Effect of Mg on carbides in 21-4N valve steel

-

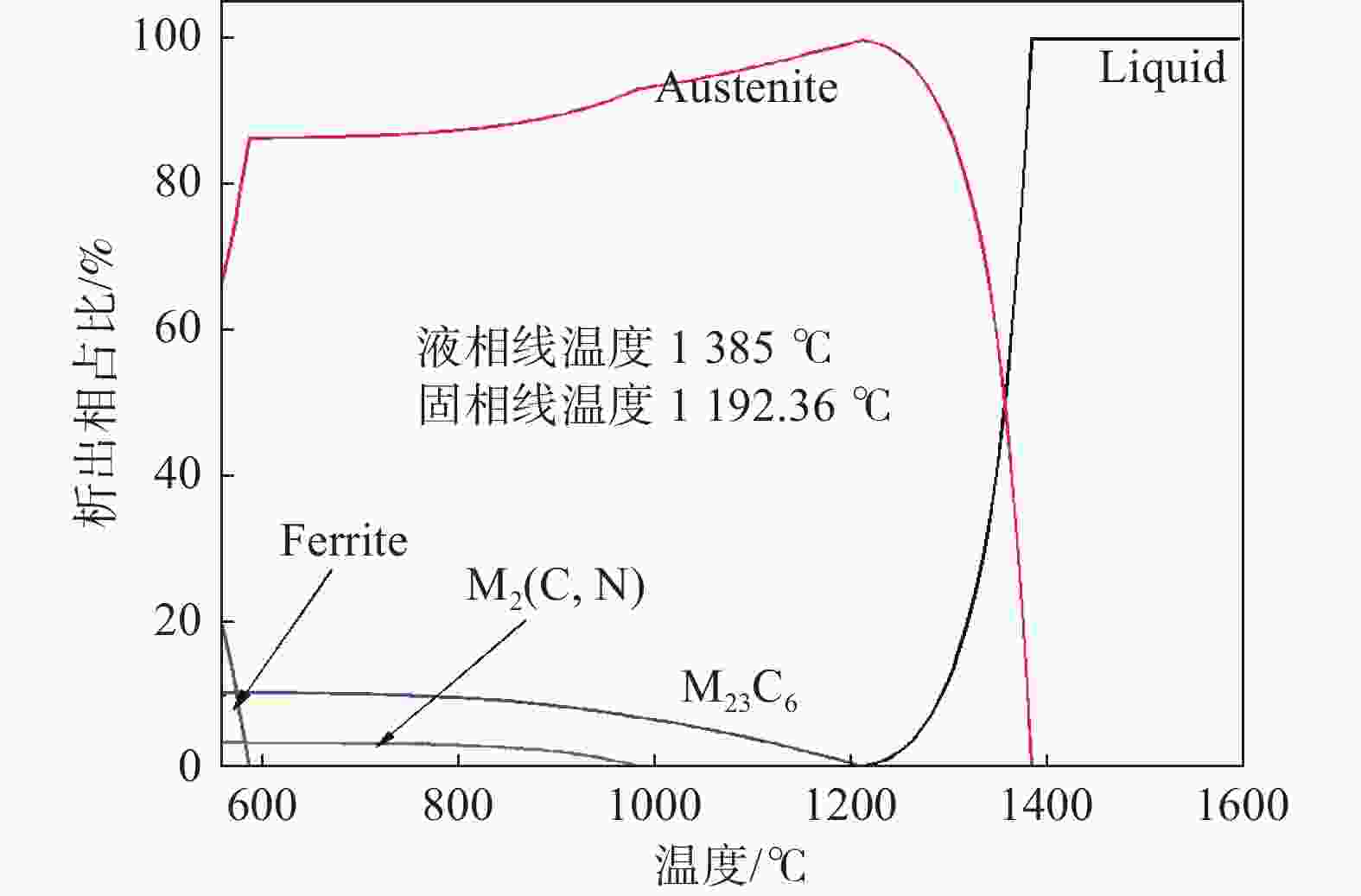

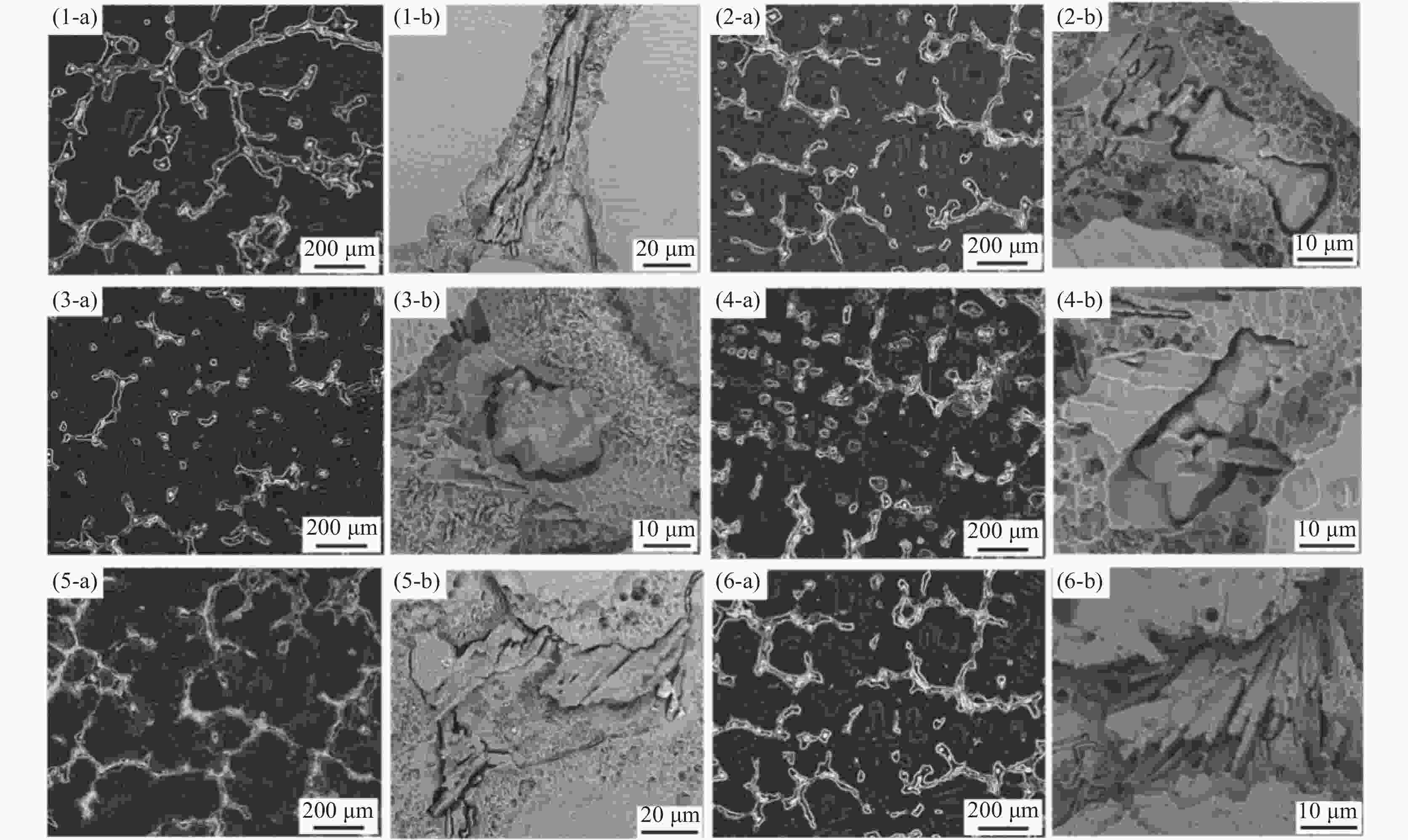

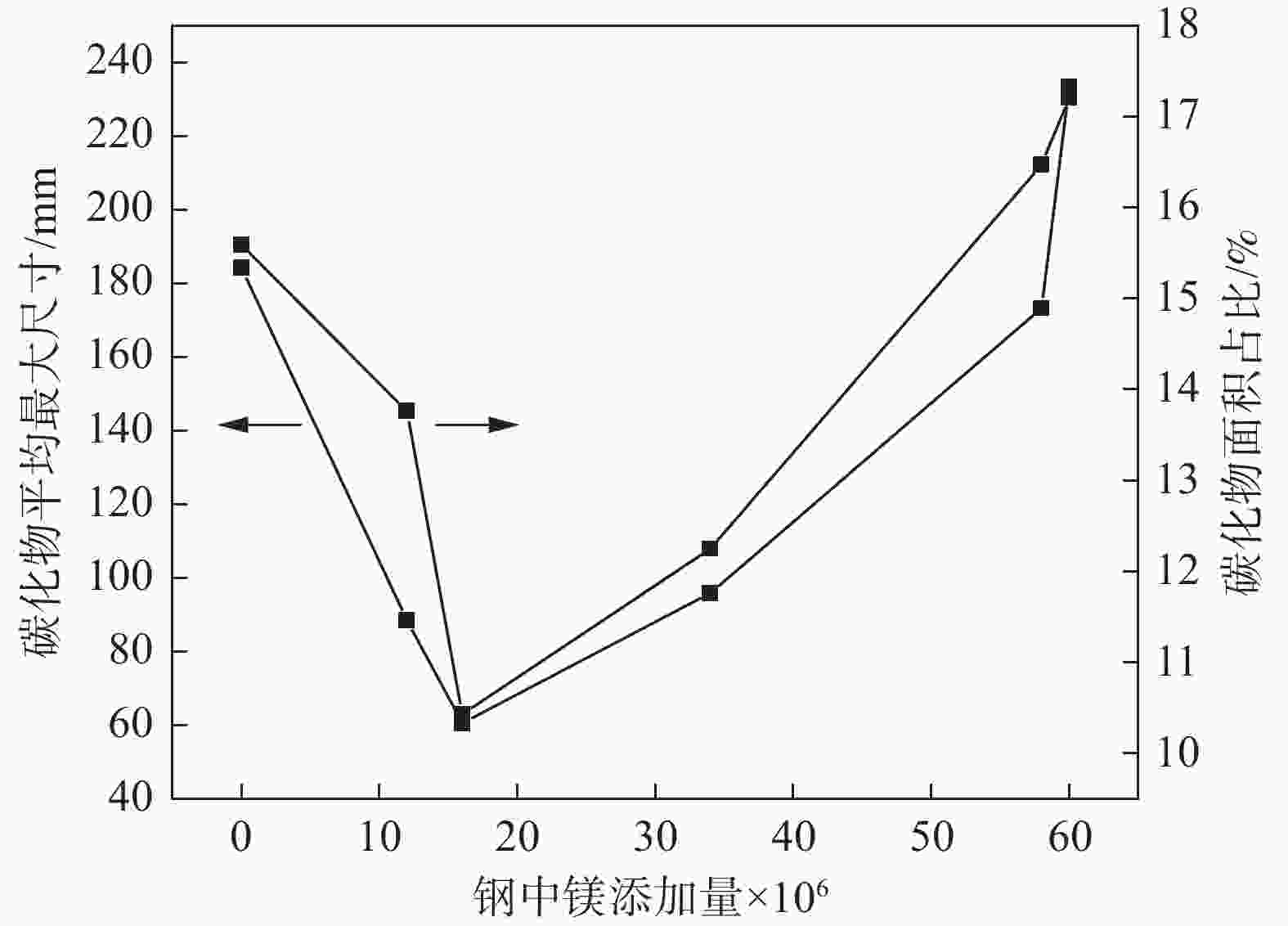

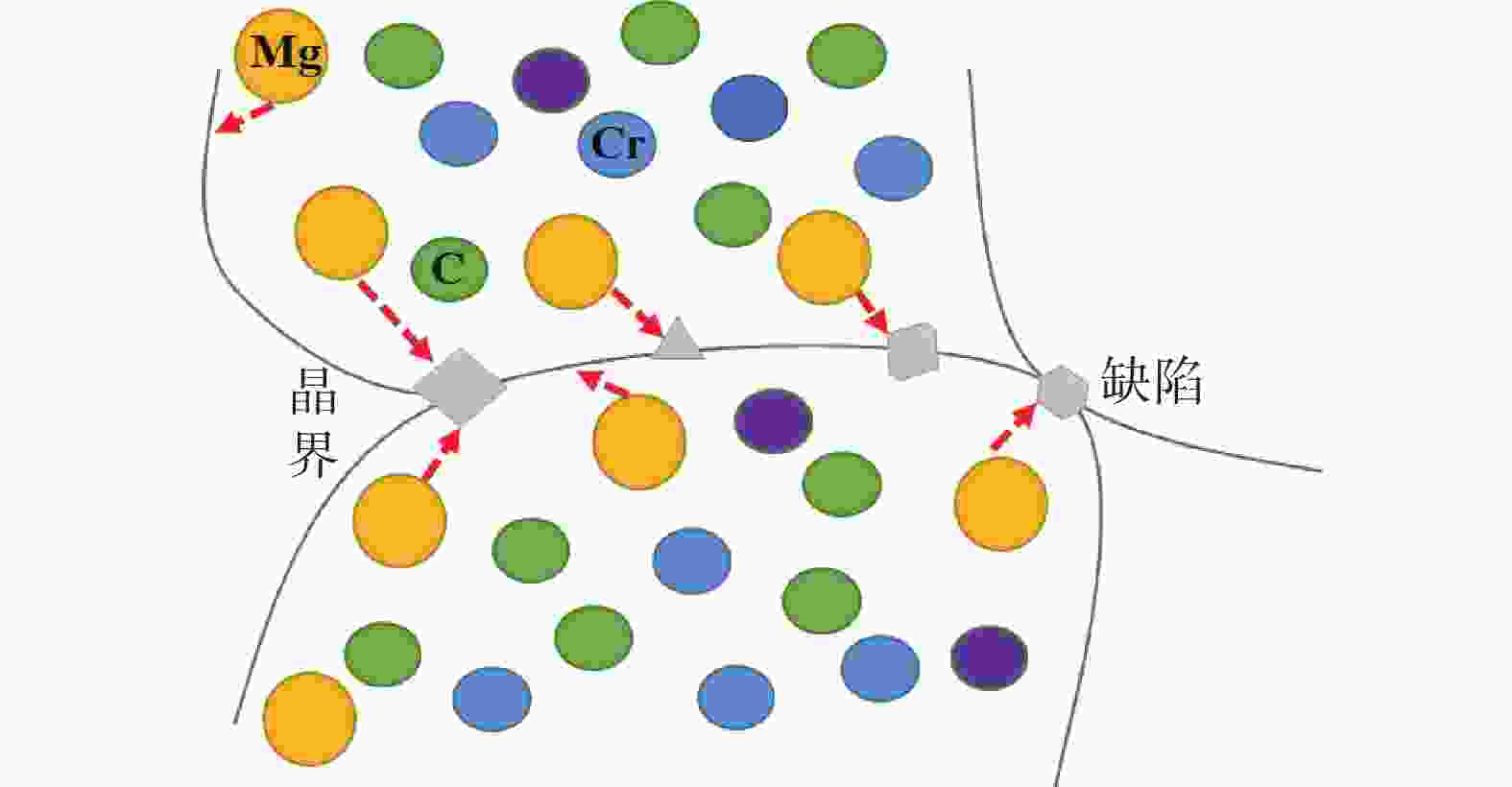

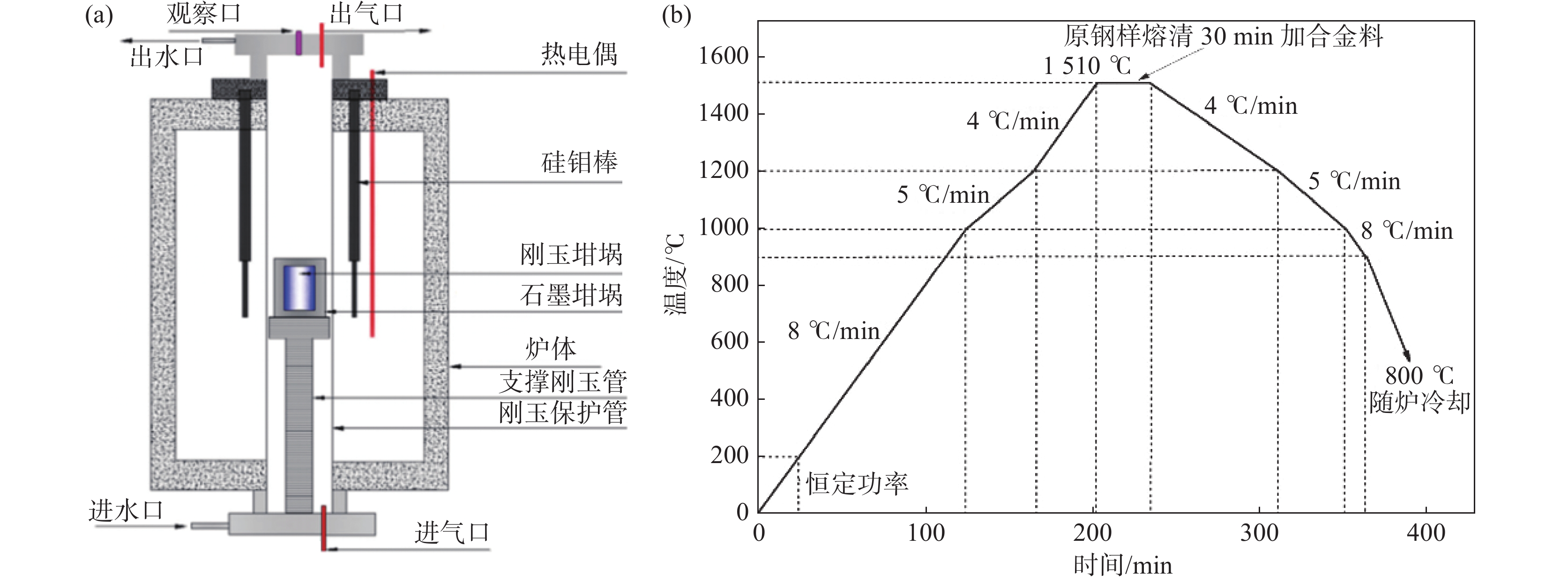

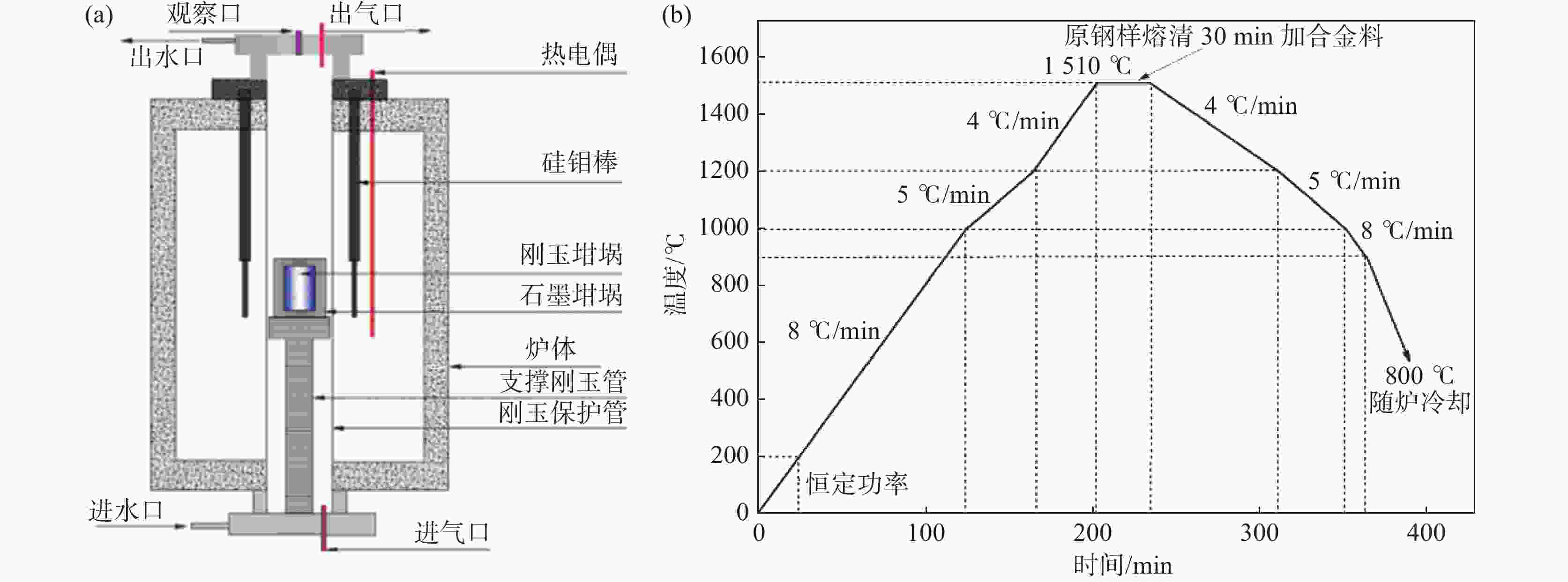

摘要: 为了探究不同镁含量对21-4N气阀钢中液析碳化物的影响规律,采用实验室高温电阻炉冶炼了不同镁添加量的21-4N气阀钢,借助蔡司金相显微镜、扫描电子显微镜、电解腐蚀等方法开展研究。结果表明,随21-4N钢中Mg含量的增加,碳化物平均最大尺寸及面积占比均先减小后增大。添加微量的镁有助于改善钢中富Cr型液析碳化物的尺寸和分布,镁的质量分数为1.6×10−5时,液析碳化物平均最大尺寸为60.55 μm,面积占比10.43%,在钢中多呈颗粒状分布,连续性被破坏,其原因是镁元素在晶界处的偏聚,能够抑制C、Cr等合金元素的扩散,阻断碳化物连续生长,从而达到细化碳化物尺寸的效果。Abstract: In order to explore the influence of different magnesium content on primary carbides in 21-4N valve steel, 21-4N valve steel with different magnesium content was smelted in a laboratory high temperature resistance furnace, and the research was carried out by use of Zeiss metallographic microscope, scanning electron microscope and electrolytic corrosion. The results show that with the increase of Mg content in 21-4N steel, both the average maximum size and area ratio of carbides firstly decrease and then increase. The addition of trace magnesium is helpful to improve the size and distribution of Cr-rich precipitated carbides in steel. When the mass fraction of magnesium is 1.6×10−5, the average maximum size of precipitated carbides is 60.55 μm and its area ratio is 10.43%, and most of them are granular in steel, and the continuity is destroyed. The reason is that the segregation of magnesium at the grain boundary can inhibit the diffusion of alloy elements such as C and Cr, and then block the continuous growth of carbide, thus achieving the effect of refining the carbide size.

-

Key words:

- 21-4N valve steel /

- Mg modification /

- primary carbide

-

表 1 21-4N气阀钢和Ni-Mg合金主要化学成分

Table 1. Main chemical compositions of raw materials and Ni-Mg alloy

% C Si Mn P S Cr Ni Al N Mg 21-4N气阀钢 0.52 0.22 9.00 0.03 0.03 20.38 3.37 0.02 0.42 Ni-Mg合金 0.56 0.11 74.19 24.19 表 2 镁含量检测结果及收得率

Table 2. Test results magnesium content and its yield

组别 目标镁含量×106 镁检测值×106 镁收得率/% 1 0 2 5 12 7.14 3 10 16 4.86 4 20 34 4.97 5 40 58 3.37 6 60 60 2.29 -

[1] Wang Yuzhou, Dong Jianxin. Review on the selection and research of valve materials used in automobile engines[J]. Materials Reports, 2016,30(13):87−93,101. (王宇宙, 董建新. 汽车发动机用气门材料的选择及研究进展[J]. 材料导报, 2016,30(13):87−93,101.Wang Yuzhou, Dong Jianxin. Review on the selection and research of valve materials used in automobile engines[J]. Materials Reports, 2016, 30(13): 87-93+101. [2] Yin Lianmin, Qu Shengguan, Lai Fuqiang, et al. Study on high temperature characteristics of 21-4N valve steel[J]. Journal of Materials Science and Engineering, 2020,38(3):409−413,517. (尹联民, 屈盛官, 赖福强, 等. 21-4N气门钢的高温性能[J]. 材料科学与工程学报, 2020,38(3):409−413,517.Yin Lianmin, Qu Shengguan, Lai Fuqiang, et al. Study on high temperature characteristics of 21-4 N valve steel[J]. Journal of Materials Science and Engineering, 2020, 38(03): 409-413+517. [3] Tian Zhiming, Wang Honggang. Research of carbide precipitation in the austenitic heat resistance steel 21-4N[J]. Metallurgical Information Review, 2006,(2):24−27. (田志明, 王洪刚. 奥氏体耐热钢21-4N碳化物析出行为研究[J]. 冶金信息导刊, 2006,(2):24−27.Tian Zhiming, Wang Honggang. Research of carbide precipitation in the austenitic heat resistance steel 21-4 N. [J]. Metallurgical Information Review, 2006(02): 24-27. [4] Wang Hongli, Du Simin, Cao Meijiao, et al. Influence of rare earth on microstructure and carbide of 21-4N steel[J]. Iron Steel Vanadium Titanium, 2020,41(1):119−124. (王洪利, 杜思敏, 曹美姣, 等. 微量稀土元素对奥氏体不锈钢21-4N显微组织及碳化物的影响[J]. 钢铁钒钛, 2020,41(1):119−124.Wang Hongli, Du Simin, Cao Meijiao, et al. Influence of rare earth on microstructure and carbide of 21-4 N steel[J]. Iron Steel Vanadium Titanium, 2020, 41(01): 119-124. [5] He Kaiwen. Discussion on the causes of warm deformation drawing cracks of 21-4N steel[J]. Sichuan Metallurgy, 2000,(5):27−30. (何开文. 21-4N钢温变形拔制裂纹原因探讨[J]. 四川冶金, 2000,(5):27−30.He Kaiwen. Discussion on the causes of warm deformation drawing cracks of 21-4N steel[J]. Sichuan Metallurgy, 2000(5): 27-30. [6] Yan Shanghua, Cao Meijiao, Li Ning, et al. Effect of solid solution temperature on microstructure and properties of 21-4N steel for gas valve[J]. Special Steel Technology, 2016,22(4):4−8. (晏尚华, 曹美姣, 李宁, 等. 固溶温度对21-4N气阀钢组织与性能的影响[J]. 特钢技术, 2016,22(4):4−8.Yan Shanghua, Cao Meijiao, Li Ning, et al. Effect of solid solution temperature on microstructure and properties of 21-4 N steel for gas valve[J]. Special Steel Technology, 2016, 22(04): 4-8. [7] Chen Bin, Bao Sarina, Jiang Min, et al. Cleanliness of molten steel improved by Mg[J]. Journal of Iron and Steel Research, 2008,(6):14−17, 22. (陈斌, 包萨日娜, 姜敏, 等. 镁提高钢水纯净度的研究[J]. 钢铁研究学报, 2008,(6):14−17, 22.Chen Bin, Baosa Rina, Jiang Min, et al. Cleanliness of molten steel improved by Mg[J]. Journal of Iron and Steel Research, 2008(06): 14-17+22. [8] Xie Jianbo, Zhang Dong, Yang Qiankun, et al. Exploration of morphology evolution of the inclusions in Mg-treated 16MnCrS5 steel[J]. Ironmaking & Steelmaking, 2019,46(6):564−573. [9] Shen Ping, Fu Jianxun. Morphology study on inclusion modifications using Mg-Ca treatment in resulfurized special steel[J]. Materials, 2019,12(2):197. [10] Zhu Haoran, Liu Nianfu, Zhou Lei, et al. Modification effect of magnesium treatment on inclusions in 0.45%C steel[J]. Special Steel, 2022,43(1):6−10. (朱浩然, 刘年富, 周蕾, 等. 镁处理对45钢中夹杂物的改质效果[J]. 特殊钢, 2022,43(1):6−10.Zhu Haoran, Liu Nianfu, Zhou Lei, et al. Modification effect of magnesium treatment on inclusions in 0.45%C steel[J]. Special Steel, 2022, 43(01): 6-10. [11] Zhang Zhang, Chang Kaihua, Chang Lizhong, et al. Effect of Mg on carbides in M2 high speed tool steel[J]. Journal of Iron and Steel Research, 2019,31(12):1046−1052. (张章, 常凯华, 常立忠, 等. Mg对M2高速工具钢中碳化物的影响[J]. 钢铁研究学报, 2019,31(12):1046−1052.Zhang Zhang, Chang Kaihua, Chang Lizhong, et al. Effect of Mg on carbides in M2 high speed tool steel[J]. Journal of Iron and Steel Research. 2019, 31(12): 1046-1052. [12] Li J, Shi C B, Wang L L, et al. Effect of trace magnesium on carbide improvement in H13 steel[J]. Canadian Metallurgical Quarterly, 2016,55(3):321-327. [13] Mao W M, Zhong X Y. Effect of the trace magnesium in M2 high speed steel[J]. Acta Metall Sin, 1993,29(11):492. [14] Bor H Y, Chao C G, Ma C Y. The influence of magnesium on carbide characteristics and creep behavior of the MARM247 superalloy[J]. Scripta Mater, 1998,38(2):329. [15] Liu Beibei, Sun Han, Xu Xiangyu, et al. Effect of Mg content on solidification structure refinement of 21-4N gas valve steel[J]. Shanghai Metals, 2022,44(1):67−73. (刘贝贝, 孙晗, 徐翔宇, 等. Mg含量对21-4N气阀钢凝固组织细化作用的研究[J]. 上海金属, 2022,44(1):67−73.Liu Beibei, Sun Han, Xu Xiangyu, et al. Effect of Mg content on solidification structure refinement of 21-4 N gas valve steel[J]. Shanghai Metals, 2022, 44(01): 67-73. [16] Mclean D. Grain boundaries in metals[M]. London: Oxford University Press, 1957. [17] Speight M V. Growth kinetics of grain-boundary precipitates[J]. Acta Metallurgica, 1968,16(1):133−135. -

下载:

下载: