High-temperature heat capacity and metallurgical performance of Ca3TiFe2O8

-

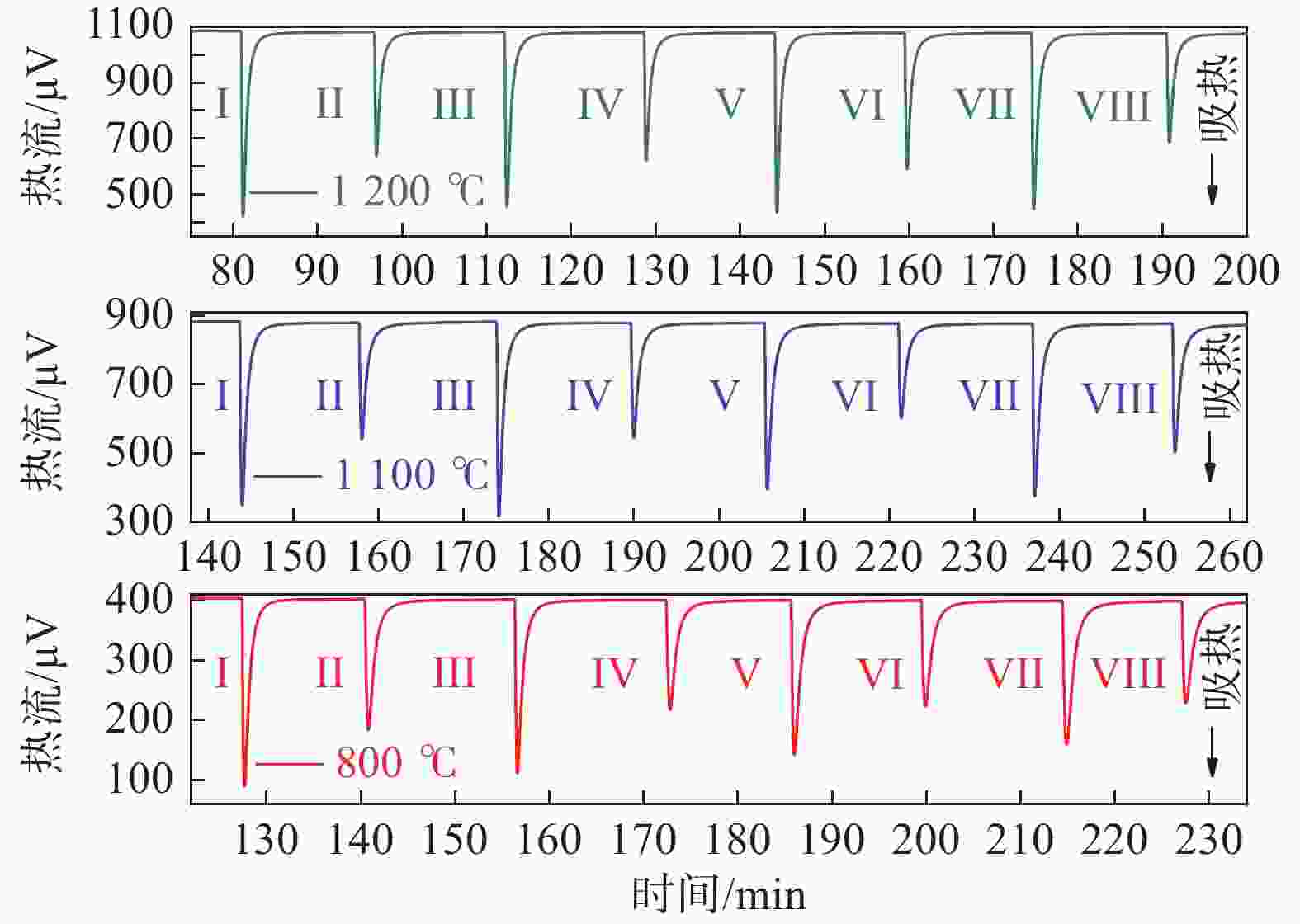

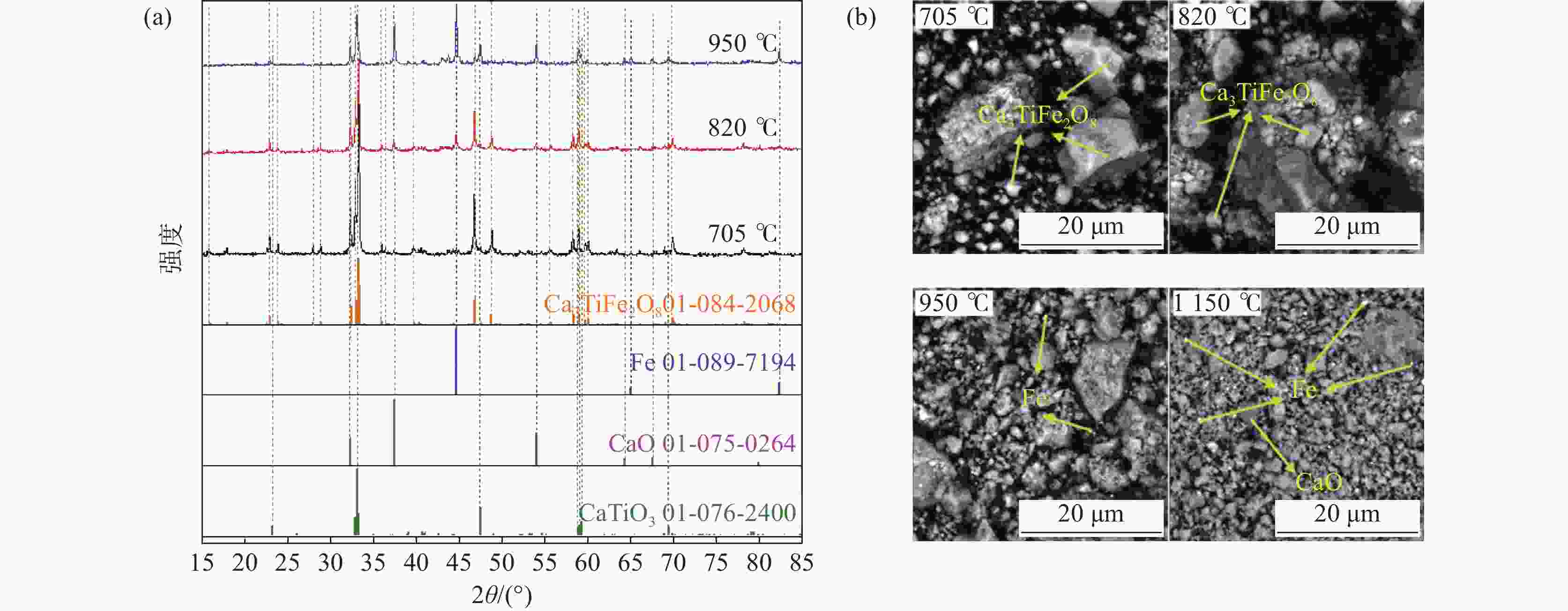

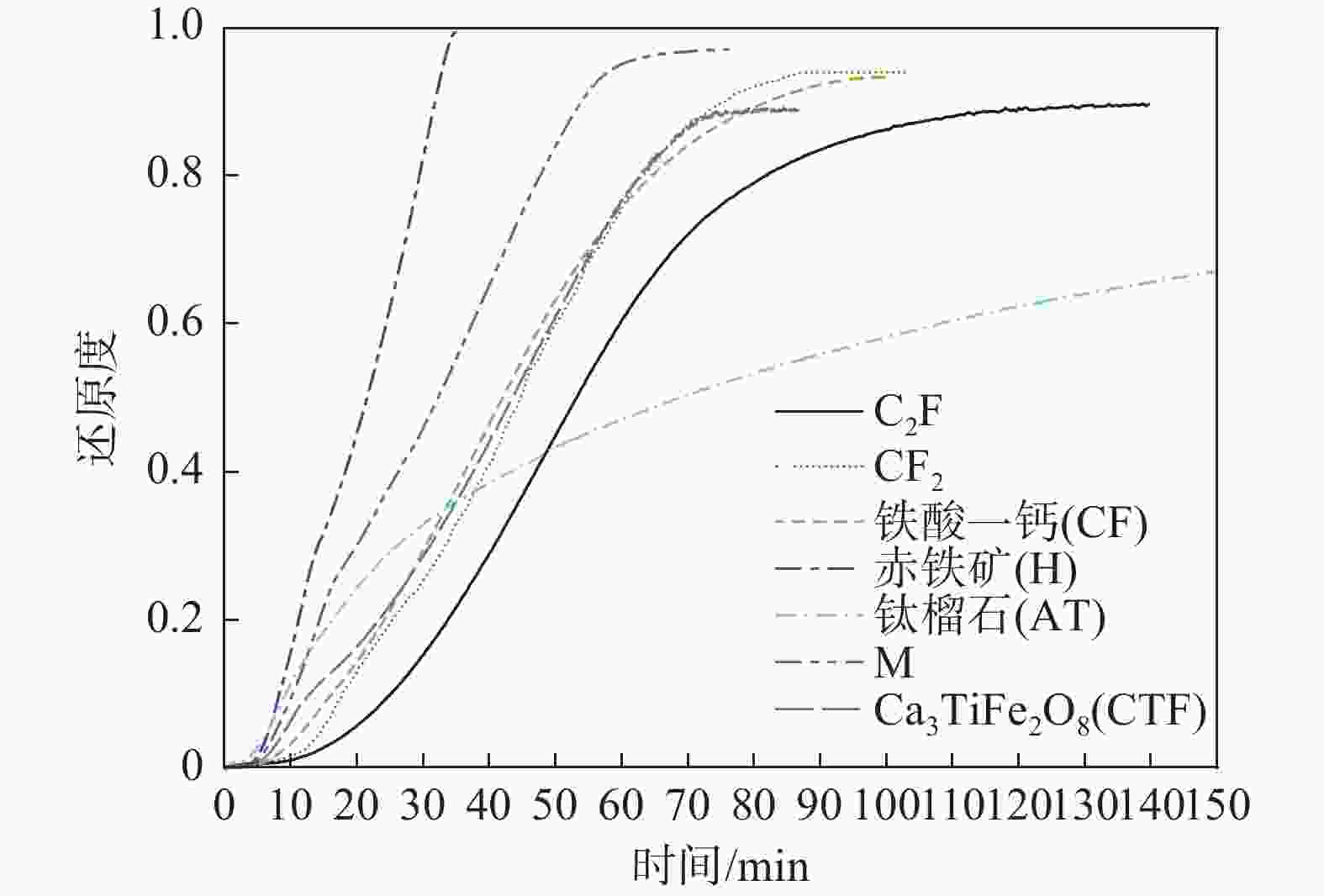

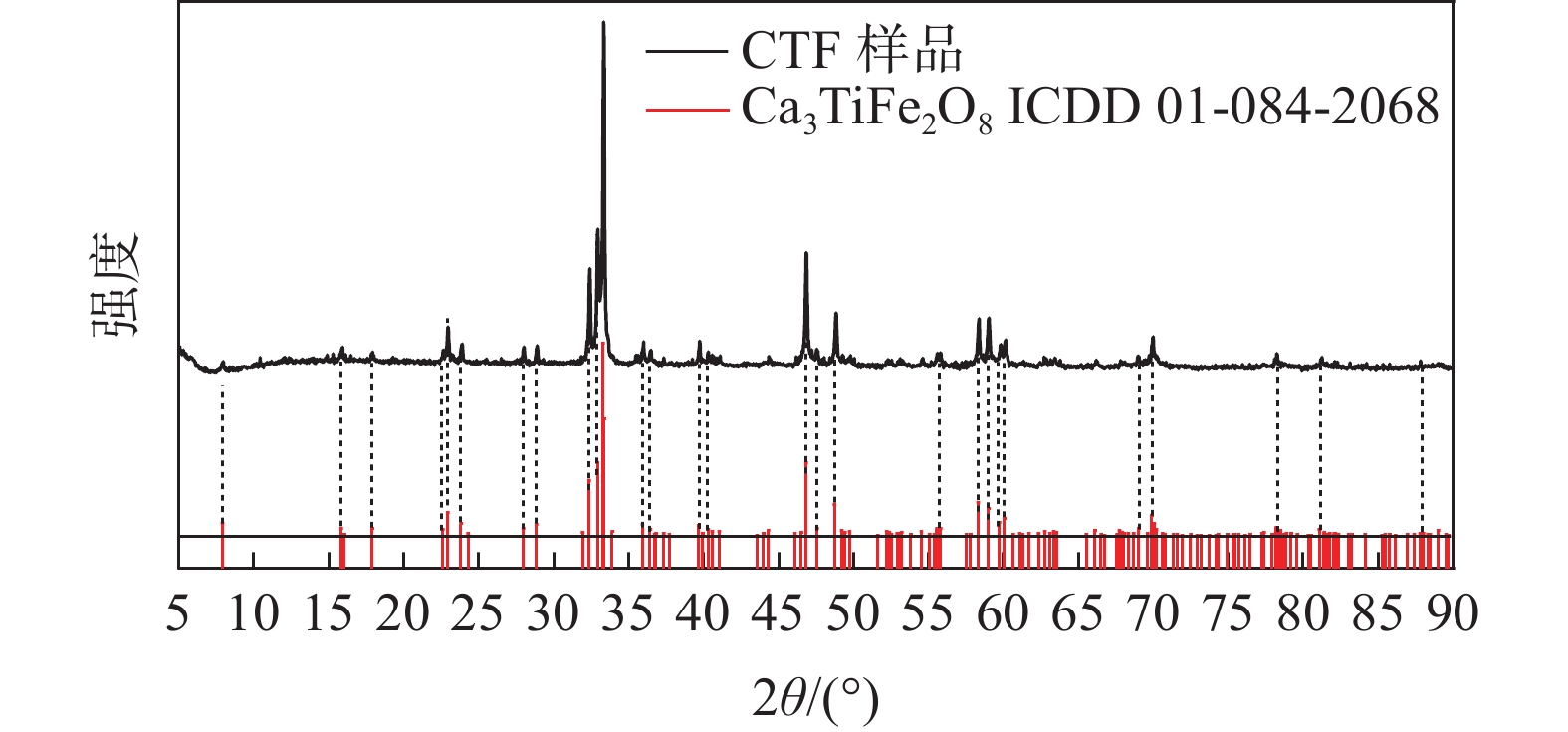

摘要: 烧结矿的质量很大程度上取决于其粘结相的特性。为促进钒钛磁铁矿资源在烧结领域的高效利用,对含TiO2的钙铁氧体体系进行了研究。在含钛铁矿烧结矿中发现了Ca3TiFe2O8(CTF)的存在,后经由固态反应成功制备出了CTF,并通过Drop法测定了CTF的高温热容,得到了其高温热容量的拟合函数。同时,还对其冶金性能(熔化性能和还原行为)进行了检测分析。结果表明,CTF的软化温度、熔化温度和流动温度分别为1418、1461 ℃和1480 ℃。非等温还原结果表明,CTF被一步还原成Fe、CaO和CaO·TiO2,当温度达到1150 ℃时,CTF还原完成。

-

关键词:

- 烧结 /

- 钒钛磁铁矿 /

- Ca3TiFe2O8 /

- 高温热容 /

- 冶金性能

Abstract: The quality of the sintered iron ores is dominated by their bonding phases properties. The calcium ferrite system containing TiO2 was investigated to promote the efficient utilization of vanadium and titanium magnetite resources in the field of sintering. In this paper, Ca3TiFe2O8 (CFT) was found in titanium-bearing sintering ores, and CTF was successfully prepared by solid-state reaction. The high-temperature heat capacity of CTF was determined by the Drop method, and the corresponding fitting function was obtained. In addition, the metallurgical properties (including melting properties and reduction behavior) of CTF were determined. The results showed that the softening, melting and flowing temperatures of CTF were 1418 ℃, 1461 ℃ and 1480 ℃, respectively. The non-isothermal reduction results showed that CTF was reduced to Fe, CaO and CaO·TiO2 in one step, and the reduction process of CTF was completed when the temperature reached 1150 ℃. -

表 1 烧结矿典型物相在900 ℃的最大还原度及其还原时间

Table 1. Reduction degree of the typical phases in sintered ores and the corresponding reduction time

物相 还原度/% 还原时间/min 物相 还原度/% 还原时间/min H 0.99 35.5 CTF 0.89 79.2 M 0.97 76.1 C2F 0.89 114.4 CF2 0.94 92.8 Ki 0.83 141.5 CF 0.93 99.7 AT 0.67 150 -

[1] Li Shuo, Chen Fulin, Cai Xianyan, et al. Experimental study on quality improvement and impurity reduction of a vanadium-titanium iron concentrate in Panxi[J]. Iron Steel Vanadium Titanium, 2023,44(5):105−110. (李硕, 陈福林, 蔡先炎, 等. 攀西某钒钛铁精矿提质降杂试验研究[J]. 钢铁钒钛, 2023,44(5):105−110. doi: 10.7513/j.issn.1004-7638.2023.05.016Li Shuo, Chen Fulin, Cai Xianyan, et al. Experimental study on quality improvement and impurity reduction of a vanadium-titanium iron concentrate in Panxi[J]. Iron Steel Vanadium Titanium, 2023, 44(5): 105−110. doi: 10.7513/j.issn.1004-7638.2023.05.016 [2] Deng Jun, Xue Xun, Liu Gongguo. Current situation and development of comprehensive utilization of vanadium-bearing titanomagnetite at Pangang[J]. Joumal of Materials and Metallurgy, 2007(2):83−86,93. (邓君, 薛逊, 刘功国. 攀钢钒钛磁铁矿资源综合利用现状与发展[J]. 材料与冶金学报, 2007(2):83−86,93. doi: 10.3969/j.issn.1671-6620.2007.02.001Deng Jun, Xue Xun, Liu Gongguo. Current situation and development of comprehensive utilization of vanadium-bearing titanomagnetite at Pangang[J]. Joumal of Materials and Metallurgy, 2007(2): 83−86,93. doi: 10.3969/j.issn.1671-6620.2007.02.001 [3] Jiang Tao, Xu Jing, Guan Shanfei, et al. Study on coal-based direct reduction of high-chromium vanadium-titanium magnetite[J]. Journal of Northeastern University( Natural Science), 2015,36(1):77−80,85. (姜涛, 徐静, 关山飞, 等. 高铬型钒钛磁铁矿煤基直接还原研究[J]. 东北大学学报(自然科学版), 2015,36(1):77−80,85. doi: 10.3969/j.issn.1005-3026.2015.01.017Jiang Tao, Xu Jing, Guan Shanfei, et al. Study on coal-based direct reduction of high-chromium vanadium-titanium magnetite[J]. Journal of Northeastern University( Natural Science), 2015, 36(1): 77−80,85. doi: 10.3969/j.issn.1005-3026.2015.01.017 [4] Chen Haibin, Zhou Zhenhua, Zhang Zuojin, et al. Research progress in the comprehensive recovery of vanadium-titanium magnetite[J]. Modern Mining, 2023,39(1):7−9. (陈海彬, 周振华, 张作金, 等. 钒钛磁铁矿综合回收研究进展[J]. 现代矿业, 2023,39(1):7−9. doi: 10.3969/j.issn.1674-6082.2023.01.002Chen Haibin, Zhou Zhenhua, Zhang Zuojin, et al. Research progress in the comprehensive recovery of vanadium-titanium magnetite[J]. Modern Mining, 2023, 39(1): 7−9. doi: 10.3969/j.issn.1674-6082.2023.01.002 [5] Wang Yanjun. Study on the BF burden structure optimization of Cr-bearing vanadium-titanium magnetite[D]. Shenyang: Northeastern University, 2019. (王艳军. 含铬型钒钛磁铁矿高炉炉料结构优化研究[D]. 沈阳: 东北大学, 2019.Wang Yanjun. Study on the BF burden structure optimization of Cr-bearing vanadium-titanium magnetite[D]. Shenyang: Northeastern University, 2019. [6] Zhang Yong. Key technology research on blast furnace smelting high chromium vanadium-titanium magnetite[D]. Shenyang: Northeastern University, 2014. (张勇. 高铬型钒钛磁铁矿高炉冶炼关键技术研究[D]. 沈阳: 东北大学, 2014.Zhang Yong. Key technology research on blast furnace smelting high chromium vanadium-titanium magnetite[D]. Shenyang: Northeastern University, 2014. [7] Hong Lukuo, Wu Bingqiang, Li Mingduo, et al. Direct reduction process for carbon-containing pellets of vanadium-bearing titanomagnetite[J]. Mining and Metallurgical Engineering, 2017,37(3):86−89,93. (洪陆阔, 武兵强, 李明铎, 等. 钒钛磁铁精矿含碳球团直接还原工艺分析[J]. 矿冶工程, 2017,37(3):86−89,93. doi: 10.3969/j.issn.0253-6099.2017.03.022Hong Lukuo, Wu Bingqiang, Li Mingduo, et al. Direct reduction process for carbon-containing pellets of vanadium-bearing titanomagnetite[J]. Mining and Metallurgical Engineering, 2017, 37(3): 86−89,93. doi: 10.3969/j.issn.0253-6099.2017.03.022 [8] Xue Xun. Research on direct reduction of vanadic titanomagnetite[J]. Iron Steel Vanadium Titanium, 2007,28(3):37−41. (薛逊. 钒钛磁铁矿直接还原实验研究[J]. 钢铁钒钛, 2007,28(3):37−41. doi: 10.3969/j.issn.1004-7638.2007.03.009Xue Xun. Research on direct reduction of vanadic titanomagnetite[J]. Iron Steel Vanadium Titanium, 2007, 28(3): 37−41. doi: 10.3969/j.issn.1004-7638.2007.03.009 [9] Yang Yang, Li Yang, Guo Min, et al. Selective enrichment of Ti element and phase transformation of MgAl2O4 in titanium-containing electric furnace molten slag during the alkali fusion process[J]. Chinese Journal of Engineering, 2015,37(1):78−85. (杨洋, 李杨, 郭敏, 等. 含钛电炉熔分渣碱熔过程中Ti元素的选择性富集及MgAl2O4的物相转化规律[J]. 工程科学学报, 2015,37(1):78−85.Yang Yang, Li Yang, Guo Min, et al. Selective enrichment of Ti element and phase transformation of MgAl2O4 in titanium-containing electric furnace molten slag during the alkali fusion process[J]. Chinese Journal of Engineering, 2015, 37(1): 78−85. [10] Pownceby M I, Webster N A S, Manuel J R, et al. The influence of ore composition on sinter phase mineralogy and strength[J]. Mineral Processing and Extractive Metallurgy, 2016,125(3):140−148. doi: 10.1080/03719553.2016.1153276 [11] Zhou Mi, Yang S T, Jiang Tao, et al. Influence of MgO in form of magnesite on properties and mineralogy of high chromium, vanadium, titanium magnetite sinters[J]. Ironmaking & Steelmaking, 2015,42(3):217−225. [12] Pimenta H P, Seshadri V. Influence of Al2O3 and TiO2 degradation behaviour of sinter and hematite at low temperatures on reduction[J]. Ironmaking & Steelmaking, 2002,29(3):175−179. [13] Paananen Timo, Kinnunen Kimmo. Effect of TiO2‐content on reduction of iron ore agglomerates[J]. Steel Research International, 2009,80(6):408−414. [14] Dehghan-Manshadi Ali, Manuel James, Hapugoda Sarath, et al. Sintering characteristics of titanium containing iron ores[J]. ISIJ International, 2014,54(10):2189−2195. doi: 10.2355/isijinternational.54.2189 [15] Bristow Neil John, Loo Chin Eng. Sintering properties of iron ore mixes containing titanium[J]. ISIJ International, 1992,32(7):819−828. doi: 10.2355/isijinternational.32.819 [16] Lin Wenkang, Hu Peng. Influence of TiO2 content and basicity level on the metallogenic regularity of V-Ti sinter[J]. Iron Steel Vanadium Titanium, 2020,41(2):94−100. (林文康, 胡鹏. TiO2含量和碱度水平对钒钛烧结矿成矿规律的影响研究[J]. 钢铁钒钛, 2020,41(2):94−100. doi: 10.7513/j.issn.1004-7638.2020.02.018Lin Wenkang, Hu Peng. Influence of TiO2 content and basicity level on the metallogenic regularity of V-Ti sinter[J]. Iron Steel Vanadium Titanium, 2020, 41(2): 94−100. doi: 10.7513/j.issn.1004-7638.2020.02.018 [17] Wang Yaozu, Zhang Jianliang, Liu Zhengjian. Effects of w(TiO2) on mineral structure and softening-melting property of sinter[J]. Iron and Steel, 2017,52(10):20−28. (王耀祖, 张建良, 刘征建. w(TiO2)对烧结矿矿相结构及软熔滴落性能的影响[J]. 钢铁, 2017,52(10):20−28.Wang Yaozu, Zhang Jianliang, Liu Zhengjian. Effects of w(TiO2) on mineral structure and softening-melting property of sinter[J]. Iron and Steel, 2017, 52(10): 20−28. [18] Gan Qin, He Qun. The influence factors of calcium ferrite generation during vanadium-titanium iron ore concentrates sintering[J]. Sintering and Pelletizing, 2008(2):9−14. (甘勤, 何群. 影响钒钛烧结矿铁酸钙生成因素的研究[J]. 烧结球团, 2008(2):9−14.Gan Qin, He Qun. The influence factors of calcium ferrite generation during vanadium-titanium iron ore concentrates sintering[J]. Sintering and Pelletizing, 2008(2): 9−14. [19] Yin Zhenkui, Li Jingshe, Yang Shufeng. Sintering pot test on improving TiO2-containing ore’s allocated proportion[J]. Advanced Materials Research, 2011,311:850−853. [20] Xiang Nan, Guo Yufeng, Guo Xingmin. Formation mechanism of Ca3TiFe2O8 in a CaO-TiO2-Fe2O3 system[J]. Chinese Journal of Engineering, 2017, 39(11): 1669−1673. (项南, 郭玉峰, 郭兴敏. CaO-TiO2-Fe2O3三元系中Ca3TiFe2O8的生成机理[J]. 工程科学学报, 2017, 39(11): 1669−1673.Xiang Nan, Guo Yufeng, Guo Xingmin. Formation mechanism of Ca3TiFe2O8 in a CaO-TiO2-Fe2O3 system[J]. Chinese Journal of Engineering, 2017, 39(11): 1669−1673. [21] Fu Xinyuan, Guo Xingmin. Effect of Ca3TiFe2O8 on temperature of liquid phase appeared in sintering process of iron ore fines[J]. Iron Steel Vanadium Titanium, 2020,41(1):105−112. (付信元, 郭兴敏. Ca3TiFe2O8对铁矿石烧结过程中液相生成温度的影响[J]. 钢铁钒钛, 2020,41(1):105−112. doi: 10.7513/j.issn.1004-7638.2020.01.019Fu Xinyuan, Guo Xingmin. Effect of Ca3TiFe2O8 on temperature of liquid phase appeared in sintering process of iron ore fines[J]. Iron Steel Vanadium Titanium, 2020, 41(1): 105−112. doi: 10.7513/j.issn.1004-7638.2020.01.019 [22] Li Gang, Ding Chengyi, Xuan Senwei, et al. Non-isothermal reduction kinetics of calcium ferrite and hematite[J]. Chinese Journal of Engineering, 2018,40(11):1317−1324. (李刚, 丁成义, 宣森炜, 等. 铁酸钙与赤铁矿非等温还原动力学[J]. 工程科学学报, 2018,40(11):1317−1324.Li Gang, Ding Chengyi, Xuan Senwei, et al. Non-isothermal reduction kinetics of calcium ferrite and hematite[J]. Chinese Journal of Engineering, 2018, 40(11): 1317−1324. [23] Li Gang. Research on sintering technology of vanadium titanomagnetite with the preformed calcium ferrite[D]. Chongqing: Chongqing University, 2022. (李刚. 钒钛磁铁矿预制铁酸钙烧结技术研究 [D]. 重庆: 重庆大学, 2022.Li Gang. Research on sintering technology of vanadium titanomagnetite with the preformed calcium ferrite[D]. Chongqing: Chongqing University, 2022. [24] Sayama S, Ueda Y, Yokoyama S, et al. Carbon deposition in the reduction of iron ore by CO under high pressure[J]. Tetsu-to-Hagane, 1975, 61(8): 2115−2117. [25] Ding Chengyi, Lü Xuewei, Xuan Senwei, et al. Powder reduction kinetics of dicalcium ferrite, calcium ferrite, and hematite: Measurement and modeling[J]. Advanced Powder Technology, 2017, 28(10): 2503−2513. [26] Ding Chengyi, Lü Xuewei, Xuan Senwei, et al. Effect of Ca-Fe oxides additives on NOx reduction in iron ore sintering[J]. Journal of Iron and Steel Research, 2017, 24(12): 1184−1189. [27] Ding Chengyi. Crystallization and reduction behavior of calcium ferrites[D]. Chongqing: Chongqing University, 2019. (丁成义. 复合铁酸钙结晶和还原行为研究[D]. 重庆: 重庆大学, 2019.Ding Chengyi. Crystallization and reduction behavior of calcium ferrites[D]. Chongqing: Chongqing University, 2019. [28] Li Gang, Chen Dan, You Yang, et al. Andradite titanium: Preparation, characterization and metallurgical performance[J]. Journal of the American Ceramic Society, 2021,105(3):2209−2220. -

下载:

下载: