Effect of pre-strain on impact fracture behavior of X80 pipeline steel

-

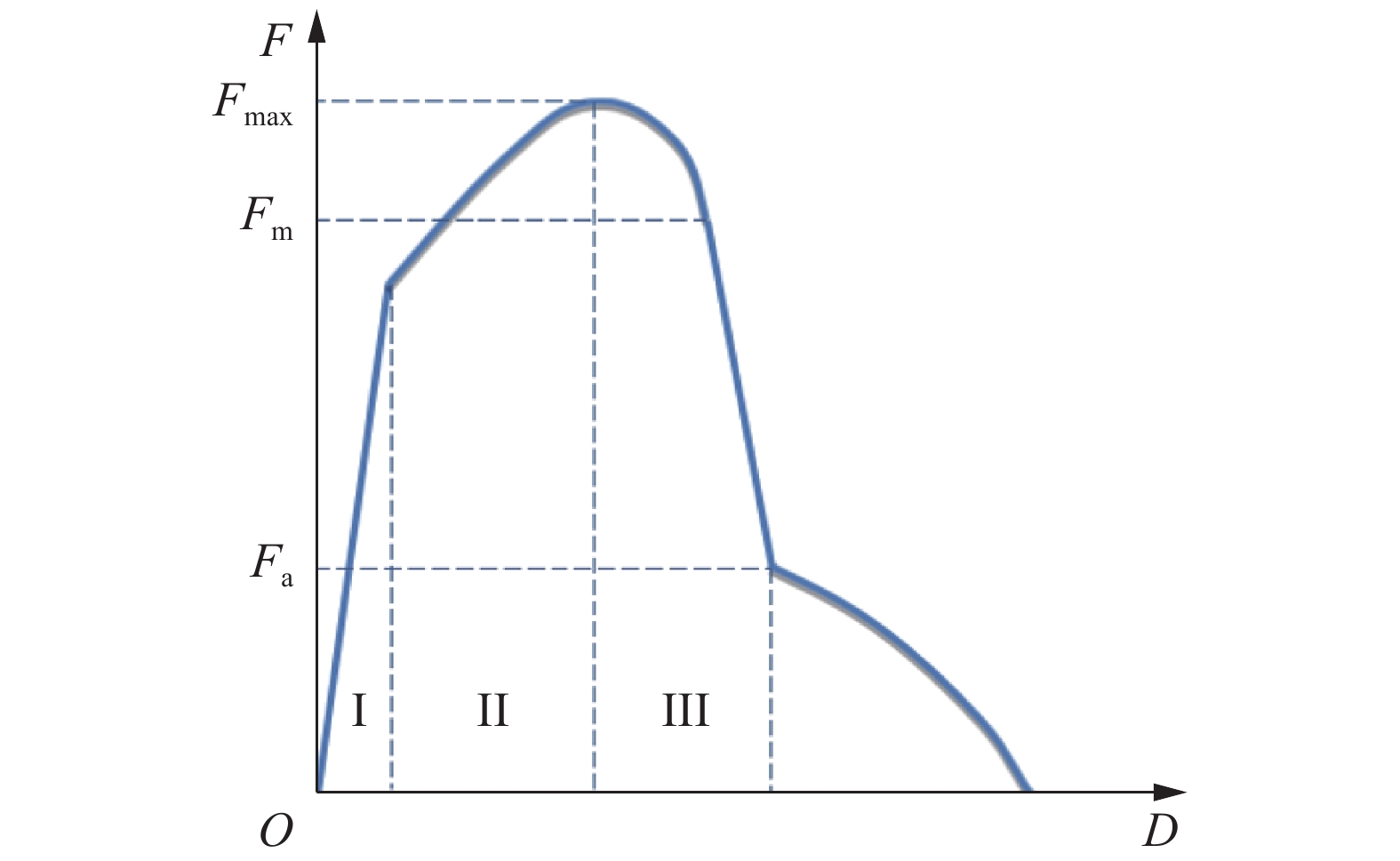

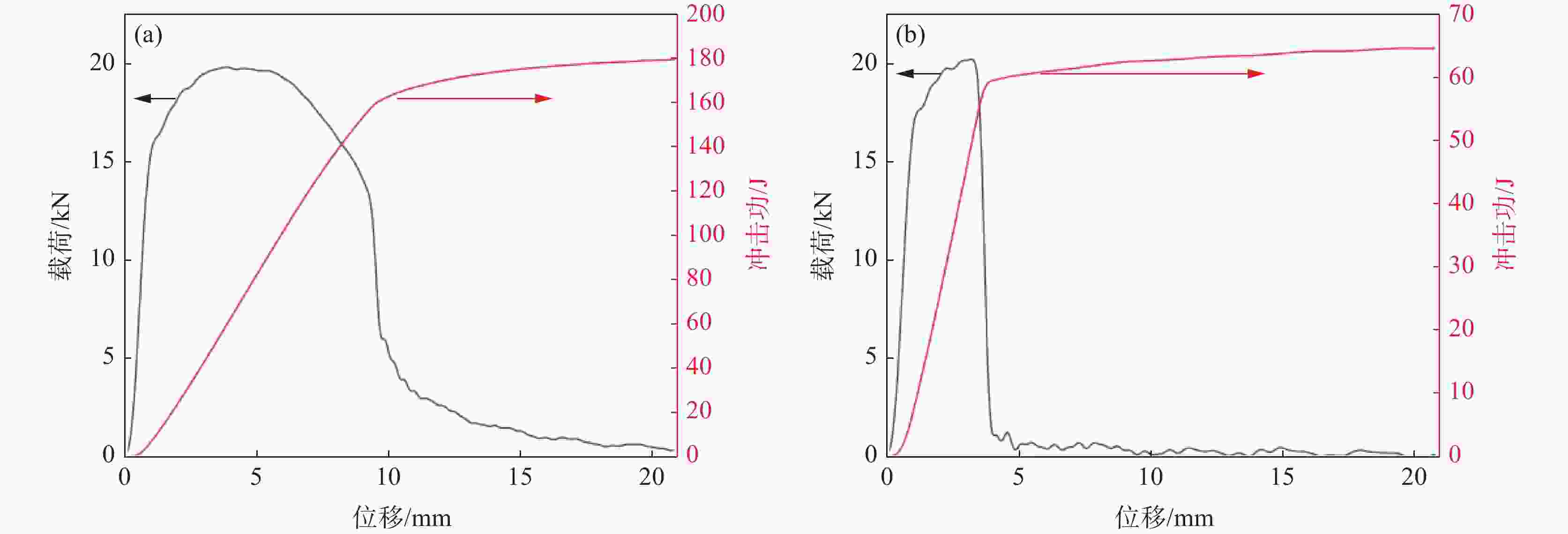

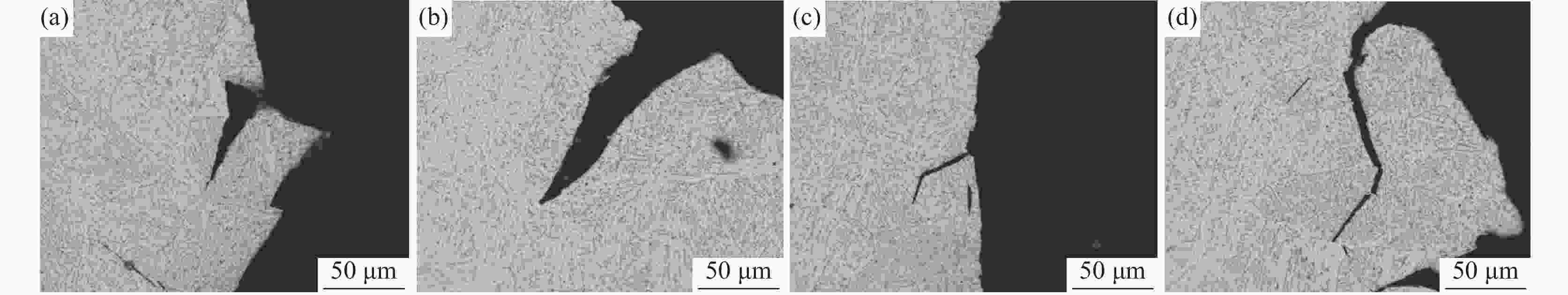

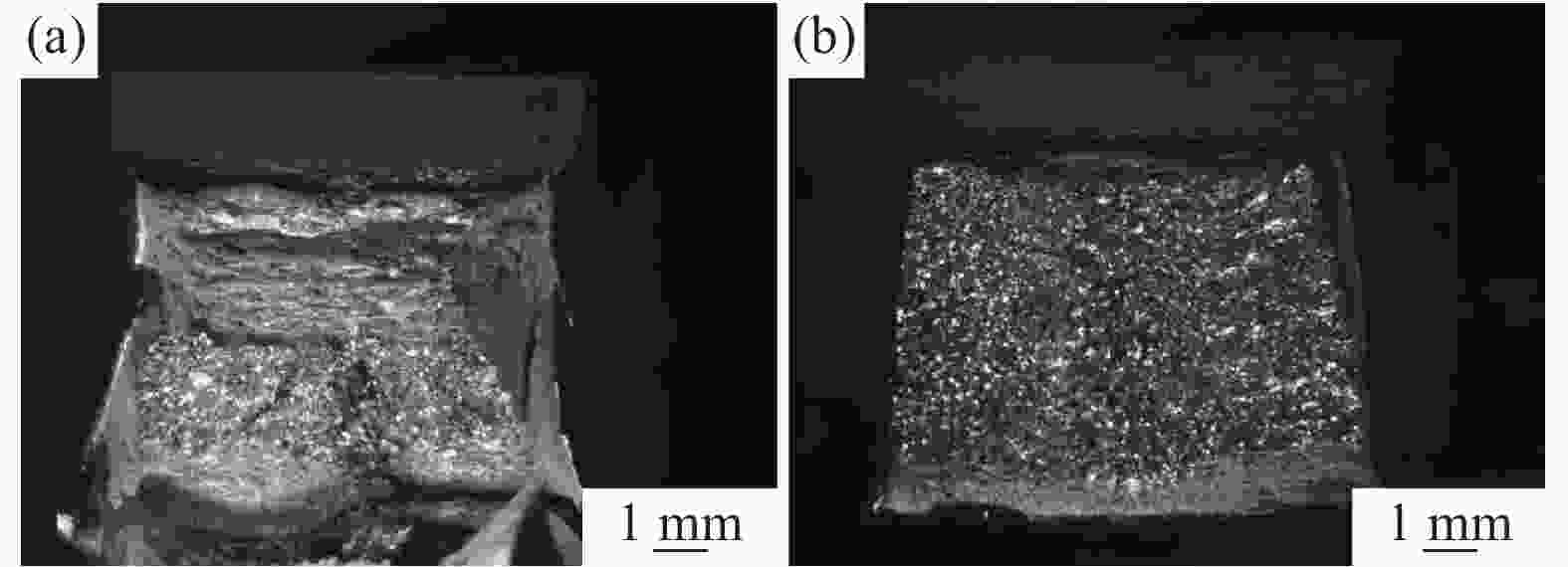

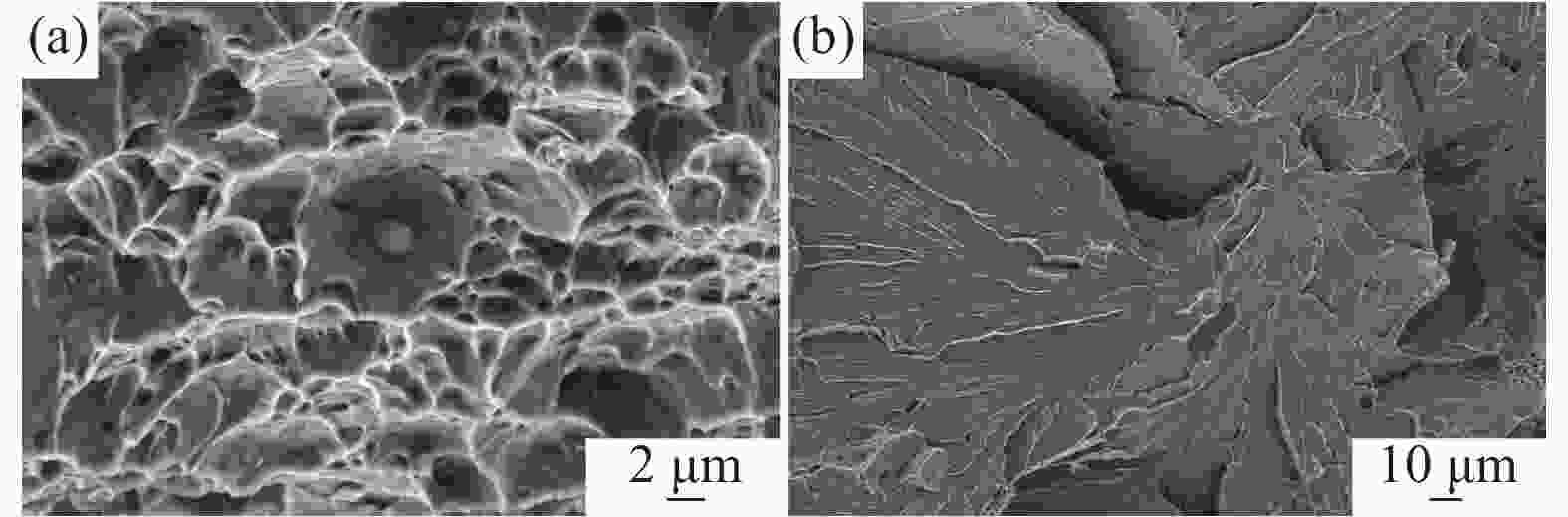

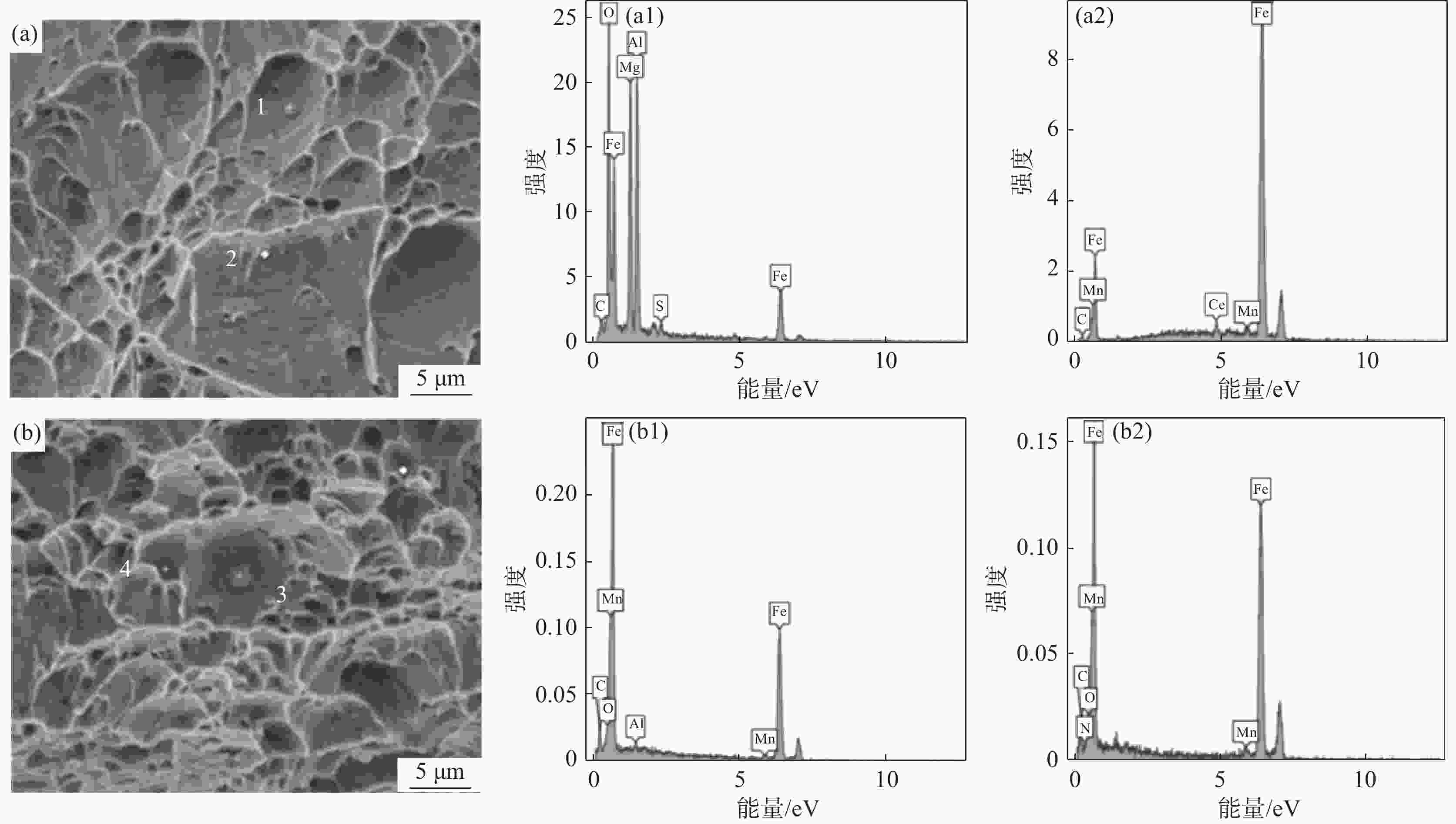

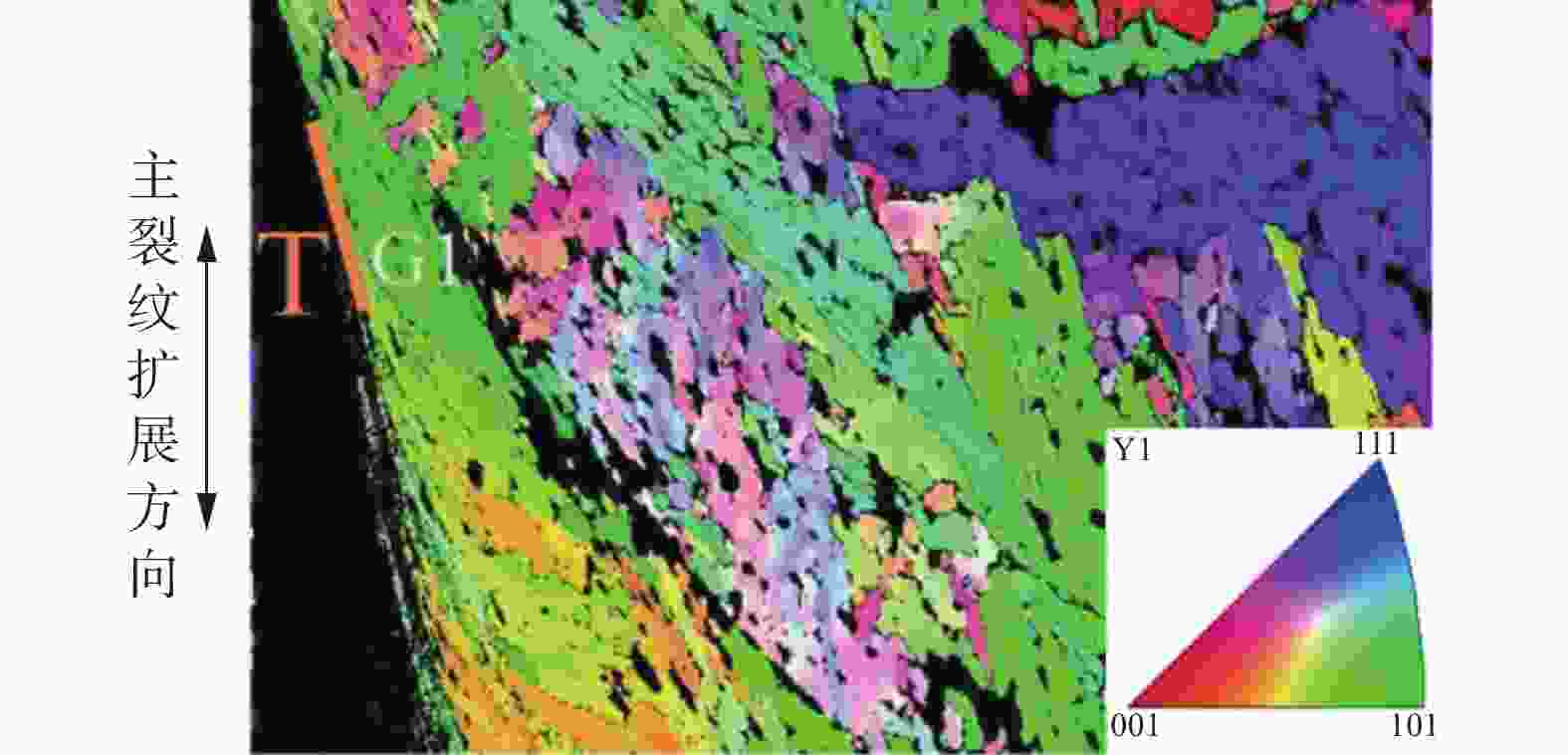

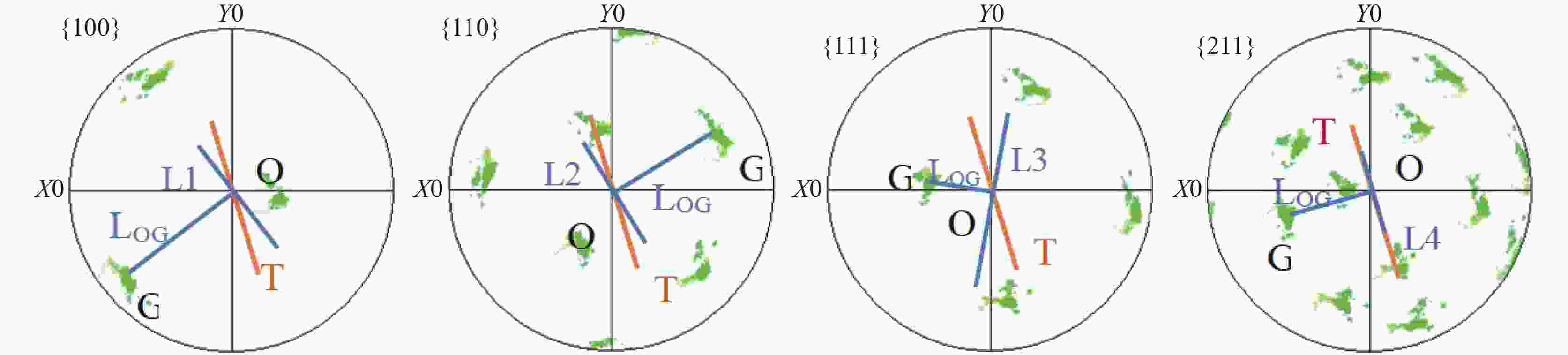

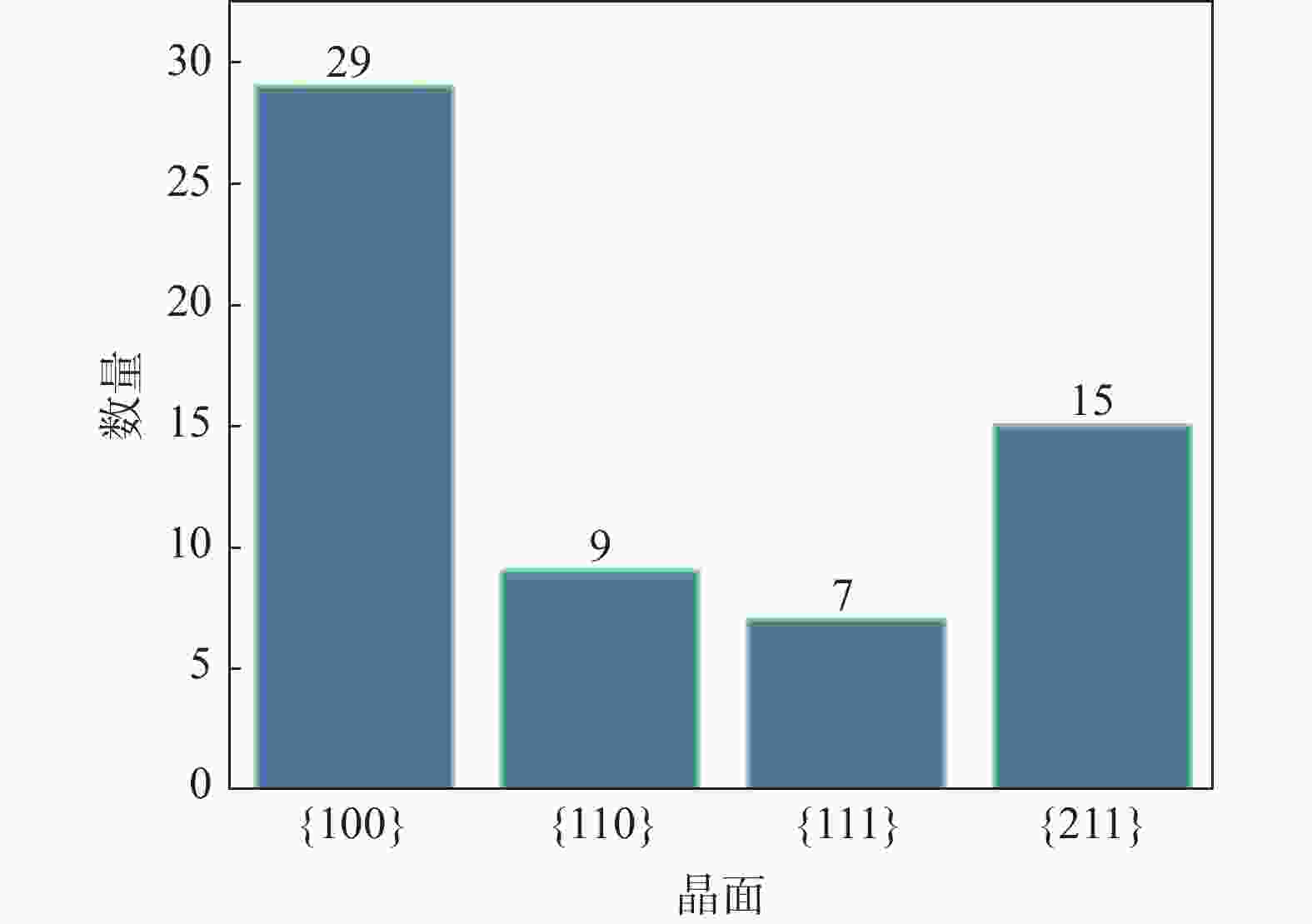

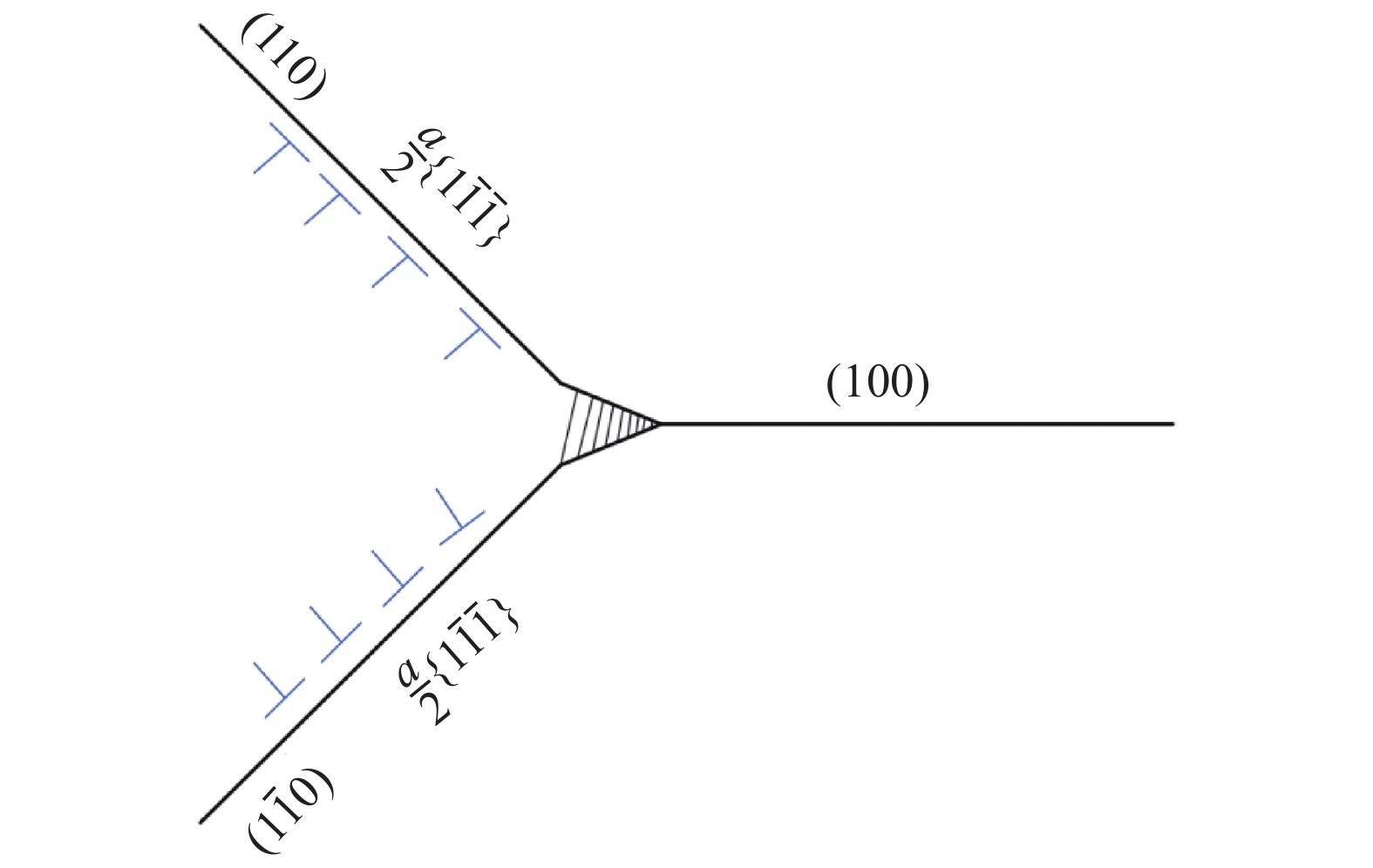

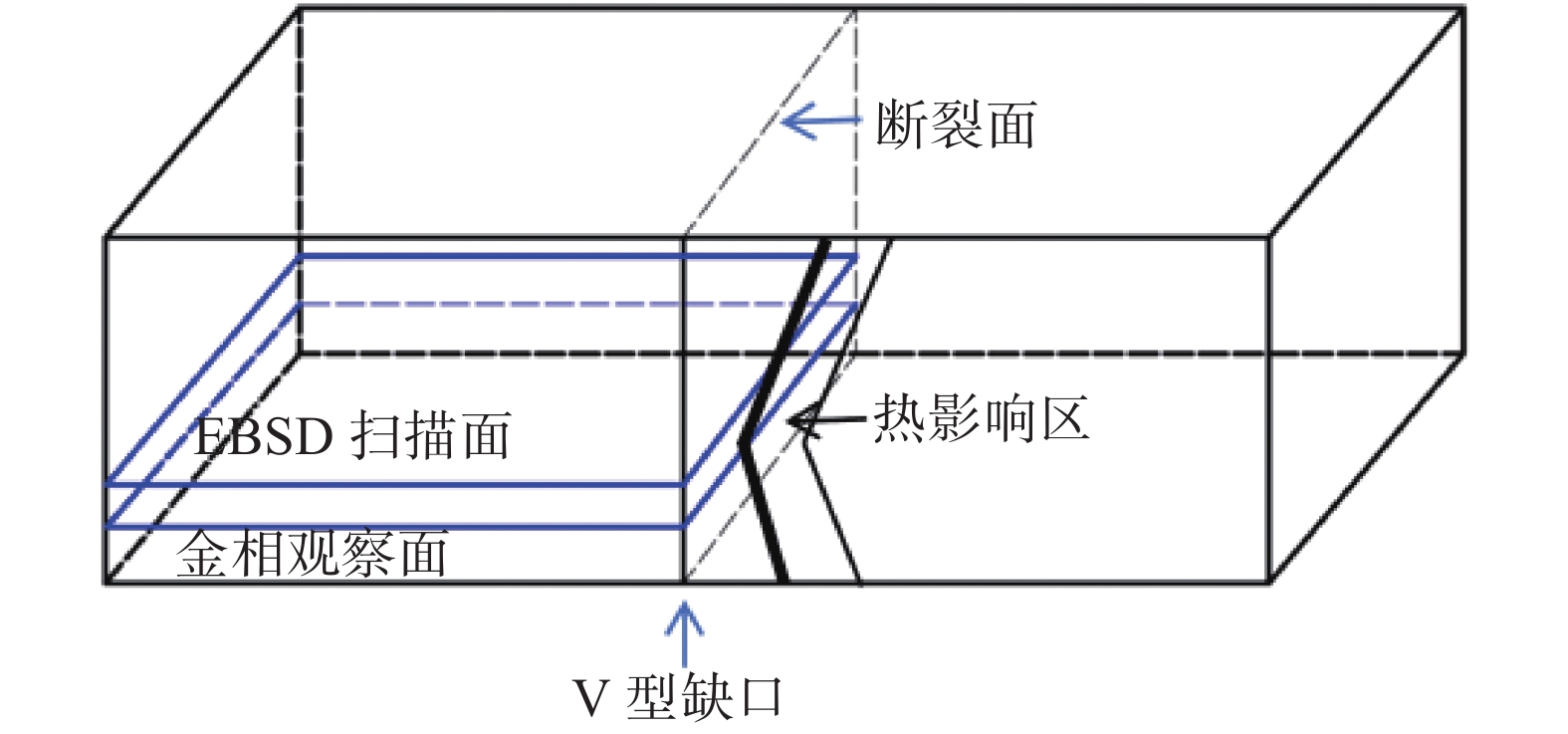

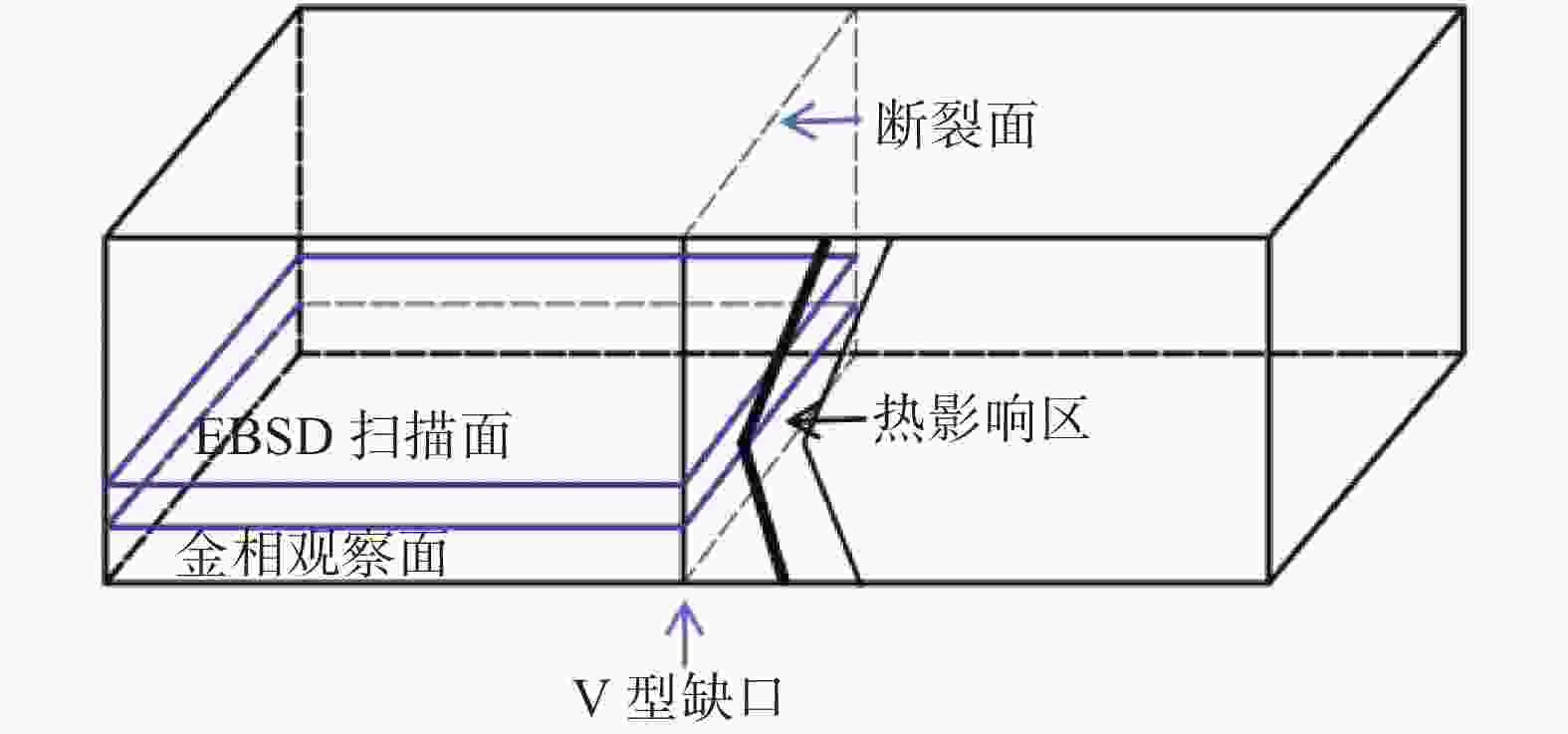

摘要: 开展了预应变对X80管线钢冲击断裂行为影响的研究,采用OM、SEM、EDS能谱对断口形貌及夹杂物进行分析,利用EBSD获取断口横截面上二次裂纹附近晶体学特征。结果表明,预应变对最大冲击载荷没有显著影响,但当材料中存在预应变时,材料脆性断裂趋势增加、缺口敏感度增加、裂纹形成功和材料对裂纹的止裂能力降低;在冲击断裂过程中,预应变导致材料内部位错相互缠结,位错运动受到阻碍,当受到外力时易发生脆性断裂,同时材料内部的脆性夹杂物也是裂纹源。由于相邻晶粒之间存在取向差,裂纹扩展遇到晶界时,裂纹的扩展路径进入下一个晶粒时发生偏转。此外对横截面近断口区晶体取向进行分析,发现X80管线钢的主要解理面为{100},其次为{211}。Abstract: The influence of pre-strain on the impact fracture behavior of X80 pipeline steel was studied. Fracture morphology and inclusions were analyzed by OM, SEM, EDS spectroscopy, and the crystallographic characteristics near the secondary crack on the fracture cross-section were obtained by EBSD. The results show that the pre-strain has no significant effect on the maximum impact load, but pre-strain will increase brittle fracture tendency and notch sensitivity, which leads to decreasing the crack formation energy and crack resistance. In the process of impact fracture, the pre-strain causes the internal dislocations of the material to become entangled with each other, and dislocation movement is hindered. Therefore, brittle fracture is easy to occur when the material is subjected to external force, and the brittle inclusions inside the material also act as the source of cracks. Due to the misorientation between adjacent grains, when the crack propagation encounters the grain boundary, the crack propagation path is deflected when it enters the next grain. In addition, analysis on the crystal orientation of the cross-section near the fracture area indicated that the main cleavage plane of X80 pipeline steel was {100}, followed by {211}.

-

Key words:

- X80 pipeline steel /

- impact fracture /

- pre-strain /

- cleaved surface

-

表 1 焊缝处化学成分

Table 1. Chemical composition of the weld

% C Si Mn P S V+Nb+Ti Cu Ni Cr Mo Fe 0.057 0.11 1.37 0.01 0.0004 0.022 0.001 1.7 0.07 0.03 Bal. -

[1] Sun Hua, Sun Yanhui, Wang Shuai, et al. Formation mechanism of abnormal carbide in API X80 pipeline steel[J]. Journal of Materials and Heat Treatment, 2011,32(6):45-50. (孙华, 孙彦辉, 王帅, 等. API X80管线钢异常碳化物形成机理[J]. 材料热处理学报, 2011,32(6):45-50.Sun Hua, Sun Yanhui, Wang Shuai, et al. Formation mechanism of abnormal carbide in API X80 pipeline steel[J]. Journal of Materials and Heat Treatment, 2011, 32(6): 45-50. [2] Liu Gan, Kong Xianglei, Huang Minghao, et al. Effect of post-rolling cooling process on microstructure of high-capacity X80M pipeline steel[J]. China Metallurgy, 2023,32(9):1-8. (刘干, 孔祥磊, 黄明浩, 等. 轧后冷却工艺对大输量X80M管线钢显微组织的影响[J]. 中国冶金, 2023,32(9):1-8.Liu Gan, Kong Xianglei, Huang Minghao, et al. Effect of post-rolling cooling process on microstructure of high-capacity X80M pipeline steel[J]. China Metallurgy, 2023, 32(9): 1-8. [3] Song Ming, Wang Hankui, Xu Tong, et al. Research on girth weld fracture of high-steel grade oil and gas pipelines[J]. China Special Equipment Safety, 2021,37(5):93-97, 101. (宋明, 王汉奎, 徐彤, 等. 高钢级油气管道环焊缝断裂问题研究[J]. 中国特种设备安全, 2021,37(5):93-97, 101.Song Ming, Wang Hankui, Xu Tong, et al. Research on girth weld fracture of high-steel grade oil and gas pipelines[J]. China Special Equipment Safety, 2021, 37(5): 93-97, 101. [4] Wang Hankui, Shang Xuexin, Liu Wang, et al. Research on strain aging embrittlement of girth weld of high-steel grade oil and gas pipelines[J]. Pressure Vessel, 2021,38(5):8-13. (王汉奎, 商学欣, 柳旺, 等. 高钢级油气管线环焊缝应变时效脆化研究[J]. 压力容器, 2021,38(5):8-13.Wang Hankui, Shang Xuexin, Liu Wang, et al. Research on strain aging embrittlement of girth weld of high-steel grade oil and gas pipelines[J]. Pressure Vessel, 2021, 38(5): 8-13. [5] Luo Kai, Wang Yunhui, Zhu Liaoyu, et al. Risk assessment method of girth weld failure of oil and gas pipeline based on two-dimensional cloud model[J]. World Petroleum Industry, 2023,30(3):75-81. (罗凯, 王云辉, 朱辽宇, 等. 基于二维云模型的油气管道环焊缝失效风险评价方法[J]. 世界石油工业, 2023,30(3):75-81.Luo Kai, Wang Yunhui, Zhu Liaoyu, et al. Risk assessment method of girth weld failure of oil and gas pipeline based on two-dimensional cloud model[J]. World Petroleum Industry, 2023, 30(3): 75-81. [6] Wu Lin’en, Liu Yu, Xia Peipei, et al. Effect of heat input on metal microstructure properties of X80 grade gas shielded flux-cored welding wire[J]. Electric Welding Machine, 2023,53(10):90-96, 114. (吴林恩, 刘宇, 夏培培, 等. 热输入对X80级气保护药芯焊丝焊缝金属组织性能的影响[J]. 电焊机, 2023,53(10):90-96, 114.Wu Lin’en, Liu Yu, Xia Peipei, et al. Effect of heat input on metal microstructure properties of X80 grade gas shielded flux-cored welding wire[J]. Electric Welding Machine, 2023, 53(10): 90-96, 114. [7] Wu Gang, Luo Jinheng, Xu Guangda, et al. Effect of pre-strain on strain response characteristics and tensile properties of X80 pipeline steel with weld zone[J]. Natural Gas Industry, 2019,39(7):120-126. (武刚, 罗金恒, 许光达, 等. 预应变对含焊缝区X80管线钢应变响应特征及拉伸性能的影响[J]. 天然气工业, 2019,39(7):120-126.Wu Gang, Luo Jinheng, Xu Guangda, et al. Effect of pre-strain on strain response characteristics and tensile properties of X80 pipeline steel with weld zone[J]. Natural Gas Industry, 2019, 39(7): 120-126. [8] Shu Delin. Mechanical properties of engineering materials[M]. Beijing: China Machine Press, 2004: 30-53. (束德林. 工程材料力学性能[M]. 北京: 机械工业出版社, 2004: 30-53.Shu Delin. Mechanical properties of engineering materials[M]. Beijing: China Machine Press, 2004: 30-53. [9] Chen Jianqiao. Strength of engineering materials[M]. Wuhan: Huazhong University of Science and Technology Press, 2008: 100. (陈建桥. 材料强度学[M]. 武汉: 华中科技大学出版社, 2008: 100.Chen Jianqiao. Strength of engineering materials[M]. Wuhan: Huazhong University of Science and Technology Press, 2008: 100. [10] Deng Wei, Gao Xiuhua, Qin Xiaomei, et al. Impact fracture behavior of X80 pipeline steel[J]. Acta Metallurgica Sinica, 2010,46(5):533-540. (邓伟, 高秀华, 秦小梅, 等. X80管线钢的冲击断裂行为[J]. 金属学报, 2010,46(5):533-540. doi: 10.3724/SP.J.1037.2009.00461Deng Wei, Gao Xiuhua, Qin Xiaomei, et al. Impact fracture behavior of X80 pipeline steel[J]. Acta Metallurgica Sinica, 2010, 46(5): 533-540. doi: 10.3724/SP.J.1037.2009.00461 [11] Liu Xue, Zhong Shifang, Xu Lianyong, et al. Corrosion fatigue behavior of X65 pipeline steel welded joints under different stress amplitudes[J]. Journal of Welding Society, 2023,44(7):24-31. (刘雪, 钟史放, 徐连勇, 等. 不同应力幅下X65管线钢焊接接头的腐蚀疲劳行为[J]. 焊接学报, 2023,44(7):24-31.Liu Xue, Zhong Shifang, Xu Lianyong, et al. Corrosion fatigue behavior of X65 pipeline steel welded joints under different stress amplitudes[J]. Journal of Welding Society, 2023, 44(7): 24-31. [12] Yang Xiaowei, Zhou Yun, Chen Huande, et al. Effect of cooling control process on microstructure and refractory mechanism of Mo-Cr-Nb refractory steel bar[J]. Thermal Processing Technology, 2023(22):99-103. (杨晓伟, 周云, 陈焕德, 等. 控冷工艺对Mo-Cr-Nb耐火钢筋组织性能的影响及耐火机理研究[J]. 热加工工艺, 2023(22):99-103.Yang Xiaowei, Zhou Yun, Chen Huande, et al. Effect of cooling control process on microstructure and refractory mechanism of Mo-Cr-Nb refractory steel bar[J]. Thermal Processing Technology, 2023(22): 99-103. [13] Guo Wenbin, Xiao Pengcheng, Yao Jingwen, et al. Development practice of large-line energy welding series hull steel[J]. Wide and Heavy Plate, 2023,29(4):13-16. (郭文斌, 肖鹏程, 么敬文, 等. 大线能量焊接系列船体钢开发实践[J]. 宽厚板, 2023,29(4):13-16.Guo Wenbin, Xiao Pengcheng, Yao Jingwen, et al. Development practice of large-line energy welding series hull steel[J]. Wide and Heavy Plate, 2023, 29(4): 13-16. [14] Liu Min, Lu Meipeng, Liu Jiachen, et al. Analysis on the causes of head cracking of sour gas aftercooler[J]. Metal Heat Treatment, 2023,48(8):265-271. (刘民, 鲁美朋, 刘嘉晨, 等. 酸气后冷器封头开裂原因分析[J]. 金属热处理, 2023,48(8):265-271.Liu Min, Lu Meipeng, Liu Jiachen, et al. Analysis on the causes of head cracking of sour gas aftercooler[J]. Metal Heat Treatment, 2023, 48(8): 265-271. [15] Davies P A, Novovic M, Randle V, et al. Application of electron backscatter diffraction (EBSD) to fracture studies of ferritic steels[J]. Journal of Microscopy, 2010, 205(3): 278-284. [16] Mohseni P, Solberg J K, Karlsen M, et al. Application of combined EBSD and 3D-SEM technique on crystallographic facet analysis of steel at low temperature[J]. Journal of Microscopy, 2013, 251(1): 45-56. [17] An Qi. Study on low temperature mechanical behavior and compositional phase interaction of tin-lead alloy[D]. Harbin: Harbin Institute of Technology, 2022. (安琪. 锡铅合金低温力学行为及组成相交互作用研究[D]. 哈尔滨: 哈尔滨工业大学, 2022.An Qi. Study on low temperature mechanical behavior and compositional phase interaction of tin-lead alloy[D]. Harbin: Harbin Institute of Technology, 2022. [18] Aghemenloh E, Umukoro J O, Azi S O, et al. Surface energy calculation of bcc metals using the analytical equivalent crystal theory method[J]. Materials Chemistry and Physics, 2011, 50(12): 3290-3296. -

下载:

下载: