Enhanced dispersion-magnetic separation tests for micro-fine titanomagnetite in Panxi area

-

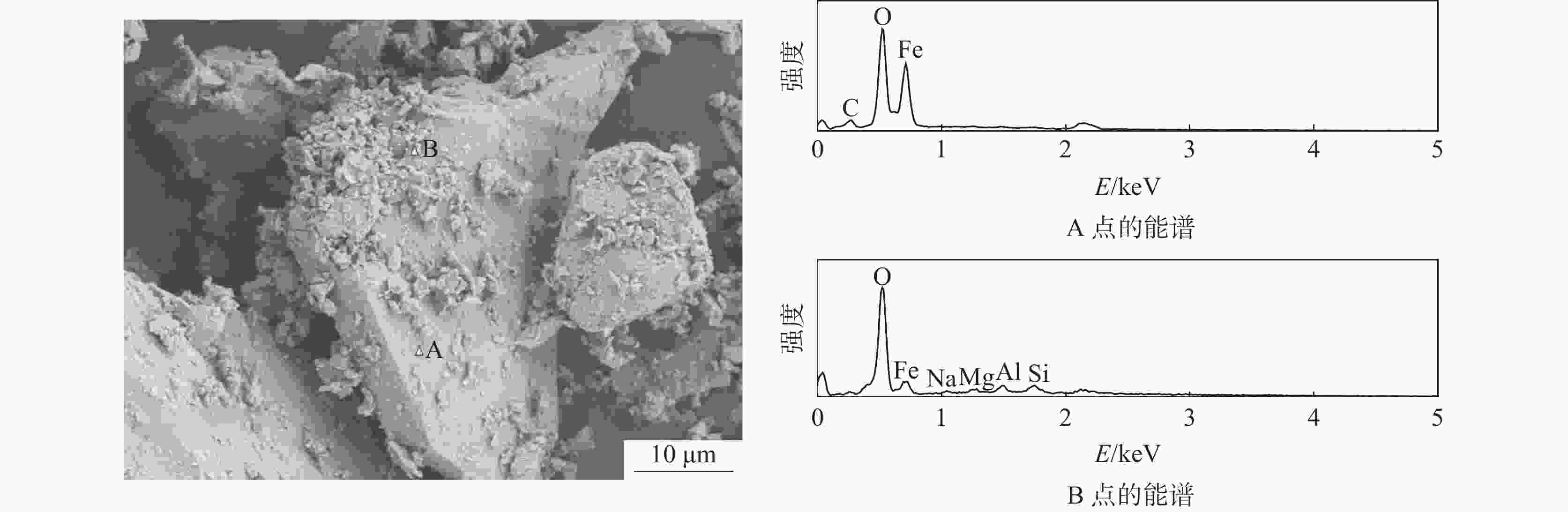

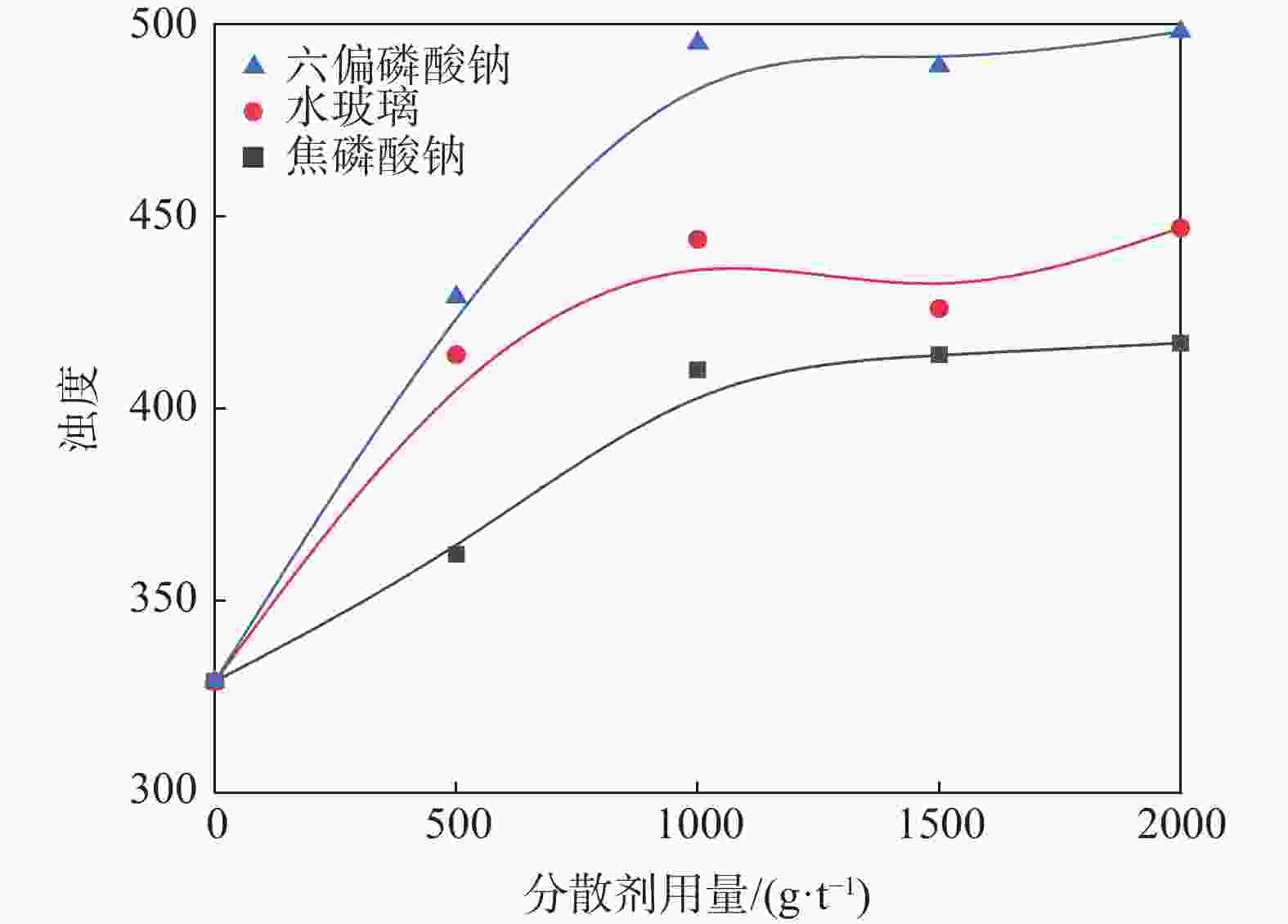

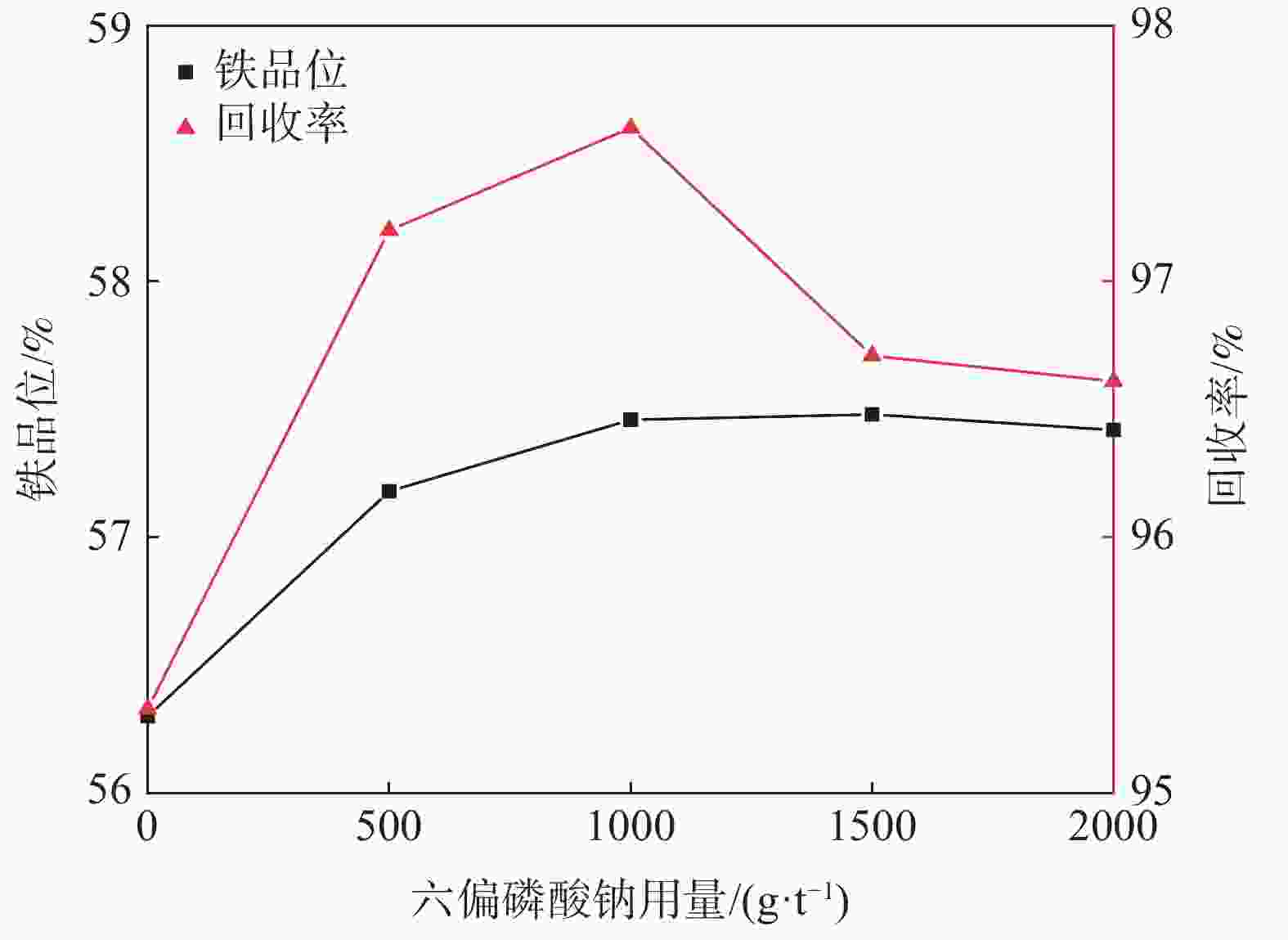

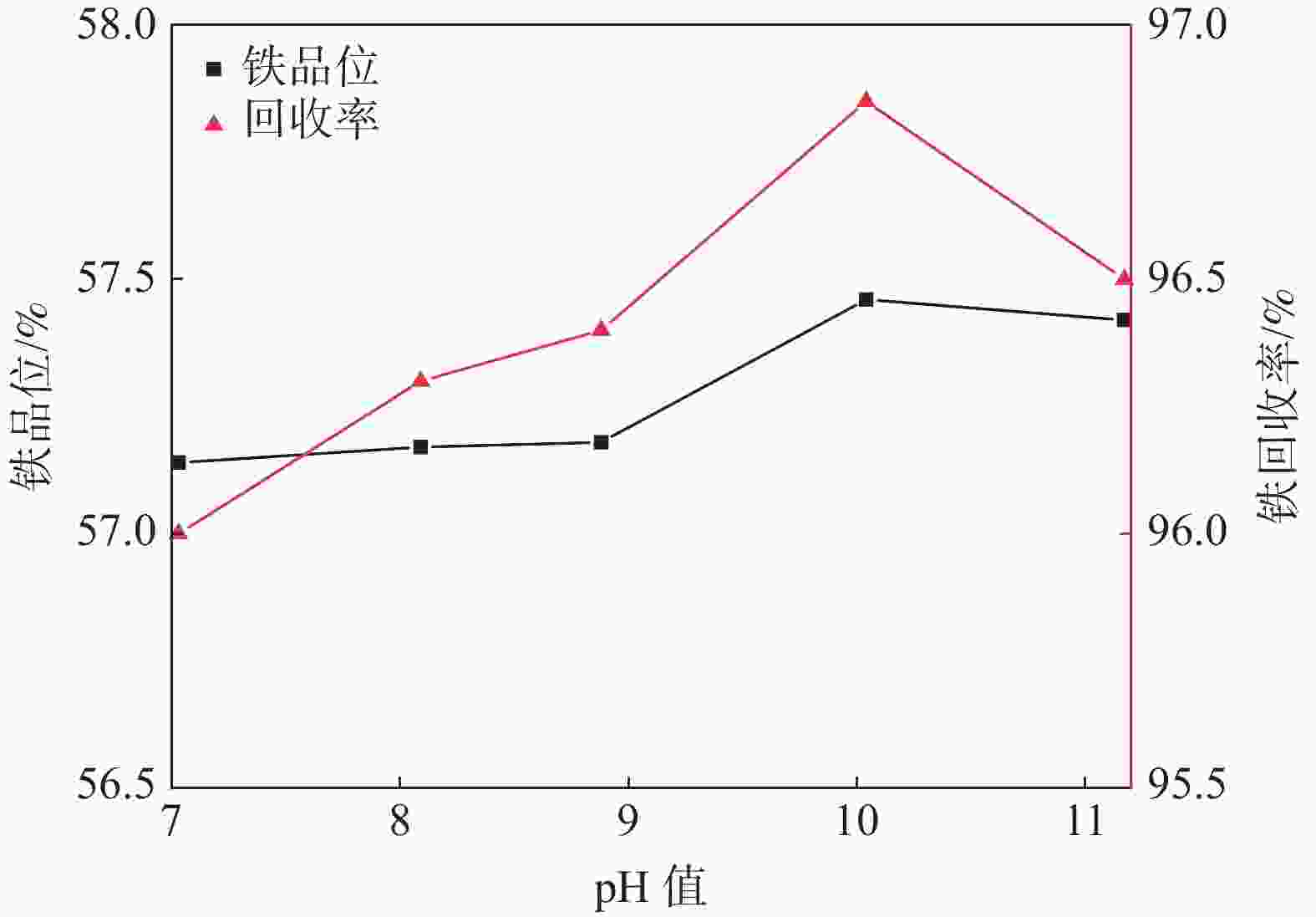

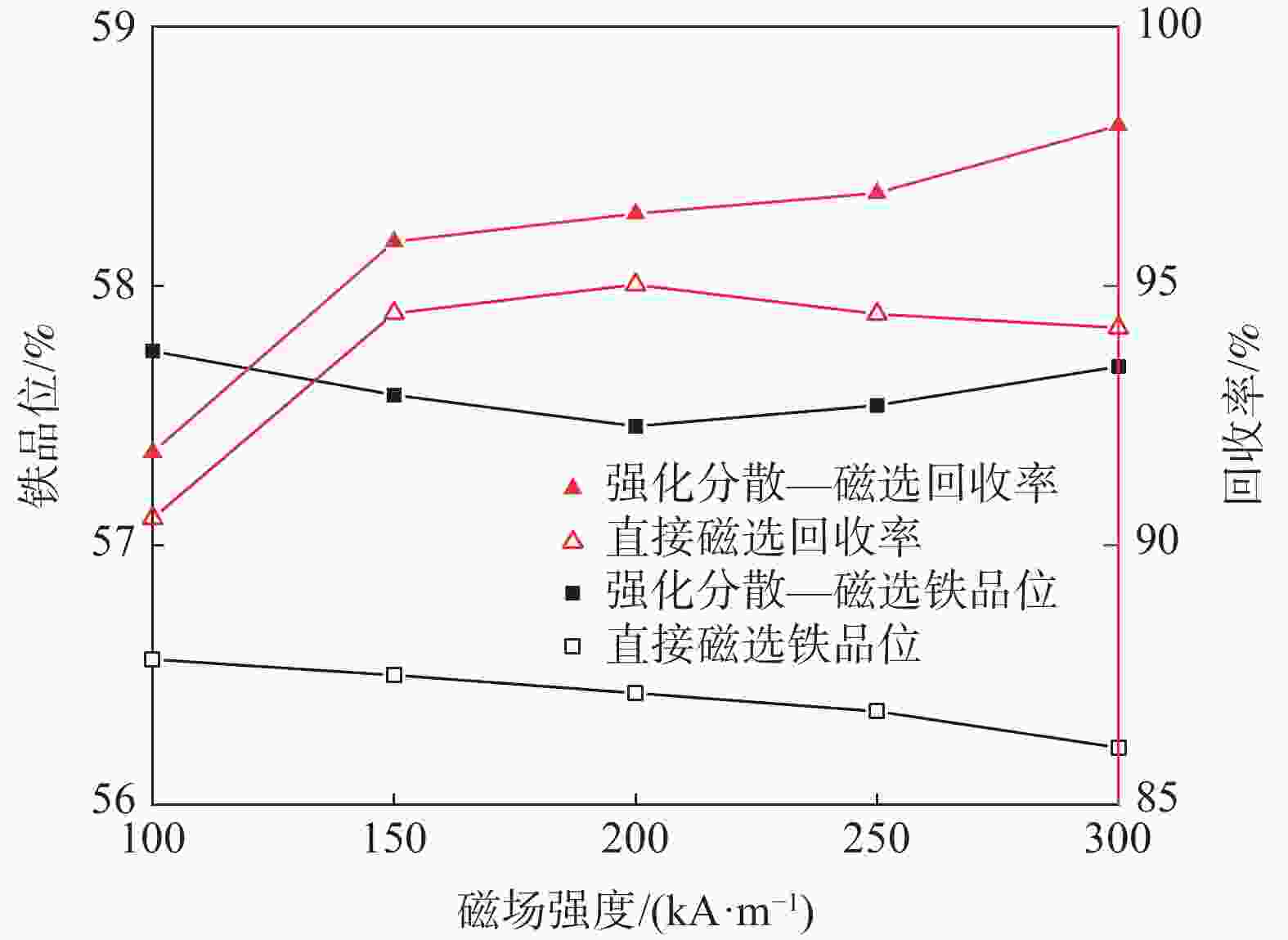

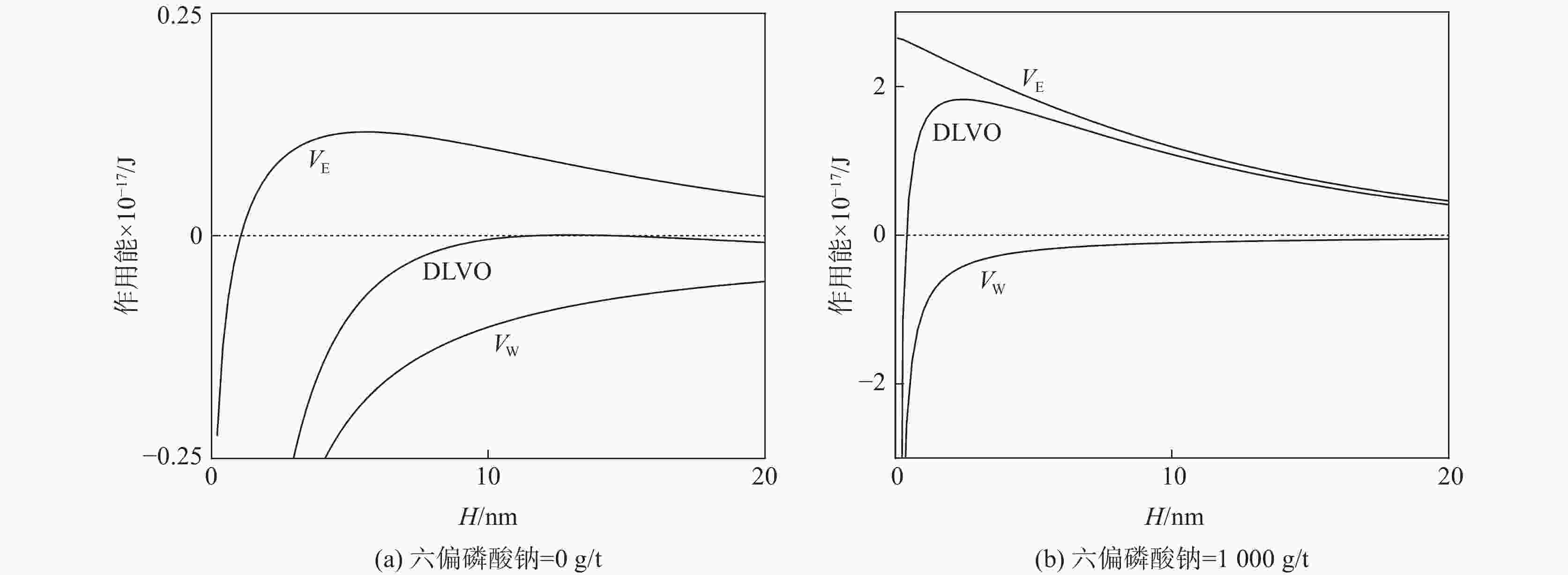

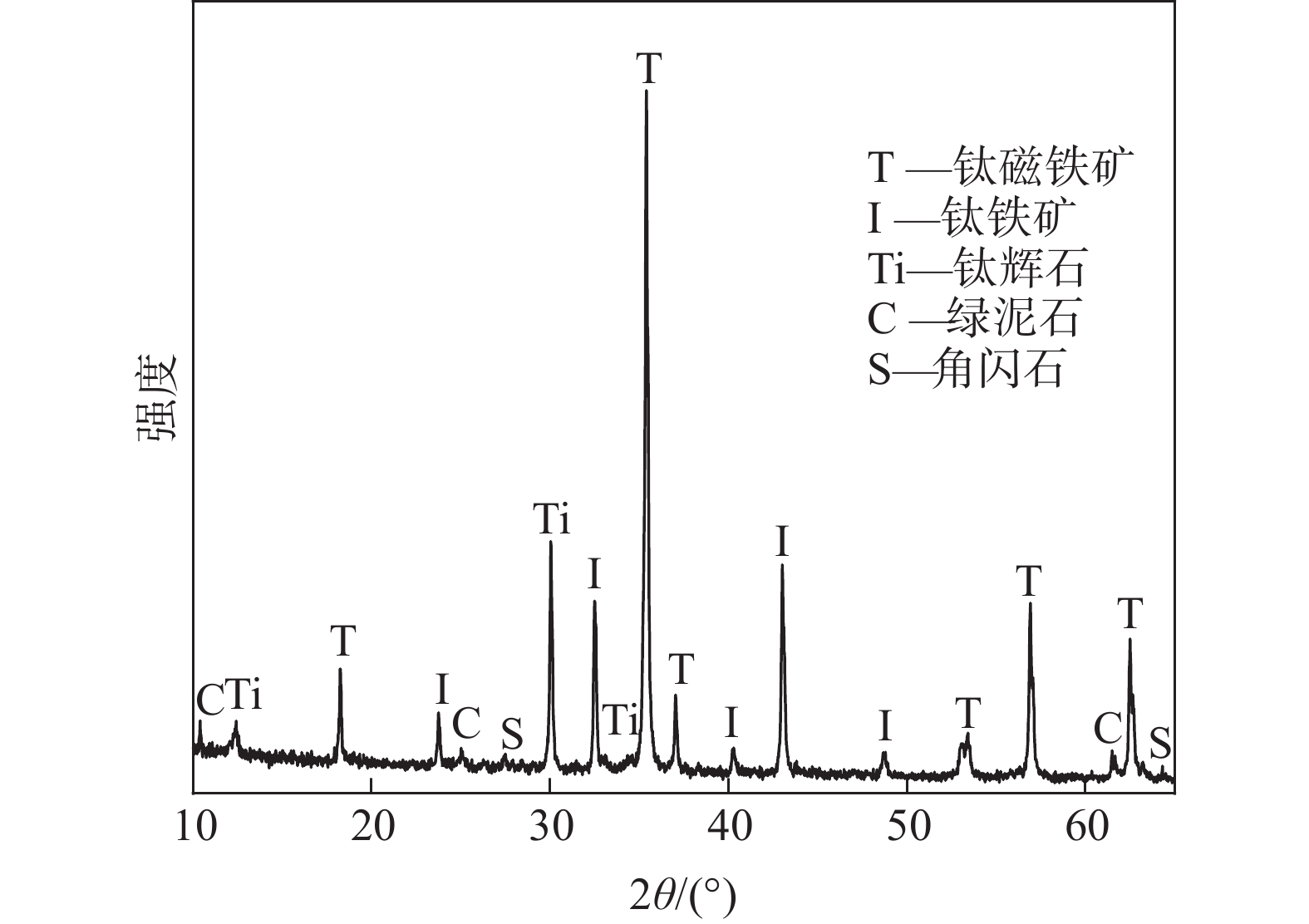

摘要: 攀西某微细粒钛磁铁矿混合粗精矿因微细粒脉石矿物与钛磁铁矿异相凝聚,常规弱磁选提铁降杂指标较差,采用强化分散—磁选可有效改善选别效果、提高分选指标。为了强化分选矿样中的微细粒铁矿物,对强化分散—磁选工艺条件开展试验研究,考察了分散剂种类、分散剂用量、矿浆pH值、磁场强度等因素对分选效果的影响。试验结果表明:在矿浆浓度20%、机械搅拌速度1 992 r/min、搅拌时间3 min、六偏磷酸钠用量1 000 g/t、矿浆pH值10、磁场强度300 kA/m的条件下,获得了精矿铁品位57.69%,铁回收率98.10%的良好指标。与直接磁选结果相比,铁品位提高了1.26个百分点。DLVO理论分析表明,六偏磷酸钠通过降低钛磁铁矿和钛辉石表面电位,增大了二者异相之间的静电斥力,从而削弱微细粒脉石矿物与钛磁铁矿异相凝聚。Abstract: Due to the heterogeneous coagulation of fine-grained gangue minerals and titanomagnetite in the mixed rough concentrate of a fine-grained titanomagnetite in Panxi area, the iron extraction and impurity reduction index of conventional low-intensity magnetic separation is poor. The enhanced dispersion-magnetic separation can effectively improve the separation effect and improve the separation index. In order to strengthen the separation of fine-grained iron minerals in the ore samples, the experimental study on the process conditions of enhanced dispersion-magnetic separation was carried out to investigate the effects of dispersant type, dispersant dosage, slurry pH, magnetic field strength and other factors on the separation effect. The test results show that under the conditions of 20% slurry concentration, mechanical stirring speed of 1 992 r/min, stirring time of 3 min, dosage of SHMP of 1 000 g/t, slurry pH of 10 and magnetic field strength of 300 kA/m, a good index of 57.69% iron grade in concentrate and 98.10% iron recovery was obtained. Compared with the results of direct magnetic separation, the iron grade increased by 1.26%. DLVO theoretical analysis shows that sodium hexametaphosphate increases the electrostatic repulsion between titanomagnetite and titanaugite by reducing the surface potential of titanomagnetite and titanaugite, thus weakening the heterogeneous coagulation of fine gangue minerals and titanomagnetite.

-

Key words:

- fine-grained titanium magnetite /

- titanium concentration /

- dispersant /

- DLVO theory

-

表 1 矿样化学多元素分析结果

Table 1. Chemical multi-element analysis of the sample

% TFe TiO2 SiO2 Al2O3 CaO MgO V2O5 Cr2O3 55.61 11.50 2.70 3.51 1.97 1.46 0.57 0.29 表 2 矿样筛析试验结果

Table 2. The sieve analysis results of the sample

粒级/μm 产率/% TFe品位/% TFe分布率/% −74~+48 20.45 54.18 19.92 −48~+38 11.27 54.69 11.08 −38~+30 12.82 55.03 12.69 −30~+23 51.27 57.25 52.78 −23~+18 2.99 48.75 2.62 −18 1.20 41.83 0.91 合计 100.00 55.61 100.00 表 3 最终精矿筛析试验结果

Table 3. The sieve analysis results of the final concentrate

粒级/μm 产率/% TFe品位/% TFe分布率/% −74~+48 19.41 56.08 18.88 −48~+38 14.96 56.46 14.65 −38~+30 17.08 58.08 17.21 −30~+23 38.25 59.02 39.15 −23~+18 6.87 56.83 6.77 −18 3.43 56.23 3.34 合计 100.00 57.65 100.00 -

[1] Zhang Xiang. The present situation and countermeasures of iron ore resource safety in China[J]. Fujian Metallurgy, 2021,50(3):3. (张翔. 浅谈我国铁矿资源安全的现状和对策[J]. 福建冶金, 2021,50(3):3.Zhang Xiang. The present situation and countermeasures of iron ore resource safety in China[J]. Fujian Metallurgy, 2021, 50(3): 3. [2] Cheng Xiangyu, Qian Gongming, Cai Xianyan. The research progress of pretreatment technology for complex refractory iron ore[J]. Metal Mine, 2020(12):1−11. (程翔宇, 钱功明, 蔡先炎, 等. 复杂难选铁矿石预处理方法的研究进展[J]. 金属矿山, 2020(12):1−11.Cheng Xiangyu, Qian Gongming, Cai Xianyan. The research progress of pretreatment technology for complex refractory iron ore[J]. Metal Mine, 2020(12): 1−11. [3] Chen Chao, Zhang Yushu, Li Xiaoyu, et al. Research progress in titanium-magnetite beneficiation technology[J]. Multipurpose Utilization of Mineral Resources, 2021(3):7. (陈超, 张裕书, 李潇雨, 等. 钛磁铁矿选矿技术研究进展[J]. 矿产综合利用, 2021(3):7.Chen Chao, Zhang Yushu, Li Xiaoyu, et al. Research progress in titanium-magnetite beneficiation technology[J]. Multipurpose Utilization of Mineral Resources, 2021(3): 7. [4] Wang Xun, Han Yuexin, Li Yanjun, et al. Research status on comprehensive development and utilization of vanadium-titanium magnetite[J]. Metal Mine, 2019(6):33−37. (王勋, 韩跃新, 李艳军, 等. 钒钛磁铁矿综合利用研究现状[J]. 金属矿山, 2019(6):33−37.Wang Xun, Han Yuexin, Li Yanjun, et al. Research status on comprehensive development and utilization of vanadium-titanium magnetite[J]. Metal Mine, 2019(6): 33−37. [5] Ku Jiangang, Zhang Wenbin. Experimental study on -45 μm part of Panzhihua vanadium and titanium bearing magnetic ore to improve the concentrate[J]. China Mining Magazine, 2005,14(11):3. (库建刚, 张文彬. 提高攀枝花钒钛磁铁矿-45μm精矿指标的试验研究[J]. 中国矿业, 2005,14(11):3.Ku Jiangang, Zhang Wenbin. Experimental study on -45 μm part of Panzhihua vanadium and titanium bearing magnetic ore to improve the concentrate[J]. China Mining Magazine, 2005, 14(11): 3. [6] Chen Bi, Li Weiwei, Wang Yong. Study on the difficulties of improving the quality of Panzhihua and Baima vanadium titanium magnetite iron concentrates[J]. Modern Mining, 2022,38(10):258−261. (陈碧, 李韦韦, 王勇. 攀枝花白马钒钛磁铁矿铁精矿提质的难点研究[J]. 现代矿业, 2022,38(10):258−261.Chen Bi, Li Weiwei, Wang Yong. Study on the difficulties of improving the quality of Panzhihua and Baima vanadium titanium magnetite iron concentrates[J]. Modern Mining, 2022, 38(10): 258−261. [7] Su Youshun, Zeng Haipeng, Huang Hongjun. Dispersion mechanism of sodium hexametaphosphate on potassium feldspar and hematite[J]. Mining and Metallurgical Engineering, 2023,43(2):61−65. (舒有顺, 曾海鹏, 黄红军. 六偏磷酸钠对钾长石和赤铁矿的分散作用机理[J]. 矿冶工程, 2023,43(2):61−65.Su Youshun, Zeng Haipeng, Huang Hongjun. Dispersion mechanism of sodium hexametaphosphate on potassium feldspar and hematite[J]. Mining and Metallurgical Engineering, 2023, 43(2): 61−65. [8] Lu Yiping, Zhang Mingqiang, Feng Qiming, et al. Effect of sodium hexametaphosphate on separation of serpentine from pyrite[J]. Transactions of Nonferrous Metals Society of China, 2011,21(1):208−213. (卢毅屏, 张明强, 冯其明, 等. 六偏磷酸钠在蛇纹石与黄铁矿分离中的作用[J]. 中国有色金属学报, 2011,21(1):208−213. doi: 10.1016/S1003-6326(11)60701-2Lu Yiping, Zhang Mingqiang, Feng Qiming, et al. Effect of sodium hexametaphosphate on separation of serpentine from pyrite[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(1): 208−213. doi: 10.1016/S1003-6326(11)60701-2 [9] Li Dong, Zhong Hedong, Yin Wanzhong, et al. Classification-dispersion flotation of fine mixed magnetic concentrate[J]. Journal of Northeastern University(Natural Science), 2021,42(12):1761−1767. (李东, 钟河东, 印万忠, 等. 微细粒混合磁选精矿分级——分散浮选试验研究[J]. 东北大学学报(自然科学版), 2021,42(12):1761−1767.Li Dong, Zhong Hedong, Yin Wanzhong, et al. Classification-dispersion flotation of fine mixed magnetic concentrate[J]. Journal of Northeastern University(Natural Science), 2021, 42(12): 1761−1767. [10] Deng Chuanhong, Ma Juner, Zhang Guofan, et al. Effect of water glass on floatation of ilmenite[J]. The Chinese Journal of Nonferrous Metals, 2010,20(3):6. (邓传宏, 马军二, 张国范, 等. 水玻璃在钛铁矿浮选中的作用[J]. 中国有色金属学报, 2010,20(3):6.Deng Chuanhong, Ma Juner, Zhang Guofan, et al. Effect of water glass on floatation of ilmenite[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 6. [11] Wang Yuhua, Chen Xinghua, Hu Yeming, et al. Influences of phosphates on dispersion of fine alumin-silicate minerals[J]. Journal of Central South University(Science and Technology), 2007,38(2):7. (王毓华, 陈兴华, 胡业民, 等. 磷酸盐对细粒铝硅酸盐矿物分散行为的影响[J]. 中南大学学报:自然科学版, 2007,38(2):7.Wang Yuhua, Chen Xinghua, Hu Yeming, et al. Influences of phosphates on dispersion of fine alumin-silicate minerals[J]. Journal of Central South University(Science and Technology), 2007, 38(2): 7. [12] Su Tao, Chen Tiejun, Zhang Yimin, et al. Influence of dispersion-flocculation on micro-fine magnetite low intensity magnetic separation[J]. Metal Mine, 2016(9):83−87. (苏涛, 陈铁军, 张一敏, 等. 分散—絮凝对某微细粒磁铁矿弱磁精选效果的影响[J]. 金属矿山, 2016(9):83−87.Su Tao, Chen Tiejun, Zhang Yimin, et al. Influence of dispersion-flocculation on micro-fine magnetite low intensity magnetic separation[J]. Metal Mine, 2016(9): 83−87. [13] Xu Pengyun. Study on dispersion-magnetic separation of finely-grained weakly-magnetic iron minerals[D]. Changsha: Central South University, 2013. (许鹏云. 细粒级弱磁性铁矿物分散—磁选研究 [D]. 长沙: 中南大学, 2013.Xu Pengyun. Study on dispersion-magnetic separation of finely-grained weakly-magnetic iron minerals[D]. Changsha: Central South University, 2013. [14] Li Lixia, Shen Shuaiping, Yuan Zhitao, et al. Loss mechanism of fine-grainedilmenite in magnetic separation[J]. China Mining Magazine, 2018,27(11):138−144. (李丽匣, 申帅平, 袁致涛, 等. 微细粒钛铁矿磁选回收率低原因分析[J]. 中国矿业, 2018,27(11):138−144.Li Lixia, Shen Shuaiping, Yuan Zhitao, et al. Loss mechanism of fine-grainedilmenite in magnetic separation[J]. China Mining Magazine, 2018, 27(11): 138−144. [15] Seno Manabu. Handbook of chemical formulas[M]. Li Xuefen, Cao Yong, Translator. Beijing: Science Press, 1987. (妹尾 学. 化学公式手册 [M]. 李学芬, 曹镛, 译. 北京: 科学出版社, 1987.Seno Manabu. Handbook of chemical formulas[M]. Li Xuefen, Cao Yong, Translator. Beijing: Science Press, 1987. [16] Zhu Yangge. Research on theory and technology of micro-fine ilmenite flotation[D]. Changsha: Central South University, 2013. (朱阳戈. 微细粒钛铁矿浮选理论与技术研究 [D]. 长沙: 中南大学, 2013.Zhu Yangge. Research on theory and technology of micro-fine ilmenite flotation[D]. Changsha: Central South University, 2013. -

下载:

下载: