Study on long time corrosion resistance of titanium welded tube

-

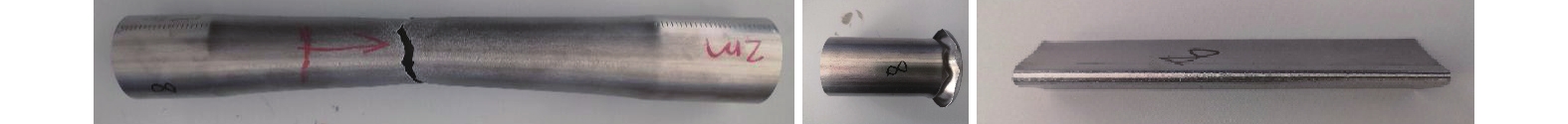

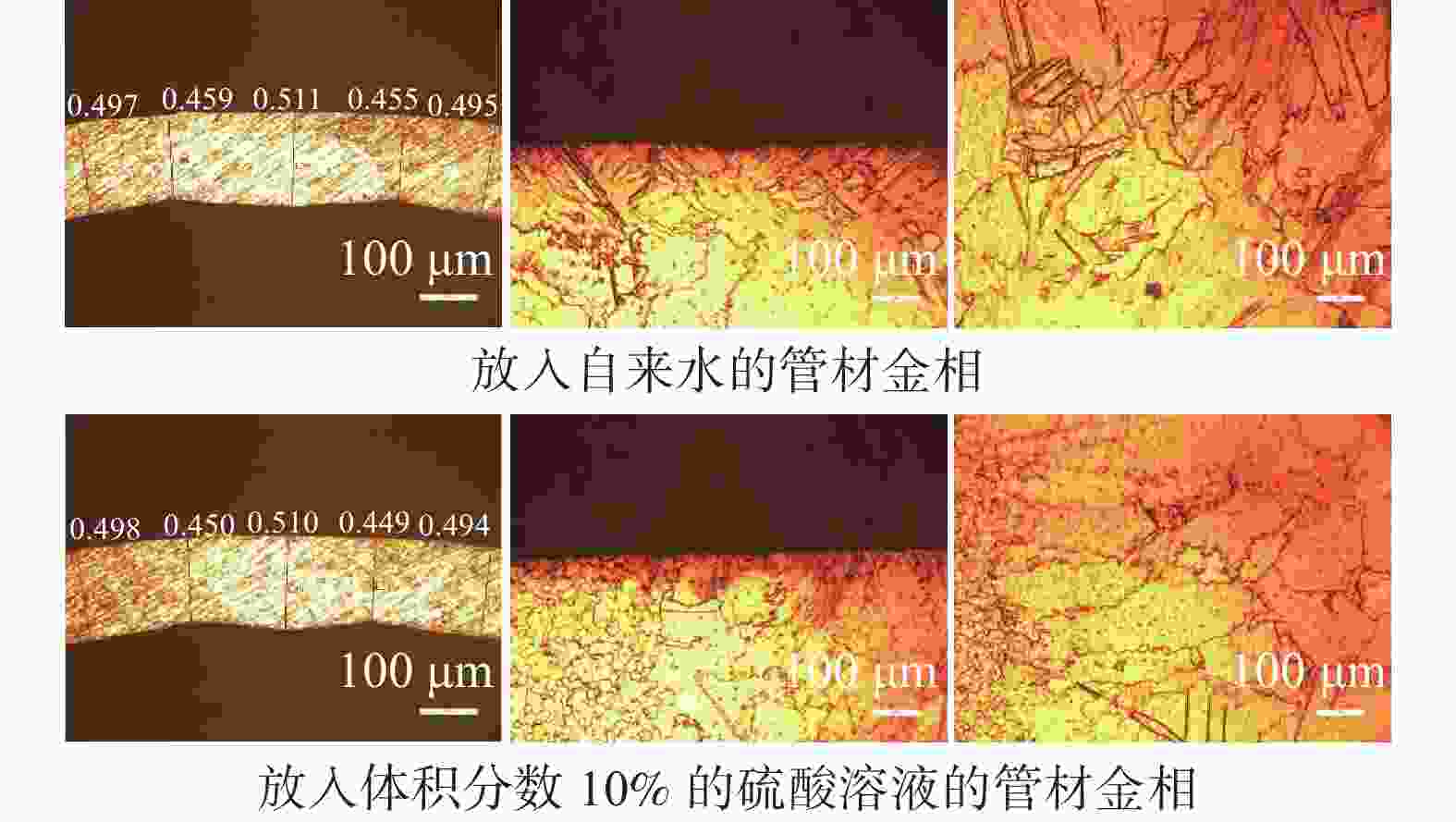

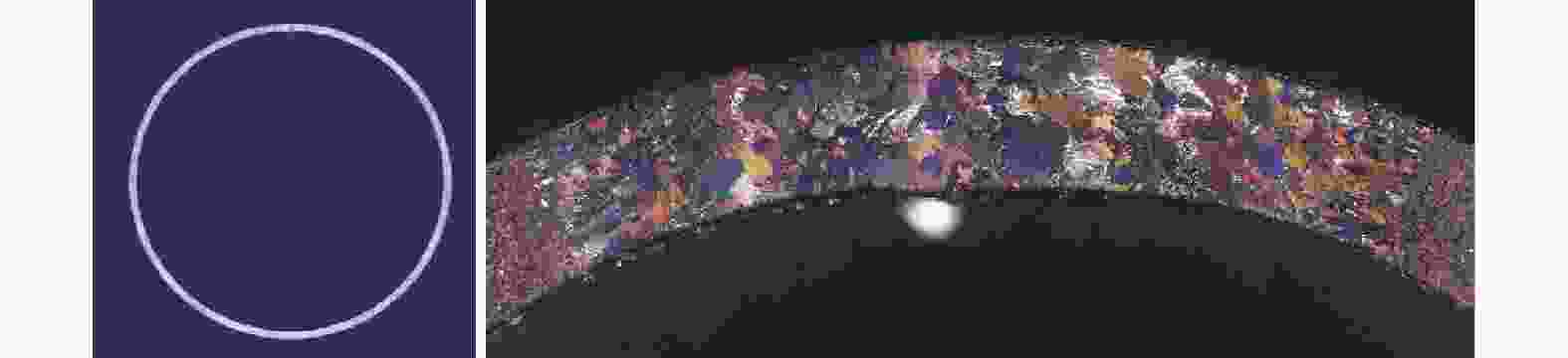

摘要: 模拟不同工况条件,通过宏观尺寸检测、金相分析、力学性能测试等,研究钛焊管在自来水、质量分数为5%的氯化镁水溶液、海水、体积分数为10%的硫酸溶液中长时浸泡的耐腐蚀性能。结果表明,钛焊管在自来水、质量分数为5%的氯化镁水溶液、海水三种溶液中浸泡长达7年,几乎不出现腐蚀现象,腐蚀速率分别为0.333、0.466、0.466 μm/a,具备良好的耐腐蚀性能。钛焊管在体积分数为10%的硫酸溶液中长期浸泡,会出现腐蚀现象,壁厚减薄,减薄率为2%,腐蚀速率为1.398 μm/a,耐腐蚀性能较其他三种溶液下差。该研究对钛焊管在生活用水、制盐、海洋工程、海水淡化等环境的应用具有重要意义。Abstract: Simulating different operating conditions the corrosion resistance of titanium welded pipe in tap water, 5% magnesium chloride aqueous solution, seawater and 10% sulfuric acid solution soaked for a long time was studied through macro-size detection, metallographic analysis and mechanical properties test. The results show that there is almost no evident corrosion of titanium welded pipe after long-term immersion in tap water, 5% magnesium chloride aqueous solution and seawater. The corrosion rate is 0.333, 0.466 μm /year and 0.466 μm/year, respectively, representing a predominant corrosion resistance of titanium welded pipe. The titanium welded pipe can be corroded after a long-term immersion in 10% sulfuric acid solution. The wall of titanium welded pipe becomes thinned with a reduction rate of 2% . The corrosion rate is 1.398 μm/year, and the corrosion resistance is worse than the other three solutions. This research is of great significance to the application of titanium welded pipe in domestic water, salt making, ocean engineering and seawater desalination.

-

表 1 钛焊管成分和性能

Table 1. Composition and properties of titanium welded tube

w/% 抗拉强度/MPa 屈服强度/MPa 延伸率/% Fe C O N H Ti 其他总和 0.045 0.02 0.08 0.003 0.0005 余量 <0.4 454 342 39.2 表 2 试验所用腐蚀介质

Table 2. Corrosion medium used in the experiment

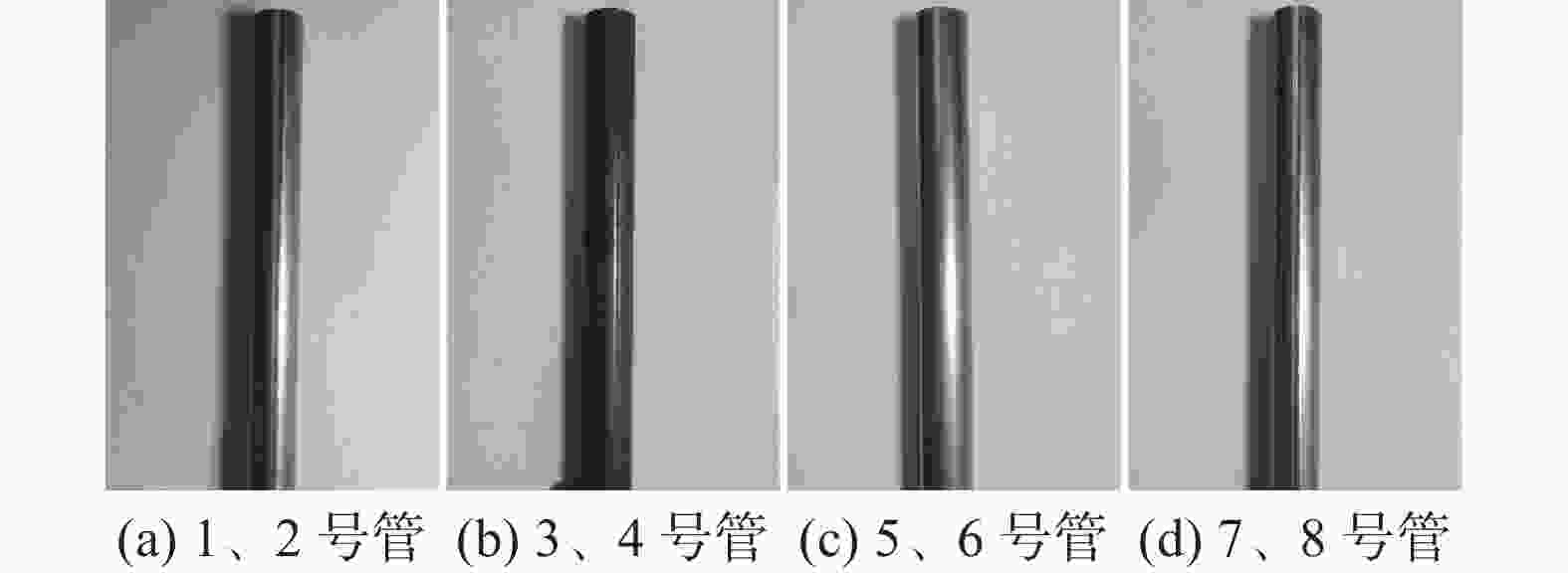

试剂 级别 生产厂家 管材编号 模拟场景 自来水 1、2 生活用水 硫酸 AR 株洲市星空化玻

有限责任公司3、4 化工行业 氯化镁 AR 天津市风船化学试剂

科技有限公司5、6 制盐 海水 三亚地区 7、8 海洋工程、海水淡化 表 3 钛焊管力学性能测试结果

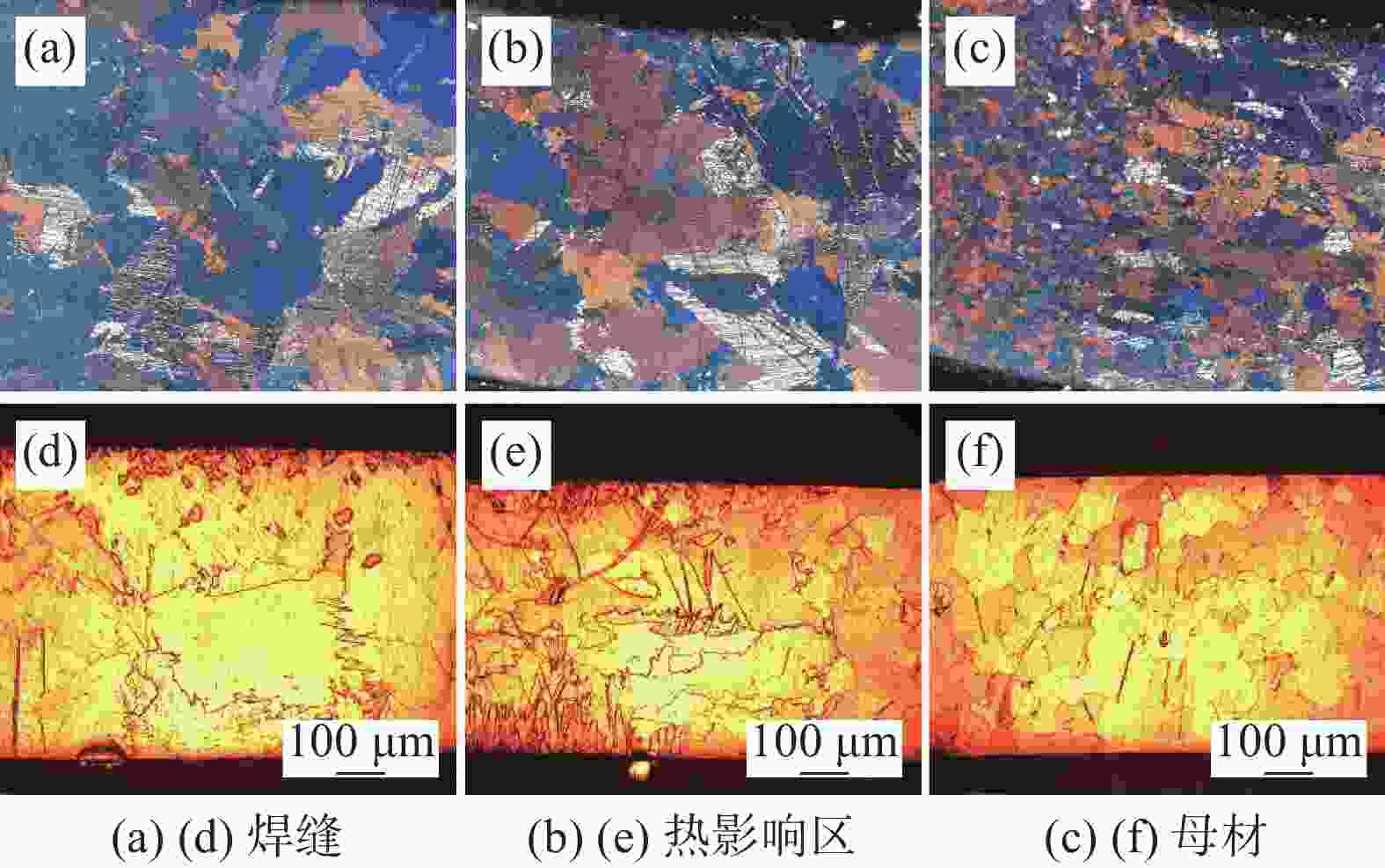

Table 3. Mechanical properties results of titanium welded tube

Rm/

MPaRp0.2/

MPaA50/

%反向

展平压扁 扩口 硬度( HV1 ) 焊缝 基材 热影响区 350 295 23 OK OK OK 175 152 155 表 4 长时浸泡腐蚀前后钛焊管截面厚度和腐蚀速率

Table 4. Section thickness and corrosion rate of titanium welded tube before and after long time immersion corrosion

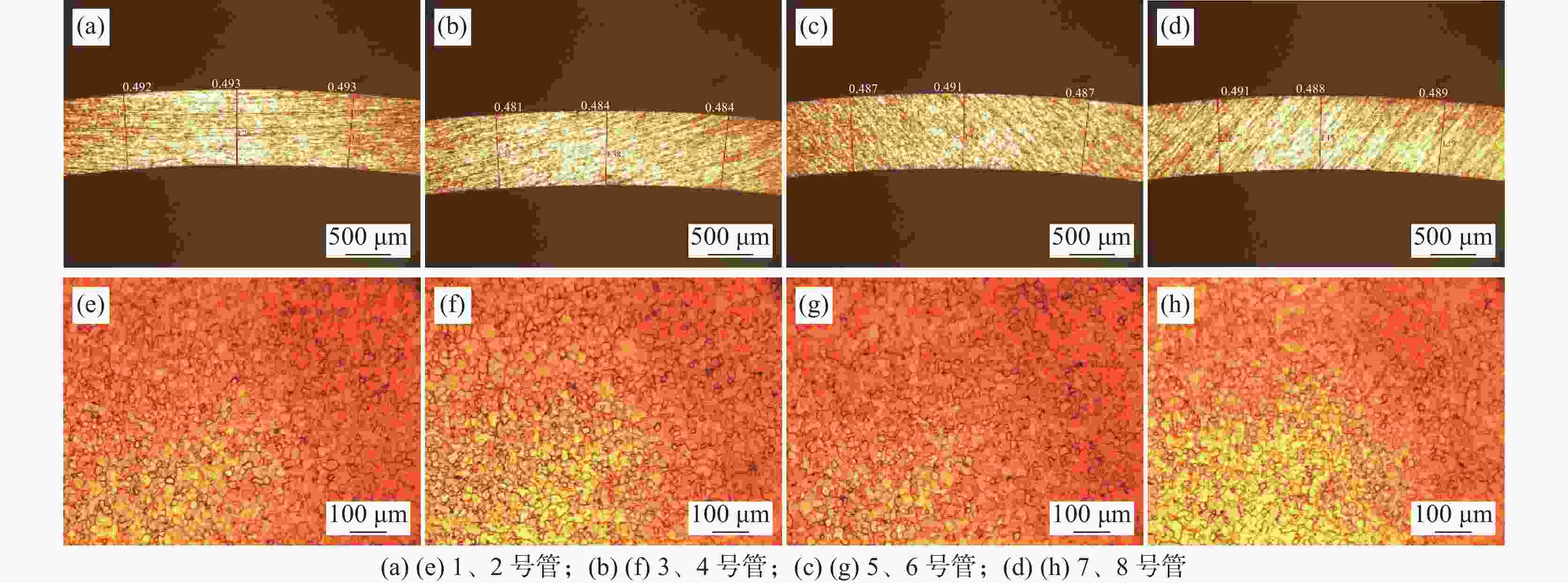

试样编号 母材质量/mm 减薄率/% 腐蚀速率/(μm·a−1) 浸泡前 浸泡后 1 0.494 0.490 0.81 0.533 2 0.494 0.493 0.20 0.133 3 0.494 0.484 2.02 1.332 4 0.494 0.483 2.23 1.465 5 0.494 0.492 0.40 0.266 6 0.493 0.488 1.01 0.666 7 0.494 0.489 1.01 0.666 8 0.493 0.491 0.41 0.266 -

[1] Qu Jie, Sun Yujiang, Yuan Shining, et al. Corrosion analysis and protection of a submarine pipeline[J]. Welded Tube, 2022,45(12):42−45. (曲杰, 孙玉江, 苑世宁, 等. 某海底管道内腐蚀原因分析及防护[J]. 焊管, 2022,45(12):42−45.Qu Jie, Sun Yujiang, Yuan Shining, et al. Corrosion analysis and protection of a submarine pipeline [J]. Welded Tube, 2022, 45(12): 42-45. [2] Li Zhen, Zhao Wei, Yu Kedong, et al. Study on microstructure and corrosion resistance of laser welded joint of TC4 titanium alloy[J]. Welded Tube, 2022,45(10):1−5. (李镇, 赵伟, 于克东, 等. TC4钛合金激光焊接接头组织及耐腐蚀性研究[J]. 焊管, 2022,45(10):1−5.Li Zhen, Zhao Wei, Yu Kedong, et al. Study on microstructure and corrosion resistance of laser welded joint of TC4 titanium alloy[J]. Welded Tube, 2022, 45(10): 1-5. [3] Li Changjiang, Fan Jiangteng, Hu Chenglong, et al. Localization analysis of titanium welded tube for PTA oxidation reaction condenser[J]. Titanium Industry Progress, 2021,38(4):38−42. (李长江, 范江腾, 胡成龙, 等. PTA氧化反应冷凝器用钛焊管国产化分析[J]. 钛工业进展, 2021,38(4):38−42.Li Changjiang, Fan Jiangteng, Hu Chenglong, et al. Localization analysis of titanium welded tube for PTA oxidation reaction condenser[J]. Titanium Industry Progress, 2021, 38(4): 38-42. [4] Guo Jialin, Dong Yanni, Xu Yongfeng, et al. Study on steam corrosion fatigue properties of titanium welded tube used in condenser of nuclear power plant[J]. Non-ferrous Metal Materials and Engineering, 2019,40(1):43−48. (郭佳林, 董燕妮, 徐永锋, 等. 核电站凝汽器用钛焊管蒸汽腐蚀疲劳性能研究[J]. 有色金属材料与工程, 2019,40(1):43−48.Guo Jialin, Dong Yanni, Xu Yongfeng, et al. Study on steam corrosion fatigue properties of titanium welded tube used in condenser of nuclear power plant[J]. Non-ferrous Metal Materials and Engineering, 2019, 40(1): 43-48. [5] Xie Yi. Study on manufacturing process of ultra-thin-walled titanium welded tube[J]. Welded Tube, 2016,39(5):44−48. (谢祎. 超薄壁钛焊管制造工艺研究[J]. 焊管, 2016,39(5):44−48.Xie Yi. Study on manufacturing process of ultra-thin-walled titanium welded tube[J]. Welded Tube, 2016, 39(5): 44-48. [6] Zhang Zhengbang, Hu Zhi’an. Study on corrosion resistance of welded titanium tubes[J]. Chemical Machinery, 1990,17(6):320−323. (张振邦, 胡志安. 焊接钛管的耐腐蚀研究[J]. 化工机械, 1990,17(6):320−323.Zhang Zhengbang, Hu Zhi, an. Study on corrosion resistance of welded titanium tubes[J]. Chemical Machinery, 1990, 17(6): 320-323. [7] Fei Dong. Study on corrosion resistance of tig welded joint of titanium tube[J]. Welded Tube, 2017,40(11):28−32. (费东. 钛管钨极氩弧焊焊接接头耐蚀性研究[J]. 焊管, 2017,40(11):28−32.Fei Dong. Study on corrosion resistance of tig welded joint of titanium tube[J]. Welded Tube, 2017, 40(11): 28-32. [8] Li Xiaojun, Qi Lianyi, Jiang Yiyang. Corrosion resistance of titanium[J]. Chemical Engineer, 2000,(1):46−47. (李晓君, 戚连义, 姜奕阳. 钛的耐腐蚀性能[J]. 化学工程师, 2000,(1):46−47.Li Xiaojun, Qi Lianyi, Jiang Yiyang. Corrosion resistance of titanium[J]. Chemical Engineer, 2000 (1): 46-47. [9] Zhang Lihua, Jin Yunxue, Guo Yuhang. Study on corrosion resistance of titanium matrix composites[J]. Total Corrosion Control, 2007,21(4):12−14. (张丽华, 金云学, 郭宇航. 钛基复合材料的耐腐蚀性能研究[J]. 全面腐蚀控制, 2007,21(4):12−14.Zhang Lihua, JinYunxue, Guo Yuhang. Study on corrosion resistance of titanium matrix composites [J]. Total Corrosion Control, 2007, 21(4): 12-14. [10] Liu Qiang, Song Shengyin, Li Dejun, et al. Research progress in corrosion resistance and application of titanium alloy tubing[J]. Petroleum Mining Machinery, 2014,43(12):88−94. (刘强, 宋生印, 李德君, 等. 钛合金油井管的耐腐蚀性能及应用研究进展[J]. 石油矿场机械, 2014,43(12):88−94. doi: 10.3969/j.issn.1001-3482.2014.12.021Liu Qiang, Song Shengyin, Li Dejun, et al. Research progress in corrosion resistance and application of titanium alloy tubing[J]. Petroleum Mining Machinery, 2014, 43(12): 88-94. doi: 10.3969/j.issn.1001-3482.2014.12.021 -

下载:

下载: