Preparation of high quality spherical powder of TC4 ELI titanium alloy

-

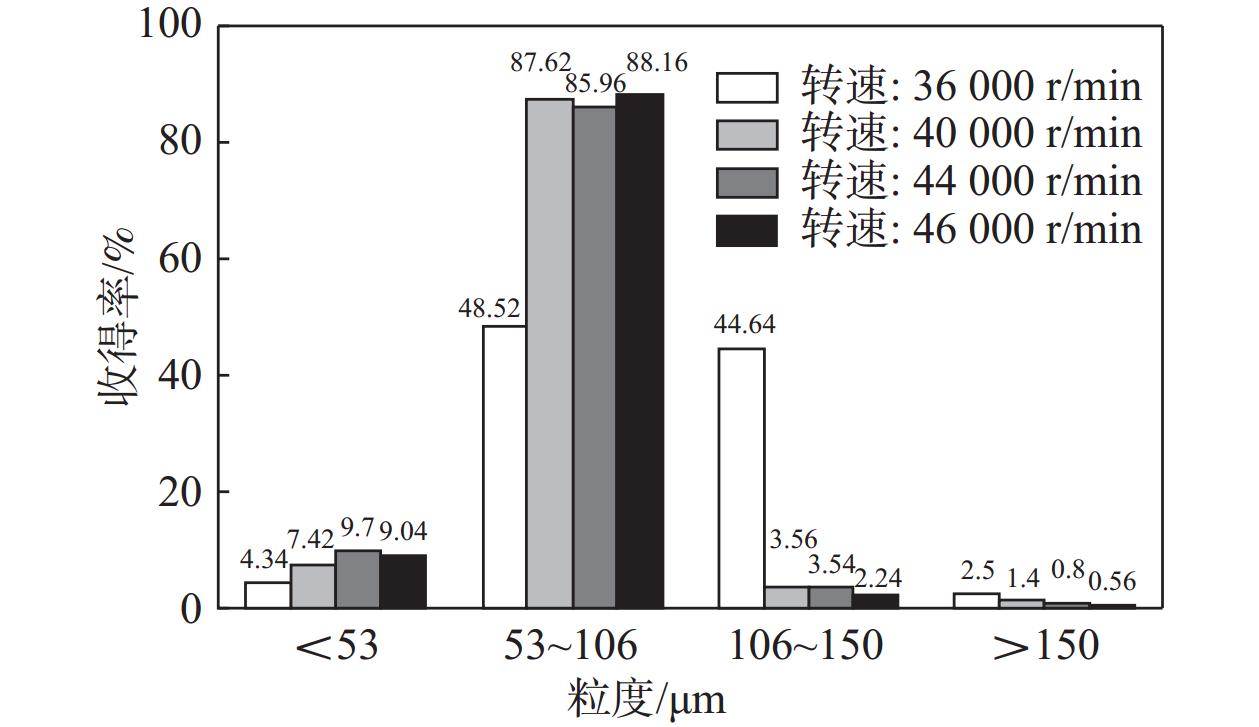

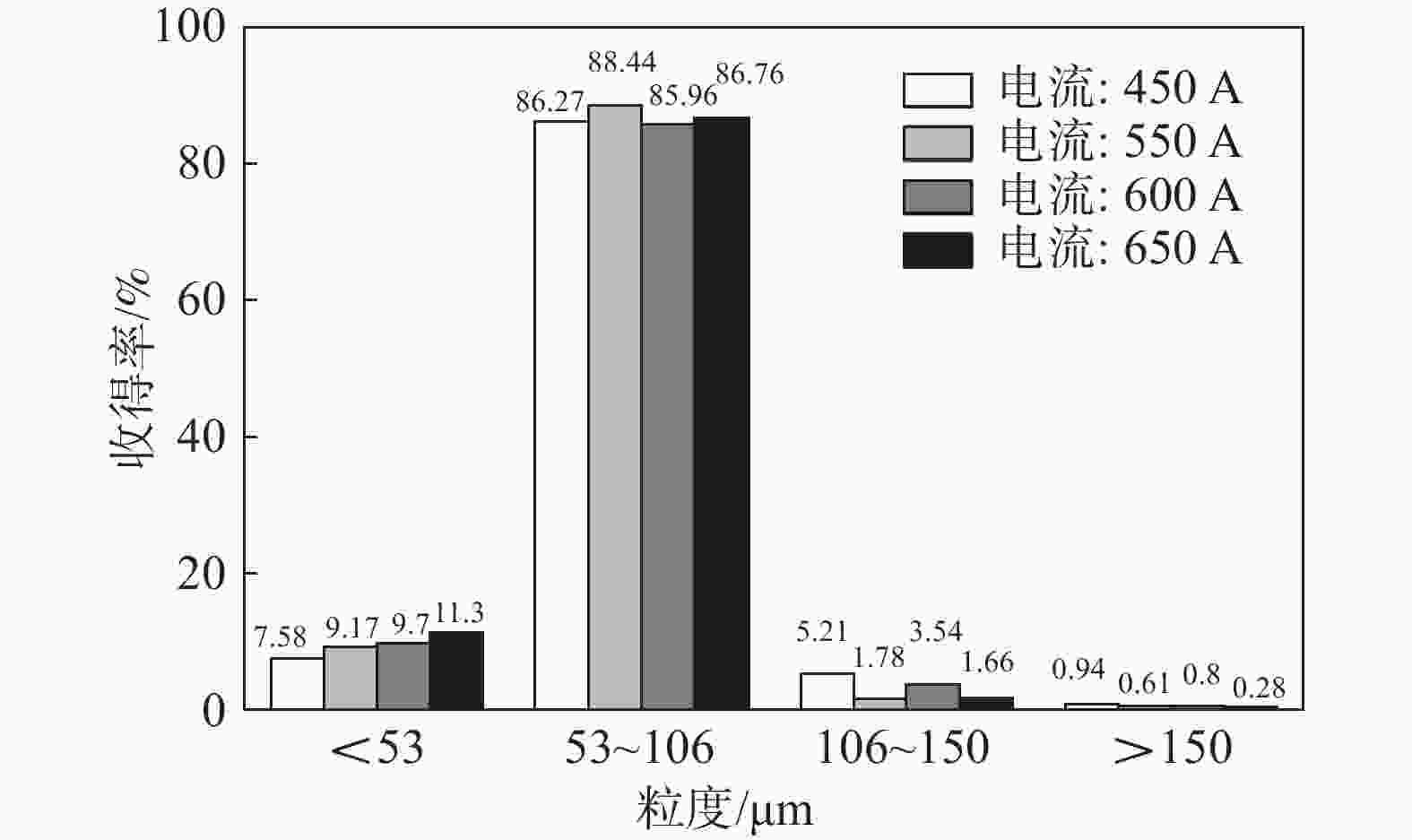

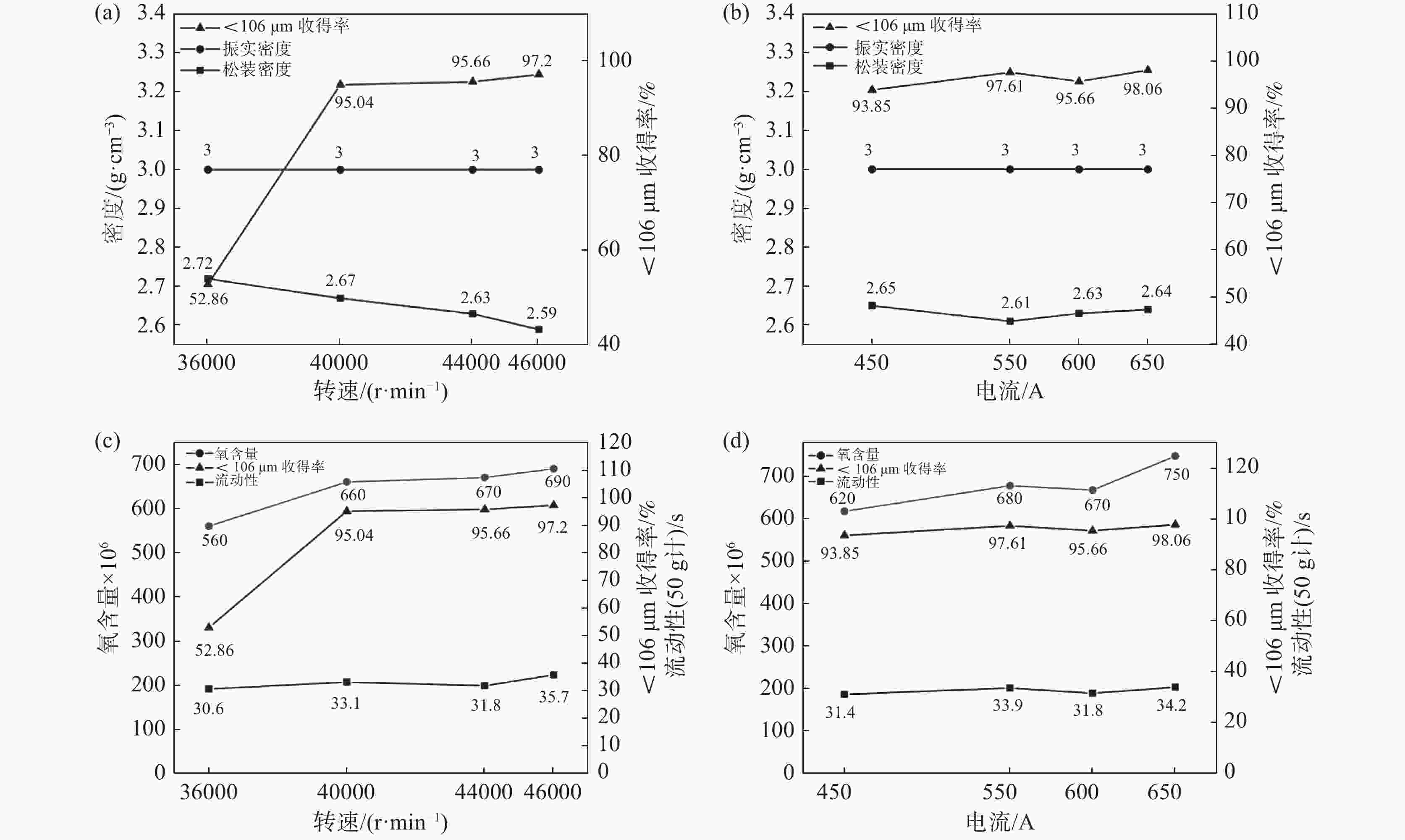

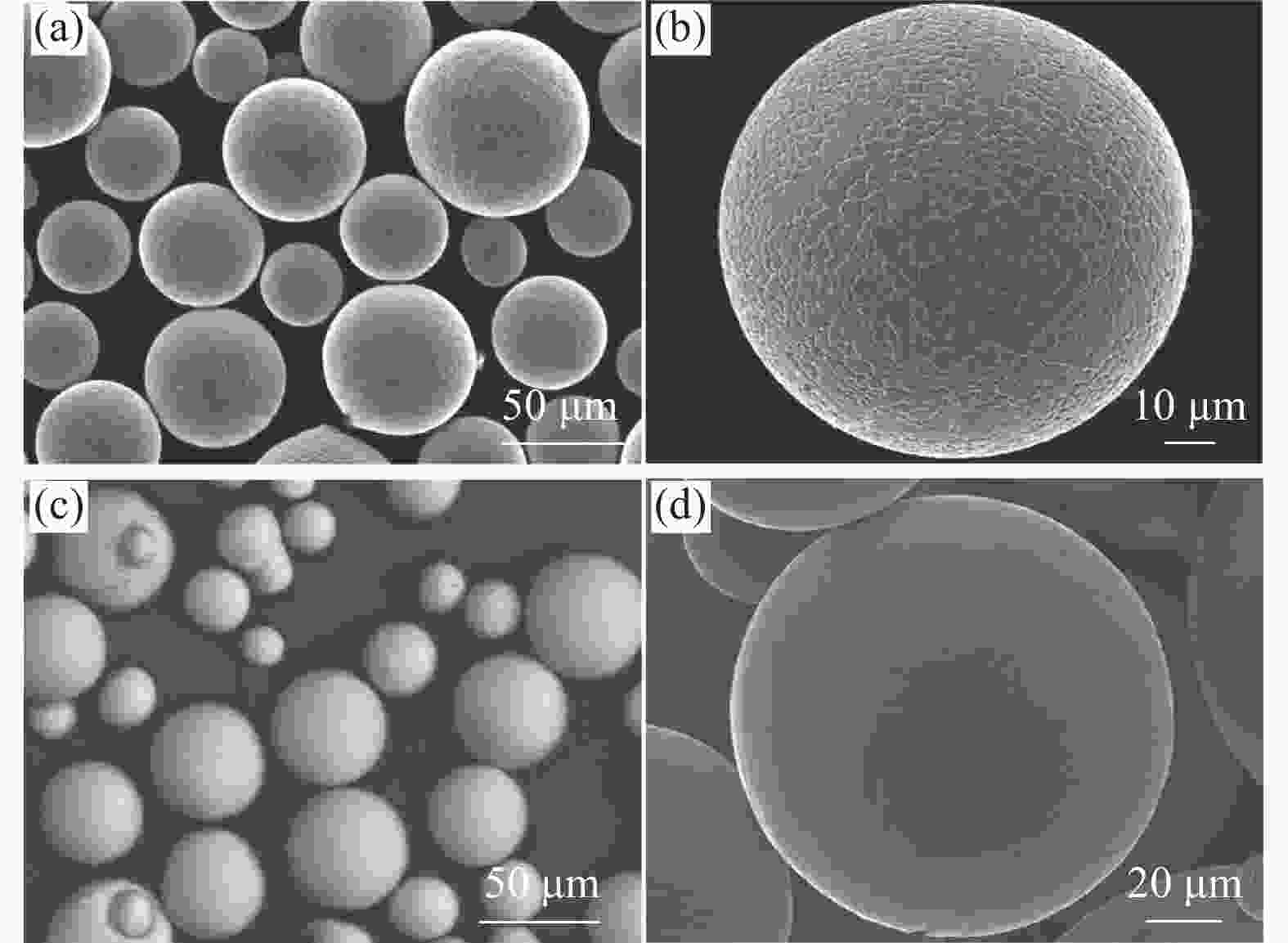

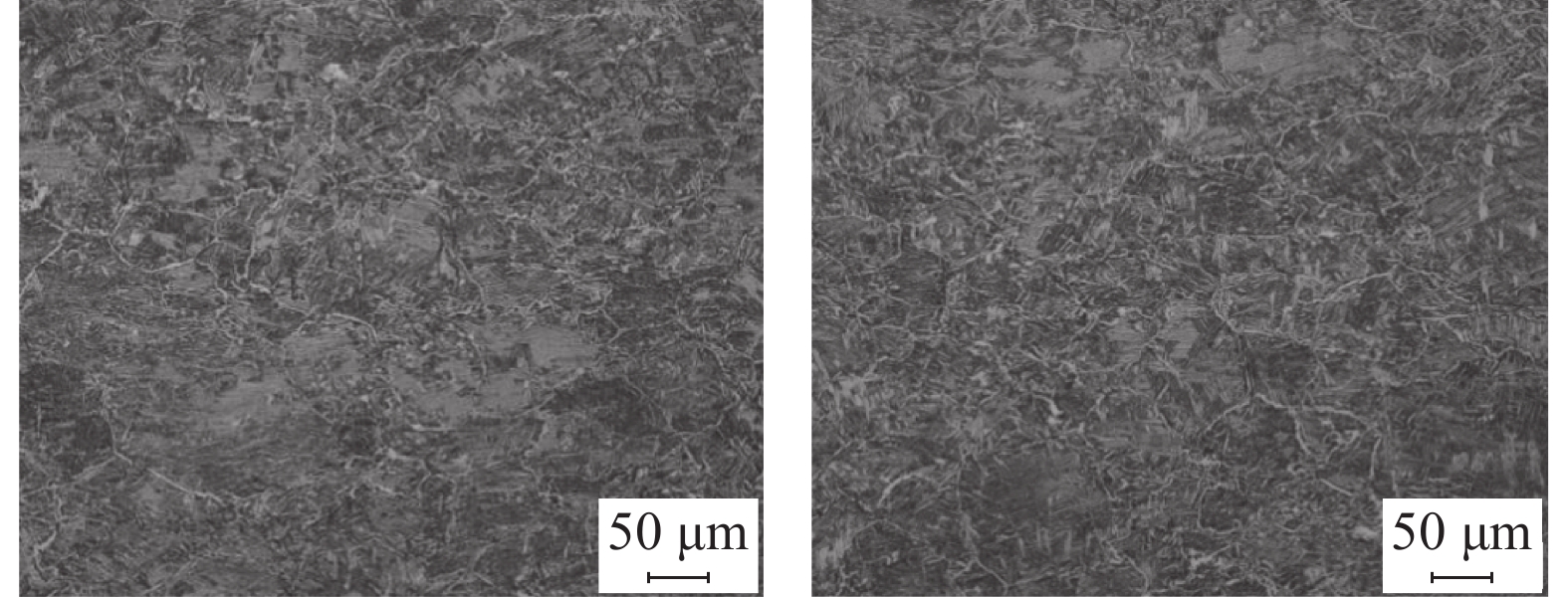

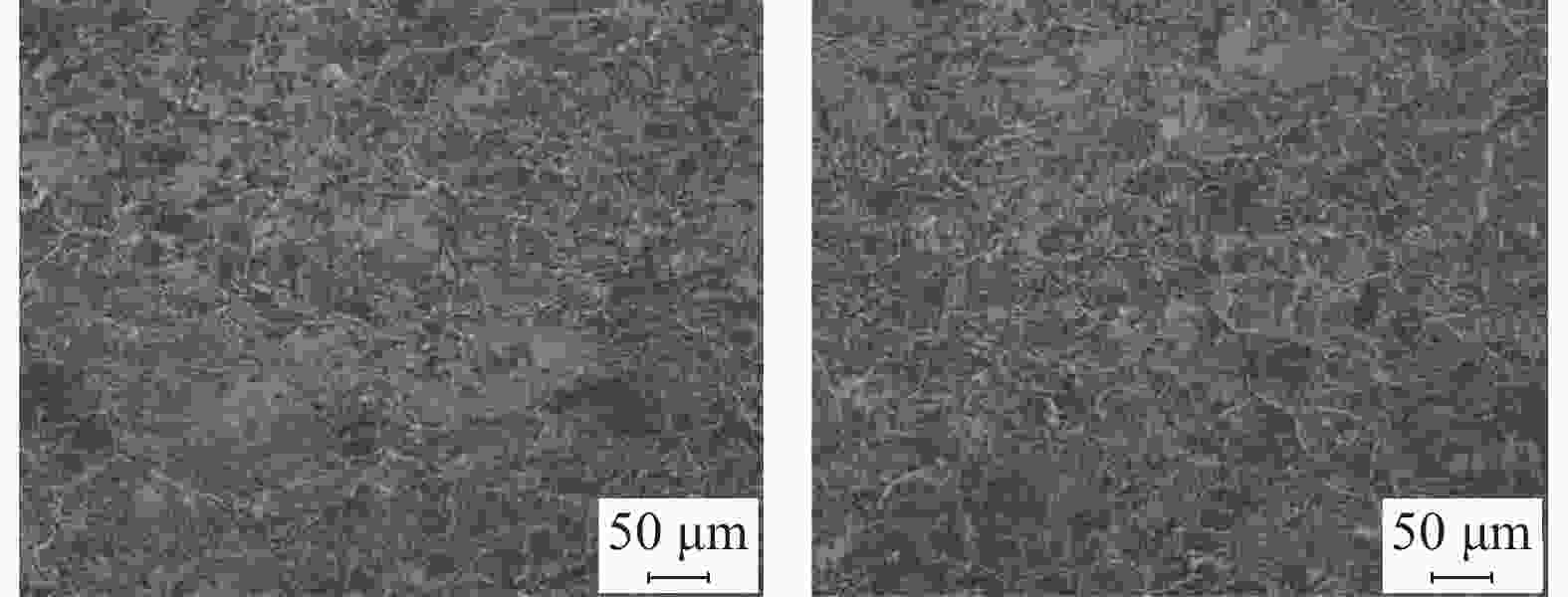

摘要: 以Ti6Al4V ELI(TC4 ELI)钛合金棒料为原料,采用等离子旋转电极雾化法制备TC4 ELI球形粉末,研究了电流和电极转速对粉末粒度分布及粉末特性的影响,利用扫描电镜(SEM)对粉体形貌进行了观察。结果表明:电流保持600 A不变时,随着电极转速提高,53~106 µm TC4 ELI粉末收得率增大;当电极转速为

44000 r/min时,随着电流的增大,粒径<106 µm的粉末收得率略有增加,所得粉末松装密度在2.59~2.72 g/cm3范围内,振实密度为3.0 g/cm3,氧含量(质量分数)在560×10-6~750 ×10-6,流动性(50 g计)为30.6~35.7 s;粉末成球率高、球形度好,边缘光滑无杂质,球形度>90%。-

关键词:

- Ti6Al4V /

- 球形粉末 /

- 等离子旋转电极雾化法 /

- 收得率

Abstract: Using titanium alloy rod TC4 ELI as raw material, spherical TC4 ELI powder was prepared by plasma rotating electrode method (PREP). The effects of current and electrode speed on the particle size distribution and powder properties were investigated. The morphology of the powder was observed using a scanning electron microscope (SEM). The research results show that when the current remained constant at 600 A, the yield of 53~106 µm TC4 ELI powder increases with the increase of electrode speed. At an electrode speed of 44000 r/min, the yield of powder with a particle size of less than 106 μm increases slightly with increasing current. The obtained powder has a loose packing density in the range of 2.59~2.72 g/cm3, a compacted density of 3.0 g/cm3, an oxygen content in the range of 560×10-6~750×10-6 and a fluidity(calculated as 50 g) of 30.6~35.7 s. The powder has high sphericity rate, good sphericity, smooth edges without impurities and a sphericity greater than 90%.-

Key words:

- TC4 /

- spherical powder /

- plasma rotating electrode method /

- yield

-

表 1 TC4 ELI钛合金棒材化学成分

Table 1. Chemical composition of TC4 ELI titanium alloy bar

% Al Fe V N O Ti 5.92 0.021 4.10 0.007 0.044 余量 -

[1] Han Zhirong, Lin Yun, Liu Jie. Preparation of TC4 alloy powder for laser 3D printing[J]. Enterprise Science and Technology and Development, 2019(1):57-59. (韩志嵘, 林芸, 刘洁. 激光3D打印用TC4合金粉末的制备研究[J]. 企业科技与发展, 2019(1):57-59. doi: 10.3969/j.issn.1674-0688.2019.01.027Han Zhirong, Lin Yun, Liu Jie. Preparation of TC4 alloy powder for laser 3D printing[J]. Enterprise Science and Technology and Development, 2019(1): 57-59. doi: 10.3969/j.issn.1674-0688.2019.01.027 [2] Chen Yingying, Xiao Zhiyu, Li Shangkui, et al. The preparation technology and research progress of metal powder for 3D printing[J]. Powder Metallurgy Industry, 2018,28(4):56-61. (陈莹莹, 肖志瑜, 李上奎, 等. 3D打印用金属粉末的制备技术及其研究进展[J]. 粉末冶金工业, 2018,28(4):56-61.Chen Yingying, Xiao Zhiyu, Li Shangkui, et al. The preparation technology and research progress of metal powder for 3D printing[J]. Powder Metallurgy Industry, 2018, 28(4): 56-61. [3] Liu Chang, Li Hui, Zhang Hanxin, et al. Research progress and development trend of titanium powder preparation process[J]. Rare Metals and Cemented Carbides, 2020,48(1):35-39. (刘畅, 李慧, 张汉鑫, 等. 钛粉制备工艺的研究进展及发展趋势[J]. 稀有金属与硬质合金, 2020,48(1):35-39.Liu Chang, Li Hui, Zhang Hanxin, et al. Research progress and development trend of titanium powder preparation process[J]. Rare Metals and Cemented Carbides, 2020, 48(1): 35-39. [4] Li An, Liu Shifeng, Wang Bojian, et al. Research progress of metal powder preparation technology for 3D printing[J]. Journal of Iron and Steel Research, 2018,30(6):419-426. (李安, 刘世锋, 王伯健, 等. 3D打印用金属粉末制备技术研究进展[J]. 钢铁研究学报, 2018,30(6):419-426.Li An, Liu Shifeng, Wang Bojian, et al. Research progress of metal powder preparation technology for 3D printing[J]. Journal of Iron and Steel Research, 2018, 30(6): 419-426. [5] Sui Yi, Feng Yicheng, Zhang Yu, et al. Research status of plasma rotating electrode atomization[J]. Heilongjiang Science, 2023,14(14):61-63. (隋毅, 冯义成, 张煜, 等. 等离子旋转电极雾化制粉研究现状[J]. 黑龙江科学, 2023,14(14):61-63. doi: 10.3969/j.issn.1674-8646.2023.14.016Sui Yi, Feng Yicheng, Zhang Yu, et al. Research status of plasma rotating electrode atomization[J]. Heilongjiang Science, 2023, 14(14): 61-63. doi: 10.3969/j.issn.1674-8646.2023.14.016 [6] Tang Huiping. Research progress on engineering application technology of powder bed electron beam 3D printing Ti-6Al-4V alloy[J]. China Material Progress, 2020,39(Z1):551-558. (汤慧萍. 粉末床电子束3D打印Ti-6Al-4V合金的工程应用技术研究进展[J]. 中国材料进展, 2020,39(Z1):551-558. doi: 10.7502/j.issn.1674-3962.202006031Tang Huiping. Research progress on engineering application technology of powder bed electron beam 3D printing Ti-6Al-4V alloy[J]. China Material Progress, 2020, 39(Z1): 551-558. doi: 10.7502/j.issn.1674-3962.202006031 [7] Li Xiaohui, Chen Binke, Feng Zhihua, et al. Preparation and characterization of tungsten powder by plasma rotating electrode atomization[J]. Powder Metallurgy Industry, 2022,32(1):15-19. (李晓辉, 陈斌科, 凤治华, 等. 等离子旋转电极雾化制备钨粉及性能表征[J]. 粉末冶金工业, 2022,32(1):15-19.Li Xiaohui, Chen Binke, Feng Zhihua, et al. Preparation and characterization of tungsten powder by plasma rotating electrode atomization[J]. Powder Metallurgy Industry, 2022, 32(1): 15-19. [8] Lei Nanzhi. Research on the process and properties of spherical metal powder prepared by plasma rotating electrode atomization [D]. Xi 'an : Xi 'an University of Technology, 2019. (雷囡芝. 等离子旋转电极雾化法制备球形金属粉末的工艺及性能研究[D]. 西安: 西安理工大学, 2019.Lei Nanzhi. Research on the process and properties of spherical metal powder prepared by plasma rotating electrode atomization [D]. Xi 'an : Xi 'an University of Technology, 2019. [9] Tang Huiping. Research progress of plasma rotating electrode milling technology [J]. Powder Metallurgy Technology, 2023, 41(1): 2-11 , 54. (汤慧萍. 等离子旋转电极制粉技术研究进展[J]. 粉末冶金技术, 2023, 41(1): 2-11, 54.Tang Huiping. Research progress of plasma rotating electrode milling technology [J]. Powder Metallurgy Technology, 2023, 41(1): 2-11 , 54. [10] Yang Xingbo, Zhu Jilei, Chen Binke, et al. Research status of plasma rotating electrode atomization technology and powder particle size control[J]. Powder Metallurgy Industry, 2022,32(2):90-95. (杨星波, 朱纪磊, 陈斌科, 等. 等离子旋转电极雾化技术及粉末粒度控制研究现状[J]. 粉末冶金工业, 2022,32(2):90-95.Yang Xingbo, Zhu Jilei, Chen Binke, et al. Research status of plasma rotating electrode atomization technology and powder particle size control[J]. Powder Metallurgy Industry, 2022, 32(2): 90-95. [11] Hou Weiqiang, Meng Jie, Liang Jingjing, et al. Preparation technology and research progress of superalloy powder for additive manufacturing[J]. Powder Metallurgy Technology, 2022, 40 ( 2 ) : 131-138, 144. (侯维强, 孟杰, 梁静静, 等. 增材制造用高温合金粉末制备技术及研究进展[J]. 粉末冶金技术, 2022, 40(2): 131-138, 144.Hou Weiqiang, Meng Jie, Liang Jingjing, et al. Preparation technology and research progress of superalloy powder for additive manufacturing[J]. Powder Metallurgy Technology, 2022, 40 ( 2 ) : 131-138, 144. [12] Wang Hua, Bai Ruimin, Zhou Xiaoming, et al. Comparative analysis of Inconel 71 powder prepared by PREP method and AA method[J]. New Technol New Prod China, 2019, (19): 1-4. (王华, 白瑞敏, 周晓明, 等. PREP法和AA法制取Inconel 718粉末对比分析[J]. 中国新技术新产品, 2019, (19): 1-4.Wang Hua, Bai Ruimin, Zhou Xiaoming, et al. Comparative analysis of Inconel 71 powder prepared by PREP method and AA method[J]. New Technol New Prod China, 2019, (19): 1-4. [13] Liu Shaowei, Duan Wangchun, Dong Bingbin. Effect of PREP process parameters on the properties of AlSi10Mg aluminum alloy powder for 3D printing[J]. Non Ferrous Metals Engineering, 2019,9(9):45-50. (刘少伟, 段望春, 董兵斌. PREP工艺参数对3D打印用AlSi10Mg铝合金粉末性能的影响[J]. 有色金属工程, 2019,9(9):45-50.Liu Shaowei, Duan Wangchun, Dong Bingbin. Effect of PREP process parameters on the properties of AlSi10Mg aluminum alloy powder for 3D printing[J]. Non Ferrous Metals Engineering, 2019, 9(9): 45-50. [14] Hsu T I,Wei C M,Wu L D, et al. Nitinol powders generate from plasma rotation electrode process provide clean powder for biomedical devices used with suitable size, spheroid surface and pure composition[J]. Scientific Reports, 2018,8:13776. doi: 10.1038/s41598-018-32101-1 [15] Tang Junjie, Nie Yan, Lei Qian, et al. Characteristics and atomization behavior of Ti-6Al-4V powder produced by plasma rotating electrode process[J]. Advanced Powder Technology: The Internation Journal of the Society of Powder Technology, Japan, 2019,30(10):2330-2337. [16] Champagne B, Angers R. REP atomization mechanisms[J]. International Journal of Powder Metallurgy, 1984,16(3):125. [17] Xie Bo, Li Jianjun, Qiao Zhonglu. Oxygenation of TC4 powder for 3D printing by electrode induction gas atomization[J]. Vacuum, 2020,57(6):80-83. (谢波, 李建军, 乔忠路. 电极感应气雾化法制备3D打印用TC4粉末增氧量研究[J]. 真空, 2020,57(6):80-83.Xie Bo, Li Jianjun, Qiao Zhonglu. Oxygenation of TC4 powder for 3D printing by electrode induction gas atomization[J]. Vacuum, 2020, 57(6): 80-83. [18] Wang Dongjun, Zhou Rui, Shen Jun. Solidification characteristics of rapidly solidified water atomized high strength steel powder[J]. Acta Metallurgica Sinica, 2008,44(2):159-164. (王东君, 周瑞, 沈军. 快速凝固水雾化高强钢粉末的凝固特征[J]. 金属学报, 2008,44(2):159-164. doi: 10.3321/j.issn:0412-1961.2008.02.007Wang Dongjun, Zhou Rui, Shen Jun. Solidification characteristics of rapidly solidified water atomized high strength steel powder[J]. Acta Metallurgica Sinica, 2008, 44(2): 159-164. doi: 10.3321/j.issn:0412-1961.2008.02.007 [19] Wang Qi, Li Shenggang, Lü Hongjun, et al. Research on high quality titanium alloy production by atomization technology[J]. Titanium Industry Progress, 2010,27(5):16-18. (王琪,李圣刚,吕宏军,等. 雾化法制备高品质钛合金粉末技术研究[J]. 钛工业进展, 2010,27(5):16-18.Wang Qi, Li Shenggang, Lü Hongjun, et al. Research on high quality titanium alloy production by atomization technology[J]. Titanium Industry Progress, 2010, 27(5): 16-18. -

下载:

下载: