Formation and evolution of non-metallic inclusions in 20CrMnTiH gear steel during LF-RH-CC process

-

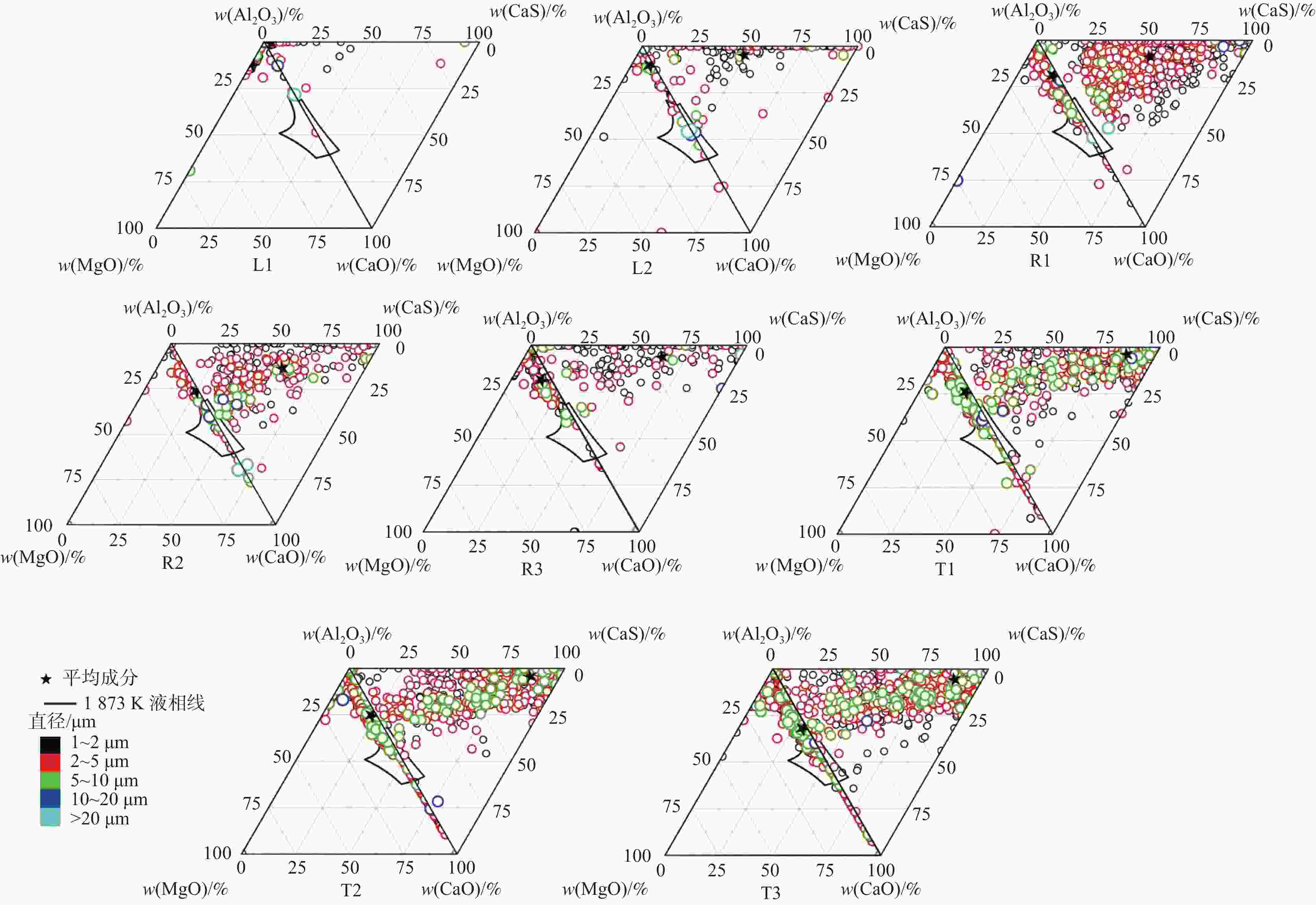

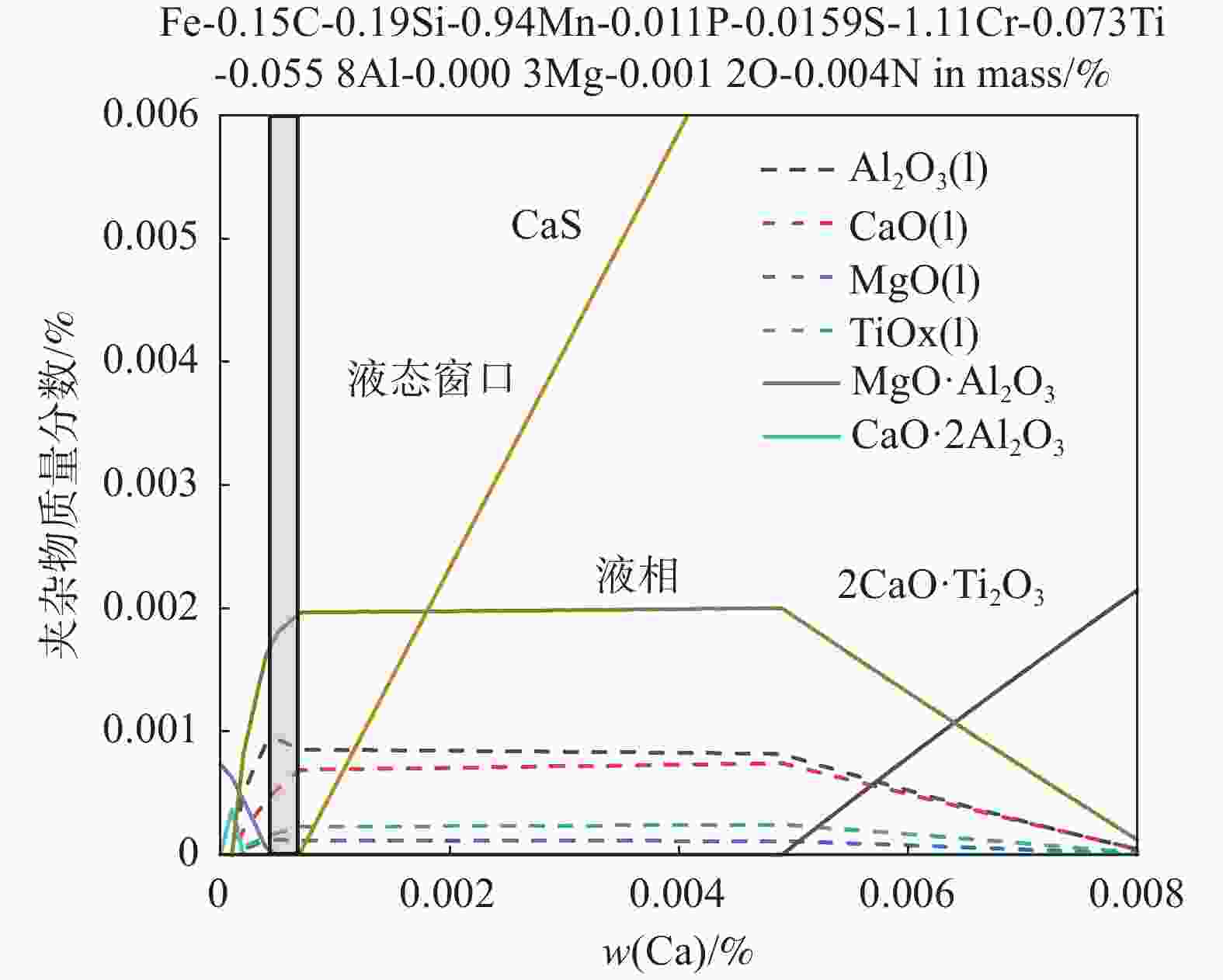

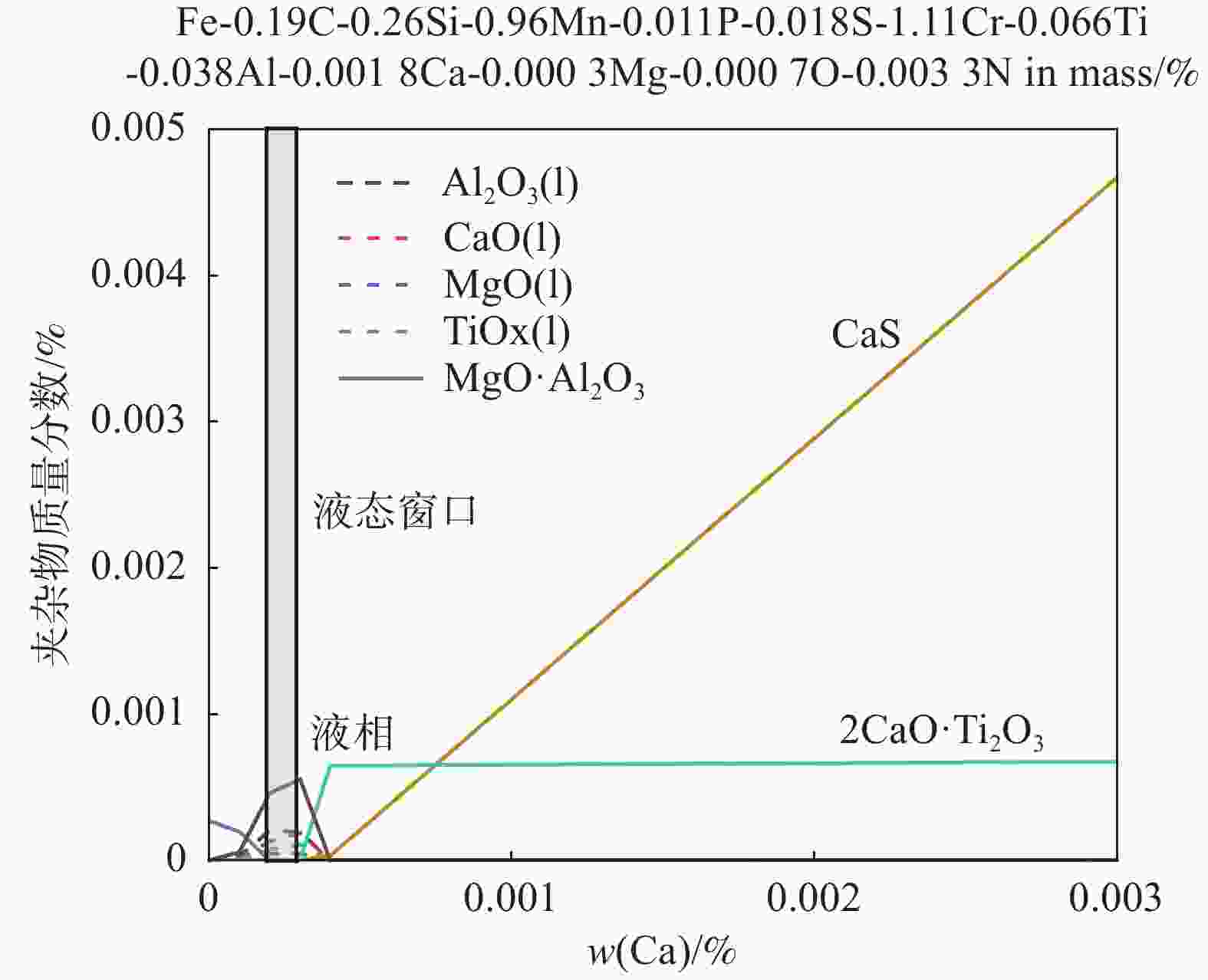

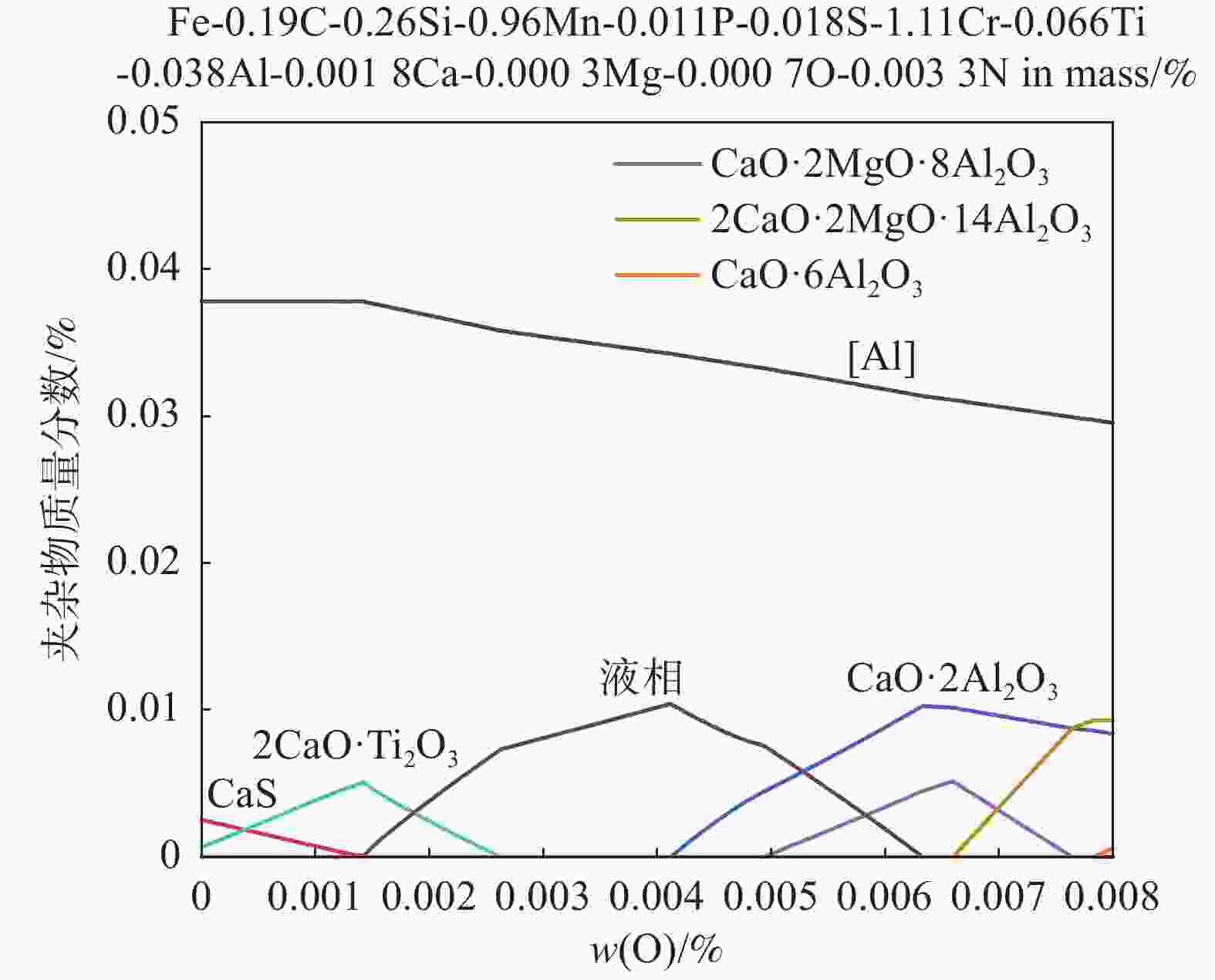

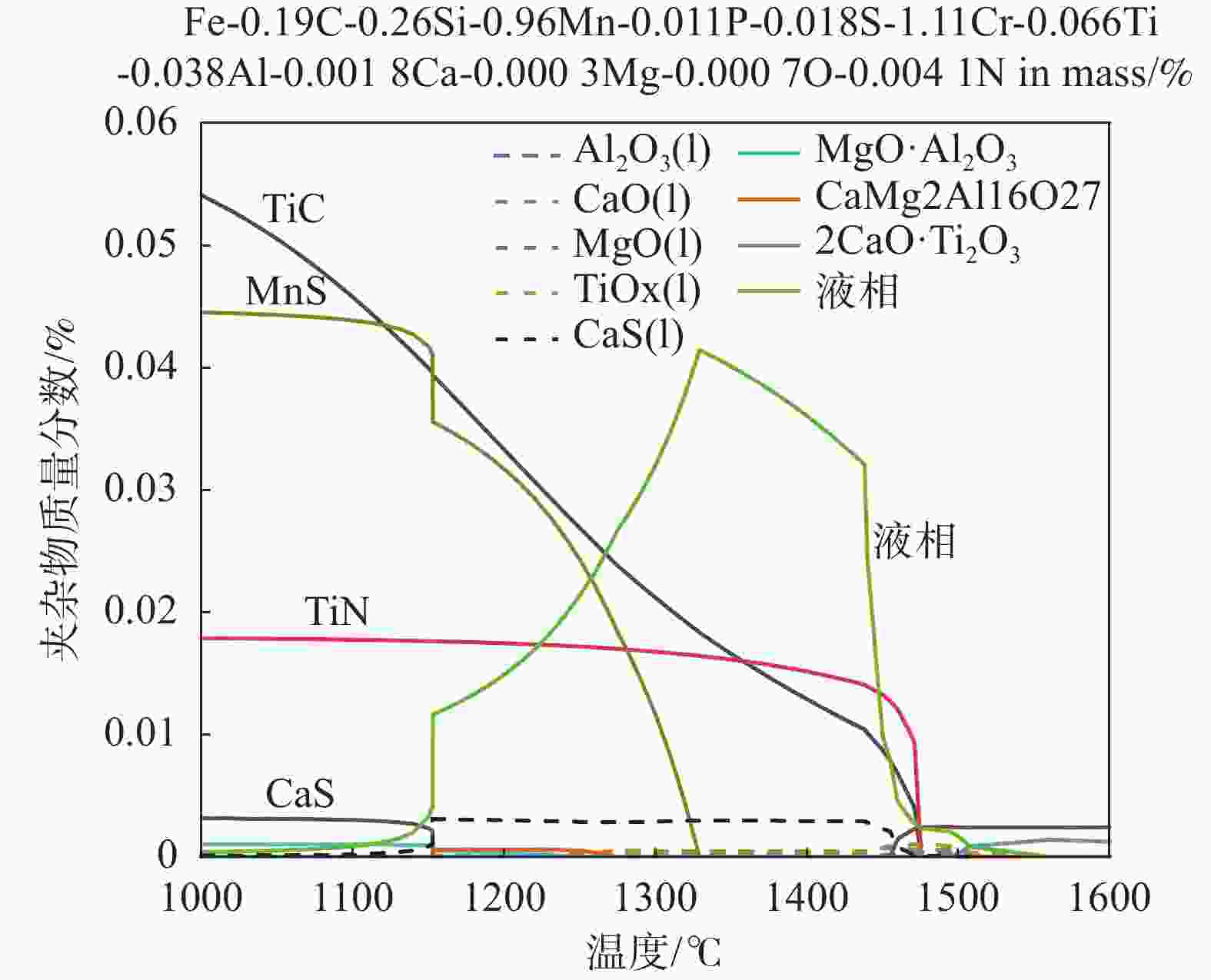

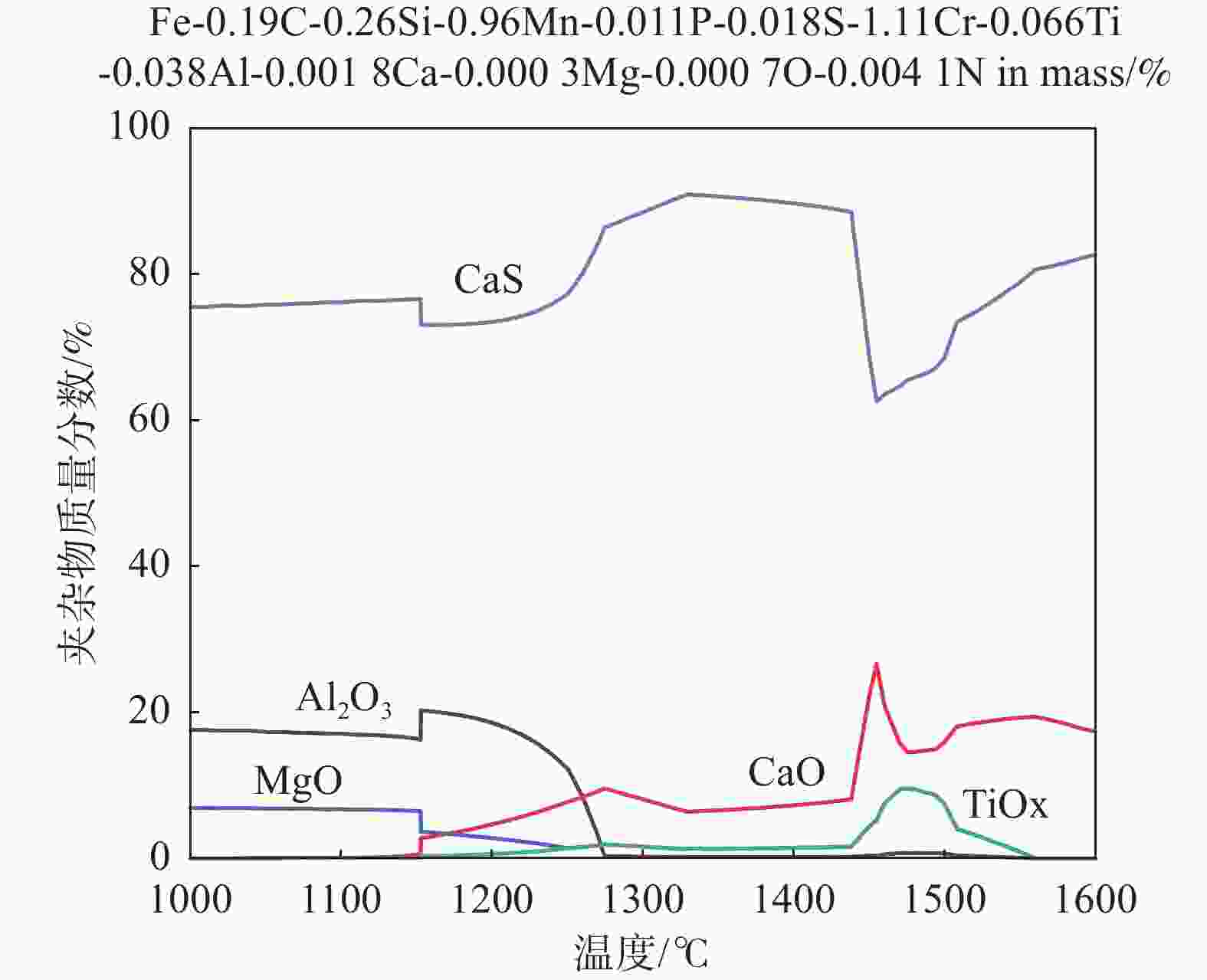

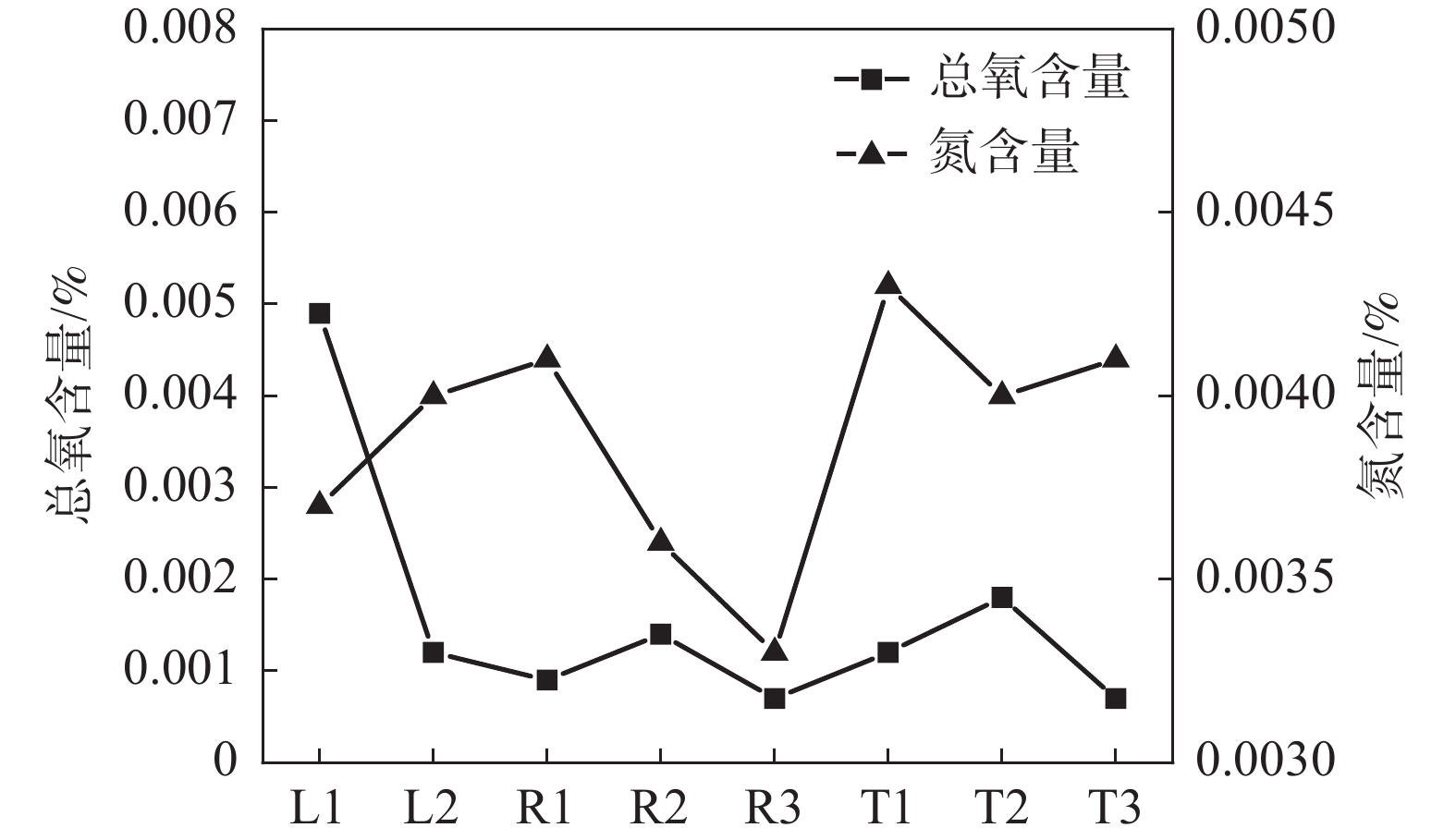

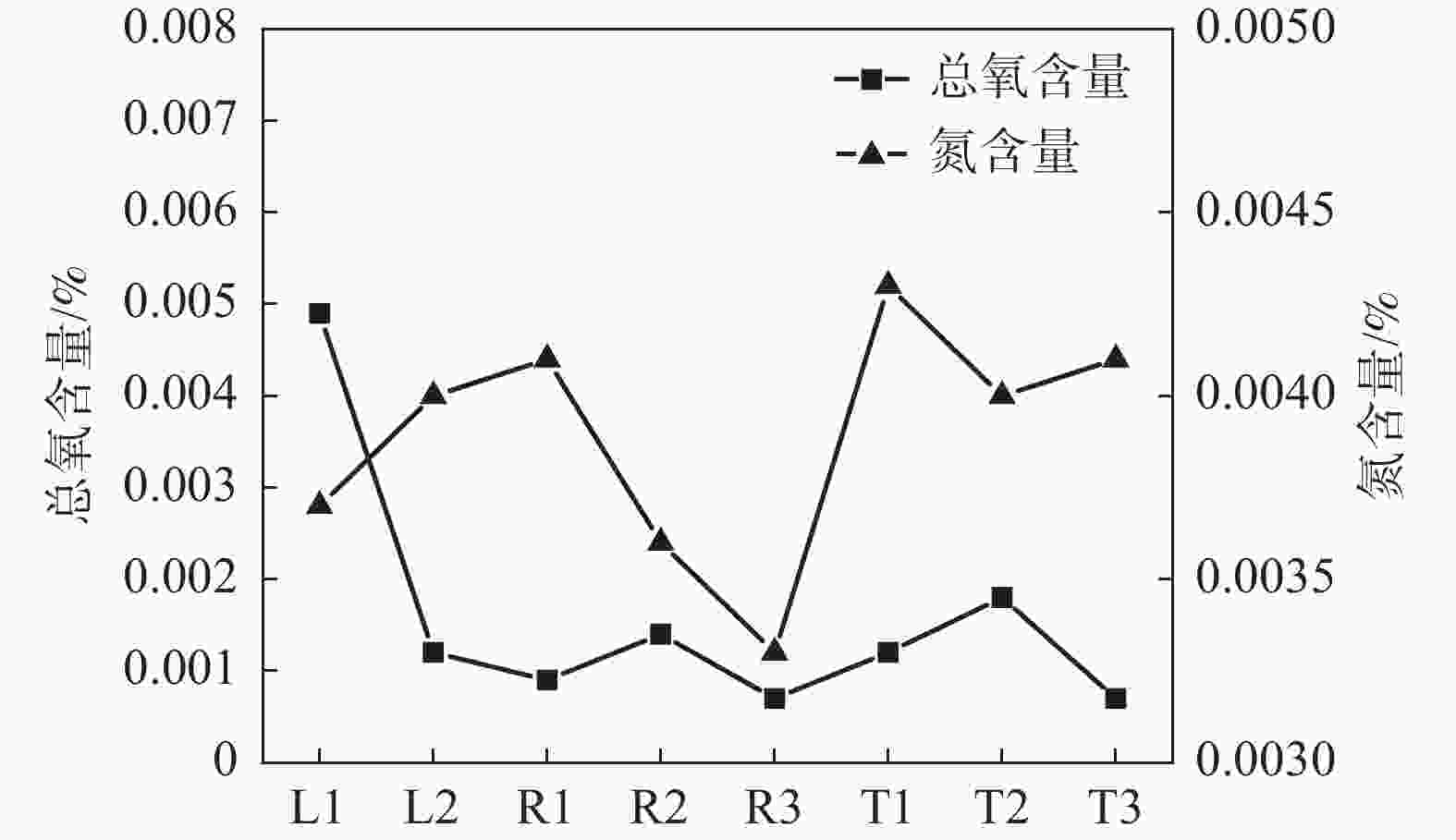

摘要: 通过工业试验分析了20CrMnTiH在精炼过程中非金属夹杂物的演变行为,并采用FactSage8.0热力学软件计算了20CrMnTiH在钙处理、二次氧化和冷却凝固过程中夹杂物的转变趋势。结果表明,LF精炼过程中夹杂物由Al2O3向MgO-Al2O3和CaO-MgO-Al2O3转变,经过钙处理后,夹杂物改性为CaO-MgO-Al2O3和CaO-Al2O3-CaS,随后经过RH真空精炼,在真空精炼结束时进行第二次钙处理,夹杂物转变为高CaS含量的CaO-Al2O3-CaS和CaO-MgO-Al2O3,连铸过程中钢液发生再氧化,夹杂物中CaS含量进一步升高。热力学计算表明,在钢液中加入0.003%~0.0005%的[Ca]时,钢液中会生成高熔点的MgO-Al2O3,当[Ca]的加入量在0.0005%~0.0007%时,夹杂物主要为液态夹杂物,当[Ca]含量大于0.0007%时,钢液中开始有CaS生成。此外,二次氧化的发生会使得钢液中的液态夹杂物更多地转变为固态夹杂物。随着温度的降低,夹杂物中CaO、CaS含量在逐渐降低,而MgO、Al2O3含量逐渐增加,最终形成高CaS含量的CaS-CaO-MgO-Al2O3。Abstract: The formation and evolution of non-metallic inclusions in 20CrMnTiH gear steel during LF-RH-CC process were analyzed by industrial trials, and the transformation trend of non-metallic inclusions during reoxidation and cooling solidification in 20CrMnTiH gear steel was analyzed by thermodynamic calculations. During LF refining, inclusions experience evolutions from Al2O3 to MgO-Al2O3 and CaO-MgO-Al2O3. After calcium treatment, inclusions are modified into CaO-MgO-Al2O3 and CaO-Al2O3-CaS. After calcium treatment at the end of RH vacuum refining, inclusions are modified into CaO-Al2O3-CaS with high CaS contents and CaO-MgO-Al2O3. During continuous casting, the content of CaS in inclusions increase with the reoxidation of steel. Thermodynamic calculations reveal that when 0.000 3% to 0.000 5% [Ca] is added to the steel, MgO-Al2O3 would be formed in the steel. When 0.000 5% to 0.000 7% [Ca] is added to the steel, liquid calcium aluminates would be largely formed. When the content of [Ca] exceeds 0.000 7%, CaS would be formed. Moreover, liquid inclusions would be gradually transformed into solid inclusions with the reoxidation of steel. With the decrease of temperature, the contents of CaO and CaS in inclusions decrease and the contents of MgO and Al2O3 in inclusions increase, leading to the formation of CaS-CaO-MgO-Al2O3 with high CaS contents eventually.

-

Key words:

- 20CrMnTiH /

- inclusions /

- calcium treatment /

- reoxidation

-

表 1 精炼过程20CrMnTiH的主要化学成分

Table 1. Main chemical compositions of 20CrMnTiH during refining

% 节点 C Si Mn P S Cr Ti [Al] [Ca] [Mg] L1 0.13 0.13 0.89 0.011 0.0245 1.11 0.005 0.024 0.0002 L2 0.15 0.19 0.94 0.011 0.0159 1.11 0.073 0.0558 0.0018 0.0003 R1 0.15 0.19 0.94 0.011 0.0159 1.11 0.073 0.0558 0.0018 0.0003 R2 0.19 0.26 0.96 0.011 0.022 1.11 0.075 0.041 0.0005 0.0003 R3 0.19 0.26 0.96 0.011 0.018 1.11 0.066 0.038 0.0018 0.0003 T1 0.19 0.26 0.96 0.011 0.018 1.11 0.066 0.038 0.0018 0.0003 T2 0.19 0.26 0.96 0.011 0.018 1.11 0.066 0.038 0.0018 0.0003 T3 0.19 0.26 0.96 0.011 0.018 1.11 0.066 0.038 0.0018 0.0003 表 2 夹杂物的尺寸分布

Table 2. Size distribution of the inclusions

节点 占比/% 1~2 μm 2~5 μm 5~10 μm 10~20 μm >20 μm L1 72.12 26.06 0.91 0.61 0.30 L2 75.68 19.82 2.25 1.35 0.90 R1 73.02 25.55 0.85 0.43 0.14 R2 54.90 38.24 5.23 0.98 0.65 R3 71.84 22.82 3.88 0.49 0.97 T1 70.53 26.39 2.96 0.11 0.00 T2 67.36 29.66 2.78 0.20 0.00 T3 64.39 31.94 3.50 0.17 0.00 -

[1] Fuchs D, Tobie T, Stahl K. Challenges in determination of microscopic degree of cleanliness in ultra-clean gear steels[J]. Journal of Iron and Steel Research International, 2022,29(10):1583−1600. doi: 10.1007/s42243-021-00730-y [2] Juan R, Wang M, Li L, et al. Relationship between inclusions and internal defect spatial distribution in large forging piece for wind power generation gear[J]. ISIJ International, 2022,62(1):133−141. doi: 10.2355/isijinternational.ISIJINT-2021-356 [3] Liu R, Sun D, Hou J, et al. Fatigue life analysis of wind turbine gear with oxide inclusion[J]. Fatigue Fracture of Engineering Materials Structures, 2021,44(3):776−787. doi: 10.1111/ffe.13393 [4] Ji Sha, Zhang Lifeng, Luo Yan, et al. Effect of calcium treatment on nonmetallic inclusions in 20CrMnTiH gear steel[J]. Chinese Journal of Engineering, 2021,43(6):825−834. (季莎, 张立峰, 罗艳, 等. 钙处理对20CrMnTiH齿轮钢中非金属夹杂物的影响[J]. 工程科学学报, 2021,43(6):825−834.Ji Sha, Zhang Lifeng, Luo Yan, et al. Effect of calcium treatment on nonmetallic inclusions in 20 CrMnTiH gear steel [J]. Chinese Journal of Engineering, 2021, 43(6): 825-834. [5] Wang Kunpeng, Wang Ying, Xu Jianfei, et al. Investigation on evolution of inclusions in bearing steel during secondary refining[J]. Iron and Steel, 2022,57(6):42−49. (王昆鹏, 王郢, 徐建飞, 等. 轴承钢二次精炼过程夹杂物演变规律[J]. 钢铁, 2022,57(6):42−49. doi: 10.13228/j.boyuan.issn0449-749x.20210660Wang Kunpeng, Wang Ying, Xu Jianfei, et al. Investigation on evolution of inclusions in bearing steel during secondary refining [J]. Iron and Steel, 2022, 57 (6): 42-49. doi: 10.13228/j.boyuan.issn0449-749x.20210660 [6] Yang Guang, Yang Wen, Zhang Lifeng. Calcium treatment modification and influencing factors of inclusions in aluminum-killed steel[J]. Iron and Steel, 2022,57(12):66−78. (杨光, 杨文, 张立峰. 铝镇静钢中夹杂物钙处理改性及其影响因素[J]. 钢铁, 2022,57(12):66−78. doi: 10.13228/j.boyuan.issn0449-749x.20220313Yang Guang, Yang Wen, Zhang Lifeng. Calcium treatment modification and influencing factors of inclusions in aluminum-killed steel [J]. Iron and Steel, 2022, 57(12): 66-78. doi: 10.13228/j.boyuan.issn0449-749x.20220313 [7] Dieter Janke Z M, Peter V, Heinen A. Improvement of castability and quality of continuously cast steel[J]. ISIJ International, 2000,40(1):31−39. doi: 10.2355/isijinternational.40.31 [8] Gollapalli V, Raomb V, Karmached P S, et al. Modification of oxide inclusions in calcium-treated Al-killed high sulphur steels[J]. Ironmaking & Steelmaking, 2019,46(7):663−670. [9] Pretorius E B, Oltman H G, Cash T. The effective modification of spinel inclusions by Ca treatment in LCAK steel[J]. Iron & Steel Technology, 2011,7(7):31−44. [10] Xu J, Huang F, Wang X. Formation mechanism of CaS-Al2O3 inclusions in low sulfur Al-killed steel after calcium treatment[J]. Metall. Mater. Trans. B, 2016,47(2):1217−1227. doi: 10.1007/s11663-016-0599-8 [11] Choudhary S K, Ghosh A. Thermodynamic evaluation of formation of oxide–sulfide duplex inclusions in steel[J]. ISIJ International, 2008,48(11):1552−1559. doi: 10.2355/isijinternational.48.1552 [12] Verma N, Pistorius P C, Fruehan R J, et al. Calcium modification of spinel inclusions in aluminum-killed steel: Reaction steps[J]. Metall. Mater. Trans. B, 2012,43(4):830−840. doi: 10.1007/s11663-012-9660-4 [13] Xie Y, Meng X, Deng X, et al. Evolution of sulphide inclusion in Mg–Ca treating gear steel [J]. Ironmaking & Steelmaking, 2022: 1−7. [14] Xu G, Jiang Z, Li Y. Formation mechanism of CaS-bearing inclusions and the rolling deformation in Al-killed, low-alloy steel with Ca treatment[J]. Metall. Mater. Trans. B, 2016,47(4):2411−2420. doi: 10.1007/s11663-016-0695-9 [15] Zhao D, Li H, Bao C, et al. Inclusion evolution during modification of alumina inclusions by calcium in liquid steel and deformation during hot rolling process[J]. ISIJ International, 2015,55(10):2115−2124. doi: 10.2355/isijinternational.ISIJINT-2015-064 [16] Bielefeldt W V, Vilela A C F. Computational thermodynamic study of inclusions formation in the continuous casting of SAE 8620 steel[J]. Steel Research International, 2010,81(12):1064−1069. doi: 10.1002/srin.201000057 [17] Ahmad H, Zhao B, Sha L, et al. Formation of complex inclusions in gear steels for modification of manganese sulphide[J]. Metals, 2021,11(12):2051−2064. doi: 10.3390/met11122051 [18] Ren Y, Zhang L, Ling H, et al. A reaction model for prediction of inclusion evolution during reoxidation of Ca-treated Al-killed steels in tundish[J]. Metall. Mater. Trans. B, 2017,48(3):1−6. [19] Gao Shengya, Jiang Min, Hou Zewang, et al. Effect of calciumtreatment on non-metallic inclusions in high carbon aluminum killed steel(Article)[J]. Iron and Steel, 2017,52(4):25−30. (高胜亚, 姜敏, 侯泽旺, 等. 钙处理对高碳铝镇静钢中夹杂物的影响[J]. 钢铁, 2017,52(4):25−30. doi: 10.13228/j.boyuan.issn0449-749x.20160311Gao Shengya, Jiang Min, Hou Zewang, et al. Effect of calciumtreatment on non-metallic inclusions in high carbon aluminum killed steel(Article) [J]. Iron and Steel, 2017, 52(4): 25-30. doi: 10.13228/j.boyuan.issn0449-749x.20160311 [20] Yang G, Wang X, Huang F, et al. Influence of calcium addition on inclusions in LCAK steel with ultralow sulfur content[J]. Metall. Mater. Trans. B, 2014,46(1):145−154. [21] Hou Z, Jiang M, Yang E, et al. Inclusion characterization in aluminum-deoxidized special steel with certain sulfur content under combined influences of slag refining, calcium treatment, and reoxidation[J]. ISIJ International, 2018,49(6):3056−3066. [22] Kim T S, Chung Y, Holappa L, et al. Effect of rice husk ash insulation powder on the reoxidation behavior of molten steel in continuous casting tundish[J]. Metall. Mater. Trans. B, 2017,48(3):1736−1747. doi: 10.1007/s11663-017-0971-3 [23] Shi C, Zheng D, Guo B, et al. Evolution of oxide-sulfide complex inclusions and its correlation with steel cleanliness during electroslag rapid remelting (ESRR) of tool steel[J]. Metall. Mater. Trans. B, 2018,49(6):3390−3402. doi: 10.1007/s11663-018-1398-1 -

下载:

下载: