| [1] |

Zeeshan Ajmal, Mahmood ul Haq, Yassine Naciri, et al. Recent advancement in conjugated polymers based photocatalytic technology for air pollutants abatement: Cases of CO2, NOx, and VOCs[J]. Chemosphere, 2022,308(2):136358.

|

| [2] |

Guo Yiqi, Zhu Lisha, Wang Xiaopeng, et al. Assessing environmental impact of NOx and SO2 emissions in textiles production with chemical footprint[J]. Science of the Total Environment, 2022,831:154961. doi: 10.1016/j.scitotenv.2022.154961

|

| [3] |

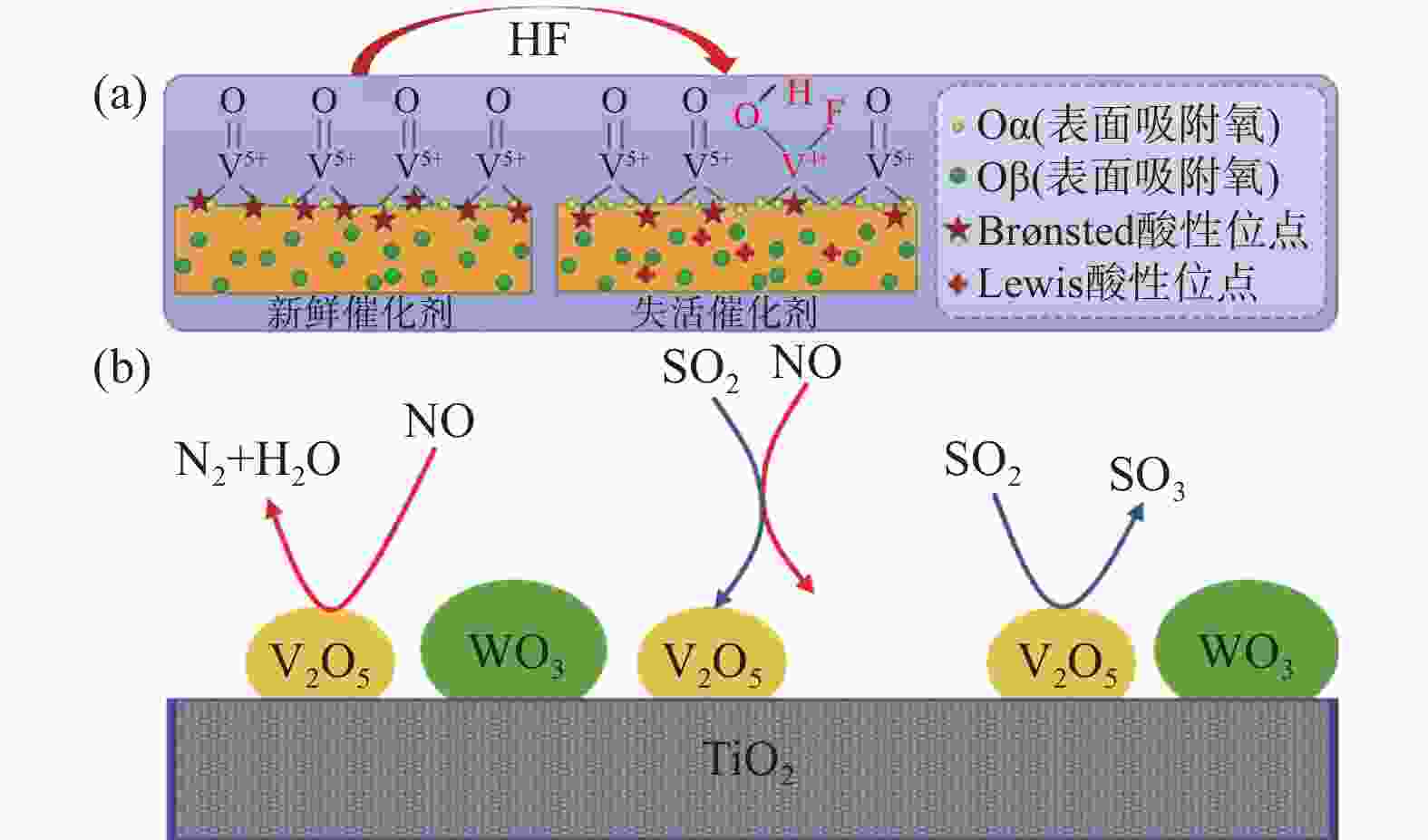

Zhao Shilin, Peng Junlin, Ge Runqi. Poisoning and regeneration of commercial V2O5−WO3/TiO2 selective catalytic reduction (SCR) catalyst in coal-fired power plants[J]. Process Safety and Environmental Protection, Part B, 2022,168:971-992.

|

| [4] |

Zhang Zhenquan, Zhao Beibei, Li Lanjie, et al. Study on selective separation of vanadium, titanmium and tungsten from spent SCR denitration catalyst[J]. Iron Steel Vanadium Titanium, 2021,42(1):24-31. (张振全, 赵备备, 李兰杰, 等. 废SCR脱硝催化剂钒、钛、钨选择性分离研究[J]. 钢铁钒钛, 2021,42(1):24-31. doi: 10.7513/j.issn.1004-7638.2021.01.004Zhang Zhenquan, Zhao Beibei, Li Lanjie, et al. Study on selective separation of vanadium, titanmium and tungsten from spent SCR denitration catalyst[J]. Iron Steel Vanadium Titanium, 2021, 42(1): 24-31. doi: 10.7513/j.issn.1004-7638.2021.01.004

|

| [5] |

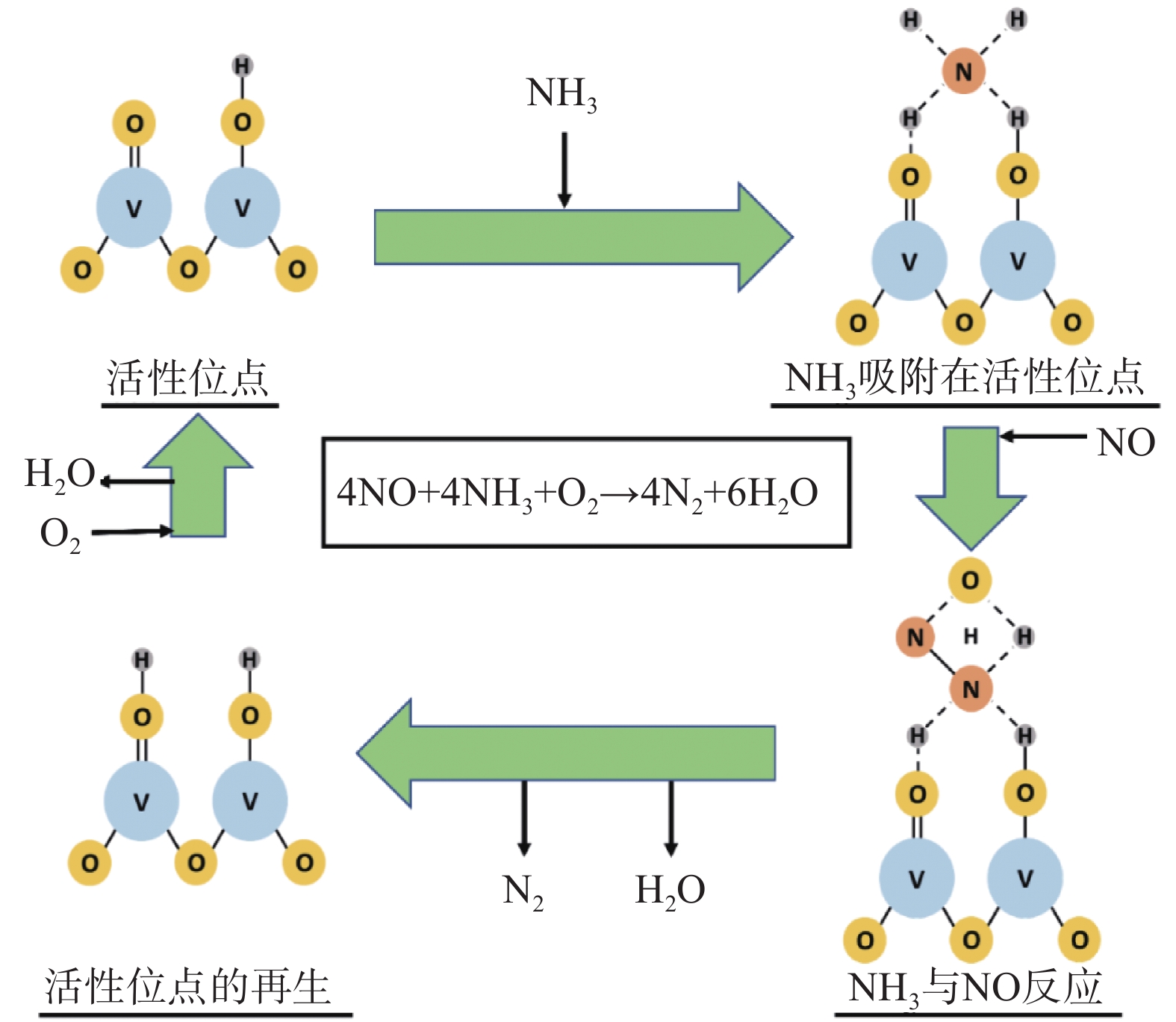

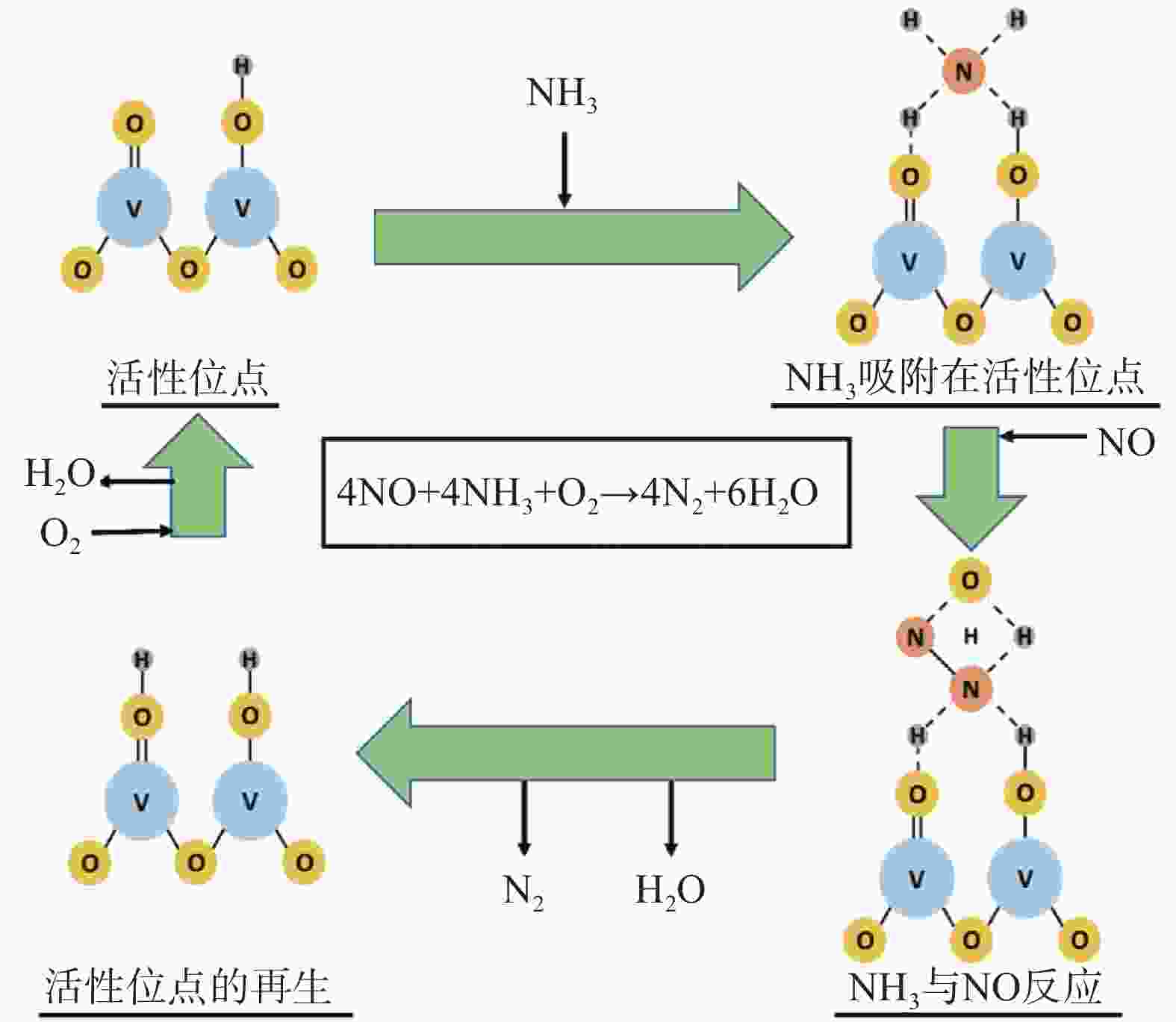

Topsøe N. Mechanism of the selective catalytic reduction of nitric oxide by ammonia elucidated by in situ on-line fourier transform infrared spectroscopy[J]. Science, 1994,265(5176):1217-1219. doi: 10.1126/science.265.5176.1217

|

| [6] |

Mei Yuefei, Yue Ni, Duo Hongjian, et al. Analysis and optimization of SCR catalyst partial wear principle in denitration system[J]. Science and Technology Innovation Herald, 2023(1):38-41. (梅跃飞, 岳妮, 多鸿建, 等. 脱硝系统SCR催化剂局部磨损原理分析和优化改造[J]. 科学技术创新, 2023(1):38-41. doi: 10.3969/j.issn.1673-1328.2023.01.011Mei Yuefei, Yue Ni, Duo Hongjian, et al. Analysis and optimization of SCR catalyst partial wear principle in denitration system[J]. Science and Technology Innovation Herald, 2023(1): 38-41. doi: 10.3969/j.issn.1673-1328.2023.01.011

|

| [7] |

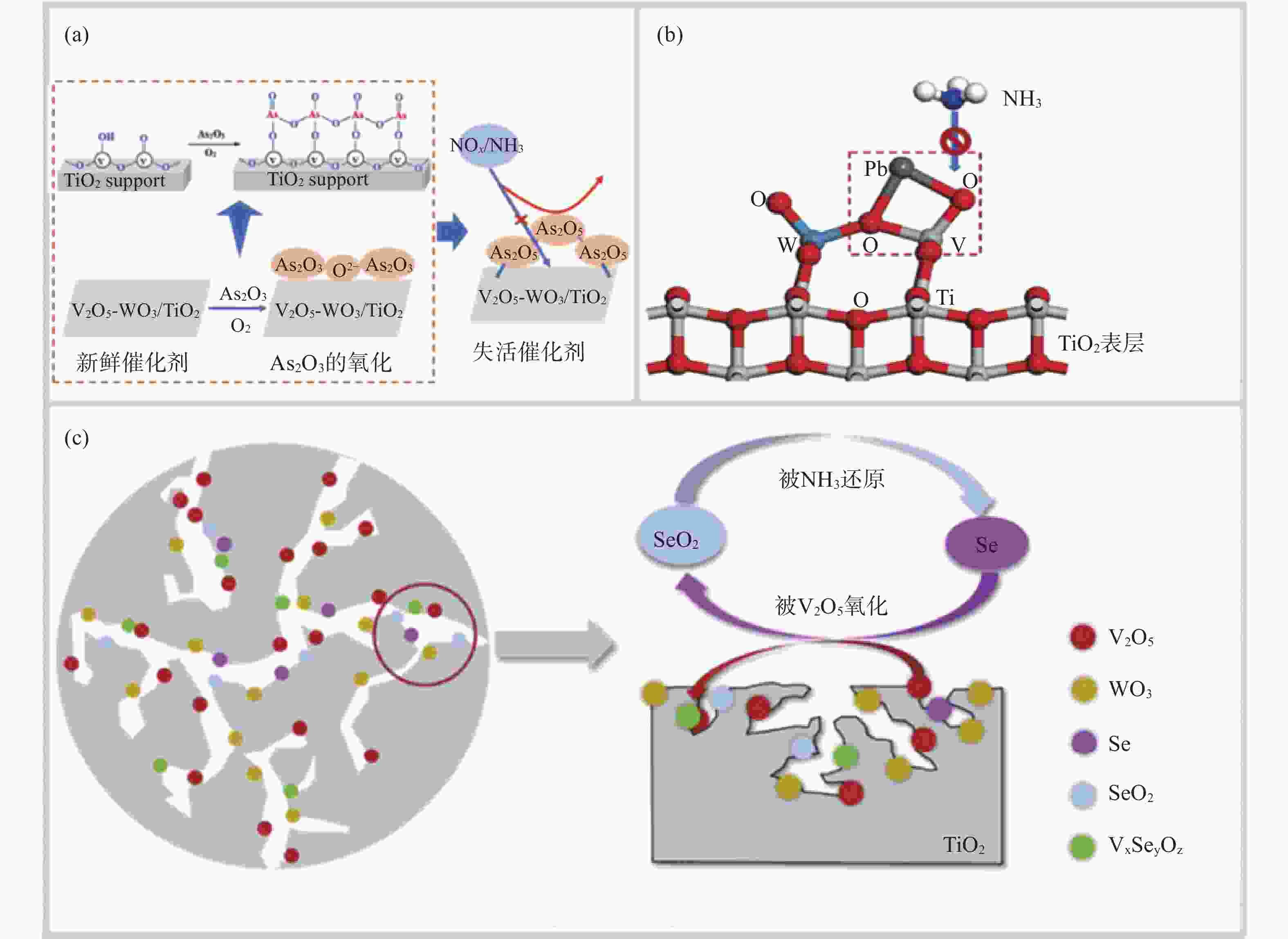

Hu Wenshuo, Gao Xiang, Deng Yawen, et al. Deactivation mechanism of arsenic and resistance effect of SO42- on commercial catalysts for selective catalytic reduction of NOx with NH3[J]. Chemical Engineering Journal, 2016,293:118-128. doi: 10.1016/j.cej.2016.02.095

|

| [8] |

Liu Zhong, Han Jian, Zhao Li, et al. Effects of Se and SeO2 on the denitrification performance of V2O5−WO3/TiO2 SCR catalyst[J]. Applied Catalysis, A. General: An International Journal Devoted to Catalytic Science and Its Applications, 2019,587:117263.

|

| [9] |

Lanza Aldo, Usberti Nicola, Forzatti Pio, et al. Kinetic and mass transfer effects of fly ash deposition on the performance of SCR monoliths: A study in microslab reactor[J]. Industrial & Engineering Chemistry Research, 2021,60(18):6742-6752.

|

| [10] |

Stobert T R P E , Wang Jianbo, George Wensell, et al. Application of SCR catalyst in high CaO coal project[C]// Chinese Society of Environmental Science Annual Conference Excellent Proceedings. Suzhou: China Environmental Science Press, 2006. (Stobert T R P E , 王剑波, George Wensell, 等. SCR催化剂在高CaO煤项目中的应用[C]// 中国环境科学学会学术年会优秀论文集. 苏州:中国环境科学出版社, 2006.Stobert T R P E , Wang Jianbo, George Wensell, et al. Application of SCR catalyst in high CaO coal project[C]// Chinese Society of Environmental Science Annual Conference Excellent Proceedings. Suzhou: China Environmental Science Press, 2006.

|

| [11] |

Wang Xiangmin, Du Xuesen, Zhang Li, et al. Promotion of NH4HSO4 decomposition in NO/NO2 contained atmosphere at low temperature over V2O5−WO3/TiO2 catalyst for NO reduction[J]. Applied Catalysis A: General, 2018,559:112-121. doi: 10.1016/j.apcata.2018.04.025

|

| [12] |

Xu Liwen, Wang Chizhong, Chang Huazhen, et al. New insight into SO2 poisoning and regeneration of CeO2–WO3/TiO2 and V2O5–WO3/TiO2 catalysts for low-temperature NH3–SCR[J]. Environmental Science & Technology, 2018,52(12):7064-7071.

|

| [13] |

Cimino Stefano, Ferone Claudio, Cioffi Raffaele, et al. A case study for the deactivation and regeneration of a V2O5−WO3/TiO2 catalyst in a tail-end SCR unit of a municipal waste incineration plant[J]. Catalysts, 2019,9(5):464. doi: 10.3390/catal9050464

|

| [14] |

Zheng Yang, Guo Yangyang, Wang Jian, et al. Ca doping effect on the competition of NH3–SCR and NH3 oxidation reactions over vanadium-based catalysts[J]. The Journal of Physical Chemistry C, 2021,125(11):6128-6136. doi: 10.1021/acs.jpcc.1c00677

|

| [15] |

Nicosia D, Czekaj I, Kröcher O. Chemical deactivation of V2O5−WO3/TiO2 SCR catalysts by additives and impurities from fuels, lubrication oils and urea solution: Part II. Characterization study of the effect of alkali and alkaline earth metals[J]. Applied Catalysis B: Environmental, 2008,77(3-4):228-236. doi: 10.1016/j.apcatb.2007.07.032

|

| [16] |

Ali Zulfiqar, Lu Qiang, Iqbal Tahir, et al. Poisoning effects of lead species on the V2O5−WO3/TiO2 type NH3﹕elective catalytic reduction catalyst[J]. Asia-Pacific Journal of Chemical Engineering, 2019,14(4):2309.

|

| [17] |

Janssen F J J G, Kerkhof F M G V D, Bosch H, et al. Cheminform abstract: mechanism of the reaction of nitric oxide, ammonia, and oxygen over vanadia catalysts. part 2. isotopic transient studies with oxygen-18 and nitrogen-15[J]. Chem. Inform, 1988,19(14):198814017.

|

| [18] |

Zheng Yuanjing, Jensen Anker Degn, Johnsson Jan Erik, et al. Deactivation of V2O5−WO3-TiO2 SCR catalyst at biomass fired power plants: Elucidation of mechanisms by lab-and pilot-scale experiments[J]. Applied Catalysis B: Environmental, 2008,83(3-4):186-194. doi: 10.1016/j.apcatb.2008.02.019

|

| [19] |

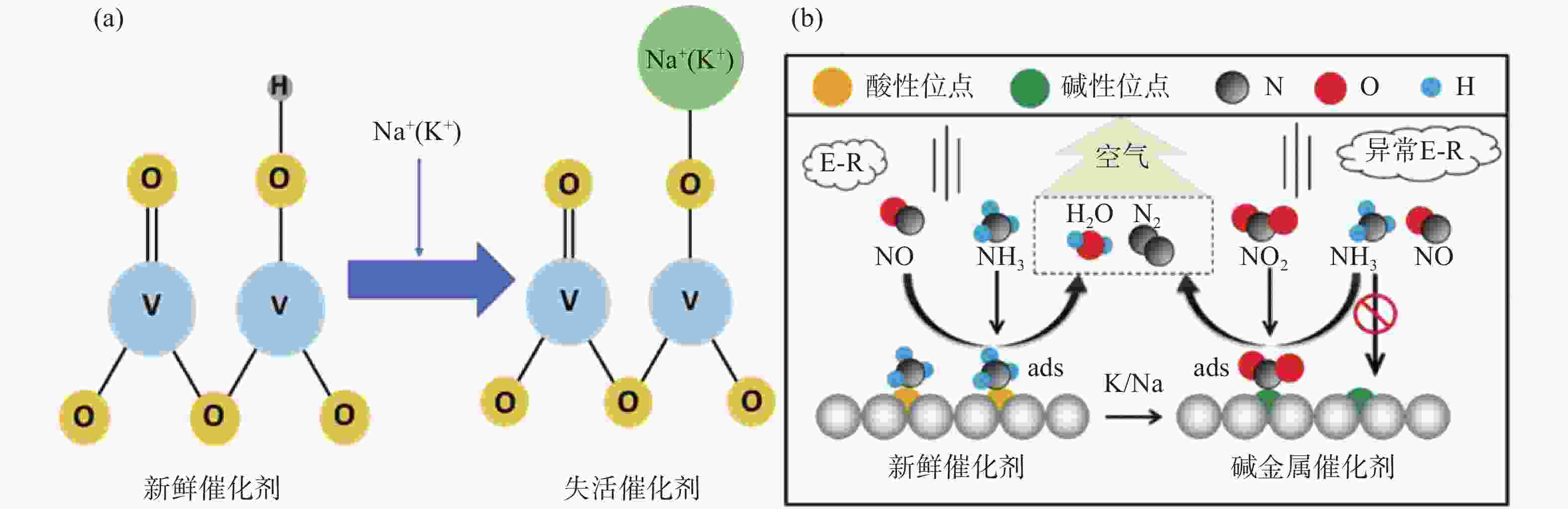

Tian Yuanmeng, Yang Jian, Yang Chen, et al. Comparative study of the poisoning effect of NaCl and Na2O on selective catalytic reduction of NO with NH3 over V2O5−WO3/TiO2 catalyst[J]. Journal of the Energy Institute, 2019,92:1045-1052. doi: 10.1016/j.joei.2018.07.002

|

| [20] |

Xiao Haiping, Chen Yu, Qi Cong, et al. Effect of Na poisoning catalyst (V2O5–WO3/TiO2) on denitration process and SO3 formation[J]. Applied Surface Science, 2018,433(1):341-348.

|

| [21] |

Jiang Ye, Gao Xiang, Zhang Yongxin, et al. Effect of KCl on the selective catalytic reduction of NO with NH3 over vanadia‐based catalysts for biomass combustion[J]. Environmental Progress & Sustainable Energy, 2014,33(2):390-395.

|

| [22] |

Nie Hua, Li Wei, Wu Qirong, et al. The poisoning of V2O5−WO3/TiO2 and V2O5-Ce(SO4)2/TiO2 SCR catalysts by KCl and the partial regeneration by SO2[J]. Multidisciplinary Digital Publishing Institute, 2020,10:207.

|

| [23] |

Li Xiang, Li Xiansheng, Yang Ralph T, et al. The poisoning effects of calcium on V2O5−WO3/TiO2 catalyst for the SCR reaction: Comparison of different forms of calcium[J]. Molecular Catalysis, 2017,434:16-24. doi: 10.1016/j.mcat.2017.01.010

|

| [24] |

Xiang Jinyao, Du Xuesen, Wan Yuyi, et al. Alkali-driven active site shift of fast SCR with NH3 on V2O5–WO3/TiO2 catalyst via a novel Eley–Rideal mechanism[J]. Catal. Sci. Technol, 2019,9(21):6085-6091. doi: 10.1039/C9CY01565E

|

| [25] |

He Deliang, Ren Huiying, Zhu Tianshi, et al. Study on the calcium-poisoning mechanism of the V2O5–WO3/TiO2 SCR catalyst[J]. Journal of Basic Science and Engineering, 2018,26(1):1-11. (何德良, 任慧莺, 朱天时, 等. V2O5−WO3/TiO2 SCR催化剂的钙中毒机理研究[J]. 应用基础与工程科学学报, 2018,26(1):1-11.He Deliang, Ren Huiying, Zhu Tianshi, et al. Study on the calcium-poisoning mechanism of the V2O5–WO3/TiO2 SCR catalyst[J]. Journal of Basic Science and Engineering, 2018, 26(1): 1-11.

|

| [26] |

Zhang Yusheng, Li Changming, Wang Chao, et al. Pilot-scale test of a V2O5–WO3/TiO2-coated type of honeycomb DeNO x catalyst and its deactivation mechanism[J]. Industrial & Engineering Chemistry Research, 2018,58(2):828-835.

|

| [27] |

Deng Lei, Liu Xuan, Cao Peiqing, et al. A study on deactivation of V2O5−WO3/TiO2 SCR catalyst by alkali metals during entrained-flow combustion[J]. Elsevier, 2017,90:743-751.

|

| [28] |

Deng Lei, Zhu Zhengrong, Wang Yikun, et al. Deactivation influence of HF on the V2O5−WO3/TiO2 SCR catalyst[J]. Energy & Fuels, 2021,35:4377-4386.

|

| [29] |

Wang Yazhou, Yi Wen, Yu Jie, et al. Novel methods for assessing the SO2 poisoning effect and thermal regeneration possibility of MO x–WO3/TiO2 (M = Fe, Mn, Cu, and V) catalysts for NH3-SCR[J]. Environmental Science & Technology: ES&T, 2020,54(19):12612-12620.

|

| [30] |

Du Xuesen, Yang Guangpeng, Chen Yanrong, et al. The different poisoning behaviors of various alkali metal containing compounds on SCR catalyst[J]. Appl. Surf. Sci, 2017,392:162-168. doi: 10.1016/j.apsusc.2016.09.036

|

| [31] |

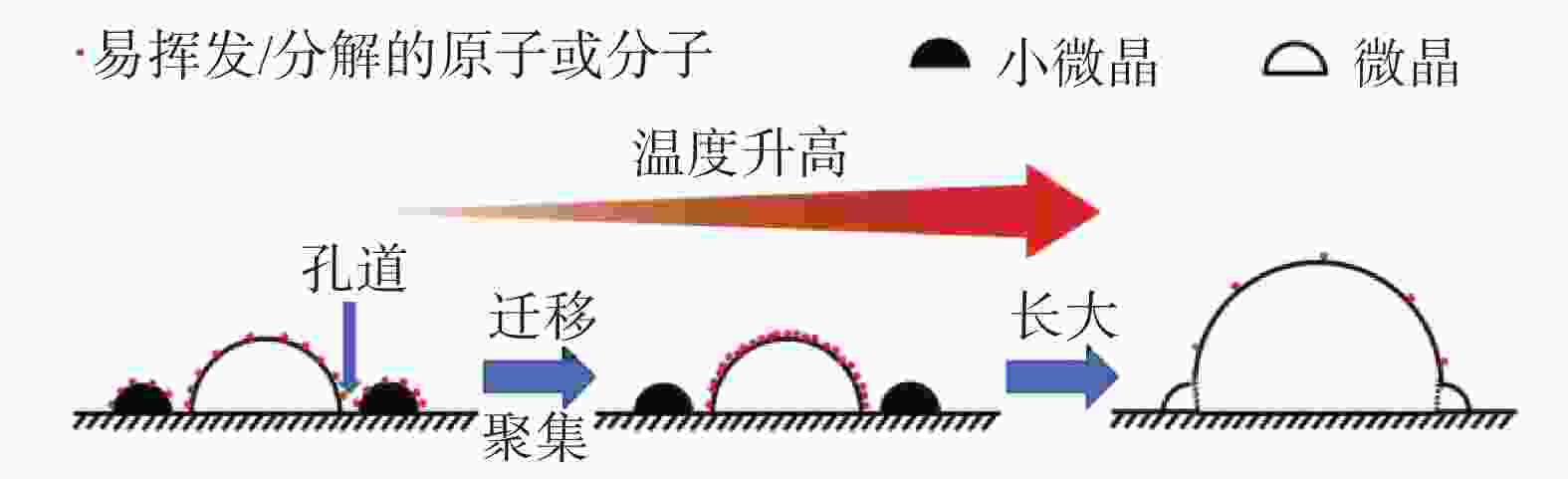

Lu Qiang, Wu Yachang, Xu Mingxin, et al. Progress in the development of SCR denitration catalysts with resistance of high-temperature deactivation[J]. Materials Reports, 2022,36(13):64-72. (陆强, 吴亚昌, 徐明新, 等. 抗高温失活SCR脱硝催化剂研究进展[J]. 材料导报, 2022,36(13):64-72. doi: 10.11896/cldb.20090242Lu Qiang, Wu Yachang, Xu Mingxin, et al. Progress in the development of SCR denitration catalysts with resistance of high-temperature deactivation[J]. Materials Reports, 2022, 36(13): 64-72. doi: 10.11896/cldb.20090242

|

| [32] |

Chapman David M. Behavior of titania-supported vanadia and tungsta SCR catalysts at high temperatures in reactant streams: Tungsten and vanadium oxide and hydroxide vapor pressure reduction by surficial stabilization[J]. Applied Catalysis A General, 2011,392(1-2):143-150. doi: 10.1016/j.apcata.2010.11.005

|

| [33] |

Lu Qiang, Pei Xinqi, Xu Mingxin, et al. Progress in the development and regeneration of SCR catalysts for anti-arsenic poisoning[J]. Chem Ind Eng Prog, 2021,40(5):2365-2374.

|

| [34] |

Wang Dong, Chen Qiuzhun, Zhang Xiang, et al. Multipollutant control (MPC) of flue gas from stationary sources using SCR technology: A critical review[J]. Environmental Science & Technology, 2021,55(7):2743-2766.

|

| [35] |

Chen Gongda, Xiong Shangchao, Chen Xiaoping, et al. Penetration of arsenic and deactivation of a honeycomb V2O5−WO3/TiO2 catalyst in a glass furnace[J]. Environmental Science & Technology, 2021,55:11368-11374.

|

| [36] |

Ding Long, Wang Yifan, Qian Lixin, et al. Flue gas deNOxing spent V2O5−WO3/TiO2 catalyst: A review of deactivation mechanisms and current disposal status[J]. Fuel, 2023,338:127268. doi: 10.1016/j.fuel.2022.127268

|

| [37] |

Xu Dong, Wu Wenhao, Wang Penglu, et al. Boosting the alkali/heavy metal poisoning resistance for NO removal by using iron-titanium pillared montmorillonite catalysts[J]. Journal of Hazardous Materials, 2020,399:122947. doi: 10.1016/j.jhazmat.2020.122947

|

| [38] |

Xu Liwen, Wu Qingru, Chang Huazhen, et al. Chemical deactivation of selective catalytic reduction catalyst: Investigating the influence and mechanism of SeO2 poisoning[J]. Fuel, 2020,269:117435. doi: 10.1016/j.fuel.2020.117435

|

| [39] |

Wu Yangwen, Zhou Xinyue, Hu Zhuang, et al. A comprehensive review of the heavy metal issues regarding commercial vanadium-titanium-based SCR catalyst[J]. Journals & Books, 2023,857:159712.

|

| [40] |

Wu Yangwen, Zhou Xinyue, Cai Qi, et al. Intrinsic mechanism insight of the interaction between lead species and the vanadium-based catalysts based on first-principles investigation[J]. Journal of Colloid and Interface Science, 2022,607:1362-1372. doi: 10.1016/j.jcis.2021.09.081

|

| [41] |

Wu Pengju, Tang Xianggang, He Zhaohui, et al. Alkali metal poisoning and regeneration of selective catalytic reduction denitration catalysts: recent advances and future perspectives[J]. Energy and Fuels, 2022,36(11):5622-5646. doi: 10.1021/acs.energyfuels.2c01036

|

| [42] |

Wu Yangwen, Zhou Xinyue, Mi Tengge, et al. First-principles insights into the adsorption and interaction mechanism of selenium on selective catalytic reduction catalyst[J]. Chemosphere, 2021,275:130057. doi: 10.1016/j.chemosphere.2021.130057

|

| [43] |

Liu Xianghui, Yang Qiaowen. Research on the deactivation mechanism of a denitration catalyst WO3–V2O5/TiO2 at a coal-fired power plant[J]. RSC Advances, 2020,10(72):44025-44033. doi: 10.1039/D0RA06812H

|

| [44] |

Granger Pascal, Siaka Hermann W, Umbarkar Shubhangi B. What news in the surface chemistry of bulk and supported vanadia based SCR-catalysts: Improvements in their resistance to poisoning and thermal sintering[J]. The Chemical Record, 2018,19(9):1813-1828.

|

| [45] |

Hu Xiaofu, Liu Xiuru, Chen Feng, et al. Research progress on deactivation mechanism and cyclic regeneration technology of tiv-based selective catalytic reduction NOx catalysts[C]//Proceedings of the 2018 National Academic Conference on Environmental Engineering (Volume 2). Beijing:《Environmental Engineering》Editorial, 2018: 253-259. (胡小夫, 刘秀如, 陈锋, 等. 钒钛系SCR脱硝催化剂失活机理及循环再生技术[C]//《环境工程》2018年全国学术年会论文集(中册). 北京:《环境工程》编辑部, 2018: 253-259.Hu Xiaofu, Liu Xiuru, Chen Feng, et al. Research progress on deactivation mechanism and cyclic regeneration technology of tiv-based selective catalytic reduction NOx catalysts[C]//Proceedings of the 2018 National Academic Conference on Environmental Engineering (Volume 2). Beijing:《Environmental Engineering》Editorial, 2018: 253-259.

|

| [46] |

Wang Bo, Yang Qiaowen. Optimization of roasting parameters for recovery of vanadium and tungsten from spent SCR catalyst with composite roasting[J]. Processes, 2021,9(11):1923. doi: 10.3390/pr9111923

|

| [47] |

Hubei Siboying Environmental Protection Technology Co., Ltd. A pre-dust removal device for a flue gas SCR denitration system: China, CN201821222137.1[P]. 2019-04-09. (湖北思搏盈环保科技有限公司. 一种烟气SCR脱硝系统预除尘装置: 中国,CN201821222137.1[P]. 2019-04-09.Hubei Siboying Environmental Protection Technology Co., Ltd.. A pre-dust removal device for a flue gas SCR denitration system: China, CN201821222137.1[P]. 2019-04-09.

|

| [48] |

Lei Yu. Research on large particle ash interceptor in SCR flue gas denitrification system[D]. Wuhan: Huazhong University of Science and Technology, 2022. (雷彧. SCR脱硝大颗粒灰拦截装置及技术研究[D]. 武汉:华中科技大学, 2022.Lei Yu. Research on large particle ash interceptor in SCR flue gas denitrification system[D]. Wuhan: Huazhong University of Science and Technology, 2022.

|

| [49] |

Zhang Changhui, Tian Yanfeng, Jiang Jianzhong. Cause analysis and preventive measures of SCR catalyst plugging in CFB boiler[J]. Journal of Electric Power, 2022,37(4):324-328. (张昌会, 田言峰, 江建忠. 循环流化床锅炉烟道型SCR催化剂堵灰原因分析和预防措施[J]. 电力学报, 2022,37(4):324-328.Zhang Changhui, Tian Yanfeng, Jiang Jianzhong. Cause analysis and preventive measures of SCR catalyst plugging in CFB boiler[J]. Journal of Electric Power, 2022, 37(4): 324-328.

|

| [50] |

Ren Fuchun, Ren Yujie, Zhang Jiping. Research on protection of denitrification catalyst by high-temperature dedusting before SCR for coal-fired boiler[J]. Journal of Energy Conservation, 2023,42(3):49-52. (任福春, 任育杰, 张纪平. 燃煤锅炉SCR前高温除尘对脱硝催化剂保护的研究[J]. 节能, 2023,42(3):49-52. doi: 10.3969/j.issn.1004-7948.2023.03.013Ren Fuchun, Ren Yujie, Zhang Jiping. Research on protection of denitrification catalyst by high-temperature dedusting before SCR for coal-fired boiler[J]. Journal of Energy Conservation, 2023, 42(3): 49-52. doi: 10.3969/j.issn.1004-7948.2023.03.013

|

| [51] |

Yu Wenchao, Wu Xiaodong, Si Zhichun, et al. Influences of impregnation procedure on the SCR activity and alkali resistance of V2O5−WO3/TiO2 catalyst[J]. Applied Surface Science, 2013,283:209-214.

|

| [52] |

Kong Ming, Liu Qingcai, Jiang Lijun, et al. K+ deactivation of V2O5−WO3/TiO2 catalyst during selective catalytic reduction of NO with NH3: Effect of vanadium content[J]. Chemical Engineering Journal, 2019,370:518-526. doi: 10.1016/j.cej.2019.03.156

|

| [53] |

Cao Jun, Liu Weizao, Kang Keke, et al. Effects of the morphology and crystal-plane of TiO2 on NH3-SCR performance and K tolerance of V2O5−WO3/TiO2 catalyst[J]. Applied Catalysis A: General, 2021,623:118285. doi: 10.1016/j.apcata.2021.118285

|

| [54] |

Peng Yaoyao, Song Lei, Lu Siru, et al. Superior resistance to alkali metal potassium of vanadium-based NH3-SCR catalyst promoted by the solid superacid SO42−−TiO2[J]. Chinese Journal of Chemical Engineering, 2023,55:246-256. doi: 10.1016/j.cjche.2022.05.031

|

| [55] |

Yan Zidi, Shi Xiaoyan, Yu Yunbo, et al. Alkali resistance promotion of Ce-doped vanadium-titanic- based NH3-SCR catalysts[J]. Journal of Environmental Sciences, 2018,73(11):155-161.

|

| [56] |

Guo Kai, Ji Jiawei, Song Wang, et al. Conquering ammonium bisulfate poison over low-temperature NH3-SCR catalysts: A critical review[J]. Applied Catalysis B: Environmental, 2021,297:120388. doi: 10.1016/j.apcatb.2021.120388

|

| [57] |

Wang Xiangmin, Du Xuesen, Zhang Li, et al. Promotion of NH4HSO4 decomposition in NO/NO2 contained atmosphere at low temperature over V2O5−WO3/TiO2 catalyst for NO reduction[J]. Applied Catalysis A General An International Journal Devoted to Catalytic Science & Its Applications, 2018,559:112-121.

|

| [58] |

Xin Qi, Yang Yang, Liu Shaojun, et al. Mass transfer of multi-pollutants over titania-based SCR catalyst: A molecular dynamics study[J]. Applied Energy, 2023,331:120450. doi: 10.1016/j.apenergy.2022.120450

|

| [59] |

Song Inhak, Lee Hwangho, Jeon Se Won, et al. Simple physical mixing of zeolite prevents sulfur deactivation of vanadia catalysts for NO x removal[J]. Nature Communications, 2021,12(1):901. doi: 10.1038/s41467-021-21228-x

|

| [60] |

Ye Dong, Qu Ruiyang, Liu Shaojun, et al. New insights into the decomposition behavior of NH4HSO4 on the SiO2-decorated SCR catalyst and its enhanced SO2 -resistant ability[J]. Acs Omega, 2019,4(3):4927-4935. doi: 10.1021/acsomega.8b03128

|

| [61] |

Jeon Se Won, Song Inhak, Lee Hwangho, et al. Enhanced SO2 resistance of V2O5/WO3-TiO2 catalyst physically mixed with alumina for the selective catalytic reduction of NO x with NH3[J]. Transactions of The Institution of Chemical Engineers. Process Safety and Environmental Protection, Part B, 2022,433(3):133836.

|

| [62] |

Jung Yoo Jin, Cha Jin Sun, Kim Beom Sik. Characteristics of deactivation and thermal regeneration of Nb-doped V2O5−WO3/TiO2 catalyst for NH3–SCR reaction[J]. Environmental Research, 2023,227:115744. doi: 10.1016/j.envres.2023.115744

|

| [63] |

Shin Jung Hun, Choi Gyeong Ryun, Hong Sung Chang. Vanadium catalyst based on a tungsten trioxide structure modified with antimony in NH3-selective catalytic reduction for improved low-temperature activity[J]. Applied Surface Science: A Journal Devoted to the Properties of Interfaces in Relation to the Synthesis and Behaviour of Materials, 2022,574:151571.

|

| [64] |

Chen Mengyin, Zhao Mengmeng, Tang Fushun, et al. Effect of Ce doping into V2O5−WO3/TiO2 catalysts on the selective catalytic reduction of NO x by NH3[J]. Journal of Rare Earths, 2017,35(12):1206-1215. doi: 10.1016/j.jre.2017.06.004

|

| [65] |

Guo Yangyang, Xu Xiaofei, Gao Hong, et al. Ca-poisoning effect on V2O5−WO3/TiO2 and V2O5−WO3-CeO2/TiO2 catalysts with different vanadium loading[J]. Catalysts, 2021,11:445. doi: 10.3390/catal11040445

|

| [66] |

Chen Mengmeng, Jin Qijie, Tao Xingjun, et al. Novel W-Zr-O-x /TiO2 catalyst for selective catalytic reduction of NO by NH3 at high temperature[J]. Catalysis Today, 2020,358:254-262. doi: 10.1016/j.cattod.2019.06.045

|

| [67] |

Shi Anju, Wang Xinquan, Yu Tie. The effect of zirconia additive on the activity and structure stability of V2O5−WO3/TiO2 ammonia SCR catalysts[J]. Applied Catalysis, B. Environmental: An International Journal Devoted to Catalytic Science and Its Applications, 2011,106(3/4):359-369.

|

| [68] |

Tan Piqiang, Chen Yingjie, Wang Zitong, et al. Experimental study of emission characteristics and performance of SCR coated on DPF with different catalyst washcoat loadings[J]. Fuel, 2023,346:128288. doi: 10.1016/j.fuel.2023.128288

|

| [69] |

Yu Hongchao, Yan Shejiao, Wu Feng, et al. Research on optimization of flue gas flow field in high temperature SCR denitration system of 110 m2 sintering machine in a steel plant[J]. Mining Engineering, 2023,21(2):57-60. (于宏超, 严社教, 武峰, 等. 某钢厂110 m2烧结机高温SCR脱硝系统烟气流场优化研究[J]. 矿业工程, 2023,21(2):57-60.Yu Hongchao, Yan Shejiao, Wu Feng, et al. Research on optimization of flue gas flow field in high temperature SCR denitration system of 110 m2 sintering machine in a steel plant[J]. Mining Engineering, 2023, 21(2): 57-60.

|

下载:

下载: