Optimization of VAR melting process of TB9 titanium alloy based on numerical simulation

-

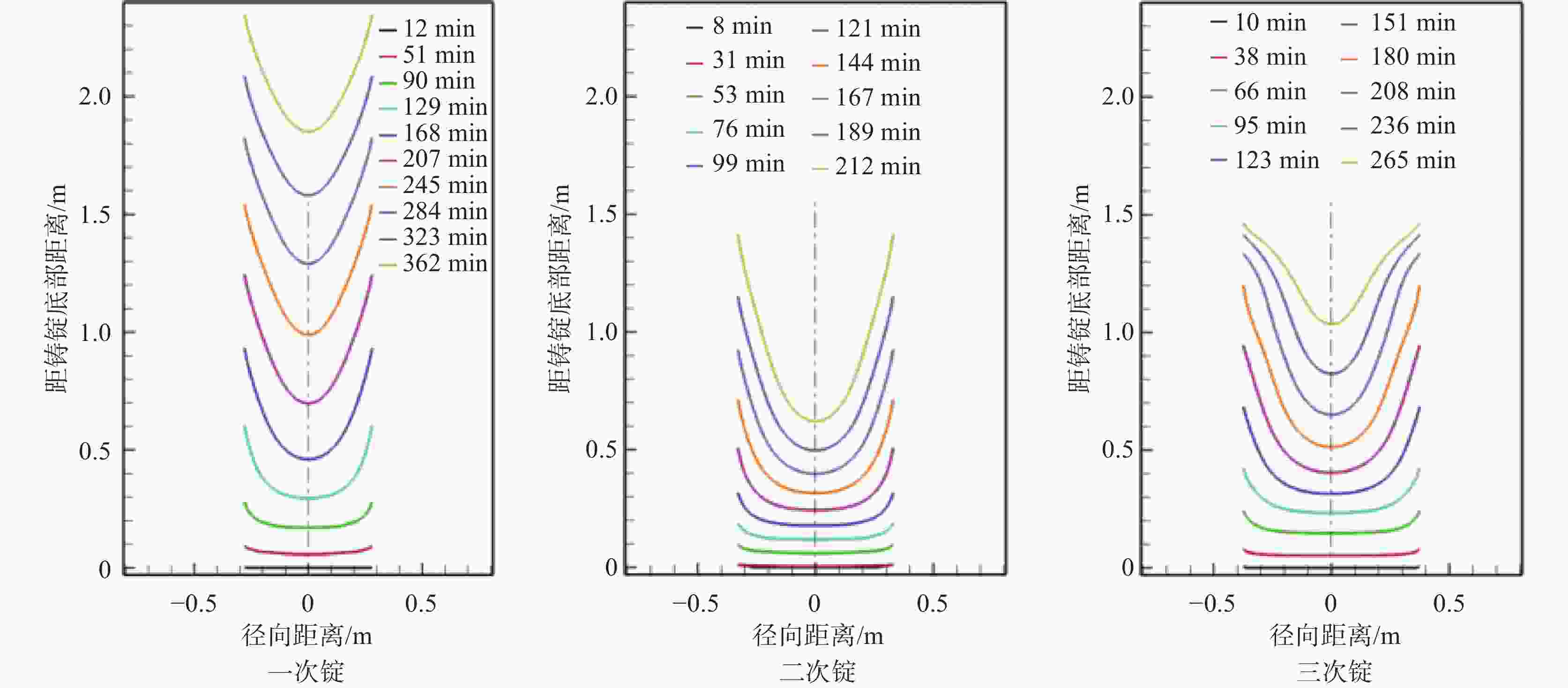

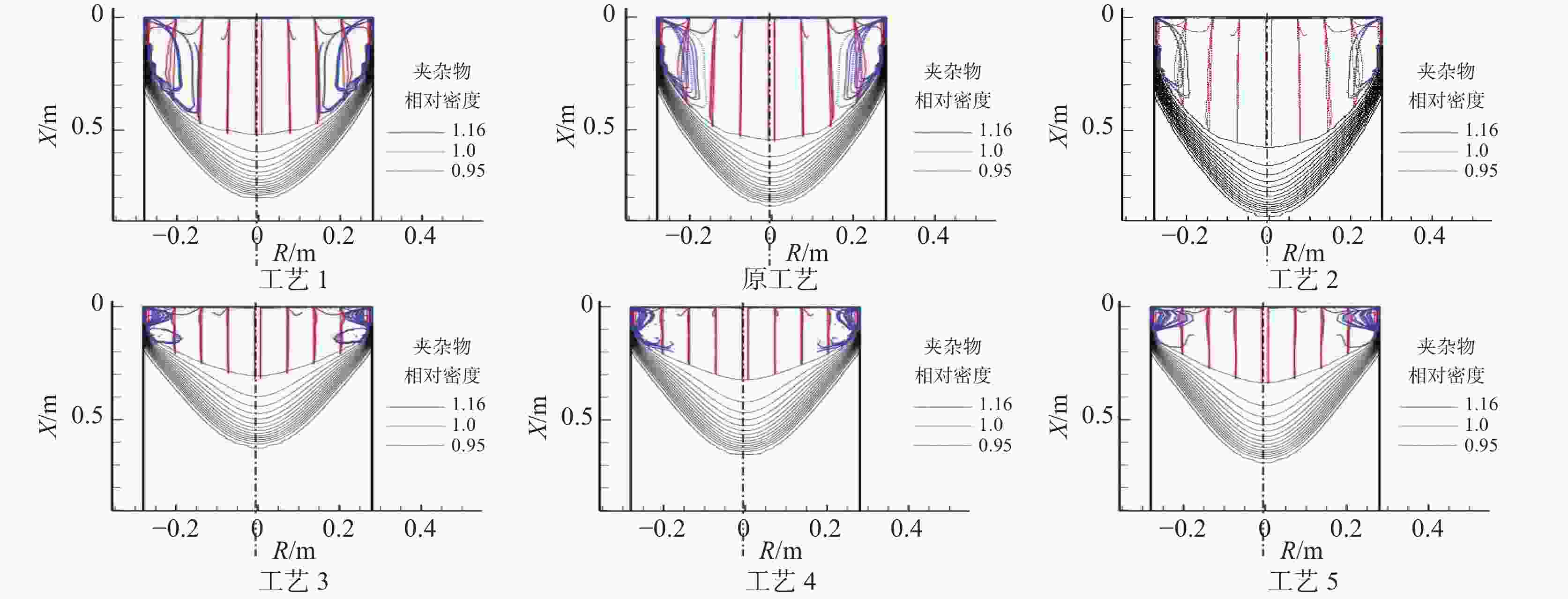

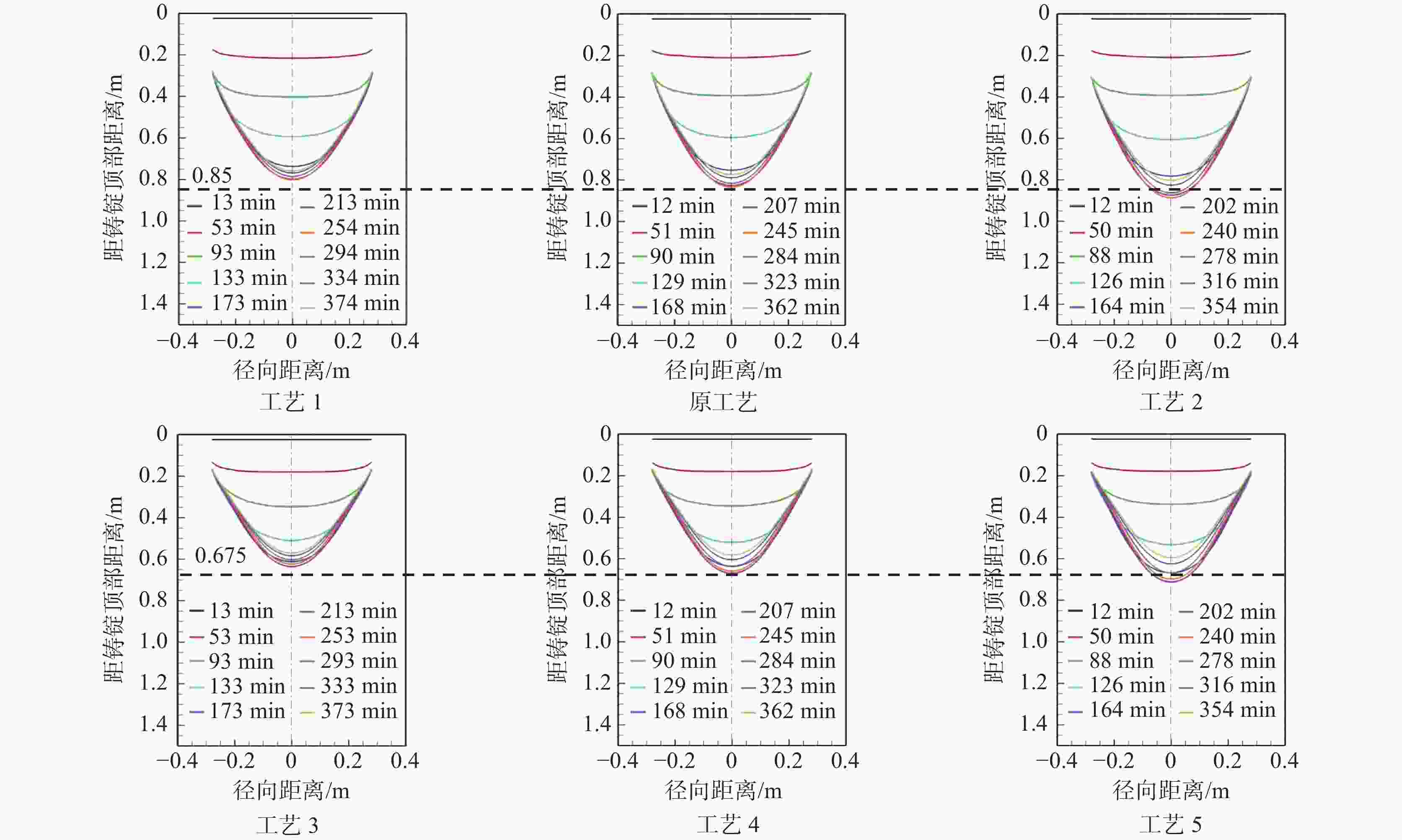

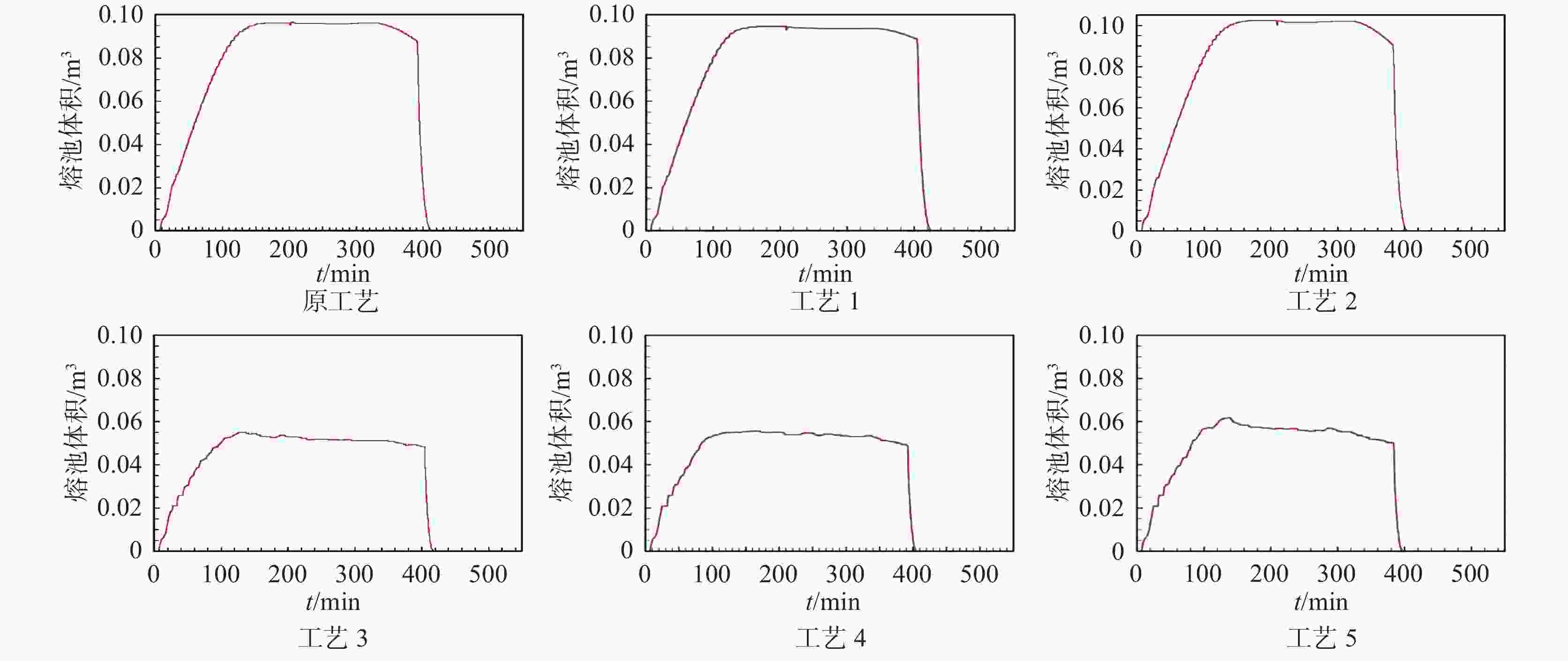

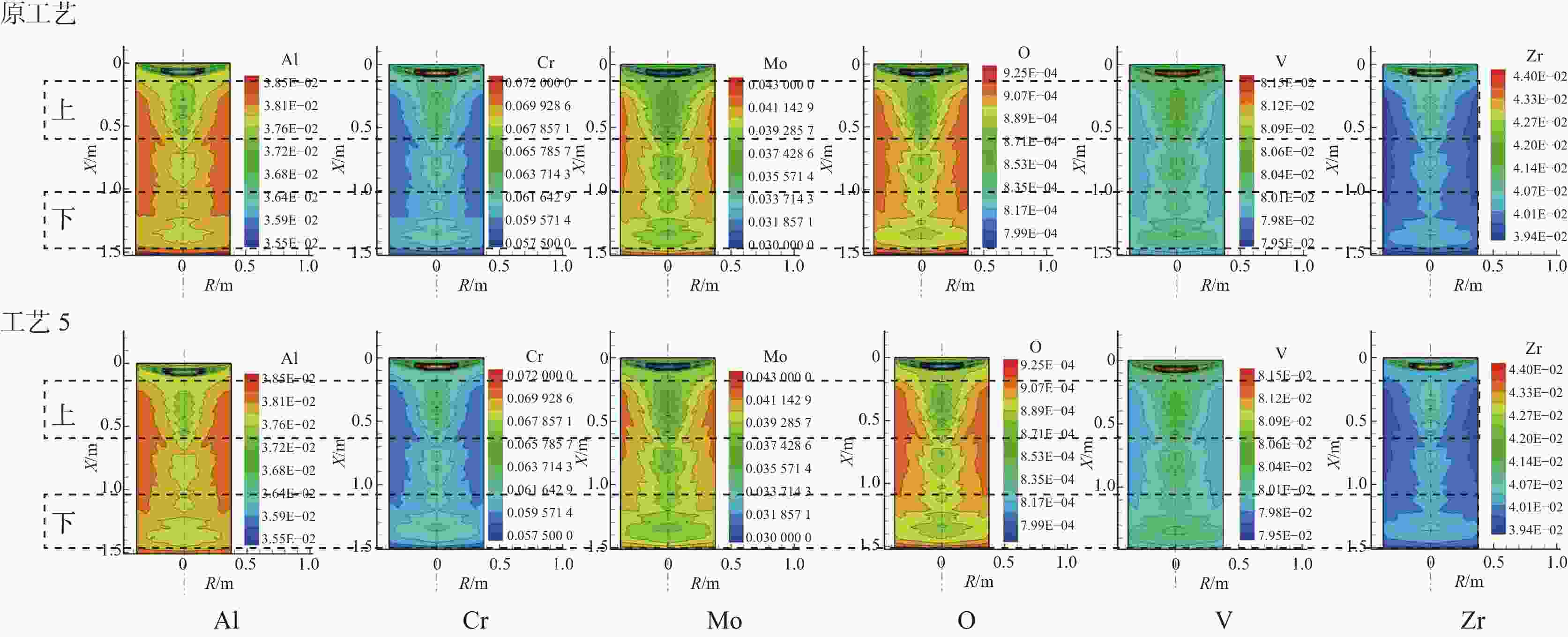

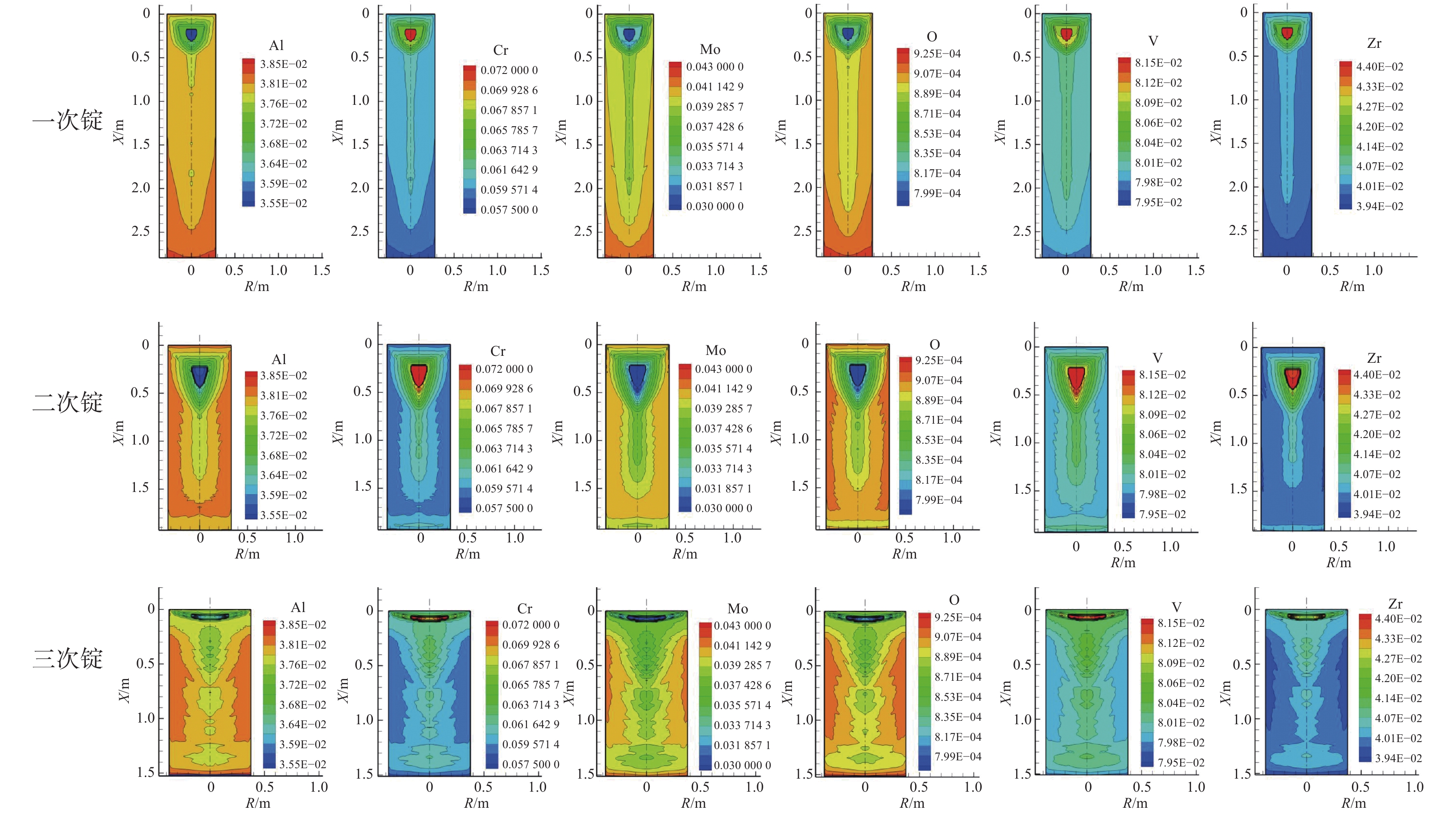

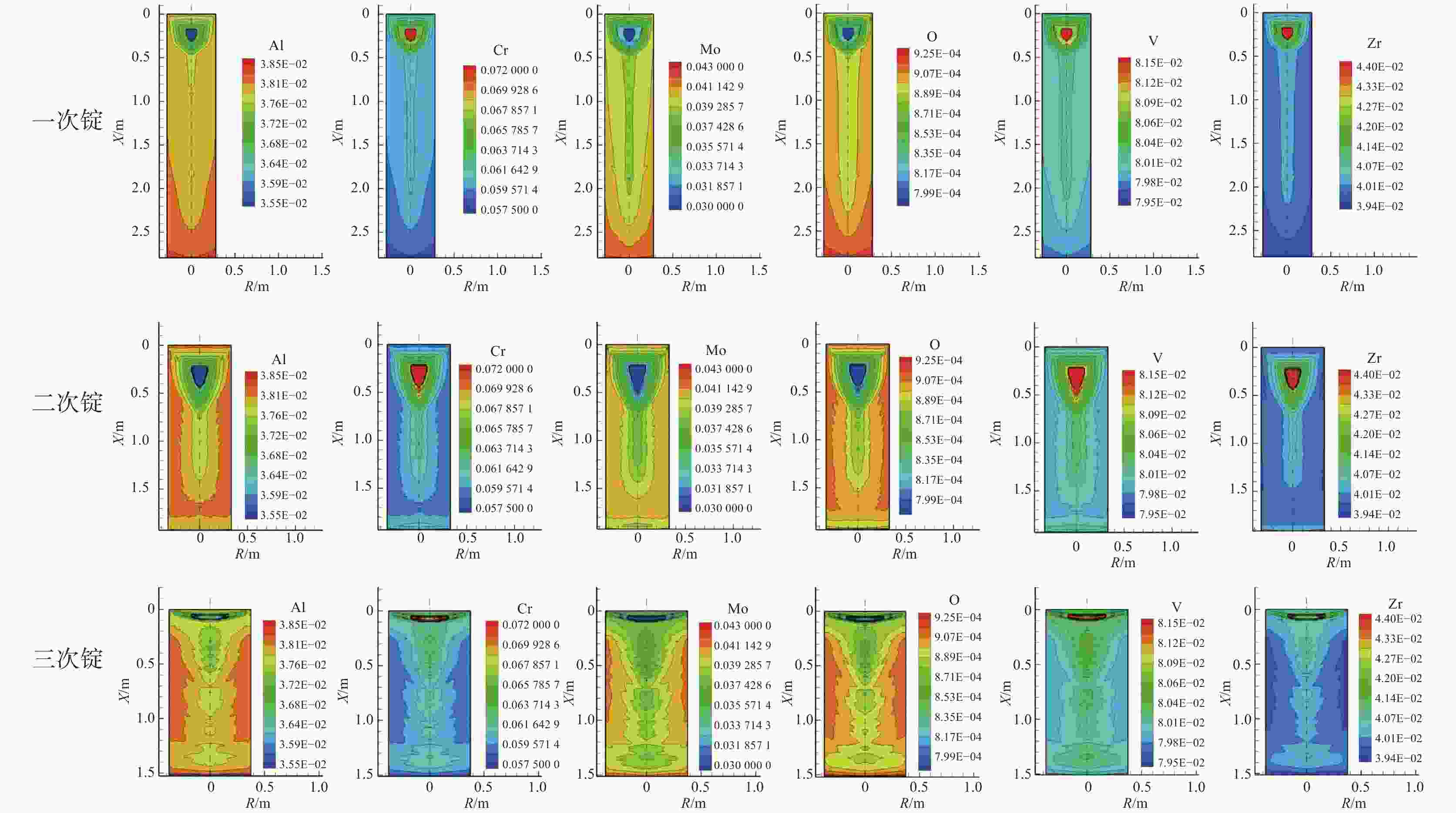

摘要: 采用真空自耗电弧熔炼(VAR)法熔炼TB9钛合金会产生偏析和夹杂等冶金缺陷。采用MeltFlow-VAR仿真软件对某厂TB9钛合金VAR一次熔炼过程进行模拟,考察熔炼电流大小、稳弧类型对熔炼过程的影响,通过分析不同工艺条件下铸锭的元素分布、熔池深度、抛杂路径等,获得了最佳一次熔炼工艺,分别采用该厂原工艺和优化后的工艺参数,对TB9钛合金三次VAR熔炼过程进行全流程模拟,获得了三次锭的元素分布情况。结果表明,宏观偏析在多次熔炼过程中存在“遗传”现象,对该厂一次熔炼原工艺进行优化后,可以显著提高三次成品锭的成分均匀性。Abstract: Metallurgical defects such as segregation and inclusion will occur when vacuum arc remelting (VAR) is used to melt TB9 titanium alloy. MeltFlow-VAR simulation software was used to simulate the primary melting process of TB9 titanium alloy VAR, and the influence of melting current and arc stabilization type on the melting process was investigated. By analyzing the element distribution, molten pool depth and impurity throwing path of ingot under different technological conditions, the optimal primary melting process was obtained. Using the original process and optimized process parameters, the whole process of tertiary VAR melting process of TB9 titanium alloy was simulated, and the element distribution of tertiary ingots was obtained. The results show that there is a “genetic” phenomenon in the process of multiple melting. After optimizing the original process of primary melting in this factory, the composition uniformity of tertiary finished ingots can be significantly improved.

-

Key words:

- TB9 titanium alloy /

- Vacuum arc remelting /

- Numerical simulation /

- Element distribution

-

表 1 TB9钛合金铸锭化学成分范围值和计算输入值

Table 1. Chemical composition range value and calculation input value of TB9 titanium alloy ingot

% 元素 Al V Cr Zr Mo 范围值 3.0~4.0 7.5~8.5 5.5~6.5 3.5~4.5 3.5~4.5 计算输入值 3.8 8.0 6.0 4.0 4.0 表 2 第一次熔炼不同工艺参数的模拟计算

Table 2. Simulation calculation of different process parameters in the first melting

正常熔炼阶段电流 稳弧电流交流/直流 原工艺 原工艺 直流 工艺1 减少 直流 工艺2 增加 直流 工艺3 减少 交流 工艺4 原工艺 交流 工艺5 增加 交流 注:原工艺为某厂实际熔炼TB9钛合金的工艺 表 3 不同的一次熔炼工艺对最终铸锭影响的模拟计算

Table 3. Simulation calculation of the influence of different primary melting processes on the final ingot

一次熔炼 二次熔炼 三次熔炼 最佳工艺 原工艺 原工艺 原工艺 原工艺 原工艺 表 4 计算采用的TB9钛合金物性参数

Table 4. Physical parameters of TB9 titanium alloy used in calculation

液态密度/

(kg·m−3)固态密度/

(kg·m−3)体积膨胀

系数/K−1固相线

温度/K液相线

温度/K相变潜热/

(J·kg−1)导电率/

(S·m−1)导热性/

(W·m−1·K−1)比热(1800 K)/

(J· kg−1· K−1 )动力粘度(1930 K)/

(Pa·s)4.33×103 4.84×103 9.78×10−5 1 825 1 930 2.84×105 8.5×105 34.48 8.35×102 5.52×10−3 -

[1] Shi W, Dong L, Zhang X, et al. Simulation and experimental study of the hole-making process of Ti-6Al-4V titanium alloy for selective laser melting[J]. Journal of Manufacturing Processes, 2023,106:223−239. doi: 10.1016/j.jmapro.2023.10.004 [2] Xu Jianqing, Tan Jing. Study on numerical model of high temperature compression behavior of forged TB9 titanium alloy[J]. Foundry Technology, 2018,39(6):1305−1308. (徐健清, 谭静. 锻态TB9钛合金高温压缩行为数值模型研究[J]. 铸造技术, 2018, 39(6): 1305−1308.Xu Jianqing, Tan Jing. Study on numerical model of high temperature compression behavior of forged TB9 titanium alloy[J]. Foundry Technology, 2018,39(6):1305−1308. [3] Yang X, Li W, Fu Y, et al. Finite element modelling for temperature, stresses and strains calculation in linear friction welding of TB9 titanium alloy[J]. Journal of Materials Research and Technology, 2019,8(5):4797−4818. doi: 10.1016/j.jmrt.2019.08.026 [4] Jin Xiaochao, Xu Qipeng, Qiu Ji, et al. A strain rate‐dependent constitutive model for asymmetric hardening behavior of TB9 titanium alloy[J]. Advanced Engineering Materials, 2022,24(12):2200545. doi: 10.1002/adem.202200545 [5] Liu Le, Xu Qipeng, Hou Cheng, et al. Strain rate effect of yield strength of new TB9 titanium alloy[J]. Science Technology and Engineering, 2022,22(35):15470−15476. (刘乐, 许琦鹏, 侯成, 等. 新型TB9钛合金屈服强度的应变率效应[J]. 科学技术与工程, 2022,22(35):15470−15476.Liu Le, Xu Qipeng, Hou Cheng, et al. Strain rate effect of yield strength of new TB9 titanium alloy[J]. Science Technology and Engineering, 2022, 22(35): 15470−15476. [6] Li Xiong, Pang Kechang, Guo Hua, et al. Melting technology of wrought Ti and Ti alloy[J]. The Chinese Journal of Nonferrous Metals, 2010,20(S1):906−913. (李雄, 庞克昌, 郭华, 等. 变形钛及钛合金熔炼技术[J]. 中国有色金属学报, 2010,20(S1):906−913.Li Xiong, Pang Kechang, Guo Hua, et al. Melting technology of wrought Ti and Ti alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): 906−913. [7] Zagrebelnyy D, Krane M J M. Segregation development in multiple melt vacuum arc remelting[J]. Metallurgical and Materials Transactions B, 2009,40:281−288. doi: 10.1007/s11663-008-9163-5 [8] Jing Zhenquan, Sun Yanhui, Liu Rui, et al. Effect of vacuum arc remelting process parameters on macrosegregation in TC4 titanium alloy[J]. Rare Metal Materials and Engineering, 2023,52(3):815−822. [9] Yamanaka A, Ichihashi H. Dissolution of refractory elements to titanium alloy in var[J]. ISIJ International, 1992,32(5):600−606. doi: 10.2355/isijinternational.32.600 [10] Dong Hequan, Guo Ziming, Mao Xiemin, et al. Prospect of development trend of melting technology of titanium and/or its alloys with high efficiency and low energy consumption[J]. Materials Review, 2008,22(5):68−73. (董和泉, 国子明, 毛协民, 等. 低能耗节约型钛及钛合金熔炼技术的发展趋势[J]. 材料导报, 2008,22(5):68−73.Dong Hequan, Guo Ziming, Mao Xiemin, et al. Prospect of development trend of melting technology of titanium and/or its alloys with high efficiency and low energy consumption[J]. Materials Review, 2008, 22(5): 68−73. [11] Liu Xibo, Wang Shujun, Jia Xiangya, et al. Research on the preparation of TC4 titanium alloy plate by the ingot with bad composition[J]. Titanium Industry Progress, 2017,34(1):29−32. (刘喜波, 王树军, 贾祥亚, 等. 利用成分不良的TC4钛合金铸锭制备合格板材的工艺研究[J]. 钛工业进展, 2017,34(1):29−32.Liu Xibo, Wang Shujun, Jia Xiangya, et al. Research on the preparation of TC4 titanium alloy plate by the ingot with bad composition[J]. Titanium Industry Progress, 2017, 34(1): 29−32. [12] Li Mingyu, Yang Shufeng, Liu Wei, et al. A review on segregation and control of titanium alloy during vacuum arc remelting process[J]. China Metallurgy, 2023, 33(9): 1-10,18. (李明宇, 杨树峰, 刘威, 等. 真空自耗熔炼钛合金的偏析缺陷及控制研究进展[J]. 中国冶金, 2023, 33(9): 1−10, 18.Li Mingyu, Yang Shufeng, Liu Wei, et al. A review on segregation and control of titanium alloy during vacuum arc remelting process[J]. China Metallurgy, 2023, 33(9): 1-10,18. [13] Cen M, Liu Y, Chen X, et al. Inclusions in melting process of titanium and titanium alloys[J]. China Foundry, 2019,16(4):223−231. doi: 10.1007/s41230-019-9046-1 [14] Karimi-Sibaki E, Kharicha A, Vakhrushev A, et al. Numerical modeling and experimental validation of the effect of arc distribution on the as-solidified Ti64 ingot in vacuum arc remelting (VAR) process[J]. Journal of Materials Research and Technology, 2022,19:183−193. doi: 10.1016/j.jmrt.2022.05.036 [15] Huang Liqing, Wu Jingyang, Guo Jie, et al. Effect of self-induced magnetic field on liquid flow and segregation during VAR process for titanium alloys[J]. Iron Steel Vanadium Titanium, 2023,44(4):55−61, 84. (黄立清, 吴京洋, 郭杰, 等. 钛合金VAR过程中自感电磁场对流场与偏析行为的影响[J]. 钢铁钒钛, 2023,44(4):55−61, 84.Huang Liqing, Wu Jingyang, Guo Jie, et al. Effect of self-induced magnetic field on liquid flow and segregation during VAR process for titanium alloys[J]. Iron Steel Vanadium Titanium, 2023, 44(4): 55−61, 84. [16] Jing Zhenquan, Sun Yanhui, Chen Lian, et al. Numerical simulation of current, magnetic field and electromagnetic force in vacuum arc remelting of titanium alloy[J]. Rare Metal Materials and Engineering, 2023,52(6):1994−2001. [17] Fu Hangtao, Wang Kaixuan, Zhao Xiaohua, et al. Numerical simulation analysis of inclusion evolution during VAR melting of TC4 titanium alloy[J]. Foundry Technology, 2021,42(9):770−773. (付航涛, 王凯旋, 赵小花, 等. TC4钛合金VAR熔炼过程中夹杂物演变的数值模拟分析[J]. 铸造技术, 2021,42(9):770−773.Fu Hangtao, Wang Kaixuan, Zhao Xiaohua, et al. Numerical simulation analysis of inclusion evolution during VAR melting of TC4 titanium alloy[J]. Foundry Technology, 2021, 42(9): 770−773. [18] Wen Hao, Zheng Yabo, Chen Feng, et al. Research on melting technology of TC2 titanium alloy ingot depend on MeltFlow-VAR[J]. World Nonferrous Metals, 2022(14):12−15. (文豪, 郑亚波, 陈峰, 等. 基于MeltFlow-VAR的TC2钛合金铸锭熔炼工艺研究[J]. 世界有色金属, 2022(14):12−15.Wen Hao, Zheng Yabo, Chen Feng, et al. Research on melting technology of TC2 titanium alloy ingot depend on MeltFlow-VAR[J]. World Nonferrous Metals, 2022(14): 12−15. [19] Zhao Xiaohua, Wang Jincheng, Liu Peng, et al. Effect of electrode block’s mixing uniformity on titanium alloy ingot’s composition[J]. Titanium Industry Progress, 2021,38(4):1−4. (赵小花, 王锦程, 刘鹏, 等. 钛合金电极块混料均匀性对铸锭成分的影响[J]. 钛工业进展, 2021,38(4):1−4.Zhao Xiaohua, Wang Jincheng, Liu Peng, et al. Effect of electrode block’s mixing uniformity on titanium alloy ingot’s composition[J]. Titanium Industry Progress, 2021, 38(4): 1−4. [20] Guo Jie, Huang Liqing, Wu Jingyang, et al. Evolution of macrosegregation during three-stage vacuum arc remelting of titanium alloys[J/OL]. Acta Metallurgica Sinica, 2023. DOI: 10.11900/0412.1961.2022.00544 (郭杰, 黄立清, 吴京洋, 等. 钛合金三次真空自耗电弧熔炼过程中的宏观偏析传递行为[J/OL]. 金属学报, 2023. DOI: 10.11900/0412.1961.2022.00544Guo Jie, Huang Liqing, Wu Jingyang, et al. Evolution of macrosegregation during three-stage vacuum arc remelting of titanium alloys[J/OL]. Acta Metallurgica Sinica, 2023. DOI: 10.11900/0412.1961.2022.00544 -

下载:

下载: