Influence of pre strain on the mechanical properties of TA2 and the establishment of constitutive model

-

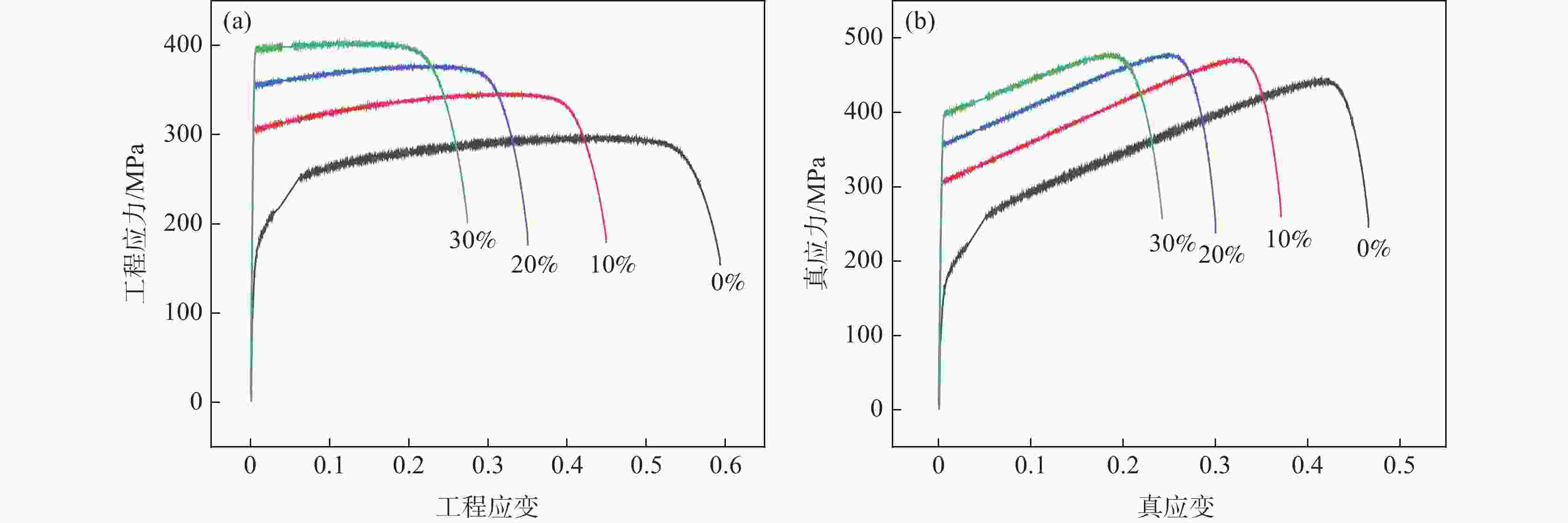

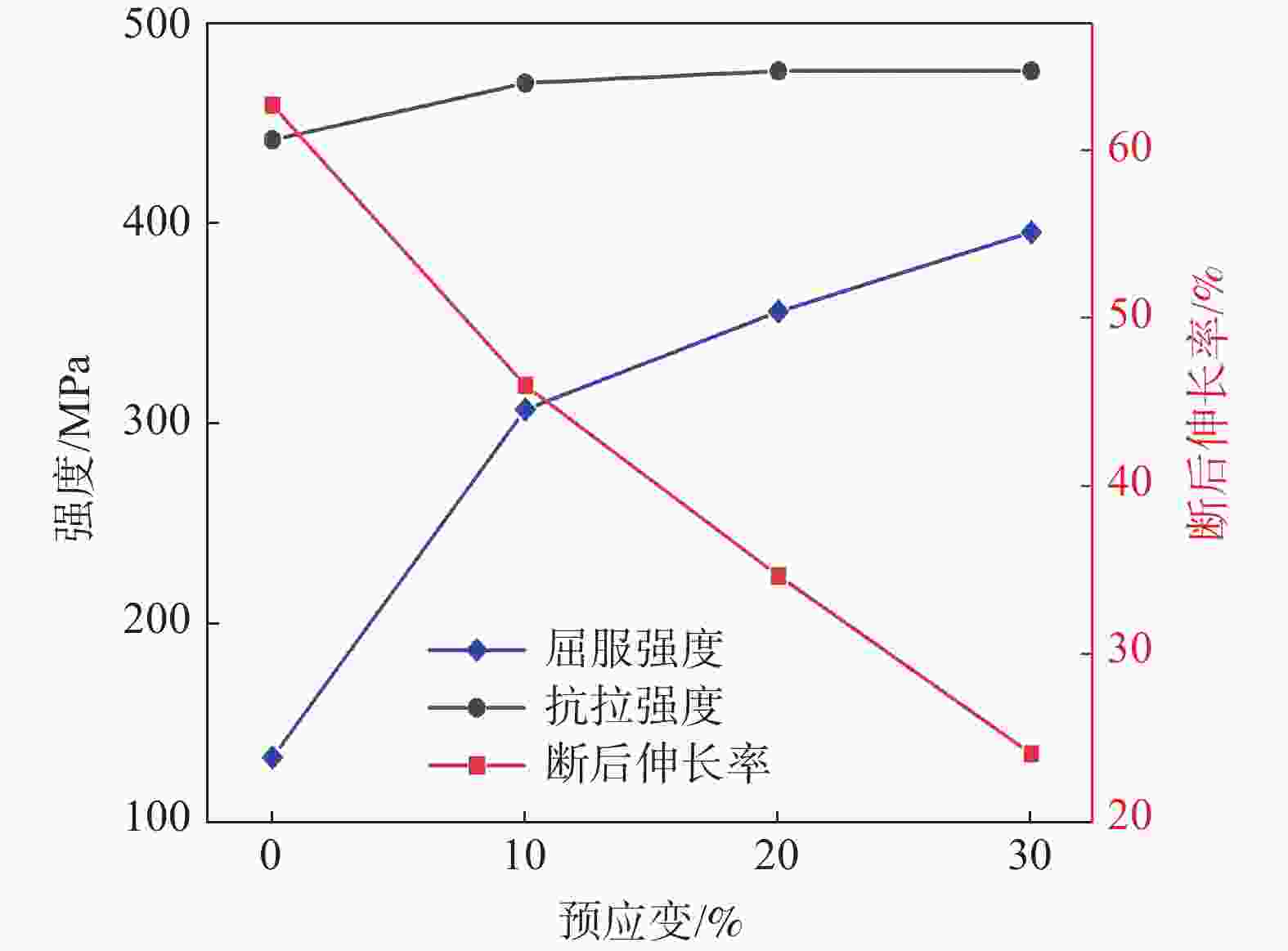

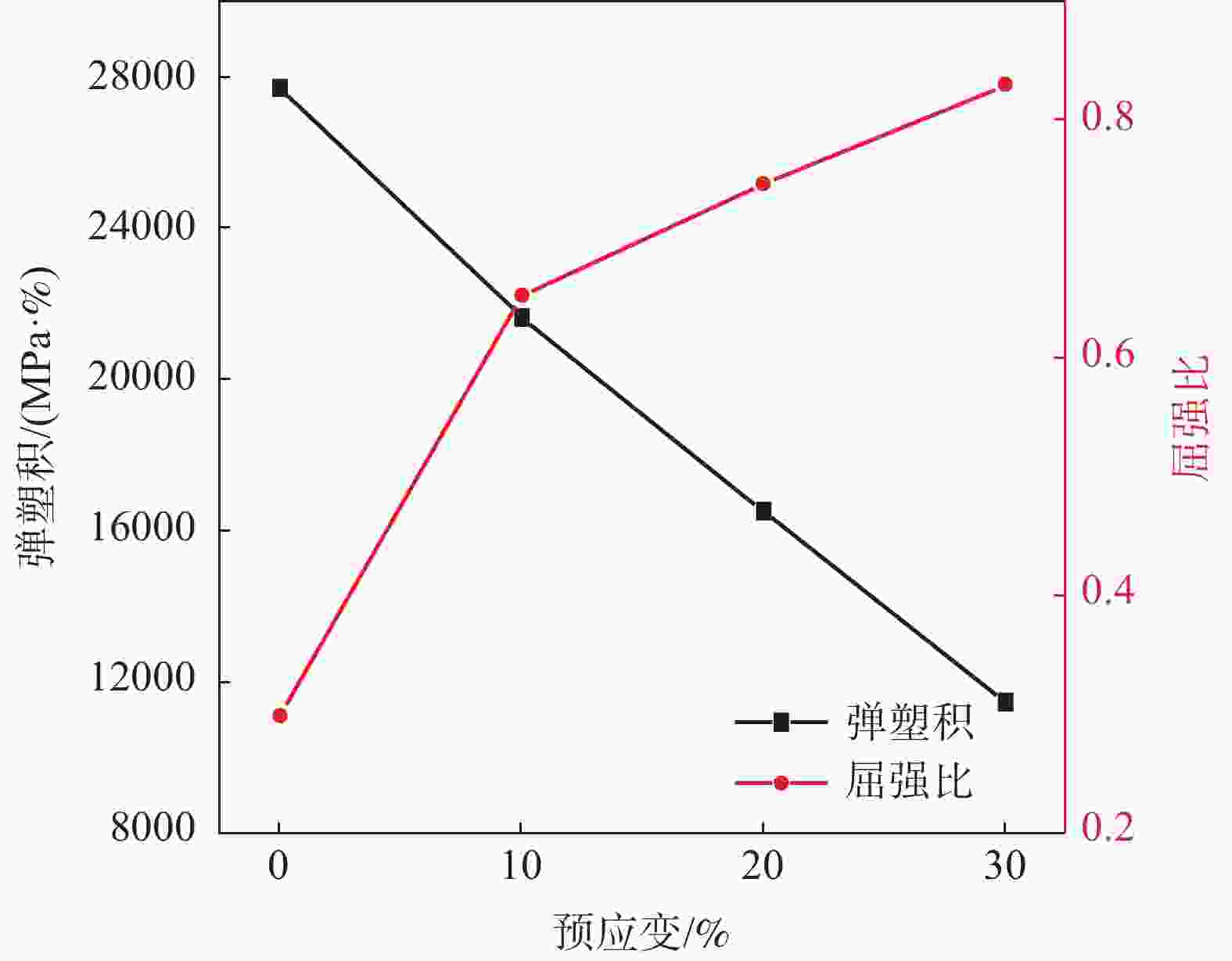

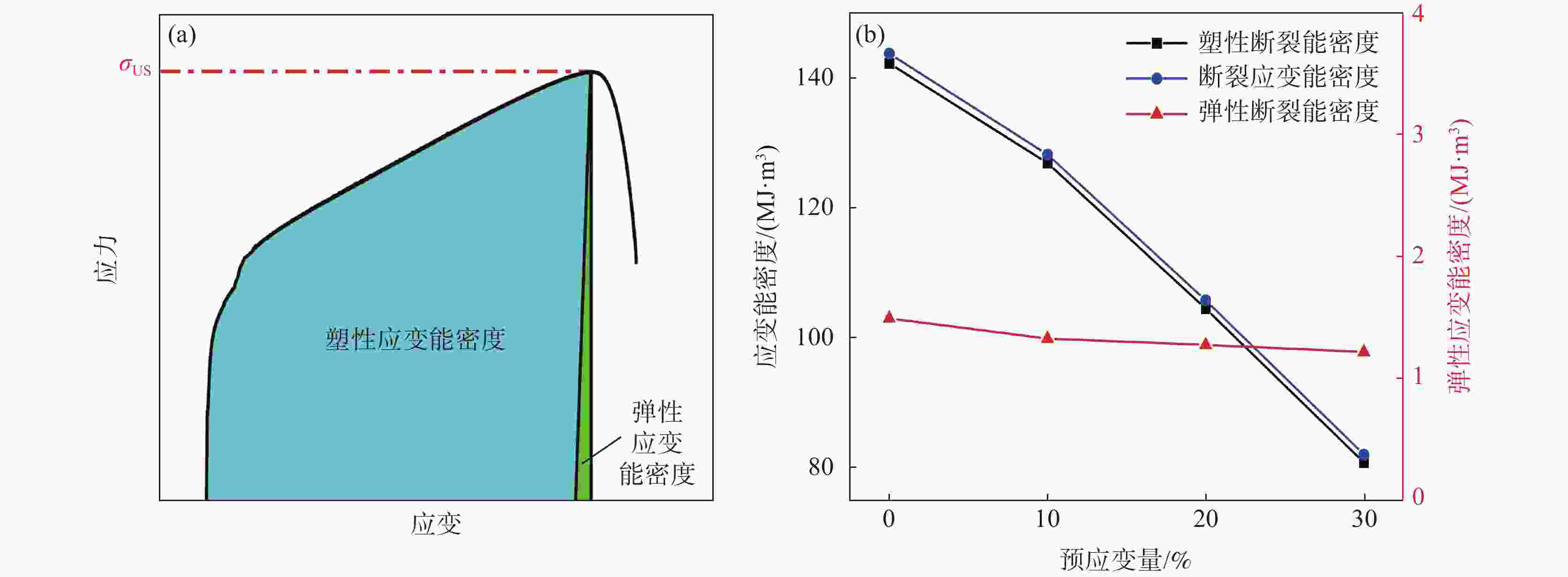

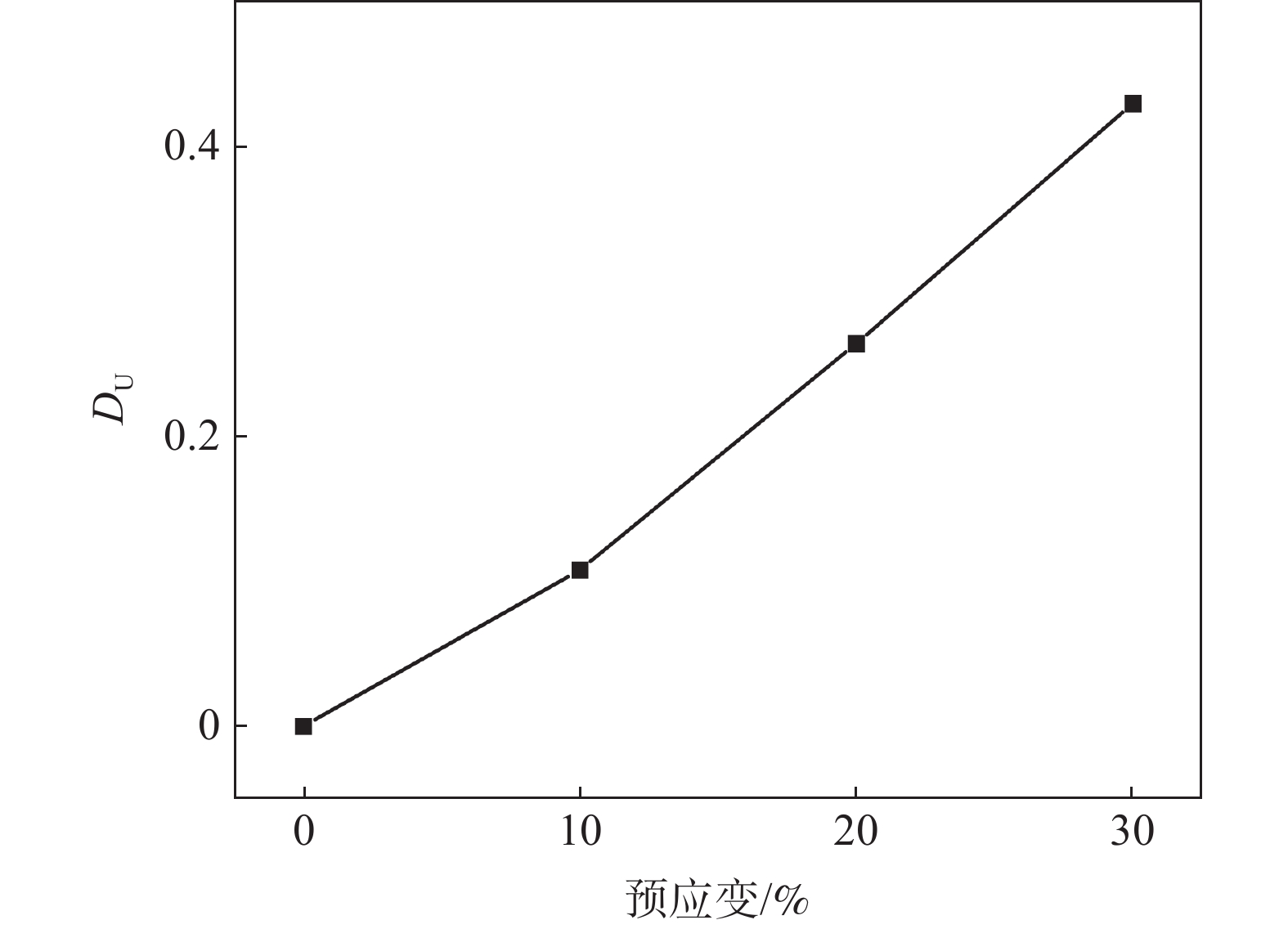

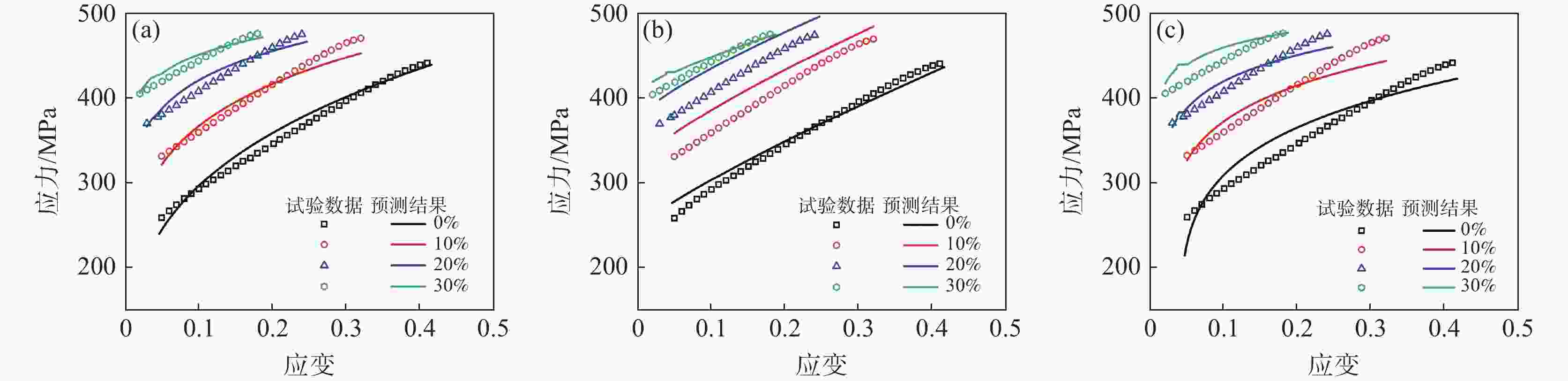

摘要: 为研究预应变对TA2力学性能的影响,对原始材料和预应变量为10%、20%和30%的TA2进行室温拉伸试验;根据预应变对TA2力学性能的影响规律,引入预应变量对Hollomon 模型、Ludwik 模型和Swift 模型进行修正,以预测预应变TA2的力学行为。结果表明,随预应变量的增加,TA2的屈服强度显著增大、抗拉强度小幅增大,而断后伸长率、强塑积和应变硬化指数减小。预应变通过消耗塑性性能来提升TA2的强度,TA2塑性应变能密度和断裂应变能密度随预应变量的增加而明显减小。各修正模型预测结果与试验值相关性系数的平均值分别为

0.9862 、0.9994 、0.9744 ,最大预测误差为6.34%、8.33%、16.42%,其中Hollomon 模型结构精简且具有良好的预测精度,是描述预应变对TA2力学行为影响的最佳选择。Abstract: To investigate the effect of prestrain on the mechanical properties of TA2, room temperature tensile tests were conducted on the TA2 original material and specimens with the prestrains of 10%, 20%, and 30%. Based on the influence of prestrain on the mechanical properties of TA2, prestrain variables were introduced to modify the Hollomon model, Ludwik model, and Swift model to predict the mechanical behavior of prestrained TA2. The results show that with the increase of prestrain, the yield strength of TA2 increases significantly, the tensile strength slightly increases, and the elongation after fracture, strength plastic product, and strain hardening indexes decrease. Prestrain enhances the strength of TA2 by consuming plastic properties, and the plastic strain energy density and fracture strain energy density of TA2 decrease significantly with the increase of prestrain. The average correlation coefficients between the predicted results of each modified model and the experimental values are0.9862 ,0.9994 , and0.9744 , with the maximum prediction errors of 6.34%, 8.33%, and 16.42%, respectively. Among them, the Hollomon model has a simplified structure and good prediction accuracy, making it the best choice to describe the effect of prestrain on the mechanical behavior of TA2.-

Key words:

- TA2 /

- pre-strain /

- mechanical properties /

- constitutive model

-

表 1 TA2化学成分

Table 1. Main chemical composition of TA2

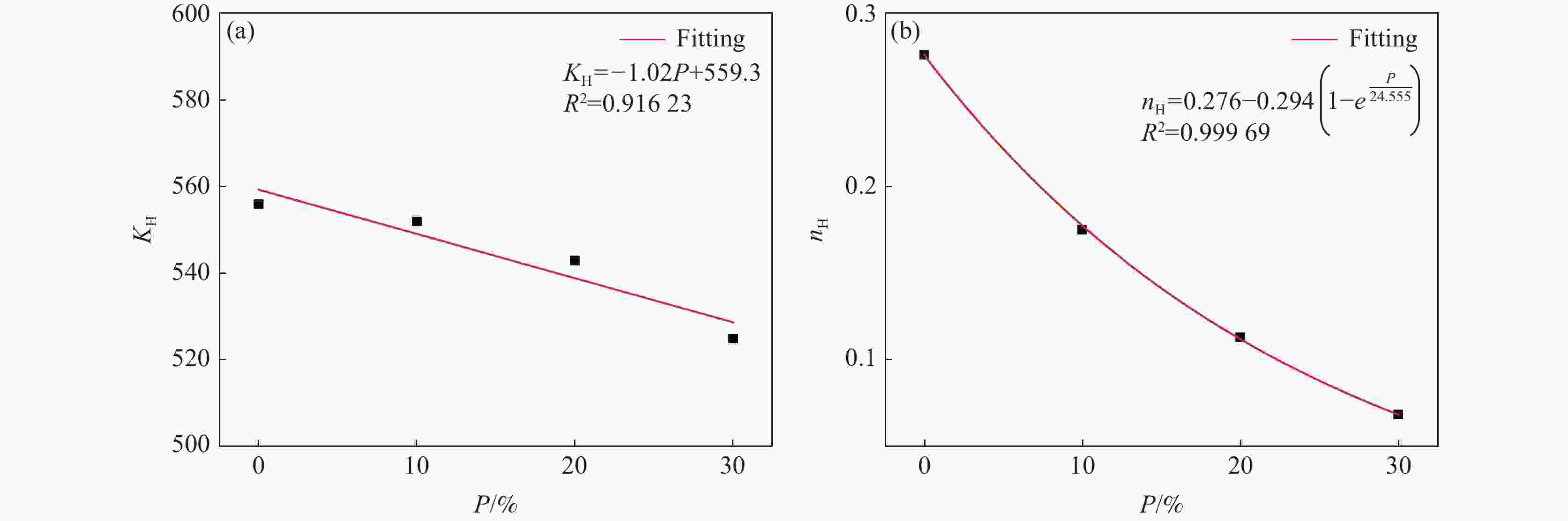

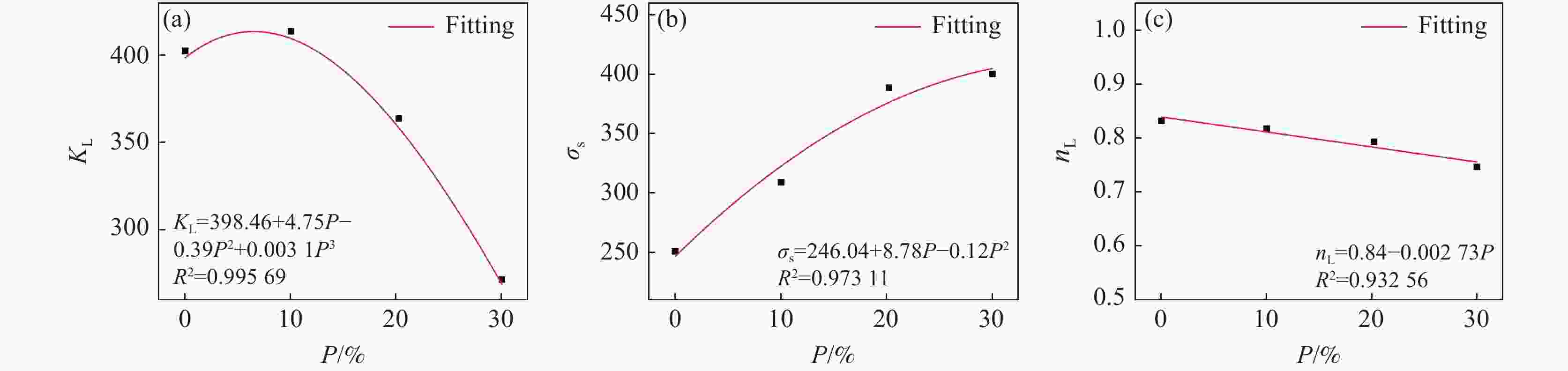

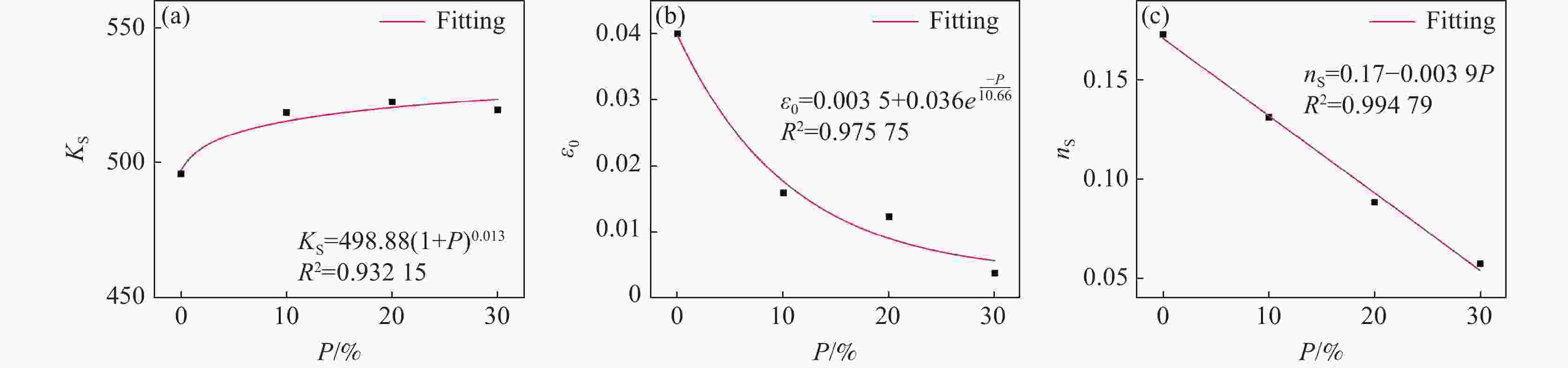

% Ti O Fe C N H >99 0.13 0.08 0.02 0.01 0.001 表 2 各本构模型参数

Table 2. Parameters of each constitutive model

应变/% Hollomon模型 Ludwik模型 Swift模型 KH nH KL σS nL KS ε0 nS 0 556 0.27613 402.49 250.52 0.83904 495.97 0.04 0.17316 10 552 0.17515 413.49 308.75 0.81699 523.58 0.01594 0.13123 20 543 0.11325 363.73 388.45 0.79863 522.85 0.01236 0.08834 30 525 0.06853 278.48 400.09 0.74608 514.37 0.00382 0.05758 表 3 各修正模型预测结果的相关性系数和最大误差

Table 3. The correlation coefficients and maximum errors of the predicted results of each modified model

P=0% P=10% P=20% P=30% R δmax/% R δmax/% R δmax/% R δmax/% Hollomon 模型 0.9913 6.34 0.9870 3.89 0.9823 3.36 0.9841 2.63 Ludwik 模型 0.9996 8.25 0.9996 8.33 0.9994 8.03 0.9991 4.14 Swift 模型 0.9643 16.42 0.9788 5.80 0.9758 3.61 0.9786 6.11 -

[1] Liu G, Sun H, Wang E, et al. Effect of deformation on the microstructure of cold-rolled TA2 alloy after low-temperature nitriding[J]. Coatings, 2021,11(8):1011. doi: 10.3390/coatings11081011 [2] Tian Xiaodan. Key points for manufacturing supervision and inspection of titanium pressure vessels[J]. Chemical Equipment Technology, 2020,41(4):52-54. (田小丹. 钛制压力容器制造监检要点[J]. 化工装备技术, 2020,41(4):52-54.Tian Xiaodan. Key points for manufacturing supervision and inspection of titanium pressure vessels[J]. Chemical Equipment Technology, 2020, 41(4): 52-54. [3] Liu P, Wen Z, Wang Z, et al. Effect of pre-strain on microstructure and stamping ability of TA2 titanium alloy and H260 low-alloy steel[C]. Journal of Physics: Conference Series. IOP Publishing, 2023, 2483(1): 012064. [4] Li Kaishang, Peng Jian, Peng Jian. The influence of pre strain on the mechanical behavior of austenitic stainless steel and the construction of a constitutive model[J]. Materials Engineering, 2018,46(11):148-154. (李凯尚, 彭剑, 彭健. 预应变对奥氏体不锈钢力学行为的影响及本构模型的构建[J]. 材料工程, 2018,46(11):148-154. doi: 10.11868/j.issn.1001-4381.2017.000815Li Kaishang, Peng Jian, Peng Jian. The influence of pre strain on the mechanical behavior of austenitic stainless steel and the construction of a constitutive model[J]. Materials Engineering, 2018, 46(11): 148-154. doi: 10.11868/j.issn.1001-4381.2017.000815 [5] Xu Jingsheng, Wang Manfu. Effect of tensile pre-strain on mechanical properties of austenitic 301 stainless steel[J]. Journal of Materials Engineering and Performance, 19 Octobe2023: 1-8. [6] Chang Le, Zhou Changyu, He Xiaohua. The effects of prestrain and subsequent annealing on tensile properties of CP-Ti[J]. Metals, 2017,7(3):99. doi: 10.3390/met7030099 [7] Peng Jian, Li Kaishang, Pei Junfeng, et al. The effect of pre-strain on tensile behaviour of 316L austenitic stainless steel[J]. Materials Science and Technology, 2018,34(5):547-560. doi: 10.1080/02670836.2017.1421735 [8] Zulfi F R, Korda A A. Effect of pre-strain on mechanical properties and deformation induced transformation of 304 stainless steel[C]. Journal of Physics: Conference Series. IOP Publishing, 2016, 739(1): 012039. [9] Saravanan K, Manikandan P, Jalaja K, et al. Effect of uniaxial pre-strain on tensile, work hardening, fracture toughness, and fatigue crack growth rate of titanium alloy Ti–6Al–4V[J]. Metallurgical and Materials Transactions A, 2023,54(9):3603-3619. doi: 10.1007/s11661-023-07117-6 [10] Hu Hanjiang, Zhao Aimin, Yin Zhukai, et al. The effect of pre strain on the mechanical properties and hardening behavior of TRIP steel[J]. Journal of Materials Heat Treatment, 2016,37(5):128-132. (胡汉江, 赵爱民, 印珠凯, 等. 预应变对TRIP钢力学性能及硬化行为的影响[J]. 材料热处理学报, 2016,37(5):128-132.Hu Hanjiang, Zhao Aimin, Yin Zhukai, et al. The effect of pre strain on the mechanical properties and hardening behavior of TRIP steel[J]. Journal of Materials Heat Treatment, 2016, 37(5): 128-132. [11] Xue Zhichao, Peng Jian, Wang Linhai, et al. Comparative study on the effect of strain strengthening on the mechanical properties of S30403 and S30408 stainless steel[J]. Hot Working Process, 2022,51(6):26-31. (薛智超, 彭剑, 汪林海, 等. 应变强化对S30403与S30408不锈钢力学性能影响的对比研究[J]. 热加工工艺, 2022,51(6):26-31.Xue Zhichao, Peng Jian, Wang Linhai, et al. Comparative study on the effect of strain strengthening on the mechanical properties of S30403 and S30408 stainless steel[J]. Hot Working Process, 2022, 51(6): 26-31. [12] Peng Jian, Li Kaishang, Dai Qiao. Mechanical properties of pre-strained austenitic stainless steel from the view of energy density[J]. Results in Physics, 2018,10:187-193. doi: 10.1016/j.rinp.2018.05.034 [13] Zhao Qing, Chang Le, Zhou Changyu, et al. The effect of pre strain on the tensile mechanical properties of industrial pure titanium TA2 welded joints[J]. Iron Steel Vanadium Titanium, 2023,44(3):68-74. (赵青, 常乐, 周昌玉, 等. 预应变对工业纯钛TA2焊接接头拉伸力学性能的影响[J]. 钢铁钒钛, 2023,44(3):68-74. doi: 10.7513/j.issn.1004-7638.2023.03.010Zhao Qing, Chang Le, Zhou Changyu, et al. The effect of pre strain on the tensile mechanical properties of industrial pure titanium TA2 welded joints[J]. Iron Steel Vanadium Titanium, 2023, 44(3): 68-74. doi: 10.7513/j.issn.1004-7638.2023.03.010 [14] Gao Huilin. Analysis and review of bending strength ratio of pipeline steel[J]. Welded Pipe, 2010,33(6):10-14. (高惠临. 管线钢屈强比分析与评述[J]. 焊管, 2010,33(6):10-14. doi: 10.3969/j.issn.1001-3938.2010.06.002Gao Huilin. Analysis and review of bending strength ratio of pipeline steel[J]. Welded Pipe, 2010, 33(6): 10-14. doi: 10.3969/j.issn.1001-3938.2010.06.002 [15] Gao Yi, Peng Jian, Dai Qiao, et al. The effect of strain strengthening on the fatigue behavior of 022Cr17Ni12Mo2 stainless steel[J]. Journal of Central South University (Natural Science Edition), 2020,51(1):23-32. (高毅, 彭剑, 代巧, 等. 应变强化对022Cr17Ni12Mo2不锈钢疲劳行为的影响[J]. 中南大学学报(自然科学版), 2020,51(1):23-32.Gao Yi, Peng Jian, Dai Qiao, et al. The effect of strain strengthening on the fatigue behavior of 022Cr17Ni12Mo2 stainless steel[J]. Journal of Central South University (Natural Science Edition), 2020, 51(1): 23-32. [16] Jin Fengnian, Jiang Meirong, Gao Xiaoling. Method for defining damage variables based on energy dissipation[J]. Journal of Rock Mechanics and Engineering, 2004(12):1976-1980. (金丰年, 蒋美蓉, 高小玲. 基于能量耗散定义损伤变量的方法[J]. 岩石力学与工程学报, 2004(12):1976-1980. doi: 10.3321/j.issn:1000-6915.2004.12.004Jin Fengnian, Jiang Meirong, Gao Xiaoling. Method for defining damage variables based on energy dissipation[J]. Journal of Rock Mechanics and Engineering, 2004(12): 1976-1980. doi: 10.3321/j.issn:1000-6915.2004.12.004 [17] Wang Zhen. Research on mechanical properties and forming limit of aluminum lithium alloy sheets[D]. Tangshan: North China University of Technology, 2020. (王震. 铝锂合金板材的力学特性和成形极限研究[D]. 唐山: 华北理工大学, 2020.Wang Zhen. Research on mechanical properties and forming limit of aluminum lithium alloy sheets[D]. Tangshan: North China University of Technology, 2020. [18] Lei Yu. Study on plastic deformation behavior of typical high-strength steel under high strain rate of pre strain[D]. Wuhan: Wuhan University of Technology, 2018. (雷雨. 预应变高应变速率下典型高强钢的塑性变形行为研究[D]. 武汉: 武汉理工大学, 2018.Lei Yu. Study on plastic deformation behavior of typical high-strength steel under high strain rate of pre strain[D]. Wuhan: Wuhan University of Technology, 2018. -

下载:

下载: