High temperature mechanical properties and hot working properties of high magnetic orientation silicon steel

-

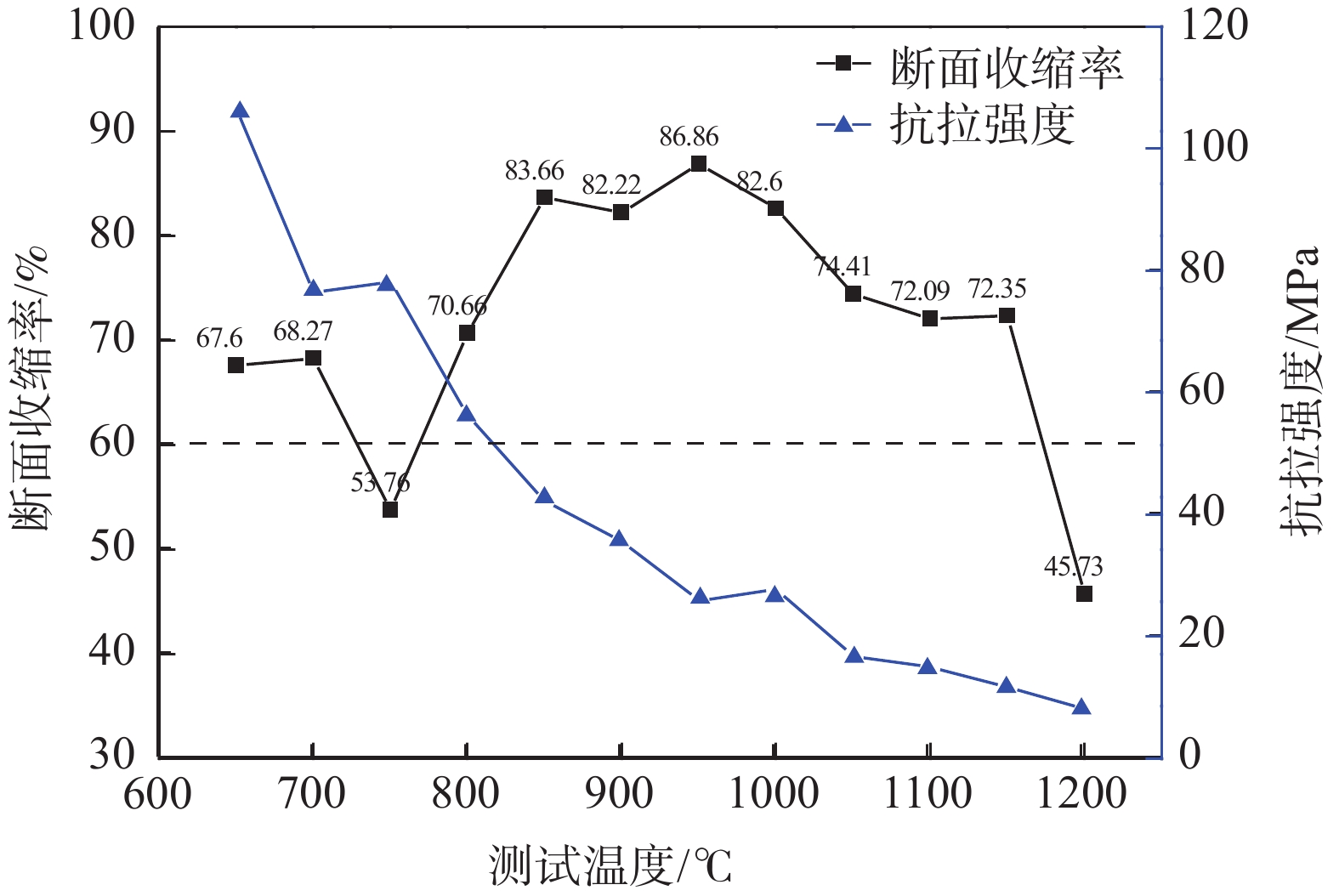

摘要: 采用Gleeble3800热模拟试验机对高磁感取向硅钢铸坯进行高温拉伸和高温压缩试验,研究温度对高磁感取向硅钢的高温力学性能(抗拉强度和断面收缩率)的影响关系,同时研究了高磁感取向硅钢的热加工性能。结果表明,高磁感取向硅钢的第Ⅰ脆性区温度为熔点~1200 ℃,第Ⅲ脆性区温度为750 ℃附近,不存在第Ⅱ脆性区;750 ℃试样断裂机制为沿晶脆性,且在断口处存在Al、Si等的氧化夹杂物;当形变量和温度一定的情况下,试样随应变速率增大,变形抗力大幅提高。Abstract: In this paper, Gleeble3800 thermal simulation test machine was used to conduct high temperature tensile and high temperature compression experiments on high magnetic induction oriented silicon steel billets. The influence of temperature on high temperature mechanical properties (tensile strength and section shrinkage) of high magnetic induction oriented silicon steel, and the hot working properties of high magnetic induction oriented silicon steel were studied. The results showed that the temperature of the first brittle zone of high magnetic orientation silicon steel was around the melting point ~1200 ℃, and the temperature of the third brittle zone was about 750 ℃, and there was no second brittle zone. The fracture mechanism of the sample at 750 ℃ is intergranular brittle fracture, and there are Al, Si and other oxidation inclusions at the fracture surface. When the shape variable and temperature are constant, the deformation resistance of the specimen increases with the increase of strain rate.

-

表 1 试样的主要化学成分

Table 1. Main chemical composition of samples

% C Si Mn P S Cr 0.05~0.06 3.0~3.3 0.08~0.1 0.02~0.03 0.005~0.009 <0.15 表 2 拉伸试验数据

Table 2. Tensile tests data

测试温度/℃ 断后总长度/mm 断面收缩率/% 抗拉强度/MPa 650 124.93 67.60 106.7 700 124.95 68.27 76.4 750 123.53 53.76 78.2 800 125.21 70.66 56.3 850 127.49 83.66 42.2 900 127.34 82.22 35.7 950 127.56 86.86 25.9 1000 127.20 82.60 27.8 1050 124.83 74.41 16.8 1100 124.42 72.09 15.0 1150 124.35 72.35 11.7 1200 122.54 45.73 8.2 -

[1] 何忠治, 赵宇, 罗海文. 电工钢[M]. 北京: 冶金工业出版社, 2012.He Zhongzhi , Zhao Yu, Luo Haiwen. Electrical steel [M]. Beijing: Metallurgical Industry Press, 2012. [2] Duan Weiping, Yuan Hang, Li Jingshe. High temperature mechanical properties of 30CrMo fine blanking steel continuous casting slab[J]. Special Steel, 2021,42(5):4. (段卫平, 袁航, 李京社, 等. 30CrMo精冲钢连铸板坯高温力学性能研究[J]. 特殊钢, 2021,42(5):4.Duan Weiping, Yuan Hang, Li Jingshe. High temperature mechanical properties of 30 CrMo fine blanking steel continuous casting slab[J]. Special Steel, 2021, 42(5): 4. [3] Li Li, Du Yizhe, Wang Qinzheng, et al. Mechanical properties of Q345 steel continuous casting billet under compression at high temperature[J]. China Metallurgy, 2021,31(4):5. (李丽, 杜一哲, 汪勤政, 等. Q345钢连铸坯压缩状态下的高温力学性能[J]. 中国冶金, 2021,31(4):5.Li Li, Du Yizhe, Wang Qinzheng, et al. Mechanical properties of Q345 steel continuous casting billet under compression at high temperature [J]. China Metallurgy, 2021, 31(4): 5. [4] Yuan Hang, Yang Shufeng, Wang Tiantian, et al. Research progress of transverse crack at corner of continuous casting slab in subperitectic microalloyed steel[J]. China Metallurgy, 2020,30(10):1−8. (袁航, 杨树峰, 王田田, 等. 亚包晶微合金钢连铸板坯角部横裂纹研究进展[J]. 中国冶金, 2020,30(10):1−8.Yuan Hang, Yang Shufeng, Wang Tiantian, et al. Research progress of transverse crack at corner of continuous casting slab in subperitectic microalloyed steel [J]. China Metallurgy, 2020, 30(10): 1-8. [5] Ma Jingchao. Cause analysis of transverse crack in abnormal corner of slab[J]. China Metallurgy, 2021,31(6):77−81. (马静超. 板坯非正常角部横裂纹产生原因分析[J]. 中国冶金, 2021,31(6):77−81.Ma Jingchao. Cause analysis of transverse crack in abnormal corner of slab [J]. China Metallurgy, 2021, 31(6): 77-81. [6] Lan Peng, Tang Haiyan, Ji Yuan, et al. Thermal plasticity and fracture mechanism of Fe-22Mn-0.7C TWIP steel[J]. Journal of Engineering Science, 2016,38(6):795−804. (兰鹏, 唐海燕, 纪元, 等. Fe-22Mn-0.7C TWIP钢的热塑性与断裂机制[J]. 工程科学学报, 2016,38(6):795−804.Lan Peng, Tang Haiyan, Ji Yuan, et al. Thermal plasticity and fracture mechanism of Fe-22 Mn-0.7 C TWIP steel [J]. Journal of Engineering Science, 2016, 38(6): 795-804. [7] Pei Yinghao, Zhang Chen, Chen Qi 'an, et al. High temperature mechanical properties of oriented silicon steel[J]. Special Steel, 2010,31(4):3. (裴英豪, 张晨, 陈其安, 等. 取向硅钢的高温力学性能[J]. 特殊钢, 2010,31(4):3. doi: 10.3969/j.issn.1003-8620.2010.04.016Pei Yinghao, Zhang Chen, Chen Qi 'an, et al. High temperature mechanical properties of oriented silicon steel [J]. Special Steel, 2010, 31(4): 3. doi: 10.3969/j.issn.1003-8620.2010.04.016 [8] Hou Zewang, Zhang Chen, Xiang Li, et al. Study on thermoplasticity of common oriented silicon steel[J]. Iron Steel Vanadium Titanium, 2010,31(4):5. (侯泽旺, 张晨, 项利, 等. 普通取向硅钢的热塑性研究[J]. 钢铁钒钛, 2010,31(4):5.Hou Zewang, Zhang Chen, Xiang Li, et al. Study on thermoplasticity of common oriented silicon steel [J]. Iron Steel Vanadium Titanium, 2010, 31(4): 5. [9] Chi Hongxiao, Xu Huixia, Fang Feng, et al. High temperature mechanical properties of M2 high speed steel[J]. China Metallurgy, 2016,26(1):31−34. (迟宏宵, 徐辉霞, 方峰, 等. M2高速钢的高温力学性能[J]. 中国冶金, 2016,26(1):31−34.Chi Hongxiao, Xu Huixia, Fang Feng, et al. High temperature mechanical properties of M2 high speed steel [J]. China Metallurgy, 2016, 26(1): 31-34. [10] Zeng Xiangqun, Liu Runzao, Zhu Rong, et al. Research on hot working properties of high nitrogen steel[J]. Industrial Heating, 2016,45(2):1−4,11. (曾祥群, 刘润藻, 朱荣, 等. 高氮钢热加工性能研究[J]. 工业加热, 2016,45(2):1−4,11. doi: 10.3969/j.issn.1002-1639.2016.02.001Zeng Xiangqun, Liu Runzao, Zhu Rong, et al. Research on hot working properties of high nitrogen steel [J]. Industrial Heating, 2016, 45(2): 1-4, 11. doi: 10.3969/j.issn.1002-1639.2016.02.001 [11] Lin Lin. Research on hot working performance of duplex stainless steel[J]. Engineering Technology Research, 2017,(7):89−91. (林琳. 双相不锈钢的热加工性能研究[J]. 工程技术研究, 2017,(7):89−91.Lin Lin. Research on hot working performance of duplex stainless steel [J]. Engineering Technology Research, 2017(7): 89- 91. [12] Wen Sheng, Han Chao, Bao Ze, et al. Flow behavior characteristics and processing map of Fe-6.5%Si alloys during hot compression[J]. Metals - Open Access Metallurgy Journal, 2018,8(3):186. (温胜, 韩超, 鲍泽, 等. Fe-6.5%Si合金热压缩过程研究[J]. 金属, 2018,8(3):186.Wen Sheng , Han Chao , Bao Ze , et al. Flow behavior characteristics and processing map of Fe-6.5%Si alloys during hot compression[J]. Metals - Open Access Metallurgy Journal, 2018, 8(3): 186. [13] Yuan Pengfei, Wu Huajie, Yue Feng, et al. Study on mechanical properties of Nb-Ti-V microalloyed ship plate steel at high temperature[J]. Iron Steel Vanadium Titanium, 2012,33(1):76−81. (元鹏飞, 吴华杰, 岳峰, 等. Nb-Ti-V微合金化船板钢的高温力学性能研究[J]. 钢铁钒钛, 2012,33(1):76−81.Yuan Pengfei, Wu Huajie, Yue Feng, et al. Study on mechanical properties of Nb-Ti-V microalloyed ship plate steel at high temperature [J]. Iron Steel Vanadium Titanium, 2012, 33(1): 76-81. [14] Wang Jianfeng, Deng Shen, Rao Jiangping, et al. Study on mechanical properties of niob-titanium and niob-vanadium titanium microalloyed steel at high temperature[J]. Steelmaking, 2011,27(1):46−49. (王建锋, 邓深, 饶江平, 等. 铌钛及铌钒钛微合金钢的高温力学性能研究[J]. 炼钢, 2011,27(1):46−49.Wang Jianfeng, Deng Shen, Rao Jiangping, et al. Study on mechanical properties of niob-titanium and niob-vanadium titanium microalloyed steel at high temperature [J]. Steelmaking, 2011, 27(1): 46-49. [15] 蔡开科. 连铸坯质量控制[M]. 北京: 冶金工业出版社, 2010.Cai Kaike. Quality control of continuous casting billet [M]. Beijing: Metallurgical Industry Press, 2010. [16] Ai Xi, Sun Yanhui, Zeng Yanan, et al. Effect of low temperature brittle zone on surface transverse crack of S355 J2 steel[J]. Steelmaking, 2014,30(3):69−73. (艾西, 孙彦辉, 曾亚南, 等. S355 J2钢低温脆性区对表面横裂纹的影响研究[J]. 炼钢, 2014,30(3):69−73.Ai Xi, Sun Yanhui, Zeng Yanan, et al. Effect of low temperature brittle zone on surface transverse crack of S355 J2 steel [J]. Steelmaking, 2014, 30(3): 69-73. [17] Kong Wei, Chen Yingfeng, Cang Daqiang. Effect of different hot rolling parameters on deformation resistance of non-oriented silicon steel[J]. Science Technology and Engineering, 2018,18(34):6. (孔为, 陈迎锋, 苍大强. 不同热轧参数对无取向硅钢变形抗力的影响[J]. 科学技术与工程, 2018,18(34):6. doi: 10.3969/j.issn.1671-1815.2018.34.005Kong Wei, Chen Yingfeng, Cang Daqiang. Effect of different hot rolling parameters on deformation resistance of non-oriented silicon steel[J]. Science Technology and Engineering, 2018, 18(34): 6. doi: 10.3969/j.issn.1671-1815.2018.34.005 [18] Wang Dongchen, Ruan Shipeng, Wang Ningtao, et al. Effect of Si content on deformation resistance of medium carbon cold heading steel[J]. Steel Rolling, 2021,38(4):5. (王冬晨, 阮士朋, 王宁涛, 等. Si含量对中碳冷镦钢变形抗力的影响[J]. 轧钢, 2021,38(4):5.Wang Dongchen, Ruan Shipeng, Wang Ningtao, et al. Effect of Si content on deformation resistance of medium carbon cold heading Steel[J]. Steel Rolling, 2021, 38(4): 5. [19] Ma Menghan, Huang Ting, Shen Yongfeng. Effect of rolling process on microstructure and mechanical properties of D6A steel[J]. Materials Science and Technology, 2021,29(1):7. (马梦晗, 黄婷, 申勇峰. 轧制工艺对D6A钢微观组织和力学性能的影响[J]. 材料科学与工艺, 2021,29(1):7.Ma Menghan, Huang Ting, Shen Yongfeng. Effect of rolling process on microstructure and mechanical properties of D6 A steel [J]. Materials Science and Technology, 2021, 29(1): 7. [20] 张文东. H型钢热轧温度场及轧制力模拟[D]. 昆明: 昆明理工大学, 2010.Zhang Wendong. Simulation of temperature field and rolling force of H-beam hot rolling [D]. Kunming: Kunming University of Science and Technology, 2010. -

下载:

下载: