Study on interfacial thermal stability of SiCf/TC25G composites

-

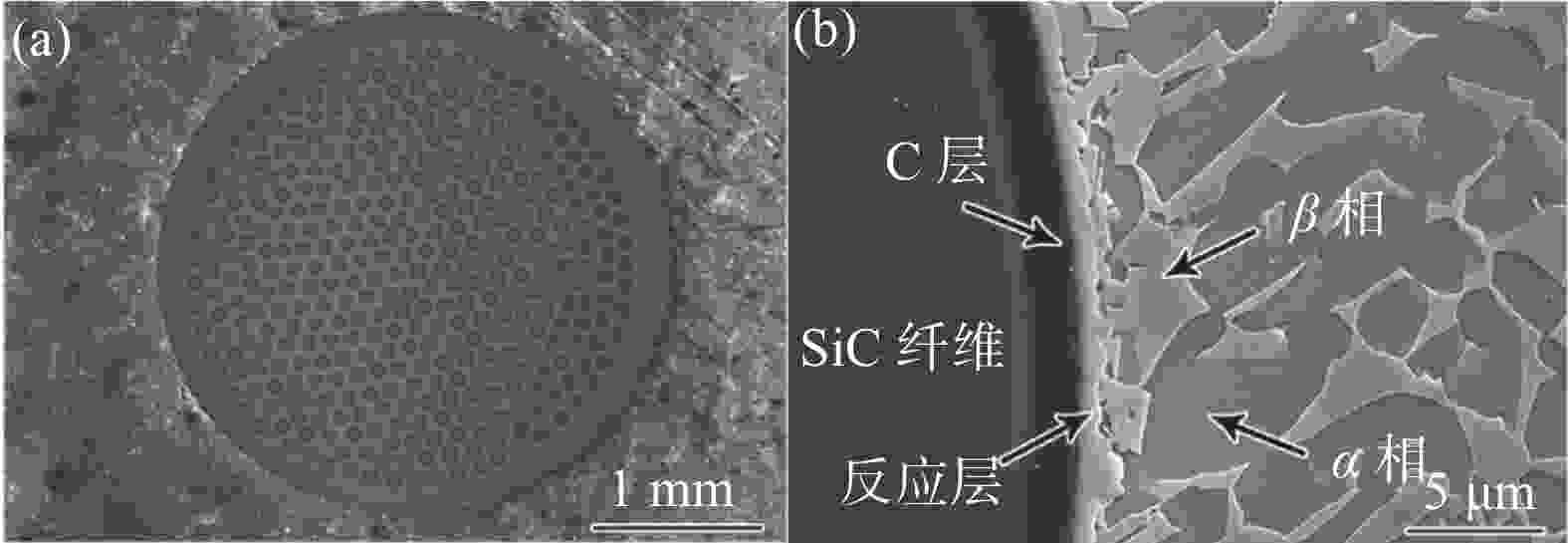

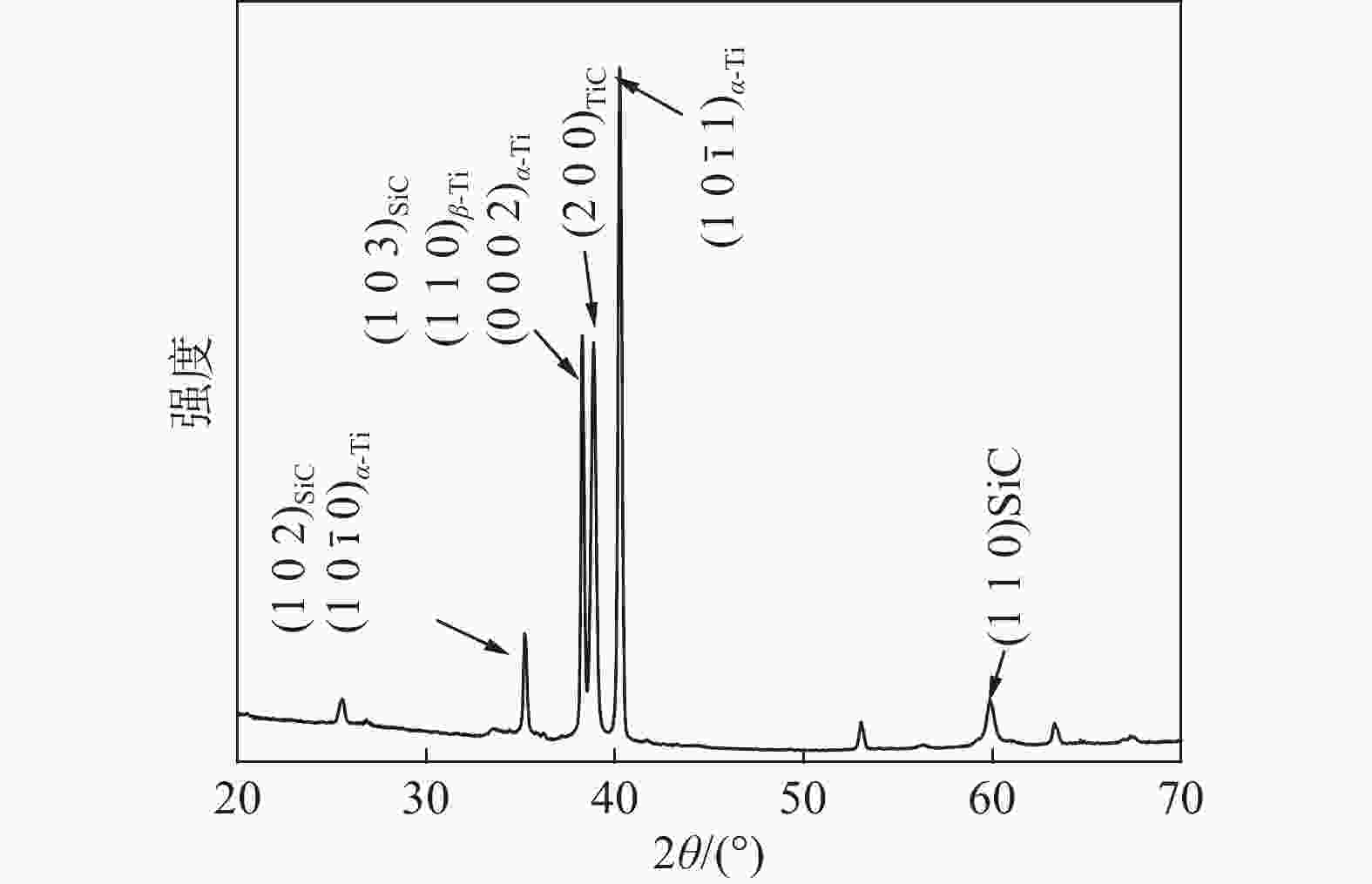

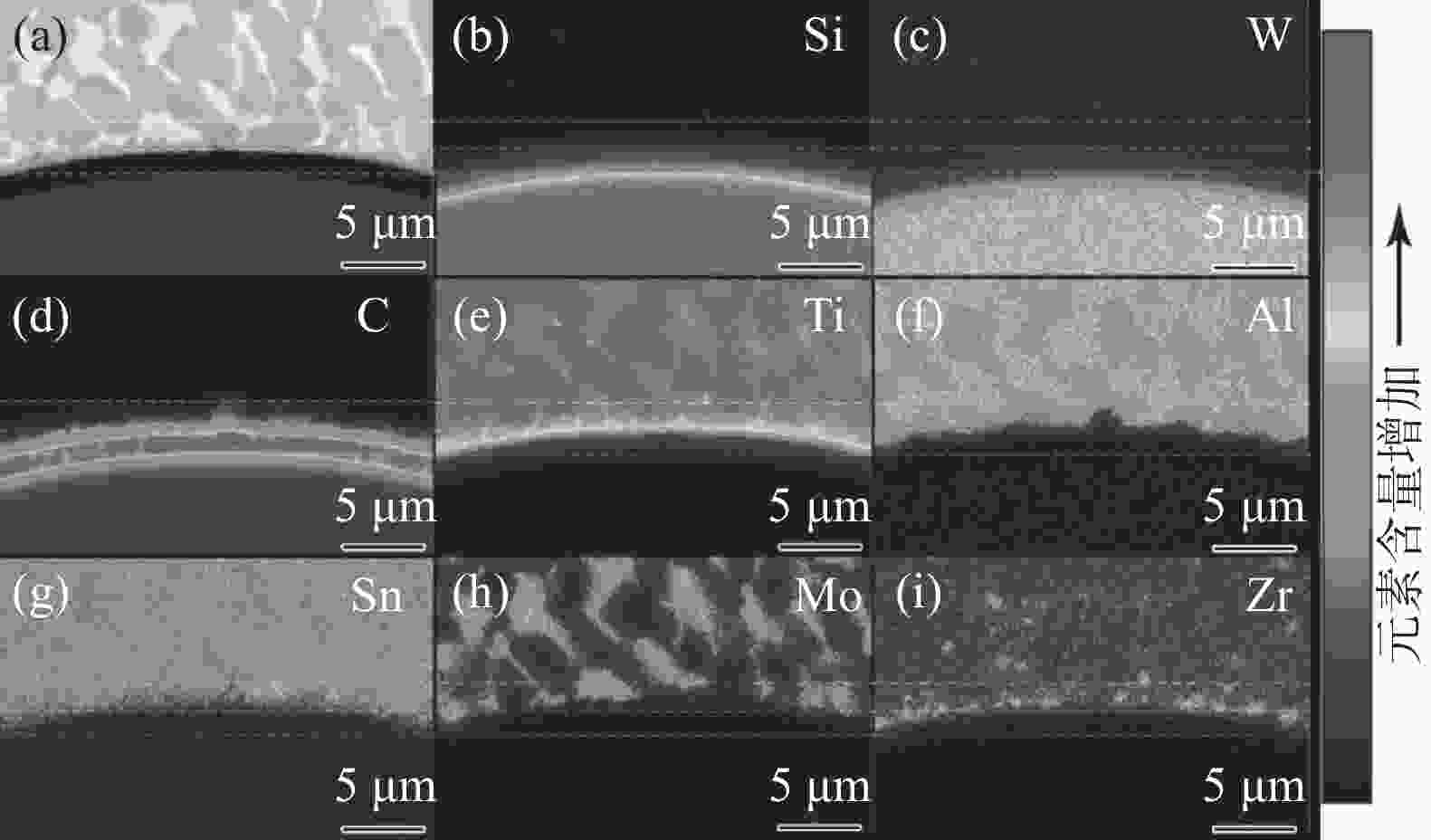

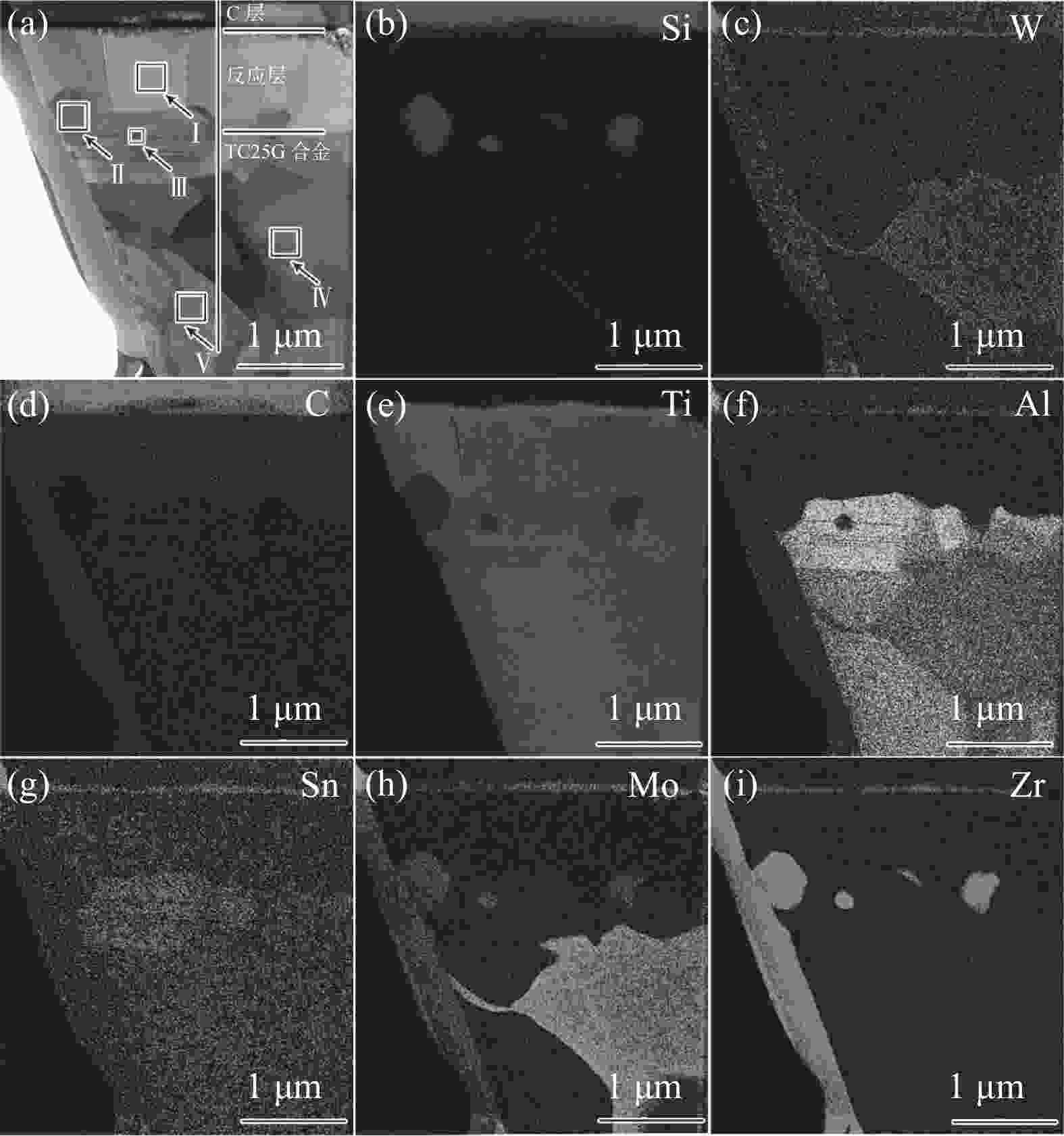

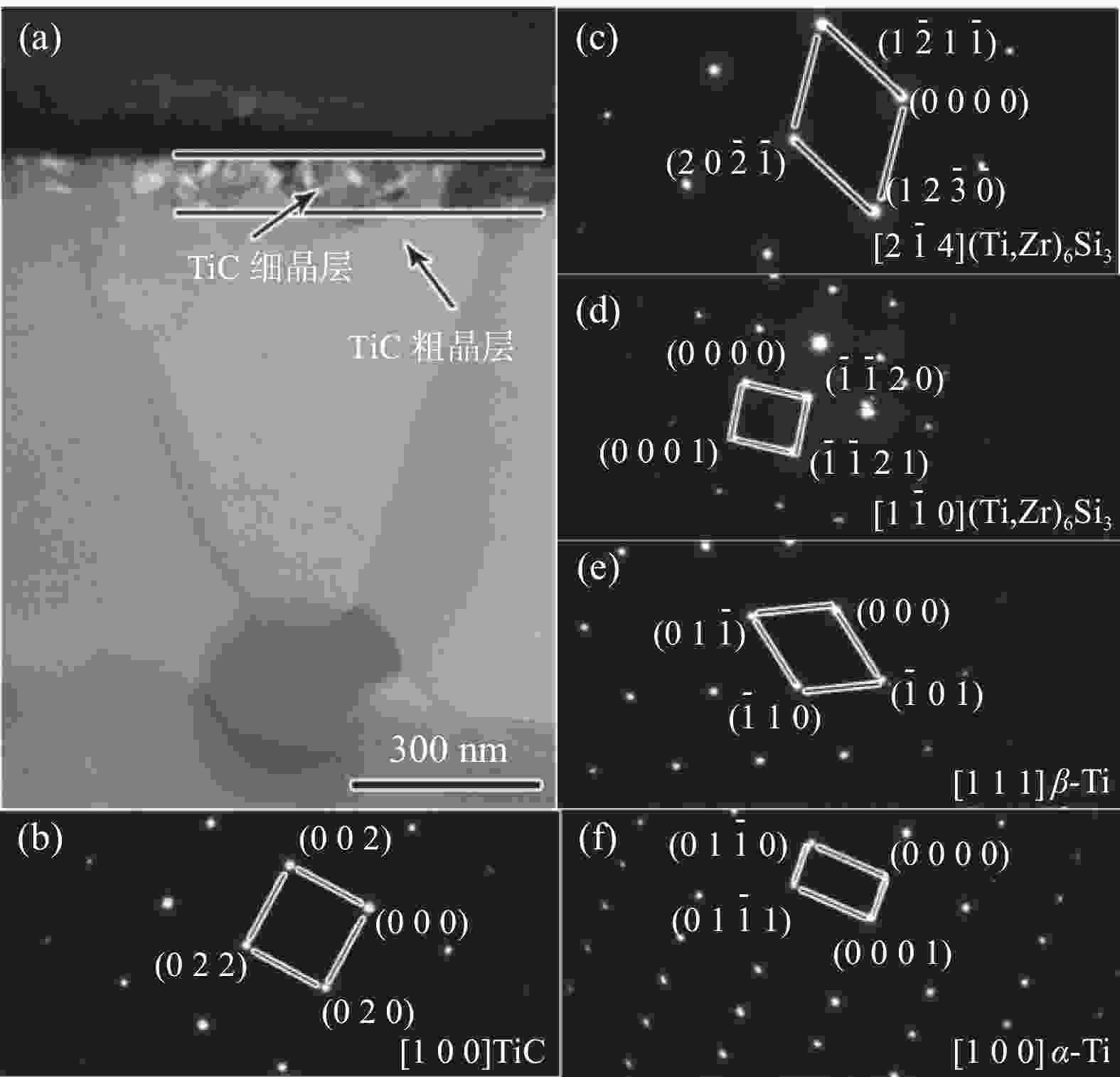

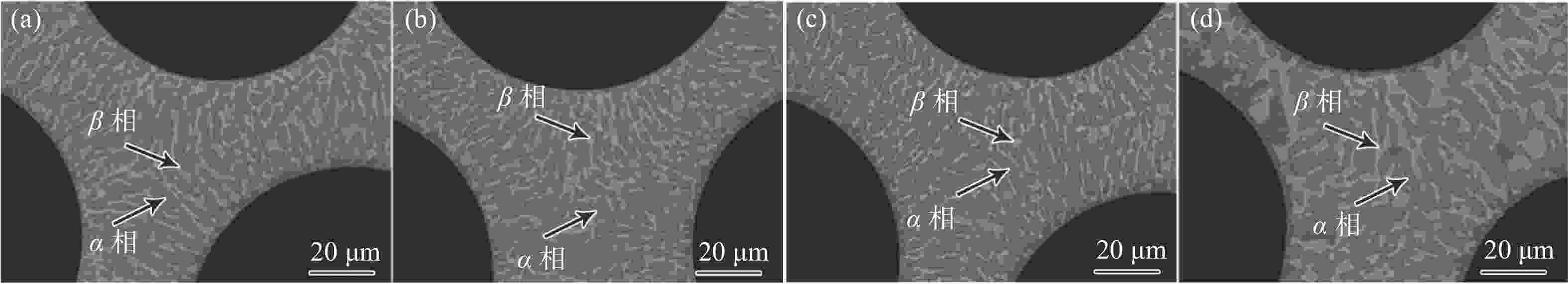

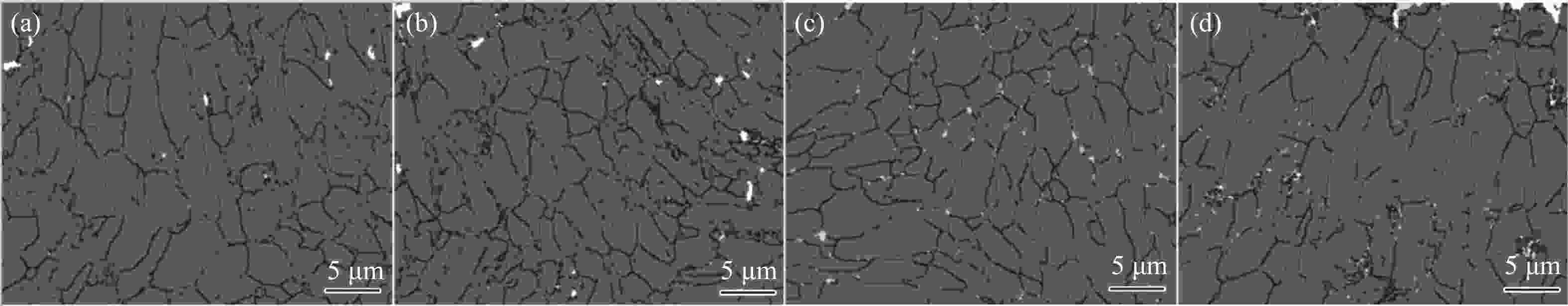

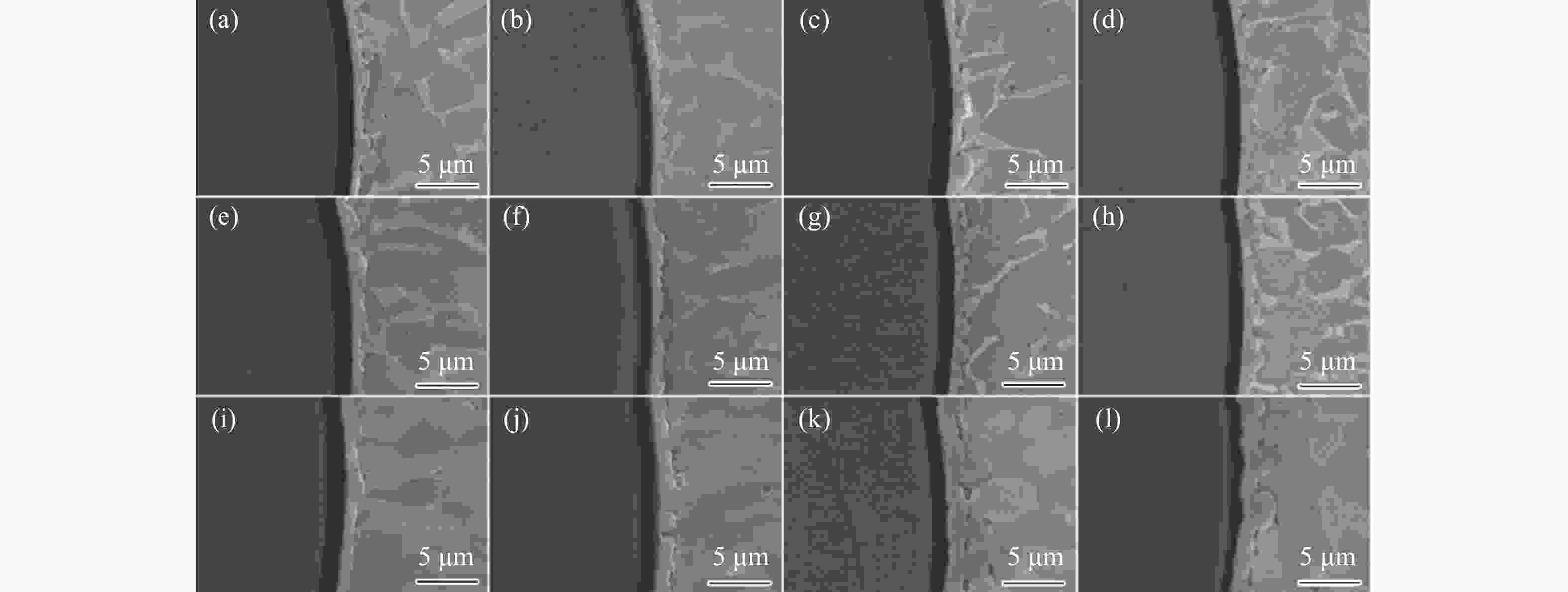

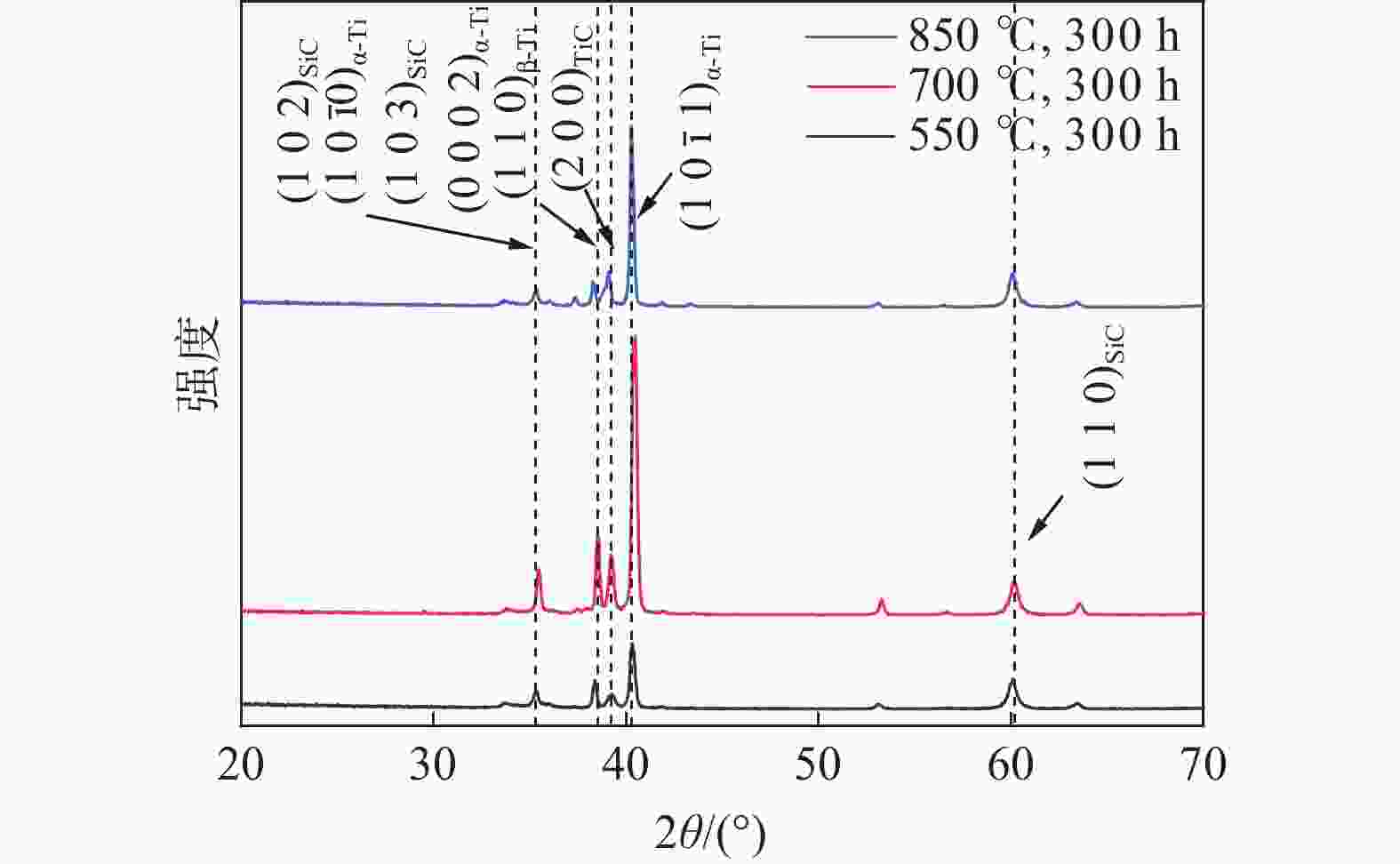

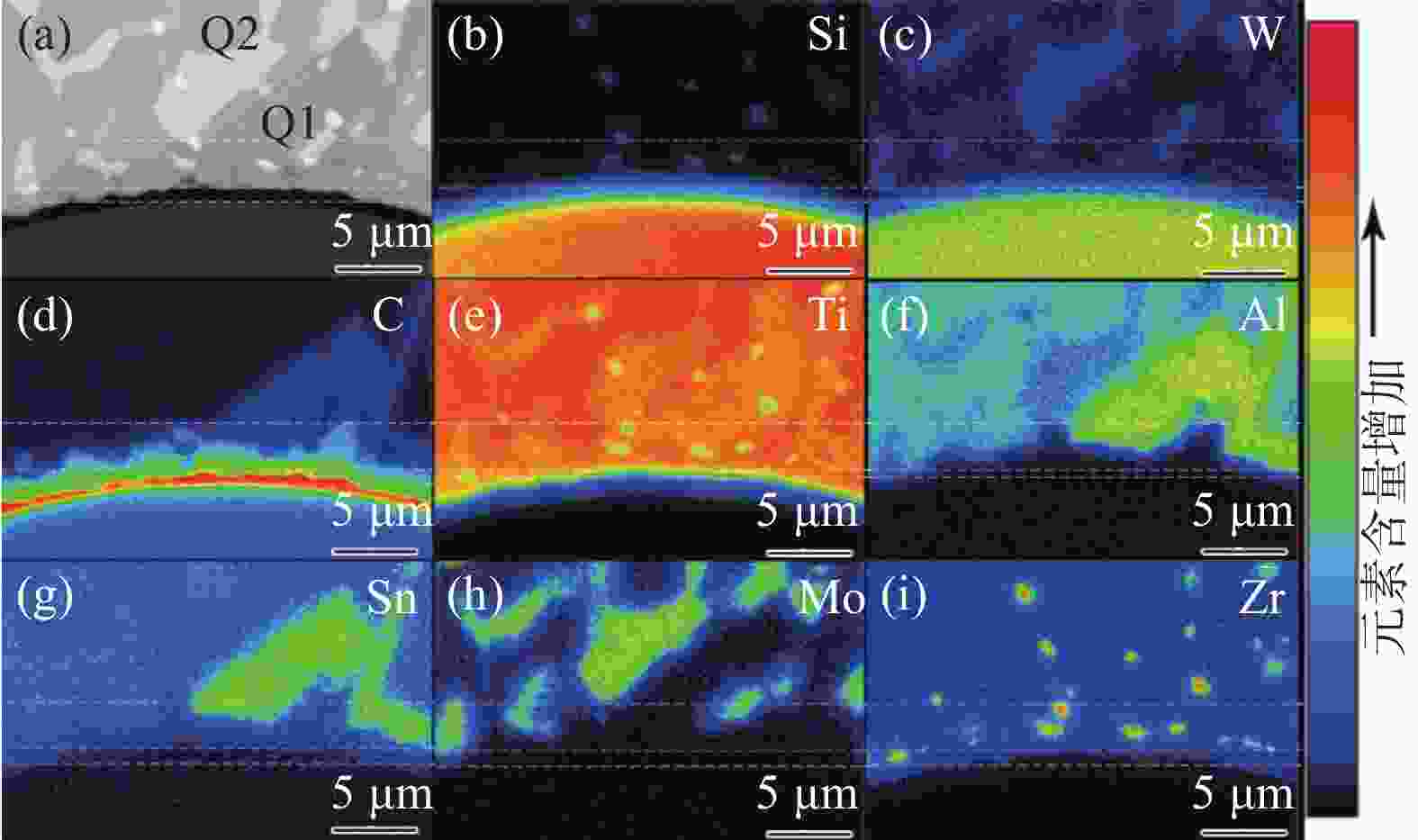

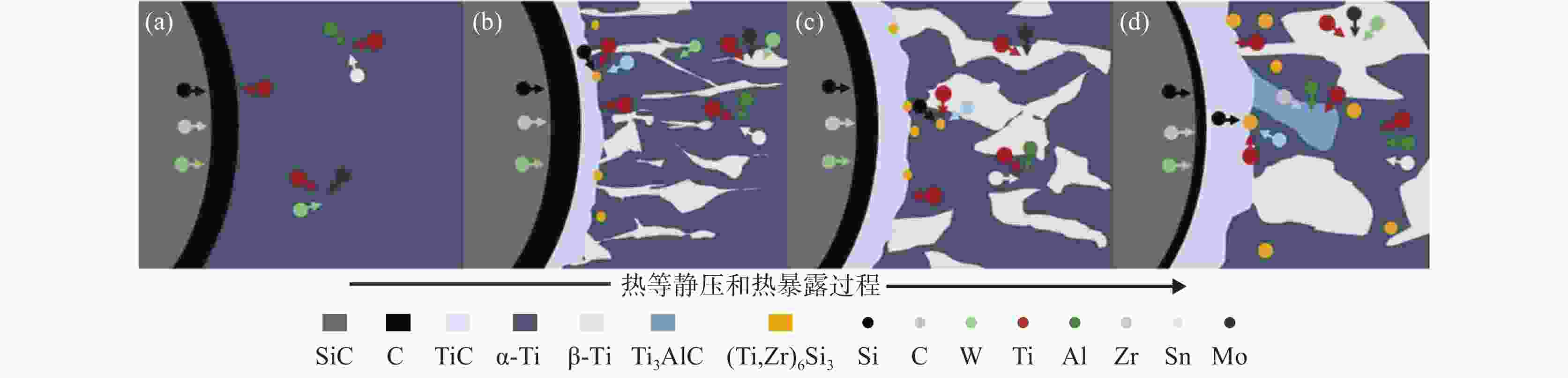

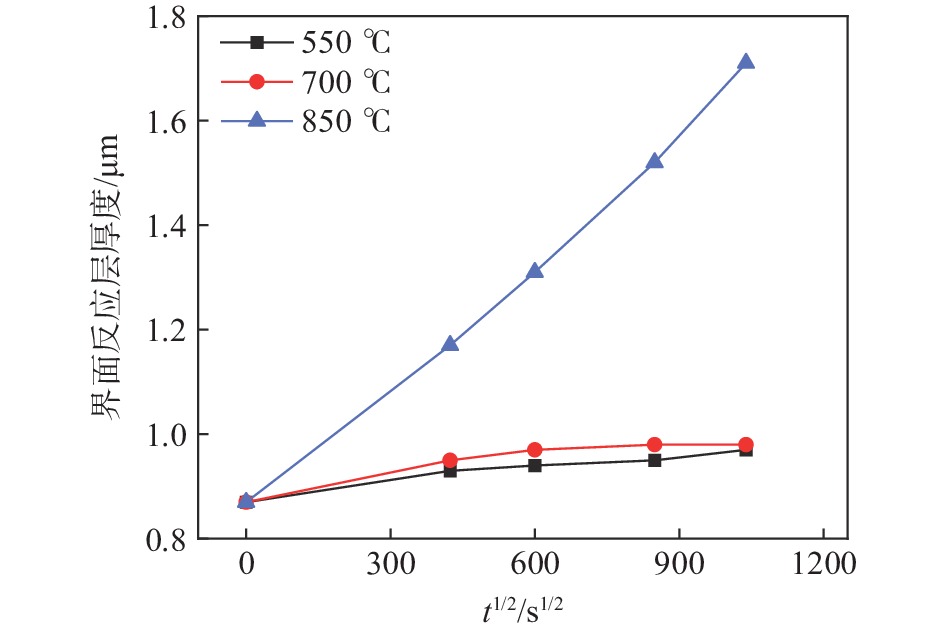

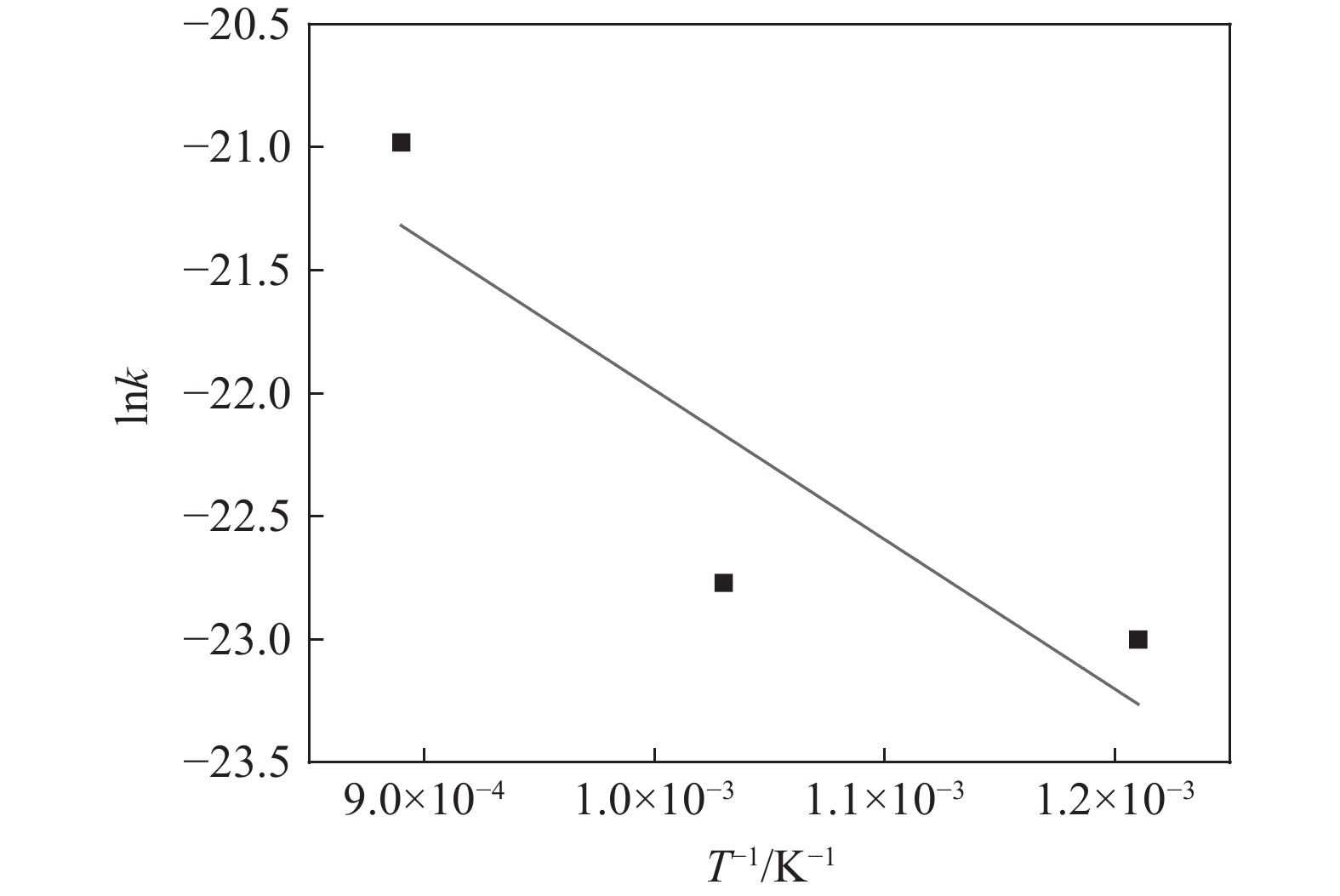

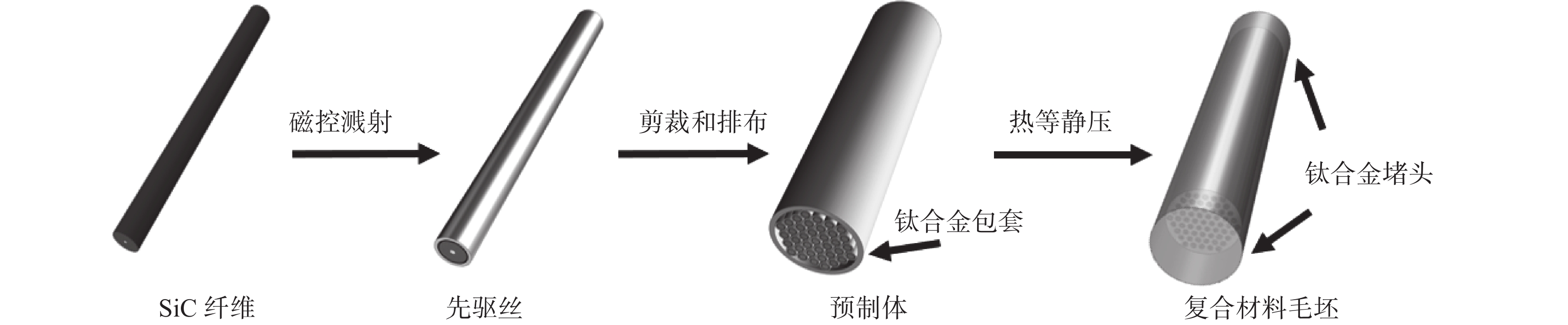

摘要: TMCs在高温服役长时使用过程中,基体与纤维会发生严重的界面反应,导致复合材料力学性能下降。以磁控溅射先驱丝法+热等静压工艺制备的SiCf/TC25G复合材料作为研究对象,结合TC25G钛合金服役温度,系统设计了不同热暴露条件下复合材料界面热稳定性试验,分析了热等静压态和热暴露态SiCf/TC25G复合材料界面形貌和界面产物。结合SEM、TEM、EPMA、XRD、EBSD等技术分析表明,热等静压态的SiCf/TC25G复合材料界面反应层主要产物为TiC,反应层靠近基体侧和基体中存在硅化物的析出。随着热暴露温度和保温时间增加,界面反应层厚度增加。根据界面反应层增量,总结出SiCf/TC25G复合材料界面长大规律,利用Arrhenius公式计算获得SiCf/TC25G复合材料界面反应层长大激活能为50.53 kJ/mol,反应层长大指数因子为1.23×10−7 m/s1/2。Abstract: The prolonged exposure of TMCs to high temperatures results in severe interfacial reactions between the matrix and the fiber, leading to a degradation in the mechanical properties of the composites. In this study, SiCf/TC25G composites were prepared using a magnetron sputtering precursor wire method followed by hot isostatic pressing process. The interface reaction and thermal stability of the composites were investigated. Specifically designed interfacial thermal stability experiments under different thermal exposure conditions were conducted based on the service temperature of TC25G titanium alloy. The resulting interfacial morphology and products of the composites under hot isostatic pressure and hot exposure were analyzed using various techniques including SEM, TEM, EPMA, XRD, and EBSD techniques. The primary product of the interface reaction layer in SiCf/TC25G composites under hot isostatic pressure is validated as TiC, and the silicides in the reaction layer near the matrix side and the matrix precipitate in the form of (Ti, Zr)6Si3. As thermal exposure temperature and holding time increased, both the thickness of the interface reaction layer increases while that of the C coating decreases. Based on these observations, a growth law for SiCf/TC25G composite was summarized. The activation energy for the growth of the interfacial reaction layer in SiCf/TC25G composites is 50.53 kJ /mol, and the exponential factor for the reaction layer growth is 1.23×10−7 m/s1/2.

-

Key words:

- titanium matrix composites /

- TC25 G /

- SiC fiber /

- thermal stability /

- interfacial reaction

-

表 1 热等静压态和不同热暴露温度保温300 h后SiCf/TC25G复合材料的晶粒平均面积尺寸

Table 1. The average grain area sizes of HIPed SiCf/TC25G composites after 300 h thermal exposure to different temperatures

物相 热等静压态 平均面积/μm2 550 ℃/300 h 700 ℃/300 h 850 ℃/300 h α-Ti 0.52 0.65 1.07 2.21 β-Ti 0.11 0.14 0.22 0.80 TiC 0.15 0.22 0.21 0.36 (Ti,Zr)6Si3 0.05 0.09 0.07 0.16 表 2 热等静压态和不同热暴露温度保温300 h后SiCf/TC25G复合材料不同相在基体中的面积分数

Table 2. The area fraction of different phases in SiCf/TC25G composites matrix

物相 热等静压态 面积分数/% 550 ℃/300 h 700 ℃/300 h 850 ℃/300 h α-Ti 83.2 81.0 80.4 64.2 β-Ti 15.7 15.7 12.3 23.7 TiC 0.9 2.8 6.9 11.0 (Ti,Zr)6 Si3 0.1 0.4 0.3 1.0 表 3 SiCf/TC25G复合材料在不同热暴露条件下界面反应层的厚度

Table 3. Thicknesses of interfacial reaction layer of SiCf/TC25G composites under different thermal exposure conditions

温度/ ℃ 反应层厚度/μm 50 h 100 h 200 h 300 h 550 0.93±0.28 0.94±0.24 0.95±0.32 0.97±0.27 700 0.95±0.26 0.97±0.27 0.98±0.25 0.98±0.23 850 1.17±0.32 1.31±0.29 1.52±0.32 1.71±0.47 表 4 不同材料的指数因子(k0)和界面反应层长大激活能(Q)

Table 4. Exponential factors (k0) and interfacial reactive layer growth activation energy (Q) of different materials

-

[1] Fu Hengzhi. Challenges and development trends of aero-engine materials in the future[J]. J. Aerona. Mater., 1998(4):54. (傅恒志. 未来航空发动机材料面临的挑战与发展趋向[J]. 航空材料学报, 1998(4):54.Fu Hengzhi. Challenges and development trends of aero-engine materials in the future[J]. J. Aerona. Mater., 1998(4): 54. [2] Mackay R, Brindley P, Froes F. Continuous fiber-reinforced titanium aluminide composites[J]. JOM, 1991,43:23. [3] Larsen J M, Russ S M, Jones J. An evaluation of fiber-reinforced titanium matrix composites for advanced high-temperature aerospace applications[J]. Metall. Mater. Trans. A., 1995,26:3211. doi: 10.1007/BF02669450 [4] Yang Rui, Shi Nanlin, Wang Yumin, et al. Research progress of SiC fiber reinforced titanium matrix composites[J]. Titanium Ind. Prog., 2005(5):37. (杨锐, 石南林, 王玉敏, 等. SiC纤维增强钛基复合材料研究进展[J]. 钛工业进展, 2005(5):37.Yang Rui, Shi Nanlin, Wang Yumin, et al. Research progress of SiC fiber reinforced titanium matrix composites[J]. Titanium Ind. Prog., 2005(5): 37. [5] Zhang Xuesong, Chen Yongjun, Hu Junling. Recent advances in the development of aerospace materials[J]. Prog. Aeosp. Sci., 2018,97:22-34. doi: 10.1016/j.paerosci.2018.01.001 [6] Wang Yumin, Zhang Guoxing, Zhang Xu, et al. Research progress of continuous SiC fiber reinforced titanium matrix composites[J]. Acta. Metall. Sin. , 2016, 52(10): 1153. (王玉敏, 张国兴, 张旭, 等. 连续SiC纤维增强钛基复合材料研究进展[J]. 金属学报, 2016, 52(10): 1153.Wang Yumin, Zhang Guoxing, Zhang Xu, et al. Research progress of continuous SiC fiber reinforced titanium matrix composites[J]. Acta. Metall. Sin. , 2016, 52(10): 1153. [7] Leyens C, Kocian F, Hausmann J, et al. Materials and design concepts for high performance compressor components[J]. Aerosp. Sci. Technol., 2003,7:201. doi: 10.1016/S1270-9638(02)00013-5 [8] Singh M, Dickerson R M, Olmstead F A, et al. SiC (SCS-6) fiber reinforced–reaction formed SiC matrix composites: Microstructure and interfacial properties[J]. J. Mater. Res., 2011,12(3):706-713. [9] Fu Y C, Shi N L, Zhang D Z, et al. Effect of C coating on the interfacial microstructure and properties of SiC fiber-reinforced Ti matrix composites[J]. Mater. Sci. Eng. A., 2006,426(1):278. [10] Baik K H, Grant P S. Chemical interaction between sigma 1140+ SiC fibre and Ti-6Al-4V[J]. Scr. Mater., 2001,44(4):607. doi: 10.1016/S1359-6462(00)00649-7 [11] Yang Yanqing, Zhu Yan, Zhang Jingyu, et al. Interfacial reaction of SCS-6SiC fiber reinforced titanium matrix composites[J]. Acta. Metall. Sin., 2002,38(suppl):4. (杨延清, 朱艳, 张晶宇, 等. SCS-6SiC纤维增强钛基复合材料的界面反应[J]. 金属学报, 2002,38(增刊):4.Yang Yanqing, Zhu Yan, Zhang Jingyu, et al. Interfacial reaction of SCS-6SiC fiber reinforced titanium matrix composites[J]. Acta. Metall. Sin., 2002, 38(suppl): 4. [12] Liu Qiaomu. Microstructure and texture of wrought TC25G titanium alloy bar[J]. Trans. Mater. Heat Treat., 2018,39(6):5. (刘巧沐. 锻态TC25G钛合金棒材的显微组织和织构[J]. 材料热处理学报, 2018,39(6):5.Liu Qiaomu. Microstructure and texture of wrought TC25G titanium alloy bar[J]. Trans. Mater. Heat Treat., 2018, 39(6): 5. [13] Yang Qing. Study on preparation and tensile properties of SiCf/BT25 composites [D]. Beijing: University of Chinese Academy of Sciences, 2018. (杨青. SiCf/BT25复合材料制备工艺及其拉伸性能研究 [D]. 北京:中国科学院大学, 2018.Yang Qing. Study on preparation and tensile properties of SiCf/BT25 composites [D]. Beijing: University of Chinese Academy of Sciences, 2018. [14] Wu Ming, Zhang Kan, Huang Hao, et al. Interfacial reactions in SiCf/C/Ti17 composites dominated by texture of carbon coatings[J]. Carbon, 2017,124:238. doi: 10.1016/j.carbon.2017.08.065 [15] Xiao Peng. Study on interface optimization and residual stress of SiC fiber reinforced Ti-22Al-26Nb composites [D]. Beijing: Graduate School of Chinese Academy of Sciences, 2010. (肖鹏. SiC纤维增强Ti-22Al-26Nb复合材料的界面优化及残余应力研究[D]. 北京:中国科学院研究生院, 2010.Xiao Peng. Study on interface optimization and residual stress of SiC fiber reinforced Ti-22Al-26Nb composites [D]. Beijing: Graduate School of Chinese Academy of Sciences, 2010. [16] Zhang Xu, Wang Yumin, Lei Jiafeng, et al. Interfacial thermal stability and element diffusion mechanism of SiCf/TC17 composites[J]. Acta. Metall. Sin., 2012,48(11):1306. (张旭, 王玉敏, 雷家峰, 等. SiCf/TC17复合材料界面热稳定性及元素扩散机理[J]. 金属学报, 2012,48(11):1306. doi: 10.3724/SP.J.1037.2012.00347Zhang Xu, Wang Yumin, Lei Jiafeng, et al. Interfacial thermal stability and element diffusion mechanism of SiCf/TC17 composites[J]. Acta. Metall. Sin., 2012, 48(11): 1306. doi: 10.3724/SP.J.1037.2012.00347 [17] Dudek H J, Borath R, Leucht R, et al. Transmission electron microscopy of the fibre-matrix interface in SiC-SCS-6-fibre-reinforced IMI834 alloys[J]. J. Mater. Sci., 1997,32(20):5355. doi: 10.1023/A:1018623012948 [18] Lü Xianghong, Yang Yanqing, Ma Zhijun, et al. Research progress on interfacial reaction-diffusion of SiC continuous fiber reinforced Ti matrix composites[J]. Rare Metal Mat. Eng., 2006,35(1):164. (吕祥鸿, 杨延清, 马志军, 等. SiC连续纤维增强Ti基复合材料界面反应扩散研究进展[J]. 稀有金属材料与工程, 2006,35(1):164. doi: 10.3321/j.issn:1002-185X.2006.01.042Lü Xianghong, Yang Yanqing, Ma Zhijun, et al. Research progress on interfacial reaction-diffusion of SiC continuous fiber reinforced Ti matrix composites[J]. Rare Metal Mat. Eng., 2006, 35(1): 164. doi: 10.3321/j.issn:1002-185X.2006.01.042 [19] Zeng Kejun, Jin Zhanpeng. Interfacial reaction mechanism of SiC fiber reinforced titanium matrix composites[J]. Acta Mater. Compos. Sin., 1989(4):5. (曾科军, 金展鹏. SiC纤维增强钛基复合材料界面反应机理[J]. 复合材料学报, 1989(4):5.Zeng Kejun, Jin Zhanpeng. Interfacial reaction mechanism of SiC fiber reinforced titanium matrix composites[J]. Acta Mater. Compos. Sin., 1989(4): 5. [20] Ghosal P, Prasad R, Ramachandra C. Microstructural stability of the (α + β) Solution-treated and quenched near- α titanium alloy Ti-5.8Al-4Sn-3.5Zr-0.70Nb-0.50Mo-0.35Si-0.06C[J]. Metall. Mater. Trans. A., 1995,26(10):2751. doi: 10.1007/BF02669431 [21] Madsen A, Andrieu E, Ghonem H. Microstructural changes during aging of a near-α titanium alloy[J]. Mater. Sci. Eng. A., 1993,171(1-2):191. doi: 10.1016/0921-5093(93)90406-5 [22] Yang J M, Jeng S M. Interfacial reactions in titanium-matrix composites[J]. JOM, 1989,41(11):56. doi: 10.1007/BF03220385 [23] Martineau P, Lahaye M, Pailer R, et al. SiC filament/titanium matrix composites regarded as model composites[J]. J. Mater. Sci., 1984,19(8):2731. doi: 10.1007/BF00550831 [24] Kong Xu, Wang Yumin, Zhang Xu, et al. Thermal stability of SiCf/Ti60 composites[J]. Rare Metal Mat. Eng., 2017(S1):5. (孔旭, 王玉敏, 张旭, 等. SiCf/Ti60复合材料热稳定性研究[J]. 稀有金属材料与工程, 2017(S1):5.Kong Xu, Wang Yumin, Zhang Xu, et al. Thermal stability of SiCf/Ti60 composites[J]. Rare Metal Mat. Eng., 2017(S1): 5. [25] Wang Chao, Zhang Xu, Wang Yumin, et al. Mechanism of interfacial reaction and matrix transformation of SiCf/Ti65 composites[J]. Acta. Metall. Sin., 2020,56(9):1275. (王超, 张旭, 王玉敏, 等. SiCf/Ti65复合材料界面反应与基体相变机理[J]. 金属学报, 2020,56(9):1275.Wang Chao, Zhang Xu, Wang Yumin, et al. Mechanism of interfacial reaction and matrix transformation of SiCf/Ti65 composites[J]. Acta. Metall. Sin., 2020, 56(9): 1275. [26] Fu Yuechun, Wei Zeqi, Yang Lina, et al. Interfacial reaction and thermal stability of SiCf/Ti2AlNb composites[J]. J Northeastern Univ(Nat Sci), 2022(8):43. (符跃春, 韦泽麒, 杨丽娜, 等. SiCf/Ti2AlNb复合材料的界面反应及热稳定性[J]. 东北大学学报: 自然科学版, 2022(8):43.Fu Yuechun, Wei Zeqi, Yang Lina, et al. Interfacial reaction and thermal stability of SiCf/Ti2AlNb composites[J]. J Northeastern Univ(Nat Sci), 2022(8): 43. -

下载:

下载: