Study on microstructure and properties of laser welded thin-walled straight seam titanium pipes

-

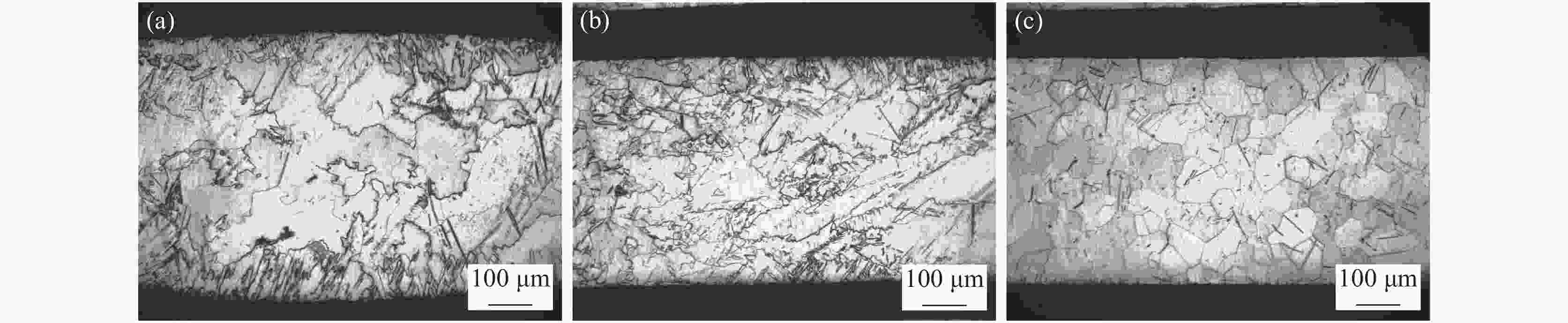

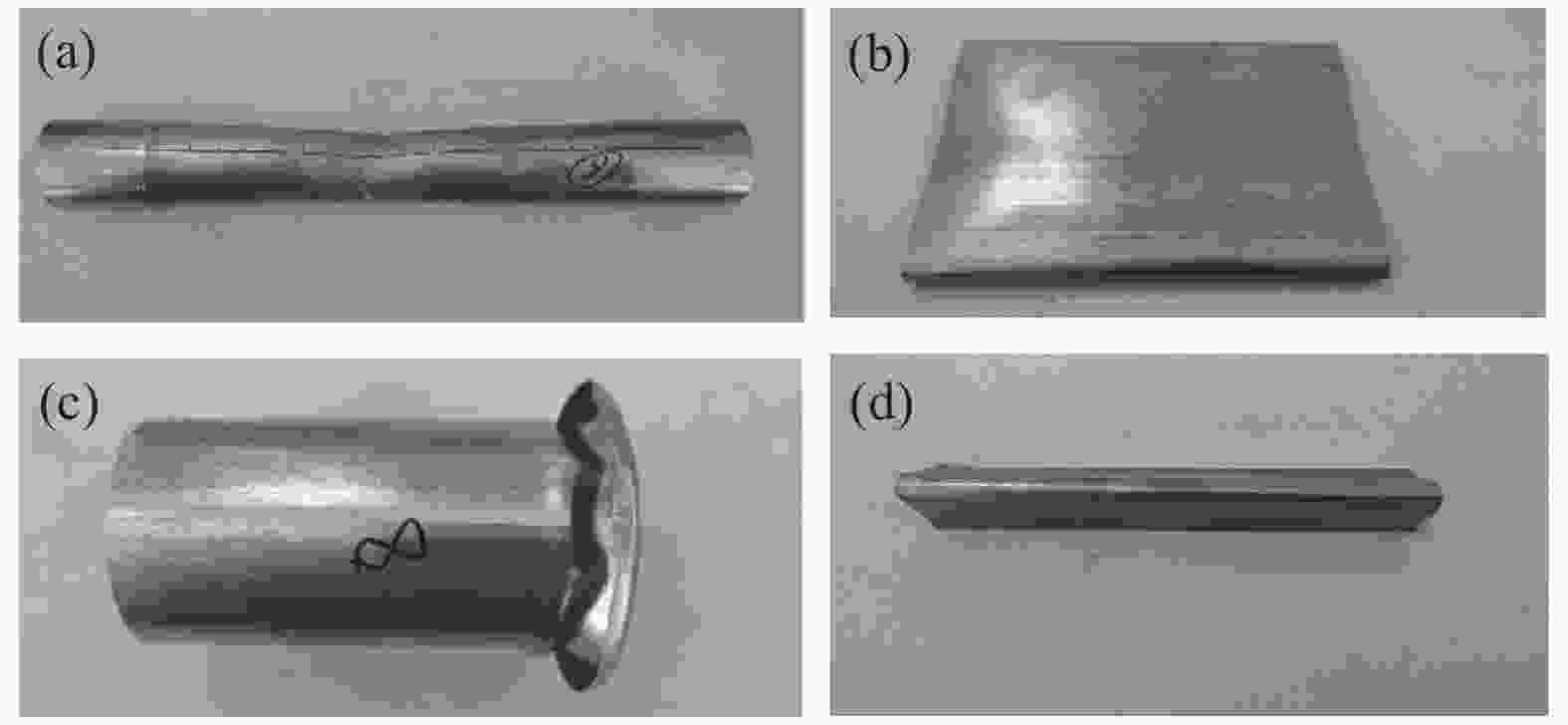

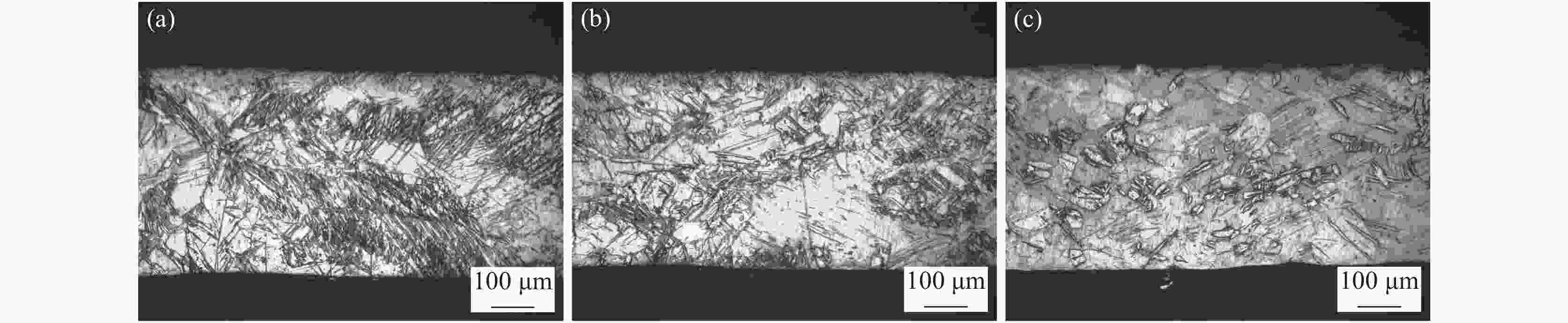

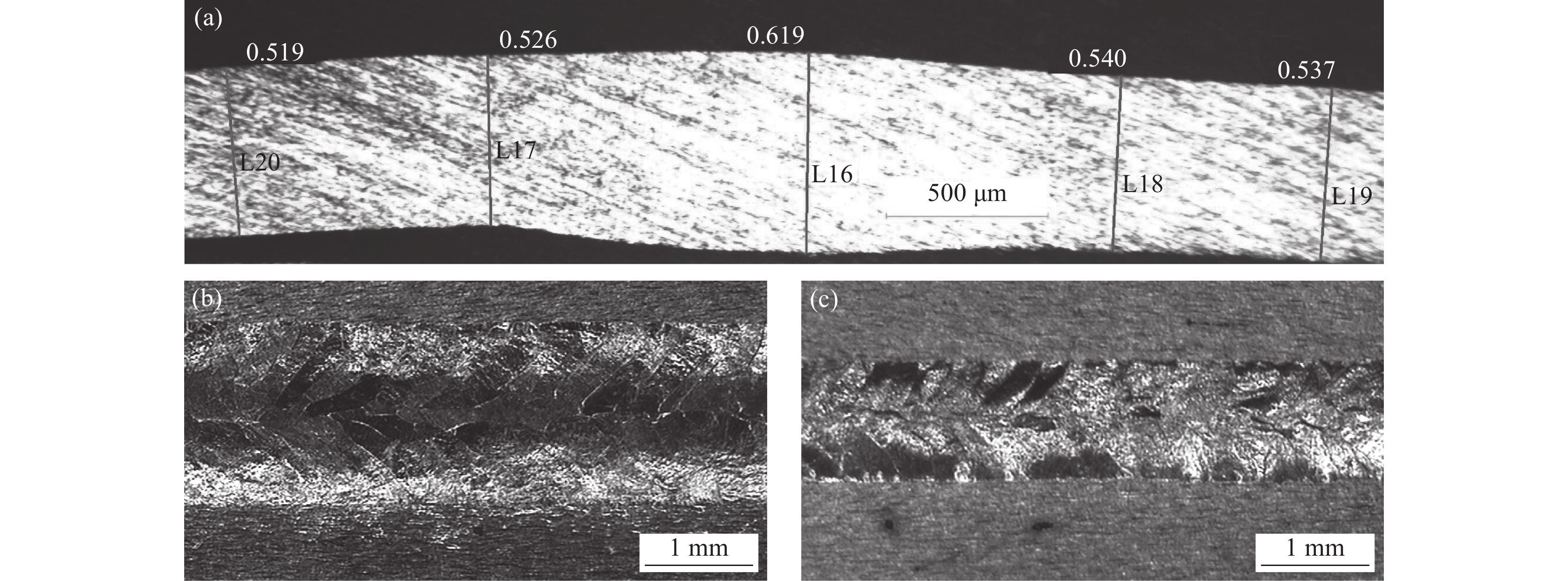

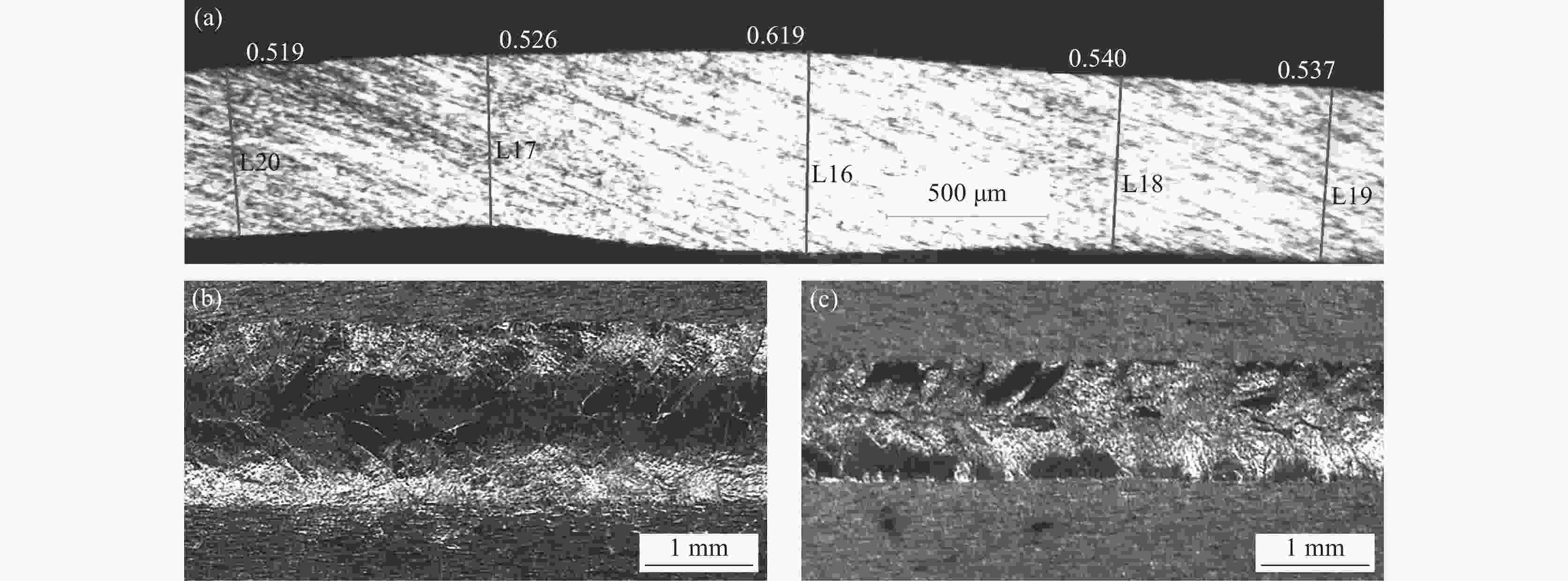

摘要: 对薄壁Gr.1纯钛直缝焊管采用激光焊接方式焊接,并对试验获得的样管进行了宏观形貌、显微组织分析和力学性能测试。结果表明,直缝薄壁焊管焊缝宽度较窄,外焊缝宽度为1.51 mm,内焊缝宽度为0.98 mm。钛焊管焊缝微观组织主要为柱状α相、锯齿状α相和少量针状α相。扩口、压扁、反弯试验结果均合格。最后对样管进行胀管试验,胀幅达到18.4%,外观变形较为均匀。从胀管后微观组织可知,胀管后焊缝、热影响区以及母材大部分晶粒受到拉伸作用明显变形和破碎,并产生较多针状α相,但均没有产生裂纹。Abstract: The thin-walled Gr.1 pure titanium straight seam welded pipe was welded by laser, and the samples obtained from the experiment were analyzed for macroscopic morphology, microstructure and mechanical properties. The results show that the weld width of longitudinally welded thin-walled pipe is relatively narrow, with an outer weld width of 1.51 mm and an inner weld width of 0.98 mm. The microstructure of titanium welded pipe weld is mainly columnar α phase, serrated α phase and a small amount of needle shape α phase. The results of flaring, flattening, and reverse bending tests are all qualified. Finally, an expansion test was conducted on the sample tube, and the expansion amplitude reached 18.4%, with a relatively uniform deformation in appearance. From the microstructure after tube expansion, it can be seen that after tube expansion, most of the grains in the weld seam, heat affected zone, and base metal are significantly deformed and broken due to tensile action, and many needle shaped α phase grains are produced , but no cracks occurred.

-

Key words:

- laser welding /

- titanium pipe /

- microstructure /

- mechanical properties /

- expand tube

-

表 1 Gr.1带卷主要化学成分

Table 1. Main chemical composition of Gr.1

% Fe C O N H Ti 其他 0.03 0.01 0.04 0.01 0.001 余量 <0.4 表 2 原材料性能

Table 2. Raw material performance

抗拉强度/MPa 屈服强度/MPa 延伸率/% 晶粒度等级 328 188 39.5 5 表 3 激光焊接工艺参数

Table 3. Laser welding process parameters

激光功率/W 焊接速度/(m·min−1) 离焦量/mm 600 0.75 +20 表 4 焊缝尺寸

Table 4. Weld macro-size

mm 焊缝宽度 母材厚度 焊缝余高 外焊缝宽度 内焊缝宽度 0.619 0.537 0.082 1.51 0.98 -

[1] Ma Lei, Fu Chaoqiang. Research progress on the application of laser welding technology[J]. Die Mould Manufacture, 2023,23(11):157-159. (马磊, 付朝强. 激光焊接技术的应用研究进展[J]. 模具制造, 2023,23(11):157-159.Ma Lei, Fu Chaoqiang. Research progress on the application of laser welding technology[J]. Die Mould Manufacture, 2023, 23(11): 157-159. [2] Huang Jiuling, Kong Liang, Wang Min, et al. Welding of titanium and titanium alloy thin plates[J]. Welding Technology, 2018, 47(11): 1-5. (黄九龄, 孔谅, 王敏, 等. 钛及钛合金薄板的焊接[J]. 焊接技术, 2018, 47(11): 1-5.Huang Jiuling, Kong Liang, Wang Min, et al. Welding of titanium and titanium alloy thin plates[J]. Welding Technology, 2018, 47(11): 1-5. [3] Zhen Zuyang. Study on laser-arc hybrid high-speed welding process of TA2 pure titanium sheet[D]. Harbin: Harbin Institute of Technology, 2021. (甄祖阳. TA2纯钛薄板激光-电弧复合高速焊接工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2021.Zhen Zuyang. Study on laser-arc hybrid high-speed welding process of TA2 pure titanium sheet[D]. Harbin: Harbin Institute of Technology, 2021. [4] Zhao Xiaolong, Wang Bin, Gong Shuili, et al. Study on microstructure and mechanical properties of laser welded joint of 2 mm thick TC4 titanium alloy[J]. Hot Working Technology, 2017,46(9):209-211. (赵晓龙, 王彬, 巩水利, 等. 2.0 mm厚TC4钛合金激光焊接接头组织与力学性能研究[J]. 热加工工艺, 2017,46(9):209-211.Zhao Xiaolong, Wang Bin, Gong Shuili, et al. Study on microstructure and mechanical properties of laser welded joint of 2 mm thick TC4 titanium alloy[J]. Hot Working Technology, 2017, 46(9): 209-211. [5] Sun Wenjun, Wang Shanlin, Chen Yuhua, et al. Development of advanced welding technologies for titanium alloys[J]. Aeronautical Manufacturing Technology, 2019,62(18):63-72. (孙文君, 王善林, 陈玉华, 等. 钛合金先进焊接技术研究现状[J]. 航空制造技术, 2019,62(18):63-72.Sun Wenjun, Wang Shanlin, Chen Yuhua, et al. Development of advanced welding technologies for titanium alloys[J]. Aeronautical Manufacturing Technology, 2019, 62(18): 63-72. [6] Yu Hang, Li Junzhao, Zhang Wangcheng, et al. Research progress of weld formation and performance control of thin plate TC4 titanium alloy by laser welding[J]. Iron Steel Vanadium Titanium, 2022,43(1):53-66. (于航, 李军兆, 张望成, 等. 薄壁TC4钛合金激光焊缝成型与性能调控研究进展[J]. 钢铁钒钛, 2022,43(1):53-66.Yu Hang, Li Junzhao, Zhang Wangcheng, et al. Research progress of weld formation and performance control of thin plate TC4 titanium alloy by laser welding[J]. Iron Steel Vanadium Titanium, 2022, 43(1): 53-66. [7] Wang Boshi, Kong Liang, Li Fang, et al. Microstructure and properties of TIG arc assisted laser welding TA2 thin-walled straight pipe[J]. Hot Working Technology, 2023(5):135-140. (王博士, 孔谅, 李芳, 等. TIG电弧辅助激光焊TA2直缝薄壁焊管的组织性能研究[J]. 热加工工艺, 2023(5):135-140.Wang Boshi, Kong Liang, Li Fang, et al. Microstructure and properties of TIG arc assisted laser welding TA2 thin-walled straight pipe[J]. Hot Working Technology, 2023(5): 135-140. [8] Zhou Yang. Research on arc-assisted TA2 thin plate laser welding process and joint performance[D]. Shanghai: Shanghai Jiao Tong University, 2020. (周洋. 基于电弧辅助的TA2薄板激光焊工艺与接头性能研究[D]. 上海: 上海交通大学, 2020.Zhou Yang. Research on arc-assisted TA2 thin plate laser welding process and joint performance[D]. Shanghai: Shanghai Jiao Tong University, 2020. -

下载:

下载: