12):4077−4083.Li Jiahao, Liang Zongyu, Yang He, et al. Foamed ceramics prepared by titanium-bearing blast furnace slag with borax as flux agent[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(12): 4077-4083. [15] Huo Hongying, Zou Min. Preparation and performance optimization of Co-doped high-titanium blast furnace slag as photocatalytic material[J]. Iron Steel Vanadium Titanium, 2021,42(1):65−69. (霍红英, 邹敏. 钴掺杂高钛型高炉渣光催化材料制备及性能优化[J]. 钢铁钒钛, 2021,42(1):65−69. doi: 10.7513/j.issn.1004-7638.2021.01.011Huo Hongying, Zou Min. Preparation and performance optimization of Co-doped high-titanium blast furnace slag as photocatalytic material[J]. Iron Steel Vanadium Titanium, 2021, 42(1): 65-69. doi: 10.7513/j.issn.1004-7638.2021.01.011 [16] Wang Kun, Zhu Liyun, Li Peng, et al. Preparation of CaTiO3-porous geopolymer photodegradation adsorbent from Ti-bearing blast furnace slag[J]. China Metallurgy, 2022,32(4):113−120. (王琨, 朱丽云, 李鹏, 等. 含钛高炉渣制备CaTiO3-多孔地质聚合物光降解吸附材料[J]. 中国冶金, 2022,32(4):113−120.Wang Kun, Zhu Liyun, Li Peng, et al. Preparation of CaTiO3-porous geopolymer photodegradation adsorbent from Ti-bearing blast furnace slag[J]. China Metallurgy, 2022, 32(4): 113-120. [17] Lei Shan, Yang Juan, Yu Jian, et al. SCR denitration catalyst prepared from titanium-bearing blast furnace slag[J]. CIESC Journal, 2014,65(4):1251−1259. (雷珊, 杨娟, 余剑, 等. 含钛高炉渣制备SCR烟气脱硝催化剂[J]. 化工学报, 2014,65(4):1251−1259.Lei Shan, Yang Juan, Yu Jian, et al. SCR denitration catalyst prepared from titanium-bearing blast furnace slag[J]. CIESC Journal, 2014, 65(4): 1251-1259. [18] Tran Tuyetsuong, Yu Jian, Gan Lina, et al. Upgrading V2O5-WO3/TiO2 deNOx catalyst with TiO2-SiO2 support prepared from ti-bearing blast furnace slag[J]. Catalysts, 2016,6(4):14. [19] Tran Tuyetsuong, Yu Jian, Li Changming, et al. Structure and performance of a V2O5-WO3/TiO2-SiO2 catalyst derived from blast furnace slag (BFS) for DeNOx[J]. RSC Advances, 2017,7(29):18108−18119. doi: 10.1039/C7RA01252G [20] 皇甫林, 邱正秋, 王奎, 等. 一种含钛高炉渣改性制备CO2捕集材料耦合矿化的方法: 中国, CN115582105A[P]. 2023-01-10.Huangfu Lin, Qiu Zhengqiu, Wang Kui, et al. A method for preparing CO2 capture material coupling mineralization by modification of titanium-bearing blast furnace slag: China, CN115582105A[P]. 2023-01-10. [21] Wang Weiqing, Zhu Yangge, Zhang Shiqiu, et al. Flotation behaviors of perovskite, titanaugite, and magnesium aluminate spinel using octyl hydroxamic acid as the collector[J]. Minerals, 2017,7(8):18. [22] Yang Zhuoying, Yang Fan, Yi Meigui, et al. Estimation of reaction heat in ti-bearing blast furnace slag-sulfuric acid system based on mechanical mixture model[J]. Mining Metallurgy & Exploration, 2021,38(2):1247−1252. [23] Zhang Xiaoyun, Qin Hongyan, Zhang Sisi, et al. Titanium-incorporated organic-inorganic hybrid adsorbent for improved CO2 adsorption performance[J]. Materials Research Bulletin, 2015,62:200−205. doi: 10.1016/j.materresbull.2014.11.037 [24] Zhang Hong, Yuan Hong, Ma Xiuhua. Progress in synthesis and application of Ti-Si ordered mesoporous molecular sieves[J]. Applied Chemical Industry, 2018,47(12):2781−2785. (张泓, 袁红, 马秀花. 钛硅有序介孔分子筛合成及应用研究进展[J]. 应用化工, 2018,47(12):2781−2785.Zhang Hong, Yuan Hong, Ma Xiuhua. Progress in synthesis and application of Ti-Si ordered mesoporous molecular sieves[J]. Applied Chemical Industry, 2018, 47(12): 2781-2785. [25] 陈旭东. 粉煤灰制备硅基分子筛的合成优化及其CO2吸附性能研究[D]. 沈阳: 东北大学, 2019.Chen Xudong. Synthesis optimization of silica-based molecular sieves prepared from fly ash and their CO2 adsorption properties[D]. Shenyang: Northeastern University, 2019. -

下载:

下载: