Analysis of microstructures, inclusions and carbides of G95Cr18 bearing steel billets by mold casting

-

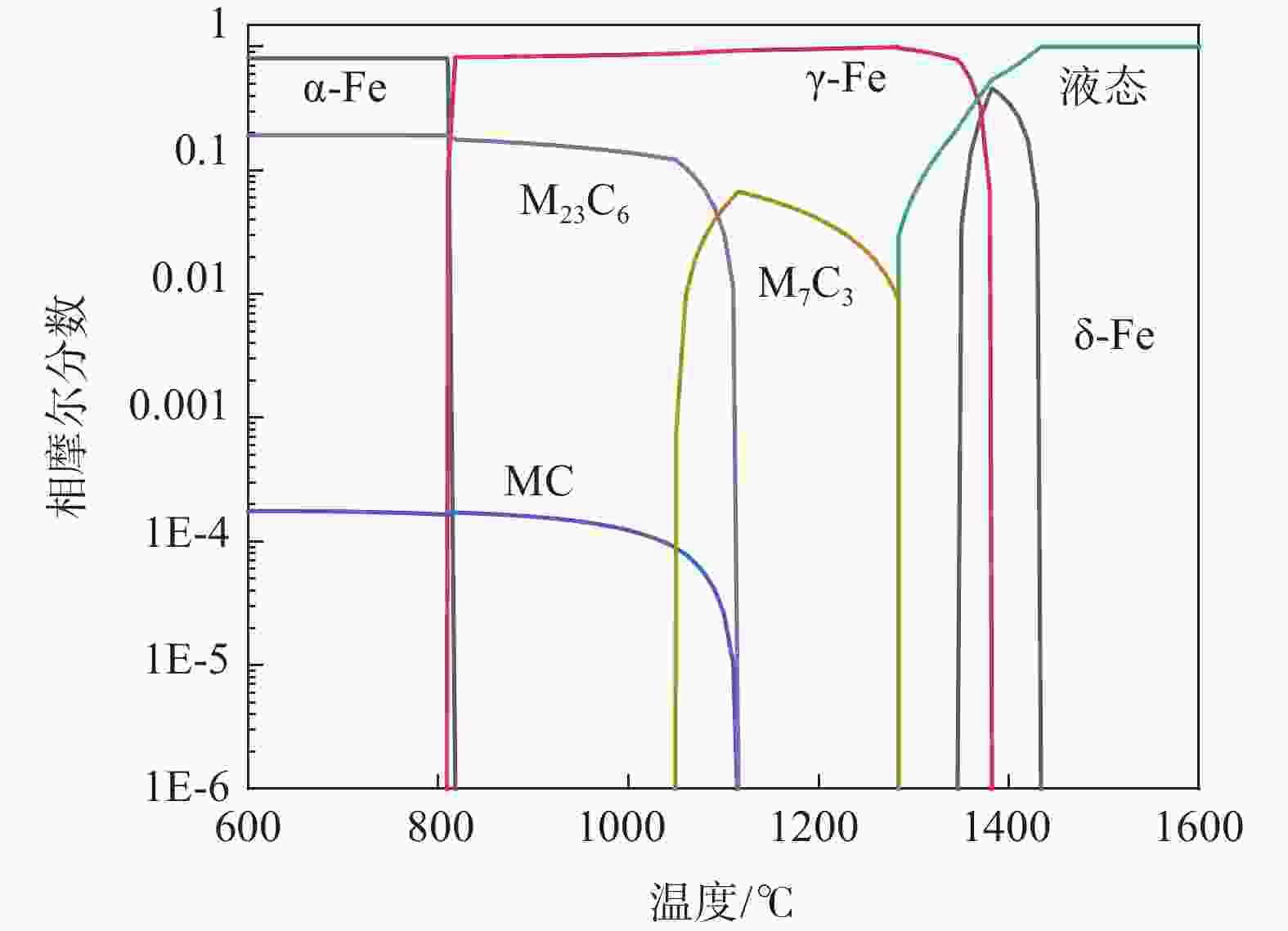

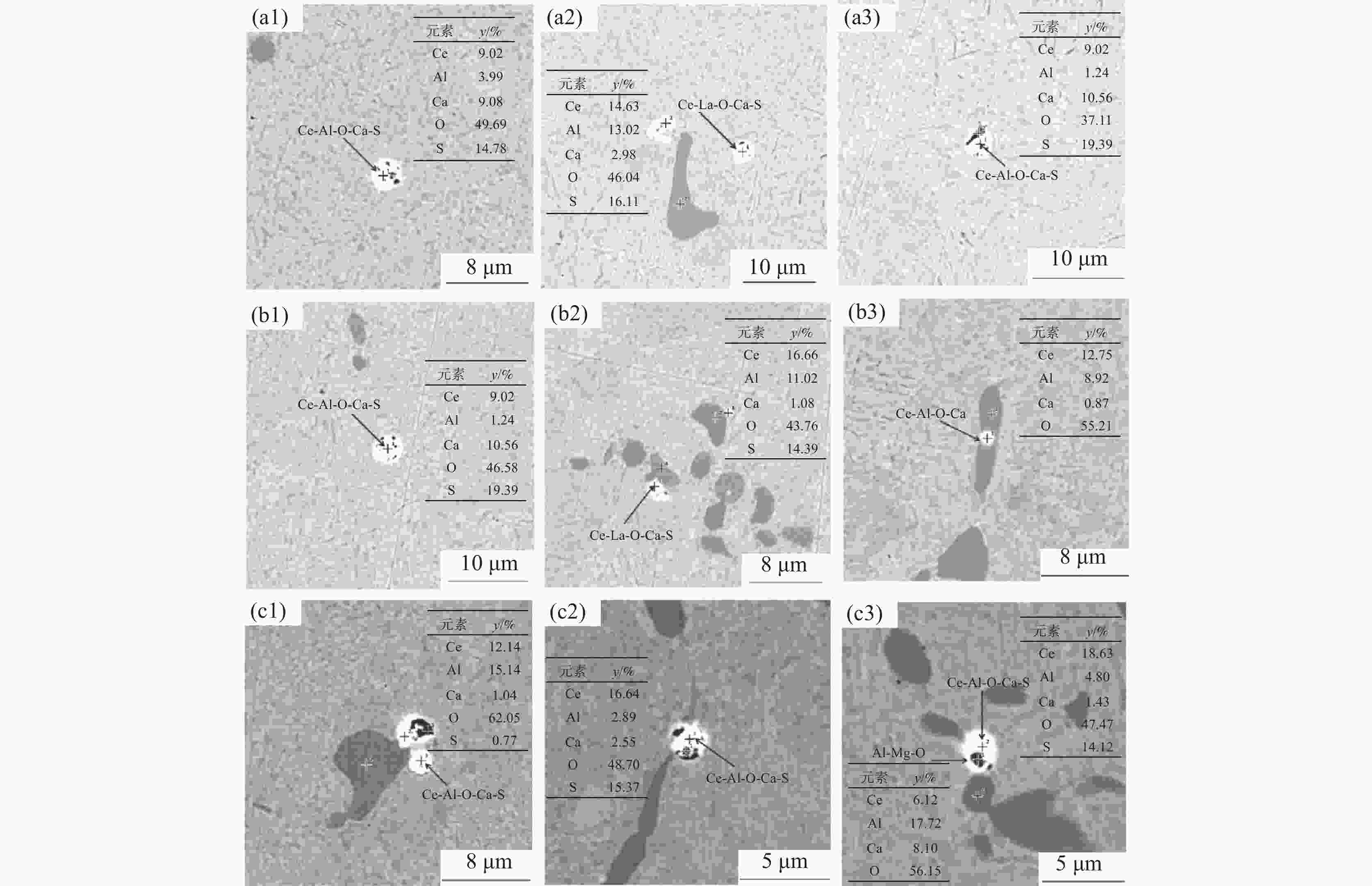

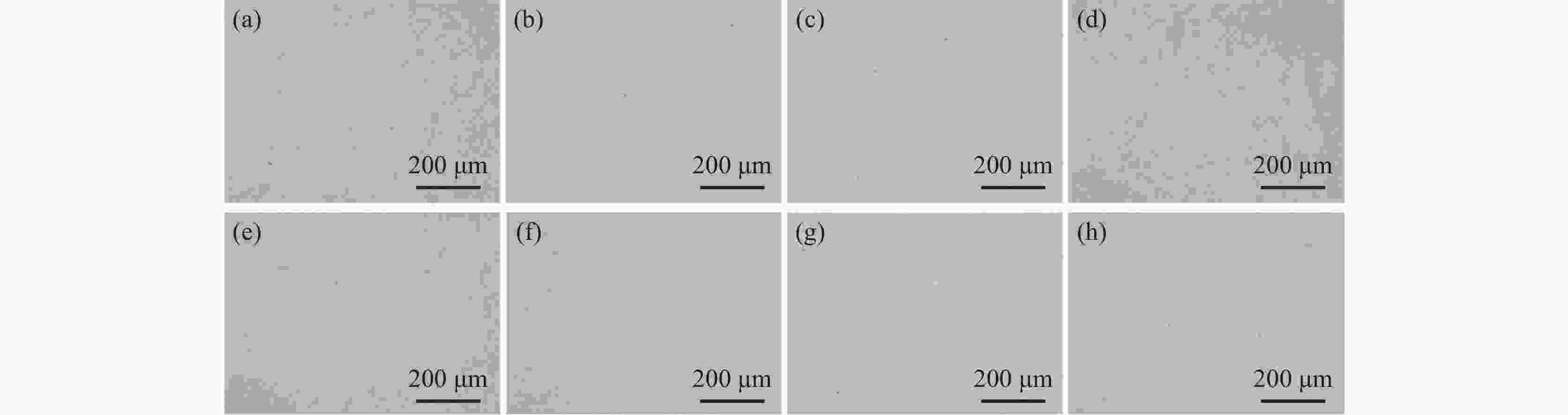

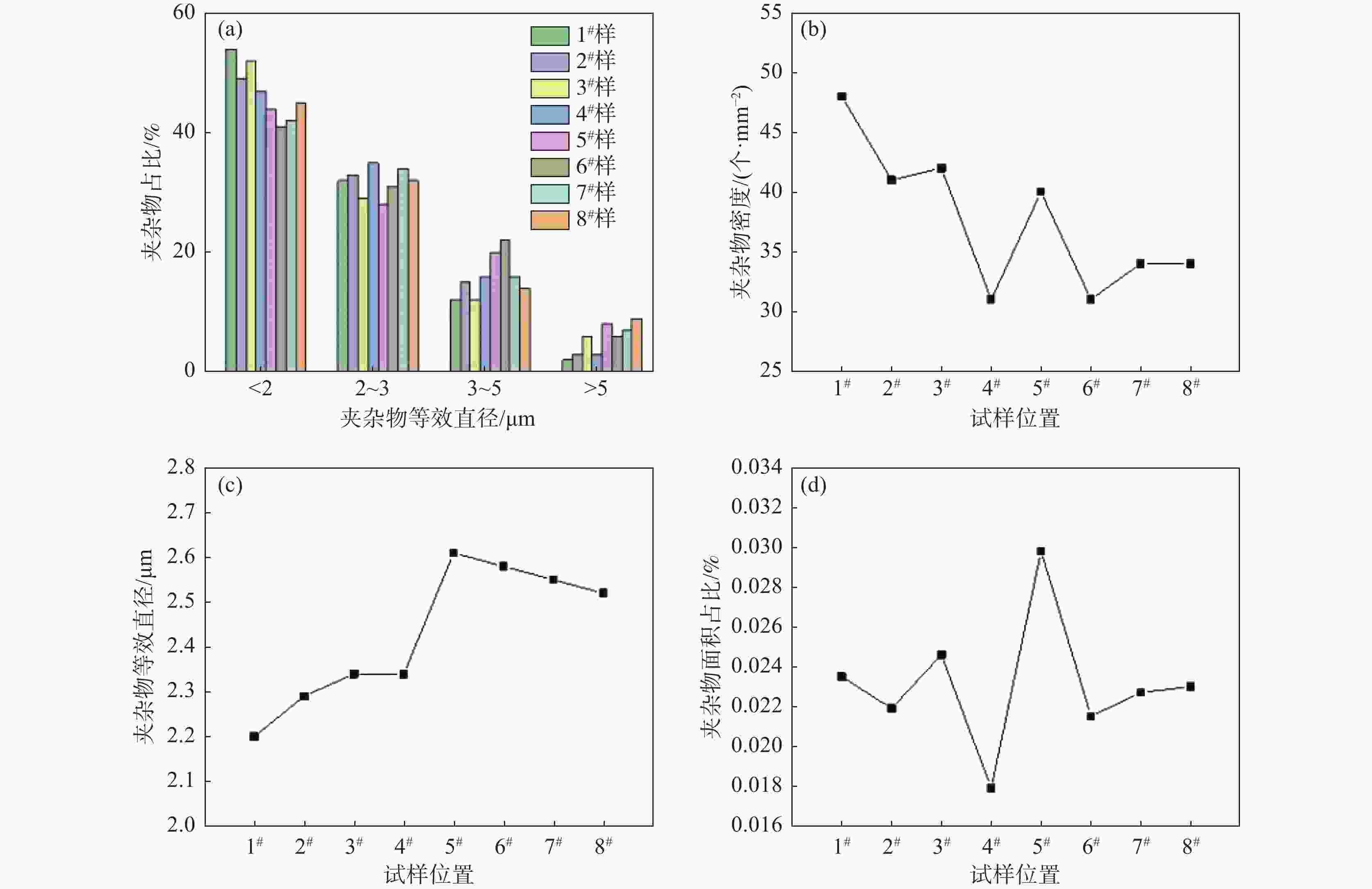

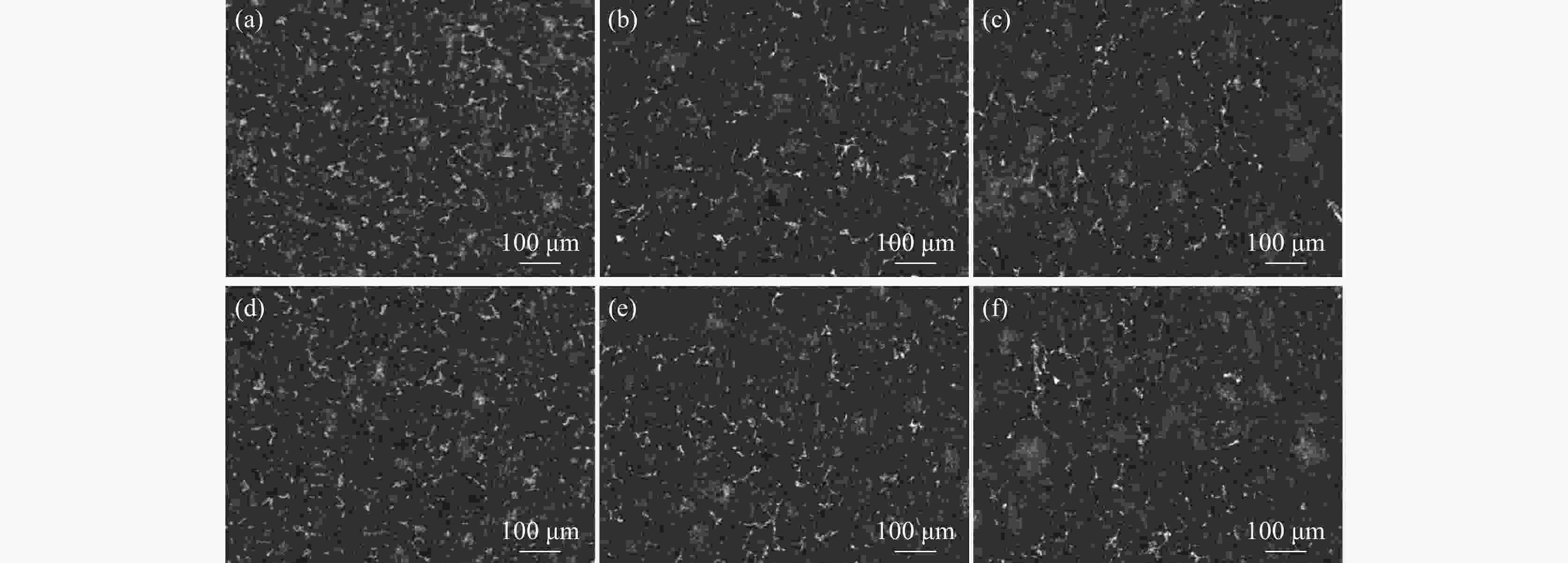

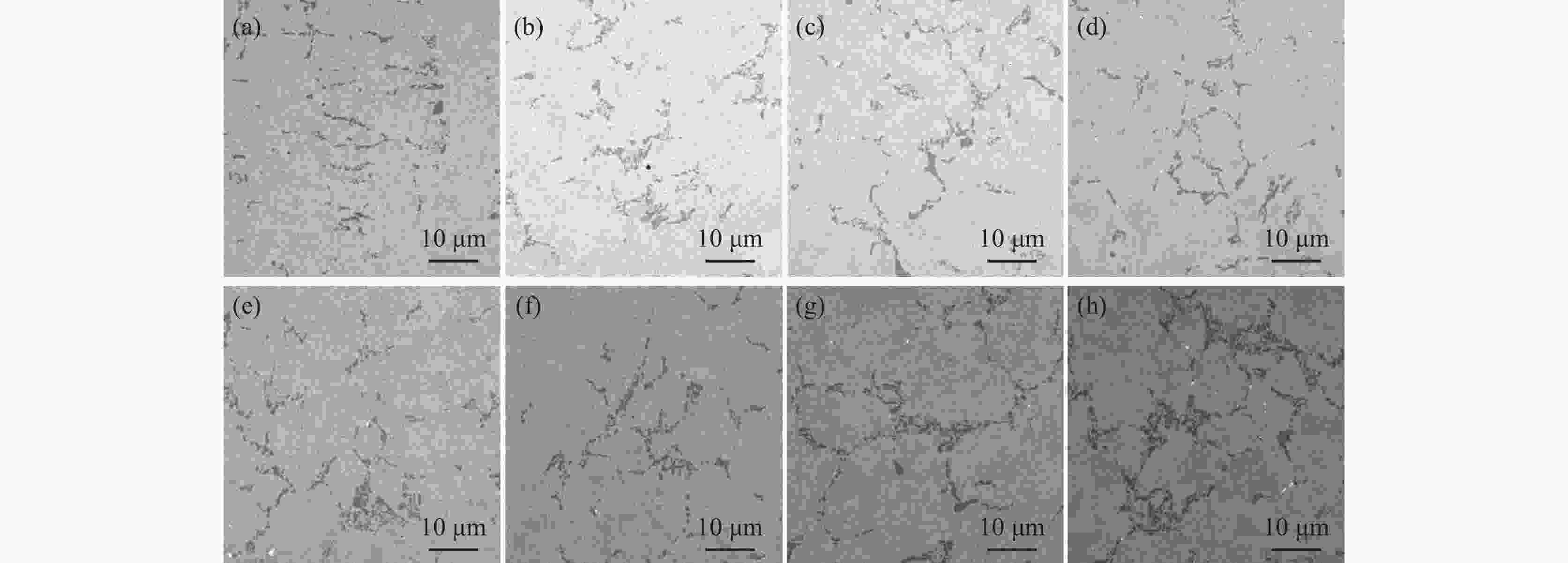

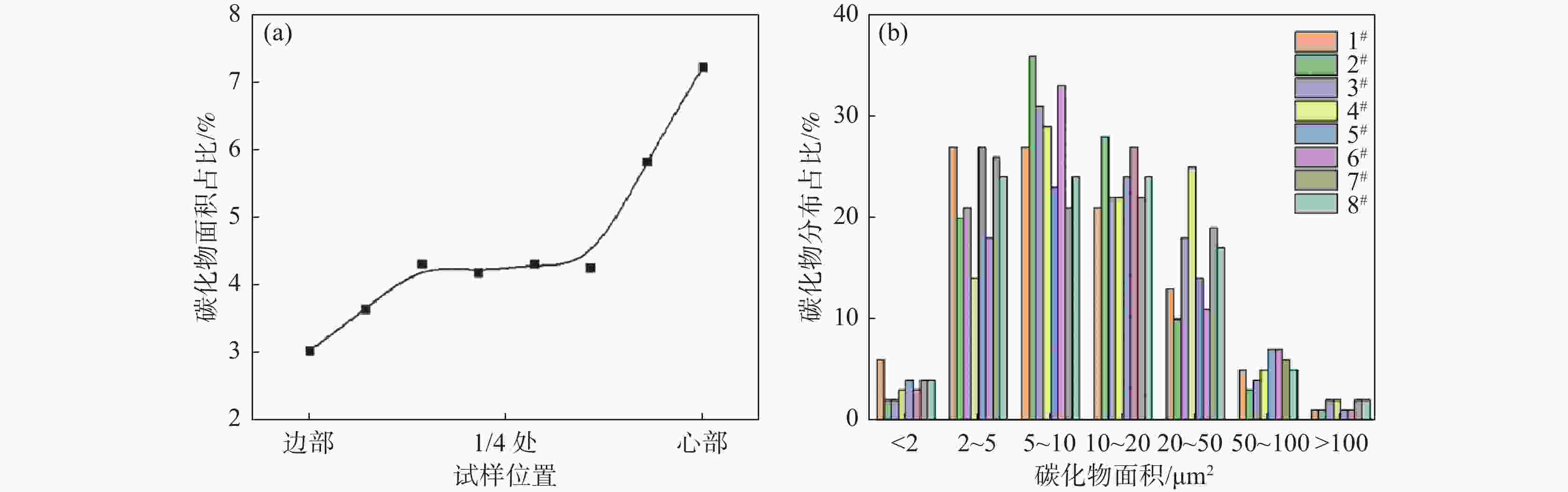

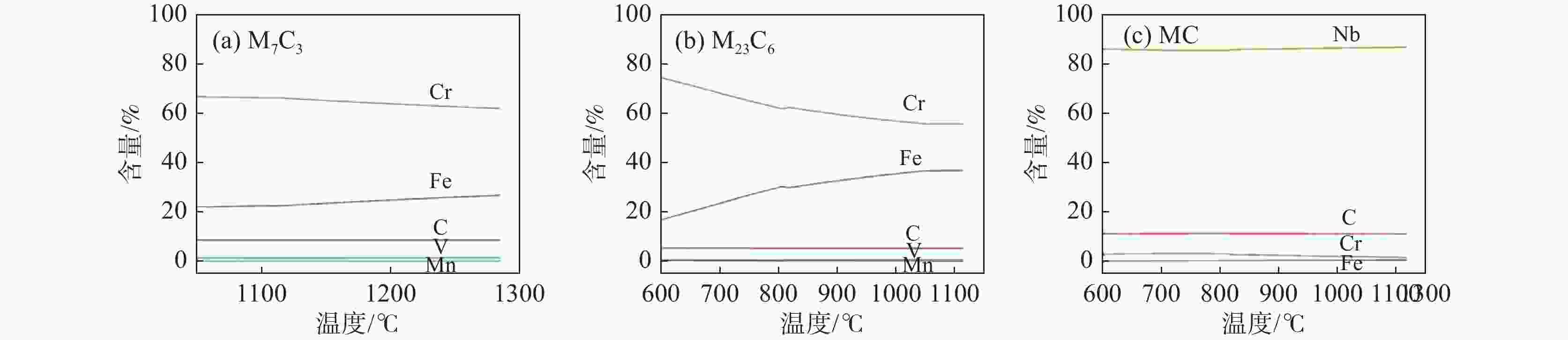

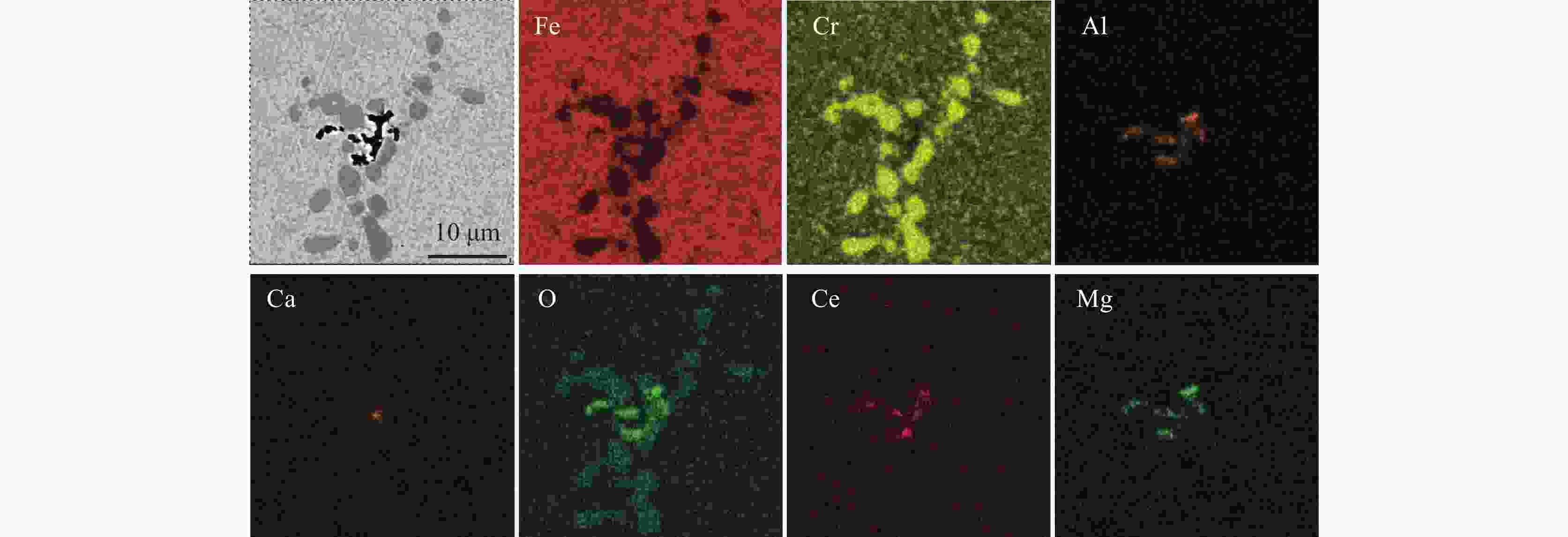

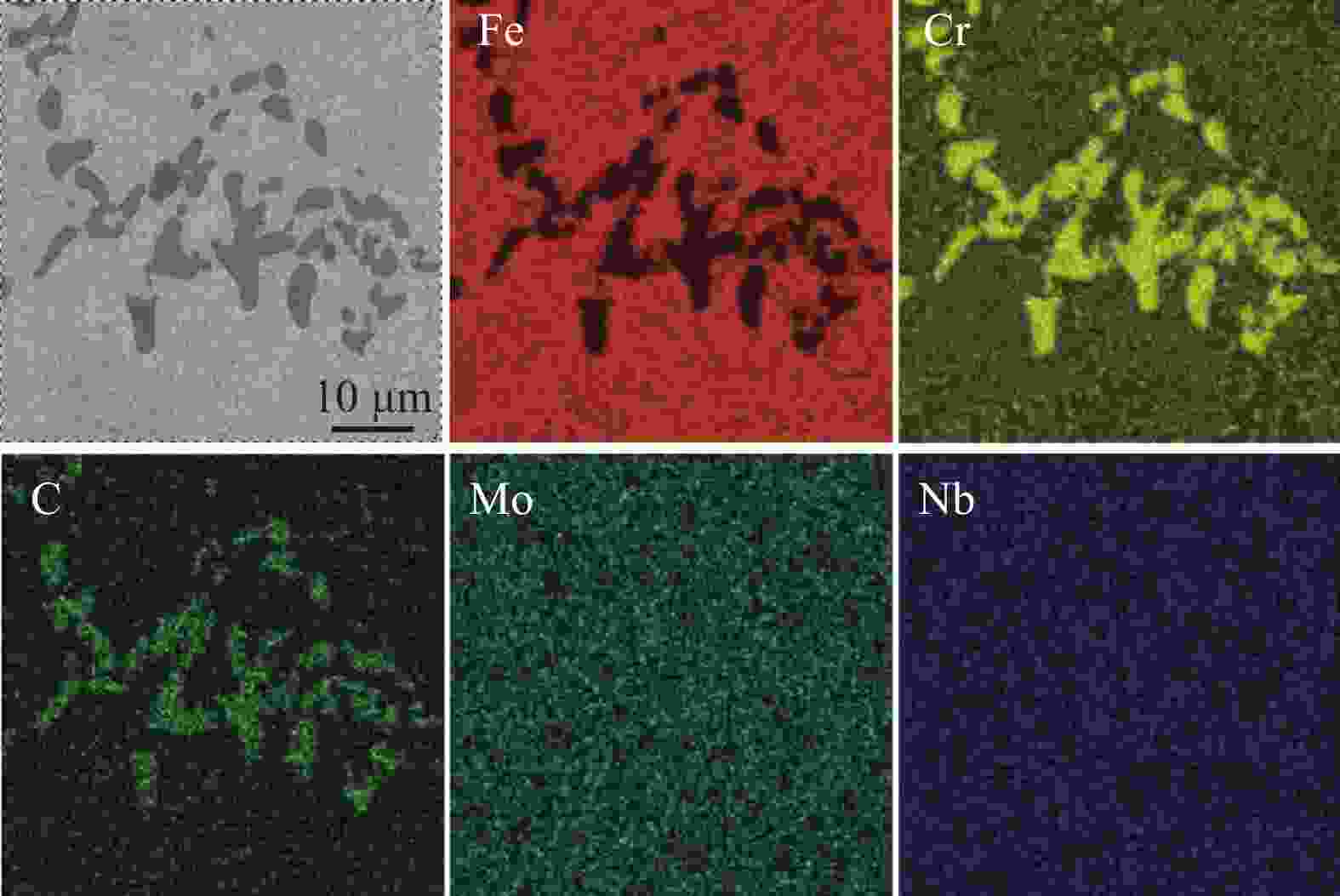

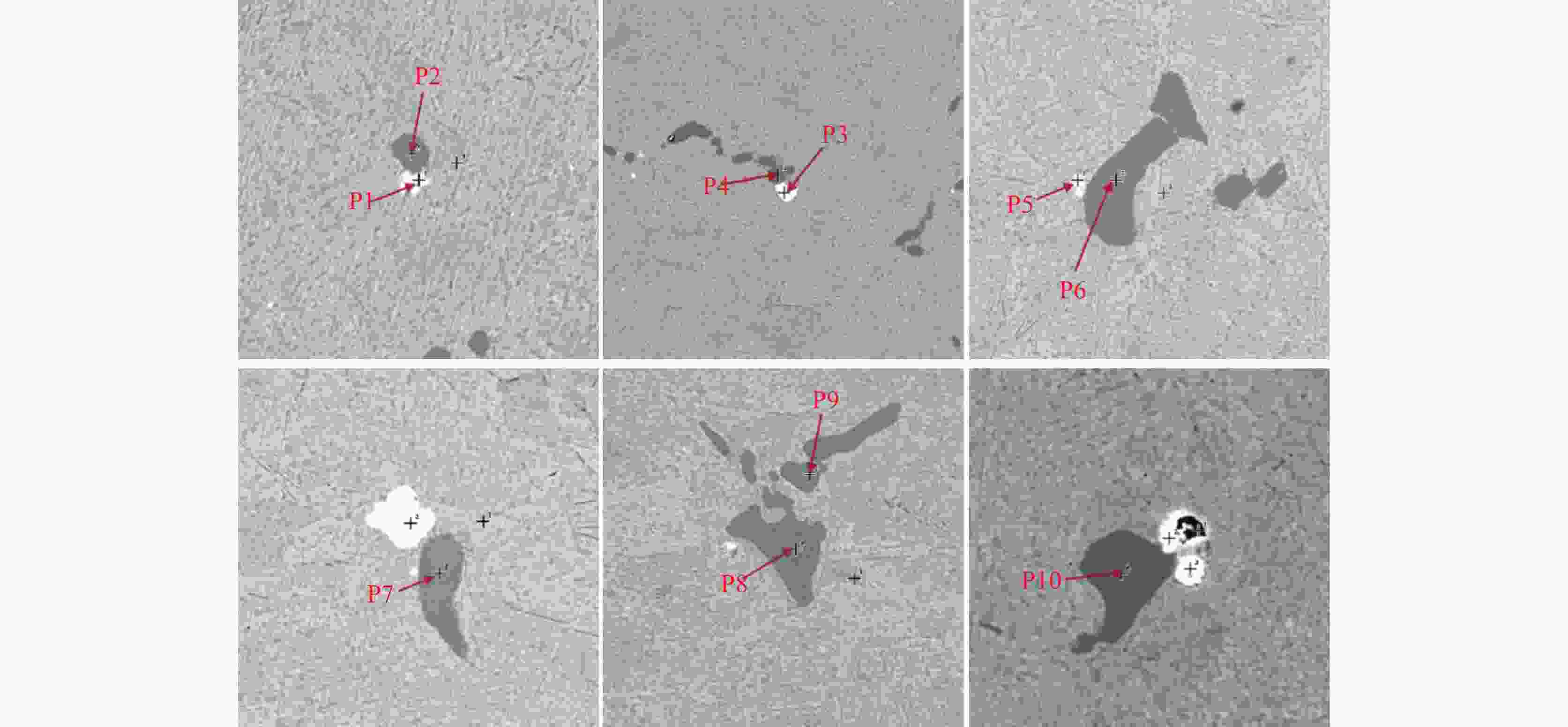

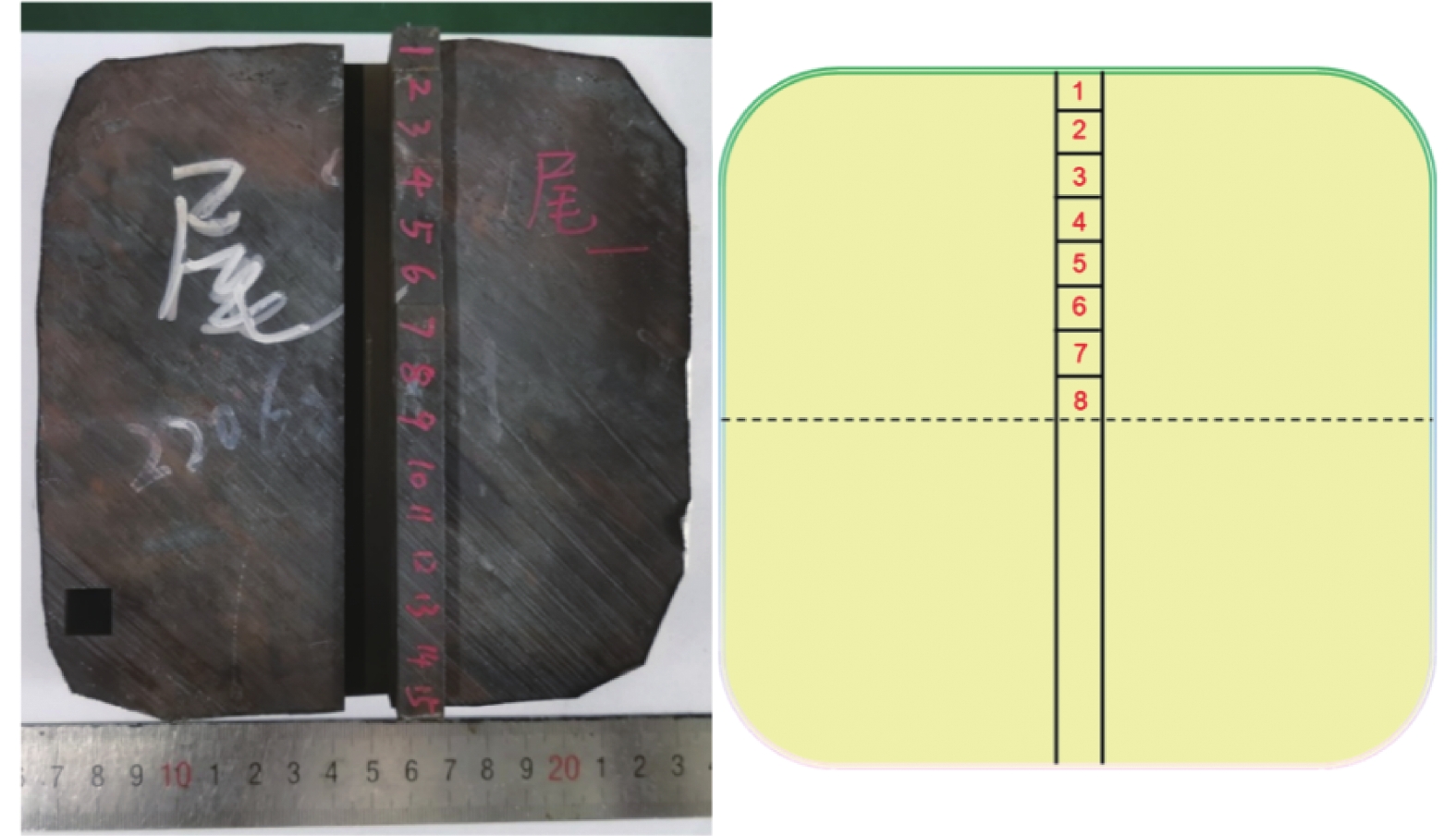

摘要: 基于Thermo-calc软件分析了G95Cr18轴承钢基体组织、相变及碳化物析出情况,用金相显微镜、扫描电镜对模铸坯组织、夹杂物和碳化物进行了解析。研究表明,在G95Cr18轴承钢铸坯中,夹杂物主要成分为Ce、O、Al、Ca等,夹杂物类型主要为稀土氧硫化物Ce-Al-O-Ca-S,同时还发现少量镁铝尖晶石Al-Mg-O,夹杂物密度为31~48 mm-2,夹杂物尺寸集中分布在2.2~2.6 μm,夹杂物面积占比为0.02%~0.03%;碳化物边部至心部面积占比由3.0%逐渐增加到7.5%,碳化物形貌有块状→棒状→长条状→网状的转变趋势,靠近铸坯心部网状碳化物大多沿晶界分布;碳化物类型为:亮白色富含Nb的MC型碳化物和灰色富含Cr元素的M7C3型碳化物。MC型碳化物的尺寸相较M7C3型碳化物小,在晶内以块状碳化物形式存在,在晶界处以网状碳化物形式存在。

-

关键词:

- G95Cr18轴承钢 /

- 夹杂物 /

- 碳化物 /

- Thermo-calc软件

Abstract: Based on Thermo-calc software, the matrix structure, phase transformation and carbides precipitation of G95Cr18 bearing steel were analyzed. Metallographic microscope and scanning electron microscope were used to analyze the mold casting billets structures, inclusions and carbides. The research shows that the main components of inclusions in the casting slab of G95Cr18 bearing steel are Ce, O, Al, Ca and a few other elements. The main type of inclusions is rare earth oxygen sulfide Ce-Al-O-Ca-S, and a small amount of magnesia-aluminum spinel Al-Mg-O is also found. The inclusion density is 31 - 48 mm-2, and the average sizes of inclusions are concentrated in a range of 2.2 μm to 2.6 μm with the inclusion area proportion of 0.02% to 0.03%. The area proportion of carbides from the edge to the core increases from 3.0% to 7.5%, and the morphology of carbides shows a transforming trend of block → rod → strip → network. Most of the network carbides near the core are distributed along the grain boundaries. These types of carbides are composed of bright white Nb-enriched MC carbides and gray M7C3 carbides enriched in Cr, respectively. The sizes of MC carbides are smaller than that of M7C3 carbides, and they present as massive carbides in the matrix and network carbides in the grain boundary.-

Key words:

- G95Cr18 bearing steel /

- inclusion /

- carbides /

- Thermo-calc software

-

表 1 G95Cr18钢主要化学成分

Table 1. Main chemical composition of G95Cr18 steel

% C Si Mn P S Cr Ni Mo Nb Al Ce 0.900 0.22 0.38 0.026 0.001 17.29 0.21 0.02 0.014 0.008 0.005 表 2 G95Cr18钢典型碳化物的能谱成分

Table 2. Energy spectrum components of typical carbide in G95Cr18 steel

% 能谱点 Fe Cr Mo C Nb Ti P1 18.80 5.61 3.00 5.22 51.05 16.31 P2 29.06 66.34 1.21 3.39 0 0 P3 0 0 6.26 7.35 73.54 12.85 P4 29.14 66.32 1.16 3.38 0 0 P5 4.76 0 3.59 6.74 67.08 17.83 P6 28.71 67.85 0 3.43 0 0 P7 28.92 65.62 1.85 3.61 0 0 P8 28.36 67.95 0 3.69 0 0 P9 28.82 67.59 0 3.59 0 0 P10 27.93 67.62 0.98 3.47 0 0 -

[1] Jin Lei. Study on stability control of inclusions in G95Cr18 steel[J]. Special Steel Technology, 2021,27(2):18-21. (金磊. G95Cr18钢夹杂物稳定控制的工艺研究[J]. 特钢技术, 2021,27(2):18-21.Jin Lei. Study on Stability control of Inclusions in G95 Cr18 Steel[J]. Special Steel Technology, 2021, 27(02): 18-21 [2] Yuan Zhaojing. Effect of heat treatment on microstructure and mechanical properties of G95Cr18 and G102Cr18Mo steels[J]. Shanghai Metal, 2018,40(2):59-63. (袁兆静. 热处理对G95Cr18和G102Cr18Mo钢的组织和力学性能的影响[J]. 上海金属, 2018,40(2):59-63. doi: 10.3969/j.issn.1001-7208.2018.02.012Yuan Zhao Jing. Effect of Heat treatment on microstructure and mechanical properties of G95 Cr18 and G102 Cr18 Mo steels[J]. Shanghai Metal, 2018, 40(02): 59-63 doi: 10.3969/j.issn.1001-7208.2018.02.012 [3] Xu Bin, Li Hongliang, Wang Xuelin, et al. Experimental study on continuous casting billet of 30Cr13 martensitic stainless steel[J]. Gansu Metallurgy, 2021,43(2):53-56. (徐斌, 李鸿亮, 王雪林, 等. 30Cr13马氏体不锈钢连铸坯的试验研究[J]. 甘肃冶金, 2021,43(2):53-56. doi: 10.3969/j.issn.1672-4461.2021.02.017Xu Bin, Li Hongliang, Wang Xuelin et al. Experimental Study on continuous casting billet of 30 Cr13 Martensitic Stainless steel[J]. Gansu Metallurgy, 2021, 43(02): 53-56 doi: 10.3969/j.issn.1672-4461.2021.02.017 [4] 朱浩然, 周茂华, 胡涛, 等. 镁对H13钢液析碳化物及组织的影响[J]. 钢铁研究学报, 2022, 34(11): 1278-1285.Zhu Haoran, Zhou Maohua, Hu Tao, et al. Effect of magnesium on carbide evolution and microstructure of H13 steel[J]. Journal of Iron and Steel Research, 202, 34(11): 1278-1285. [5] Li Haibo, Zhao Dongwei, Zhu Guosen, et al. Influence of inclusions on impact properties of J55 steel[J]. Journal of Iron and Steel Research International, 2015,22:36-41. [6] Xiao Wei, Bao Yanping, Gu Chao, et al. Ultrahigh cycle fatigue fracture mechanism of high-quality bearing steel obtained through different deoxidation methods[J]. International Journal of Minerals Metallurgy and Materials, 2021,28(5):804-815. doi: 10.1007/s12613-021-2253-y [7] Tang Guozhang, Zeng Yanan, Li Junguo, et al. Thermodynamic study of composition change on inclusion precipitation of GCr15 bearing steel during solidification[J]. Iron Steel Vanadium Titanium, 2016,37(1):122-126. (唐国章, 曾亚南, 李俊国, 等. GCr15轴承钢凝固过程组分变化对夹杂物析出的热力学研究[J]. 钢铁钒钛, 2016,37(1):122-126.Tang Guozhang, Zeng Yanan, Li Junguo, et al. Thermodynamic Study of Composition Change on Inclusion precipitation of GCr15 Bearing Steel during solidification[J]. Vanadium and Titanium Steel, 2016, 37(01): 122-126 [8] Yang Yudan, Zhao Hongshan, Liu Tengshi, et al. Microstructure and properties of new high-carbon martensitic stainless steels[J]. Journal of Iron and Steel Research, 2020,32(2):135-142. (杨玉丹, 赵洪山, 刘腾轼, 等. 新型高碳马氏体不锈钢的组织与性能[J]. 钢铁研究学报, 2020,32(2):135-142.Yang Yudan, Zhao Hongshan, Liu Tengshi et al. Microstructure and properties of new high-carbon martensitic stainless steels[J]. Journal of Iron and Steel Research, 2020, 32(02): 135-142 [9] Sun Shenhong. Research on production technology of high carbon chromium stainless 95Cr18(Mo) drawing rod[J]. Special Steel Technology, 2017,23(1):12-15. (孙慎宏. 高碳铬不锈95Cr18(Mo)拉拔盘条生产工艺研究[J]. 特钢技术, 2017,23(1):12-15.Sun Shenhong. Research on Production Technology of High carbon Chromium Stainless 95 Cr18(Mo) Drawing Rod[J]. Special Steel Technology, 2017, 23(01): 12-15 [10] Li Zhaoguo, Pan Jixiang, Ji Xianbin, et al. Effect of quenching process on microstructure and properties of 6Cr13 martensitic stainless steel[J]. Heat Treatment of Metals, 2022,47(5):226-229. (李照国, 潘吉祥, 纪显彬, 等. 淬火工艺对6Cr13马氏体不锈钢组织和性能的影响[J]. 金属热处理, 2022,47(5):226-229.Li Zhaoguo, Pan Jixiang, Ji Xianbin, et al. Effect of quenching process on microstructure and properties of 6 Cr13 martensitic Stainless Steel[J]. Heat Treatment of Metals, 2022, 47(05): 226-229 [11] Di Chongxiang, Li Kelei, Jing Jing, et al. Effect of tempering process on microstructure and properties of cast martensitic stainless steel[J]. Foundry, 2022,71(12):1499-1504. (狄崇祥, 李克雷, 荆静, 等. 回火工艺对铸造马氏体不锈钢组织和性能的影响[J]. 铸造, 2022,71(12):1499-1504. doi: 10.3969/j.issn.1001-4977.2022.12.005Di Chongxiang, Li Klei, Jing Jing et al. Effect of tempering process on microstructure and properties of cast Martensitic Stainless Steel[J]. Foundry, 2022, 71(12): 1499-1504 (in Chinese) doi: 10.3969/j.issn.1001-4977.2022.12.005 [12] Dennis W Hetzner, William Van Geertruyden. Crystallography and metallography of carbides in high alloy steels[J]. Materials Characterization, 2008,59(7):825-841. doi: 10.1016/j.matchar.2007.07.005 [13] Wang Yi, Li Changrong, Wang Linzhu, et al. Modification of alumina inclusions in SWRS82B steel by adding rare earth cerium[J]. Metals, 2020, 10(12):1696. [14] Wang Yi, Li Changrong, Zeng Zeyun, et al. Crystallography of alumina modification by rare earth elements in SWRS82B steel[J]. Iron and Steel, 2020,55(10):69-74, 88. (王奕, 李长荣, 曾泽芸, 等. SWRS82B钢中稀土元素对氧化铝改性的晶体学[J]. 钢铁, 2020,55(10):69-74, 88.Wang Yi, LI Changrong, Zeng Zeyun et al. Crystallography of alumina modification by rare earth elements in SWRS82 B steel[J]. Iron and Steel, 2020, 55(10): 69-74+88 (in Chinese) [15] Wang Yi, Li Changrong, Xiong Xingqiang, et al. Effect of rare earth lanthanum on alumina inclusions in SWRS82B steel[J]. Rare Metals, 2022,46(9):1199-1206. (王奕, 李长荣, 熊星强, 等. 稀土镧对SWRS82B钢中氧化铝夹杂物的影响[J]. 稀有金属, 2022,46(9):1199-1206.Wang Yi, LI Changrong, Xiong Xingqiang et al. Effect of rare earth lanthanum on alumina inclusions in SWRS82 B Steel[J]. Rare Metals, 2022, 46(09): 1199-1206 [16] 杨超云. 稀土对高碳铬轴承钢夹杂物-组织-性能的影响机理研究[D]. 合肥: 中国科学技术大学, 2020.Yang Chaoyun. Study on the influence mechanism of rare earth on inclusion-Structure-properties of high carbon chromium bearing steel[D]. Hefei: University of Science and Technology of China, 2020. [17] Guo Shuai, Zhu Hangyu, Han Yun, et al. Research progress on the influence of inclusions on the plasticity and toughness of steel[J]. Journal of Iron and Steel Research, 2022,34(8):713-726. (郭帅, 朱航宇, 韩赟, 等. 夹杂物对钢塑性和韧性的影响研究进展[J]. 钢铁研究学报, 2022,34(8):713-726.Guo Shuai, ZHU Hangyu, Han Yun et al. Research progress on the influence of inclusions on the plasticity and toughness of steel[J]. Journal of Iron and Steel Research, 2022, 34(08): 713-726 [18] Su Mengmeng, Ji Dengping, Yan Daocong, et al. Effect of tellurium on machinability of 303Cu free-cutting stainless steel[J]. Metallurgy in China, 2023,33(4):65-72. (苏蒙蒙, 季灯平, 严道聪, 等. 碲对303Cu易切削不锈钢切削性能的影响[J]. 中国冶金, 2023,33(4):65-72.Su Mengmeng, Ji Dengping, Yan Daocong, etc. Effect of tellurium on machinability of 303 Cu free-cutting Stainless Steel[J]. Metallurgy in China, 2023, 33(04): 65-72 [19] Kong Yonghua, Song Dongliang, Xie Lixiong, et al. Comparative analysis of microstructure and properties of GCr15 bearing steel collar[J]. Hot Working Technology, 2012,41(10):55-57, 60. (孔永华, 宋东亮, 谢黎雄, 等. GCr15轴承钢钢领组织性能的对比分析[J]. 热加工工艺, 2012,41(10):55-57, 60. doi: 10.3969/j.issn.1001-3814.2012.10.017Kong Yonghua, Song Dongliang, Xie Lixiong et al. Comparative Analysis of Microstructure and Properties of GCr15 Bearing Steel Collar[J]. Hot Working Technology, 2012, 41(10): 55-57+60 doi: 10.3969/j.issn.1001-3814.2012.10.017 [20] Yang Yaguang. Research on key technology and industrial trial production of high carbon martensitic stainless steel 95Cr18 continuous casting[J]. Special Steel Technology, 2023,29(1):17-21. (杨亚光. 高碳马氏体不锈钢95Cr18连铸关键技术研究及工业试制[J]. 特钢技术, 2023,29(1):17-21.Yang Yaguang. Research on Key Technology and Industrial trial production of High carbon Martensitic Stainless Steel 95 Cr18 Continuous casting[J]. Special Steel Technology, 2023, 29(01): 17-21 [21] Zhang Yanjun, Min Yong'an, Liu Xiangjiang, et al. Structure distribution characteristics and carbide uniformity of GCr15 bearing ring[J]. Heat Treatment of Metals, 2019,44(12):6-12. (张艳君, 闵永安, 刘湘江, 等. GCr15轴承套圈组织分布特点及碳化物均匀性[J]. 金属热处理, 2019,44(12):6-12.Zhang Yanjun, Min Yongan, Liu Xiangjiang et al. Structure distribution characteristics and carbide uniformity of GCr15 bearing ring[J]. Heat Treatment of Metals, 2019, 44(12): 6-12 [22] Yu Wentao, Li Jing, Shi Chengbin, et al. As-cast microstructure and carbides of high carbon martensitic stainless steel 8Cr13MoV steel[J]. Chinese Journal of Engineering Science, 2016,38(9):1264-1269. (于文涛, 李晶, 史成斌, 等. 高碳马氏体不锈钢8Cr13MoV钢铸态组织及碳化物[J]. 工程科学学报, 2016,38(9):1264-1269.Yu Wentao, Li Jing, Shi Chengbin et al. As-cast microstructure and carbides of high carbon martensitic stainless steel 8 Cr13 MoV steel[J]. Chinese Journal of Engineering Science, 2016, 38(09): 1264-1269 (in Chinese) -

下载:

下载: