Study on the influence of Si addition on the mechanical properties of high Mn-N type TWIP stainless steels

-

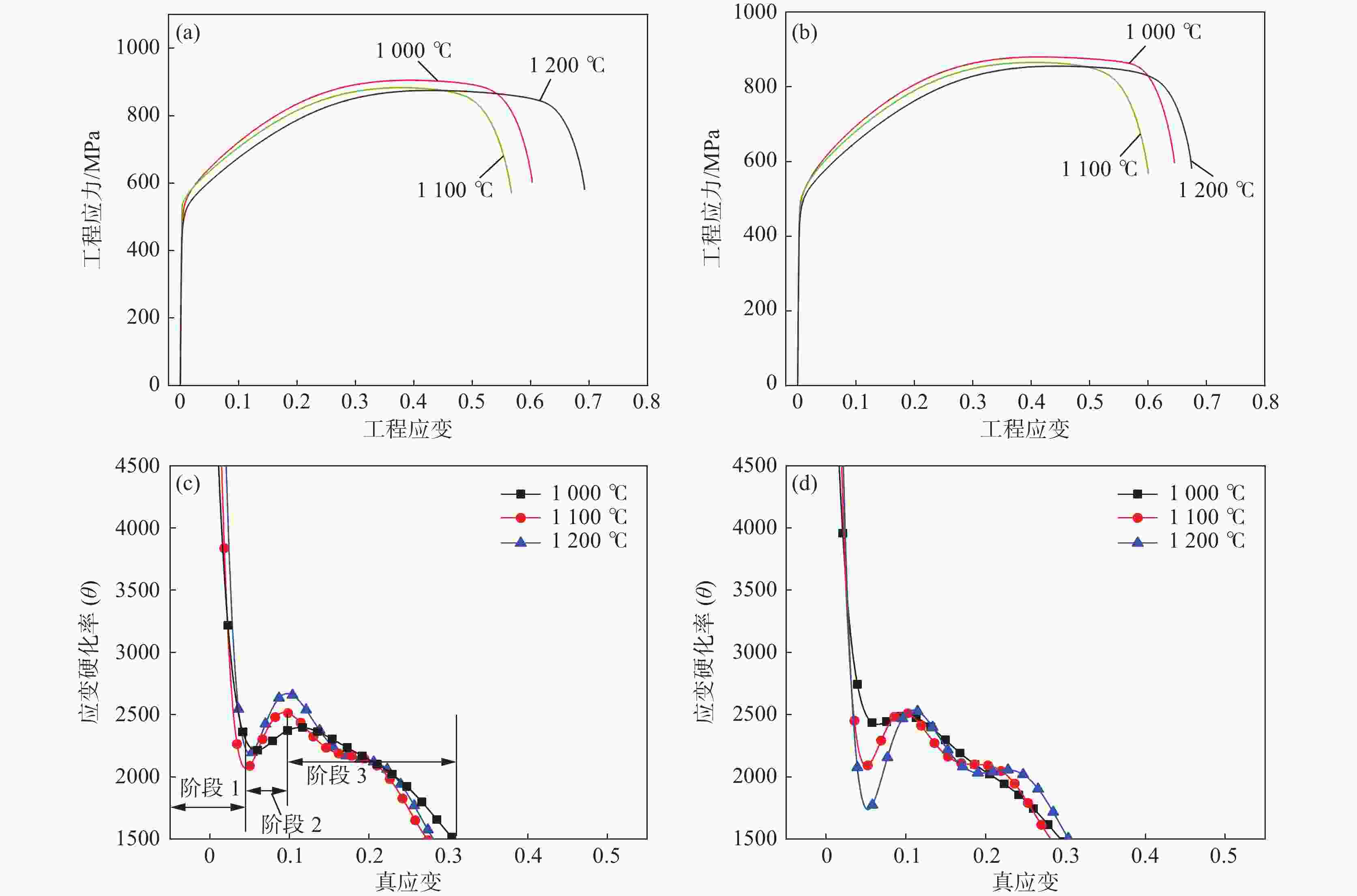

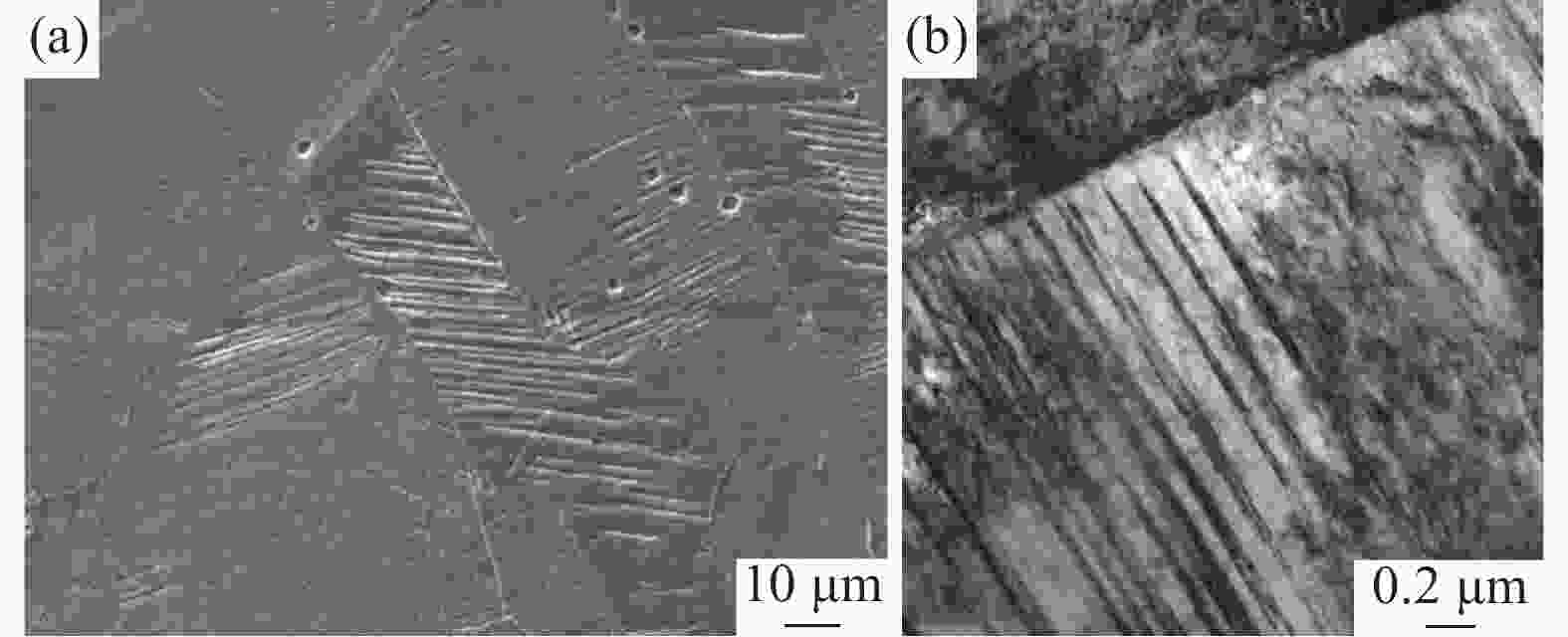

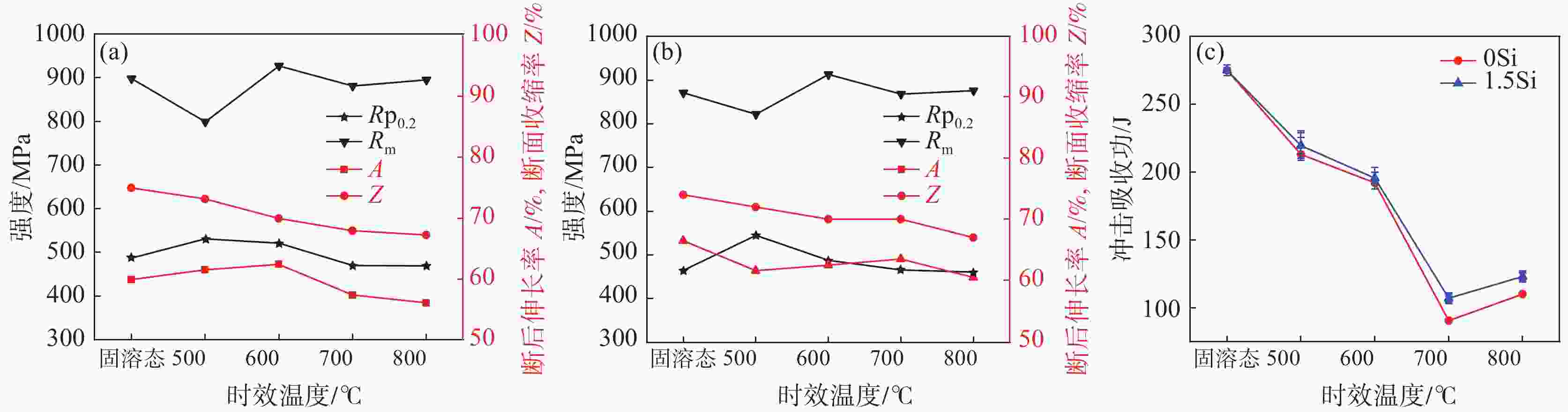

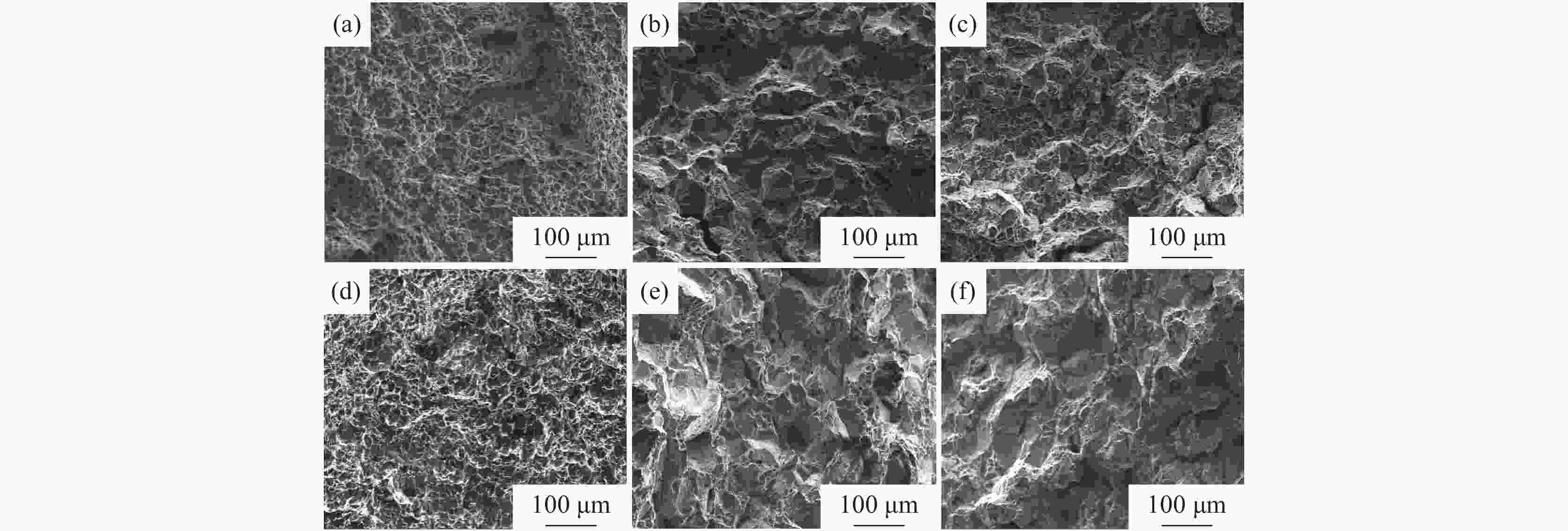

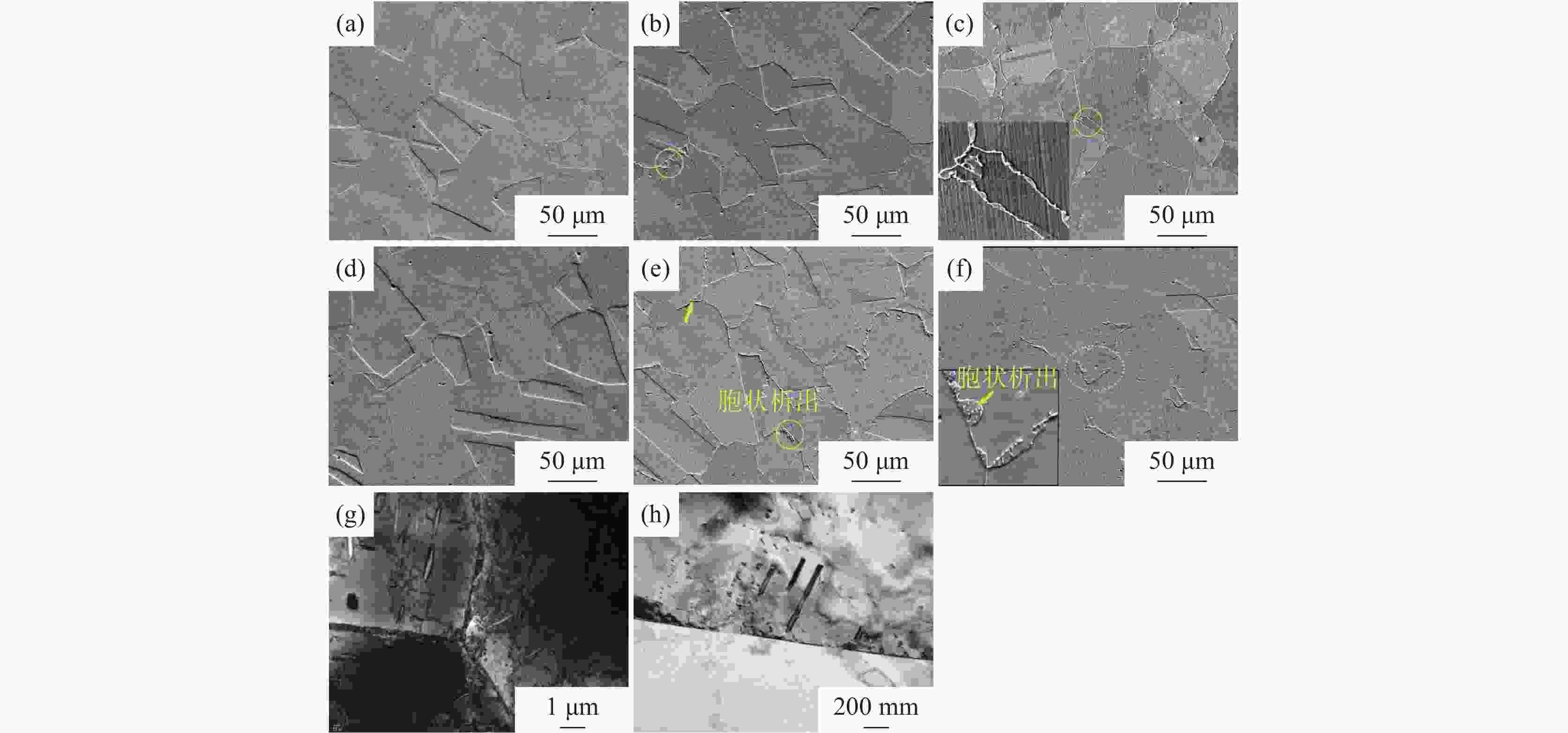

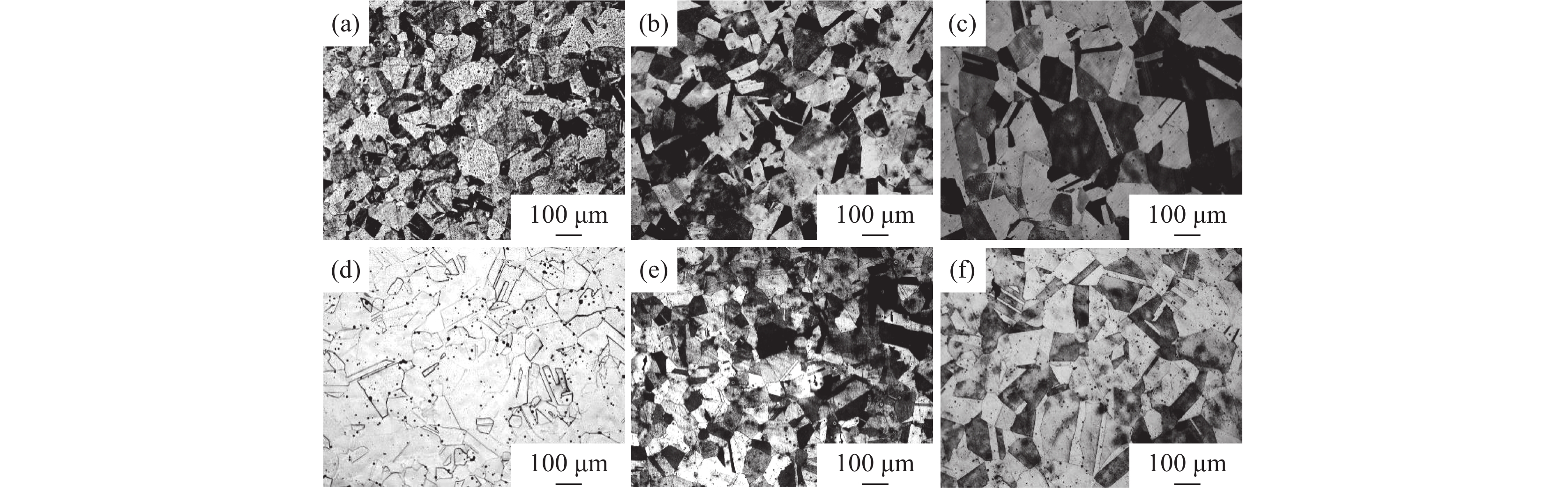

摘要: 利用SEM、TEM等分析手段研究了不同热处理工艺制度对1.5% Si添加后的高Mn-N TWIP不锈钢显微组织和力学性能的影响。结果发现,试验钢退火孪晶厚度随着固溶温度的升高而增大,在高的固溶温度下,Si添加可以提高合金的应变硬化率,拉伸变形过程中生成大量细长的形变孪晶可以有效阻碍位错滑移,提高材料强度与塑性。时效处理对拉伸性能影响较小,在700~800 ℃时效过程中生成大量晶界胞状析出物,胞状析出以短棒状Cr2N为主,在冲击载荷作用下会发生沿晶脆性断裂,冲击吸收功快速降低。Abstract: The effects of different heat treatment processes on the microstructure and mechanical properties of high Mn-N TWIP stainless steels with 1.5% Si addition were studied by SEM and TEM. The results showed that the annealing twin thickness of the tested steel increased with the increase in solution temperature. At high solution temperatures, Si was added to improve the strain hardening rate of the alloy. A large number of slender deformation twins were generated during tensile deformation, which can effectively prevent dislocation slip and improve materials strength and plasticity. The effect of aging treatment on the materials tensile properties was relatively small. During the aging process at 700~800 ℃, a large amount of grain boundary cellular precipitates were generated, which were mainly composed of short rod-shaped Cr2N particles. Under impacting loads, intergranular brittle fracture occurred, and the impact absorption energy decreased rapidly.

-

Key words:

- TWIP stainless steel /

- Si /

- precipitated phase /

- intergranular fracture /

- impact toughness

-

表 1 试验料冶炼化学成分

Table 1. Smelting chemical compositions of the tested materials

% 试样 Cr Mn Ni Si N C Fe 0Si 18.92 25.20 3.97 0.11 0.70 0.021 Bal. 1.5Si 19.02 23.98 3.99 1.55 0.71 0.018 Bal. -

[1] Li Yizhuang, Huang Mingxin. A method to calculate the dislocation density of a TWIP steel based on neutron diffraction and synchrotron X-Ray diffraction[J]. Acta Metallurgica Sinica, 2020,56(4):487-493. (李亦庄, 黄明欣. 基于中子衍射和同步辐射X射线衍射的TWIP钢位错密度计算方法[J]. 金属学报, 2020,56(4):487-493. doi: 10.11900/0412.1961.2020.00016Li Yizhuang, Huang Mingxin. A method to calculate the dislocation density of a TWIP steel based on neutron diffraction and synchrotron X-Ray diffraction[J]. Acta Metallurgica Sinica, 2020, 56(4): 487-493. doi: 10.11900/0412.1961.2020.00016 [2] Cui Xiaowen, Zhang Guijie, Lin Shaofeng. Effect of Mn content on microstructure and properties of hot rolled TWIP steel[J]. Transactions of Materials and Heat Treatment, 2022,43(1):92-98. (崔潇文, 张贵杰, 林绍峰. Mn含量对热轧TWIP钢组织性能的影响[J]. 材料热处理学报, 2022,43(1):92-98.Cui Xiaowen, Zhang Guijie, Lin Shaofeng. Effect of Mn content on microstructure and properties of hot rolled TWIP steel[J]. Transactions of Materials and Heat Treatment, 2022, 43(1): 92-98. [3] Grässel O, Krüger L, Frommeyer G, et al. High strength Fe-Mn-(Al, Si) TRIP/TWIP steels development-properties- application[J]. International Journal of Plasticity, 2000,16(10-11):1391-1409. doi: 10.1016/S0749-6419(00)00015-2 [4] Dai Yongjuan, Li Hui, Feng Jie, et al. Effect of annealing time and cooling methods on the microstructure and mechanical properties of Fe-28Mn-2.8Si-2.2Al-TWIP steel[J]. Chinese Journal of Engineering, 2016, 38(1): 238-242. (代永娟, 李辉, 冯捷, 等. 保温时间和冷却方式对 Fe-28 Mn-2.8Si-2.2Al-TWIP钢组织和力学性能的影响[J]. 工程科学学报, 2016, 38(1): 238-242.Dai Yongjuan, Li Hui, Feng Jie, et al. Effect of annealing time and cooling methods on the microstructure and mechanical properties of Fe-28Mn-2.8Si-2.2Al-TWIP steel[J]. Chinese Journal of Engineering, 2016, 38(1): 238-242. [5] Lan Peng, Song Lina, Du Chenwei, et al. Research progress on stacking fault energy in high manganese TWIP steel[J]. Journal of Iron and Steel Research, 2015,27(1):1-6. (兰鹏, 宋丽娜, 杜辰伟,等. 高锰TWIP钢层错能的研究进展[J]. 钢铁研究学报, 2015,27(1):1-6.Lan Peng, Song Lina, Du Chenwei, et al. Research progress on stacking fault energy in high manganese TWIP steel[J]. Journal of Iron and Steel Research, 2015, 27(1): 1-6. [6] Zeng Zeyao, Yang Gang, Yang Yinhui, et al. Study on stacking fault energy calculation, plastic toughness and corrosion resistance properties of TWIP stainless steel[J]. Journal of Iron and Steel Research, 2021, 33(5): 443-451. (曾泽瑶, 杨钢, 杨银辉, 等. TWIP不锈钢层错能计算, 塑韧性和耐蚀性能研究[J]. 钢铁研究学报, 2021, 33(5): 443-451.Zeng Zeyao, Yang Gang, Yang Yinhui, et al. Study on stacking fault energy calculation, plastic toughness and corrosion resistance properties of TWIP stainless steel[J]. Journal of Iron and Steel Research, 2021, 33(5): 443-451. [7] Li Huayin, Ding Hua, Cai Zhihui, et al. Effect of solid solution treatment on microstructure and properties of Fe-25Mn-1Al-0.2C steel [J]. Transactions of Materials and Heat Treatment, 2012, 33(9): 70-74. (李华英, 丁桦, 蔡志辉, 等. 固溶处理对Fe-25Mn-1Al-0.2C钢组织性能的影响[J]. 材料热处理学报, 2012, 33(9): 70-74.Li Huayin, Ding Hua, Cai Zhihui, et al. Effect of solid solution treatment on microstructure and properties of Fe-25Mn-1Al-0.2C steel [J]. Transactions of Materials and Heat Treatment, 2012, 33(9): 70-74. [8] Li Dejun, Feng Yaorong, Yin Zhifu, et al. Prediction of hot deformation behavior of Fe–25Mn–3Si–3Al TWIP steel[J]. Materials Science & Engineering A, 2011,528(28):8084-8089. [9] Li Xiaoyuan, Shi Jie, Sun Ting. Effect of finish rolling temperature on microstructure and mechanical properties of high nitrogen austenitic steel[J]. China Metallurgy, 2020, 30(5): 29-34. (李晓源, 时捷, 孙挺. 终轧温度对高氮奥氏体钢组织和力学性能的影响[J]. 中国冶金, 2020, 30(5): 6.Li Xiaoyuan, Shi Jie, Sun Ting. Effect of finish rolling temperature on microstructure and mechanical properties of high nitrogen austenitic steel[J]. China Metallurgy, 2020, 30(5): 29-34. [10] Ning Xiaozhi, Xing Changjun, Yong Qilong, et al. Effect of nitrogen content on mechanical properties of nickel-free austenitic stainless steel[J]. China Metallurgy, 2019,29(5):53-57. (宁小智, 邢长军, 雍歧龙, 等. 氮含量对无镍奥氏体不锈钢力学性能的影响[J]. 中国冶金, 2019,29(5):53-57.Ning Xiaozhi, Xing Changjun, Yong Qilong, et al. Effect of nitrogen content on mechanical properties of nickel-free austenitic stainless steel[J]. China Metallurgy, 2019, 29(5): 53-57. [11] Dai Yongjuan, Tang Di, Mi Zhenli, et al. The influence of manganese on stacking fault energy and deformation mechanism of the TWIP steel[J]. Material Engineering, 2009(7): 39-42. (代永娟, 唐荻, 米振莉, 等. 锰元素对TWIP钢层错能和变形机制的影响[J]. 材料工程, 2009(7): 39-42.Dai Yongjuan, Tang Di, Mi Zhenli, et al. The influence of manganese on stacking fault energy and deformation mechanism of the TWIP steel[J]. Material Engineering, 2009(7): 39-42. [12] Li Ye, Xia Pengcheng, Xie Kun, et al. Effect of annealing temperature on microstructure and tensile properties of Fe-Mn-Al-C steel[J]. Heat Treatment of Metals, 2021,46(4):77-82. (李烨, 夏鹏成, 谢鲲, 等. 退火温度对Fe-Mn-Al-C钢组织和拉伸性能的影响[J]. 金属热处理, 2021,46(4):77-82.Li Ye, Xia Pengcheng, Xie Kun, et al. Effect of annealing temperature on microstructure and tensile properties of Fe-Mn-Al-C steel[J]. Heat Treatment of Metals, 2021, 46(4): 77-82. [13] Bhansali K, Keche A J, Gogte C L, et al. Effect of grain size on Hall-Petch relationship during rolling process of reinforcement bar[J]. Materials Today: Proceedings, 2020, 26(5): 3173-3178. [14] Xiang Hongliang, Liu Dong, Ruan Fangru, et al. Effects of precipitation for aging on mechanical and corrosion resistance progress of cast 2507 super duplex stainless steel[J]. Acta Metallurgica Sinica, 2010,46(8):941-945. (向红亮, 刘东, 阮方如, 等. 时效析出相对铸造2507超级双相不锈钢力学及耐蚀性能的影响[J]. 金属学报, 2010,46(8):941-945. doi: 10.3724/SP.J.1037.2010.00143Xiang Hongliang, Liu Dong, Ruan Fangru, et al. Effects of precipitation for aging on mechanical and corrosion resistance progress of cast 2507 super duplex stainless steel[J]. Acta Metallurgica Sinica, 2010, 46(8): 941-945. doi: 10.3724/SP.J.1037.2010.00143 [15] Wu Congfeng. Microstructure evolution behavior of 316LN stainless steel in AP1000 main pipe[D]. Beijing:Beijing University of Science and Technology, 2016. (吴从风. AP1000主管道316LN不锈钢的组织演变行为[D]. 北京:北京科技大学, 2016.Wu Congfeng. Microstructure evolution behavior of 316LN stainless steel in AP1000 main pipe[D]. Beijing: Beijing University of Science and Technology, 2016. [16] Zheng Leigang, Hu Xiaoqiang, Kang Xiuhong, et al. Precipitation behavior of M23C6 and its effects on ductility and toughness of a novel Cr-Mn-N austenitic heat resistant steel[J]. Acta Metallurgica Sinica, 2013,9(49):1081-1088. (郑雷刚, 胡小强, 康秀红, 等. Cr-Mn-N奥氏体耐热钢中M_(23)C_6型碳化物析出特征及其对韧塑性的影响[J]. 金属学报, 2013,9(49):1081-1088.Zheng Leigang, Hu Xiaoqiang, Kang Xiuhong, et al. Precipitation behavior of M23C6 and its effects on ductility and toughness of a novel Cr-Mn-N austenitic heat resistant steel[J]. Acta Metallurgica Sinica, 2013, 9(49): 1081-1088. -

下载:

下载: