Research progress and development direction of steel grade transition

-

摘要: 针对高附加值钢种的需求量较小,一个浇次需要生产不只一个钢种的现状,梳理了国内企业进行的异钢种连浇工业试验,描述了水模型试验和数值模拟在异钢种连浇过程的应用,主要总结了中间包液位高度、非等温浇注、中间包内腔结构、结晶器流体域结构、连铸机拉速和电磁制动等因素对交接坯长度的影响。评价了目前主流的四种交接坯判定模型,最终提出了制定异钢种连浇过程规范和研究异钢种连浇过程新模型的思路。结果表明,异钢种连浇实现了新钢种的高效生产,降低了企业生产成本,同时将人工智能学科与冶金学科结合了起来,为异钢种连浇过程提供了一个新的发展方向。Abstract: The demand for high value-added steel grades is relatively low, and more than one steel grade needs to be produced per casting sequence. Industrial tests of the steel grade transition carried out by domestic enterprises is sorted out in this paper. The application of water model experiment and numerical simulation in the steel grade transition is described. And the influence of tundish level, non-isothermal casting, tundish furniture, mold fluid domain structure, casting speed and electromagnetic braking on the length of transition billets is mainly summarized. After evaluating the four main mathematical models for judging the steel grade transition, the idea of formulating the specification for the steel grade transition and studying the new model for the steel grade transition is finally put forward. It can be concluded that the steel grade transition realizes the efficient production of new steel grades, reduces the production cost of enterprises. combining the disciplines of artificial intelligence and metallurgy practice can provide a new development direction for metallurgical engineering.

-

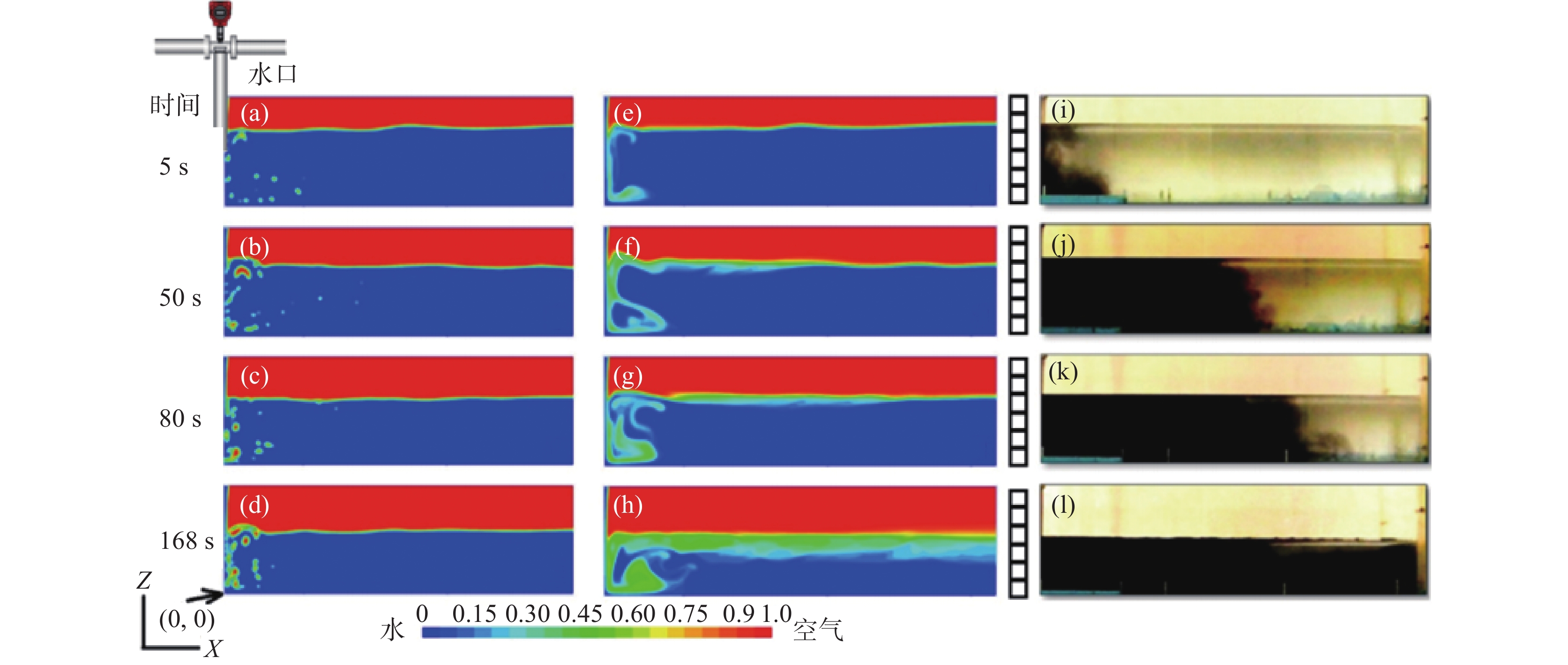

图 1 异钢种连浇过程数值模拟结果与水模型试验照片[15]

Figure 1. Numerical simulation results of the steel grade transition and photos of water model experiment

图 2 异钢种连浇过程中间包水模型试验装置[22]

Figure 2. Experimental device of tundish water model for the steel grade transition

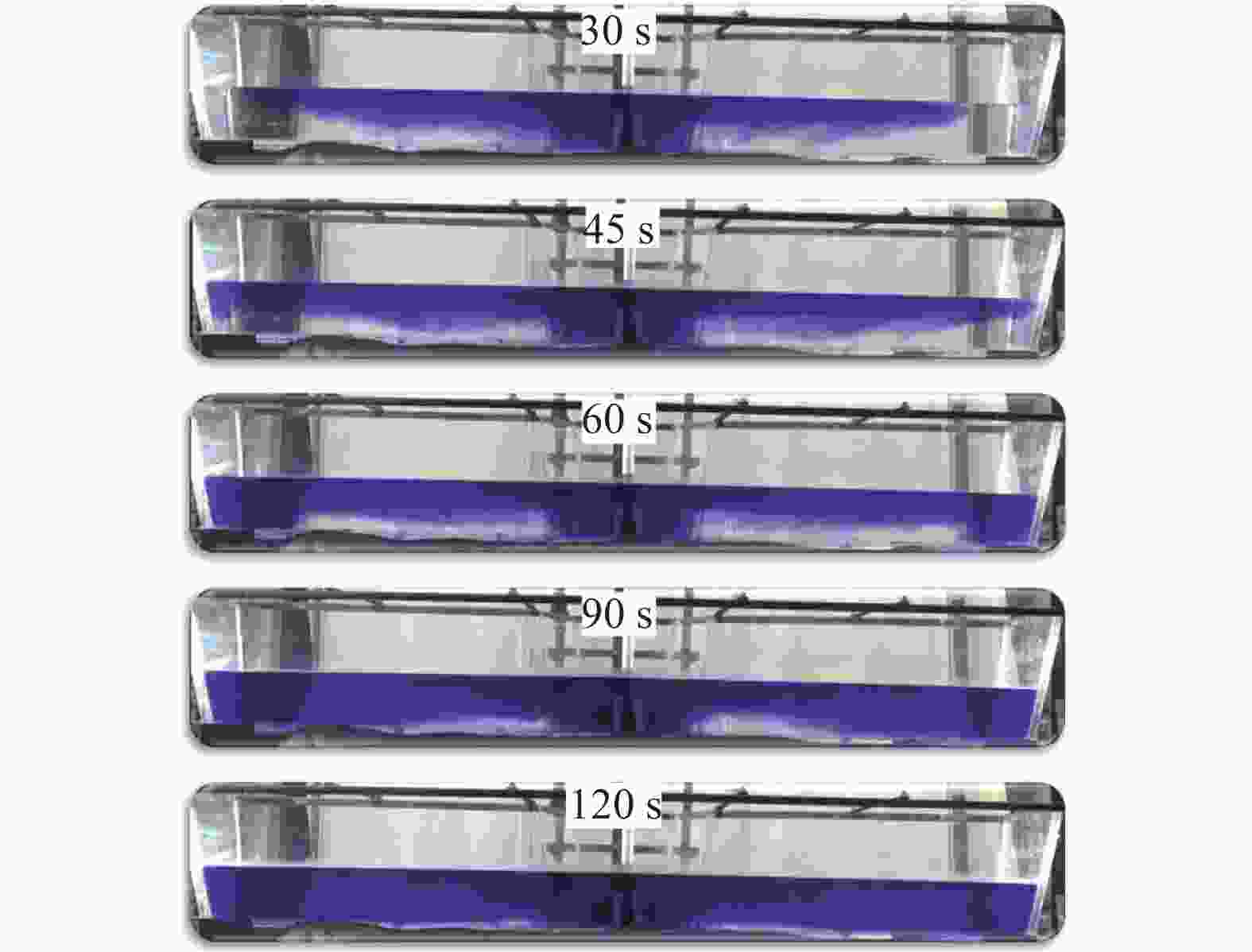

图 3 水模型墨汁试验照片[26]

Figure 3. Photos of water model ink experiment

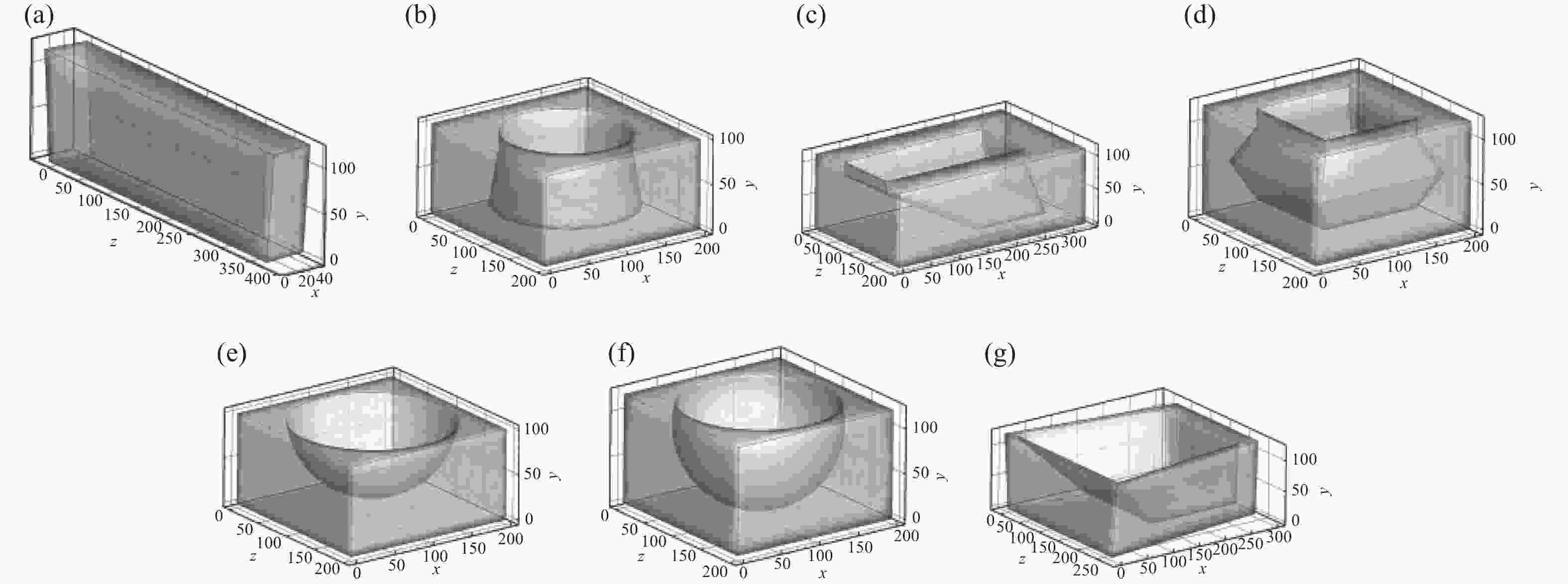

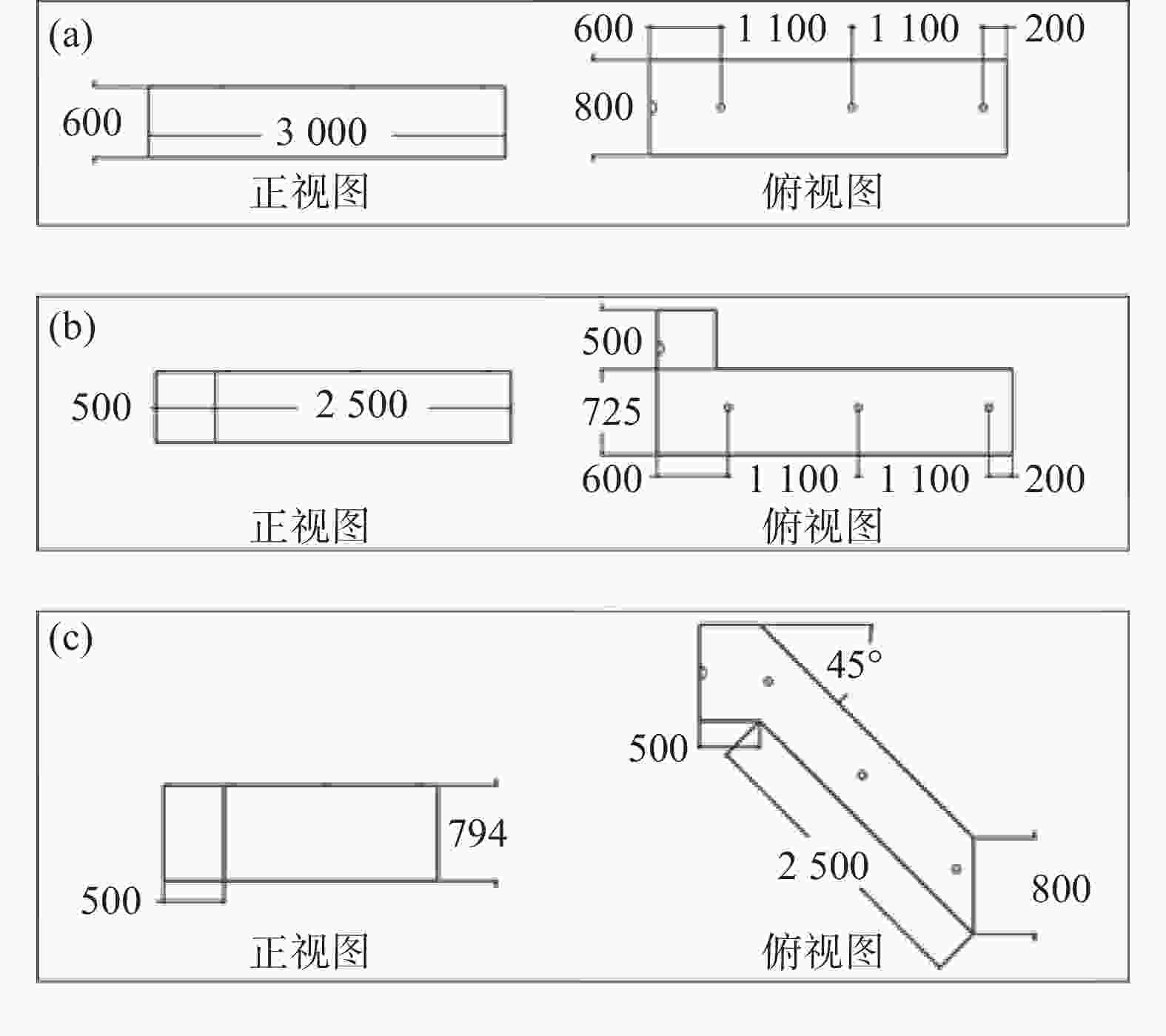

图 4 挡坝及湍流抑制器形状[28](单位:mm)

Figure 4. Schematic shape of dam and turbulence suppressor

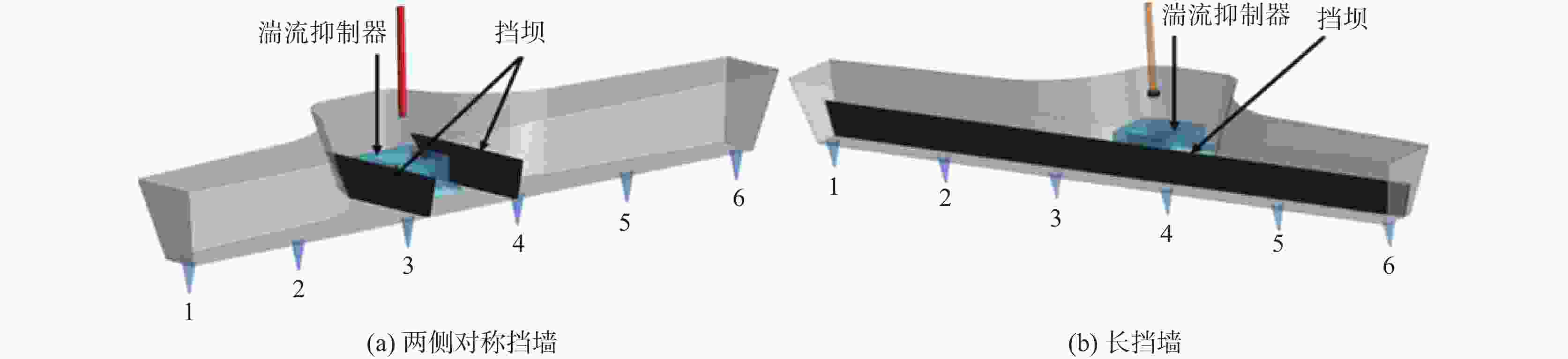

图 5 两种中间包挡坝[33]

Figure 5. Two types of tundish dam

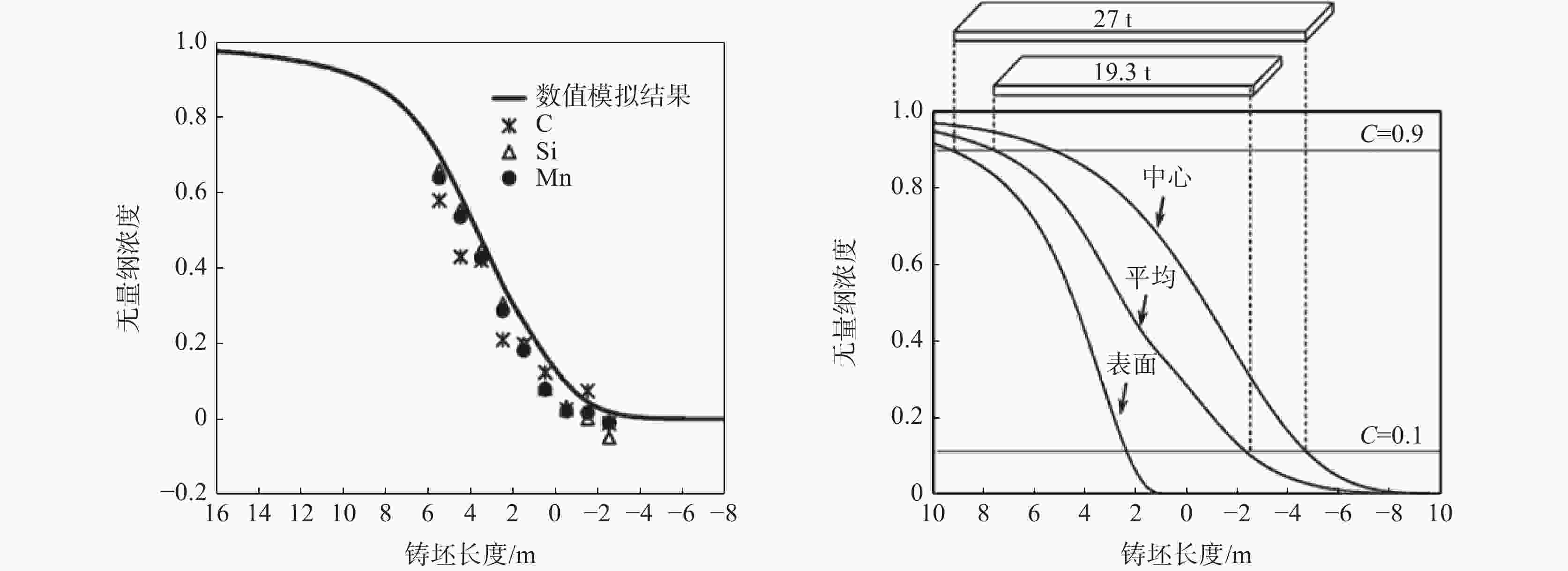

图 7 交接坯实际检测成分云图[53]

Figure 7. The measured composition contours in the mixed zone for the slab caster

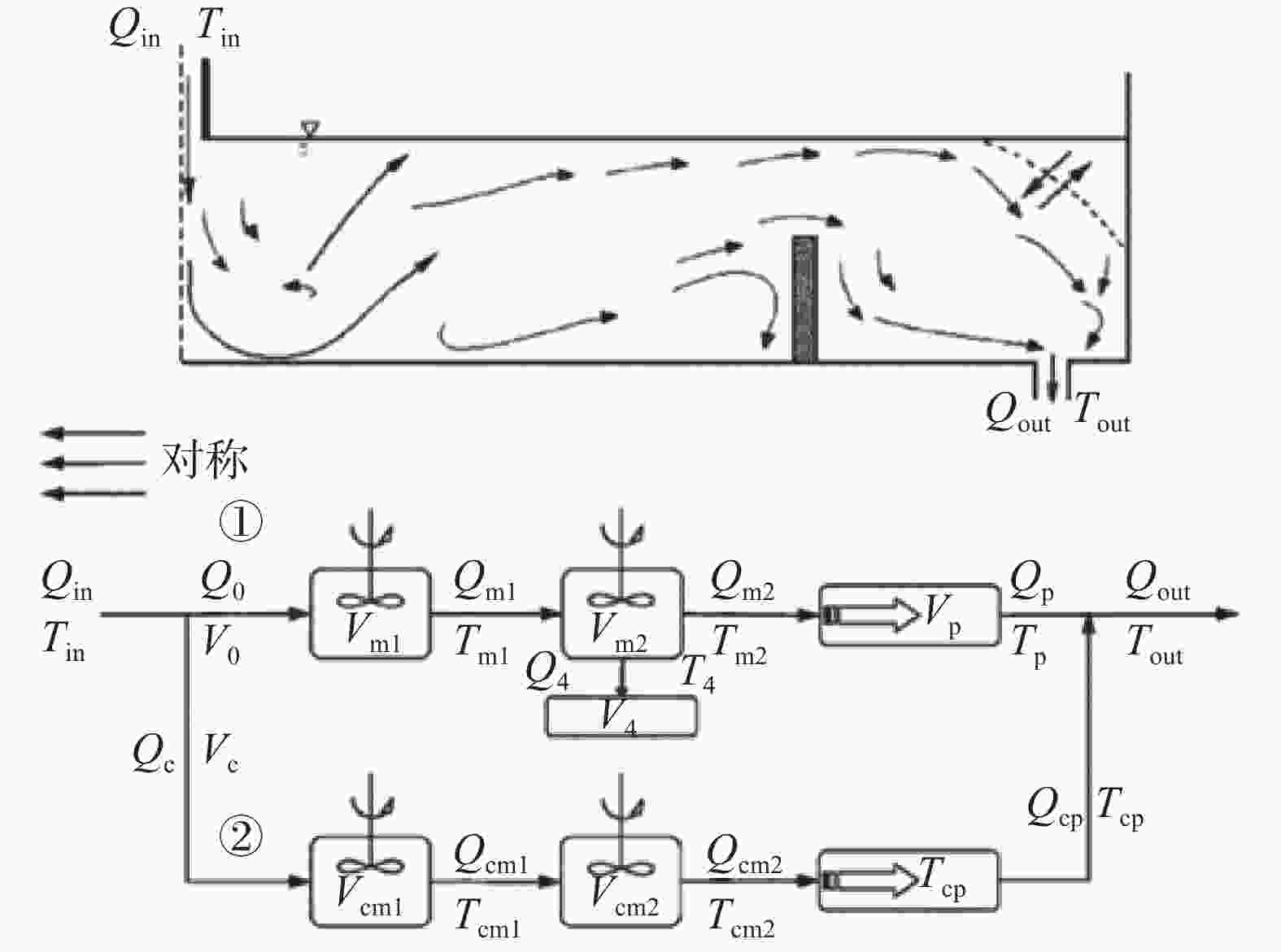

图 8 非等温条件下的中间包混合模型流程图及相应的中间包流场示意图[54]

Figure 8. Flowchart of tundish mixing model for non-isothermal conditions with schematically corresponding flow pattern in the tundish

图 9 连铸坯成分预测值和测量值的比较[54]

Figure 9. Comparison of predicted and measured slab composition

表 1 中国部分钢厂的异钢种连浇工业试验

Table 1. Industrial tests of steels grade transition in some steel plants in China

年份 作者 公司 铸机 钢种 参考文献 1995 陆云威 鞍山钢铁 小方坯 Q235 - 70Y [7] 2013 曹同友 武汉钢铁 板坯 SPHC - No.45 [8] 2014 王嘉祺 济南钢铁 板坯 微合金中碳钢、微合金包晶钢和微合金低碳钢 [6] 2014 干明 迁安钢铁 板坯 超低碳钢、低碳钢、包晶钢和中碳钢 [9] 2015 张川 湘潭钢铁 板坯 Q550D - Q345E和 Q345B - Q355QK [10] 2016 李东明 包头钢铁 大方坯 15MnNbV - No.20, No.20 - 13MnTi, 37Mn5 - 36Mn2VT和 10CrMoTi - 32Mn6 [11] 2018 吕志勇 鞍山钢铁 板坯 Q235B - SAE1012M和 Q235B - SAE1010 [12] 2019 隋亚飞 涟源钢铁 板坯 含镍钢 [13] 2021 杨丽梅 淮安钢铁 圆坯 20Cr - SCr15和4130X - 30CrMo [14] -

[1] 田志凌. 钢铁材料品种开发及其应用进展[C]//第十二届(2019)中国钢铁年会论文集. 北京: 中国金属学会, 2019: 1−2.Tian Zhiling. Development and application of steel product research in central iron and steel institute [C]//Proceedings of the 12th CSM Congress. Beijing: The Chinese Society for Metals, 2019: 1−2. [2] Guo Xiaochun, Fu Qiang, Wang Jian, et al. Research and practice of increasing continuous casting heats for RH refining aluminum killed steel[J]. Steelmaking, 2018,34(4):45-49. (郭晓春, 富强, 王健, 等. 提高RH精炼铝镇静钢连浇炉数的研究及实践[J]. 炼钢, 2018,34(4):45-49.Guo Xiaochun, Fu Qiang, Wang Jian, et al. Research and practice of increasing continuous casting heats for RH refining aluminum killed steel [J]. Steelmaking, 2018, 34(4): 45. [3] Huang Xiaoqing, Thomas Brian G. Modeling of steel grade transition in continuous slab casting processes[J]. Metall. Mater. Trans., 1993,24B:379-393. [4] Huang Xiaoqing, Thomas Brian G. Intermixing model of continuous casting during a grade transition[J]. Metall. Mater. Trans., 1996,27B:617-632. [5] Wang Baosheng, Chen Yuxin, Wang Hao. Practice of steel-grade change after flying tundish in shougang jingtang continuous caster[J]. Contin. Cast., 2013,(3):1-3. (王保生, 陈玉鑫, 王皓. 首钢京唐公司连铸机异钢种快换中间包生产实践[J]. 连铸, 2013,(3):1-3.Wang Baosheng, Chen Yuxin, Wang Hao. Practice of steel-grade change after flying tundish in shougang jingtang continuous caster [J]. Contin. Cast. , 2013, (3): 1. [6] Li Caixia. Study on composition variation law of steel grade transition during continuous casting[J]. Wide Heavy Plate, 2017,23(3):12-15. (李彩霞. 连铸异钢种混浇成分变化规律的研究[J]. 宽厚板, 2017,23(3):12-15. doi: 10.3969/j.issn.1009-7864.2017.03.003Li Caixia. Study on composition variation law of steel grade transition during continuous casting [J]. Wide Heavy Plate, 2017, 23(3): 12. doi: 10.3969/j.issn.1009-7864.2017.03.003 [7] Lu Yunwei, Cui Sulan. The transition duration and the influential factors of compound casting billets[J]. Steelmaking, 1995,(4):30-33. (陆云威, 崔素兰. 连铸混浇坯的过度时间及影响因素[J]. 炼钢, 1995,(4):30-33.Lu Yunwei, Cui Sulan. The transition duration and the influential factors of compound casting billets [J]. Steelmaking, 1995, (4): 30. [8] Cao Tongyou, Yang Xinquan. Study on interfusion rules of different steel grades during continuous casting[J]. Res. Iron Steel., 2014,42(5):11-13. (曹同友, 杨新泉. 异钢种连浇钢水互熔规律的研究[J]. 钢铁研究, 2014,42(5):11-13.Cao Tongyou, Yang Xinquan. Study on interfusion rules of different steel grades during continuous casting [J]. Res. Iron Steel. , 2014, 42(5): 11. [9] 干明, 张涛, 彭开玉, 等. 首钢迁钢恒拉速、异钢种连浇技术的开发与应用[C]// 2014年全国炼钢—连铸生产技术会论文集. 唐山: 中国金属学会, 2014: 72−77.Gan Ming, Zhang Tao, Peng Kaiyu, et al. Development and application of constant casting speed technology and different grade casting technology in shougang qian’an steel [C]// 2014 China Steelmaking and Continuous Casting Production Technology Conference. Tangshan: The Chinese Society for Metals, 2014: 72−77. [10] Zhang Chuan, Wang Hao, Zhang Yuan, et al. Production practice on steel grade transition of continuous casting[J]. Res. Iron Steel., 2015,43(4):53-56. (张川, 王皓, 张沅, 等. 连铸机异钢种混合浇铸生产实践[J]. 钢铁研究, 2015,43(4):53-56.Zhang Chuan, Wang Hao, Zhang Yuan, et al. Production practice on steel grade transition of continuous casting [J]. Res. Iron Steel. , 2015, 43(4): 53. [11] Li Dongming, Dong Fang, Fu Yue. Production practice of optimizing different steel grade continuous casting[J]. Science and Technology of Baotou Steel, 2016,42(6):28-31. (李东明, 董方, 付岳. 优化异钢种连续浇注的生产实践[J]. 包钢科技, 2016,42(6):28-31.Li Dongmin, Dong Fang, Fu Yue. Production practice of optimizing different steel grade continuous casting [J]. Science and Technology of Baotou Steel, 2016, 42(6): 28. [12] Lü Zhiyong, Zhou Liujian, Shi Yeshu, et al. Production practice of casting molten steel with different steel grades[J]. Science and Technology of Baotou Steel, 2018,(4):58-62. (吕志勇, 周刘建, 史页殊, 等. 异钢种混浇生产实践[J]. 鞍钢技术, 2018,(4):58-62.Lv Zhiyong, Zhou Liujian, Shi Yeshu, et al. Production practice of casting molten steel with different steel grades [J]. Science and Technology of Baotou Steel, 2018, (4): 58. [13] Sui Yafei, Chen Jie, Liu Peng, et al. Research and model prediction on composition change of continuous casting intermixing slab[J]. Contin. Cast., 2019,44(4):62-67. (隋亚飞, 陈杰, 刘彭, 等. 连铸混浇坯成分变化规律及模型的研究[J]. 连铸, 2019,44(4):62-67.Sui Yafei, Chen Jie, Liu Peng, et al. Research and model prediction on composition change of continuous casting intermixing slab [J]. Contin. Cast. , 2019, 44(4): 62. [14] Yang Limei, Zheng Lining. Production practice of the steel grade transition in continuous casting tundish[J]. Modern Metallurgy, 2021,49(1):43-46. (杨丽梅, 郑力宁. 连铸中间包异钢种连浇生产实践[J]. 现代冶金, 2021,49(1):43-46.Yang Limei, Zheng lining. Production practice of the steel grade transition in continuous casting tundish [J]. Modern Metallurgy, 2021, 49(1): 43. [15] Siddiqui Md Irfanul Haque, Kim Man-Hoe. Two−phase numerical modeling of grade intermixing in a steelmaking tundish[J]. Metals, 2019,9(1):1-14. doi: 10.3390/met9010040 [16] Michalek Karel, Gryc Karel, Tkadleckova Markéta, et al. Model study of tundish steel intermixing and operational verification[J]. Archives of Metallurgy and Materials, 2012,57(1):291-296. [17] Siddiqui Md Irfanul Haque, Kim Man Hoe. Optimization of flow control devices to minimize the grade mixing in steelmaking tundish[J]. J. Mech. Sci. Technol., 2018,32(7):3213-3221. doi: 10.1007/s12206-018-0624-8 [18] Oro Fernández, Morros Santolaria, Somoano Rodríguez, et al. Multiphase modelling of the steel grade transition in a continuous casting tundish [C]//Proceedings of the ASME 2009 Fluids Engineering Division Summer Meeting . Vail, Colorado USA: ASME, 2009: 2183−2194. [19] 毕经汉. 异钢种连浇交接坯位置和长度预测模型[D]. 重庆: 重庆大学, 2012.Bi Jinghan. Prediction model of intermixing slab location and length in continuous casting grade transition process[D]. Chongqing: Chongqing University, 2012. [20] 李涛. 异钢种连浇交接坯长度和位置的研究 [D]. 马鞍山: 安徽工业大学, 2016.Li Tao. Study of intermixing slab length and location in continuous casting grade transition process [D]. Ma,anshan: Anhui University of Technology, 2016. [21] Zhang Jianjun, Peng Zhugang, Wang Chunfeng, et al. Research on continuous casting grades transition process by hydraulic model of CSP 45 t single strand tundish[J]. Steelmaking, 2017,33(4):19-22. (张剑君, 彭著刚, 王春锋, 等. 薄板坯单流中间包混浇水力学模型试验研究[J]. 炼钢, 2017,33(4):19-22.Zhang Jianjun, Peng Zhugang, Wang Chunfeng, et al. Research on continuous casting grades transition process by hydraulic model of CSP 45 t single strand tundish [J]. Steelmaking, 2017, 33(4): 19. [22] Branislav Bul’ko, Marek Molnár, Peter Demeter, et al. Study of the influence of intermix conditions on steel cleanliness[J]. Metals, 2018,8(10):852-860. doi: 10.3390/met8100852 [23] 刘超. 五流中间包异钢种连浇过程多相流及混钢行为研究[D]. 武汉: 武汉科技大学, 2020.Liu Chao. Study on multiphase flow and mixing during grade change process of a five-strand bloom tundish[D]. Wuhan: Wuhan University of Science and Technology, 2020. [24] Damle Chandrashekha, Sahai Yogeshwa. A criterion for water modeling of non-isothermal melt flows in continuous casting tundishes[J]. ISIJ Int., 1996,36(6):681-689. doi: 10.2355/isijinternational.36.681 [25] Sinha A K, Vassilicos A. Physical modelling of thermal effects on steel flow and mixing in tundish[J]. Ironmaking Steelmaking, 1998,25(5):387-393. [26] Amorim Laudinei L C, Silva Carlos A, Resende Alexandre D, et al. A study of intermix in a six-strand billet caster[J]. Metall. Mater. Trans., 2018,49A:6308-6324. [27] Chattopadhyay Kinnor, Isac Mihaiela, Guthrie Roderick Ian Lawrence. Modelling of non-isothermal melt flows in a four strand felta shaped billet caster tundish validated by water model experiments[J]. ISIJ Int., 2012,52(11):2026-2035. doi: 10.2355/isijinternational.52.2026 [28] Cwudziński Adam. Physical and mathematical simulation of liquid steel mixing zone in one strand continuous casting tundish[J]. Int. J. Cast Metal. Res., 2016,30(1):50-60. [29] Chen Huiqing Sarah, Pehlke Robert D. Mathematical modeling of tundish operation and flow control to reduce transition slabs[J]. Metall. Mater. Trans., 1996,27B:745-756. [30] Guo Chunmu, Yu Fan, Zhang Xinxin. Numerical simulation of steel flow and mixing during grade transition casting[J]. Chian Metall., 2006,16(1):35-38. (郭春牧, 于帆, 张欣欣. 异钢种连浇过程中钢液流动与混合的数值模拟[J]. 中国冶金, 2006,16(1):35-38.Guo Chunmu, Yu Fan, Zhang Xinxin. Numerical simulation of steel flow and mixing during grade transition casting [J]. Chian Metall. , 2006, 16(1): 35. [31] Kant S, Jha P K, Kumar P. Investigation of effect of dam on intermixing during ladle changeover in six strand billet caster tundish[J]. Ironmaking Steelmaking, 2011,38(5):391-397. doi: 10.1179/1743281211Y.0000000007 [32] Kumar Rajneesh, Siddiqui Md Irfanul Haque, Jha Pradeep Kumar. Numerical investigations on the use of flow modifiers in multi-strand continuous casting tundish using RTD curves analysis [C]// Proceedings of International Conference on Smart Technologies for Mechanical Engineering. 2013: 603−612. [33] Agarwal Rohit, Singh Mrityunjay K, Kumar Ram Bachchan, et al. Extensive analysis of multi strand billet caster tundish using numerical technique[J]. World Journal of Mechanics, 2019,9:29-51. doi: 10.4236/wjm.2019.92003 [34] Kumar Rajneesh, Maurya Ambrish, Siddiqui Md Irfanul Haque, et al. Some studies in different shapes of tundish-intermixing and flow behavioue [C]// Department of Industrial and Production Engineering Ivth International Conference on Production and Industrial Engineering. Jalandharv, India: CPIE, 2016: 603−610. [35] Siddiqui Md Irfanul Haque, Jha Pradeep Kumar. Effect of inflow rate variation on intermixing in a steelmaking tundish during ladle change-over[J]. Steel Res. Int., 2016,87(6):733-744. doi: 10.1002/srin.201500210 [36] Muralikrishna A, Muralikrishna S, Dipak Mazumdar. Modeling and measurements of intermixing time in a water model of a four strand steelmaking tundish system[J]. Trans. Indian Inst. Met., 2013,66(3):281-295. doi: 10.1007/s12666-013-0270-x [37] Meng Na, Yu Jia, Liu Lan, et al. Numerical simulation of molten steel in tundish during continuous casting grade transition[J]. Heavy Machinery, 2012,(2):20-25. (孟娜, 余嘉, 刘岚, 等. 连铸异钢种连浇中间包内钢液流动的数值模拟[J]. 重型机械, 2012,(2):20-25.Meng Na, Yu Jia, Liu Lan, et al. Numerical simulation of molten steel in tundish during continuous casting grade transition [J]. Heavy Machinery, 2012, (2): 20. [38] Zorzut M, Vecchiet F, Kapaj N, et al. Tundish flow optimization and steel grade change prediction[J]. Berg Huettenmaenn Monatsh, 2007,152:355-360. doi: 10.1007/s00501-007-0328-3 [39] Wang Yufeng, Zhang Lifeng. Transient fluid flow phenomena during continuous casting: part II—cast speed change, temperature fluctuation, and steel grade mixing[J]. ISIJ Int., 2010,50(12):1783-1791. doi: 10.2355/isijinternational.50.1783 [40] Thomas Brian G. Modeling study of intermixing in tundish and strand during a continuous-casting grade transition[J]. Iron and Steelmaker, 1997,24(12):83-96. [41] Thomas Brian G. The importance of computational models for further improvements of the continuous casting process [C]// Voest Alpine Conference on Continuous Casting. Linz, Austria: Semantic Scholar, 2001: 1−10. [42] Lan X K, Khodadadi J M. Liquid steel flow, heat transfer and solidification in mold of continuous casters during grade transition[J]. Int. J. Heat Mass Tran., 2001,44:3431-3442. doi: 10.1016/S0017-9310(01)00005-9 [43] Michalek K, Gryc K, Tkadleckova M, et al. Type of submerged entry nozzle vs. Concentration profiles in the intermixed zone of round blooms with a diameter of 525 mm[J]. Materials and Technology, 2012,46(6):581-587. [44] Jeong Myunggeun, Choi Changyoung, Ha Man Yeong, et al. Numerical simulation of continuous casting process of different steel grades considering solidification and mixing of different steel grades[J]. Met. Mater. Int., 2015,21(2):303-310. doi: 10.1007/s12540-015-4199-y [45] 陈志平. 非稳态浇铸条件下连铸板坯质量控制研 [D]. 沈阳: 东北大学, 2008.Chen Zhiping. Study on the control of continuous casting slab quality under unsteady casting condition[D]. Shenyang: Northeastern University, 2008. [46] 孙增晓. 异钢种连浇过程的水模型验研究[D]. 包头: 内蒙古科技大学, 2010.Sun Zengxiao. Water model experiment of steel grade transition in continuous casting process[D]. Baotou: Inner Mongolia University of Science and Technology, 2010. [47] Li Baokuan, Tsukihashi Fumitaka. Effect of static magnetic field application on the mass transfer in sequence slab continuous casting process[J]. ISIJ Int., 2001,41(8):844-849. doi: 10.2355/isijinternational.41.844 [48] Ahn J H, Yoon J K, Lee J E. Analysis of mixed grade transition in continuous thin slab casting with EMBR[J]. Met. Mater. Int., 2002,8(3):271-281. doi: 10.1007/BF03186096 [49] Li Yugang, Dong Jingang, Li Gang, et al. Prediction model of slab at junction in continuous casting of dissimilar steel[J]. J. Chongqing Univ., 2006,29(8):119-122. (李玉刚, 董金刚, 李刚, 等. 异钢种连浇过程中的交接部铸坯预测模型[J]. 重庆大学学报, 2006,29(8):119-122.Li Yugang, Dong Jingang, Li Gang, et al. Prediction model of slab at junction in continuous casting of dissimilar steel [J]. J. Chongqing Univ. , 2006, 29(8): 119. [50] Hou Jilin. Study on slab judgement of multi heats continuous casting steel mixing zone[J]. Science and Technology of Baotou Steel, 2000,26(1):43-46. (侯基林. 多炉连浇混钢区铸坯判定的研究[J]. 包钢科技, 2000,26(1):43-46.Hou Jilin. Study on slab judgement of multi heats continuous casting steel mixing zone [J]. Science and Technology of Baotou Steel, 2000, 26(1): 43. [51] Goldschmit Marcela B, Ferro Sergio P, Walter Guillermo F, et al. Numerical model for the minimization of intermixed round bars in a four line continuous caster[J]. Metall. Mater. Trans., 2001,32B:537-546. [52] Cho Myung Jong, Kim In Cheol. Simple tundish mixing model of continuous casting during a grade transition[J]. ISIJ Int., 2006,46(10):1416-1420. doi: 10.2355/isijinternational.46.1416 [53] Cho Myung Jong, Kim Sang Joon. A practical model for predicting intermixed zone during grade transition[J]. ISIJ Int., 2010,50(8):1175-1179. doi: 10.2355/isijinternational.50.1175 [54] Alizadeh Mehdi, Edris Hossein, Pishevar Ahmad Reza. Behavior of mixed grade during the grade transition for different conditions in the slab continuous casting[J]. ISIJ Int., 2008,48(1):28-37. doi: 10.2355/isijinternational.48.28 [55] Braga Bernardo Martins, Tavares Roberto Parreiras. Additional information on “Simple tundish mixing model of continuous casting during a grade transition” by Cho and Kim[J]. ISIJ Int., 2018,58(6):1178-1180. doi: 10.2355/isijinternational.ISIJINT-2018-046 [56] Ruiz J, Delgado T, Cabalin L M, et al. At-line monitoring of continuous casting sequences of steel using discriminant function analysis and dual-pulse laser-induced breakdown spectroscopy[J]. J. Anal. At. Spectrom., 2017,32:1119-1128. doi: 10.1039/C7JA00093F [57] Cabalin L M, Delgado T, Ruiz J, et al. Stand-off laser-induced breakdown spectroscopy for steel-grade intermix detection in sequence casting operations. At-line monitoring of temporal evolution versus predicted mathematical model[J]. Spectrochim. Acta B, 2018,146:93-100. doi: 10.1016/j.sab.2018.05.001 [58] Zhao Liping, Dou Rushan, Yin Junjun, et al. Intelligent prediction method of quality for continuous casting process [C]//2016 IEEE Advanced Information Management, Communicates, Electronic and Automation Control Conference (IMCEC 2016) . Xian: IMCEC, 2016: 1761−1764. [59] 李曜光. 连铸过程宏观传输现象及中心偏析的模拟研究[D]. 北京: 北京科技大学, 2021.Li Yaoguang. Numerical study on macroscopic transport phenomena and center segregation for continuous casting process[D]. Beijing: University of Science and Technology Beijing, 2021. -

下载:

下载: