Research progress on resource utilization of spent SCR denitrification catalyst

-

摘要: 近年来,选择性催化还原(SCR)技术的广泛应用导致了废旧SCR脱硝催化剂的大量产生,为了节约资源,保护环境,必须对其进行妥善处理。废旧SCR脱硝催化剂通过回收有价组分、整体利用和固化处理等方式可实现资源化利用。回收有价组分的方法主要包括酸碱浸出、活化焙烧、熔盐电解、化学沉淀、有机萃取、离子交换等;整体利用的方法主要包括制备再生催化剂、生产含钛球团和含钛烧结矿;固化处理的方法主要包括熔融固化、水泥固化和陶瓷固化。对上述方法做出了详细的总结和展望,希望可以为未来废旧SCR脱硝催化剂的资源化利用提供启发和参考。

-

关键词:

- 废旧SCR脱硝催化剂 /

- 资源化利用 /

- 有价组分 /

- 整体利用 /

- 固化处理

Abstract: Recently, due to the increasing application of selective catalytic reduction (SCR) technology, a large number of spent SCR denitrification catalysts were inevitably produced. In order to save the resources and protect the environment, much attention should be attracted on their proper disposal. Spent SCR denitrification catalysts could be recycled as resources through the recovery of valuable components, overall utilization or solidification treatment, respectively. The valuable components could be effectively recovered from spent denitrification catalysts by acid-base leaching, active roasting, molten salt electrolysis, chemical precipitation, organic extraction, ion exchange. The catalyst could also be wholly used as a raw material for regenerating the catalyst and producing titanium-containing pellets or titanium-containing sinter. Moreover, it can also be solidified by melt solidification, cement solidification, ceramic solidification. Overall, the above-mentioned methods were comprehensively summarized and prospected, which will provide inspiration and reference for the resource utilization of spent SCR denitrification catalysts in the future. -

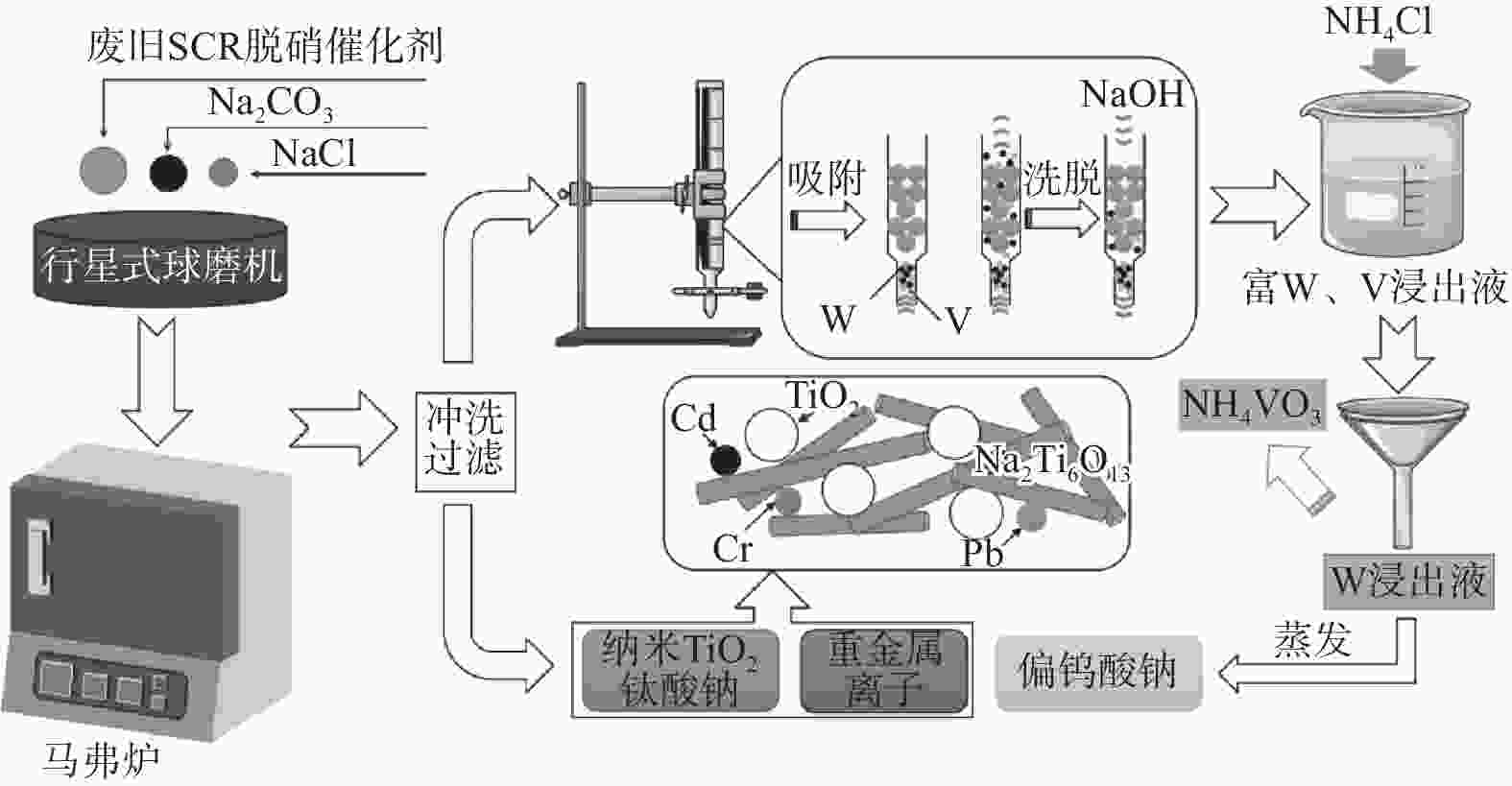

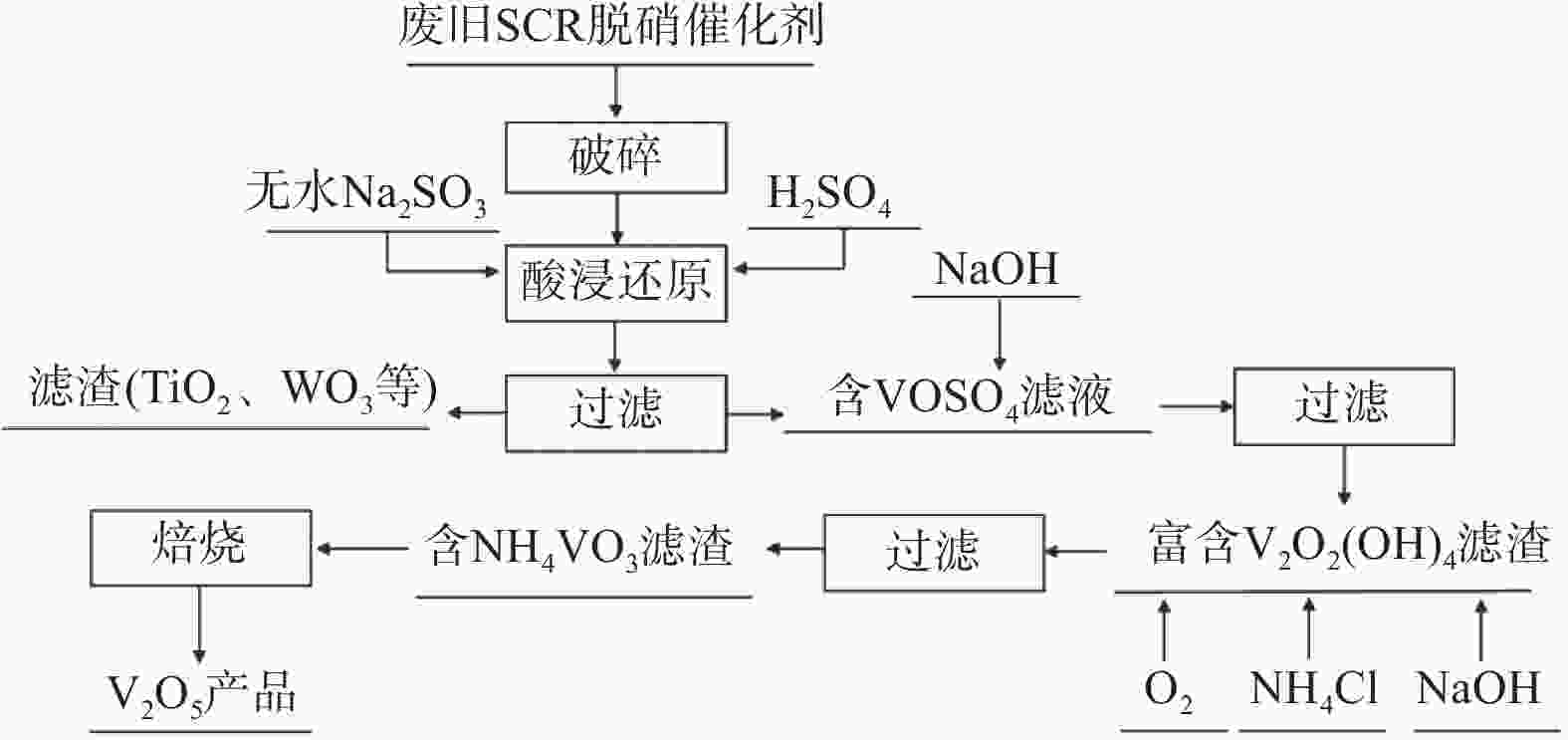

图 1 V2O5回收工艺流程[14]

Figure 1. The recovery process flow chart of V2O5

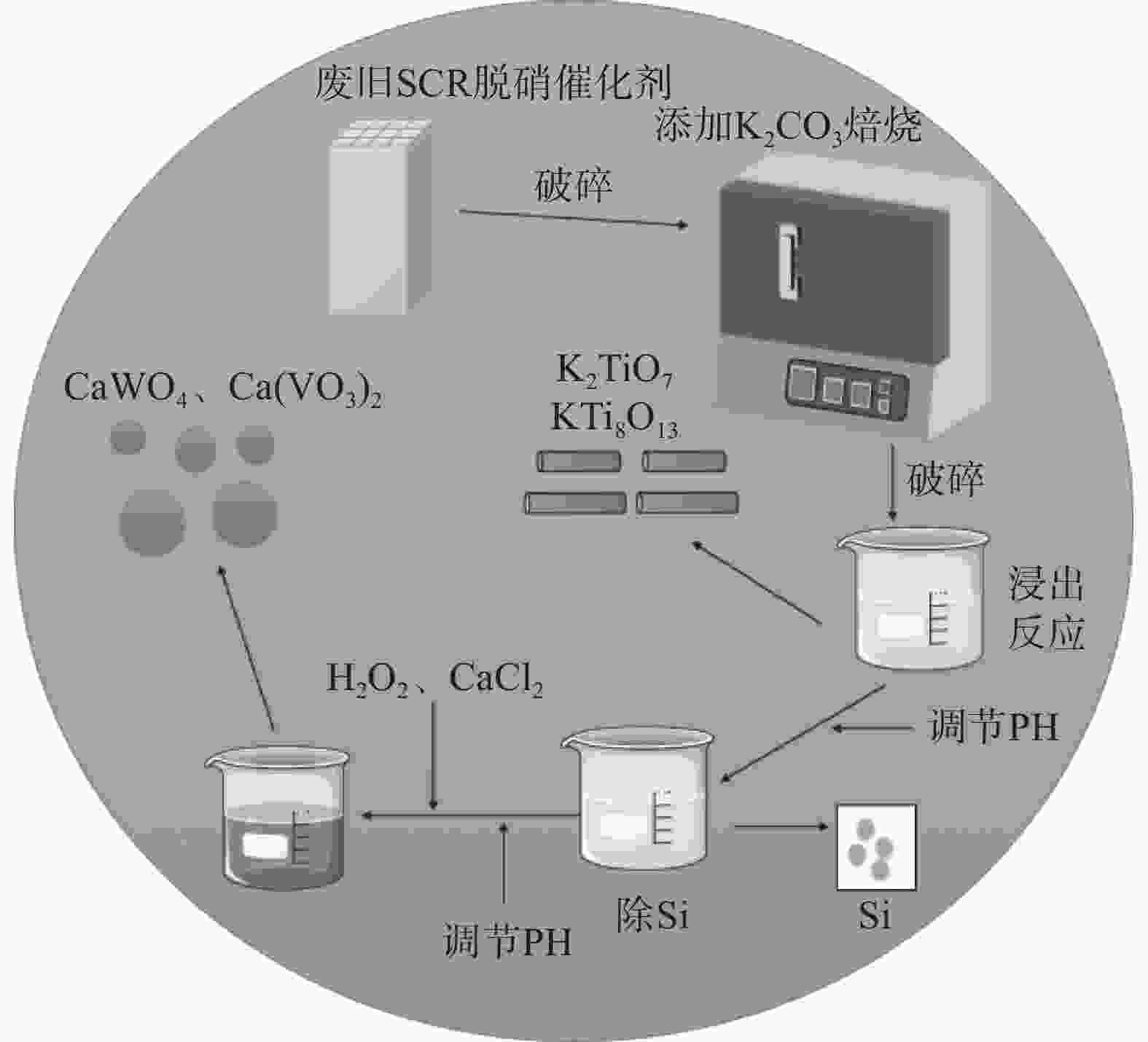

图 2 钾盐焙烧回收钒钛工艺流程[21]

Figure 2. The process flow chart for recoverying of vanadium and tungsten from spent SCR catalysts by K2CO3 roasting

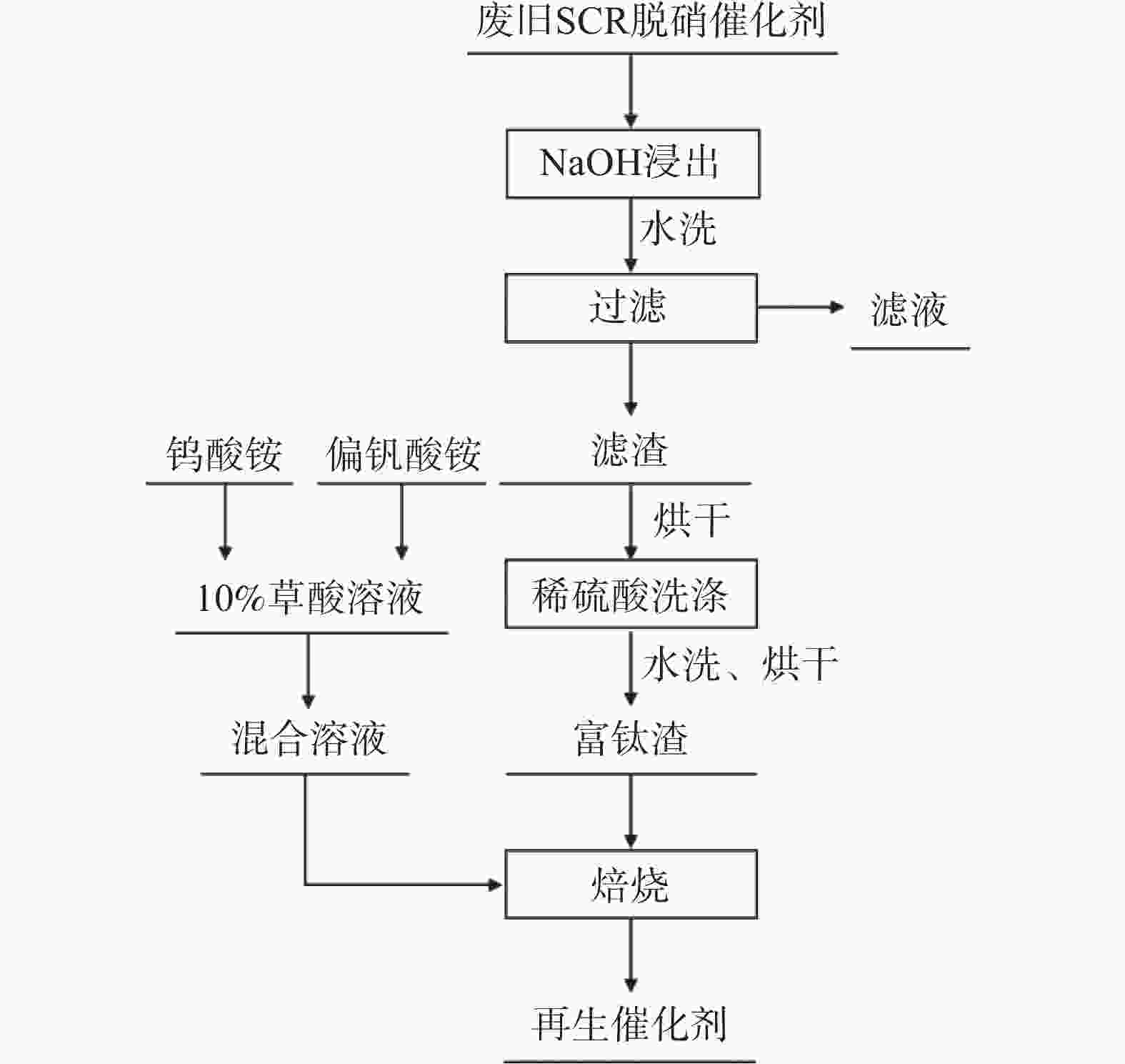

图 3 再生催化剂工艺流程[22]

Figure 3. The process flow chart for preparing regenerated catalyst

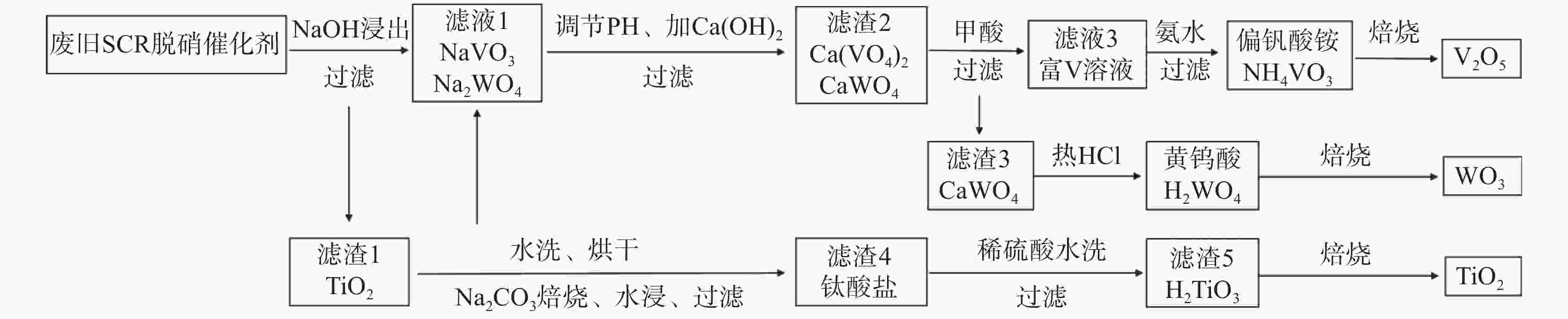

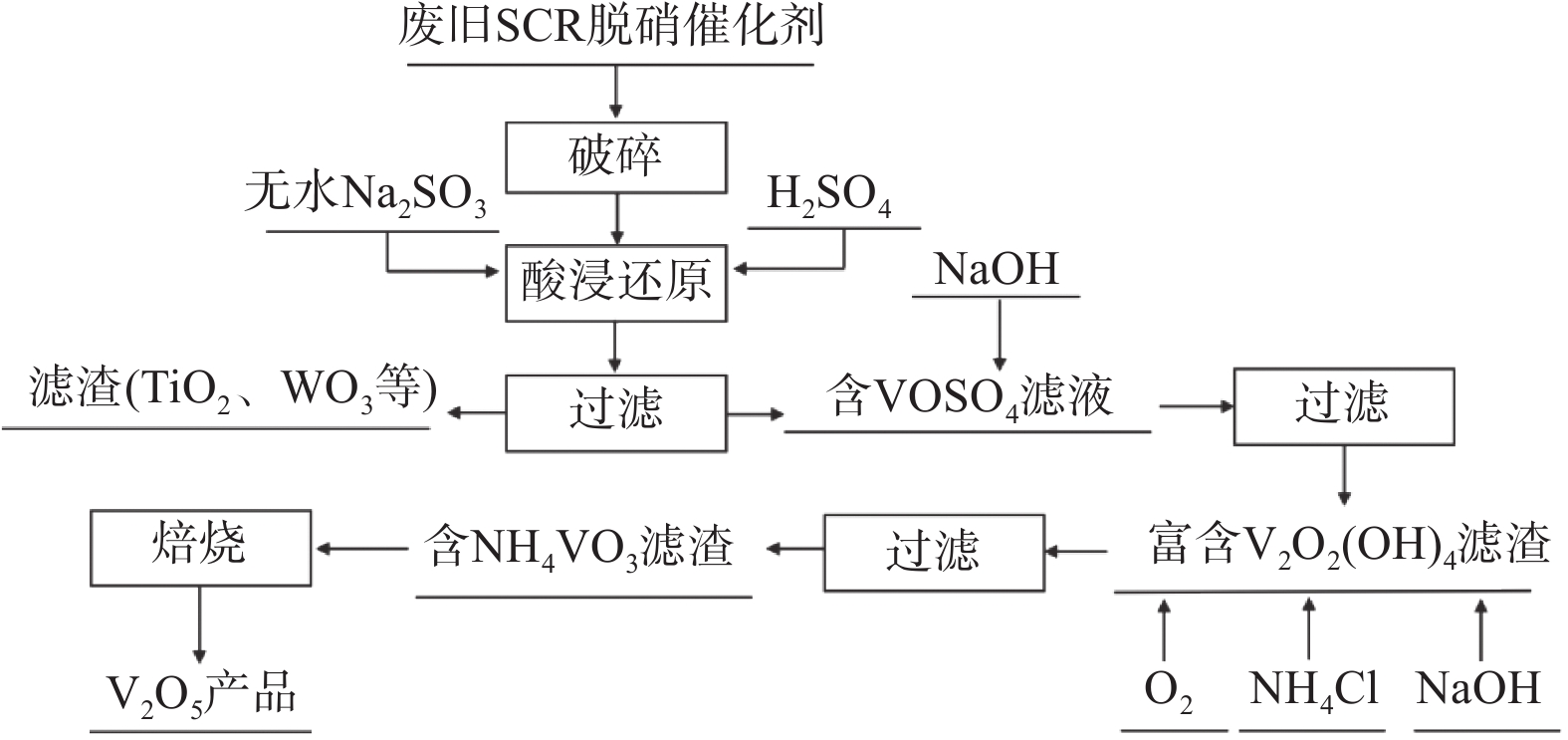

图 4 钒、钨、钛三组分的综合回收利用工艺流程[27]

Figure 4. The process flow chart of comprehensive recovery and utilization of vanadium, tungsten and titanium

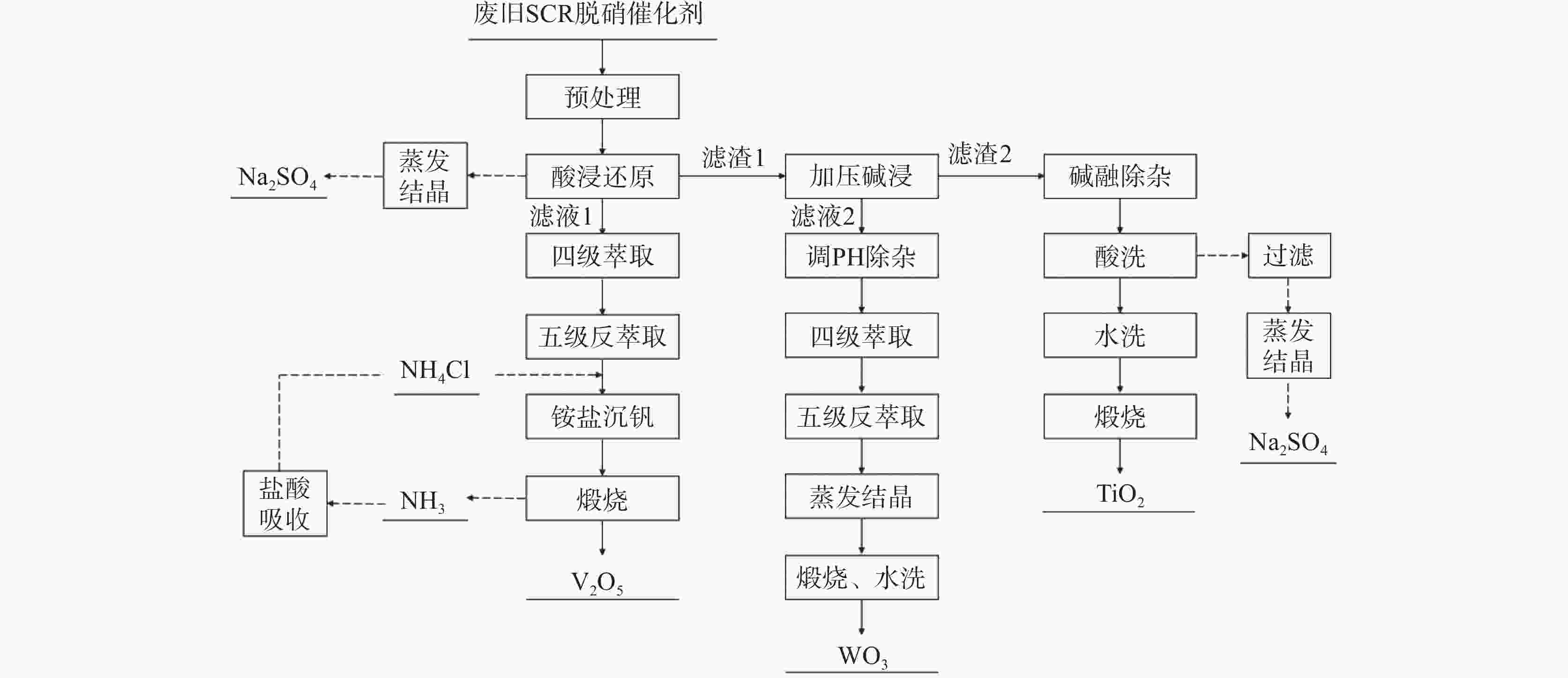

图 5 废旧SCR脱硝催化剂中钒、钨、钛高纯度回收[31]

Figure 5. The high-purity recovery process flow chart of vanadium, tungsten and titanium in spent SCR catalyst

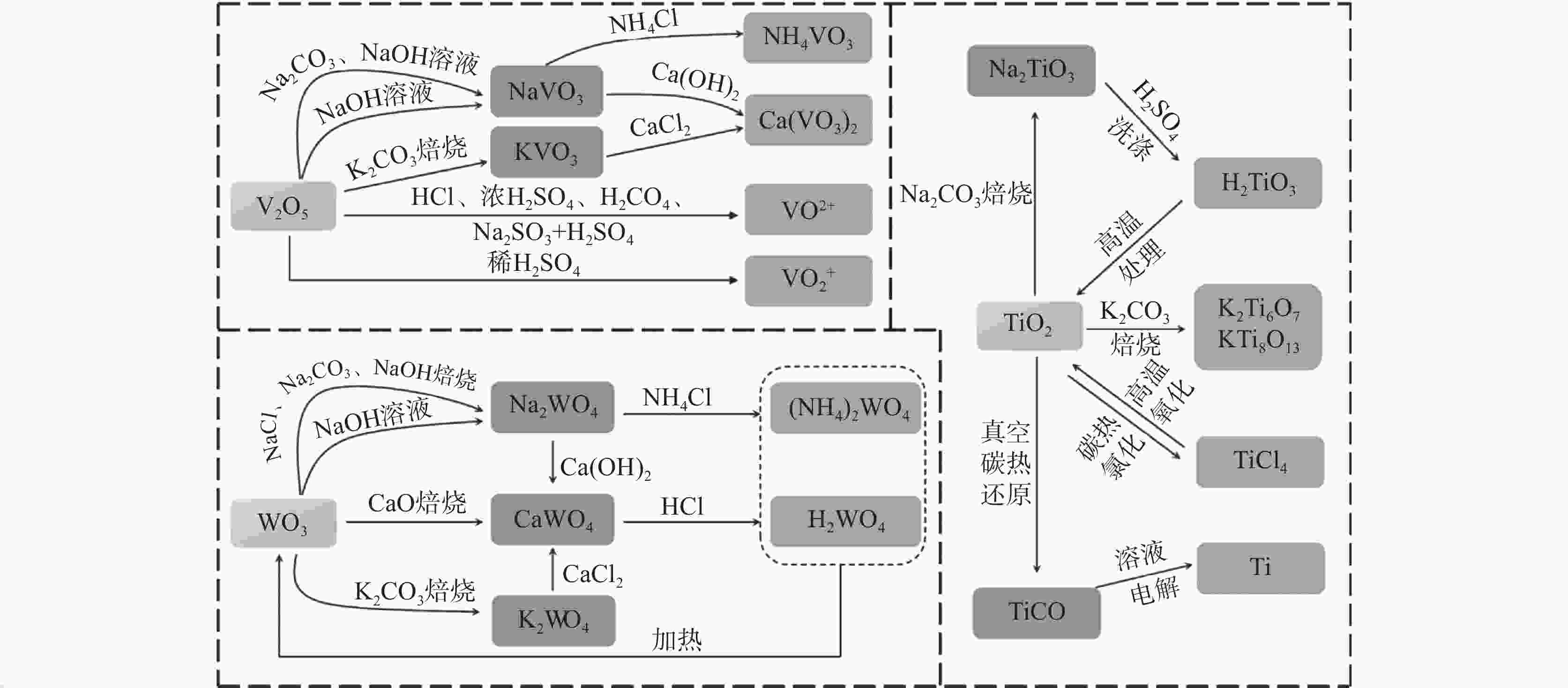

图 6 高附加值利用钒、钨、钛工艺流程[33]

Figure 6. The process chart of high value-added utilization of titanium and recovery of vanadium and tungsten elements

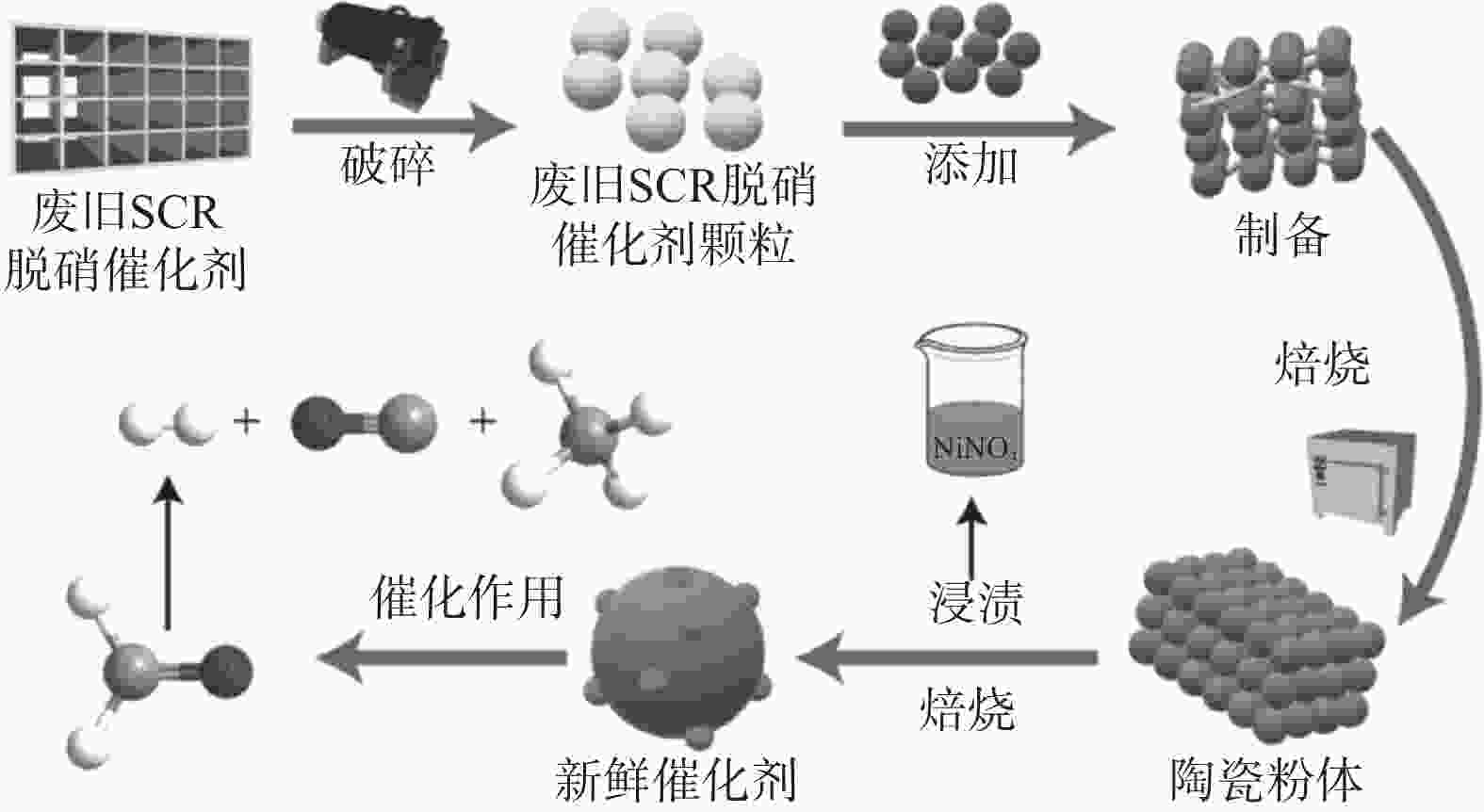

图 8 制氢催化剂的制备流程[36]

Figure 8. The process chart for preparation of the reforming hydrogen production catalyst

-

[1] Shi Zhiwei, Peng Qingguo, E Jiaqiang, et al. Mechanism, performance and modification methods for NH3-SCR catalysts: A review[J]. Fuel, 2022, 331:125885. [2] Wang Baodong, Liu Zilin, Lin Dehai. A review on recovery and utilization of spent V2O5 -WO3/TiO2 catalyst[J]. Materials Reports, 2021,35(15):15001-15010. (王宝冬, 刘子林, 林德海. 废钒-钛系脱硝催化剂回收利用策略与技术进展[J]. 材料导报, 2021,35(15):15001-15010. doi: 10.11896/cldb.20070110Wang Baodong, Liu Zilin, Lin Dehai. A review on recovery and utilization of spent V2O5 -WO3/TiO2 catalyst[J]. Materials Reports, 2021, 35(15): 15001-15010. doi: 10.11896/cldb.20070110 [3] Francesco Ferella. A review on management and recycling of spent selective catalytic reduction catalysts[J]. Journal of Cleaner Production, 2020,246:118990. doi: 10.1016/j.jclepro.2019.118990 [4] Qian Xi, Ao Weihua, Ding Hao, et al. A review on resource utilization of spent V-W-Ti based selective catalytic reduction catalysts[J]. Materials, 2022,15:7984. doi: 10.3390/ma15227984 [5] Duan Jingfang. Study of deactivation mechanism and regeneration method of deactivated commercial V2O5-WO3-MoO3/TiO2 SCR catalysts[D]. Guangzhou: South China University of Technology, 2012. (段竞芳. 商业钒钛系SCR脱硝催化剂的失活分析与再生研究[D]. 广州: 华南理工大学, 2012.Duan Jingfang. Study of deactivation mechanism and regeneration method of deactivated commercial V2O5-WO3-MoO3/TiO2 SCR catalysts[D]. Guangzhou: South China University of Technology, 2012. [6] Li Qiang, Chen Tiejun, Li Qiyong, et al. Research progress on resource utilization of waste SCR denitration catalyst[J]. China Metallurgy, 2020,30(5):1-10. (李强, 陈铁军, 李奇勇, 等. 废弃SCR脱硝催化剂资源化利用研究进展[J]. 中国冶金, 2020,30(5):1-10.Li Qiang, Chen Tiejun, Li Qiyong, et al. Research progress on resource utilization of waste SCR denitration catalyst[J]. China Metallurgy, 2020, 30(5): 1-10. [7] Long Hongming, Ding Long, Tao Jiajie, et al. Analysis on resource untilization of spent V2O5-WO3/TiO2 catalyst produced in sintering flue gas[J]. Iron and Steel, 2022,57(7):162-178. (龙红明, 丁龙, 陶家杰, 等. 烧结烟气脱硝废弃钒钨钛催化剂资源化利用途径分析[J]. 钢铁, 2022,57(7):162-178.Long Hongming, Ding Long, Tao Jiajie, et al. Analysis on resource untilization of spent V2O5-WO3/TiO2 catalyst produced in sintering flue gas[J]. Iron and Steel, 2022, 57(7): 162-178. [8] Chen J P, Yang R T. Role of WO3 in mixed V2O5-WO3/TiO2 catalysts for selective catalytic reduction of nitric oxide with ammonia[J]. Appl Catal A-Gen, 1992,80(1):135. doi: 10.1016/0926-860X(92)85113-P [9] Wang Jinliang, Hu Huazhou. Research progress on recycling spent SCR denitrification catalyst[J]. Modern Chemical Industry, 2020,40(7):40-44. (汪金良, 胡华舟. 废弃SCR脱硝催化剂资源化利用研究进展[J]. 现代化工, 2020,40(7):40-44.Wang Jinliang, Hu Huazhou. Research progress on recycling spent SCR denitrification catalyst[J]. Modern Chemical Industry, 2020, 40(7): 40-44. [10] Li Licheng, Wang Lei, Zhao Xuejuan, et al. Comparison of effect of different acid treatments on vanadium extraction of waste deNO x catalyst[J]. The Chinese Journal of Nonferrous Metals, 2016,26(10):2230-2237. (李力成, 王磊, 赵学娟, 等. 几种酸在废弃脱硝催化剂中提钒效果的比较[J]. 中国有色金属学报, 2016,26(10):2230-2237.Li Licheng, Wang Lei, Zhao Xuejuan, et al. Comparison of effect of different acid treatments on vanadium extraction of waste deNOx catalyst[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(10): 2230-2237. [11] Selbin J. The chemistry of oxovanadium(rv)[J]. Chemical Reviews, 1965,65(2):153-75 doi: 10.1021/cr60234a001 [12] Hsu L Y, Teng H. Influence of thermal treatment on the catalytic activity of Cu—loaded carbons in NO reduction with NH3 and regeneration of the thermally deactivated catalysts[J]. Applied Catalysis B(Environmental), 2003,42(1):69-76. doi: 10.1016/S0926-3373(02)00216-3 [13] Liang Xuemei. Comparison of effet of microwave and conventional heating acid leaching waste SCR catalyst on vanadium extration[J]. Materials Research and Application, 2017,11(2):97-102. (梁雪梅. 微波与常规加热酸浸废SCR催化剂提钒效果比较[J]. 材料研究与应用, 2017,11(2):97-102. doi: 10.3969/j.issn.1673-9981.2017.02.009Liang Xuemei. Comparison of effet of microwave and conventional heating acid leaching waste SCR catalyst on vanadium extration[J]. Materials Research and Application, 2017, 11(2): 97-102. doi: 10.3969/j.issn.1673-9981.2017.02.009 [14] Zhang Bingbing, Yu Dandan, Wang Fang, et al. Technology of vanadiun recovery from deactivated denitration catalyst[J]. Henan Science, 2016,34(6):866-870. (张兵兵, 于丹丹, 王芳, 等. 废脱硝催化剂中五氧化二钒回收工艺研究[J]. 河南科学, 2016,34(6):866-870.Zhang Bingbing, Yu Dandan, Wang Fang, et al. Technology of vanadiun recovery from deactivated denitration catalyst[J]. Henan Science, 2016, 34(6): 866-870. [15] Yao Junxuan, Cao Yibo, Wang Jiancheng, et al. Successive calcination-oxalate acid leaching treatment of spent SCR catalyst: A highly efficient and selective method for recycling tungsten element[J]. Hydrometallurgy, 2021,201:105576. doi: 10.1016/j.hydromet.2021.105576 [16] Kalpaki A O, Ilhan S, Kahruman C, et al. Dissolution behavior of calcium tun getate in oxalic acid solutions[J]. Hydrometallurgy, 2012,121:7-15. [17] Choi I, Moon G, Lee J, et al. Hydrometallurgical processing of spent selective catalytic reduction (SCR) catalyst for recovery of tungsten[J]. Hydrometallurgy, 2018,178:137. doi: 10.1016/j.hydromet.2018.04.011 [18] Li Huaquan, Guo Chuanhua. Comprehensive recovery of valuable elements vanadium, titanium and tungsten from abandoned denitration catalyst[J]. Inorganic Chemicals Industry, 2014,46(5):52-54. (李化全, 郭传华. 废弃脱硝催化剂中有价元素钛钒钨的综合利用研究[J]. 无机盐工业, 2014,46(5):52-54. doi: 10.3969/j.issn.1006-4990.2014.05.015Li Huaquan, Guo Chuanhua. Comprehensive recovery of valuable elements vanadium, titanium and tungsten from abandoned denitration catalyst[J]. Inorganic Chemicals Industry, 2014, 46(5): 52-54. doi: 10.3969/j.issn.1006-4990.2014.05.015 [19] Jia Yong, Ding Wanli, Ding Xilou, et al. The leaching of tungsten and vanadium from spent selective catalytic reduction catalyst[J]. Acta Scientiae Circumstantiae, 2016,36(10):3759-3764. (贾勇, 丁万丽, 丁希楼, 等. 废SCR脱硝催化剂中钨和钒的浸出试验研究[J]. 环境科学学报, 2016,36(10):3759-3764.Jia Yong, Ding Wanli, Ding Xilou, et al. The leaching of tungsten and vanadium from spent selective catalytic reduction catalyst[J]. Acta Scientiae Circumstantiae, 2016, 36(10): 3759-3764. [20] Liu Xianghui, He Faquan, Lu Guangjie, et al. Recovery of titanium, vanadium and tungsten from waste SCR catalysts by roasting with waste NaCl salts[J]. Rare Metal Materials and Engineering, 2023,52(2):454-460. [21] Liu Xianghui, Yang Qiaowen. Recovery of vanadium and tungsten from waste selective catalytic reduction catalysts by K2CO3 roasting and water leaching followed by CaCl2 precipitation[J]. International Journal of Coal Science and Technology, 2021,8(4):727. doi: 10.1007/s40789-020-00377-2 [22] Qi Chunping, Wu Wenfen, Wang Chenye, et al. Recycling and reuse of TiO2 carrier from waste SCR catalysts used in coal-fired power plants[J]. CIESC Journal, 2017,68(11):4239-4248. (戚春萍, 武文粉, 王晨晔, 等. 燃煤电厂废旧 SCR 脱硝催化剂中TiO2载体的回收与再利用[J]. 化工学报, 2017,68(11):4239-4248.Qi Chunping, Wu Wenfen, Wang Chenye, et al. Recycling and reuse of TiO2 carrier from waste SCR catalysts used in coal-fired power plants[J]. CIESC Journal, 2017, 68(11): 4239-4248. [23] Bai Xuyang, Shang Xiaojia, Wan Heli, et al. Sustainable recycling of titanium from TiO2 in spent SCR denitration catalyst cia molten aelt electrolysis[J]. J Energy Chem, 2021,58:557. doi: 10.1016/j.jechem.2020.11.002 [24] Ma Benteng, Qiu Zhaofu, Yang Ji, et al. Recovery of nano-TiO2 from spent SCR catalyst by sulfuric acid dissolution and direct precipitation[J]. Waste Biomass Valori, 2019,10(10):3037-3044. doi: 10.1007/s12649-018-0303-0 [25] Zhang Qijun, Wu Yufeng, Zuo Tieyong. Green recovery of titanium and effective regeneration of TiO2 photocatalysts from spent selective catalytic reduction catalysts[J]. ACS Sustain Chem Eng, 2018,6(3):3091. doi: 10.1021/acssuschemeng.7b03038 [26] Chen Guangyu, Kang Jialong, Liu Junjie, et al. Study on direct alloying of waste SCR catalysts[J]. Iron Steel Vanadium Titanium, 2018,39(6):99-102. (陈广玉, 康嘉龙, 刘俊杰, 等. 废弃脱硝催化剂直接合金化研究[J]. 钢铁钒钛, 2018,39(6):99-102. doi: 10.7513/j.issn.1004-7638.2018.06.016Chen Guangyu, Kang Jialong, Liu Junjie, et al. Study on direct alloying of waste SCR catalysts[J]. Iron Steel Vanadium Titanium, 2018, 39(6): 99-102. doi: 10.7513/j.issn.1004-7638.2018.06.016 [27] Xie Zong. Study on recovery of valuable metals from SCR catalyst waste in coal-fired power plants[D]. Beijing: North China Electric Power University, 2016. (谢宗. 燃煤电厂废弃SCR催化剂中回收有价金属的研究[D]. 北京: 华北电力大学, 2016.Xie Zong. Study on recovery of valuable metals from SCR catalyst waste in coal-fired power plants[D]. Beijing: North China Electric Power University, 2016. [28] Chen Jiapeng, Ma Liwen, Cao Mingxing, et al. Extraction of tungsten and vanadium from the spent SCR catalyst by high pressure alkaline leaching method[J]. Materials Science Forum, 2018,913:954. doi: 10.4028/www.scientific.net/MSF.913.954 [29] Choi I H, Moon Gyeonghye, Lee J Y, et al. Extraction of tungsten and vanadium from spent selective catalytic reduction catalyst for stationary application by pressure leaching process[J]. Journal of Cleaner Production, 2018,197(1):163-169. [30] Zhang Qijun, Wu Yufeng, Li Lili, et al. Sustainable approach for spent V2O5-WO3/TiO2 catlysts management: Selective recovery of heavy metal vanadium and production of valueadded WO3-TiO2 photocatalysts[J]. ACS Sustain Chem Eng, 2018,6(9):12502. doi: 10.1021/acssuschemeng.8b03192 [31] Teng Yuting. Recovery of waste SCR denitration catalyst resource components[D]. Nanjing: Southeast University, 2020. (滕玉婷. 废弃SCR脱硝催化剂资源化成分回收[D]. 南京: 东南大学, 2020.Teng Yuting. Recovery of waste SCR denitration catalyst resource components[D]. Nanjing: Southeast University, 2020. [32] Liu Yuanxin. Themodynamics and new technology research of sheeltie sodium hydroxide roasting[D]. Ganzhou: Jiangxi University of Science and Technology, 2016. (刘元鑫. 白钨矿氢氧化钠焙烧热力学及新工艺研究[D]. 赣州: 江西理工大学, 2016.Liu Yuanxin. Themodynamics and new technology research of sheeltie sodium hydroxide roasting[D]. Ganzhou: Jiangxi University of Science and Technology, 2016. [33] Yang Bi, Zhou Jiabei, Wang Weiwen, et al. Extraction and separation of tungsten and vanadium from spent V2O5-WO3/TiO2 SCR catalysts and recovery of TiO2 and sodium titanate nanorods as adsorbent for heavy metal ions[J]. Colloid Surface A, 2020,601:124963. doi: 10.1016/j.colsurfa.2020.124963 [34] Li Pufang, Mu Lin, Wang Shebin. Carbon thermal reduction/melting separation of valuable metals from spent SCR catalysts[J]. Inorganic Chemicals Industry, 2020,52(1):93. (李朴芳, 穆林, 王社斌. 碳热还原/熔融分离废SCR催化剂中有价金属[J]. 无机盐工业, 2020,52(1):93. doi: 10.11962/1006-4990.2019-0087Li Pufang, Mu Lin, Wang Shebin. Carbon thermal reduction/melting separation of valuable metals from spent SCR catalysts[J]. Inorganic Chemicals Industry, 2020, 52(1): 93. doi: 10.11962/1006-4990.2019-0087 [35] He Chuan, Wang Lele, Yang Xiaoning, et al. Effects of spent SCR catalyst blending on the de-NO x activity of new catalyst[J]. Chemical Industry and Engineering Progress, 2018,37(2):581-586. (何川, 王乐乐, 杨晓宁, 等. 废弃选择性催化剂混掺对新催化剂脱硝性能的影响[J]. 化工进展, 2018,37(2):581-586.He Chuan, Wang Lele, Yang Xiaoning, et al. Effects of spent SCR catalyst blending on the de-NOx activity of new catalyst[J]. Chemical Industry and Engineering Progress, 2018, 37(2): 581-586. [36] Jin Qijie, Shen Yuesong, Cai Yi, et al. Resource utilization of waste V2O5-based deNO x catalysts for hydrogen production fron formaldehyde and water via steam reforming[J]. J Hazard Mater, 2020,381:120934. doi: 10.1016/j.jhazmat.2019.120934 [37] Long Hongming, Ding Long, Yang Tao, et al. The invention relates to a method for treating invalid catalyst by using blast furnace pellet production process: China, CN202110213867.5[P]. 2021-07-23. (龙红明, 丁龙, 杨涛, 等. 一种利用高炉球团生产工序处理失效催化剂的方法: 中国,CN202110213867.5[P]. 2021-07-23.Long Hongming, Ding Long, Yang Tao, et al. The invention relates to a method for treating invalid catalyst by using blast furnace pellet production process: China, CN202110213867.5[P]. 2021-07-23. [38] Qian Lixin, Yang Tao, Long Hongming, et al. Recycle of waste V2O5-WO3/TiO2 catalysts in the iron ore sintering process via preballing approach[J]. ACS Sustgain Chem Eng, 2021,9(48):16373. doi: 10.1021/acssuschemeng.1c06271 [39] Long Hongming, Zhang Yudong, Yang Tao, et al. A promising metrhod to recover spent V2O5-WO3/TiO2 catalyst: Treatment by vanadium-titanium magnetite sintering process[J]. J Iron Steel Res Int, 2022,29:1176-1184. doi: 10.1007/s42243-021-00676-1 [40] Zhou Hao, Guo Xutao, Zhou Mingxi. Influence of different additives on harmless melting treatment of waste SCR catalysts[J]. Journal of Chinese Society of Power Engineering, 2017, 37(12): 999−1006. (周昊, 国旭涛, 周明熙. 不同添加剂对废弃SCR催化剂熔融无害化处理的影响[J]. 动力工程学报, 2017, 37(12): 999−1006.Zhou Hao, Guo Xutao, Zhou Mingxi. Influence of different additives on harmless melting treatment of waste SCR catalysts[J]. Journal of Chinese Society of Power Engineering, 2017, 37(12): 999−1006. [41] Yang Tao. Experimental study on leaching toxicity of heavy metals in spent SCR catalyst and its cement solidification/stabilization product[D]. Wuhan: Huazhong University of Science and Technology, 2017. (杨涛. 废弃钒钛系 SCR 催化剂重金属浸出毒性及其水泥固化研究[D]. 武汉: 华中科技大学, 2017.Yang Tao. Experimental study on leaching toxicity of heavy metals in spent SCR catalyst and its cement solidification/stabilization product[D]. Wuhan: Huazhong University of Science and Technology, 2017. [42] Liu Haipei, Li Zhong, Shen Yuesong, et al. Effects of different admixtures on performance of titanium-based ceramics prepared by waste denitrification catalyst[J]. Thermal Power Generation, 46(7): 66−71. (刘海沛, 李众, 沈岳松, 等. 不同外加剂对废弃脱硝催化剂制备钛基陶瓷性能的影响[J]. 热力发电, 46(7): 66−71.Liu Haipei, Li Zhong, Shen Yuesong, et al. Effects of different admixtures on performance of titanium-based ceramics prepared by waste denitrification catalyst[J]. Thermal Power Generation, 46(7): 66−71. -

下载:

下载: