| [1] |

Banerjee D, Williams J C. Perspectives on titanium science and technology[J]. Acta Materialia, 2013,61(3):844-879. doi: 10.1016/j.actamat.2012.10.043

|

| [2] |

Lütjering G G, Williams J C. Titanium[M]. Springer, 2007.

|

| [3] |

Lei Ting. Titanium and titanium alloy[M]. Beijing: Metallurgical Industry Press, 2018. (雷霆. 钛及钛合金[M]. 北京: 冶金工业出版社, 2018.Lei Ting. Titanium and titanium alloy[M]. Beijing: Metallurgical Industry Press, 2018.

|

| [4] |

Lainé S J, Knowles K M, Doorbar P J, et al. Microstructural characterisation of metallic shot peened and laser shock peened Ti–6Al–4V[J]. Acta Materialia, 2017,123:350-361. doi: 10.1016/j.actamat.2016.10.044

|

| [5] |

Castany P, Pettinari Sturmel F, Crestou J, et al. Experimental study of dislocation mobility in a Ti–6Al–4V alloy[J]. Acta Materialia, 2007,55(18):6284-6291. doi: 10.1016/j.actamat.2007.07.032

|

| [6] |

Guo Zhouqiang, Ge Liling, Yuan Hang, et al. Surface nano-crystallization of TC4 titanium alloy and its thermal stability[J]. Transactions of Materials and Heat Treatment, 2012,33(3):5. (郭周强, 葛利玲, 袁航, 等. 钛合金TC4表面纳米化及其热稳定性[J]. 材料热处理学报, 2012,33(3):5.Guo Zhouqiang, Ge Liling, Yuan Hang, et al. Surface nano-crystallization of TC4 titanium alloy and its thermal stability[J]. Transactions of Materials and Heat Treatment, 2012, 33(3): 5.

|

| [7] |

Sun J L, Trimby P W, Si X, et al. Nano twins in ultrafine-grained Ti processed by dynamic plastic deformation[J]. Scripta Materialia, 2013,68(7):475-478. doi: 10.1016/j.scriptamat.2012.11.025

|

| [8] |

Bao L, Lecomte J, Schuman C, et al. Study of plastic deformation in hexagonal metals by interrupted in-situ EBSD measurement[J]. Advanced Engineering Materials, 2010,12(10):1053-1059. doi: 10.1002/adem.201000074

|

| [9] |

Li Y, Ni S, Liu Y, et al. Phase transition induced high strength and large ductility of a hot rolled near β Ti-5Al-5Mo-5V-1Cr-1Fe alloy[J]. Scripta Materialia, 2019,170:34-37. doi: 10.1016/j.scriptamat.2019.05.031

|

| [10] |

Liu Y G, Li M Q, Liu H J. Deformation induced face-centered cubic titanium and its twinning behavior in Ti–6Al–4V[J]. Scripta Materialia, 2016,119:5-8. doi: 10.1016/j.scriptamat.2016.03.018

|

| [11] |

Ao N, Liu D, Liu C, et al. Face-centered titanium induced by ultrasonic surface rolling process in Ti-6Al-4V alloy and its tensile behavior[J]. Materials Characterization, 2018,145:527-533. doi: 10.1016/j.matchar.2018.09.004

|

| [12] |

Shahmir H, Langdon T G. Using heat treatments, high-pressure torsion and post-deformation annealing to optimize the properties of Ti-6Al-4V alloys[J]. Acta Materialia, 2017,141:419-426. doi: 10.1016/j.actamat.2017.09.018

|

| [13] |

Kwasniak P, Garbacz H, Kurzydlowski K J. Solid solution strengthening of hexagonal titanium alloys: Restoring forces and stacking faults calculated from first principles[J]. Acta Materialia, 2016, 102: 304-314.

|

| [14] |

Matsumoto H, Yoneda H, Sato K, et al. Room-temperature ductility of Ti-6Al-4V alloy with α′ martensite microstructure[J]. Materials Science and Engineering: A, 2011,528(3):1512-1520. doi: 10.1016/j.msea.2010.10.070

|

| [15] |

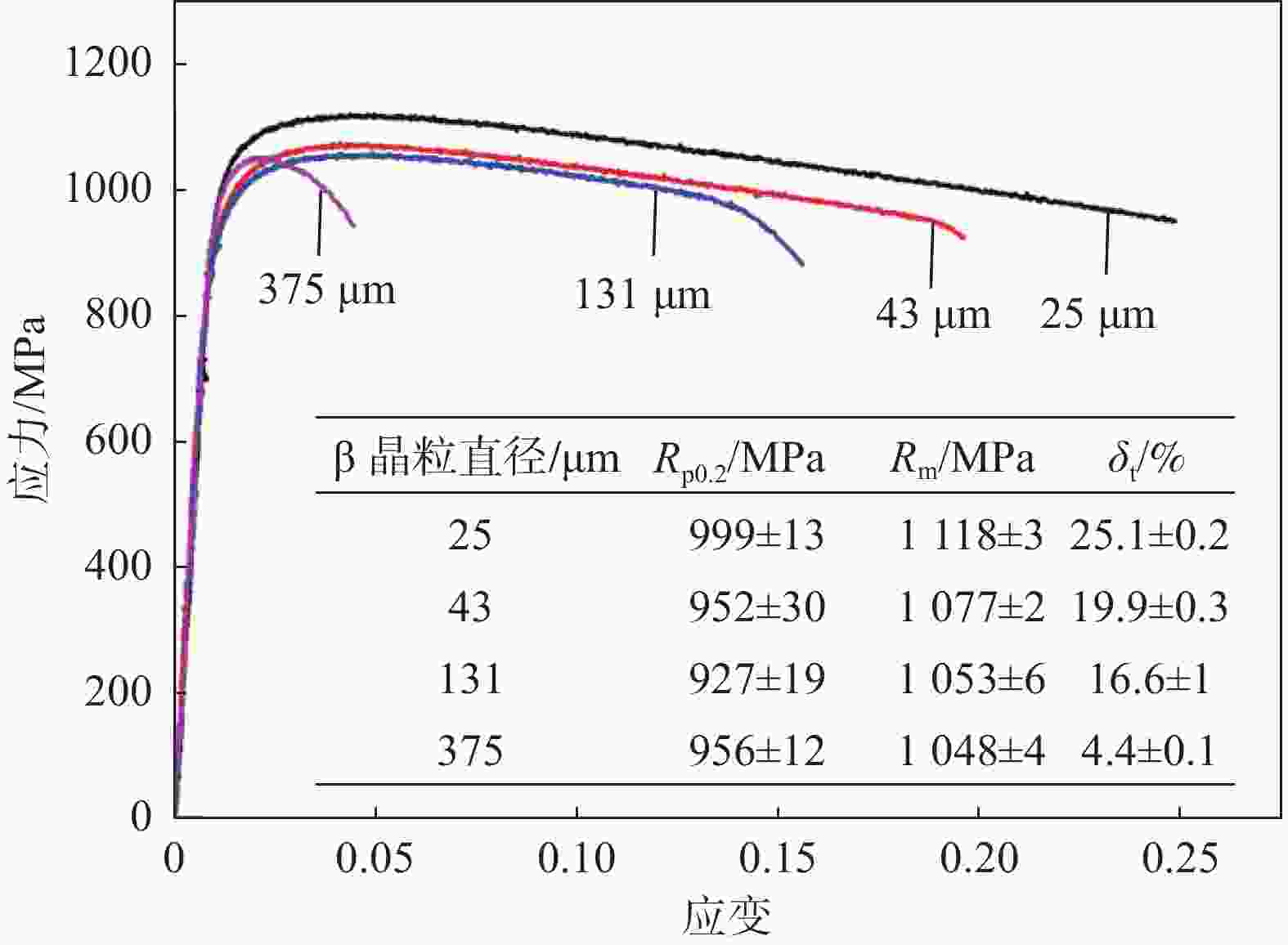

Chong Y, Bhattacharjee T, Yi J, et al. Mechanical properties of fully martensite microstructure in Ti-6Al-4V alloy transformed from refined beta grains obtained by rapid heat treatment (RHT)[J]. Scripta Materialia, 2017,138:66-70. doi: 10.1016/j.scriptamat.2017.05.038

|

| [16] |

Chao Q, Hodgson P D, Beladi H. Ultrafine grain formation in a Ti-6Al-4V alloy by thermomechanical processing of a martensitic microstructure[J]. Metallurgical and Materials Transactions A, 2014,45(5):2659-2671. doi: 10.1007/s11661-014-2205-5

|

| [17] |

Zhang Runqi, Cai Qin, Li Zhuang, et al. Microstructural evolution of Ti-6Al-4V alloy during water quenching under different processing conditions[J]. Rare Metal Materials and Engineering, 2020,49(9):3005-3011. (张润奇, 蔡钦, 李壮, 等. Ti-6Al-4V合金在不同工艺条件下水淬后的组织演变[J]. 稀有金属材料与工程, 2020,49(9):3005-3011.Zhang Runqi, Cai Qin, Li Zhuang, et al. Microstructural evolution of Ti-6Al-4V alloy during water quenching under different processing conditions[J]. Rare Metal Materials and Engineering, 2020, 49(9): 3005-3011.

|

| [18] |

Zhao H, Song M, Ni S, et al. Atomic-scale understanding of stress-induced phase transformation in cold-rolled Hf[J]. Acta Materialia, 2017,131:271-279. doi: 10.1016/j.actamat.2017.03.058

|

| [19] |

Wei B, Ni S, Liu Y, et al. Phase transformation and structural evolution in a Ti-5at.% Al alloy induced by cold-rolling[J]. Journal of Materials Science & Technology, 2020,49:211-223.

|

| [20] |

Chen P, Wang F, Li B. Transitory phase transformations during{101-2} twinning in titanium[J]. Acta Materialia, 2019,171:65-78. doi: 10.1016/j.actamat.2019.04.002

|

| [21] |

Jiang S, Huang L, Gao X, et al. Interstitial carbon induced FCC-Ti exhibiting ultrahigh strength in a Ti37Nb28Mo28-C7 complex concentrated alloy[J]. Acta Materialia, 2021,203:116456. doi: 10.1016/j.actamat.2020.10.075

|

下载:

下载: