Study on the biaxial tensile behavior of commercial pure titanium at room temperature

-

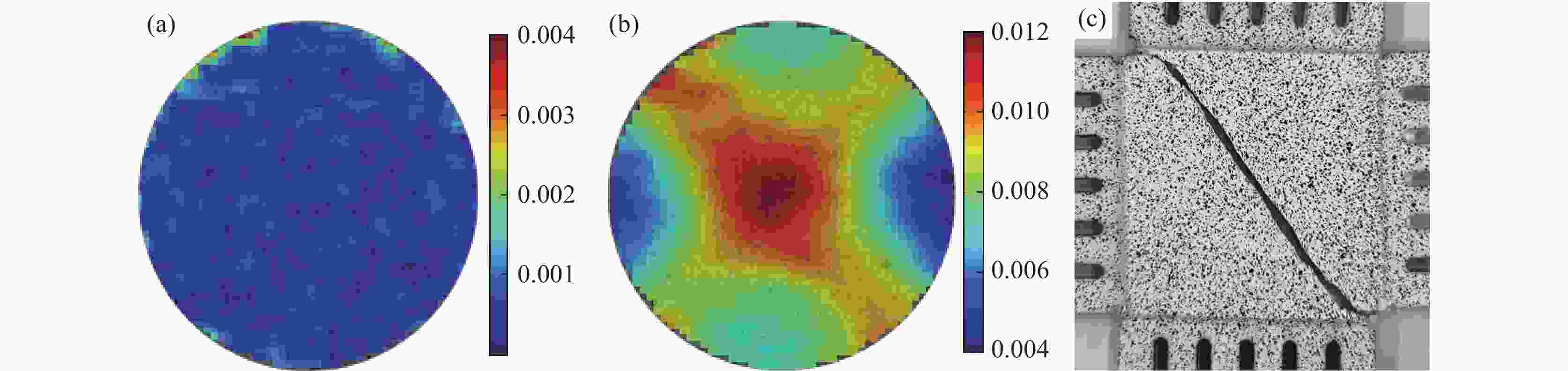

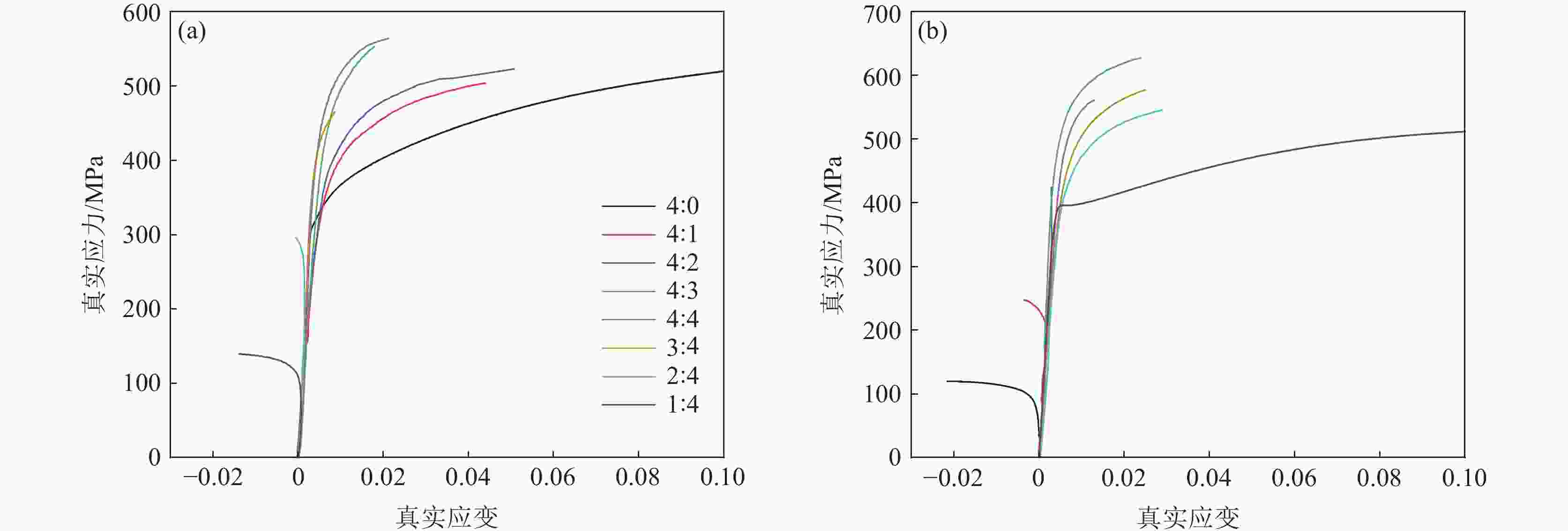

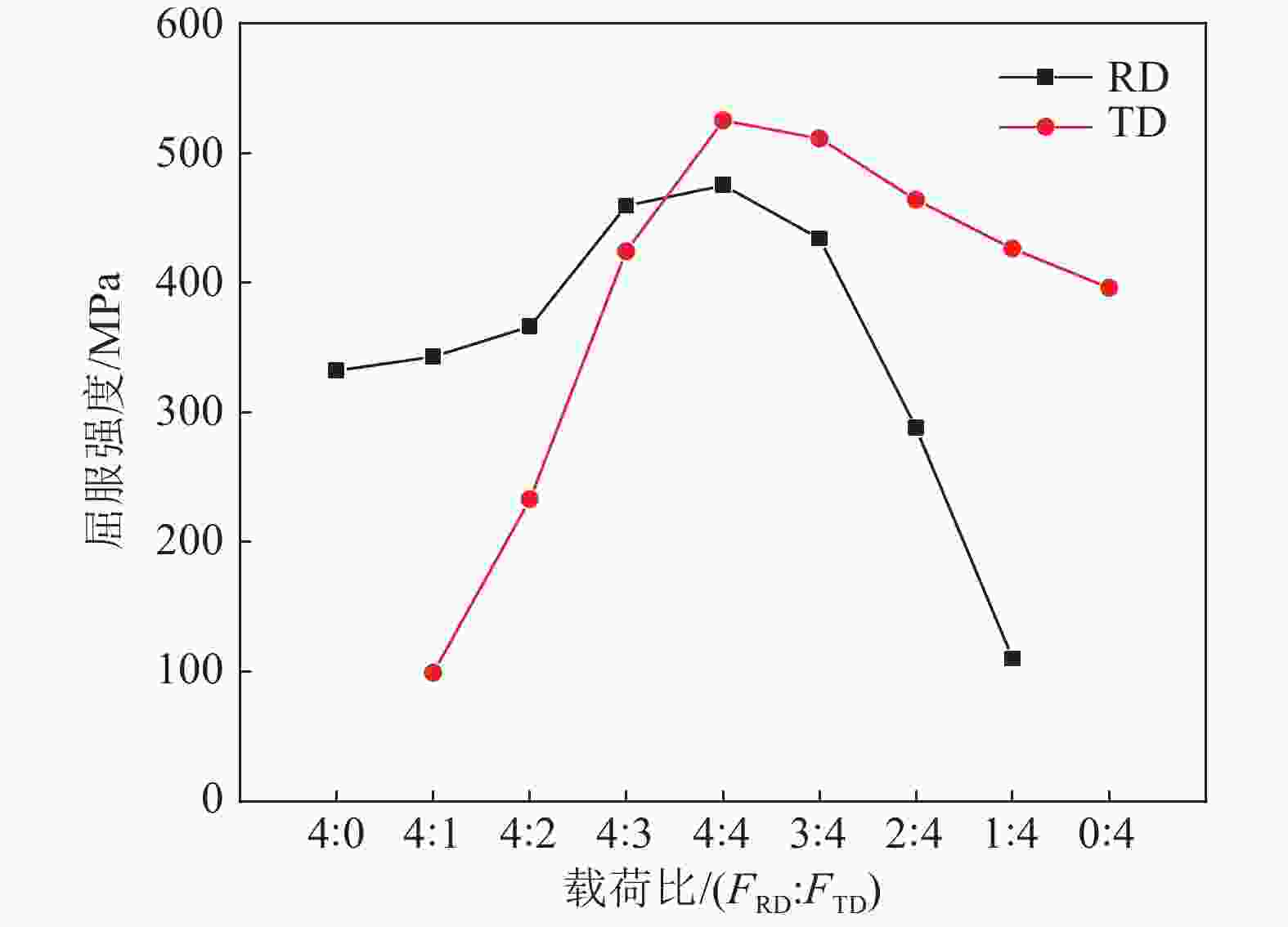

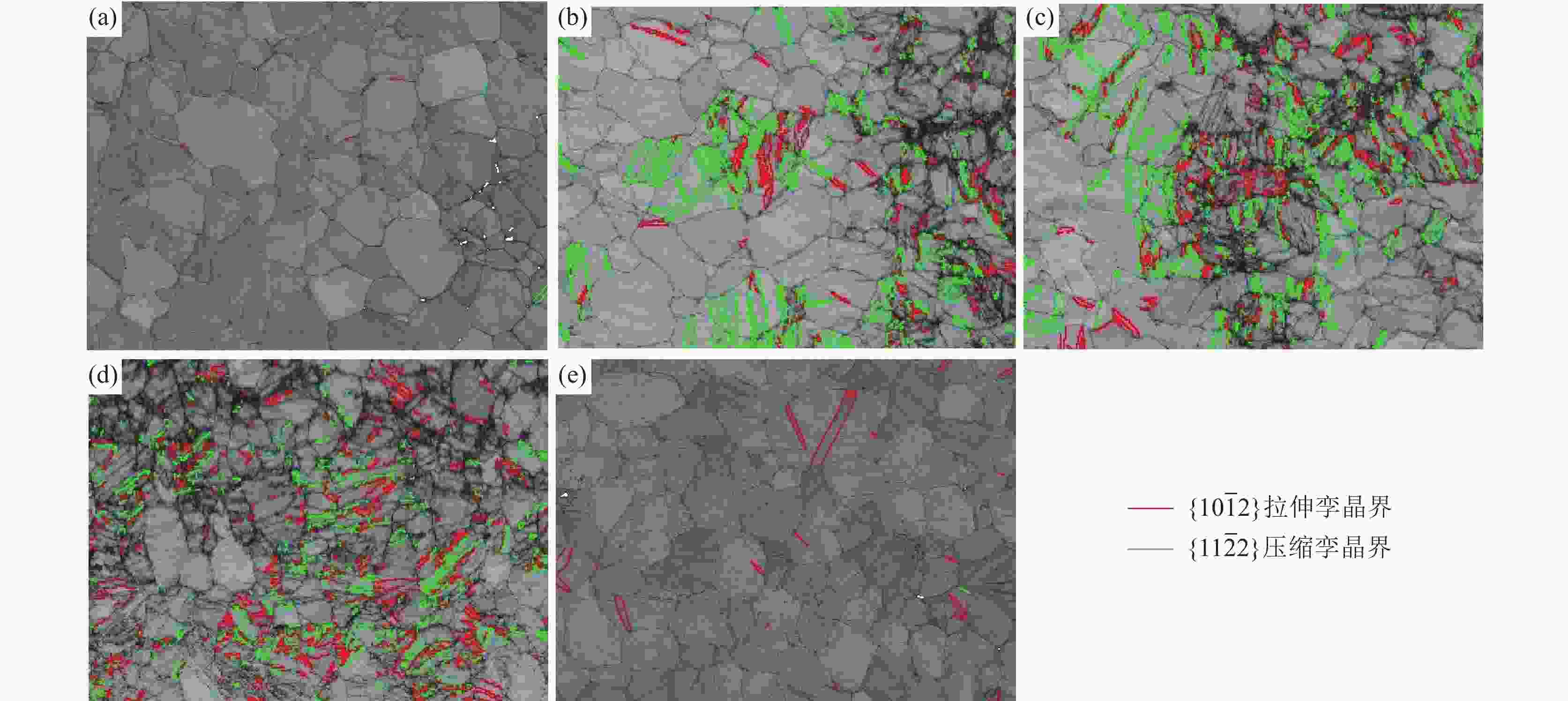

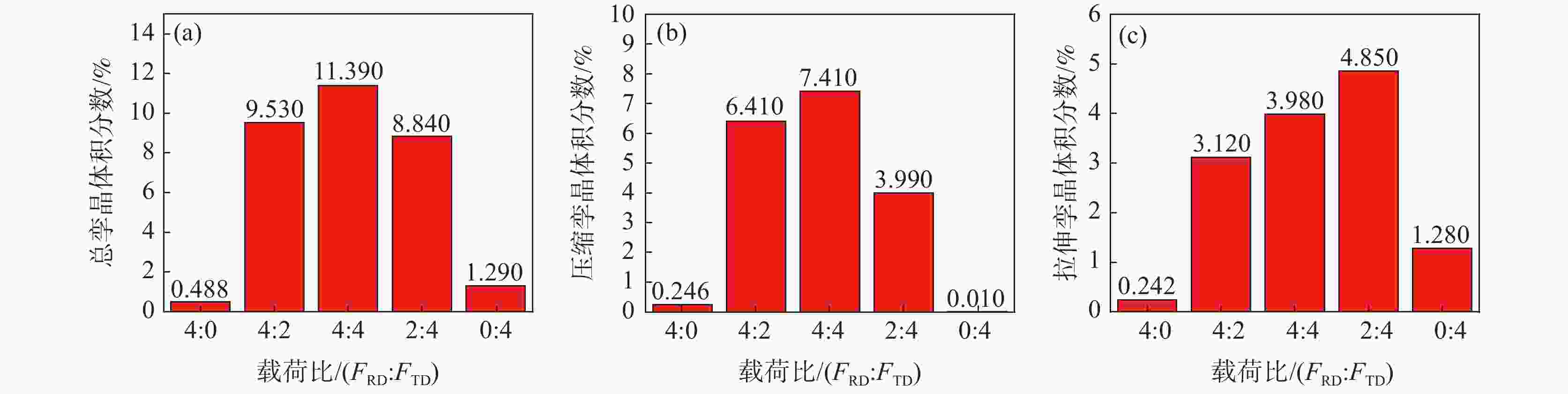

摘要: 采用十字形试样对工业纯钛板材进行了双轴拉伸试验,利用数字图像相关方法(Digital Image Correlation, DIC)捕获应变响应,探讨了双轴拉伸应力状态对力学性能的影响。与单轴力学性能相比,双轴加载下材料强度明显提升,当X、Y两轴加载速率相等时,材料的屈服强度及抗拉强度最高。进一步利用背向散射衍射技术(Electron Back Scatter Diffraction, EBSD)分析双轴载荷比对孪晶行为的影响。沿轧制方向(RD)和横向(TD)单向加载时,孪晶体积分数较小,而双轴载荷下有较多孪晶,在等比载荷时有最大的孪晶体积分数,且当横向载荷大于轧制方向载荷时,拉伸孪晶体积分数高于压缩孪晶体积分数。Abstract: In this study, biaxial tensile tests were conducted on the commercial pure titanium plates using cruciform specimens. The impact of biaxial tensile stress state on the mechanical properties was explored through Digital Image Correlation (DIC) to capture the strain response. The effect of biaxial tensile stress states on the mechanical properties of specimens was discussed. Compared to uniaxial mechanical properties, the biaxial loading material strength demonstrated a significant improvement. When the loading rates of X-axis and Y-axis are equal, the yield strength and tensile strength of the material reach the maximum. Electron Back Scatter Diffraction (EBSD) was further employed to analyze the influence of the biaxial load ratio on twinning behavior. Under uniaxial tension along the rolling direction (RD) or transverse direction (TD), the volume fraction of twins was found to be small, while there were more twins under biaxial loading and a maximum volume fraction of twins under equal load. Notably, when the load in the transverse direction exceeded that in the rolling direction, the volume fraction of tension twins surpassed that of compression twins.

-

Key words:

- TA2 /

- tensile property /

- biaxial load ratio /

- EBSD /

- DIC /

- twin

-

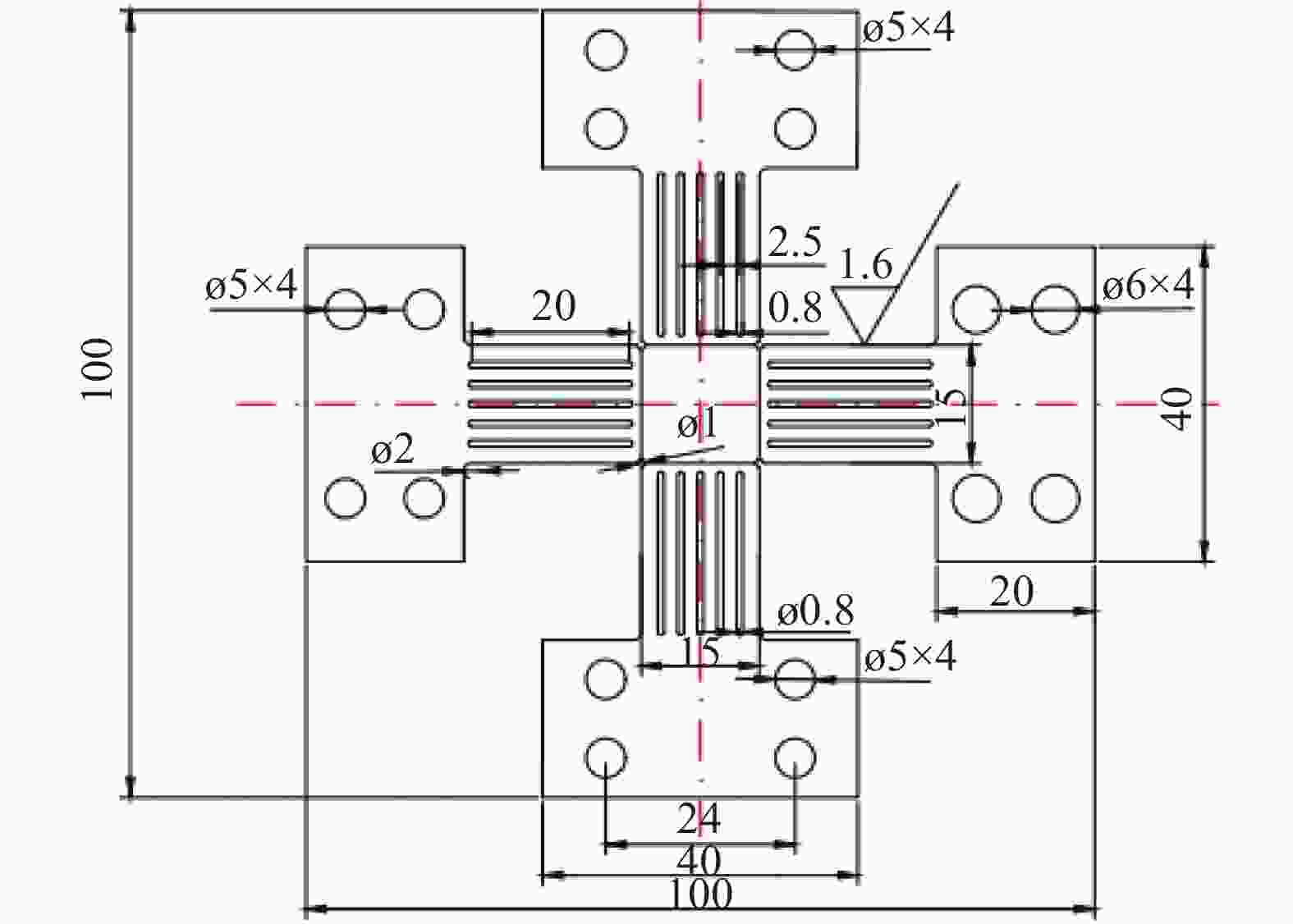

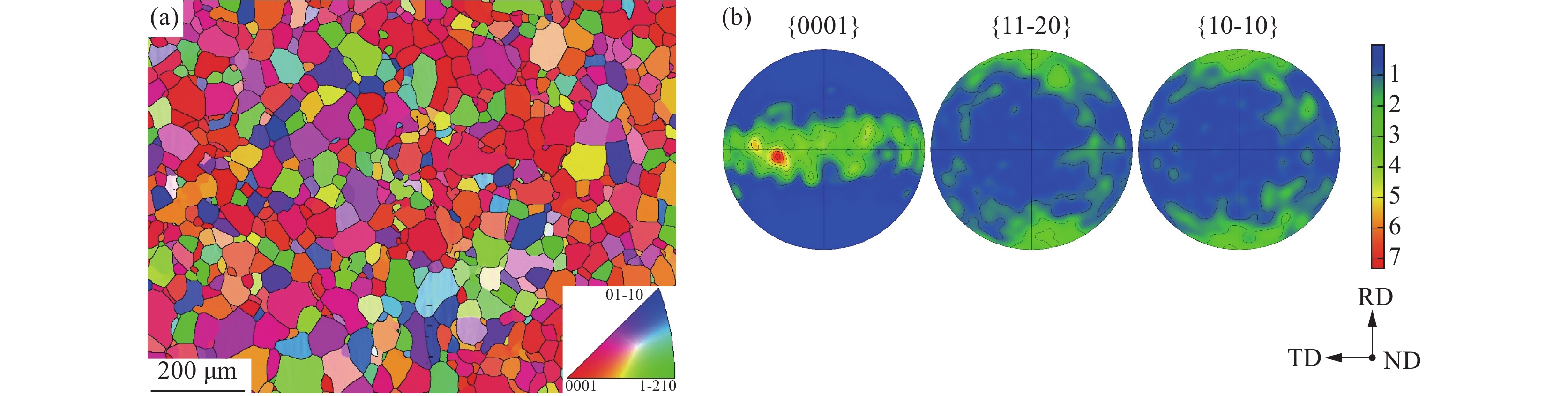

图 7 不同载荷条件下的试样晶界

Figure 7. Band contrast map with superimposed grain boundaries under different loading conditions

(a) $ {F}_{\rm{RD}} $:$ {F}_{\rm{TD}} $=4:0; (b) $ {F}_{\rm{RD}} $:$ {F}_{\rm{TD}} $=4:2; (c) $ {F}_{\rm{RD}} $:$ {F}_{\rm{TD}} $=4:4; (d) $ {F}_{\rm{RD}} $:$ {F}_{\rm{TD}} $=2:4 ;(e) $ {F}_{\rm{RD}} $:$ {F}_{\rm{TD}} $=0:4

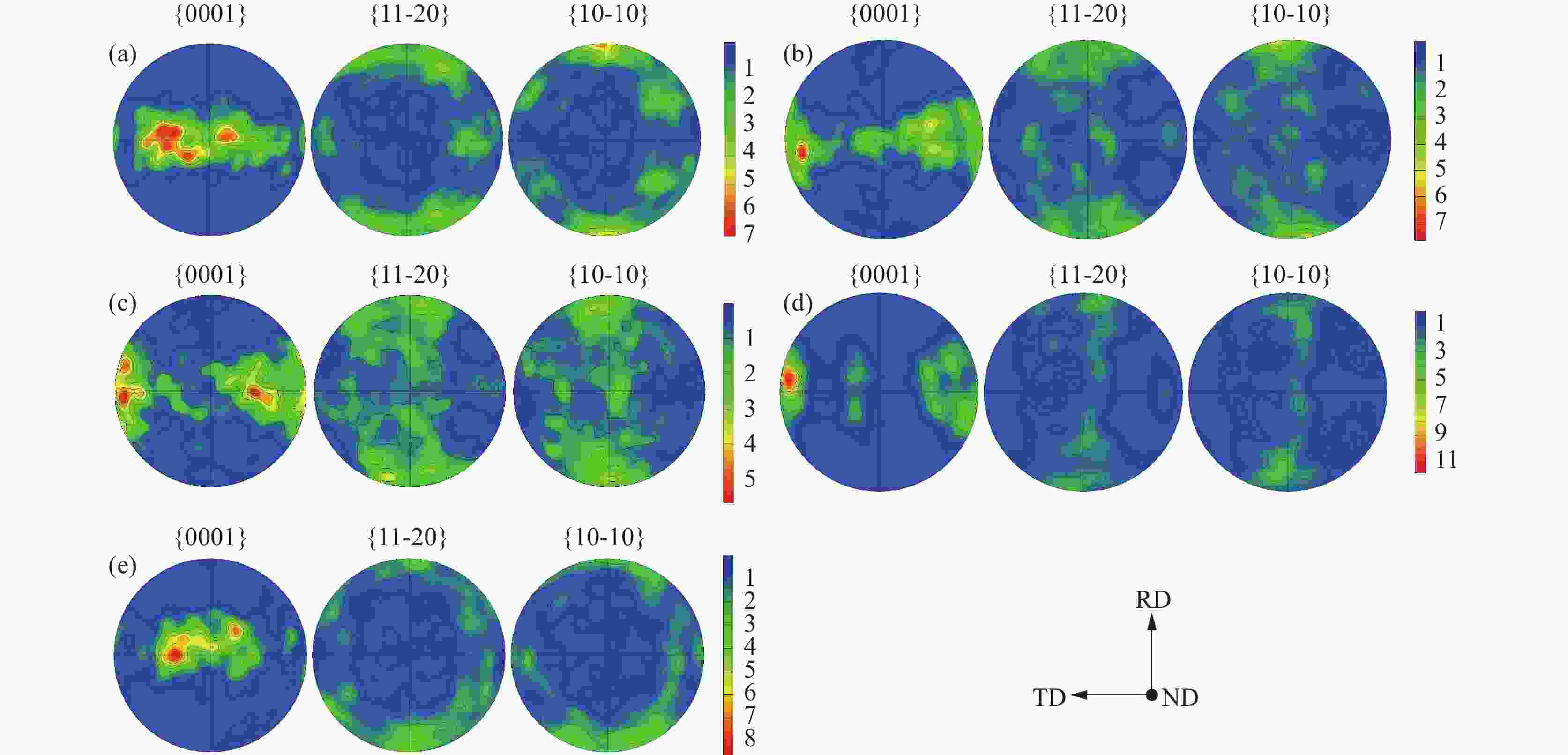

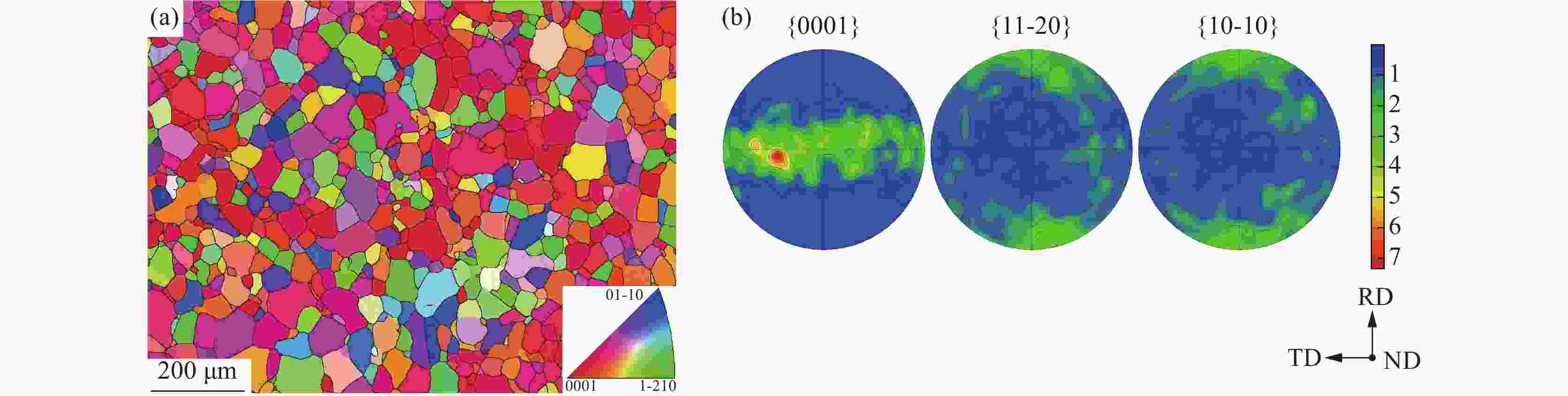

图 9 不同载荷比变形后极图

Figure 9. Pole figure maps after deformation with different loading ratios

(a) $ {F}_{{\mathrm{RD}}} $:$ {F}_{{\mathrm{TD}}} $=4:0; (b) $ {F}_{{\mathrm{RD}}} $:$ {F}_{{\mathrm{TD}}} $=4:2; (c) $ {F}_{{\mathrm{RD}}} $:$ {F}_{{\mathrm{TD}}} $=4:4; (d) $ {F}_{{\mathrm{RD}}} $:$ {F}_{{\mathrm{TD}}} $=2:4; (e) $ {F}_{{\mathrm{RD}}} $:$ {F}_{{\mathrm{TD}}} $=0:4

表 1 TA2的化学成分

Table 1. Chemical composition of TA2

% Fe C N H O Ti 0.034 0.018 0.011 0.002 0.127 99.808 -

[1] Nedunchezhian Srinivasan, Velmurugan R, Ravi Kumar, et al. Deformation behavior of commercially pure (CP) titanium under equi-biaxial tension[J]. Materials Science & Engineering A, 2016, 674:540-551. [2] Hannon Alan, Tiernan Peter. A review of planar biaxial tensile test systems for sheet metal[J]. Journal of Materials Processing Tech, 2007, 198(1):1-13. [3] Wagner F, Bozzolo N, Landuyt O Van, et al. Evolution of recrystallisation texture and microstructure in low alloyed titanium sheets[J]. Acta Materialia, 2002,50:1245-1259. doi: 10.1016/S1359-6454(01)00427-X [4] Bozzolo N, Dewobroto N, Grosdidier T, et al. Texture evolution during grain growth in recrystallized commercially pure titanium[J]. Materials Science and Engineering: A, 2005,397(1-2):346-355. doi: 10.1016/j.msea.2005.02.049 [5] Chun Y B, Yu S H, Semiatin S L, et al. Effect of deformation twinning on microstructure and texture evolution during cold rolling of CP-titanium[J]. Materials Science and Engineering: A, 2005,398:209-219. doi: 10.1016/j.msea.2005.03.019 [6] Yazar K U, Mishra S, Kumar L, et al. Texture induced planar anisotropy of dwell fatigue response in titanium: Insights from experiments and crystal plasticity simulations[J]. International Journal of Plasticity, 2022,152:103-140. [7] Chang Le, Miao Zihao, Zhou Binbin, et al. Understanding the anisotropic tensile deformation behavior of commercially pure titanium by experiments and crystal plasticity simulations[J]. Materials Letters, 2023,339:134095. doi: 10.1016/j.matlet.2023.134095 [8] Meng Jimkui, Liu Li, Jiang Jiantang, et al. The role of biaxial stress ratio on the mechanical behavior and deformation mechanisms in HCP α-Ti[J]. Materials Science and Engineering: A, 2023,862:144452. doi: 10.1016/j.msea.2022.144452 [9] Fu Yuanjie, Cheng Yao, Cui Yun, et al. Deformation mechanism of commercially pure titanium under biaxial loading at ambient and elevated temperatures[J]. Journal of Materials Science& Technology, 2022,126:237-251. [10] Sumit Bahl, Satyam Suwas, Kaushik Chatterjee. The importance of crystallographic texture in the use of titanium as an orthopedic biomaterial[J]. Rsc Advances, 2014, 4(72): 38078–38087. [11] Zhu Zhikang. Investigation on tensile mechanical behavior of commercial pure titanium TA2 under biaxial loading[D]. Nanjing: Nanjing Tech University, 2020. (朱志康. 双轴载荷下工业纯钛TA2拉伸力学行为研究[D]. 南京: 南京工业大学, 2020.Zhu Zhikang. Investigation on tensile mechanical behavior of commercial pure titanium TA2 under biaxial loading[D]. Nanjing: Nanjing Tech University, 2020. [12] Zhu Zhikang, Lu Zheng, Zhang Peng, et al. Optimal design of a miniaturized cruciform specimen for biaxial testing of TA2 alloys[J]. Metals, 2019,9(8):823-841. doi: 10.3390/met9080823 [13] Peters W H, Ranson W F. Digital imaging techniques in experimental stress analysis[J]. Optical Engineering, 1982,21(3):427-431. [14] Smits A, Hemelrijck D V, Philippidi T P, et al. Design of a cruciform specimen for biaxial testing of fibre reinforced composite laminates[J]. Composites Science and Technology, 2006,66(7-8):964-975. doi: 10.1016/j.compscitech.2005.08.011 [15] Hannon A, Tiernan P. A review of planar biaxial tensile test systems for sheet metal[J]. Journal of Materials Processing Technology, 2008,198(1-3):1-13. doi: 10.1016/j.jmatprotec.2007.10.015 [16] Nizhnik S B, Dmitrieva E A. Phase Effect on deformation anisotropy of strength and fracture resistance characteristics of titanium alloys[J]. Strength of Materials, 2014,46:785-793. doi: 10.1007/s11223-014-9612-0 [17] Li Gangling, Li Jinwei, Li Jinyu. Stress measurement of titanium pressure vessels[J]. Pressure Vessels Piping, 1996,67:41-44. doi: 10.1016/0308-0161(94)00150-2 [18] Cheng Yao. Research on deformation behavior of hcp metals under biaxial tension[D]. Chongqing: Chongqing University, 2021.(成姚.密排六方结构金属双轴拉伸变形行为研究[D]. 重庆:重庆大学,2021.Cheng Yao. Research on deformation behavior of hcp metals under biaxial tension[D]. Chongqing: Chongqing University, 2021.(成姚.密排六方结构金属双轴拉伸变形行为研究[D]. 重庆: 重庆大学, 2021.) -

下载:

下载: