Effect of different support on the catalytic performance of V-Mo/Ti De-NOx catalyst

-

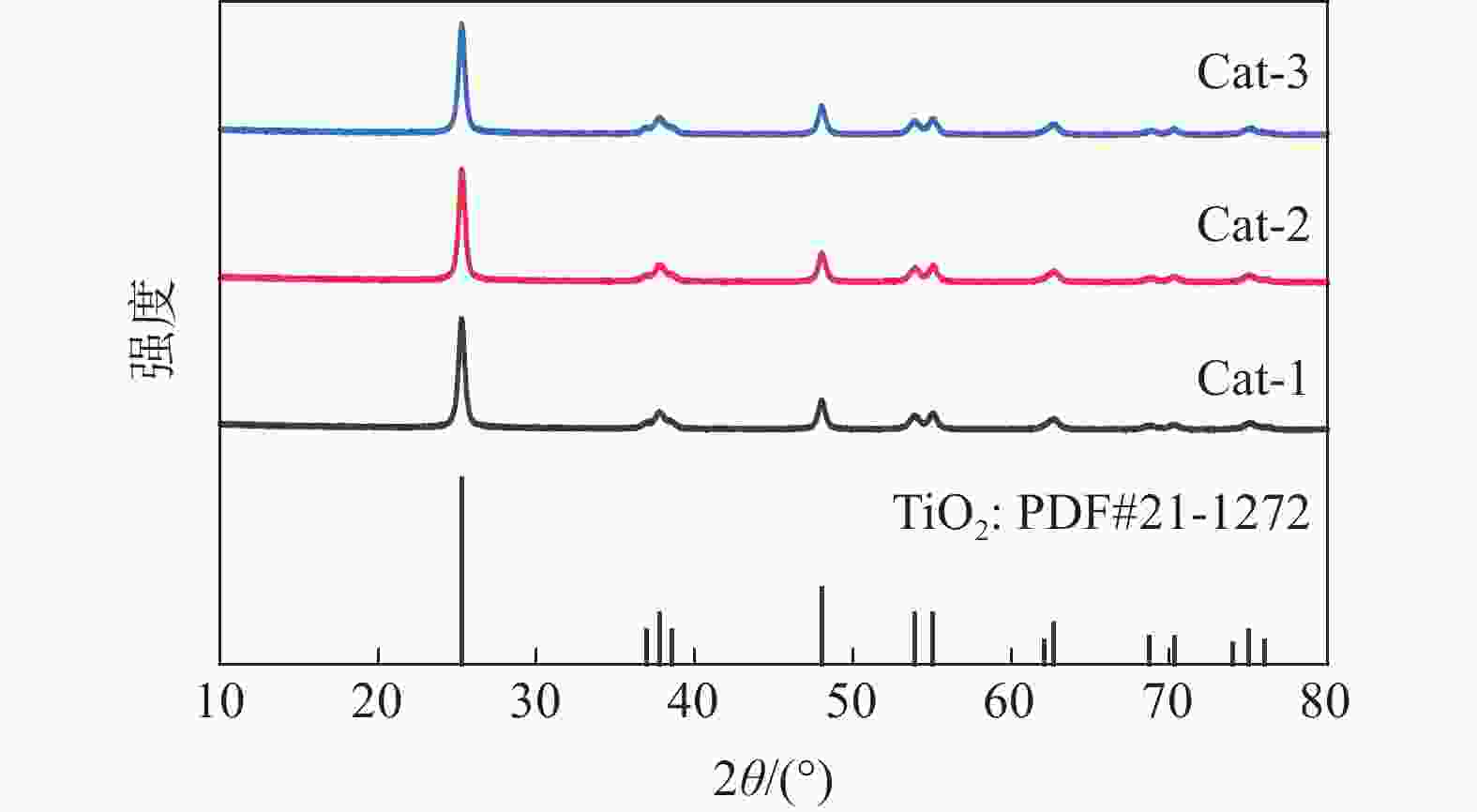

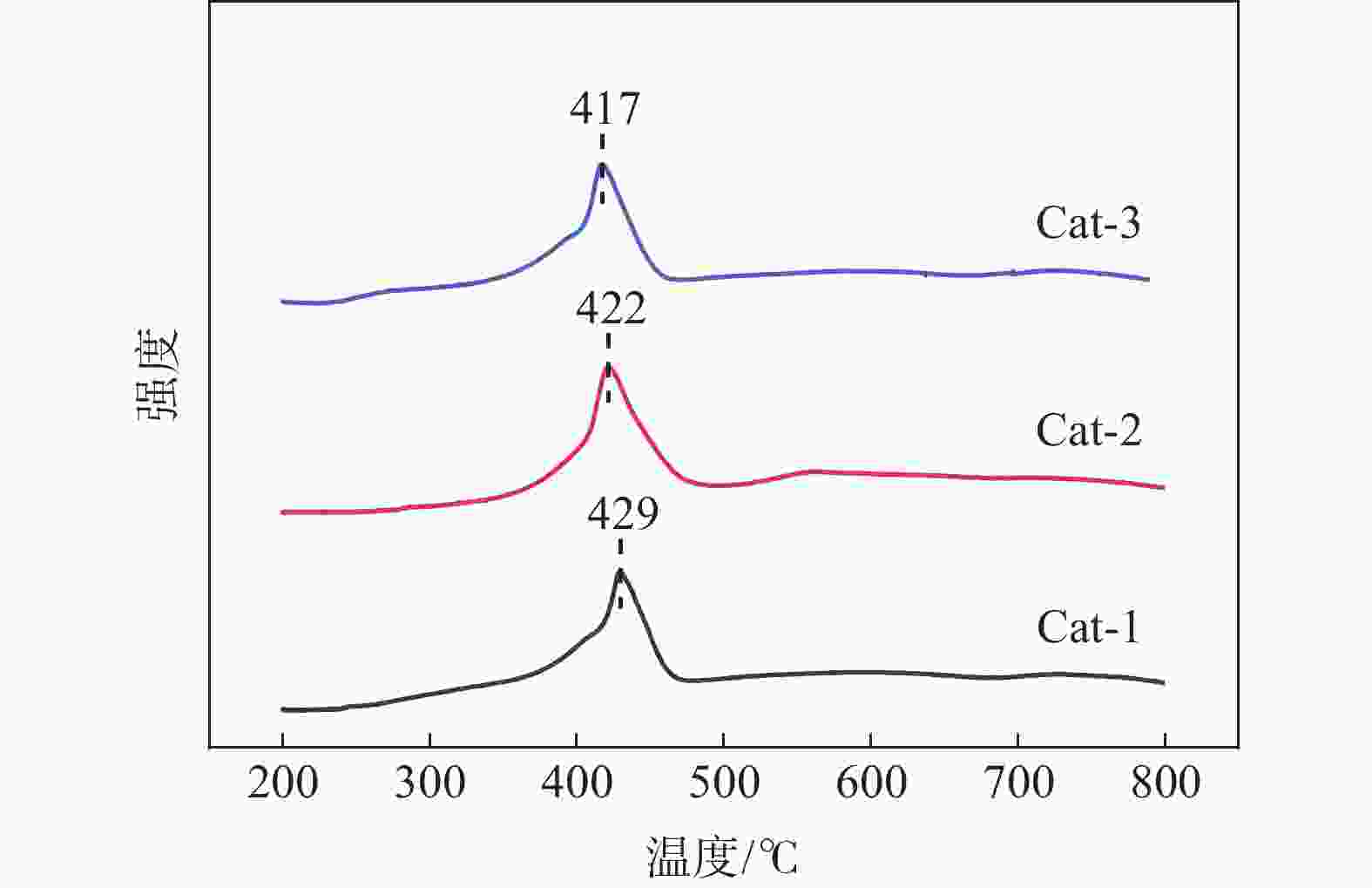

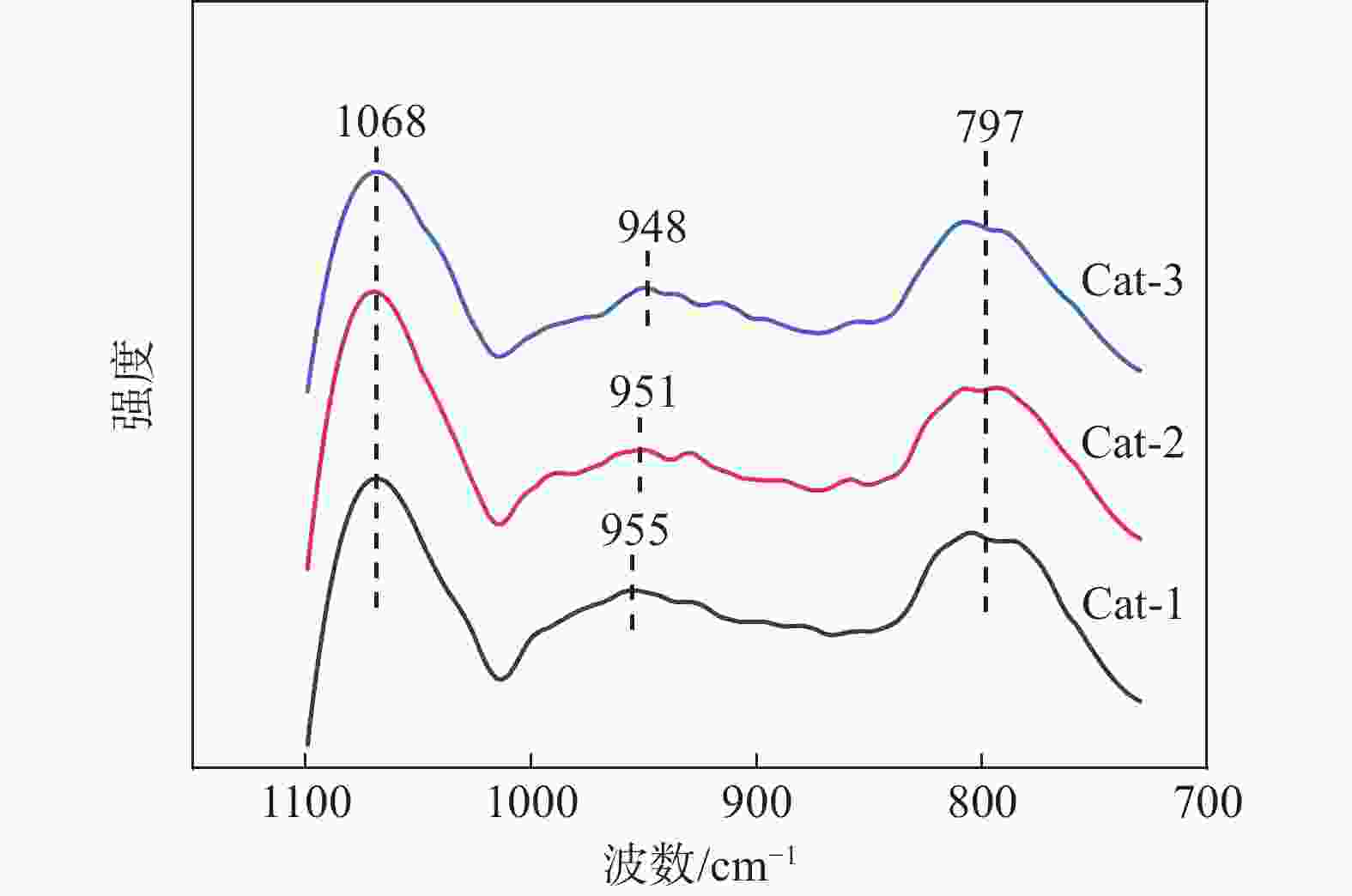

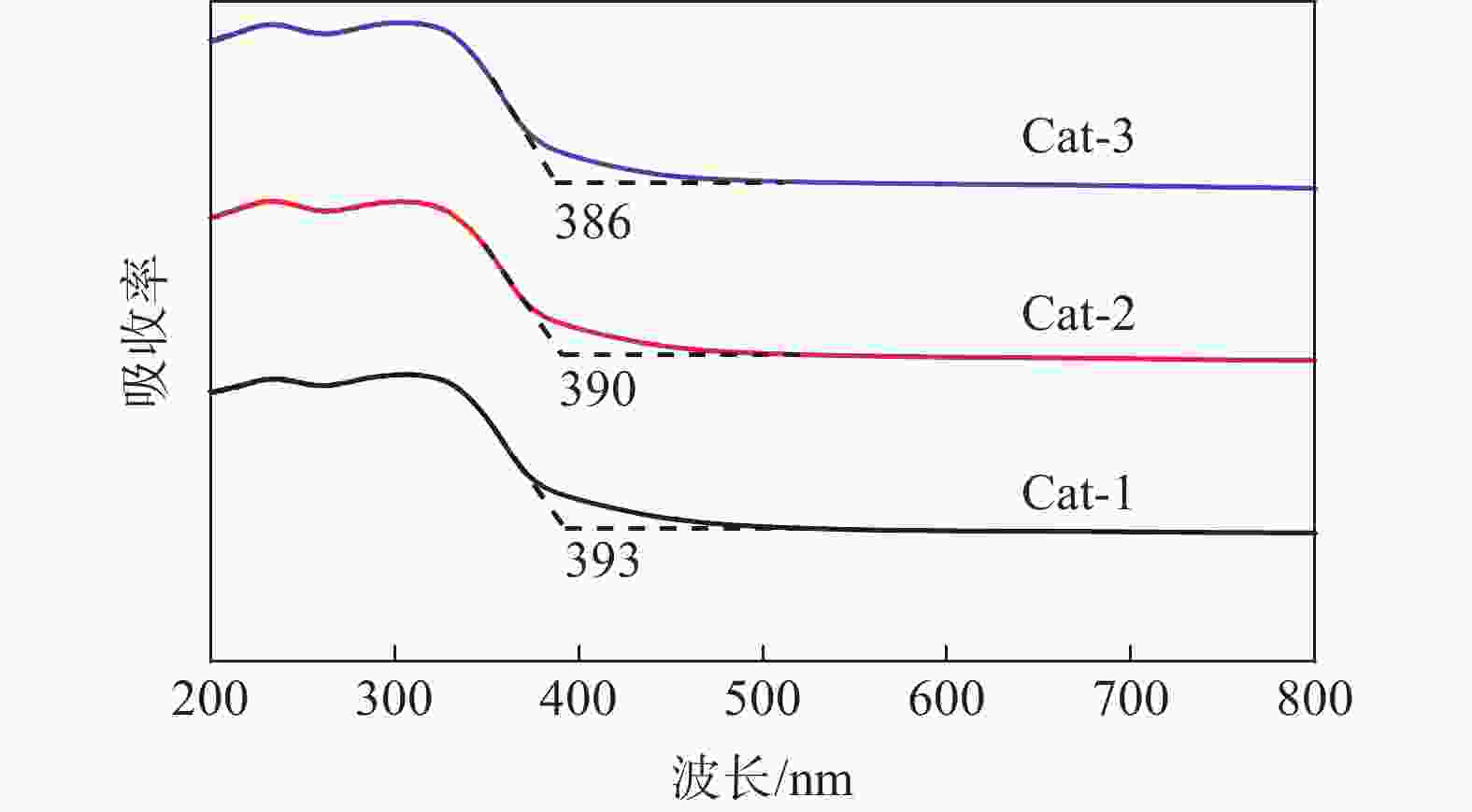

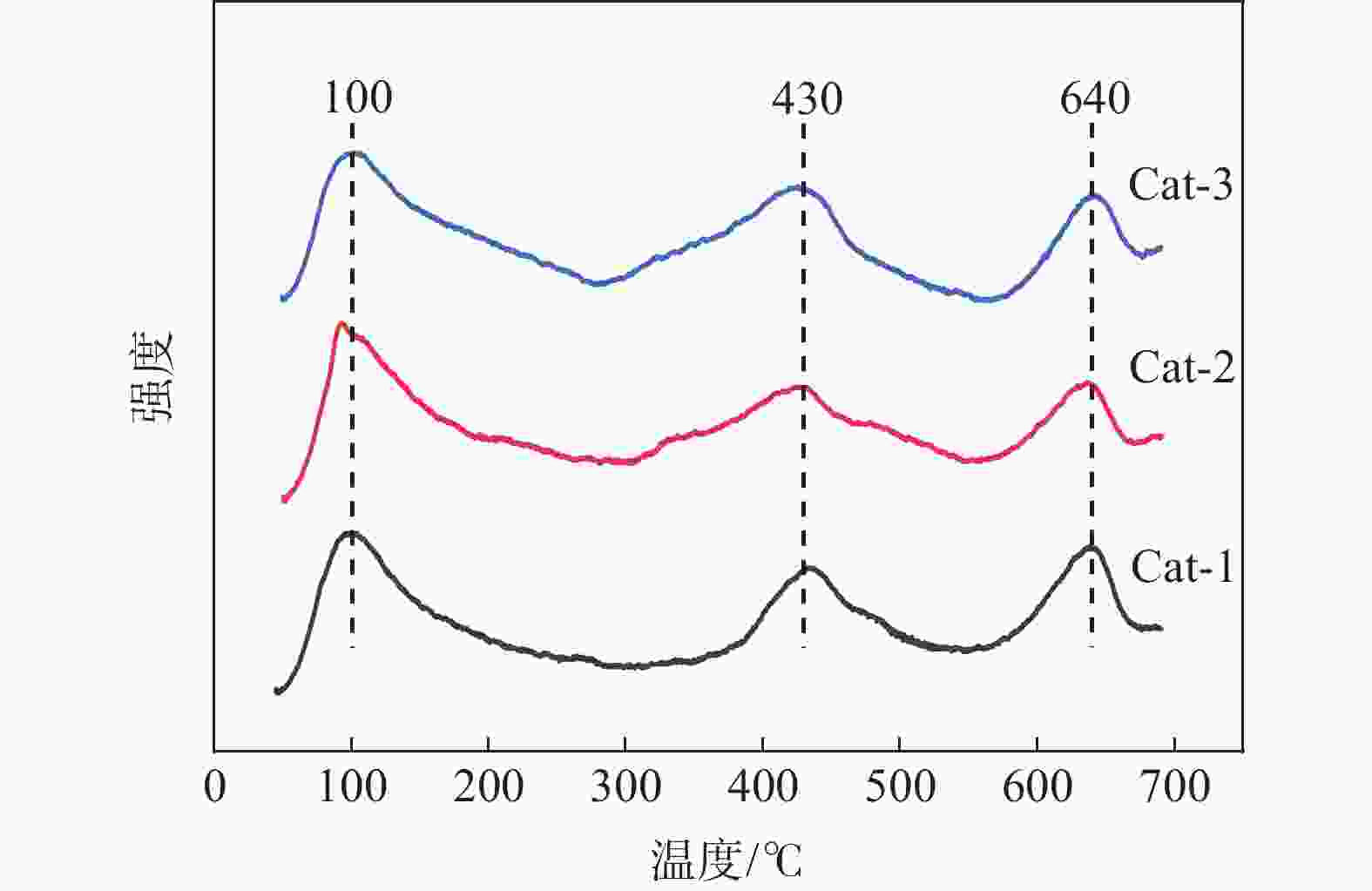

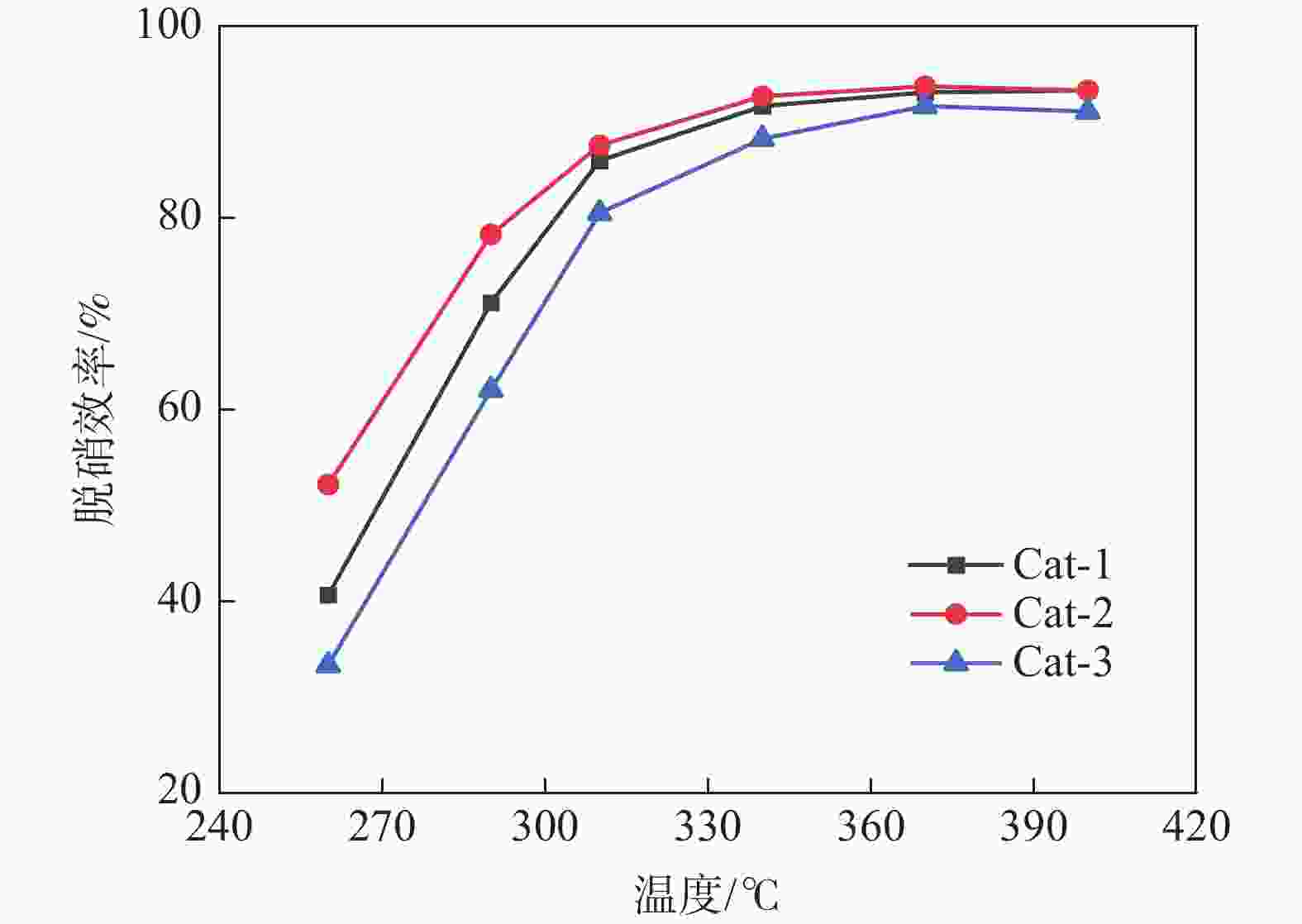

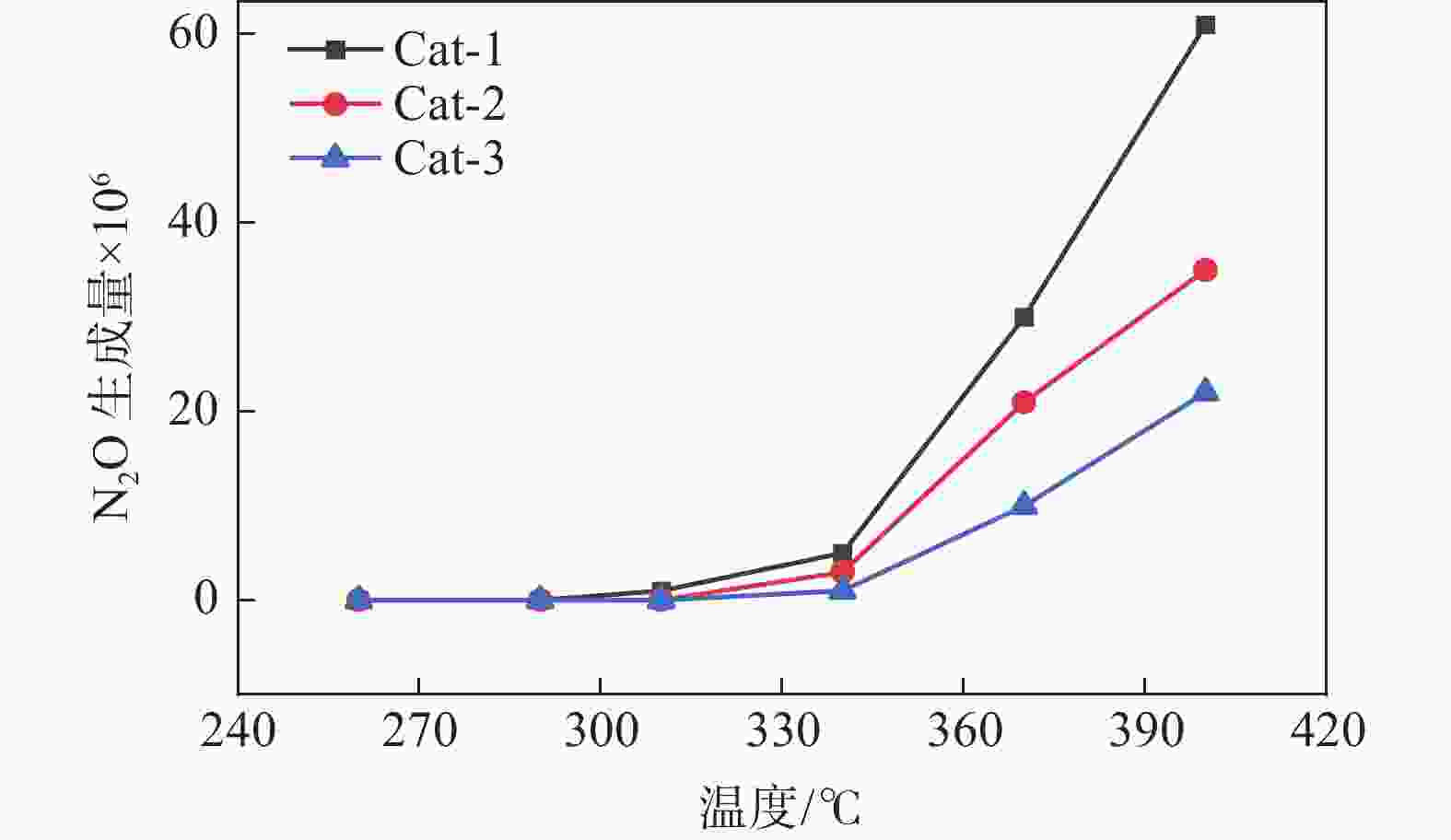

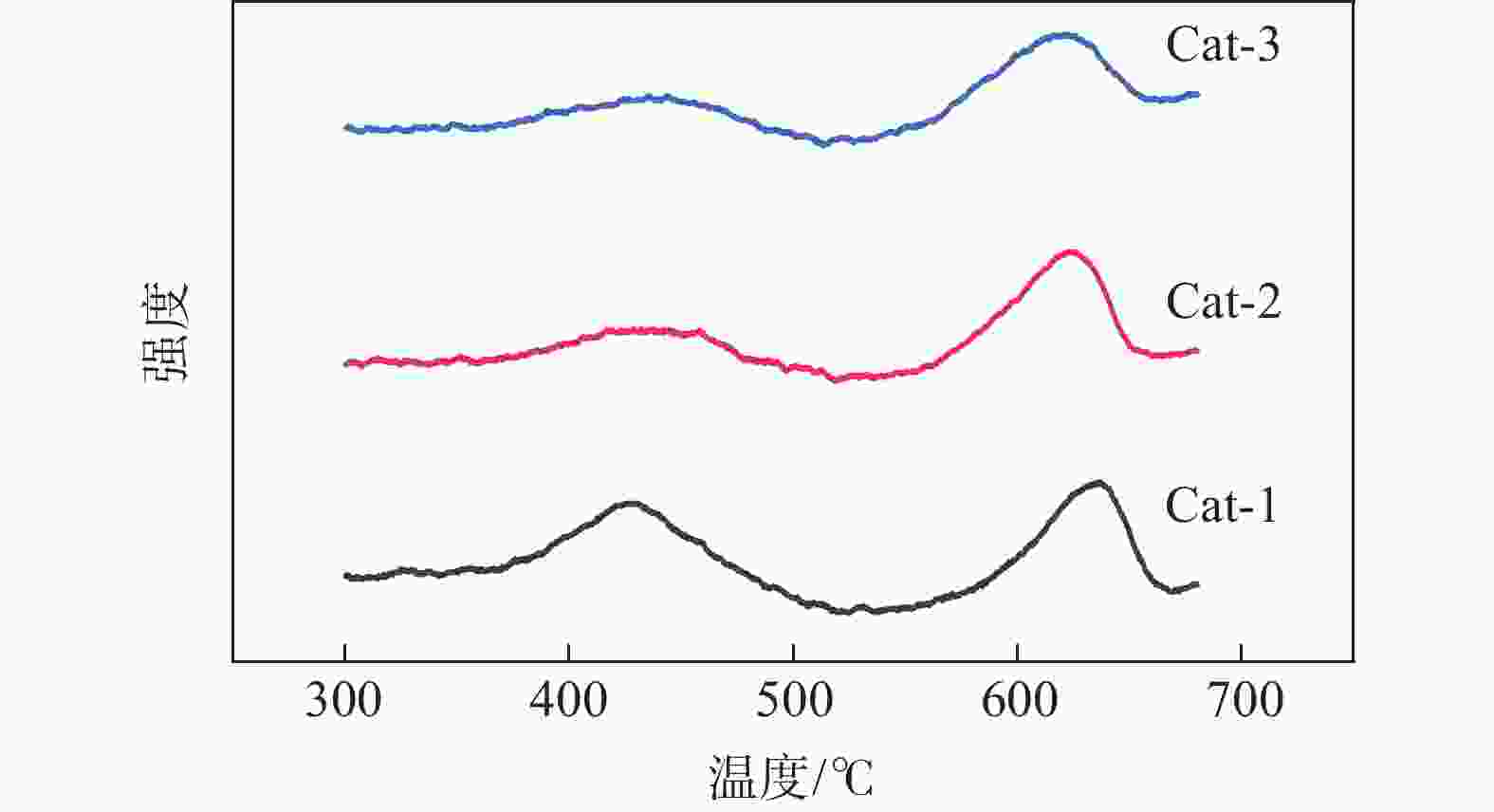

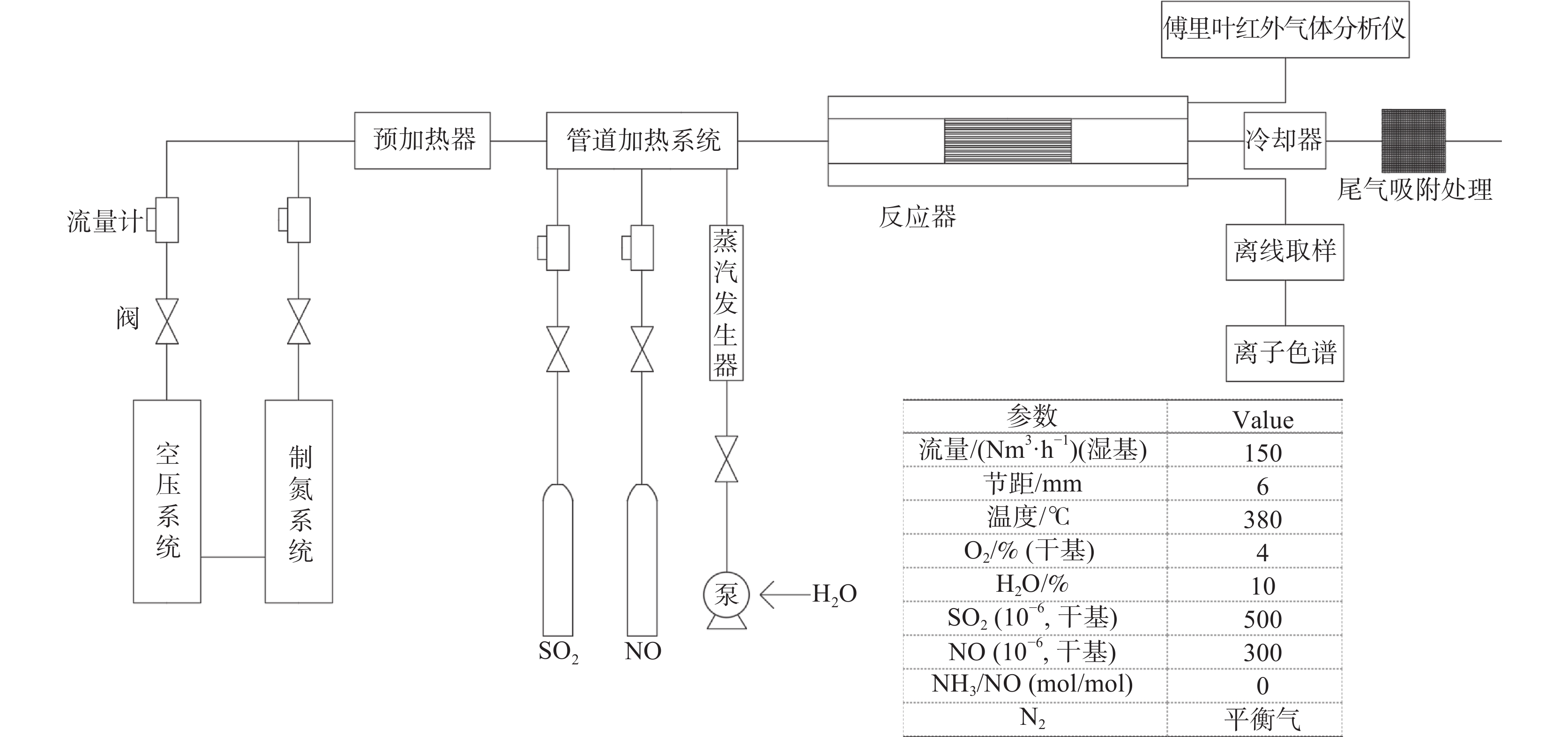

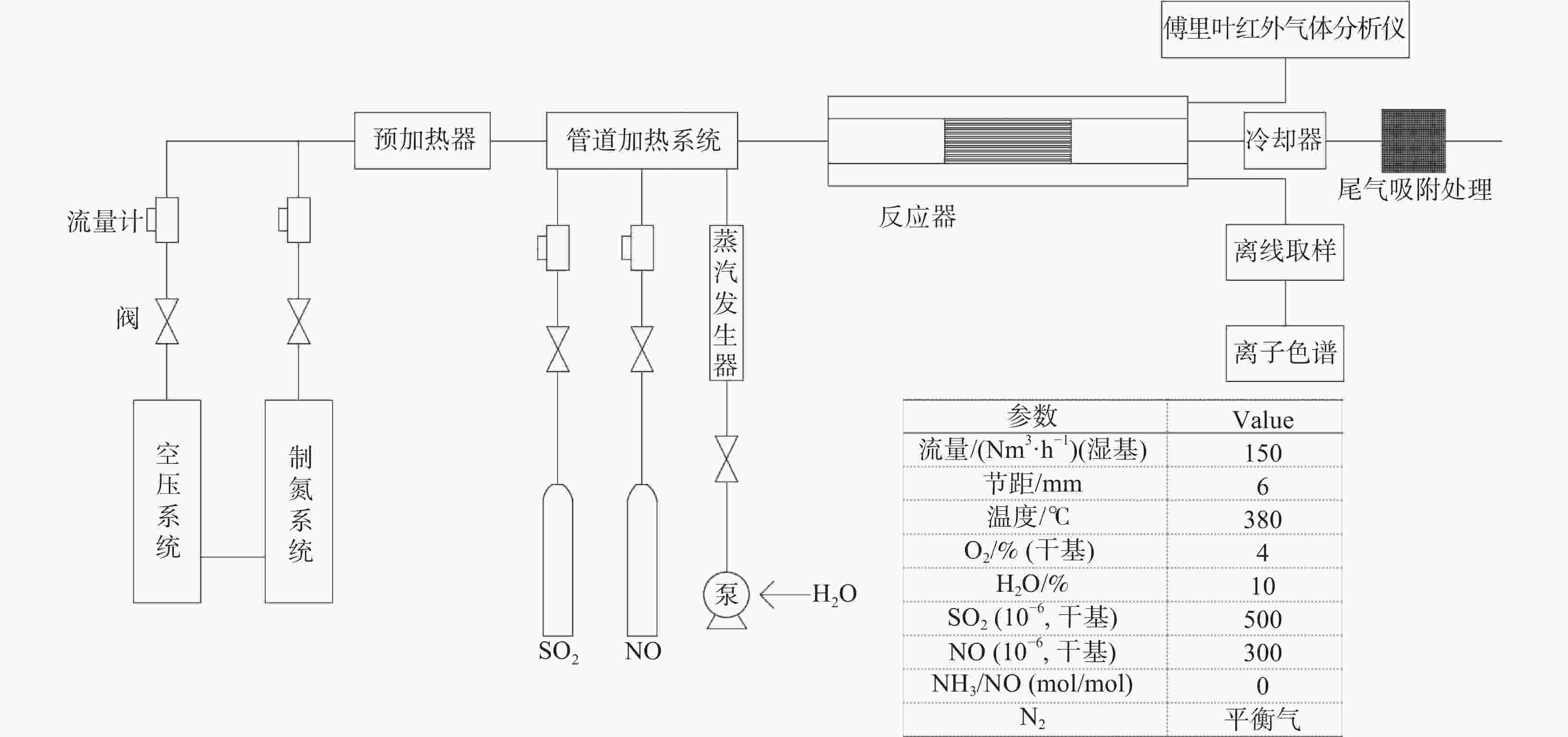

摘要: 选用了两种比表面积的TiO2制备了V-Mo/Ti脱硝催化剂。采用XRD、N2-吸附脱附、H2-TPR、Raman、NH3-TPD、O2-TPD、SO2-TPD对不同催化剂的物理化学性质进行了分析。通过固定床微型反应评价装置,对不同催化剂的脱硝性能进行了考察。通过全尺寸脱硝催化剂中试评价装置,对比了不同催化剂的SO2/SO3转化率。结果显示:V-Mo/Ti脱硝催化剂中,当小比表面积TiO2-A和大比表面积的TiO2-B的质量比为75:25时,催化剂与全用小比表面积TiO2-A制得的催化剂相比,聚合态钒物种的含量降低,催化剂的还原性能提升,酸性略有下降,催化剂的Oα含量明显增加,表明催化剂的脱硝性能增强。继续增加大比表面积TiO2-B的质量比至50%,催化剂的酸性下降明显,导致催化剂的脱硝活性下降。大比表面积的TiO2-B的用量增加可以降低催化剂的SO2/SO3转化率。总体而言,当小比表面积TiO2-A和大比表面积的TiO2-B的质量比为75:25时,制备的V-Mo/Ti脱硝催化剂展示了较优的脱硝效果。

-

关键词:

- V-Mo/Ti脱硝催化剂 /

- 载体TiO2 /

- 比表面积 /

- 脱硝性能

Abstract: V-Mo/Ti de-NOx catalysts were prepared by two kinds of TiO2 with different BET surface area. XRD, N2-adsorption, H2-TPR, Raman, NH3-TPD, O2-TPD, and SO2-TPD analysis were used to characterize the physiochemical properties of the different catalysts. The catalytic performances of the catalysts were tested via a fixed-bed micro-reactor, and the SO2/SO3 conversion of the different catalysts were tested through a pilot-scale reactor. The results show that the catalyst prepared by TiO2-A and TiO2-B (75%:25%) possesses lower content of the polymeric vanadate, higher reducibility, relatively lower acidity, and higher Oα amount than that of the catalyst prepared with pure TiO2-A. As a result, the former catalyst exhibits higher catalytic activity. However, the acidity of the catalyst decreases obviously when 50% TiO2-B is used, leading to the decline of the catalytic performance. What is more, the using of TiO2-B can decrease the SO2/SO3 conversion of the catalyst. Overall, the catalyst prepared with 75% TiO2-A and 25% TiO2-B displays the best catalytic performance.-

Key words:

- V-Mo/Ti De-NOx catalyst /

- support TiO2 /

- BET surface area /

- catalytic performance

-

表 1 不同催化剂的孔结构分析数据

Table 1. Pore structure data of different catalysts

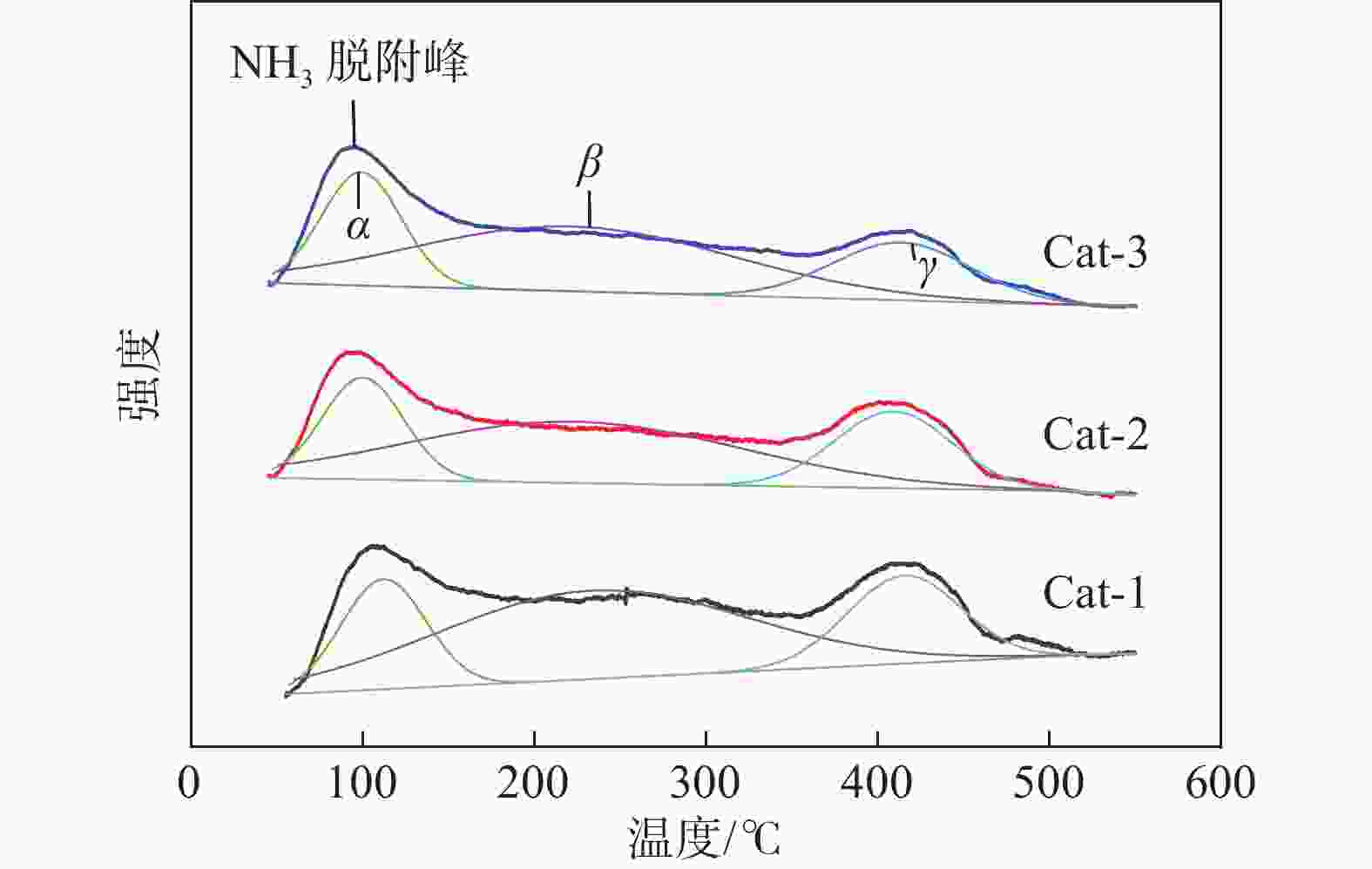

催化剂 比表面积/(m2·g−1) 孔容/(cm3·g−1) 平均孔径/nm TiO2-A 84.6 0.37 17.3 TiO2-B 245.3 0.42 14.7 Cat-1 70.6 0.31 20.1 Cat-2 75.9 0.35 18.6 Cat-3 86.3 0.39 16.0 表 2 不同催化剂的NH3脱附峰

Table 2. NH3 desorption peaks of different catalysts

催化剂 总峰面积 (β+γ)峰面积/

总峰面积/%出峰位置/ ℃ α β γ Cat-1 2.51 79.9 111.7 233.6 415.4 Cat-2 2.19 77.9 99.6 222.8 410.9 Cat-3 2.00 75.7 98.9 221.5 410.5 -

[1] Zhu Fahua, Xu Yueyang, Sun Zunqiang, et al. Practice and enlightenment of ultra-low emission and energy-saving retrofit of coal-fired power plants in China[J]. Electric Power, 2021,54(4):1-8. (朱法华, 许月阳, 孙尊强, 等. 中国燃煤电厂超低排放和节能改造的实践和启示[J]. 中国电力, 2021,54(4):1-8.Zhu Fahua, Xu Yueyang, Sun Zunqiang, et al. Practice and enlightenment of ultra-low emission and energy-saving retrofit of coal-fired power plants in China[J]. Electric Power, 2021, 54(4): 1-8. [2] Wang Yaxin, Liu Jun, Yi Honghong, et al. Research progress of desulfurization and denitration technologies for sintering flue gas in iron and steel industry[J]. Environmental Engineering, 2022,40(9):253-261. (王雅新, 刘俊, 易红宏, 等. 钢铁行业烧结烟气脱硫脱硝技术研究进展[J]. 环境工程, 2022,40(9):253-261.Wang Yaxin, Liu Jun, Yi Honghong, et al. Research progress of desulfurization and denitration technologies for sintering flue gas in iron and steel industry[J]. Environmental Engineering, 2022, 40(9): 253-261. [3] Li Yongchun, Wang Yali, Wang Jianfeng, et al. Development and research status of coal combustion catalyst[J]. Bulletin of the Chinese Ceramic Society, 2023, 42(2): 531-540, 553. (李永春, 王亚丽, 王剑锋, 等. 燃煤催化剂的发展及研究现状[J]. 硅酸盐通报, 2023, 42(2): 531-540, 553.Li Yongchun, Wang Yali, Wang Jianfeng, et al. Development and research status of coal combustion catalyst[J]. Bulletin of the Chinese Ceramic Society, 2023, 42(2): 531-540, 553. [4] Li Feng, Yu Chengzhi, Zhang Peng, et al. Application of plate-type SCR de-NOx catalyst in the high dust and high arsenic flue gas of coal-fired power plant[J]. Huadian Technology, 2010,32(5):8-11. (李锋, 於承志, 张朋, 等. 平板式催化剂在电厂高尘、高砷燃煤烟气脱硝中的应用[J]. 华电技术, 2010,32(5):8-11.Li Feng, Yu Chengzhi, Zhang Peng, et al. Application of plate-type SCR de-NOx catalyst in the high dust and high arsenic flue gas of coal-fired power plant[J]. Huadian Technology, 2010, 32(5): 8-11. [5] Jung M G, Shin J H, Kwon D W, et al. Promotional effects of Me (Sb, La, Ce, Mo) additives on the NH3-SCR activity and SO2 durability of V2O5-WO3/TiO2 catalysts[J]. Process Safety and Environmental Protection, 2024,183:911-924. doi: 10.1016/j.psep.2024.01.044 [6] Huang Li, Yue Yanwei, Zong Yuhao, et al. Investigation of the effect of Ce on the K resistance of V-Mo/Ti de-NOx catalyst[J]. Iron Steel Vanadium Titanium, 2022,43(5):52-58. (黄力, 岳彦伟, 纵宇浩, 等. Ce对V-Mo/Ti脱硝催化剂抗K中毒性能的影响研究[J]. 钢铁钒钛, 2022,43(5):52-58.Huang Li, Yue Yanwei, Zong Yuhao, et al. Investigation of the effect of Ce on the K resistance of V-Mo/Ti de-NOx catalyst[J]. Iron Steel Vanadium Titanium, 2022, 43(5): 52-58. [7] Chen M Y, Wei X X, Liang J, et al. Effects of CrOx species doping on V2O5-WO3/TiO2 catalysts on selective catalytic reduction of NOx by NH3 at low temperature[J]. Reaction Kinetics, Mechanisms and Catalysis, 2022,135:1767-1783. doi: 10.1007/s11144-022-02252-4 [8] Ma Tengkun, Fang Jingrui, Meng liubang, et al. Research progress on application of titanium dioxide in SCR denitration catalyst at low temperature[J]. Bulletin of the Chinese Ceramic Society, 2016,35(6):1734-1737. (马腾坤, 房晶瑞, 孟刘邦, 等. TiO2载体在SCR脱硝催化剂中应用的研究进展[J]. 硅酸盐通报, 2016,35(6):1734-1737.Ma Tengkun, Fang Jingrui, Meng liubang, et al. Research progress on application of titanium dioxide in SCR denitration catalyst at low temperature[J]. Bulletin of the Chinese Ceramic Society, 2016, 35(6): 1734-1737. [9] Zhou Hui, Huang Huacun, Dong Wenhua. Effect of SiO2 doped over V2O5-WO3/TiO2 catalyst for selective catalytic reduction of NO by NH3[J]. Chinese Journal of Environmental Engineering, 2017,11(8):4677-4684. (周惠, 黄华存, 董文华. SiO2掺杂对V2O5-WO3/TiO2脱硝催化性能的影响[J]. 环境工程学报, 2017,11(8):4677-4684.Zhou Hui, Huang Huacun, Dong Wenhua. Effect of SiO2 doped over V2O5-WO3/TiO2 catalyst for selective catalytic reduction of NO by NH3[J]. Chinese Journal of Environmental Engineering, 2017, 11(8): 4677-4684. [10] Li Zeqing, Zhang Xinfeng, Chen Hongping. Effect of Ge doping on performance of V-Mo-O/TiO2 catalyst removing NOx at low temperature[J]. Modern Chemical Industry, 2023,43(8):168-174. (李泽清, 张鑫丰, 陈红萍. Ge改性TiO2对V-Mo-O/TiO2催化剂低温脱硝活性的影响[J]. 现代化工, 2023,43(8):168-174.Li Zeqing, Zhang Xinfeng, Chen Hongping. Effect of Ge doping on performance of V-Mo-O/TiO2 catalyst removing NOx at low temperature[J]. Modern Chemical Industry, 2023, 43(8): 168-174. [11] Huang X, Peng Y, Liu X, et al. The promotional effect of MoO3 doped V2O5/TiO2 for chlorobenzene oxidation[J]. Catalysis Communications, 2015,69:161-164. doi: 10.1016/j.catcom.2015.04.020 [12] Qiu Y, Liu B, Du J, et al. The monolithic cordierite supported V2O5–MoO3/TiO2 catalyst for NH3-SCR[J]. Chemical Engineering Journal, 2016,294:264-272. doi: 10.1016/j.cej.2016.02.094 [13] Dong G J, Bai Y, Zhang Y F, et al. Effect of the V4+(3+)/V5+ ration on the denitration activity for V2O5-WO3/TiO2 catalysts[J]. New Journal of Chemistry, 2015,39:3588-3596. doi: 10.1039/C5NJ00015G [14] Yu W C, Wu X D, Si Z C, et al. Influences of impregnation procedure on the SCR activity and alkali resistance of V2O5-WO3/TiO2 catalyst[J]. Applied Surface Science, 2013,283:209-214. doi: 10.1016/j.apsusc.2013.06.083 [15] Tang F S, Xu B L, Shi H H, et al. The poisoning effect of Na+ and Ca2+ ions doped on the V2O5/TiO2 catalysts for selective catalytic reduction of NO by NH3[J]. Applied Catalysis B: Environmental, 2010,94(1-2):71-76. doi: 10.1016/j.apcatb.2009.10.022 [16] Huang L, Zong Y H, Wang H, et al. Influence of calcination temperature on the plate-type V2O5-MoO3/TiO2 catalyst for selective catalytic reduction of NO[J]. Reaction Kinetics Mechanisms and Catalysis, 2018,124(2):603-617. doi: 10.1007/s11144-018-1378-0 [17] Chen H F, Xia Y, Fang R Y, et al. The effects of tungsten and hydrothermal aging in promoting NH3-SCR activity on V2O5/WO3-TiO2 catalysts[J]. Applied Surface Science, 2018,459:639-646. doi: 10.1016/j.apsusc.2018.08.046 [18] Yao Jia, Liu Shaoguang, Lin Wensong, et al. Study on performance of Ce-Cr-Ni/TiO2 catalysts in CO-SCR[J]. Modern Chemical Industry, 2019,39(5):123-127. (姚佳, 刘少光, 林文松, 等. Ce-Cr-Ni/TiO2催化剂的CO-SCR性能研究[J]. 现代化工, 2019,39(5):123-127.Yao Jia, Liu Shaoguang, Lin Wensong, et al. Study on performance of Ce-Cr-Ni/TiO2 catalysts in CO-SCR[J]. Modern Chemical Industry, 2019, 39(5): 123-127. [19] Dong Guojun, Zhang Yufeng, Zhao Yuan, et al. Effect of the pH value of precursor solution on the catalytic performance of V2O5-WO3/TiO2 in the low temperature NH3-SCR of NOx[J]. Journal of Fuel Chemistry and Technology, 2014,42(12):1455-1463. doi: 10.1016/S1872-5813(15)60003-2 [20] Martín J A, Yates M, Ávila P, et al. Nitrous oxide formation in low temperature selective catalytic reduction of nitrogen oxides with V2O5/TiO2 catalysts[J]. Applied Catalysis B: Environmental, 2007,70(1-4):330-334. doi: 10.1016/j.apcatb.2005.11.026 [21] Dong Wook Kwon, Kwang Hee Park, Heon Phil Ha. The role of molybdenum on the enhanced performance and SO2 resistance of V/Mo-Ti catalysts for NH3-SCR[J]. Applied Surface Science, 2019,481:1167-1177. doi: 10.1016/j.apsusc.2019.03.118 [22] Zheng Chengqiang, Cheng Teng, Yang Linjun, et al. Effect of SiO2 addition on NH4HSO4 decomposition and SO2 poisoning over V2O5–MoO3/TiO2–CeO2 catalyst[J]. Journal of Environmental Sciences, 2020,91:279-291. doi: 10.1016/j.jes.2020.01.011 [23] Casagrande L, Lietti L, Nova I, et al. SCR of NO by NH3 over TiO2-supported V2O5–MoO3 catalysts: reactivity and redox behavior[J]. Applied Catalysis B: Environmental, 1999,22(1):63-77. doi: 10.1016/S0926-3373(99)00035-1 -

下载:

下载: