Study on microstructure and wear properties of TiAl alloy deposited by laser melting

-

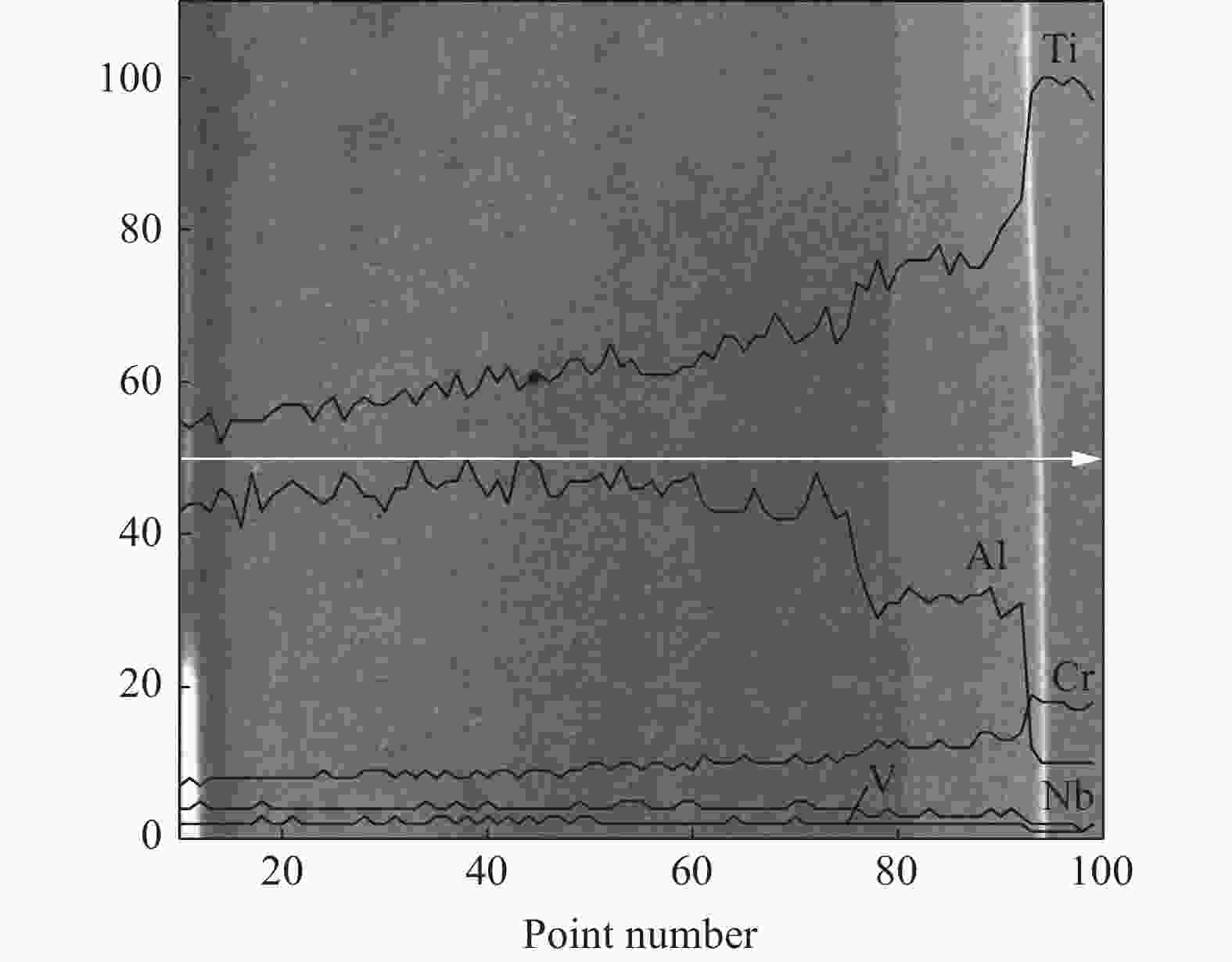

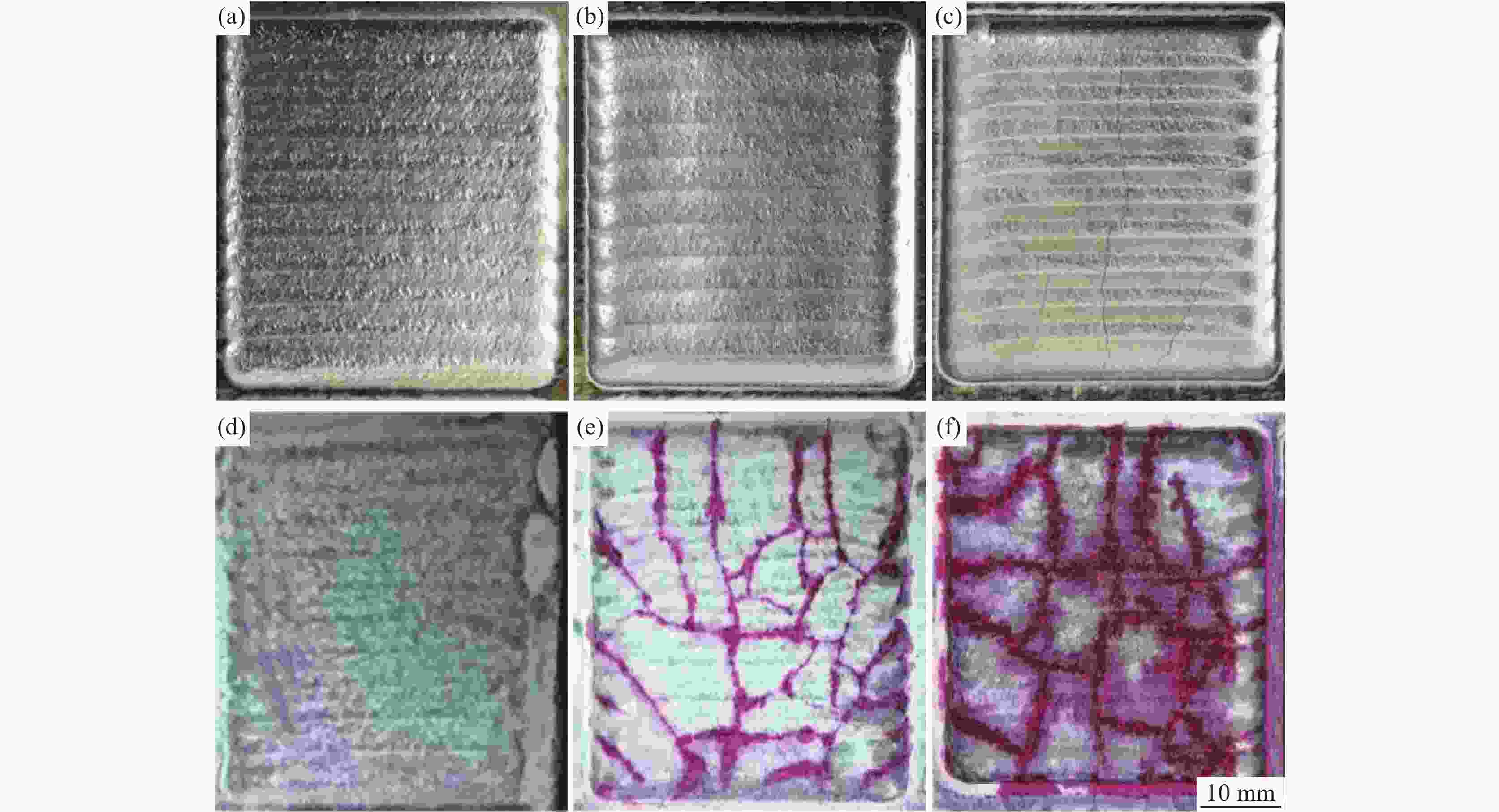

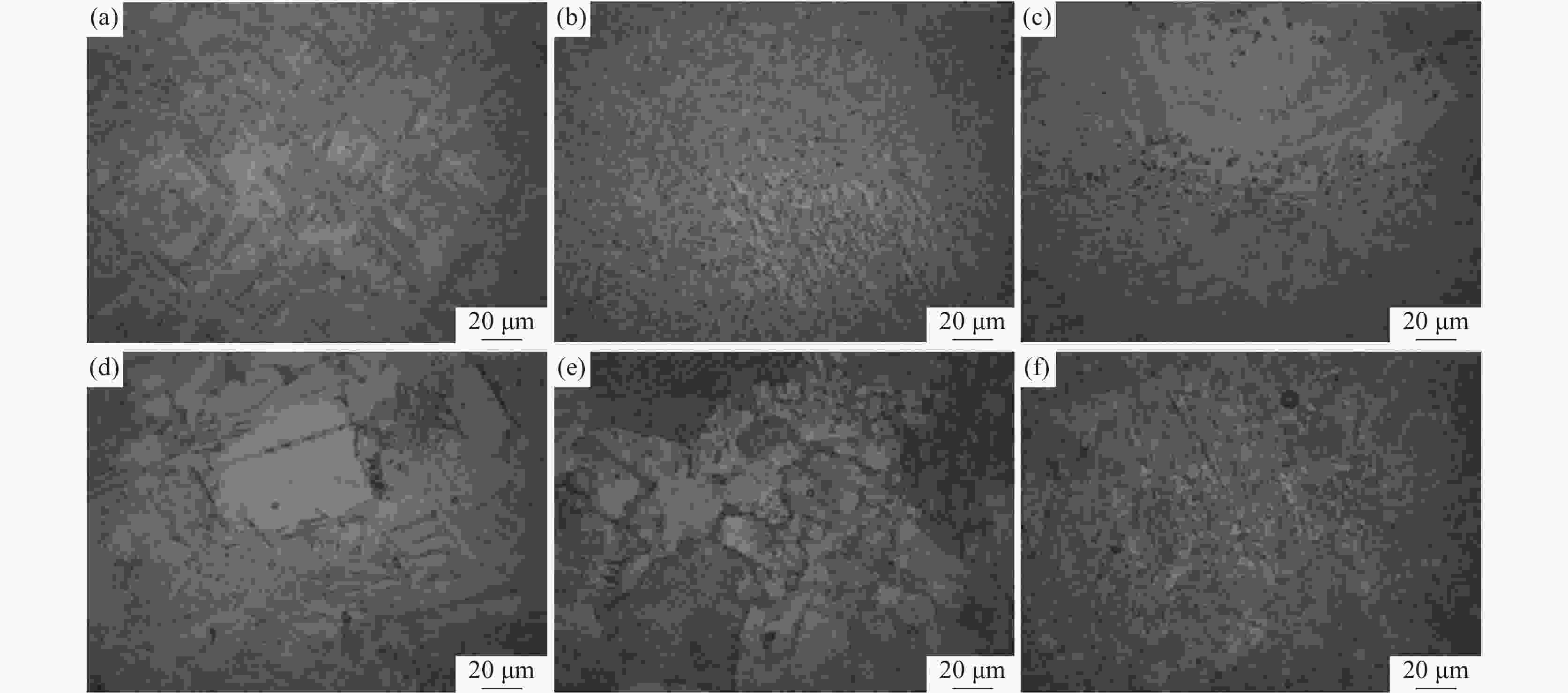

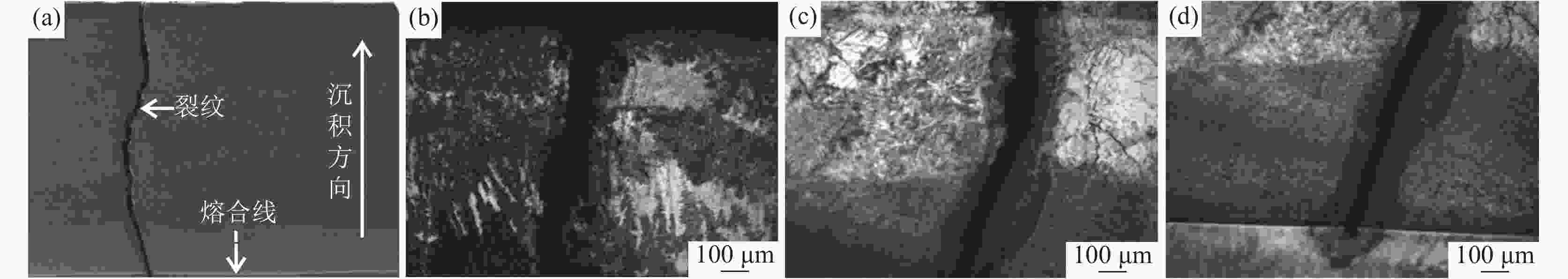

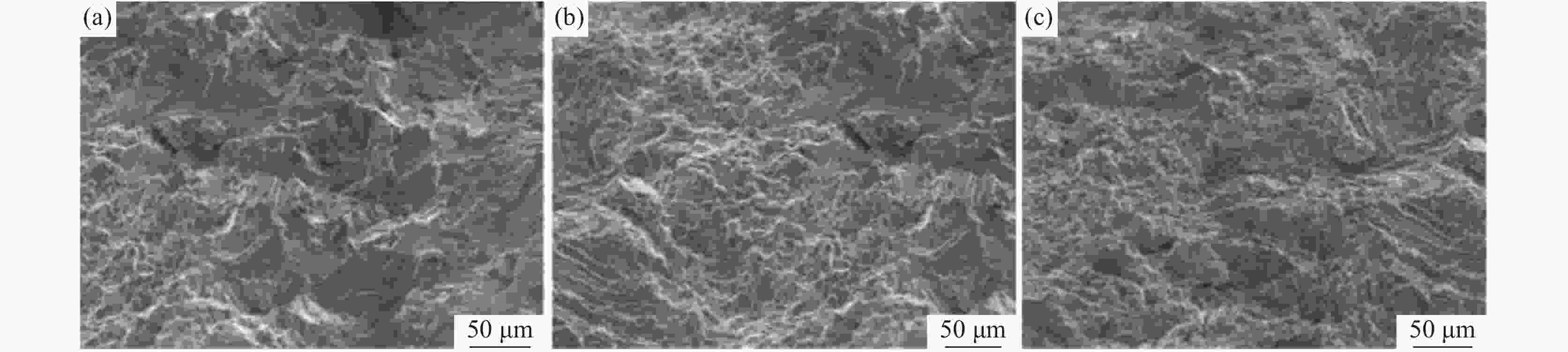

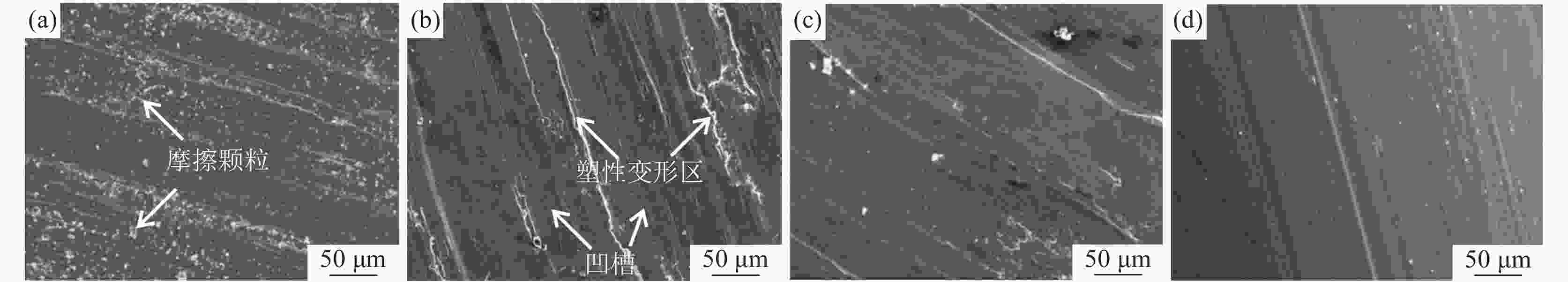

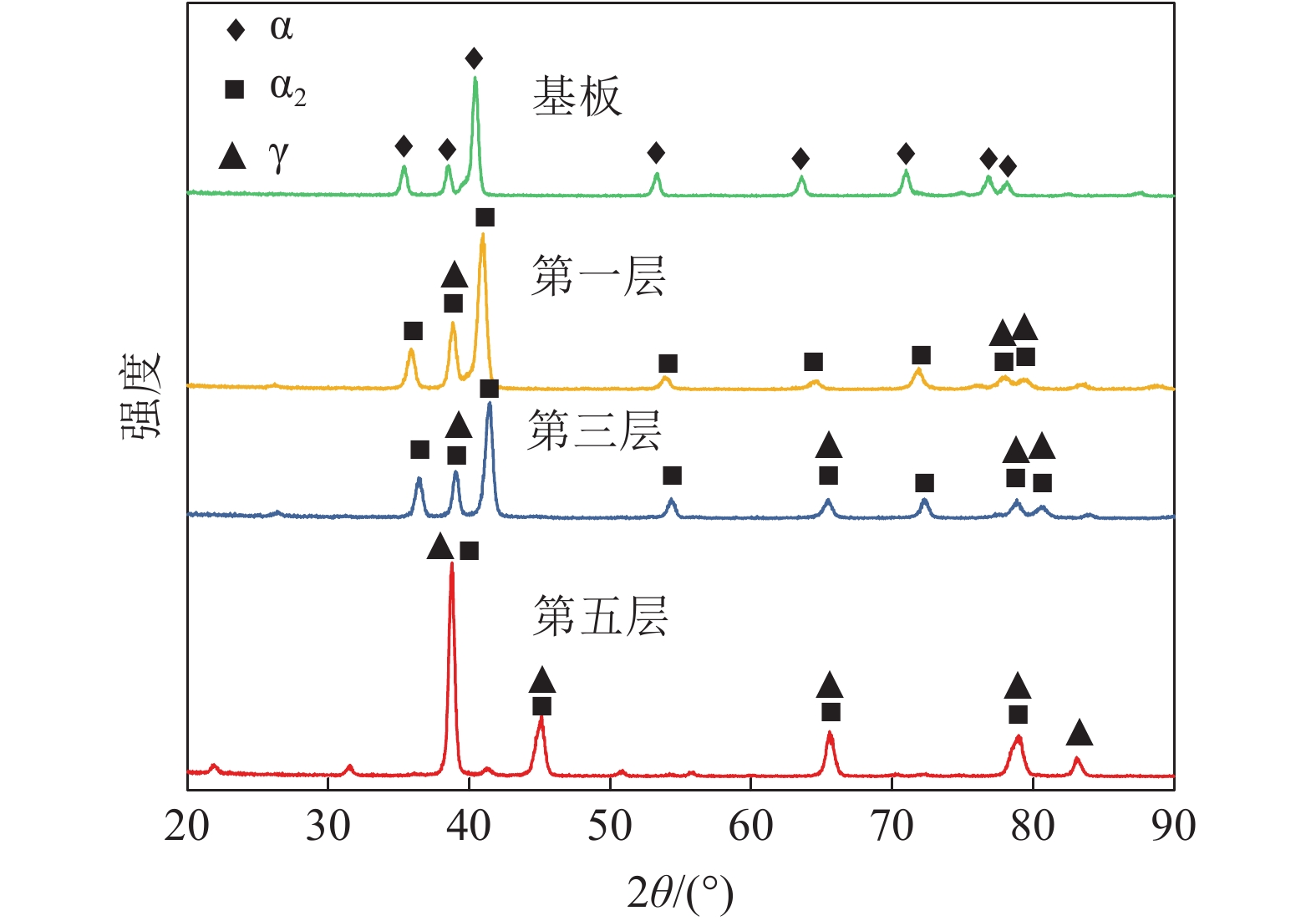

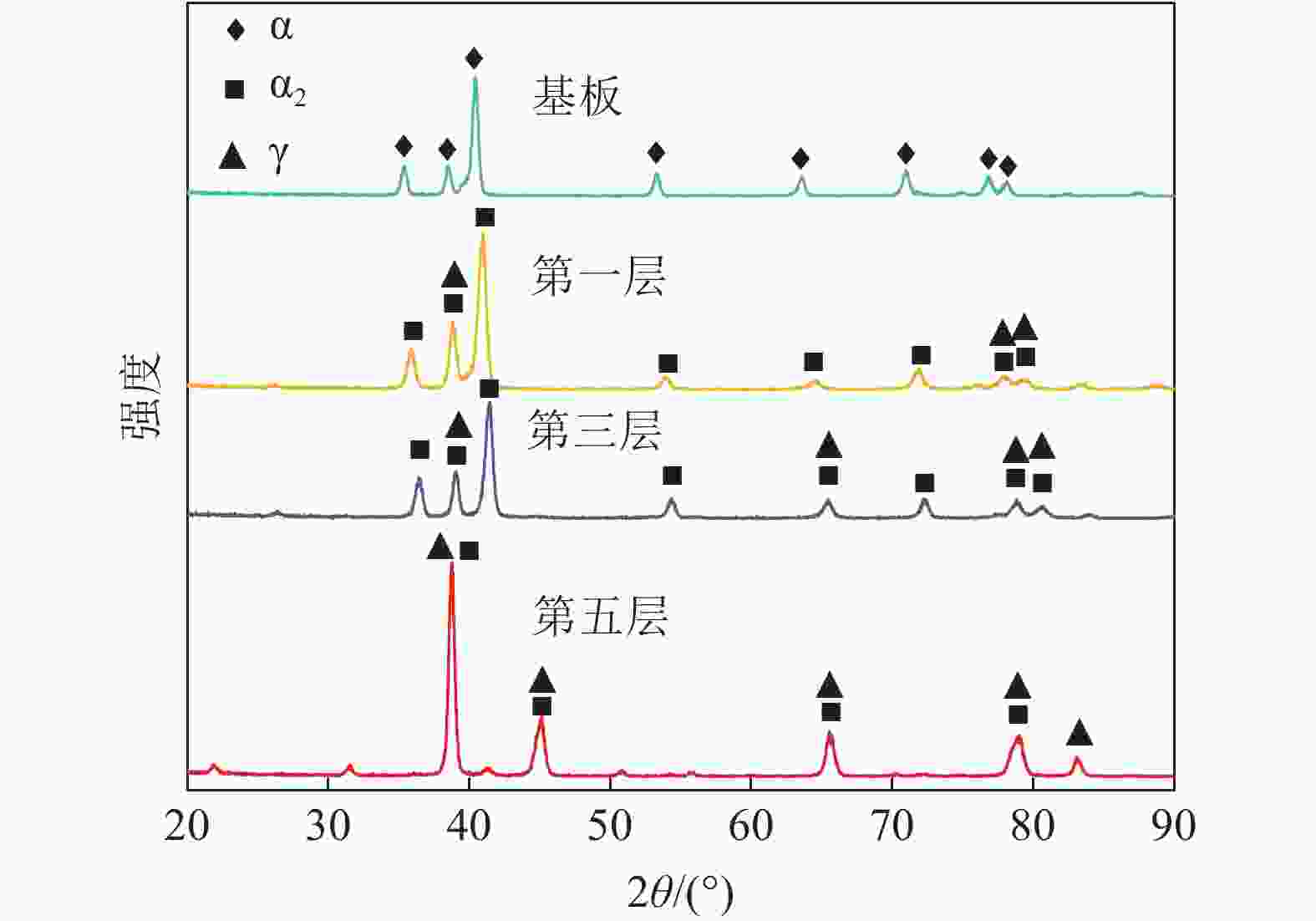

摘要: 采用激光同轴送粉沉积制造工艺在TC4基板上分别制备了一层、三层和五层的Ti-48Al-2Cr-2Nb合金样品。利用光学显微镜(OM)、扫描电子显微镜(SEM)、能谱仪(EDS)、X射线衍射(XRD)分析了沉积层的显微组织、裂纹形貌、磨损面形貌、相组成。试验结果表明,沉积一层的样品表面裂纹数量较少,沉积三层和五层的样品表面裂纹较多且裂纹数量相差不大。随着沉积层数的增加,沉积层中的显微组织结构由网篮组织向片层组织过渡,组织中相的变化是由单相α2→α2+γ双相转变。随着α2相含量的降低,耐磨性能随之降低,平均摩擦系数由0.34增加到0.55。Abstract: One-layer, three-layer and five-layer Ti-48Al-2Cr-2Nb alloy samples were prepared on TC4 substrate by coaxial laser powder-feeding deposition manufacturing process. The microstructure, crack morphology, wear surface morphology and phase composition of the deposited layer were analyzed by optical microscope (OM), scanning electron microscope (SEM), energy dispersive spectrometer (EDS) and X-ray diffraction (XRD). The test results show that the number of cracks on the surface of the sample deposited with one layer is less, and the samples deposited with three and five layers have more surface cracks and the number of cracks is not much different. As the number of sedimentary layers increases, the microstructure in the sedimentary layer transits from a basket structure to a lamellar structure, and the phase change in the structure is from a single phase α2 to α2+γ dual phase transition. As the α2 phase content decreases, the wear resistance decreases, and the average friction coefficient increases from 0.34 to 0.55.

-

Key words:

- laser deposition manufacturing /

- TiAl alloy /

- microstructure /

- wear properties

-

表 1 Ti-48Al-2Cr-2Nb合金粉末的化学成分

Table 1. 1 Chemical composition of Ti-48Al-2Cr-2Nb alloy powder

% Ti Al Cr Nb O N Bal. 32.5 2.64 4.62 0.06 0.005 -

[1] Wang Haifeng, Zhang Zhiming, Niu Yunsong, et al. Effect of pre-oxidation on microstructure and wear resistance of titanium alloy by low temperature plasma oxynitriding[J/OL]. Acta Metallurgica Sinica, 1-11[2023-03-19]. (王海峰, 张志明, 牛云松,等. 前置渗氧对TC4钛合金低温等离子复合渗层微观结构和耐磨损性能的影响[J/OL]. 金属学报, 1-11[2023-03-19].Wang Haifeng, Zhang Zhiming, Niu Yunsong, et al. Effect of pre-oxidation on microstructure and wear resistance of titanium alloy by low temperature plasma oxynitriding[J/OL]. Acta Metallurgica Sinica, 1-11[2023-03-19]. [2] Espejo H M, Bahr D F. Substrate cracking in Ti-6Al-4V driven by pulsed laser irradiation and oxidation[J]. Surface & Coatings Technology, 2017,322:46−50. [3] Aditya Kumar, Abhishek Choudhary, Abhishek Choudhary, et al. An investigation on wear characteristics of additive manufacturing materials[J]. Materials Today: Proceedings, 2021,47:3654−3660. doi: 10.1016/j.matpr.2021.01.263 [4] Emiraliolu A, Nal R. Additive manufacturing of gamma titanium aluminide alloys: A review[J]. Journal of Materials Science, 2022,57(4):1−26. [5] Xu C, Zhou Q, Xue W, et al. Surface protection of a V-4Cr-4Ti alloy through a multilayered TiAl/TiAlN composite coating[J]. Vacuum, 2023,207:111595. [6] Guo Jiaming, Liang Jinglong, Li Hui, et al. Research progress on preparation technology of titanium aluminum alloy and its intermetallic compounds[J]. Multipurpose Utilization of Mineral Resources, 2022(3):1−5. (郭佳明, 梁精龙, 李慧, 等. 钛铝合金及其金属间化合物制备工艺研究进展[J]. 矿产综合利用, 2022(3):1−5.Guo Jiaming, Liang Jinglong, Li Hui, et al. Research progress on preparation technology of titanium aluminum alloy and its intermetallic compounds[J]. Multipurpose Utilization of Mineral Resources, 2022(3): 1−5. [7] Zheng R T, Zhang Y G, Chen C Q. The ambient temperature tensile behavior of duplex γ-TiAl-based alloys[J]. Materials Science & Engineering A, 2003,362(1/2):192−199. [8] Kong B, Wang S, Zhang M, et al. Atomic-scale investigation on fretting wear mechanism of γ phase in a cast Ti-45Al alloy[J]. Applied Surface Science: A Journal Devoted to the Properties of Interfaces in Relation to the Synthesis and Behaviour of Materials, 2021,565(1):1−20. [9] Chen Y, Wang H M. Microstructure and high-temperature wear resistance of a laser surface alloyed γ-TiAl with carbon[J]. Applied Surface Science, 2003,220(1):186−192. [10] Li W, Zhu S, Chen M, et al. Development of an oxidation resistant glass-ceramic composite coating on Ti-47Al-2Cr-2Nb alloy[J]. Applied Surface Science, 2014,292(15):583−590. [11] Abboud J H, Fidel A F, Benyounis K Y. Surface nitriding of Ti–6Al–4V alloy with a high power CO2 laser[J]. Optics & Laser Technology, 2008,40(2):405−414. [12] Zhang Jun, Cai Xiaolong, Gao Siyang, et al. Study on fretting wear resistance of brazed WC wear resistant layer on TC4 titanium alloy[J]. Electric Welding Machine, 2023,53(1):56−62. (张军, 蔡晓龙, 高禩洋, 等. TC4钛合金表面钎焊WC耐磨层的微动磨损性能研究[J]. 电焊机, 2023,53(1):56−62.Zhang Jun, Cai Xiaolong, Gao Siyang, et al. Study on fretting wear resistance of brazed WC wear resistant layer on TC4 titanium alloy[J]. Electric Welding Machine, 2023, 53(1): 56−62. [13] Li J, Chen C, Squartini T, et al. A study on wear resistance and microcrack of the Ti3Al/TiAl + TiC ceramic layer deposited by laser cladding on Ti-6Al-4V alloy[J]. Appl. Surf. Sci, 2010,257:1550–1555. [14] Cheng Liang, Zhang Shuaijin, Yang Guang, et al. Tailoring microstructure and mechanical performance of a β-solidifying TiAl alloy via martensitic transformation[J]. Materials Characterization, 2021, 173(1):110970. [15] Pang W. Tribological coating of titanium alloys by laser processing[D]. Hongkong :Hongkong Polytechnic University, 2010. [16] Ramesh S, Nayaka H S. Effect of multiaxial cryoforging on wear properties of Cu-1.5%Ti alloy[C]// Materials Science Forum. Trans Tech Publications Ltd, 2019. [17] Zheng Bowen, Dong Fuyu, Zhang Yue, et al. Effects of TiC volume fraction on the microstructure and friction properties of in-situ titanium matrix composites[J]. Special Casting & Nonferrous Alloys, 2018,38(7):705−708. (郑博文, 董福宇, 张悦, 等. TiC含量对原位钛基复合材料组织与摩擦性能的影响[J]. 特种铸造及有色合金, 2018,38(7):705−708.Zheng Bowen, Dong Fuyu, Zhang Yue, et al. Effects of TiC volume fraction on the microstructure and friction properties of in-situ titanium matrix composites[J]. Special Casting & Nonferrous Alloys, 2018, 38(7): 705−708. -

下载:

下载: