Study on the hot deformation behaviors of B50A789G blade steel

-

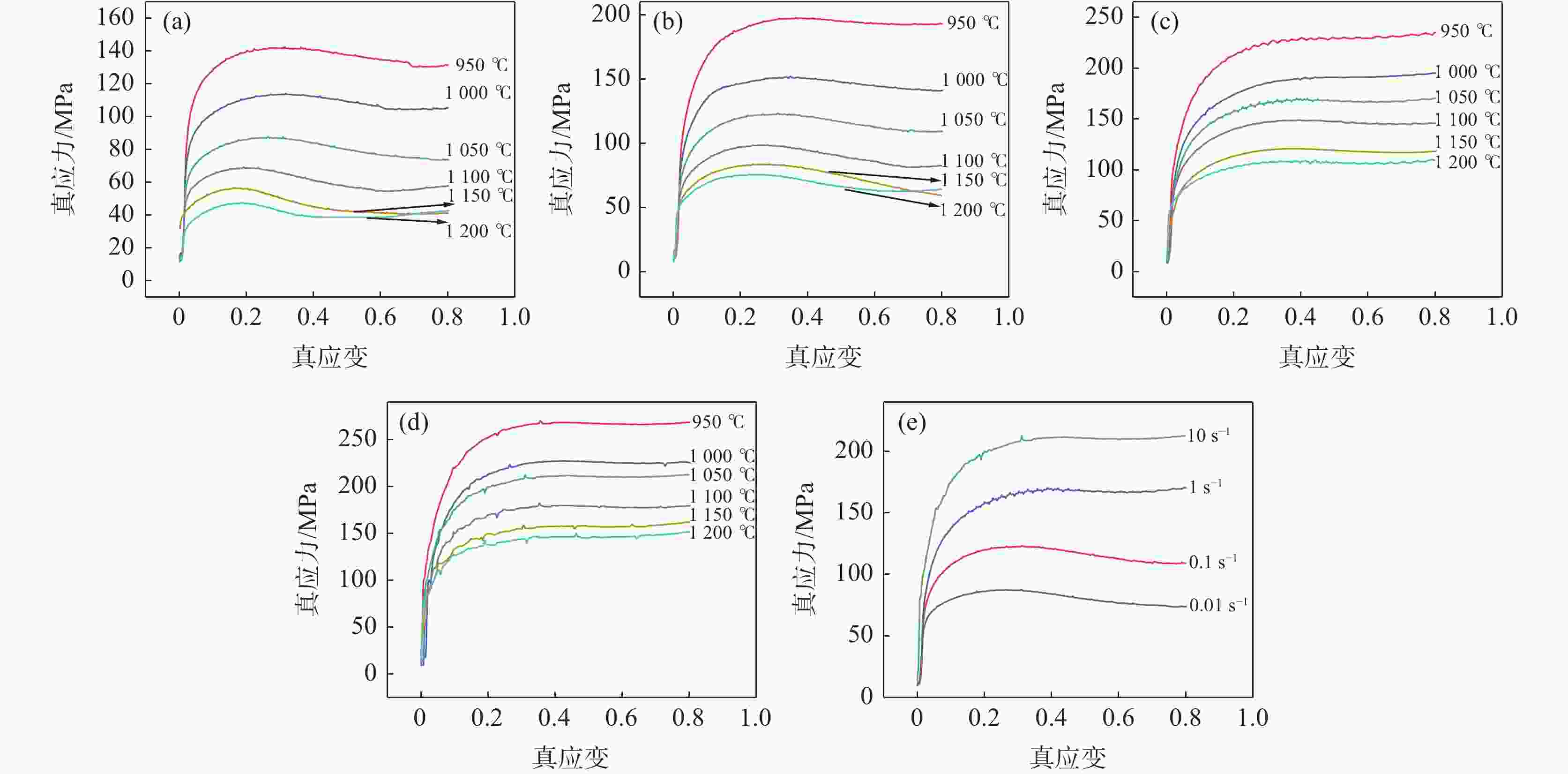

摘要: 使用Gleeble-3800热模拟试验机对B50A789G叶片钢进行等温热压缩试验,应变速率选择0.01~10 s−1,变形温度选择950~

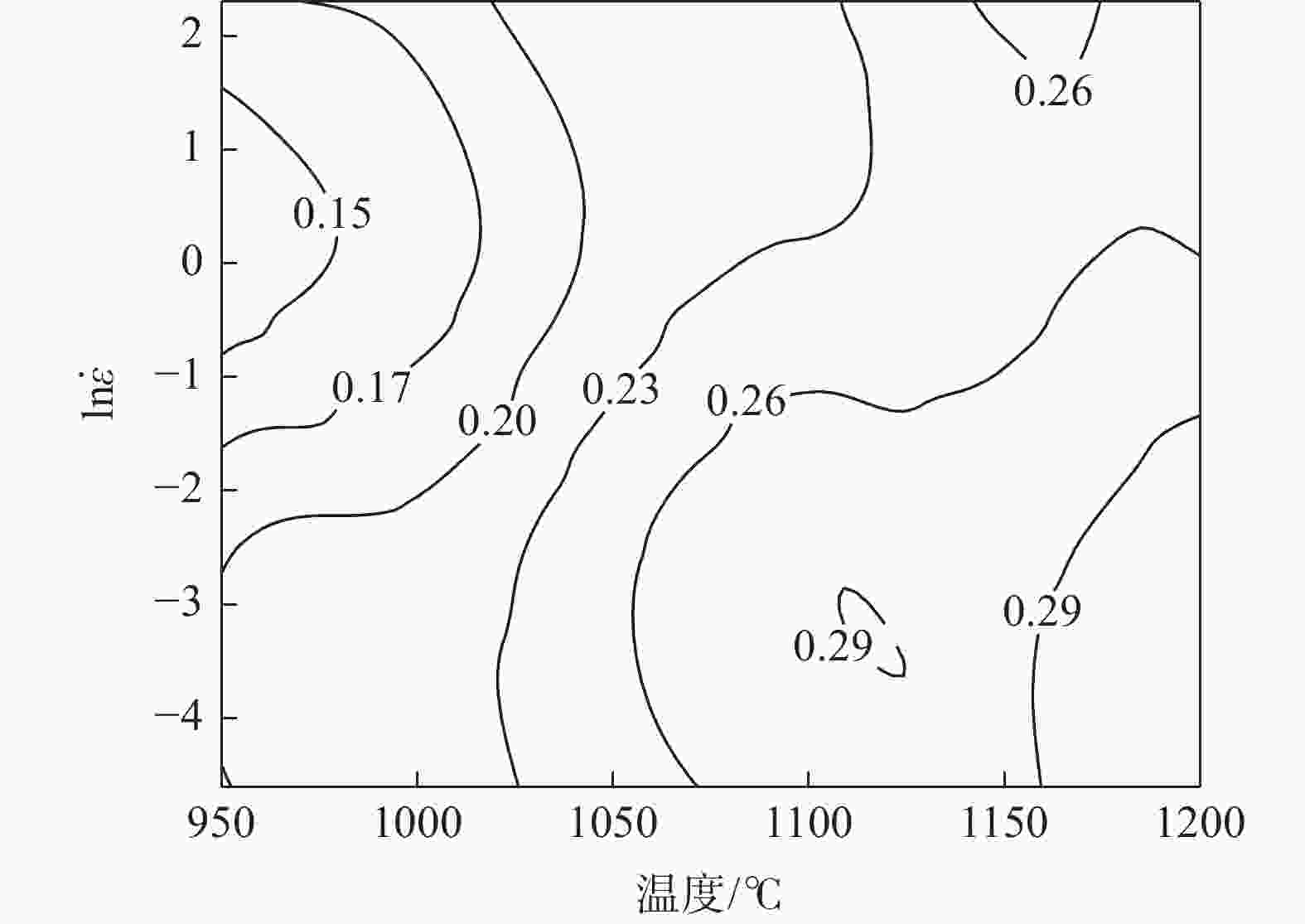

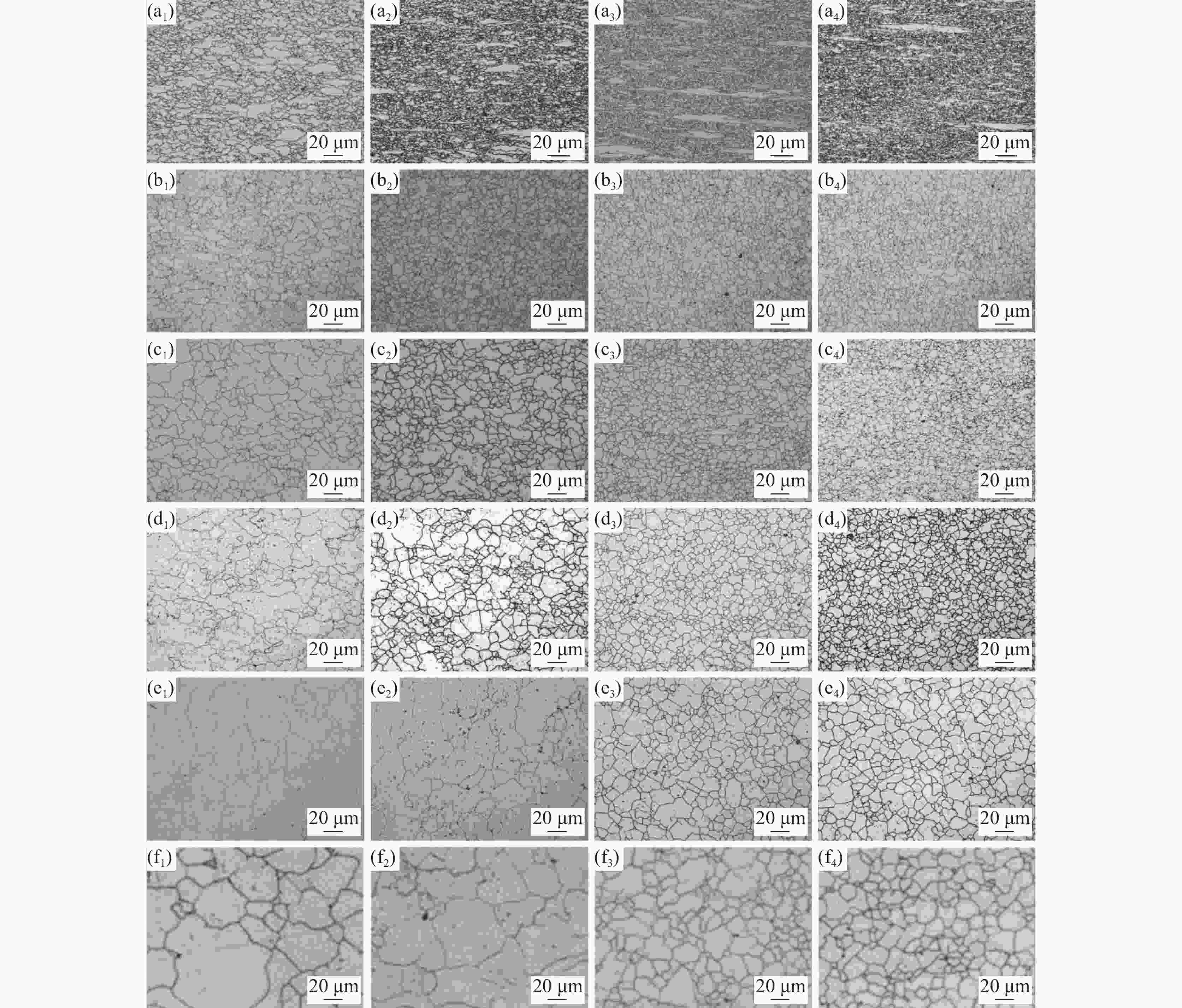

1200 ℃。基于Arrhenius模型构建了本构方程,采用动态材料模型构建了热加工图。由热加工图和变形后的组织获得了热加工窗口。结果表明:适合于B50A789G叶片钢最优的热加工区域为变形温度1000 ~1050 ℃、应变速率0.01~10 s−1以及变形温度1150 ~1200 ℃、应变速率1~10 s−1,该区域下组织能发生完全动态再结晶,且原奥氏体晶粒尺寸分布均匀且细小,有利于实现材料组织均匀化、细晶化,为B50A789G叶片钢工业化应用提供支撑。Abstract: The isothermal hot compression test of B50A789G blade steel was conducted by Gleeble-3800 thermo-mechanical simulator in the strain rate range of 0.01-10 s−1 and the deformation temperature range of 950-1200 ℃. Based on Arrhenius hyperbolic sine equation, the constitutive equation was established.The hot processing map was constructed based on dynamic material model (DMM). The hot working window was determined on the basis of hot processing map and deformed microstructures.The results show that the optimum domain for hot forming of B50A789G blade steel is determined in the temperature ranges of1000 -1050 ℃ with strain rates of 0.01-10 s−1 and1150 -1200 ℃ with strain rates of 1-10 s−1, respectively. It is found that complete dynamic recrystallization occurs in this domain.In addition, the grain size distribution of original austenite is uniform and fine, which is conducive to the homogenization and refinement of the material microstructures. This study provides support for the industrial application of B50A789G blade steel. -

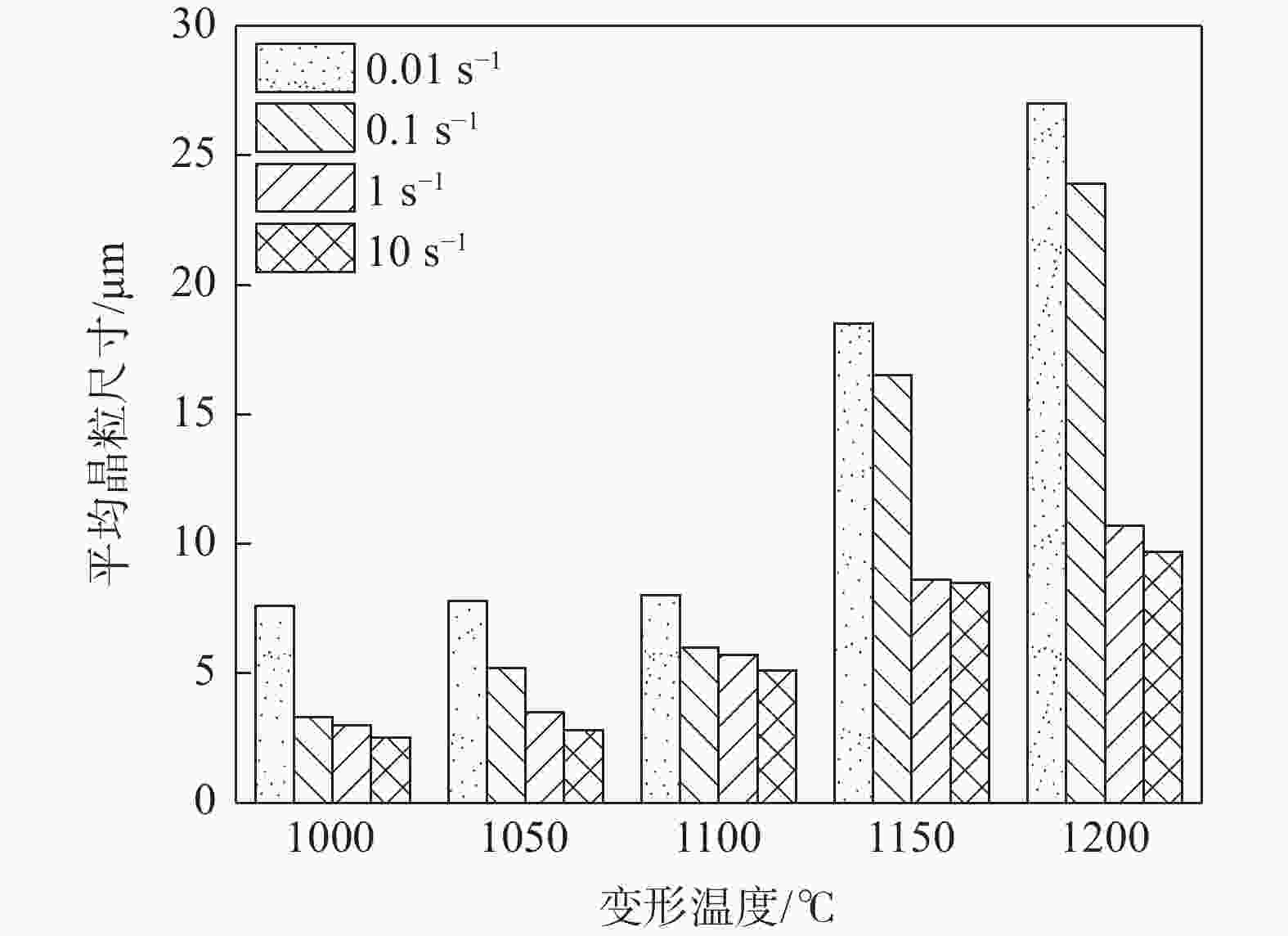

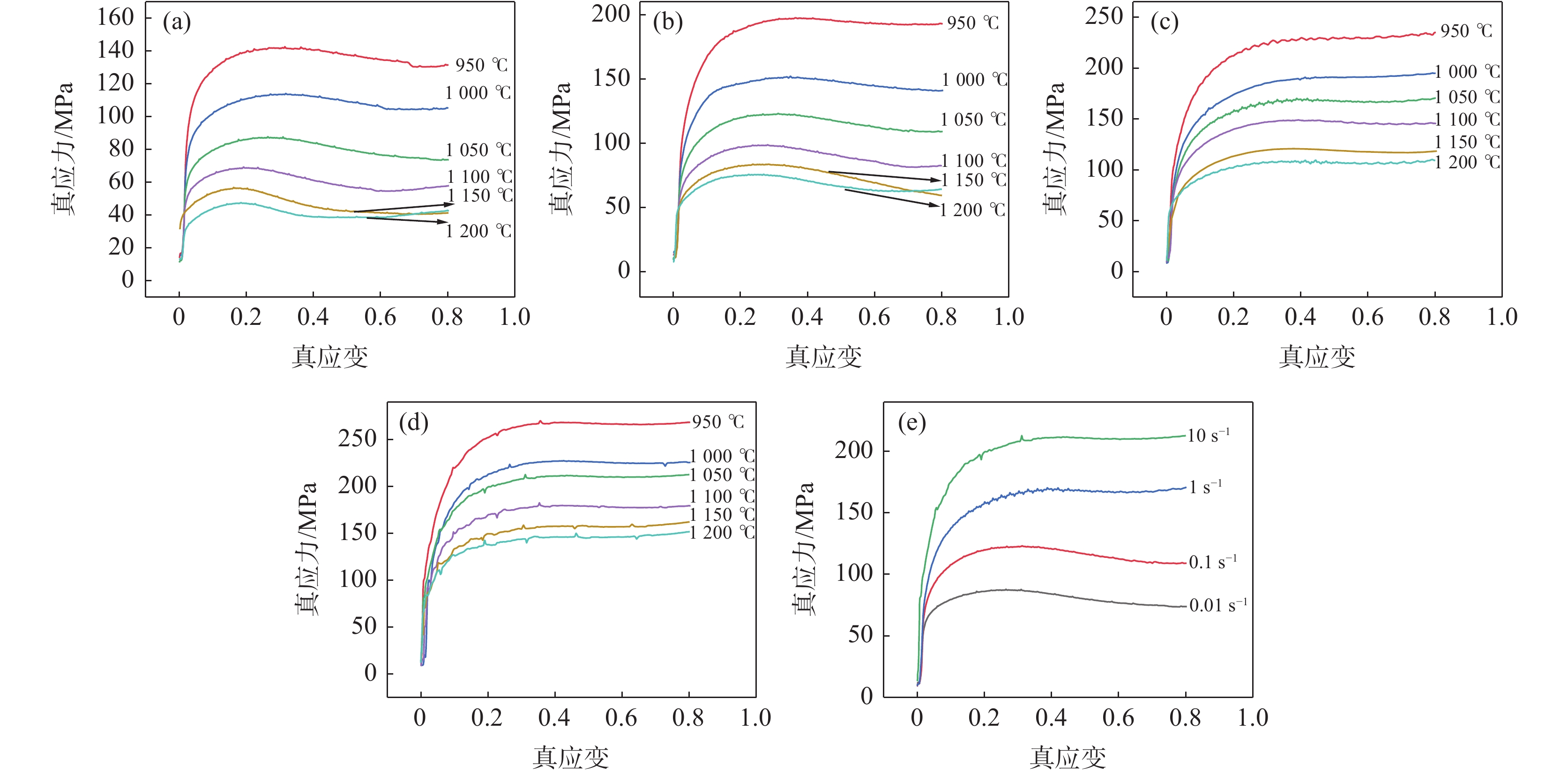

图 1 B50A789G叶片钢不同应变速率、不同应变温度下的真应力-真应变曲线

Figure 1. True stress-true strain curves of B50A789G blade steel at different strain rates and temperatures

$(a) \;\dot{\varepsilon}=0.01\; \mathrm{s}^{-1};\;(b) \;\dot{\varepsilon}=0.1\; \mathrm{s}^{-1};\;(c) \;\dot{\varepsilon}=1 \;\mathrm{s}^{-1};\;(d) \;\dot{\varepsilon}=10\; \mathrm{s}^{-1};\;(e)\; 1\;050$℃

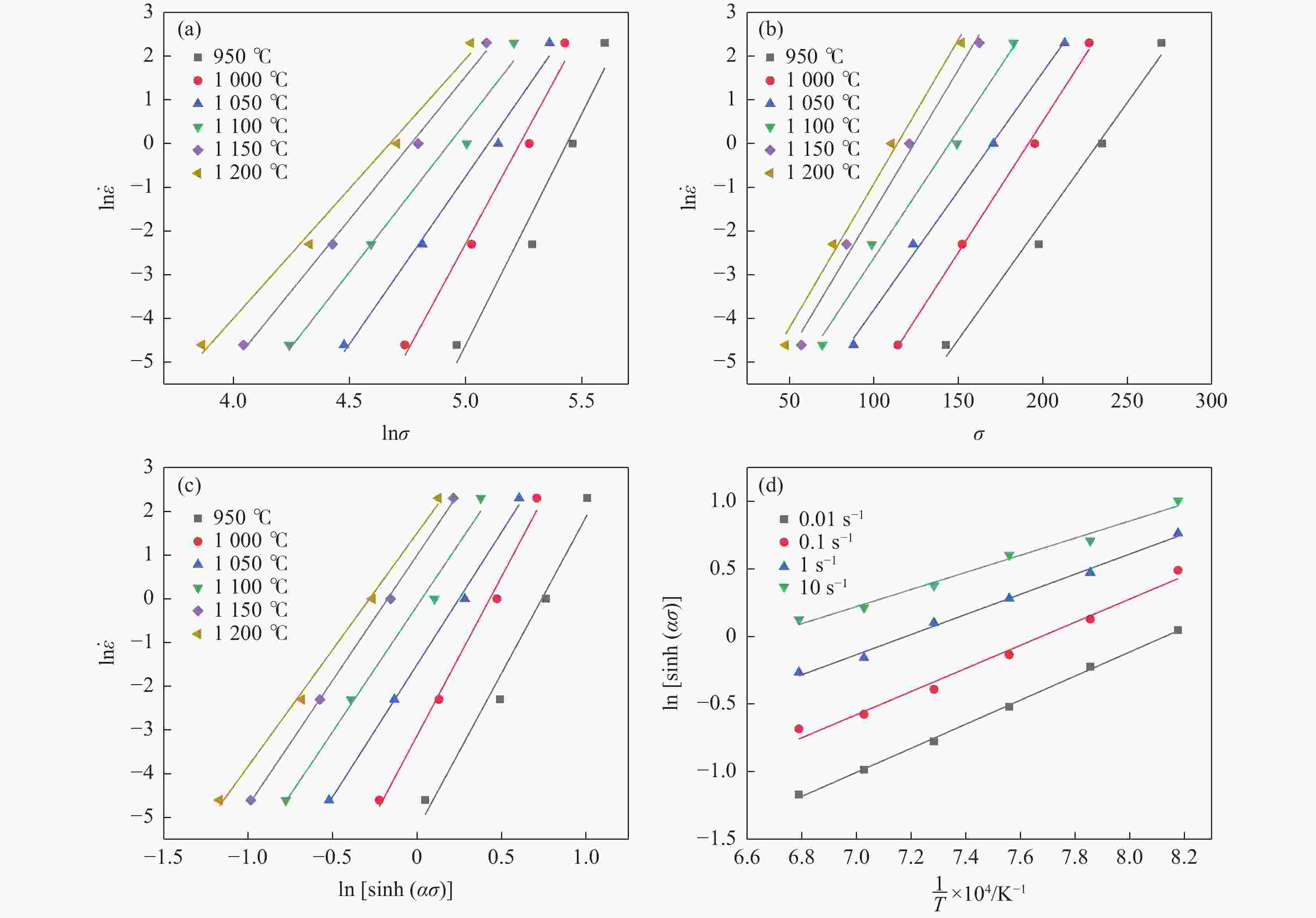

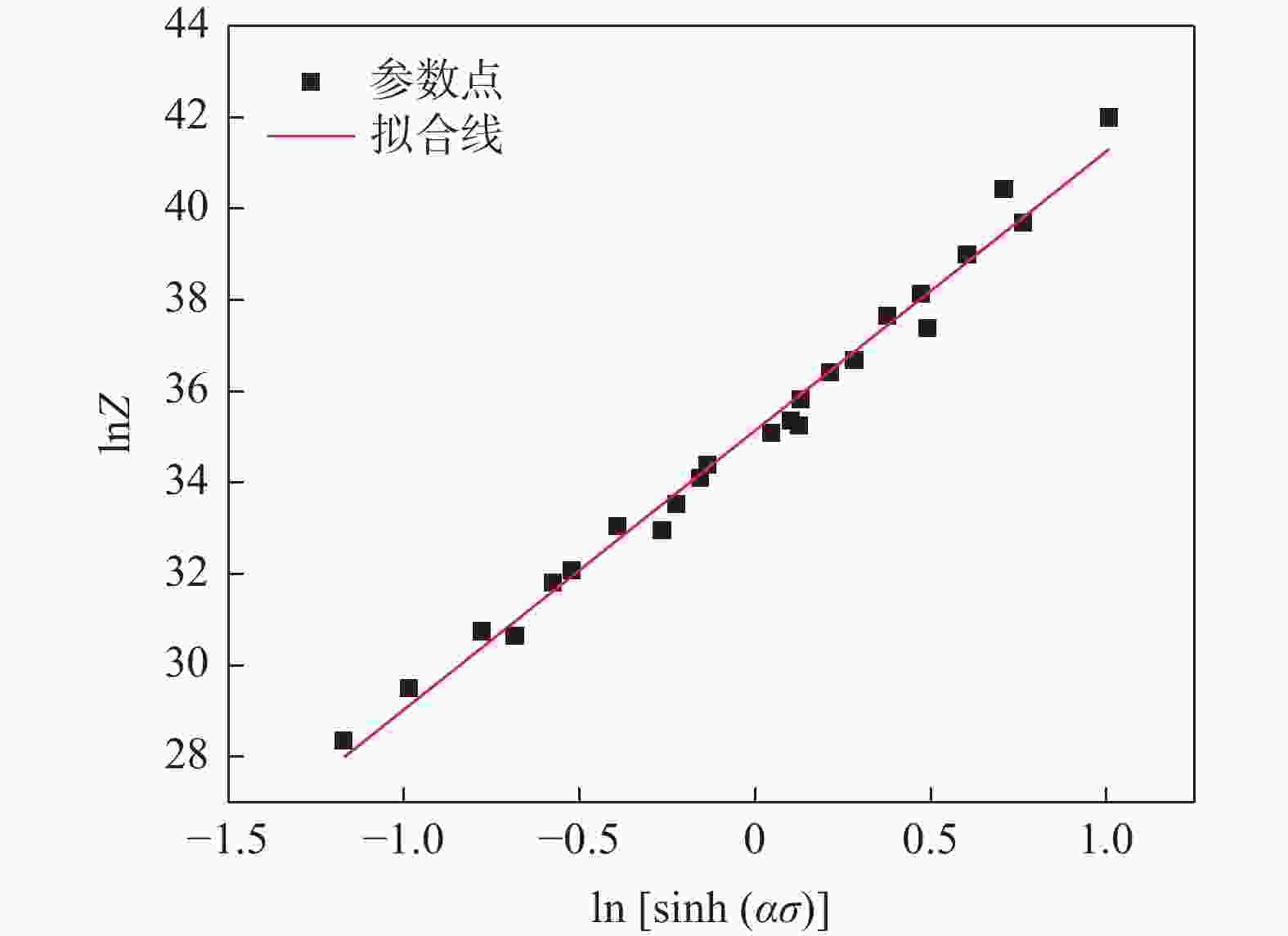

图 2 不同参数之间的关系

Figure 2. Relationships between different parameters

(a)$ {\text{ln}}\dot \varepsilon $-$ {\text{ln}}\sigma $;(b)$ {\text{ln}}\dot \varepsilon $-$ \sigma $;(c)$ {\text{ln}}\dot \varepsilon $-$ {\text{ln}}\left[ {{\text{sinh}}(\alpha \sigma )} \right] $;(d)$ {\text{ln}}\left[ {{\text{sinh}}(\alpha \sigma )} \right] $-1/T

-

[1] Liu Zhengdong, Cheng Shichang, Gan Yong, et al. Research and development of advanced boiler steel tubes and pipes used for 600 ℃ USC power plants in China[J]. Iron and Steel, 2010,45(10):1-8. (刘正东, 程世长, 干勇, 等. 中国600 ℃蒸汽参数火电机组用锅炉钢管国产化研制进展[J]. 钢铁, 2010,45(10):1-8.Liu Zhengdong, Cheng Shichang, Gan Yong, etal. Research and Development of Advanced Boiler Steel Tubes and Pipes Used for 600 ℃ USC Power Plants in China[J]. Iron and Steel, 2010, 45(10): 1-8. [2] Zhang Zhenyu, Yao Chenguang. Technology and develpoment of ultra supercritical coal-fired power generationin China[J]. Jounal of Shenyang Institute of Engineering: Natural Science, 2011,7(1):29-32. (张振宇, 姚晨光. 我国超超临界燃煤发电技术及发展[J]. 沈阳工程学院学报:自然科学版, 2011,7(1):29-32.Zhang Zhenyu, Yao Chenguang. Technology and develpoment of ultra supercritical coal-fired power generationin China[J]. Jounal of Shenyang Institute of Engineering: Natural Science, 2011, 7(1): 29-32. [3] Zhu Baotian, Zhao Yi. Development of ultra-supercritical power generation technology in China[J]. Huadain Technology, 2008,30(2):1-5. (朱宝田, 赵毅. 我国超超临界燃煤发电技术的发展[J]. 华电技术, 2008,30(2):1-5.Zhu Baotian, Zhao Yi. Development of ultra-supercritical power generation technology in China[J]. Huadain Technology, 2008, 30(2)1-5. [4] Wang Qian, Wang Weiliang, Liu Min, et al. Development and prospect of (ultra) supercritical coal-fired power generation technology[J]. Thermal Power Generation, 2021,50(2):1-9. (王倩, 王卫良, 刘敏, 等. 超(超)临界燃煤发电技术发展与展望[J]. 热力发电, 2021,50(2):1-9.WANG Qian, WANG Weiliang, LIU Min, et al. Development and prospect of (ultra) supercritical coal-fired power generation technology[J]. Thermal Power Generation, 2021, 50(2): 1-9. [5] Yang Gang, Wu Jiangfeng, Chen Xinjian, et al. Effect of heat treatment on mechanical properties of GTD-450 blade steel[J]. Iron and Steel, 2010,45(5):61-65. (杨钢, 吴江枫, 陈新建, 等. 热处理工艺对GTD-450叶片钢力学性能的影响[J]. 钢铁, 2010,45(5):61-65.Yang Gang, Wu Jiangfeng, Chen Xinjian, et al. Effect of Heat Treatment on Mechanical Properties of GTD-450 Blade Steel[J]. Iron and Steel, 2010, 45(05): 61-65. [6] Zener C, Hollomon J H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics,1944, 15( 1) : 22-32. [7] Sellars C M, Mctegart W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966,14(9):1136-1138. doi: 10.1016/0001-6160(66)90207-0 [8] Prasad Y, Gegel H L, Doraivelu S M, et al. Modeling of dynamic material behavior in hot deformation: forging of Ti-6242[J]. Metallurgical Transactions A, 1984,15(10):1883-1892. doi: 10.1007/BF02664902 [9] Prasad Y, Seshacharyulu T. Processing maps for hot working of titanium alloys[J]. Materials Science and Engineering A, 1998, 243 (1/2) : 82-88. [10] Prasad Y, Seshacharyulu T. Modelling of hot deformation for microstructural control[J]. International Materials Reviews, 1998,43(6):243-258. doi: 10.1179/imr.1998.43.6.243 -

下载:

下载: