Study on the microstructures and properties of high speed laser welded joints of CP800 high strength steel

-

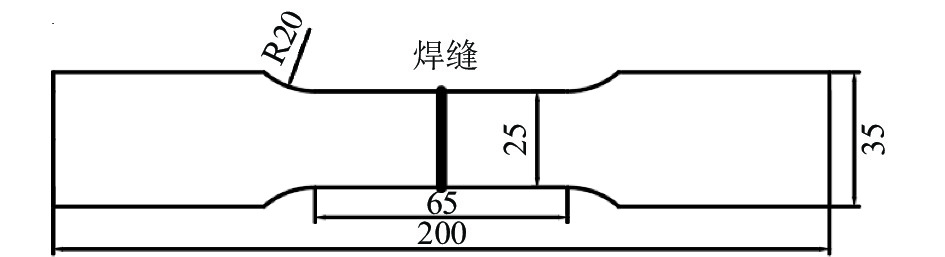

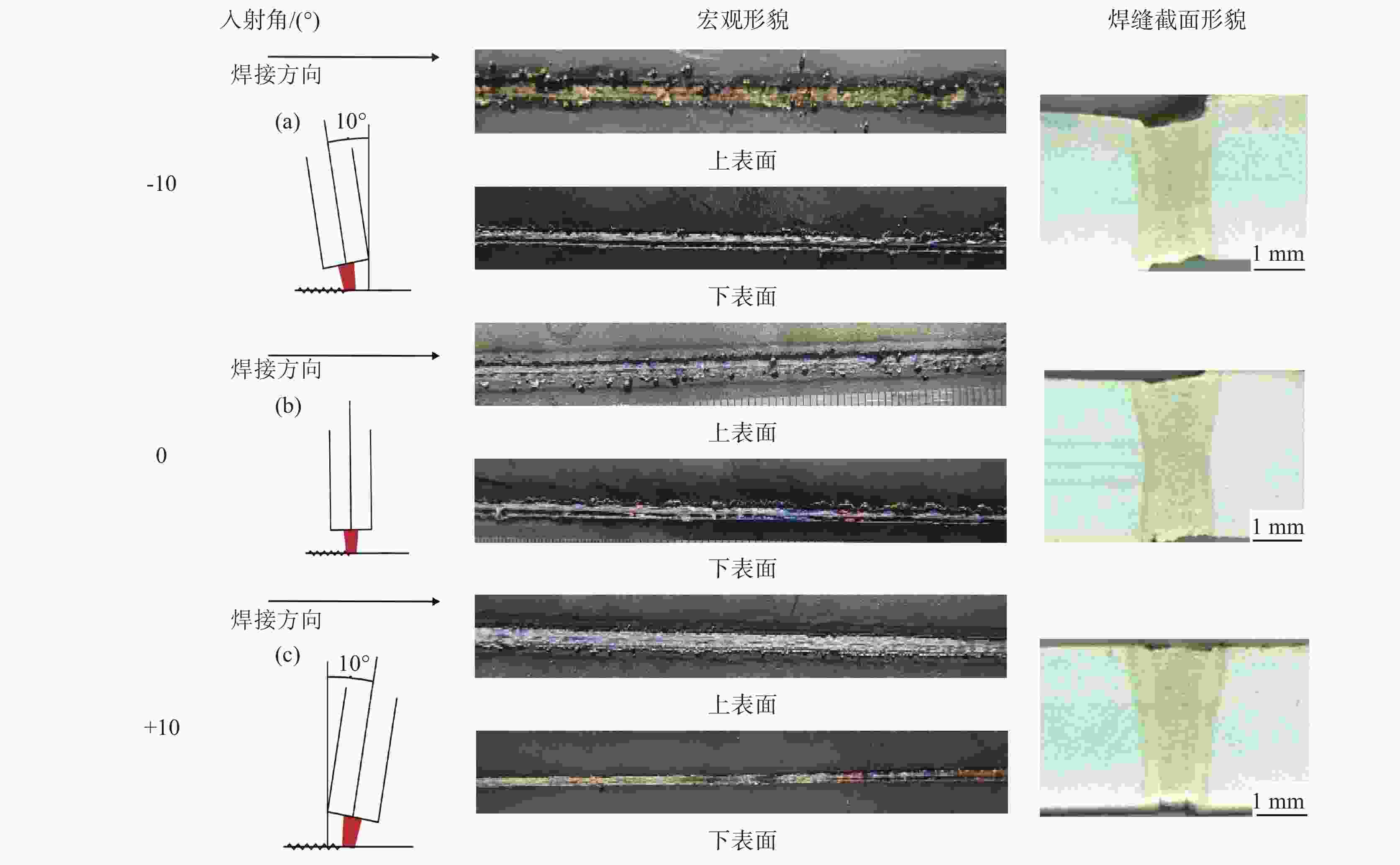

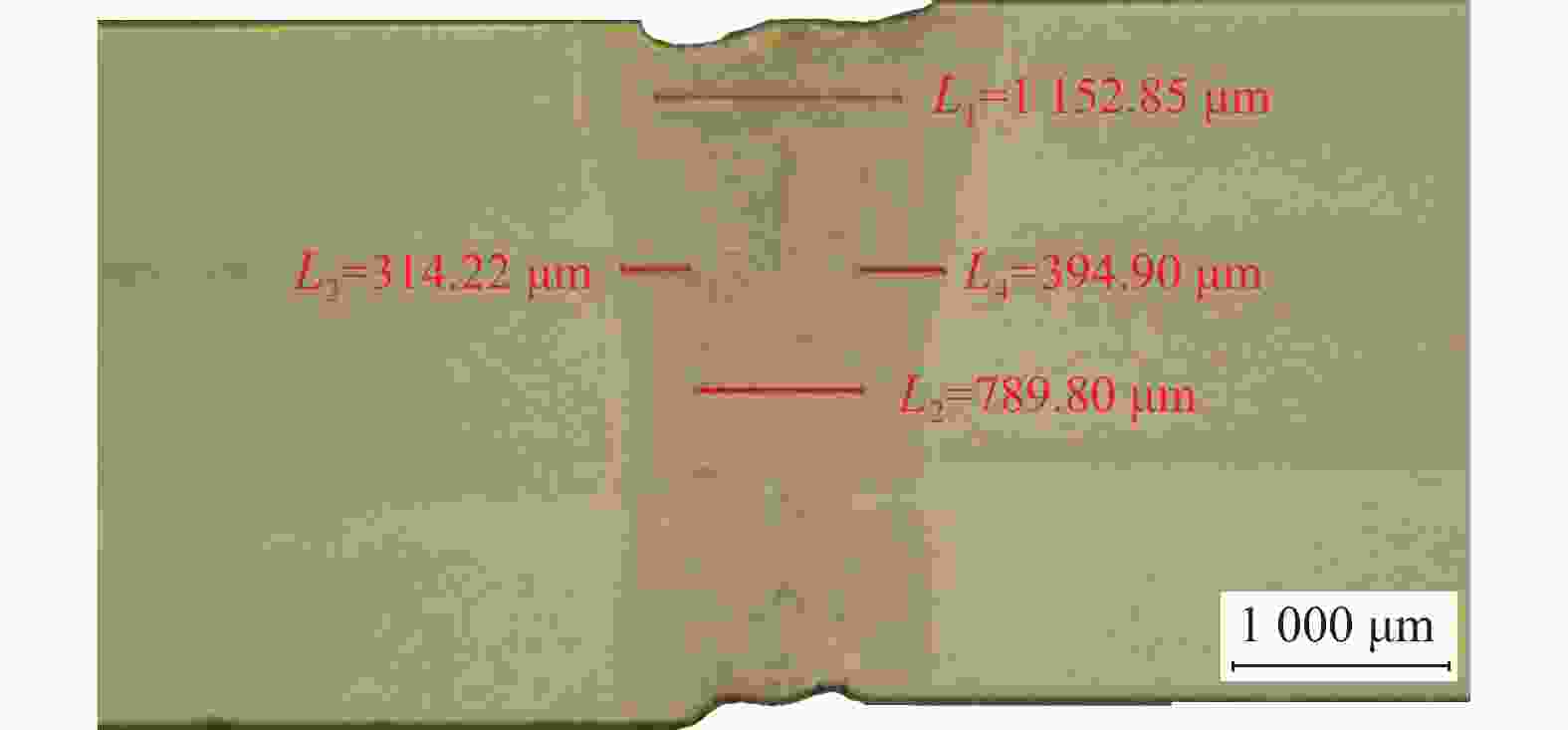

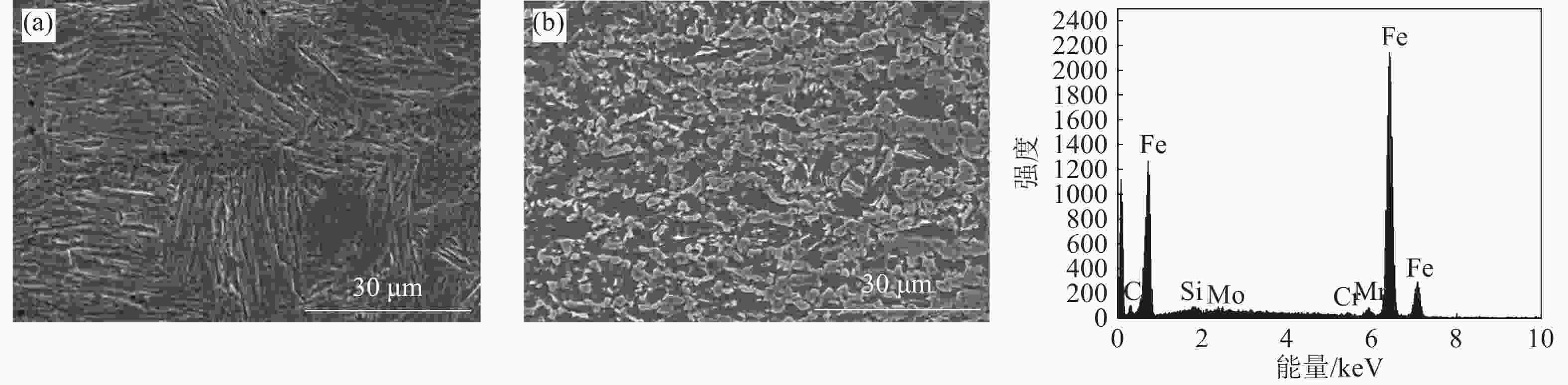

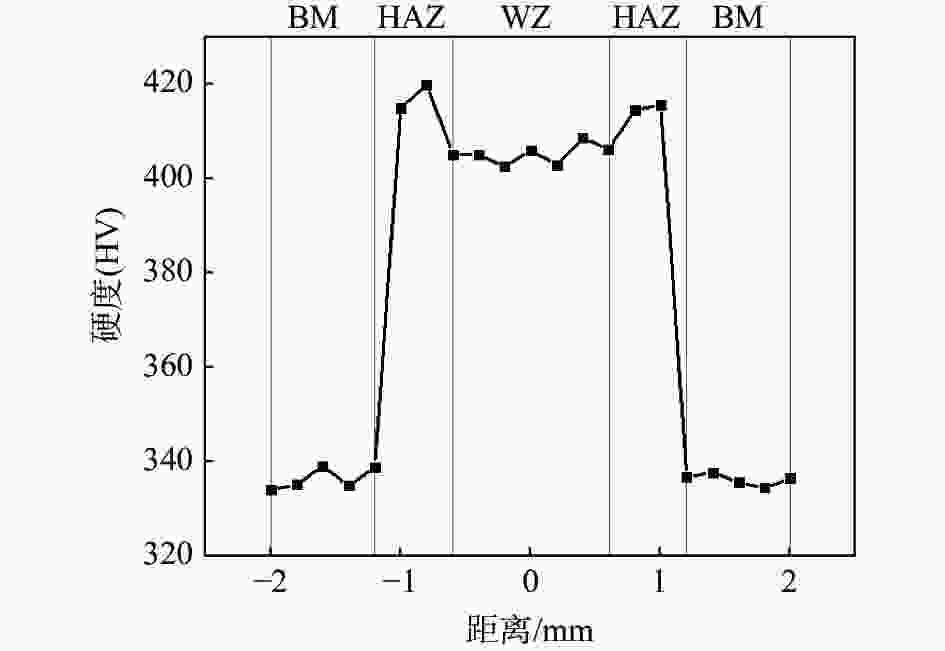

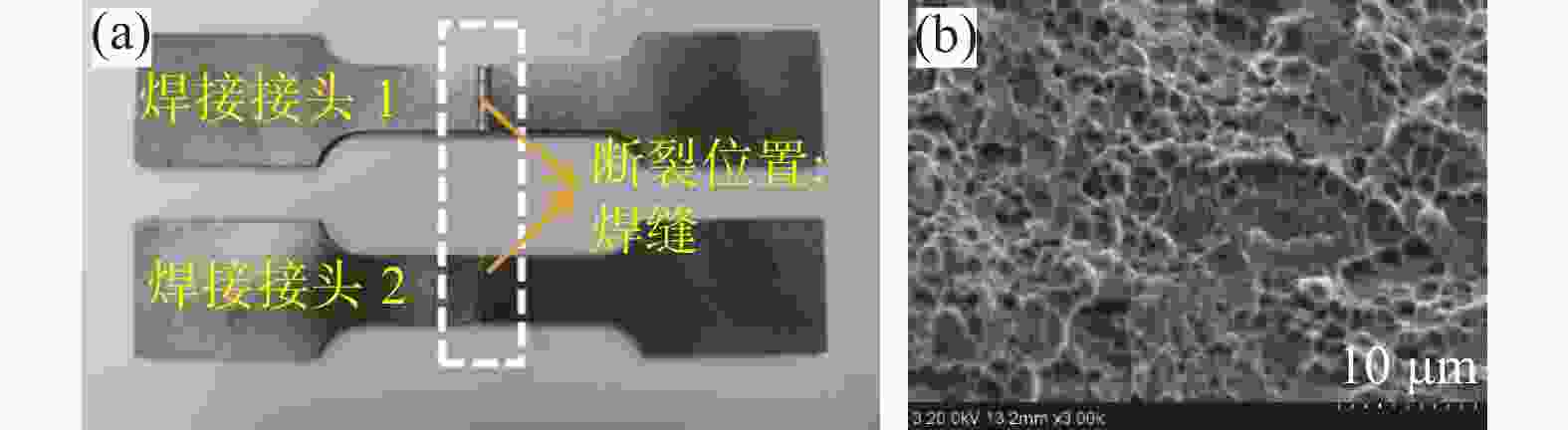

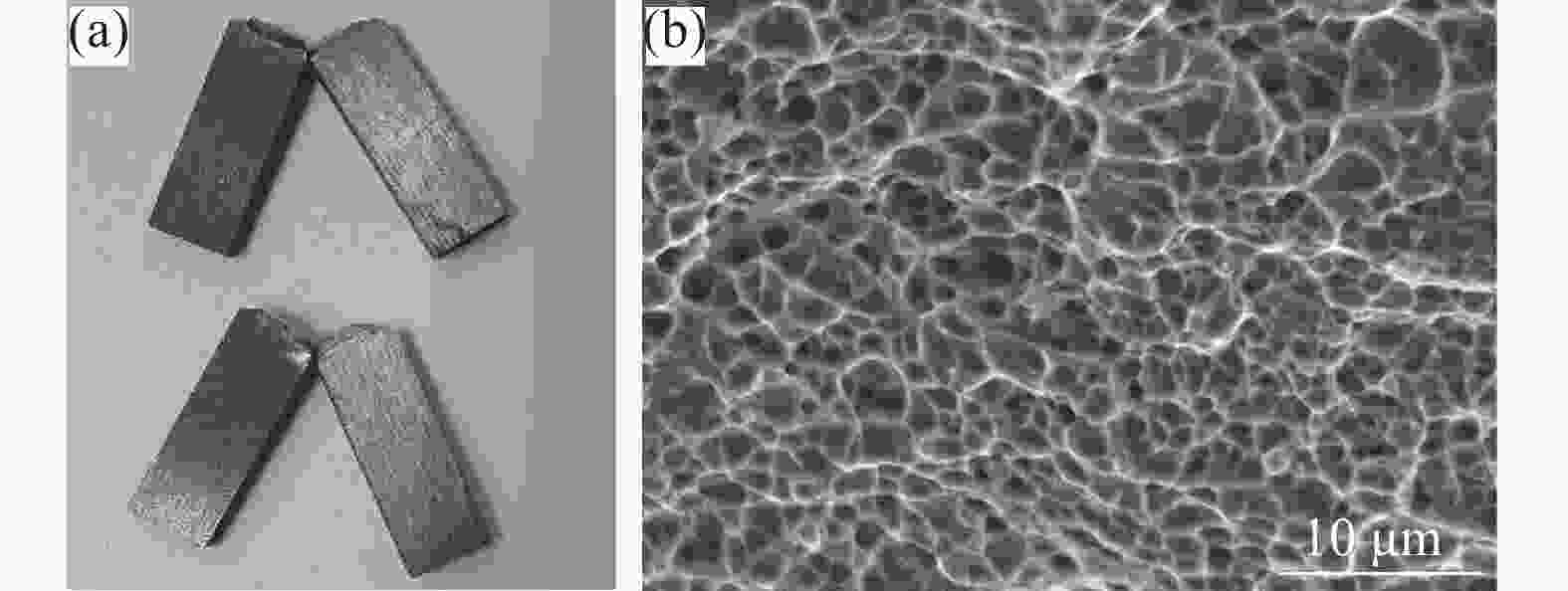

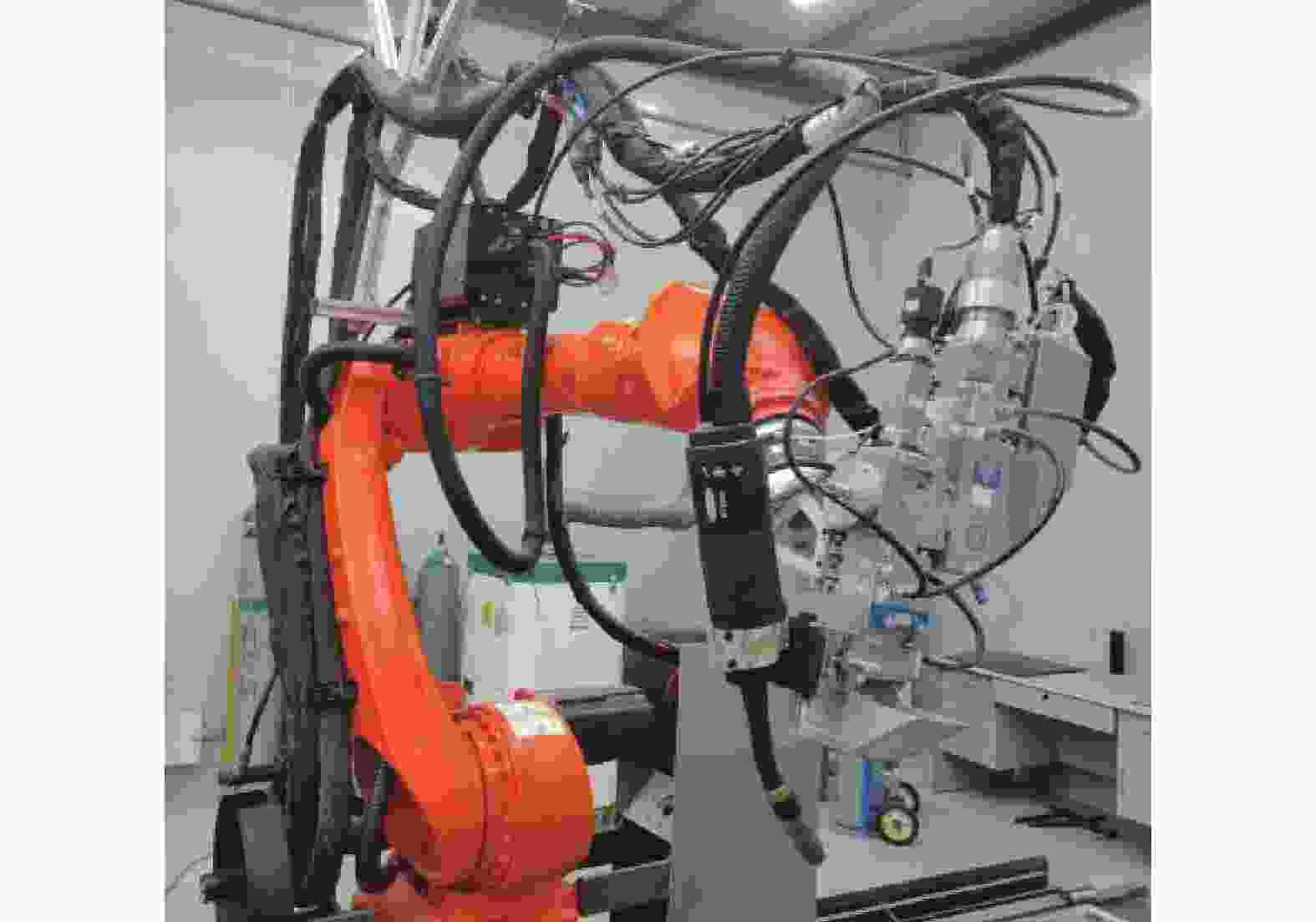

摘要: 为了进一步提高激光焊接速度,改善高速焊接过程中焊缝凹陷的问题,对CP800高强钢进行了12 m/min的高速激光焊接,研究了激光入射角对焊缝成形的影响。在最优焊接工艺参数下,对焊缝成形、焊缝质量、焊接接头组织、硬度及力学性能进行了研究。结果表明:当激光入射角度为+10°时,焊缝表面基本无飞溅,凹陷最小。此外在激光功率为12500 W,焊接速度为12 m/min,激光入射角为+10°的最佳焊接参数下,焊缝表面及内部质量较好,焊缝熔宽约为1.15 mm,热影响区宽度约为0.35 mm。焊缝组织中,主要存在的是板条状马氏体和针状铁素体以及极少量的粒状贝氏体。焊缝的显微硬度(HV)值在402.5~408.5。焊接接头抗拉强度能够达到母材抗拉强度的96%,焊接接头室温冲击功能够达到母材室温冲击功的87.5%。Abstract: In order to further improve the laser welding speed and solve the problem of weld depression in the process of high speed welding, carried out high speed laser welding of CP800 high strength steel was carried out at 12 m/min, and the influence of laser incidence angle on weld forming was studied. Under the optimal welding process parameters, the weld forming, weld quality, weld joint structure, hardness and mechanical properties were studied. The results show that when the laser incidence angle is +10°, there is basically no spatter on the surface of the weld, and the depression is minimal. In addition, under the optimal welding parameters of 12500 W laser power, 12 m/min welding speed and laser incidence angle of +10°, the surface and internal quality of the weld are better, the weld melt width is about 1.15 mm, and the width of the heat-affected zone is about 0.35 mm. Weld structure mainly consists of lathed martensitic, acicular ferrite and slight granular bainite. The measured hardness (HV) in weld ranges 402.5~408.5. The tensile strength and impact energy at room temperature of weld joint can achieve 96% and 87.5% of those of base metal respectively.

-

表 1 CP800钢的化学成分和力学性能

Table 1. Chemical compositions and mechanical properties of CP800 steel

w/% Rm/MPa Rp0.2/MPa A/% C Si Mn P S Cr Mo Fe 0.082 0.121 1.700 0.010 0.002 0.350 0.232 余量 800 705 8.5 -

[1] Kumar A P , Hrishikesh D , Ji-Woo L , et al. Texture analysis and joint performance of laser-welded similar and dissimilar dual-phase and complex-phase ultra-high-strength steels[J]. Materials Characterization, 2021, 174: 111035. [2] Kim Hyung-Ju, Keoleian Gregory A, Skerlos Steven J. Economic assessment of greenhouse gas emissions reduction by vehicle lightweighting using aluminum and high-strength steel[J]. Journal of Industrial Ecology, 2011,15(1):64−80. doi: 10.1111/j.1530-9290.2010.00288.x [3] Sun H , Wei K , Yang X , et al. Effects of pre-strain and annealing on the fatigue properties of complex phase steel CP800[J]. International Journal of Fatigue, 2020, 131(C): 105364. [4] Meng W , Li Z , Huang J , et al. Microstructure and softening of laser-welded 960 MPa grade high strength steel joints[J]. Journal of Materials Engineering and Performance, 2014, 23(2): 538−544. [5] Yang Lei, Wang Xiaonan, Huan Pengcheng, et al. Effect of heat input on microstructure and properties of CP800 complex phase steel laser welded joints[J]. Apply Lasers, 2018,38(4):562−569. (杨蕾, 王晓南, 环鹏程, 等. 热输入对CP800复相钢激光焊接接头组织性能的影响[J]. 应用激光, 2018,38(4):562−569.Yang Lei, Wang Xiaonan, Huan Pengcheng, et al. Effect of heat input on microstructure and properties of CP800 complex phase steel laser welded joints[J]. Apply Lasers, 2018, 38(4): 562−569. [6] Dong Xianchun, Zhao Yang, Han Nidan, et al. Microstructures and properties of HR800CP multiphase high strength steel welded joints[J]. Iron Steel Vanadium Titanium, 2018,39(5):144−148. (董现春, 赵阳, 韩妮丹, 等. HR800CP复相高强钢板焊接接头的显微组织和力学性能[J]. 钢铁钒钛, 2018,39(5):144−148. doi: 10.7513/j.issn.1004-7638.2018.05.025Dong Xianchun, Zhao Yang, Han Nidan, et al. Microstructures and properties of HR800CP multiphase high strength steel welded joints[J]. Iron Steel Vanadium Titanium, 2018, 39(5): 144−148. doi: 10.7513/j.issn.1004-7638.2018.05.025 [7] Eric W , Nikolay D , Ralf O , et al. Investigations on the thermal conditions during laser beam welding of high-strength steel 100Cr6[J]. Advances in Industrial and Manufacturing Engineering, 2023, 6: 100118. [8] Oktay Çavuşoğlu, Yuce Celalettin, Aydın Hakan. Mechanical characterization and microstructure of fiber laser welded TWIP980 steel depending on welding speed and focal distance[J]. Optik, 2023,274:170541. doi: 10.1016/j.ijleo.2023.170541 [9] Shehryar M K, Sarim A, Daniel W, et al. The effect of laser impingement angle on the optimization of melt pool geometry to improve process stability during high-speed laser welding of thin-gauge automotive steels[J]. Journal of Manufacturing Processes, 2022,78:242−253. doi: 10.1016/j.jmapro.2022.04.022 [10] Wang X , Sun Q , Zheng Z , et al. Microstructure and fracture behavior of laser welded joints of DP steels with different heat inputs[J]. Materials Science & Engineering A, 2017, 699:18−25. [11] Tao Peikang, Mi Gaoyang, Wang Chunming, et al. Formation, microstructure and mechanical properties of double-sided fiber laser welded ultra-high strength steel[J]. Optics and Laser Technology, 2022,153:108208. doi: 10.1016/j.optlastec.2022.108208 -

下载:

下载: