Research on properties of air-quenched steel slag abrasives with different particle sizes

-

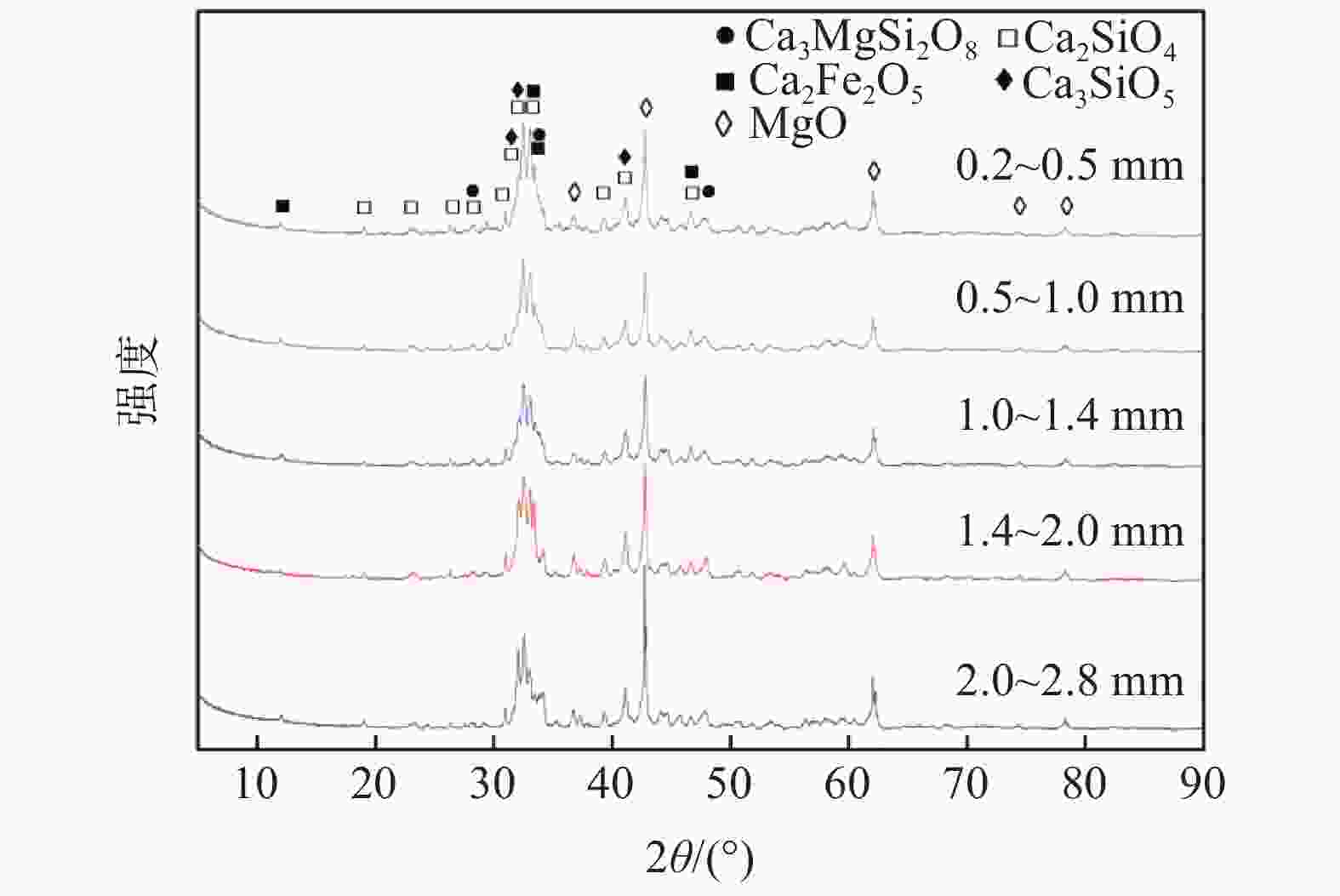

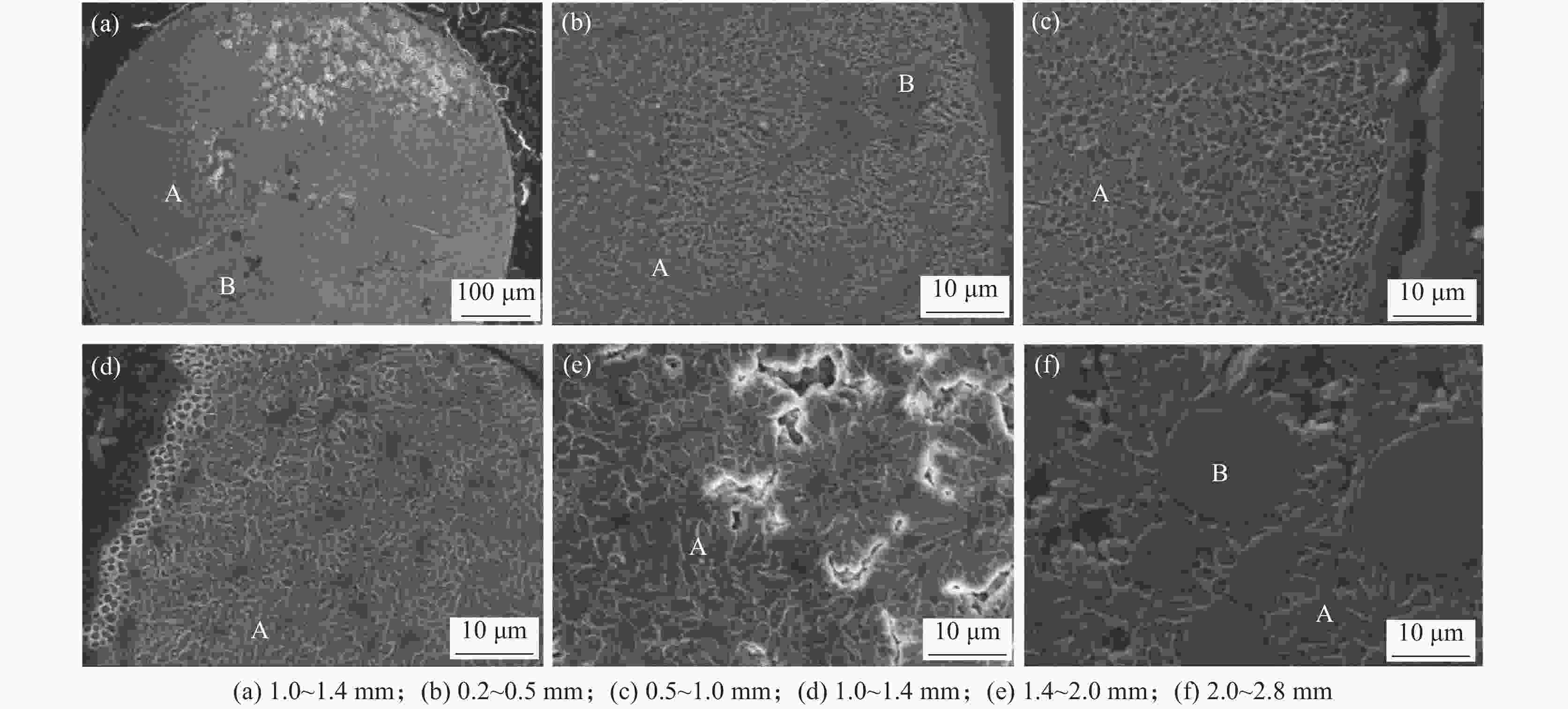

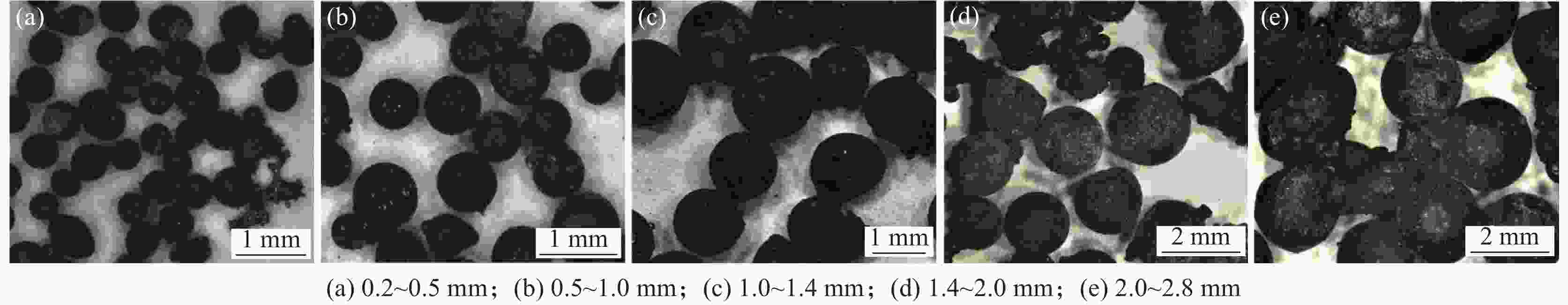

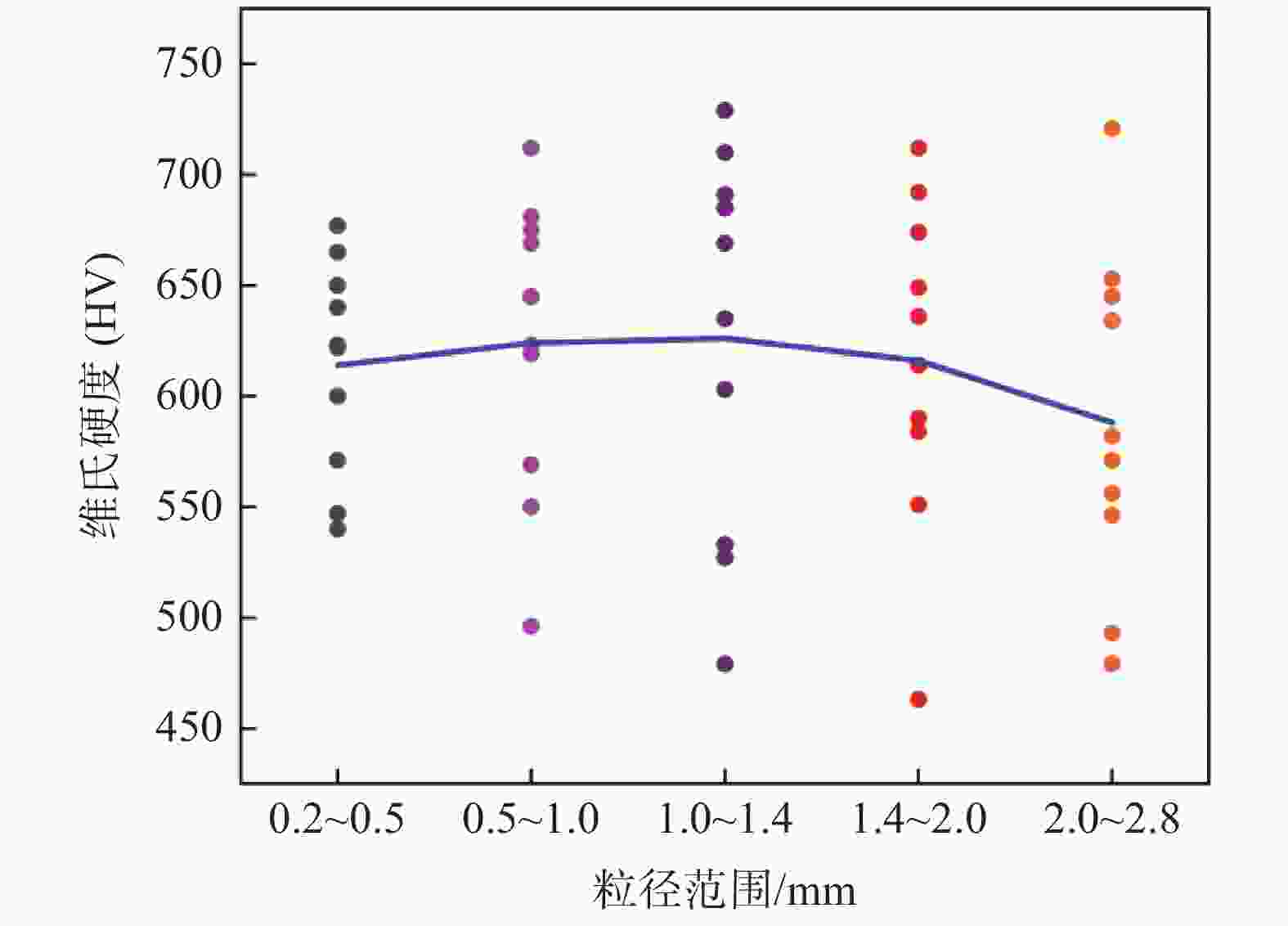

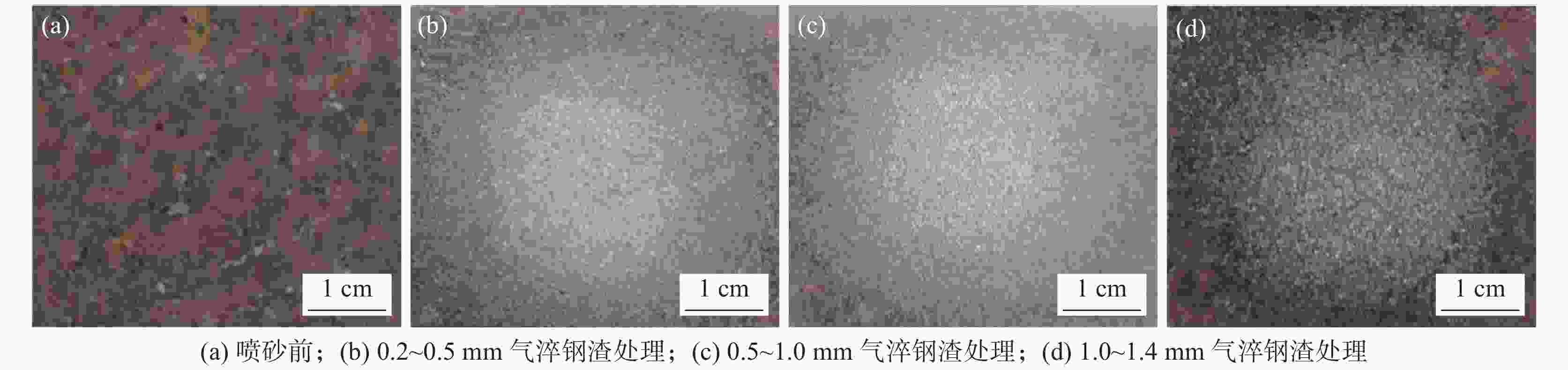

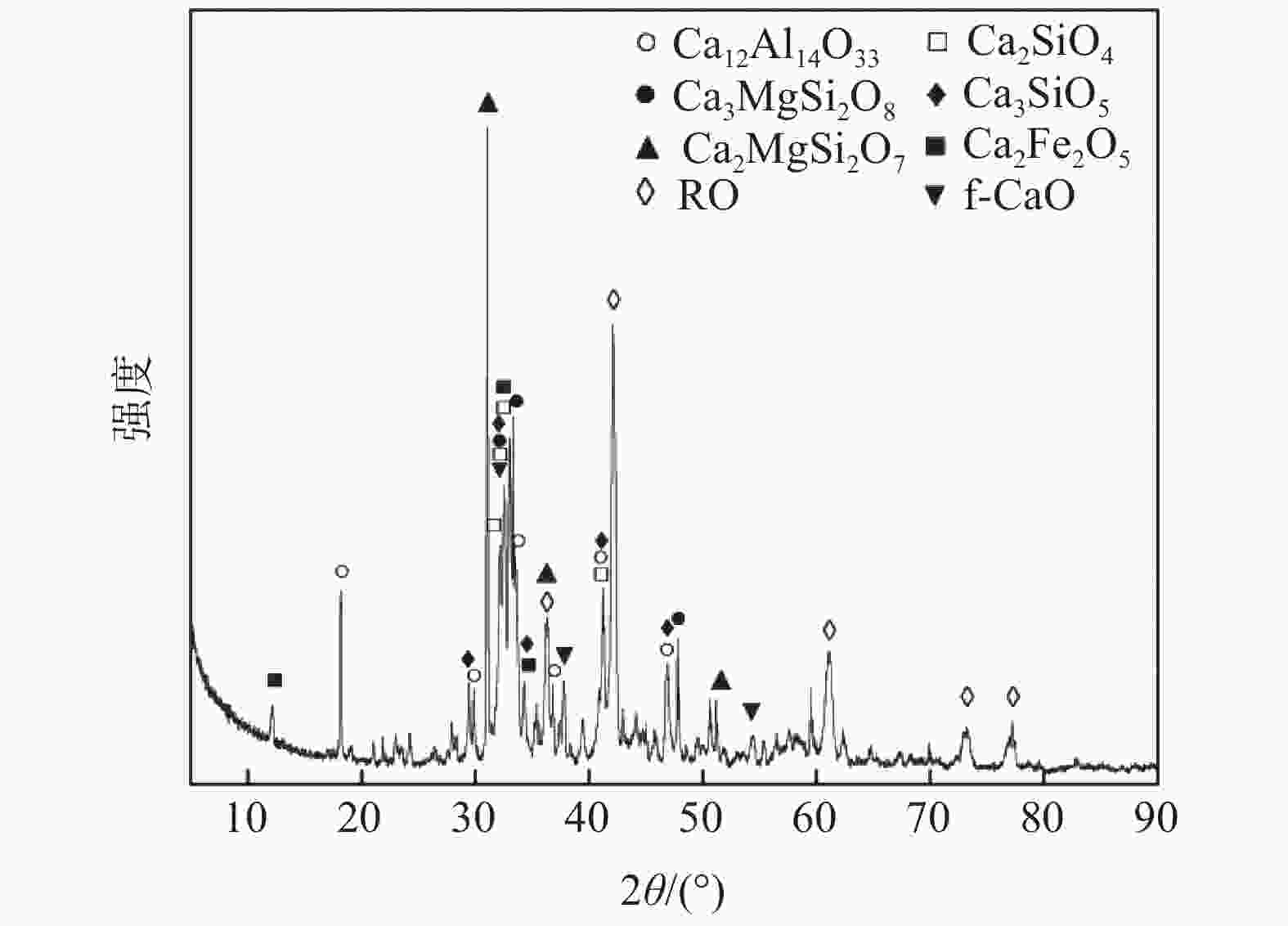

摘要: 以固态钢渣为原料,经电弧炉高温重熔后,采用气淬法制备了不同粒径的钢渣。对比不同粒径气淬钢渣在物相组成、显微结构、表观密度、形貌特征以及硬度方面的异同,并分析气淬钢渣用作喷砂磨料的可行性,选择磨料性能较好的气淬钢渣进行喷砂试验。结果表明,不同粒径气淬钢渣的物相组成基本一致,主要为硅酸钙相和方镁石相;表观密度随着粒径增大而减小,均符合非金属磨料的密度标准;五个粒径的气淬钢渣维氏硬度(HV)平均值均超过588,适合用作喷砂磨料。综合考虑不同粒径下气淬钢渣磨料的性能和喷砂效果,0.5~1.0 mm的气淬钢渣最适合用作喷砂磨料。Abstract: Using solid steel slag as raw material, steel slag with different particle sizes was prepared by air quenching after high-temperature remelting in an electric arc furnace. the differences and similarities of air-quenched steel slag with different particle sizes in terms of phase composition, microstructure, apparent density, morphological characteristics and hardness were compared, and the feasibility of using air-quenched steel slag as sandblasting abrasive was analyzed. The air-quenched steel slag with better abrasive properties was selected for sandblasting experiment. The results show that the phase composition of air-quenched steel slag is similar, mainly calcium silicate phase and cubic magnesite. The apparent density decreases with the increase of particle size, which conforms to the density standard of nonmetallic abrasives. The average Vickers hardness of the five particle sizes of air-quenched steel slag is more than 588, which is suitable for abrasive blasting. Considering the performance and blasting effect of different particle sizes of air-quenched steel slag, 0.5~1.0 mm air-quenched steel slag is the most suitable for abrasive blasting.

-

Key words:

- air-quenched steel slag /

- sandblasting abrasive /

- particle sizes /

- apparent density /

- hardness

-

表 1 钢渣的主要化学成分

Table 1. Main chemical compositions of steel slags

% 样品 CaO SiO2 MgO Al2O3 TFe FeO Fe2O3 MFe TiO2 转炉钢渣 38.52 13.96 11.92 6.02 17 1.88 20.2 1.4 0.74 气淬钢渣 47.06 18.52 14.68 3.16 6.04 3.58 1.21 表 2 气淬钢渣的表观密度

Table 2. Apparent density of air-quenched steel slag

粒径范围/mm 表观密度/(g·cm−3) 0.2~0.5 3.299 0.5~1.0 3.164 1.0~1.4 3.129 1.4~2.0 3.100 2.0~2.8 3.069 钢渣特种型砂 炼铁炉渣 石榴石 钢砂 棕刚玉 铜炉渣 3.70 3.00~3.30 4.10 7.40 3.90 3.40~3.60 表 4 工件喷砂前后的表面粗糙度

Table 4. Surface roughness of workpiece before and after sandblasting

粒径范围/mm 表面粗糙度/μm 备注 Ra Rz 喷砂前 0.104 0.520 锈蚀工件 0.2~0.5 2.596 18.363 喷砂后 0.5~1.0 3.370 20.178 喷砂后 1.0~1.4 5.076 33.297 喷砂后 -

[1] Wu Yuedong, Peng Ben, Wu Long, et al. Review on global development of treatment and utilization of steel slag[J]. Environmental Engineering, 2021,39(1):161−165. (吴跃东, 彭犇, 吴龙, 等. 国内外钢渣处理与资源化利用技术发展现状综述[J]. 环境工程, 2021,39(1):161−165. doi: 10.13205/j.hjgc.202101025Wu Yuedong, Peng Ben, Wu Long, et al. Review on global development of treatment and utilization of steel slag[J]. Environmental Engineering, 2021, 39(1): 161-165. doi: 10.13205/j.hjgc.202101025 [2] Ma Lintao, Sheng Guohua, Wang Xiaoyu, et al. Experimental study on the compressive strength of cement-based composites with super high volume of steel slag[J]. Concrete, 2022,(8):102−104. (马麟涛, 盛国华, 王肖宇, 等. 超高掺量钢渣水泥基复合材料抗压试验研究[J]. 混凝土, 2022,(8):102−104. doi: 10.3969/j.issn.1002-3550.2022.08.022Ma Lintao, Sheng Guohua, Wang Xiaoyu, et al. Experimental study on the compressive strength of cement-based composites with super high volume of steel slag [J]. Concrete, 2022(8): 102-104. doi: 10.3969/j.issn.1002-3550.2022.08.022 [3] Yan Feng, Huang Xiaoming, Guo Rongxin, et al. Research status of improving volume stability of steel slag by pretreatment[J]. Iron and Steel, 2022,57(10):30−42. (颜峰, 黄小明, 郭荣鑫, 等. 预处理改善钢渣体积安定性的研究现状[J]. 钢铁, 2022,57(10):30−42.Yan Feng, Huang Xiaoming, Guo Rongxin, et al. Research status of improving volume stability of steel slag by pretreatment[J]. Iron and Steel, 2022, 57(10): 30-42. [4] Zhang Jun, Yan Dingliu, Qi Yuanhong, et al. Difficulty analysis on treatment and utilization of iron and steel smelting slag[J]. Iron and Steel, 2020,55(1):1−5. (张俊, 严定鎏, 齐渊洪, 等. 钢铁冶炼渣的处理利用难点分析[J]. 钢铁, 2020,55(1):1−5. doi: 10.13228/j.boyuan.issn0449-749x.20190171Zhang Jun, Yan Dingliu, Qi Yuanhong, et al. Difficulty analysis on treatment and utilization of iron and steel smelting slag[J]. Iron and Steel, 2020, 55(1): 1-5. doi: 10.13228/j.boyuan.issn0449-749x.20190171 [5] Piatak N M, Parsons M S, Seal R R. Characteristics and environmental aspects of slag: A review[J]. Applied Geochemistry, 2015,57:236−266. doi: 10.1016/j.apgeochem.2014.04.009 [6] O’Connor J, Nguyen T B T, Honeyands T, et al. Production, characterization, utilization, and beneficial soil application of steel slag: A review[J]. Journal of Hazardous Materials, 2021,419:126478. doi: 10.1016/j.jhazmat.2021.126478 [7] Naidu T S, Sheridan C M, Dyk L D V. Basic oxygen furnace slag: Review of current and potential uses[J]. Minerals Engineering, 2020,149:106234. doi: 10.1016/j.mineng.2020.106234 [8] Ren Xu, Wang Huigang, Wu Yuedong, et al. Discussion on steel slag treatment and resource utilization under carbon peaking and carbon neutrality goals[J]. Environmental Engineering, 2022,40(8):220−224. (任旭, 王会刚, 吴跃东, 等. “双碳”目标下钢渣处理及资源化利用探讨[J]. 环境工程, 2022,40(8):220−224.Ren Xu, Wang Huigang, Wu Yuedong, et al. Discussion on steel slag treatment and resource utilization under carbon peaking and carbon neutrality goals[J]. Environmental Engineering, 2022, 40(8): 220-224. [9] Amran M, Murali G, Khalid N H A, et al. Slag uses in making an ecofriendly and sustainable concrete: A review[J]. Construction and Building Materials, 2021,272:121942. doi: 10.1016/j.conbuildmat.2020.121942 [10] Pan Enyi, Chen Hongtang, Guo Peiquan. Review on protective pretreatment technology on outer surface coating on ships[J]. Modern Manufacturing Technology and Equipment, 2020,283(6):40−43. (潘恩义, 陈洪堂, 郭培全. 舰船外表面涂层防护预处理技术的研究进展[J]. 现代制造技术与装备, 2020,283(6):40−43. doi: 10.3969/j.issn.1673-5587.2020.06.015Pan Enyi, Chen Hongtang, Guo Peiquan. Review on protective pretreatment technology on outer surface coating on ships[J]. Modern Manufacturing Technology and Equipment, 2020, 283(6): 40-43. doi: 10.3969/j.issn.1673-5587.2020.06.015 [11] Tang Oujing. Research and development of blasting abrasive made of steelmaking slag[J]. Baosteel Technology, 2015,183(5):23−28. (唐欧靖. 钢渣型喷砂除锈材料的研究与应用开发[J]. 宝钢技术, 2015,183(5):23−28. doi: 10.3969/j.issn.1008-0716.2015.05.005Tang Oujing. Research and development of blasting abrasive made of steelmaking slag[J]. Baosteel Technology, 2015, 183(5): 23-28. doi: 10.3969/j.issn.1008-0716.2015.05.005 [12] Zhong Peng, Zhou Li, Chang Lizhong, et al. Feasibility and application effect research of the wind quenching slag as sand blasting abrasive[J]. Surface Technology, 2014,43(2):49−54. (钟鹏, 周俐, 常立忠, 等. 风淬转炉渣作为喷砂磨料的可行性及效果研究[J]. 表面技术, 2014,43(2):49−54. doi: 10.16490/j.cnki.issn.1001-3660.2014.02.024Zhong Peng, Zhou Li, Chang Lizhong, et al. Feasibility and application effect research of the wind quenching slag as sand blasting abrasive[J]. Surface Technology, 2014, 43(2): 49-54. doi: 10.16490/j.cnki.issn.1001-3660.2014.02.024 [13] Gu Wenfeng, Diao Jiang, Liu Liang, et al. Investigation of properties of air-quenched steel slag as sandblasting abrasive[J]. JOM, 2021,73(10):2995−2999. doi: 10.1007/s11837-021-04819-3 [14] Martins A C P, Franco C J M, Costa L C B, et al. Steel slags in cement-based composites: An ultimate review on characterization, applications and performance[J]. Construction and Building Materials, 2021,291:123265. doi: 10.1016/j.conbuildmat.2021.123265 [15] Wang Jun, Li Guangqiang, Yang Xueping, et al. Change of slag composition during electroslag remelting process and prediction of the dissolved oxygen content in steel.[J]. Journal of Iron and Steel Research, 2015,27(6):18−23. (王珺, 李光强, 杨雪萍, 等. 电渣重熔过程中渣成分变化及钢中氧含量预测[J]. 钢铁研究学报, 2015,27(6):18−23. doi: 10.13228/j.boyuan.issn1001-0963.20140136Wang Jun, Li Guangqiang, Yang Xueping, et al. Change of slag composition during electroslag remelting process and prediction of the dissolved oxygen content in steel. [J]. Journal of Iron and Steel Research, 2015, 27(6): 18-23. doi: 10.13228/j.boyuan.issn1001-0963.20140136 [16] Schollbach K, Ahmed M J, Laan S R. The mineralogy of air granulated converter slag[J]. International Journal of Ceramic Engineering & Science, 2020,3(1):21−36. [17] Huang Yi, Xu Guoping, Yang Wei. Comparative analysis of physicochemical properties and utilization way of steel slags treated with different methods[J]. Multipurpose Utilization of Mineral Resources, 2014,(6):62−66. (黄毅, 徐国平, 杨巍. 不同处理工艺的钢渣理化性质和应用途径对比分析[J]. 矿产综合利用, 2014,(6):62−66.Huang Yi, Xu Guoping, Yang Wei. Comparative analysis of physicochemical properties and utilization way of steel slags treated with different methods[J]. Multipurpose Utilization of Mineral Resources, 2014(6): 62-66. [18] Arifvianto B, Suyitno, Wibisono K A, et al. Influence of grit blasting treatment using steel slag balls on the subsurface microhardness, surface characteristics and chemical composition of medical grade 316L stainless steel[J]. Surface and Coatings Technology, 2012,210:176−182. doi: 10.1016/j.surfcoat.2012.09.014 [19] Pei Jingjing, Zhang Yuzhu, Xing Hongwei, et al. Beading mechanism and performance of porous steel slag microbead abrasive[J]. Crystals, 2021,11(11):1377. doi: 10.3390/cryst11111377 [20] Yang Gang, Fu Jianhua, Wang Hailong, et al. Research on the technology of steel slag applying to non-metallic blast-cleaning abrasive[J]. China Offshore Platform, 2012,27(1):54−56. (杨刚, 傅建华, 汪海龙, 等. 钢渣型砂用于非金属除锈磨料技术探讨[J]. 中国海洋平台, 2012,27(1):54−56. doi: 10.3969/j.issn.1001-4500.2012.01.012Yang Gang, Fu Jianhua, Wang Hailong, et al. Research on the technology of steel slag applying to non-metallic blast-cleaning abrasive[J]. China Offshore Platform, 2012, 27(1): 54-56. doi: 10.3969/j.issn.1001-4500.2012.01.012 [21] Kang Yue, Liu Chao, Zhang Yuzhu, et al. Phase transition simulation of air quenching blast furnace slag during cooling and solidification[J]. China Metallurgy, 2022,32(5):116−124. (康月, 刘超, 张玉柱, 等. 气淬高炉熔渣冷却凝固相变特性仿真[J]. 中国冶金, 2022,32(5):116−124.Kang Yue, Liu Chao, Zhang Yuzhu, et al. Phase transition simulation of air quenching blast furnace slag during cooling and solidification[J]. China Metallurgy, 2022, 32(5): 116-124. [22] Rao Lei, Chen Guangyan, Zhou Chenhui, et al. Experimental research on steel slag as sand-blasting abrasive[J]. Journal of Anhui University of Technology(Natural Science), 2015,32(1):16−21. (饶磊, 陈广言, 周晨辉, 等. 钢渣用于喷砂磨料的试验研究[J]. 安徽工业大学学报(自然科学版), 2015,32(1):16−21.Rao Lei, Chen Guangyan, Zhou Chenhui, et al. Experimental research on steel slag as sand-blasting abrasive[J]. Journal of Anhui University of Technology(Natural Science), 2015, 32(1): 16-21. -

下载:

下载: