Finite element analysis of multi-physics coupling for electromagnetic welding of aluminum/steel dissimilar metals

-

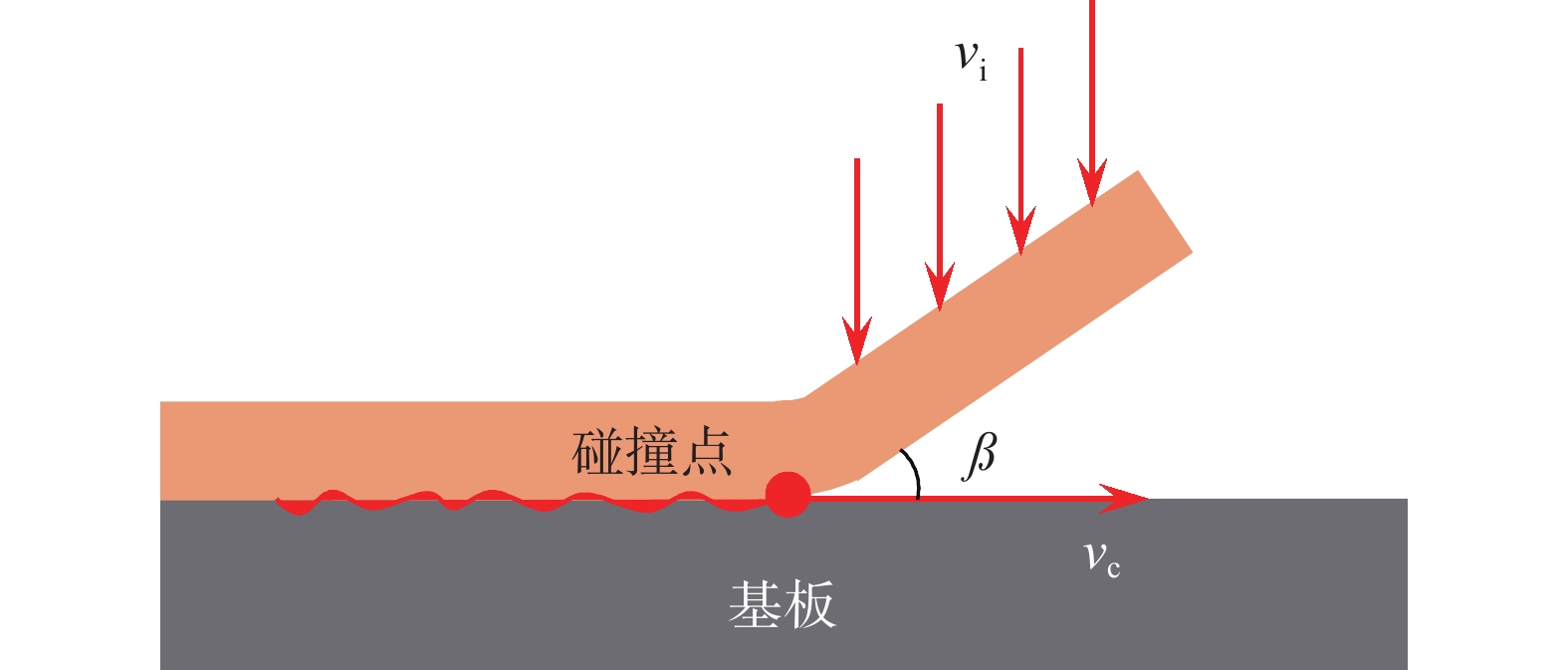

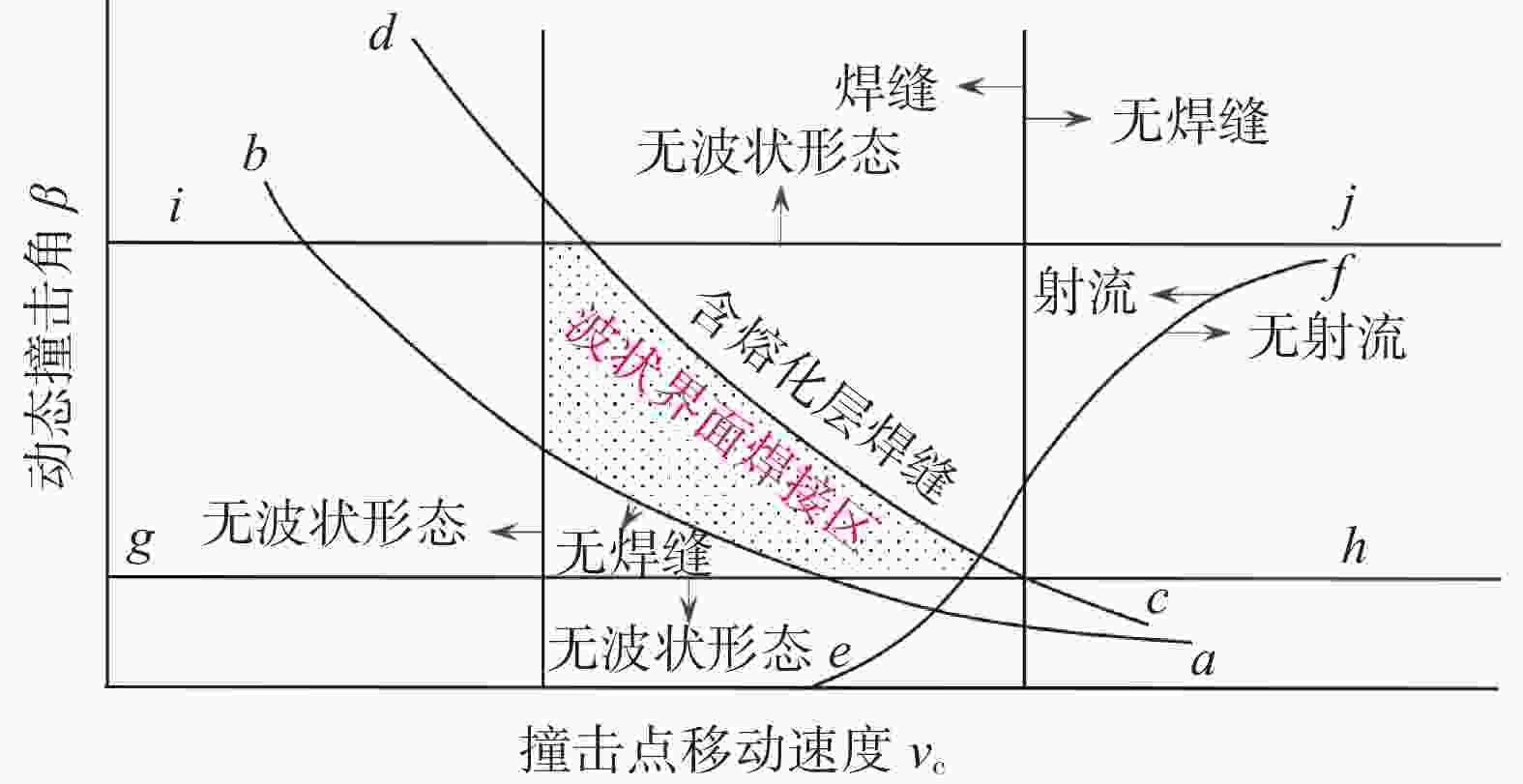

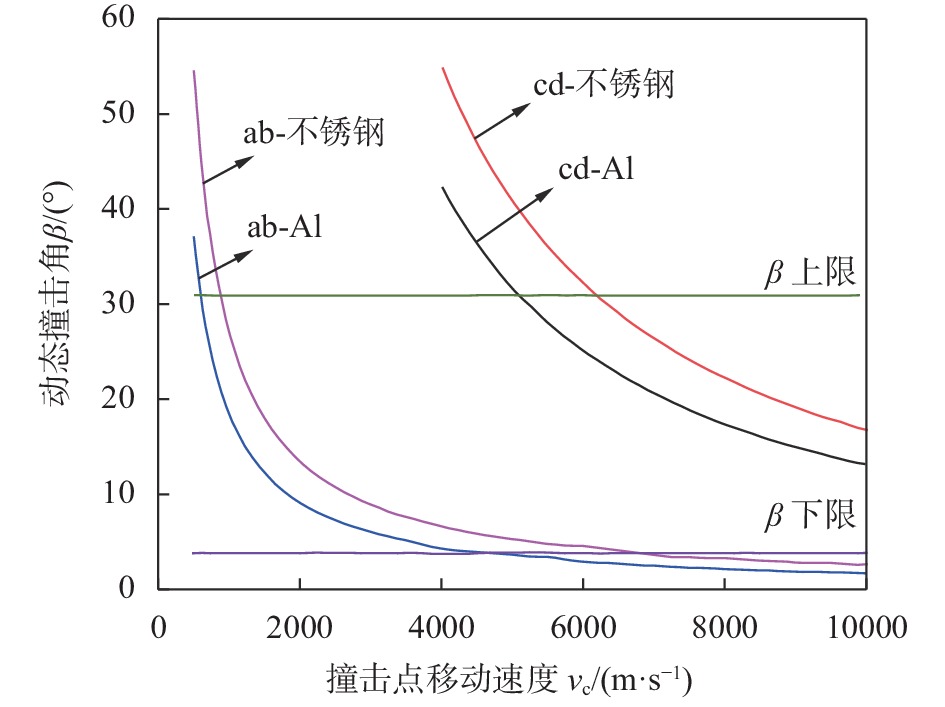

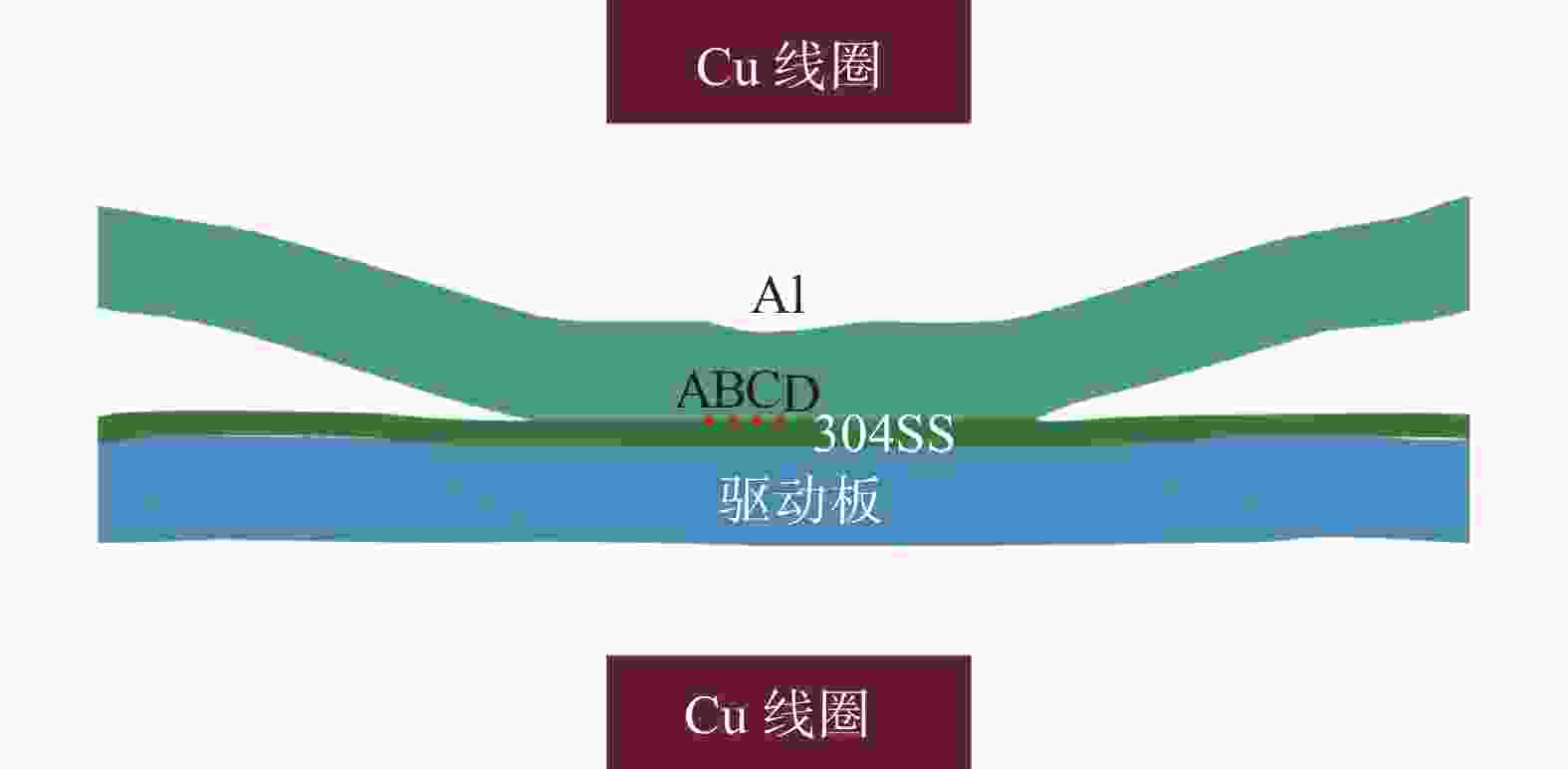

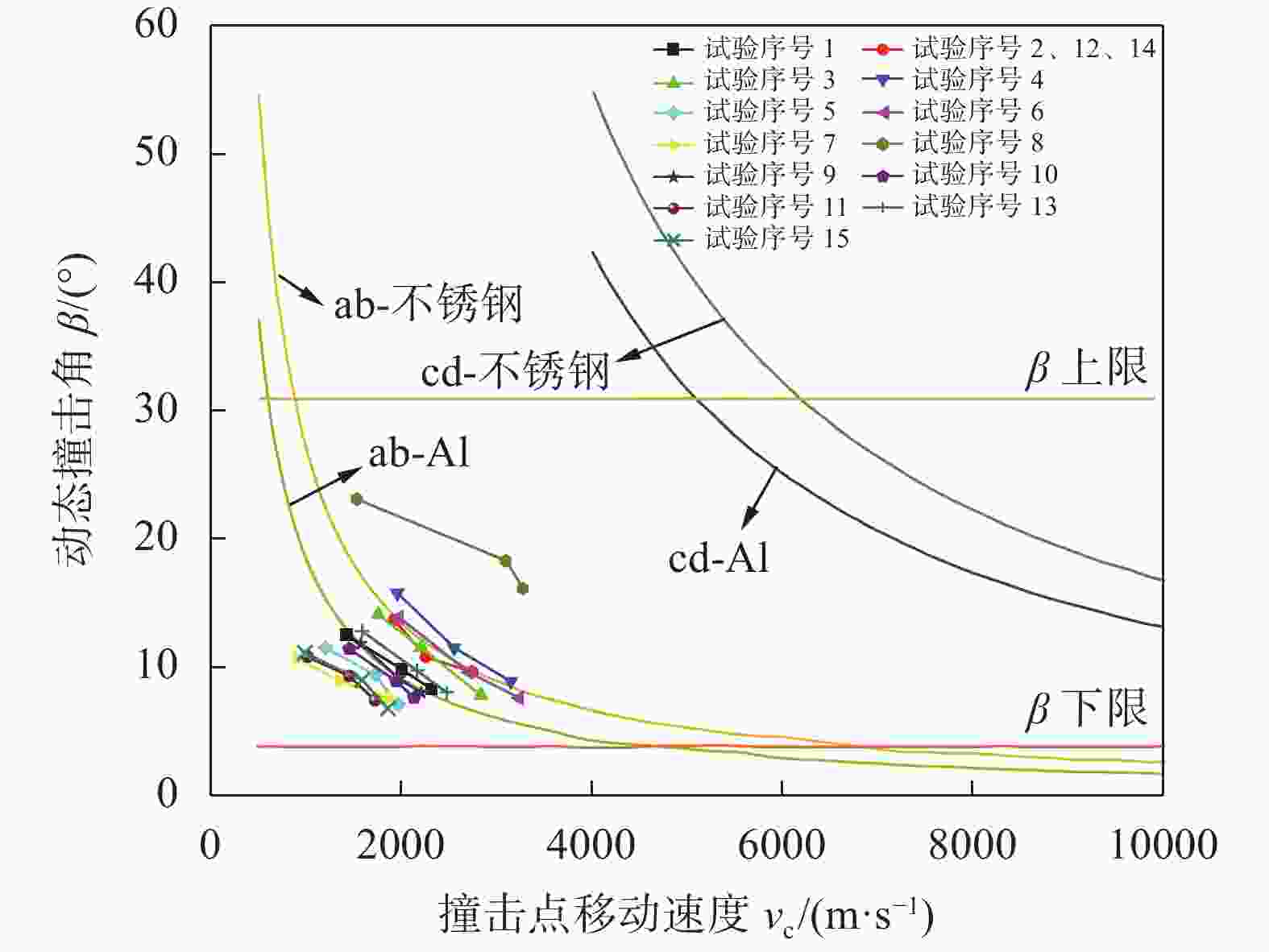

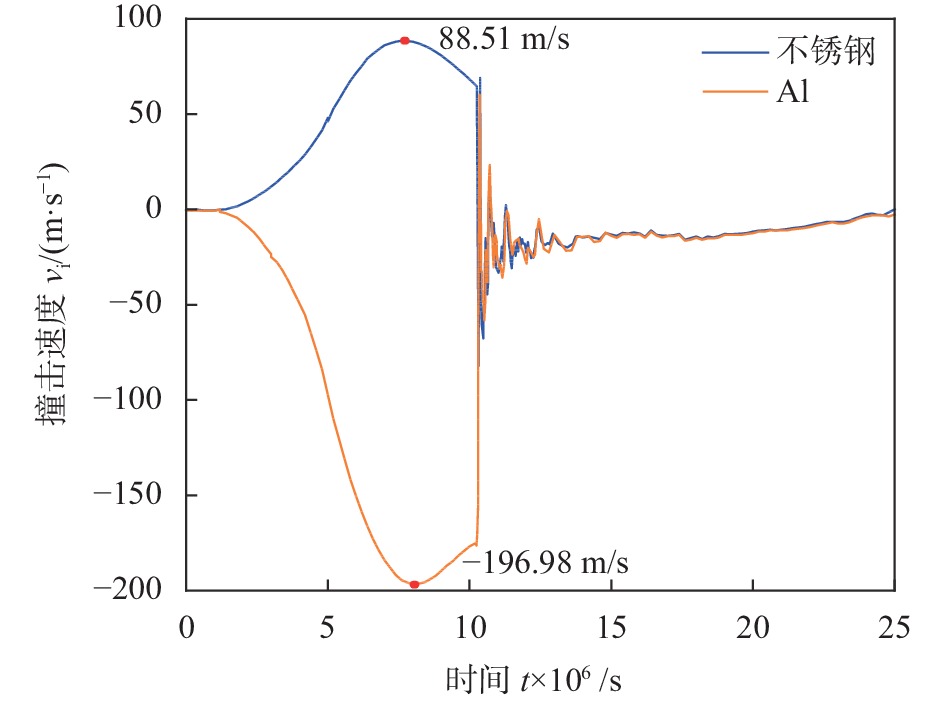

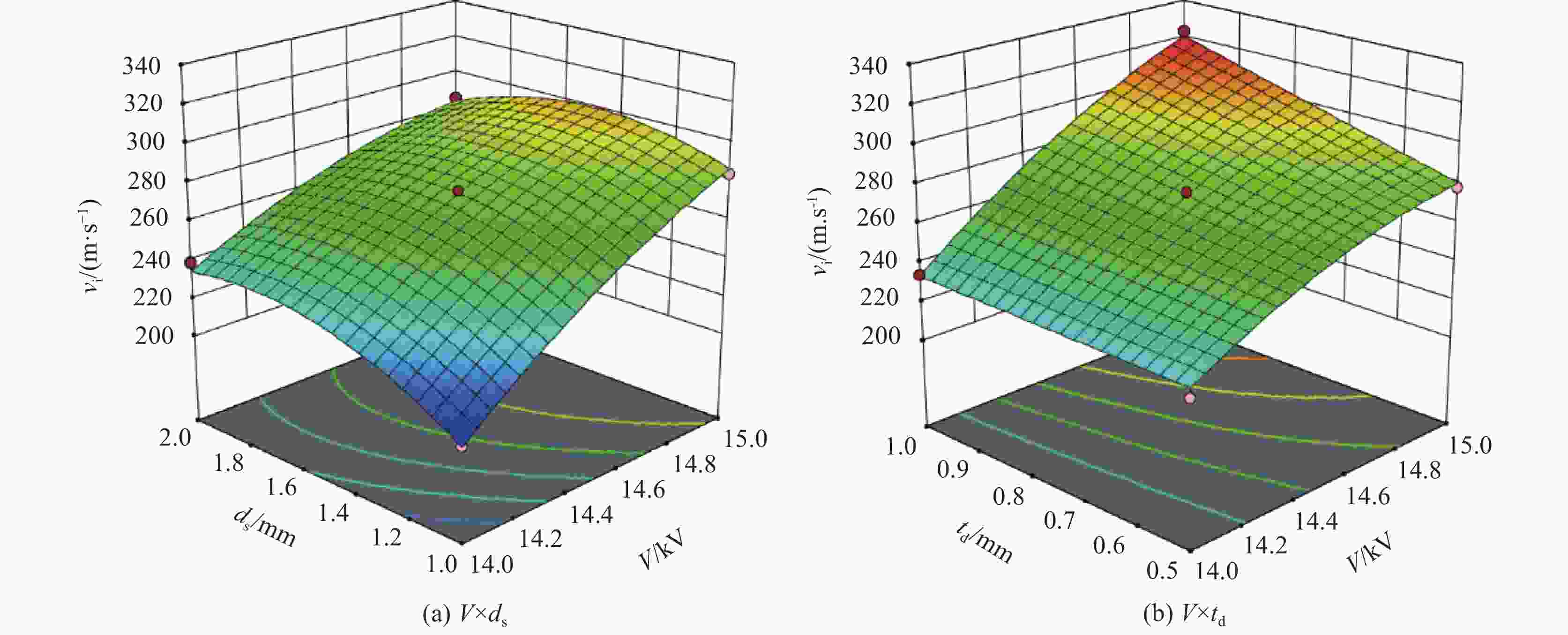

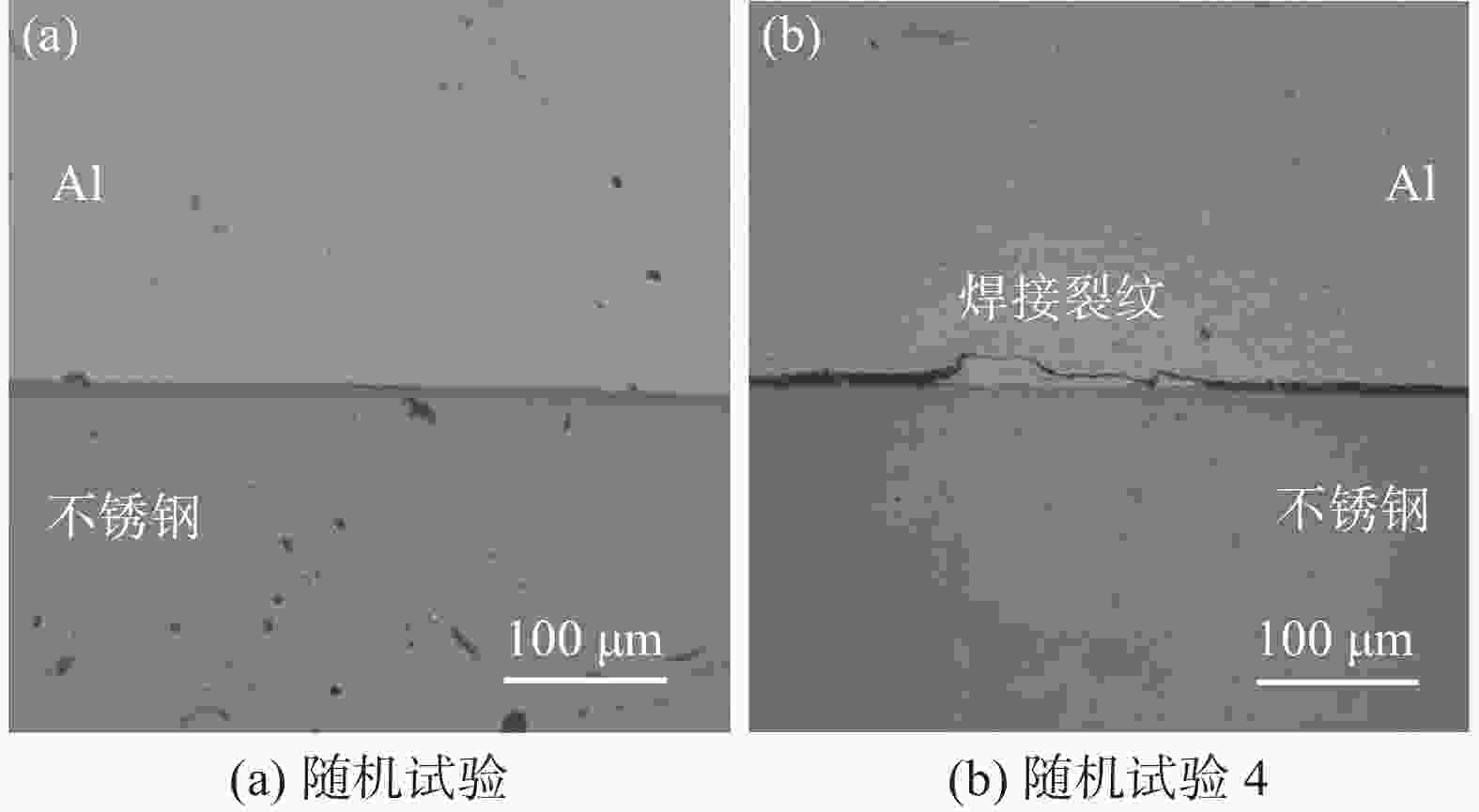

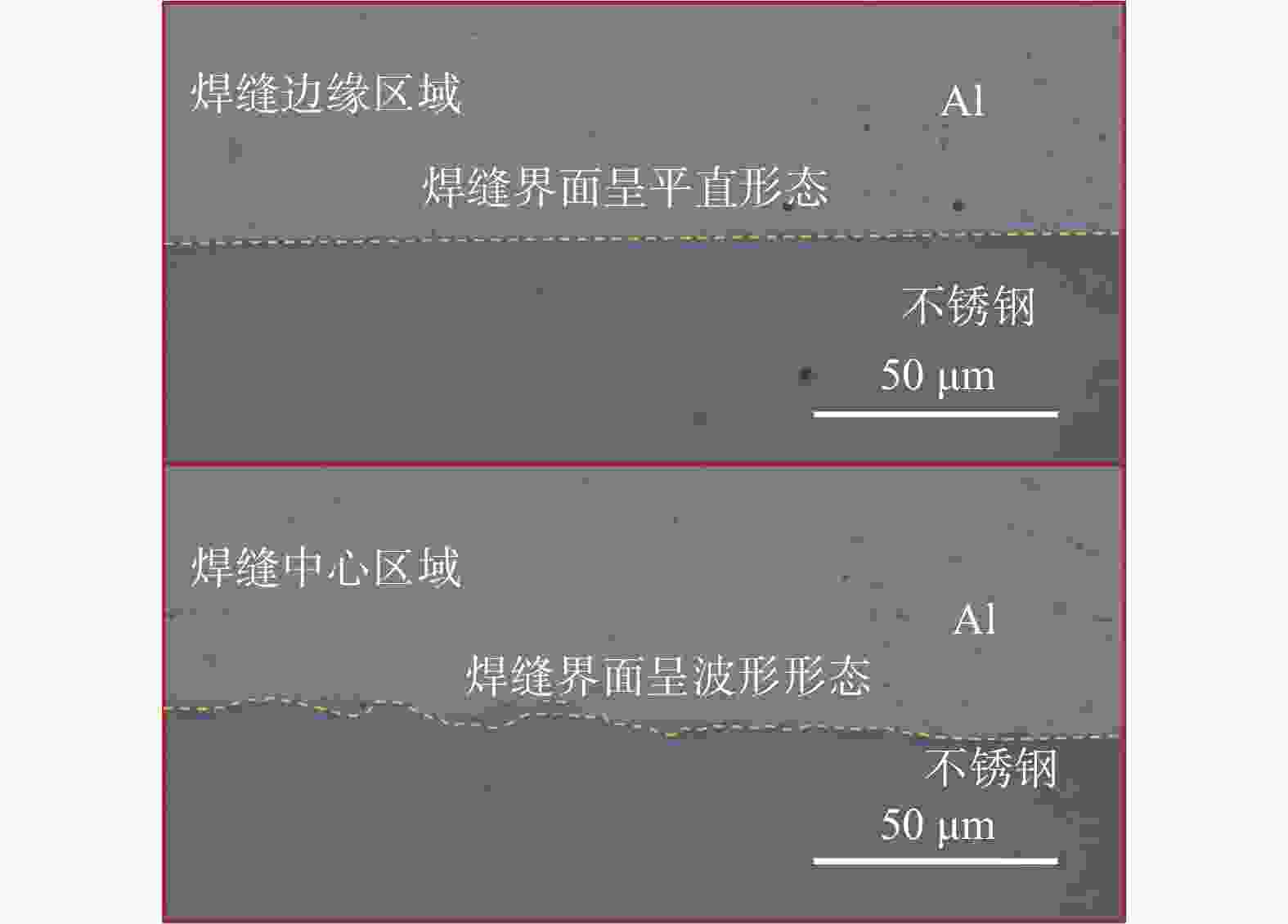

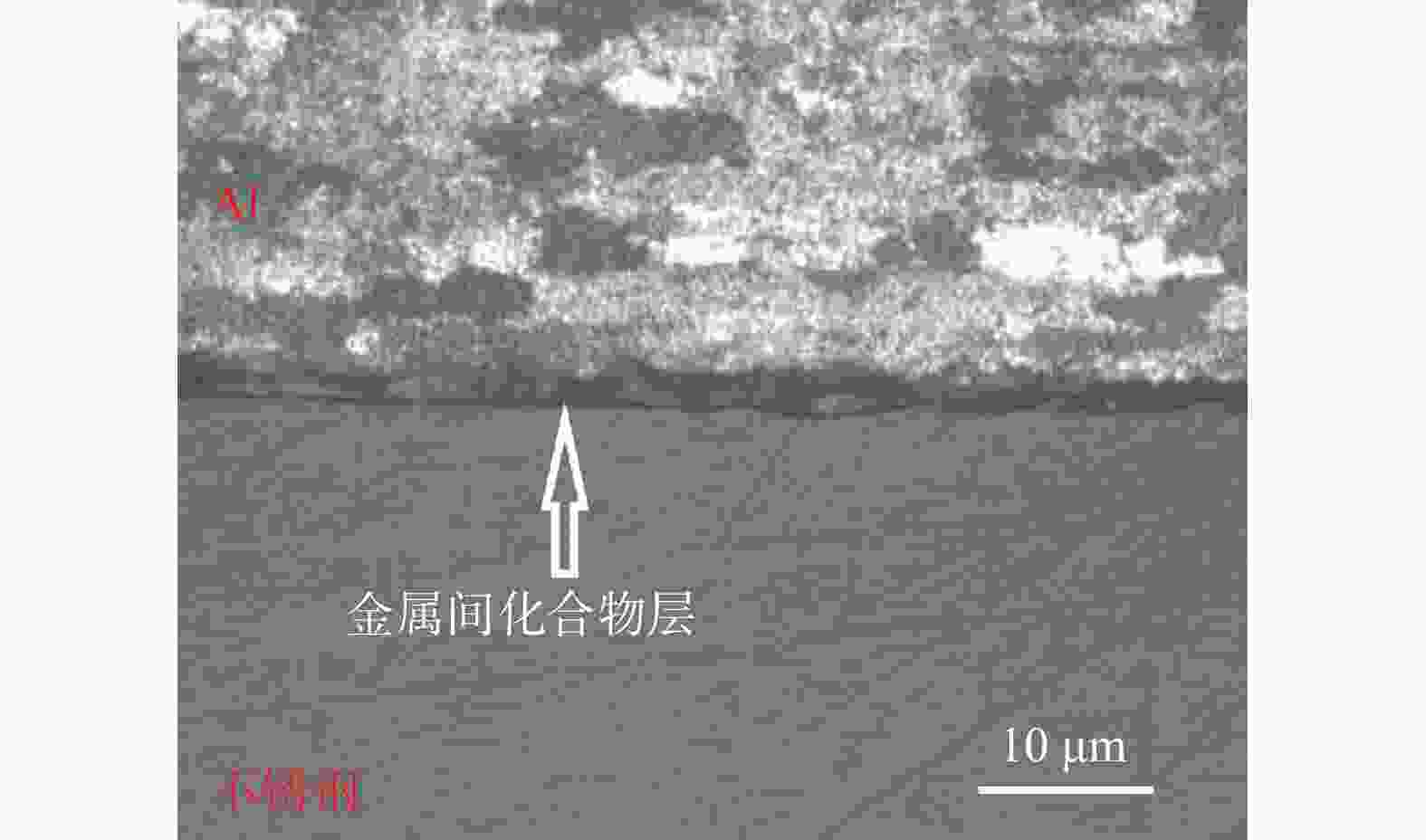

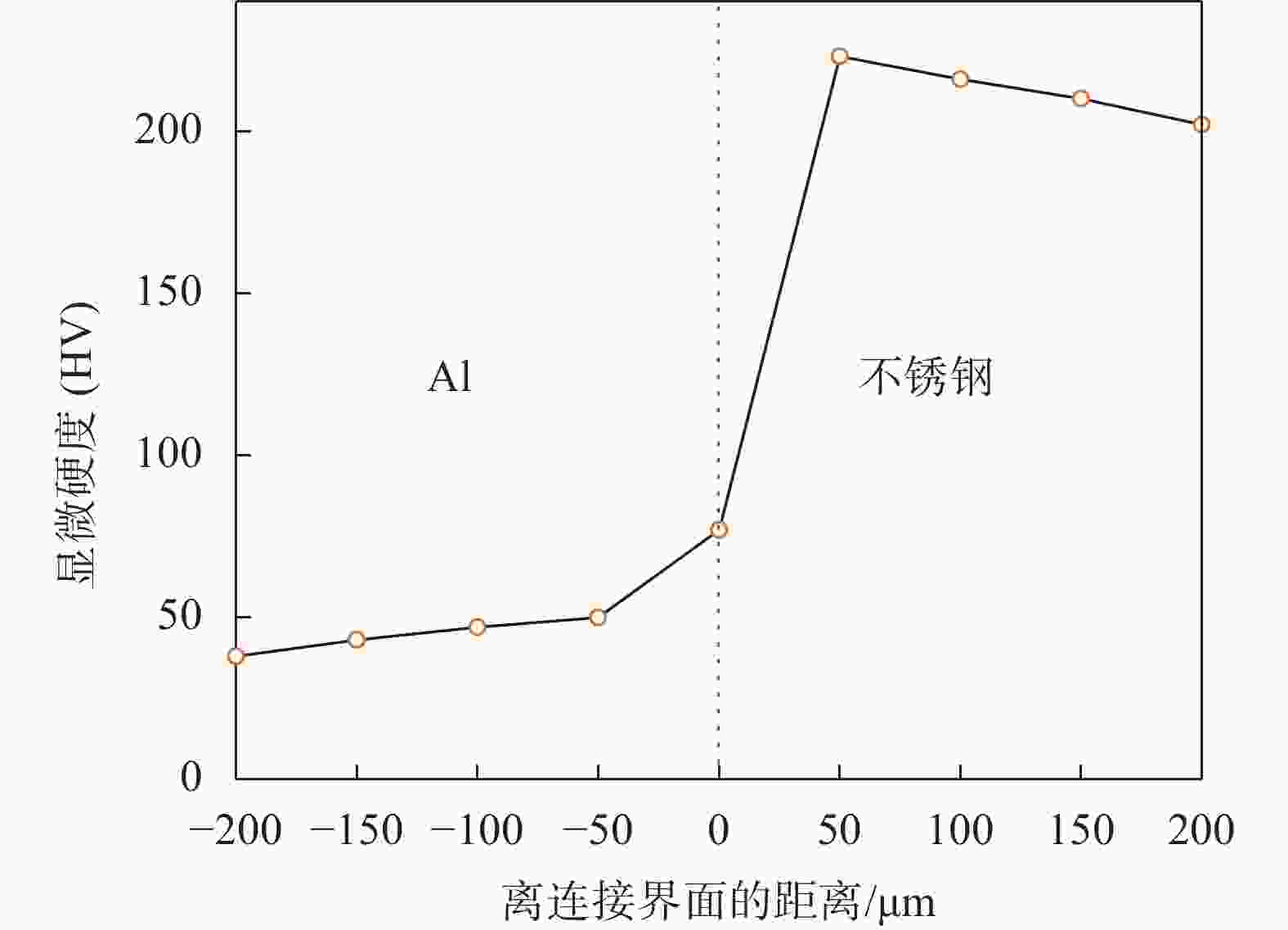

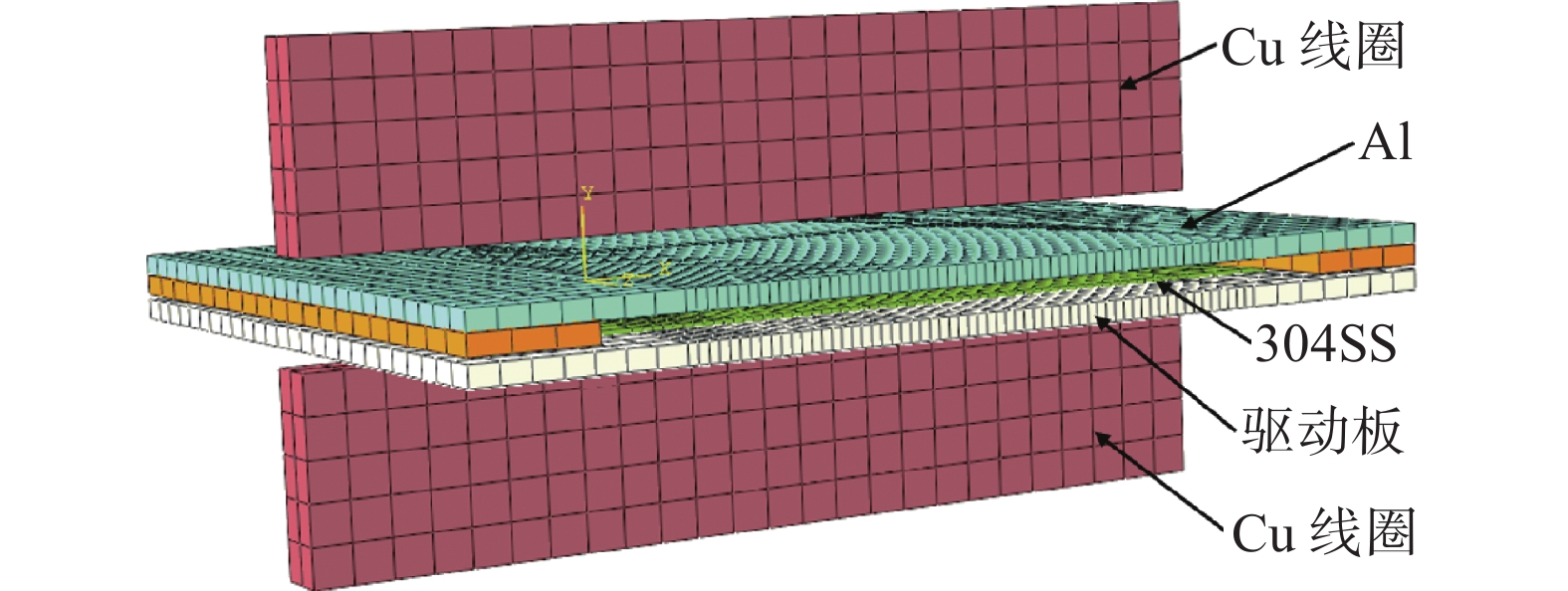

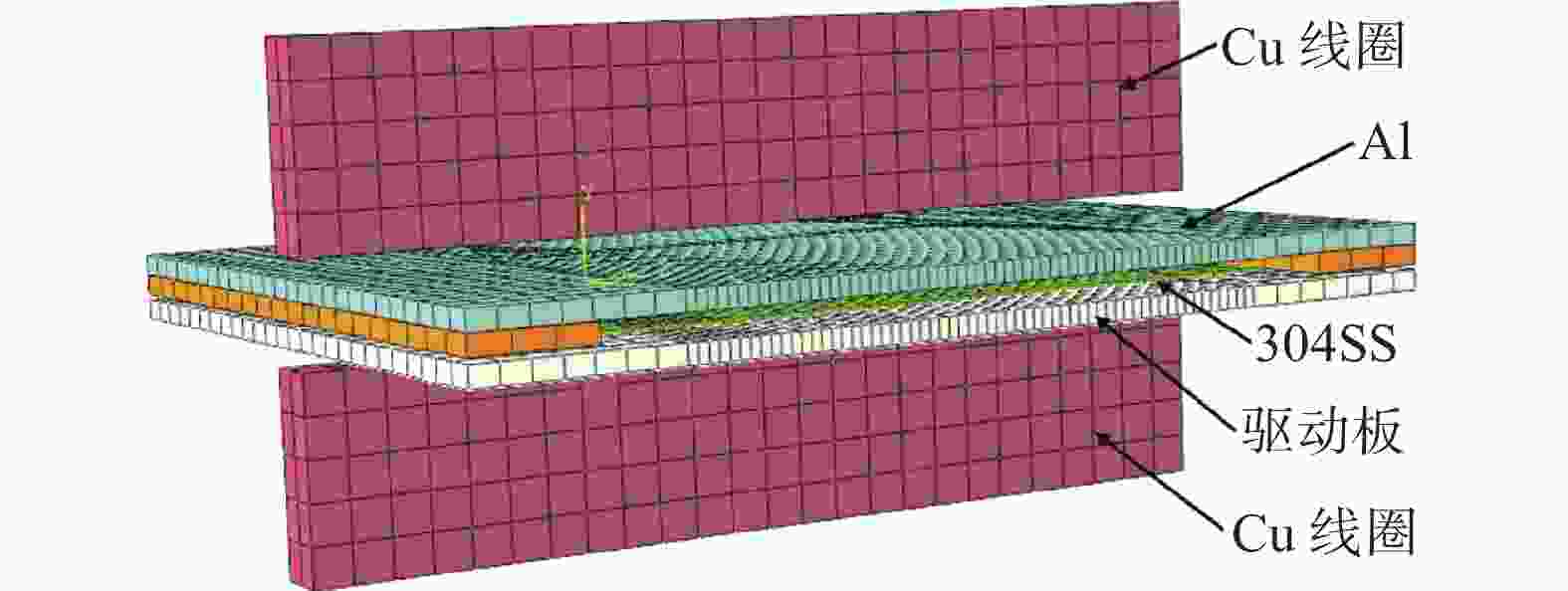

摘要: 铝/钢异种金属焊接接头易反应生成Fe-Al金属间化合物,恶化接头性能,使焊接成型困难。使用ABAQUS有限元软件模拟异种金属磁力脉冲焊(EMW)电磁-热-结构耦合过程,在最小能量下实现铝/不锈钢的高质量焊接。基于Box–Behnken响应曲面法设计试验,从电压(V)、间距(ds)和驱动板厚度(td)等工艺参数中提取重要参数。通过绘制Al/不锈钢焊接工艺窗口研究焊缝形成的可能性,并试验验证EMW仿真结果的有效性。通过分析最佳工艺参数下接头微观结构评估了接头成型质量。方差分析表明,在V =15 kV,ds =1.5 mm和td =1 mm下,可以获得用于高质量焊接的最大撞击速度。Abstract: The reaction of aluminum/steel dissimilar metals welded joints to form Fe-Al intermetallic compounds deteriorates joint performance and makes welding forming difficult. In this paper, ABAQUS finite element software was used to simulate the electromagnetic-thermal-structure coupling process of dissimilar metal electromagnetic welding (EMW) to achieve high-quality aluminum/stainless steel welding with minimal energy. The experiment was designed based on the Box-Behnken response surface method, and important parameters were extracted from the process parameters such as voltage (V), separation distance (ds) and driving plate thickness (td). By drawing the Al/stainless steel welding process window, the possibility of weld formation was studied, and the validity of the EMW simulation results was verified by experiments. In order to evaluate the joint forming quality, the joint microstructure under the optimal process parameters was analyzed. The analysis of variance shows that the maximum impact velocity for high-quality welding can be obtained under V =15 kV, ds =1.5 mm and td =1 mm.

-

表 1 1050铝和AISI304不锈钢的机械性能

Table 1. Mechanical properties of 1050 aluminum and AISI304 stainless steel

试验材料 A/MPa B/MPa C n 密度ρ/(kg·m−3) 杨氏模量E/GPa 泊松比μ 维氏硬度(HV) 1050Al 140 75.2 0.0125 0.65 2700 69 0.33 43 AISI304SS 310 1000 0.07 0.65 7900 200 0.3 129 表 2 EMW工艺参数水平编码与真实值

Table 2. Factor level coding and true value of EMW process parameters

水平编码 因素 V/kV ds/mm td/mm − 14 1 0.5 0 14.5 1.5 0.75 + 15 2 1 表 3 Box-Behnken试验设计及计算结果

Table 3. Box-Behnken experimental design and calculation results

试验序号 模式 V/kV ds/mm td/mm vi/(m·s−1) 1 0-- 14.5 1 0.5 245 2 000 14.5 1.5 0.75 276 3 +-0 15 1 0.75 284 4 ++0 15 2 0.75 286 5 -0+ 14 1.5 1 234 6 +0- 15 1.5 0.5 278 7 --0 14 1 0.75 201 8 +0+ 15 1.5 1 323 9 0++ 14.5 2 1 271 10 0-+ 14.5 1 1 262 11 -+0 14 2 0.75 239 12 000 14.5 1.5 0.75 276 13 0+- 14.5 2 0.5 257 14 000 14.5 1.5 0.75 276 15 -0- 14 1.5 0.5 227 表 4 二次模型ANOVA结果

Table 4. ANOVA for reduced quadratic model

方差来源 平方和 均方 P值 模型 12145.66 1735.09 < 0.0001 V 9112.50 9112.50 < 0.0001 ds 465.13 465.13 0.0016 td 861.13 861.13 0.0003 V×ds 324.00 324.00 0.0043 V×td 361.00 361.00 0.0032 V² 250.45 250.45 0.0082 ds² 831.43 831.43 0.0003 残差 131.67 18.81 失拟项 131.67 26.33 净误差 0.0000 0.0000 总离差 12277.33 R²=98.93% R²Adj=97.86% R²Pred=92.41% S/N=37.56 -

[1] Fan Zijie, Gui Liangjin, Su Ruiyi. Research and development of automotive lightweight technology[J]. Journal of Automotive Safety and Energy, 2014,5(1):1−16. (范子杰, 桂良进, 苏瑞意. 汽车轻量化技术的研究与进展[J]. 汽车安全与节能学报, 2014,5(1):1−16.Fan Zijie, Gui Liangjin, Su Ruiyi. Research and development of automotive lightweight technology[J]. Journal of Automotive Safety and Energy, 2014, 5(1): 1-16. [2] Wang Shaoluo, Xu Liwang, Sun Tao, et al. Effects of process parameters on mechanical performance and interfacial morphology of electromagnetic pulse welded joints between aluminum and galvanized steel[J]. Journal of Materials Research and Technology, 2021,10:552−564. [3] Dong Honggang, Hu Wenjin, Duan Yuping, et al. Effects of Si and Cu additions on properties of dissimilar aluminum-galvanized steel weld[J]. Transactions of the China Welding Institution, 2010,31(11):9−12. (董红刚, 胡文金, 段玉平, 等. Si和Cu元素对铝-镀锌钢GTAW接头性能的影响[J]. 焊接学报, 2010,31(11):9−12.Dong Honggang, Hu Wenjin, Duan Yuping, et al. Effects of Si and Cu additions on properties of dissimilar aluminum-galvanized steel weld[J]. Transactions of the China Welding Institution, 2010, 31(11): 9-12. [4] Torkamany M J, Tahamtan S, Sabbaghzadeh J. Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd: YAG pulsed laser[J]. Materials & Design, 2010,31(1):458−465. [5] 邓方雄. 基于电磁脉冲技术的金属板件高速碰撞焊接方法与实验研究[D]. 武汉: 华中科技大学, 2019.Deng Fangxiong. High speed impact welding method and experimental study of metal plates based on electromagnetic pulsed technology[D]. Wuhan: Huazhong University of Science and Technology, 2019. [6] Xu Zhidan, Cui Junjia, Yu Haiping, et al. Research on the impact velocity of magnetic impulse welding of pipe fitting[J]. Materials & Design, 2013,49:736−745. [7] Aizawa T. Methods for electromagnetic pressure seam welding of Al/Fe sheets[J]. Welding international, 2004,18(11):868−872. [8] Kore S D, Date P P, Kulkarni S V. Electromagnetic impact welding of aluminum to stainless steel sheets[J]. Journal of materials processing technology, 2008,208(1-3):486−493. [9] Zhu Congcong, Sun Liqiang, Gao Wenli, et al. The effect of temperature on microstructure and mechani-cal properties of Al/Mg lap joints manufactured by magnetic pulse welding[J]. Journal of Materials Research and Technology, 2019,8(3):3270−3280. [10] Kore S D, Date P P, Kulkarni S V, et al. Electromagnetic impact welding of copper-to-copper sheets[J]. International Journal of Material Forming, 2010,3(2):117−121. [11] Zhu Congcong, Meng Yifan, Liu Quanxiaoxiao, et al. Study on process and mechanical properties of Al/Mg dissimilar metal sheet joints by magnetic pulse welding[J]. Journal of Netshape Forming Engineering, 2021,13(4):45−51. (朱聪聪, 蒙奕帆, 柳泉潇潇, 等. Al/Mg 异种金属板材电磁脉冲焊接工艺及力学性能研究[J]. 精密成形工程, 2021,13(4):45−51.Zhu Chongchong, Meng Yifan, Liu Quanxiaoxiao, et al. Study on process and mechanical properties of Al/Mg dissimilar metal sheet joints by magnetic pulse welding[J]. Journal of Netshape Forming Engineering, 2021, 13(4): 45-51. [12] Kore S D, Date P P, Kulkarni S V, et al. Application of electromagnetic impact technique for welding copper-to-stainless steel sheets[J]. International Journal of Advanced Manufacturing Technology, 2011,54(9-12):949−955. [13] Wang Chenguang, Liu Quanxiaoxiao, Li Guangyao, et al. Study on mechanical properties and microstructural feature of magnetic pulse welding joint between Cu and Al sheets[J]. International Journal of Advanced Manufacturing Technology, 2021,113:1739−1751. [14] Kudiyarasan S, Arungalai Vendan S. Magnetic pulse welding of two dissimilar materials with various combinations adopted in nuclear applications[J]. Indian Journal of Science & Technology, 2015,8(36):1−9. [15] Cui Junjia, Ye Liang, Zhu Congcong, et al. Mechanical and microstructure investigations on magnetic pulse welded dissimilar AA3003-TC4 joints[J]. Journal of Materials Engineering and Performance, 2020,29:712−722. [16] Shiran M K G, Khalaj G, Pouraliakbar H, et al. Effects of heat treatment on the intermetallic compounds and mechanical properties of the stainless steel 321-aluminum 1230 explosive-welding interface[J]. International Journal of Minerals, Metallurgy and Materials, 2017,24:1267−1277. -

下载:

下载: